Patents

Literature

42results about How to "Reduce the risk of reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

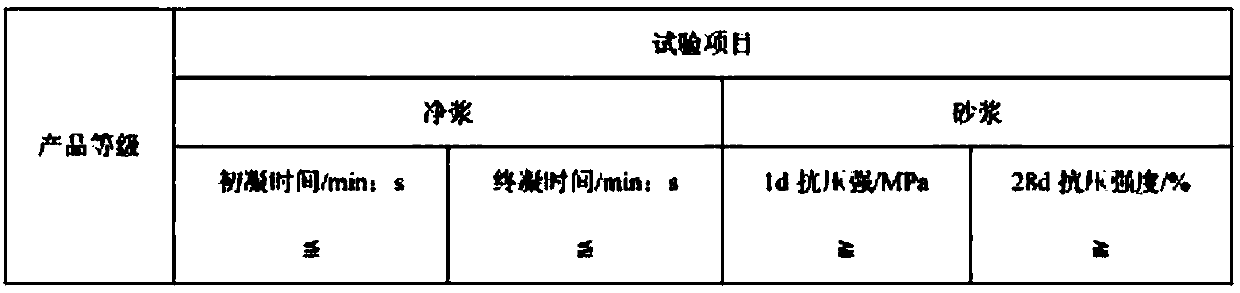

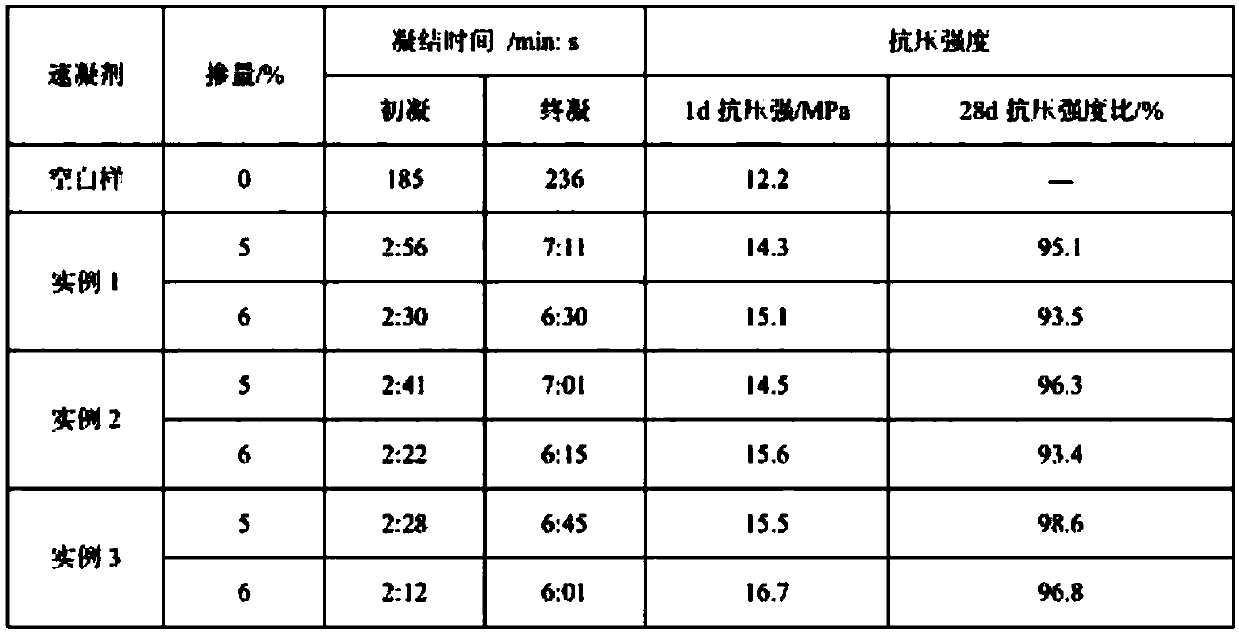

Novel alkali-free liquid accelerator based on synthesis of polymeric aluminum sulfate

ActiveCN105271867ALow alkali contentReduce the risk of alkali-aggregate reactionAlkali freeSynthesis methods

