Method for preparing high-strength fabricated artificial stone from construction waste

A construction waste, prefabricated technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems such as the inability of high-value utilization of recycled micropowder and the difficulty of separating brick and concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific examples.

[0027] A method for preparing high-strength assembled artificial stone from construction waste, which is characterized in that it comprises the following steps: separating brick and concrete construction waste through gravity separation, grinding the concrete in a hot air self-mill to obtain recycled aggregate and fine powder; After adding calcium raw material, use steam kinetic energy grinding, and then rapid thermal activation in countercurrent heater to obtain active micropowder; add activator, reinforcing agent, surfactant, water repellent, water to active micropowder, stir evenly, and shape , Obtain high-strength fabricated artificial stone after curing.

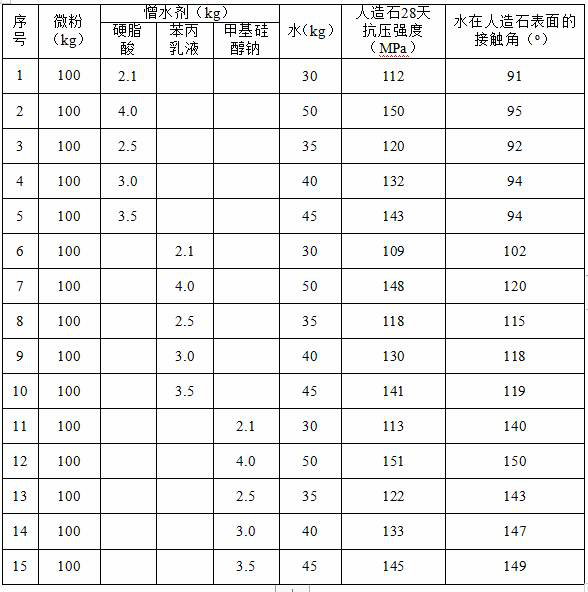

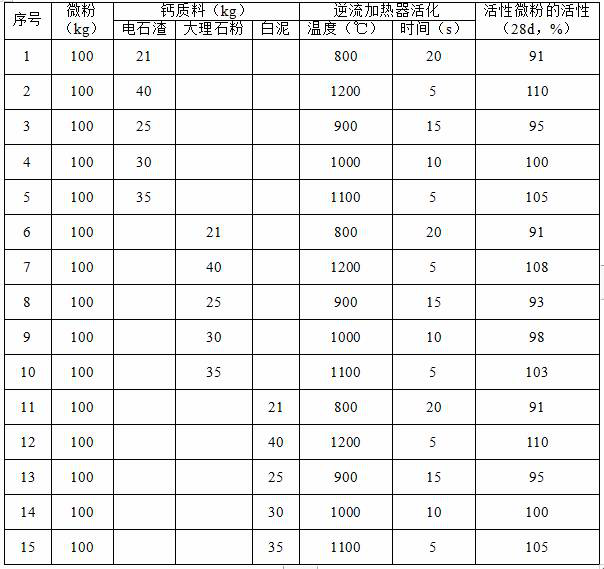

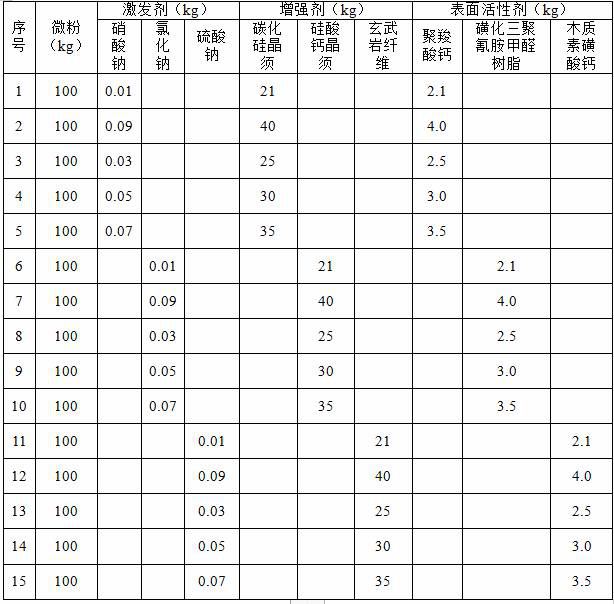

[0028] See Table 1 for the formulation of calcium raw materials added to the micropowder, the rapid thermal activation temperature and time in the countercurrent heater, and the activity of the active micropow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com