Permeable asphalt mixture and preparation method thereof

A permeable asphalt and mixture technology, applied in the field of pavement asphalt materials, can solve the problems of reducing the wrapping force of asphalt on aggregate, reducing the cohesion, and affecting the performance of asphalt mixture, so as to improve the anti-stripping performance and improve the cohesion , the effect of improving its own performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

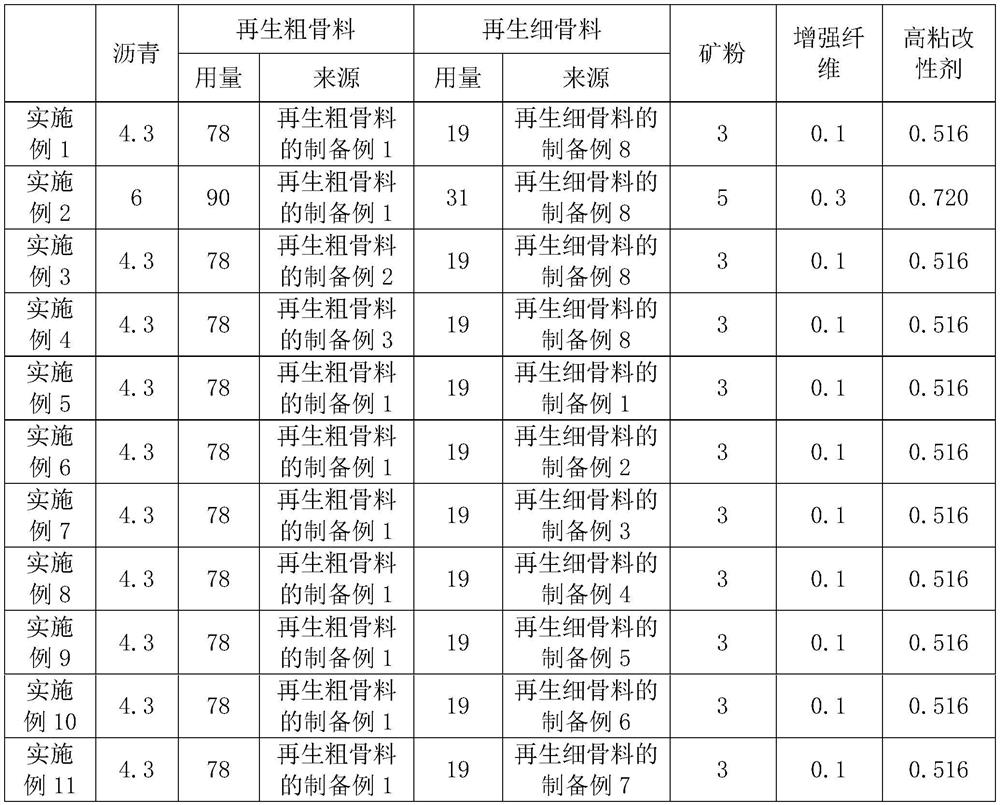

Examples

preparation example 1

[0051] The recycled coarse aggregate is prepared by the following method:

[0052] (1) After crushing and sieving the waste concrete whose original design strength is C40 and the aggregate is basalt gravel, coarse aggregate particles with a particle size of 6-19mm are obtained;

[0053] (2) taking coarse aggregate particles and placing them in dilute hydrochloric acid with a concentration of 5wt% for 3 hours to obtain acid-treated coarse aggregate particles;

[0054] (3) Take out the acid-treated coarse aggregate particles, and let them dry naturally at room temperature until there is no water dripping; then spray saturated calcium hydroxide solution on the surface of the acid-treated coarse aggregate particles to obtain alkali-treated coarse aggregate particles; wherein, saturated hydrogen The weight of the calcium oxide solution is 10% of the weight of the acid-treated coarse aggregate particles;

[0055] (4) carbonizing the alkali-treated coarse aggregate particles for 12 ...

preparation example 2

[0058] The difference between this preparation example and the preparation example 1 of recycled coarse aggregate is that the carbonization temperature in step (4) is 30°C, the volume content of carbon dioxide is 100%, and the carbonization treatment time is 6h.

preparation example 3

[0060] The difference between this preparation example and the preparation example 1 of recycled coarse aggregate is that the weight ratio of primary carbonized coarse aggregate particles and secondary carbonized coarse aggregate particles in step (5) is 38:40.

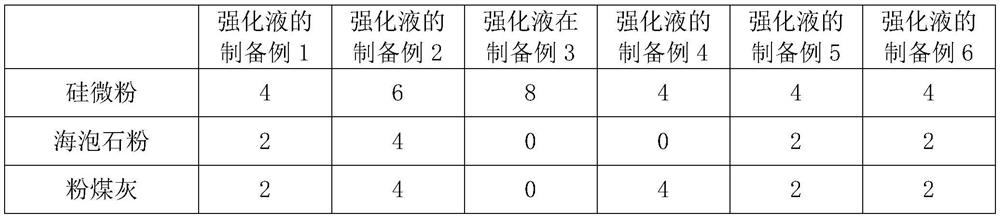

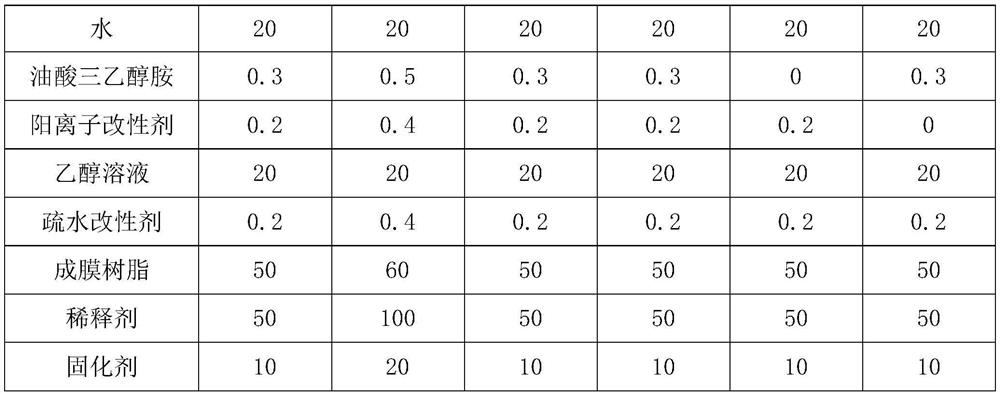

[0061] Preparation example of strengthening liquid

[0062] Unless otherwise specified, the raw materials in the preparation examples can be obtained commercially. Among them, the fineness of silica powder is 2000 mesh; the fineness of sepiolite powder is 1000 mesh; the fly ash is Class II fly ash. The cationic modifier is one of tetradecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide, octadecyl trimethyl ammonium bromide or their mixture, in the following preparation examples All cationic modifiers are cetyltrimethylammonium bromide. The hydrophobic modifier is hexadecyltrimethylsilane. The film-forming resin is E44 epoxy resin, the diluent is ethylene glycol diglycidyl ether, and the curing ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com