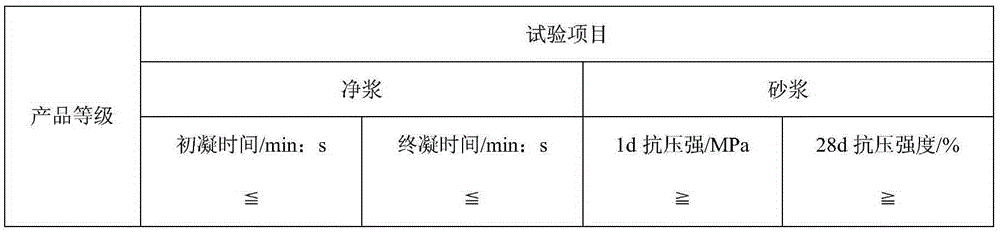

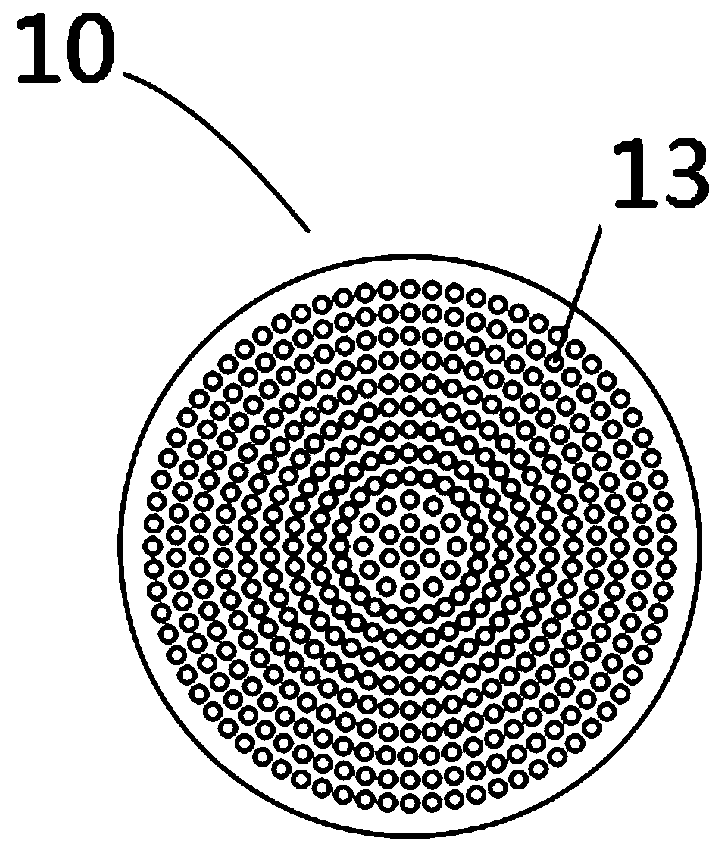

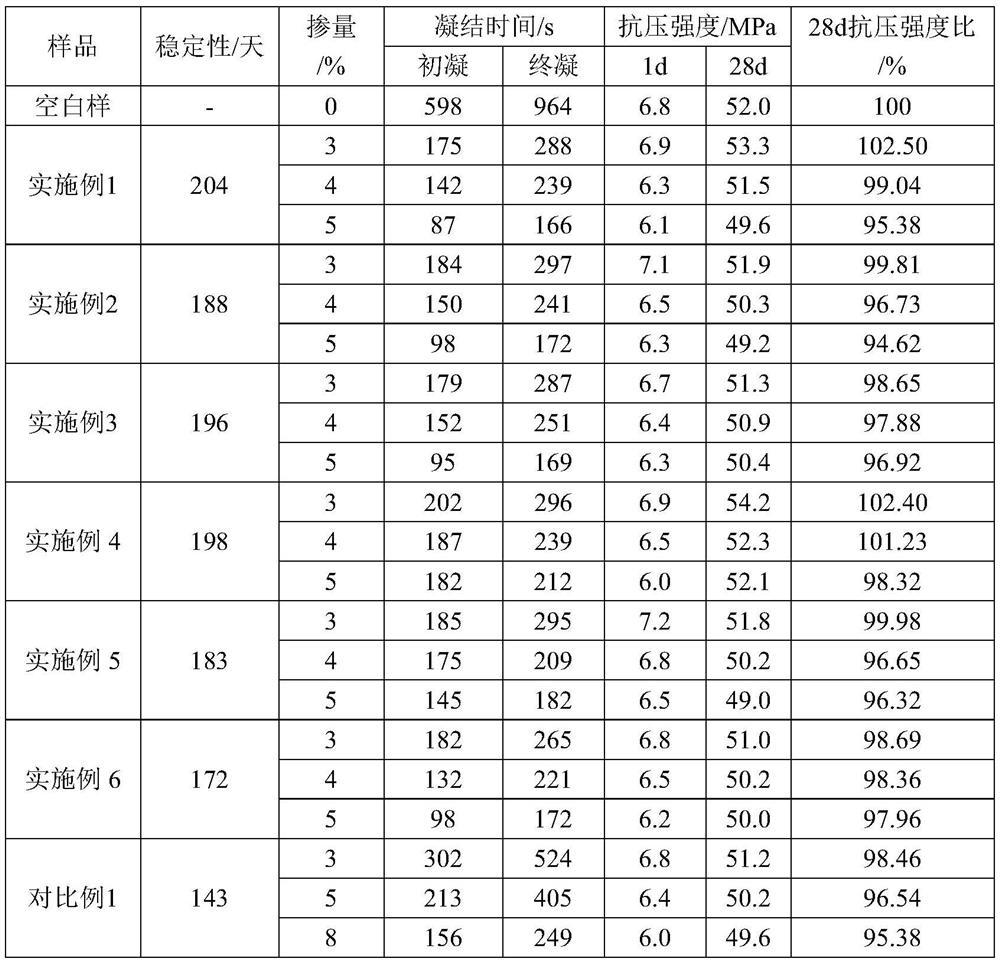

The invention discloses a polymeric aluminum sulfate synthesis method and discloses a preparation method of a novel alkali-free liquid accelerator based on synthesis of polymeric aluminum sulfate. According to the alkali-free accelerator, an aluminum sulfate solution is neutralized by ammonia water, active aluminum hydroxide gel is prepared, active aluminum hydroxide is filtered, dried and ground into powder, then the aluminum sulfate solution is added, and the polymeric aluminum sulfate is prepared. The alkali-free accelerator comprises, in percentage, 45%-55% of the polymeric aluminum sulfate, 0%-5% of inorganic acid, 0%-2% of a stabilizer, 0%-2% of an organic early strength agent, 0%-2% of an organic tackifier and the balance of water. The cement setting time and the colloidal mortar strength of the accelerator can meet the requirement of first-class accelerators for JC477-2005 sprayed concrete under the condition of the lower mixing amount, and meanwhile, the accelerator is an alkali-free liquid accelerator and can effectively avoid adverse effects caused by excessively high alkali content. The cement types of the accelerator have good adaptability.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

