Ferronickel slag aggregate treatment method

A treatment method, the technology of ferronickel slag, which is applied in the field of building materials, can solve the problems of high crushing value of ferronickel slag aggregate, and achieve the effects of reducing risks, promoting cement hydration, and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

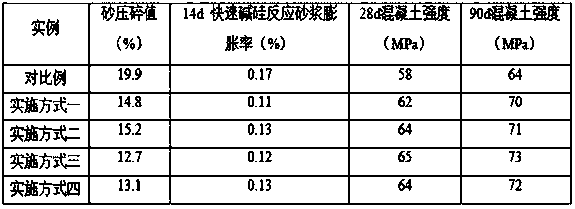

Examples

Embodiment 1

[0024] Take by weighing 100 parts of ferronickel slag aggregate, 20 parts of sodium hydroxide, 50 parts of water glass, 800 parts of water, 10 parts of sodium carbonate, and 10 parts of cement powder for subsequent use;

[0025] The processing steps of ferronickel slag aggregate are as follows:

[0026] (1) Soak the ferronickel slag aggregate in the mixed aqueous solution of sodium hydroxide and water glass;

[0027] (2) Adjust the temperature of the mixed solution obtained in step (1) to 40°C and keep it warm for 6 hours;

[0028] (3) After the heat preservation is over, stir rapidly at a stirring speed of 5 rpm for 10s;

[0029] (4) Add sodium carbonate and cement powder, and stir evenly;

[0030] (5) Static precipitation for 1 hour and separation to obtain the precipitate and clarified liquid;

[0031] (6) Sieve out the ferronickel slag aggregate with a particle size greater than 5mm in the sediment, and air-dry it naturally, and use it as concrete aggregate; dry and gri...

Embodiment 2

[0033] Take by weighing 200 parts of ferronickel slag aggregate, 50 parts of sodium hydroxide, 80 parts of water glass, 1000 parts of water, 20 parts of sodium carbonate, and 30 parts of cement powder for subsequent use;

[0034] The processing steps of ferronickel slag aggregate are as follows:

[0035] (1) Soak the ferronickel slag aggregate in the mixed aqueous solution of sodium hydroxide and water glass;

[0036] (2) Adjust the temperature of the mixed solution obtained in step (1) to 60°C and keep it warm for 1 hour;

[0037] (3) After the heat preservation is over, stir rapidly at a stirring speed of 1 rpm for 60s;

[0038] (4) Add sodium carbonate and cement powder, and stir evenly;

[0039] (5) Static precipitation for 2 hours and separation to obtain the precipitate and clarified liquid;

[0040] (6) Sieve out the ferronickel slag aggregate with a particle size greater than 5mm in the sediment, and air-dry it naturally, and use it as concrete aggregate; dry and gr...

Embodiment 3

[0042] Take by weighing 120 parts of ferronickel slag aggregate, 30 parts of sodium hydroxide, 60 parts of water glass, 900 parts of water, 15 parts of sodium carbonate, and 20 parts of cement powder for subsequent use;

[0043] The processing steps of ferronickel slag aggregate are as follows:

[0044] (1) Soak the ferronickel slag aggregate in the mixed aqueous solution of sodium hydroxide and water glass;

[0045] (2) Adjust the temperature of the mixed solution obtained in step (1) to 50°C and keep it warm for 5 hours;

[0046] (3) After the heat preservation is over, stir rapidly at a stirring speed of 3 rpm for 50s;

[0047] (4) Add sodium carbonate and cement powder, and stir evenly;

[0048] (5) Static precipitation for 2 hours and separation to obtain the precipitate and clarified liquid;

[0049] (6) Sieve out the ferronickel slag aggregate with a particle size greater than 5mm in the sediment, and air-dry it naturally, and use it as concrete aggregate; dry and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com