A kind of polyaluminum chloride waste slag recycled concrete curb and its preparation method

A technology of polyaluminum chloride and recycled concrete is applied in the field of road building materials, which can solve the problems of polluting resources and waste, and achieve the effects of increasing specific surface area, good water retention, and improving bleeding and segregation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

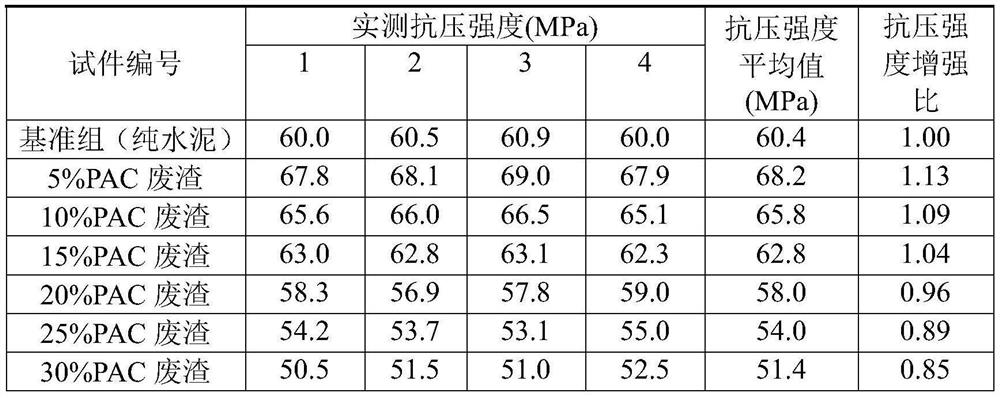

[0049] A polyaluminum chloride waste slag regenerated concrete curb, according to the mass per unit volume, including the following raw materials: sand 600kg / m 3 , recycled coarse aggregate 400kg / m 3 , natural coarse aggregate 800kg / m 3 , thermal activation (calcination at 1000°C for 2h) polyaluminum chloride waste slag 40kg / m 3 , Cement 220kg / m 3 , fly ash 80kg / m 3 , water 153kg / m 3 , water-binder ratio 0.45; Water-reducer dosage is 0.30% (mass per unit volume) of gelling material, defoamer dosage is 0.10% (mass per unit volume) of gelling material, and alkali activator includes NaOH 2.5kg / m 3 、Na 2 SiO 3 14.0kg / m 3 And gypsum 1kg / m 3 ; Among them, heat-activated polyaluminum chloride waste residue, cement and fly ash are cementitious materials.

[0050] The preparation method of polyaluminum chloride waste slag recycled concrete curb comprises the following steps:

[0051] (1) Strengthening of recycled coarse aggregate: first, use NaOH to 2 SiO 3 Adjust the mo...

Embodiment 2

[0058] A polyaluminum chloride waste slag regenerated concrete curb, according to the mass per unit volume, including the following raw materials: sand 600kg / m 3 , recycled coarse aggregate 400kg / m 3 , natural coarse aggregate 800kg / m 3 , heat activation (calcination at 1000°C for 2h) PAC waste slag 80kg / m 3 , Cement 220kg / m 3 , fly ash 40kg / m 3 , water 153kg / m 3, water-binder ratio 0.45; Water-reducer dosage is 0.30% (mass per unit volume) of gelling material, defoamer dosage is 0.10% (mass per unit volume) of gelling material, and alkali activator includes NaOH 2.5kg / m 3 、Na 2 SiO 3 14.0kg / m 3 And gypsum 1kg / m 3 ; Among them, heat-activated polyaluminum chloride waste residue, cement and fly ash are cementitious materials.

[0059] The preparation method of the polyaluminum chloride waste slag recycled concrete curb is the same as in Example 1.

Embodiment 3

[0061] A polyaluminum chloride waste slag regenerated concrete curb, according to the mass per unit volume, including the following raw materials: sand 690kg / m 3 , recycled coarse aggregate 375kg / m 3 , natural coarse aggregate 750kg / m 3 , heat activation (calcination at 1000°C for 2h) polyaluminum chloride waste residue 80kg / m 3 , cement 260kg / m 3 , fly ash 40kg / m 3 , water 152kg / m 3 , water-binder ratio 0.40; The superplasticizer dosage is 0.55% (mass per unit volume) of the gelling material, the dosage of defoamer is 0.15% (mass per unit volume) of the gelling material, and the alkali activator includes NaOH 1.25kg / m 3 、Na 2 SiO 3 7.70kg / m 3 And gypsum 0.55kg / m 3 ; Among them, heat-activated polyaluminum chloride waste residue, cement and fly ash are cementitious materials.

[0062] The preparation method of the polyaluminum chloride waste slag recycled concrete curb is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com