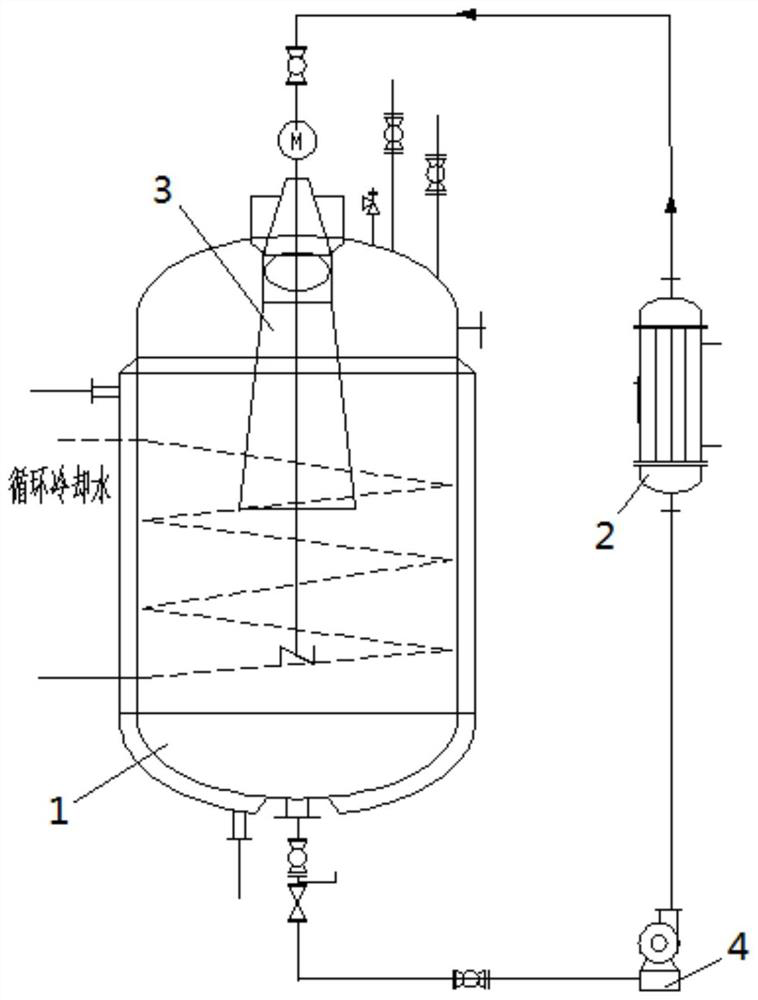

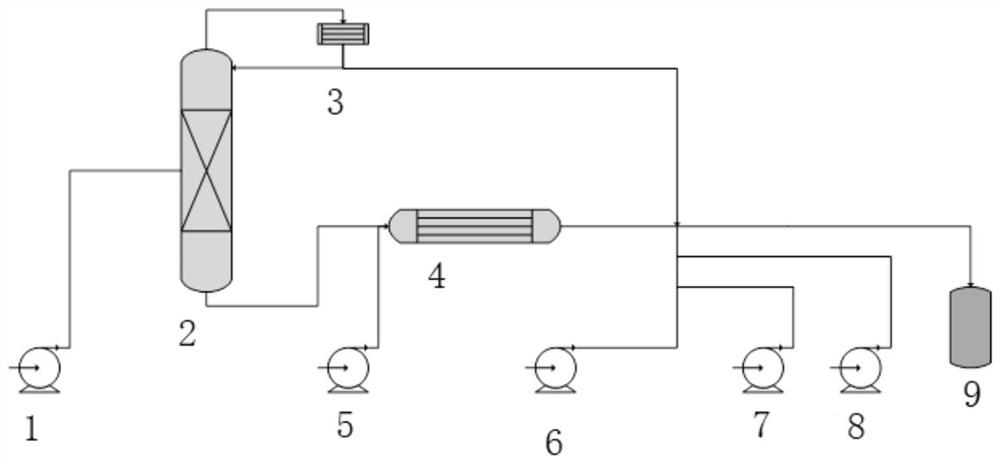

Gas-liquid phase vinyl chloride production process and device

ActiveCN110698319AInhibit surface carbonHigh catalytic efficiencyPreparation by halogen halide additionCatalytic liquid-gas reactionPtru catalystReaction temperature

The invention provides a gas-liquid phase vinyl chloride production process and a device, and belongs to the technical field of chemical product preparation. The production process comprises the following steps: raw materials are treated, wherein raw materials comprise a liquid catalyst and mixed gas composed of hydrogen chloride and acetylene; a hydrochlorination reaction is carried out on acetylene, wherein acetylene reacts with hydrogen chloride to generate vinyl chloride, and the reaction temperature is controlled by a heat exchanger during a reaction process; gas-liquid separation is carried out, wherein generated vinyl chloride gas flows out of a liquid catalyst, and when the vinyl chloride gas passes through a condenser, the liquid catalyst is cooled, liquefied and refluxed to a reaction zone for acting on the reaction again; the liquid catalyst is recovered, and a small amount of the liquid catalyst is separated again by a demister; and the acetylene conversion rate is detected, wherein the liquid catalyst is replaced when the acetylene conversion rate is lower than 95%, and the original liquid catalyst is continuously used for catalytic action when the conversion rate is higher than 95%. The invention aims to solve the problems of temperature runaway phenomenon, surface carbon deposition and low catalytic efficiency caused by a gas-solid reaction in the prior art.

