Phosphogypsum-based aggregate and preparation method thereof

A technology of phosphogypsum and aggregate, which is applied in the field of phosphogypsum-based aggregate and its preparation, and can solve the problems of long curing period and low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

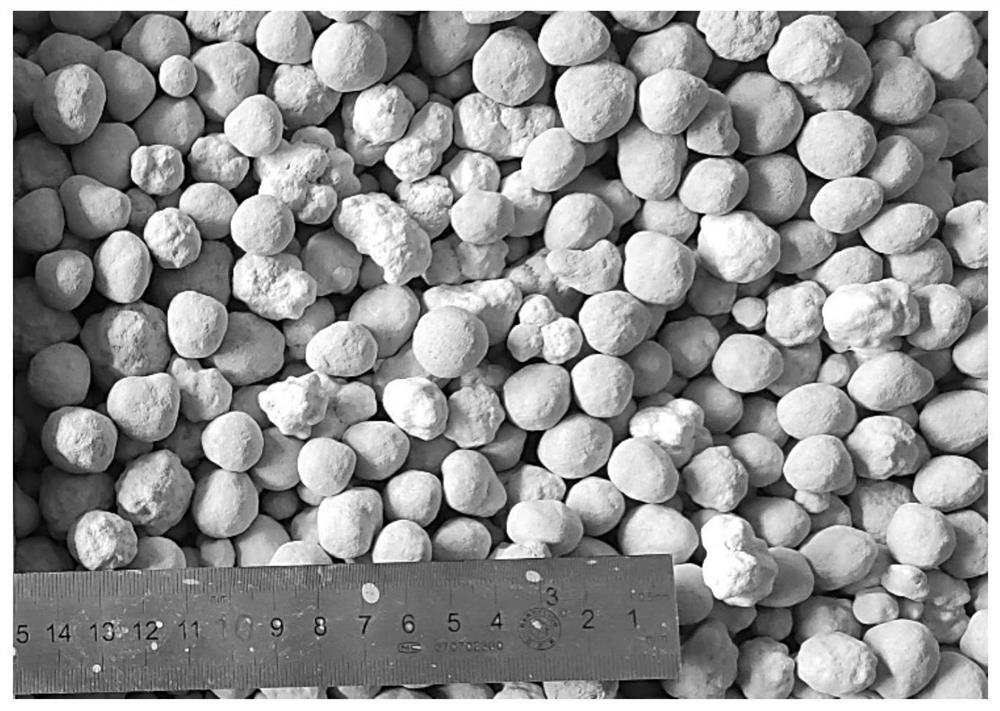

Image

Examples

preparation example Construction

[0036] This embodiment also proposes a method for preparing the above-mentioned phosphogypsum-based aggregate, comprising the following steps:

[0037] 1) According to the distribution ratio of each component, mix phosphogypsum, slag powder, and alkaline activator to obtain A powder;

[0038] 2) Dissolving sodium hexametaphosphate and cellulose ether in water to obtain solution B;

[0039] 3) Put the A powder prepared in step 1) into the ball forming machine, and at the same time continuously spray the B solution into the ball forming machine and mix with the A powder to form a ball to obtain the aggregate; the operating speed of the ball mill is 10r / min-40r / min;

[0040] 4) The phosphogypsum-based aggregate is obtained by naturally stacking and solidifying the aggregate for 1-2 days and then soaking in water; the soaking and curing can be performed by placing the cured aggregate in room temperature water for 14-28 days; The water immersion curing may also be to put the sol...

Embodiment 1

[0047] This example proposes an early-strength phosphogypsum-based aggregate, which is prepared by mixing A powder and B solution into balls; the A powder is calculated according to mass percentage, including: 80% phosphogypsum, 15% slag powder, Portland cement clinker 4%, quicklime 1%;

[0048] The B solution is calculated according to mass percentage, including 1% sodium hexametaphosphate, 0.1% cellulose ether, and the rest is water, totaling 100%;

[0049] The mass of the B solution is 25% of the mass of the A powder.

[0050] This embodiment also proposes a method for preparing the above-mentioned phosphogypsum-based aggregate, comprising the following steps:

[0051] 1) According to the distribution ratio of each component, mix phosphogypsum, slag powder, Portland cement clinker and quicklime to obtain A powder;

[0052] 2) Dissolving sodium hexametaphosphate and cellulose ether in water to obtain solution B;

[0053] 3) Put the A powder obtained in step 1) into the ba...

Embodiment 2

[0058] This embodiment proposes an early-strength phosphogypsum-based aggregate, which is prepared by mixing A powder and B solution into balls; the A powder is calculated according to mass percentage, including: phosphogypsum 70%, slag powder 10%, Coal ash powder 10%, Portland cement clinker 4%, sodium hydroxide 0.5%, sodium aluminate 0.5%;

[0059] The B solution is calculated according to mass percentage, including 1% sodium hexametaphosphate, 0.1% cellulose ether, and the rest is water, totaling 100%;

[0060] The mass of the B solution is 30% of the mass of the A powder.

[0061] This embodiment also proposes a method for preparing the above-mentioned phosphogypsum-based aggregate, comprising the following steps:

[0062] 1) According to the distribution ratio of each component, mix phosphogypsum, slag powder, Portland cement clinker, sodium hydroxide and sodium aluminate to obtain A powder;

[0063] 2) Dissolving sodium hexametaphosphate and cellulose ether in water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com