Owner:河北美邦工程科技股份有限公司

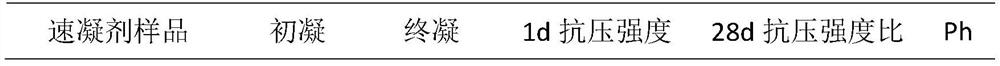

Liquid accelerator for sprayed concrete and application thereof

The invention discloses liquid accelerator for sprayed concrete and application thereof. The liquid accelerator for sprayed concrete comprises, by weight percent, 30-50% of aluminum sulfate, 0.5-1.5% of triethanolamine, 10-30% of aluminate, 1.0-5.0% of cellulose, 5-10% of efficient water reducer, and the balance of water. In construction of the sprayed concrete, the accelerator 2-5% of cement is dosed. The accelerator is effective in setting acceleration, initial setting time is 2min-4min, final setting time is 4min-8min, early strength attains fast, 28d compressive strength ratio is over 95%, and the accelerator is high in cohesiveness and low in resilience. In addition, the accelerator is chloride-free and low in alkali and is capable of lowering the risk of concrete alkali-aggregate reaction and erosion of reinforced concrete.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Continuous production method for vulcanization accelerator DPG

ActiveCN108586295ARealize continuous productionSmall liquid holding capacityOrganic chemistryOrganic compound preparationVulcanizationOrganic solvent

The invention provides a continuous production method for a vulcanization accelerator DPG. The method comprises the following steps that (1) diphenylthiourea, a catalyst, ammonium hydroxide and an organic solvent are mixed to obtain a reaction raw material mixture; (2) the reaction raw material mixture and an oxidizing agent are subjected to an oxidation reaction in a continuous flow reactor to obtain a reaction product; (3) the reaction product is post-treated to obtain the vulcanization accelerator DPG, wherein the organic solvent in step (1) can dissolve the diphenylthiourea and the vulcanization accelerator DPG. The method reduces the pressure in the reaction process, improves the utilization rate of the raw materials, stabilizes the product quality, greatly shortens the reaction timecompared with a conventional technology, improves the reaction yield, and effectively overcomes the disadvantage of traditional kettle type batch production.

Owner:KEMAI CHEM

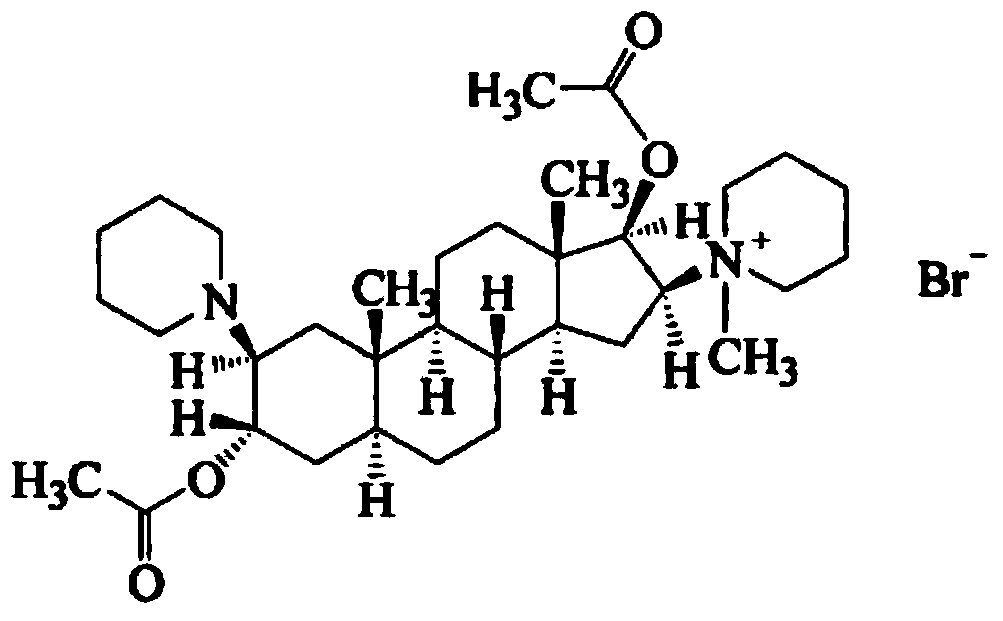

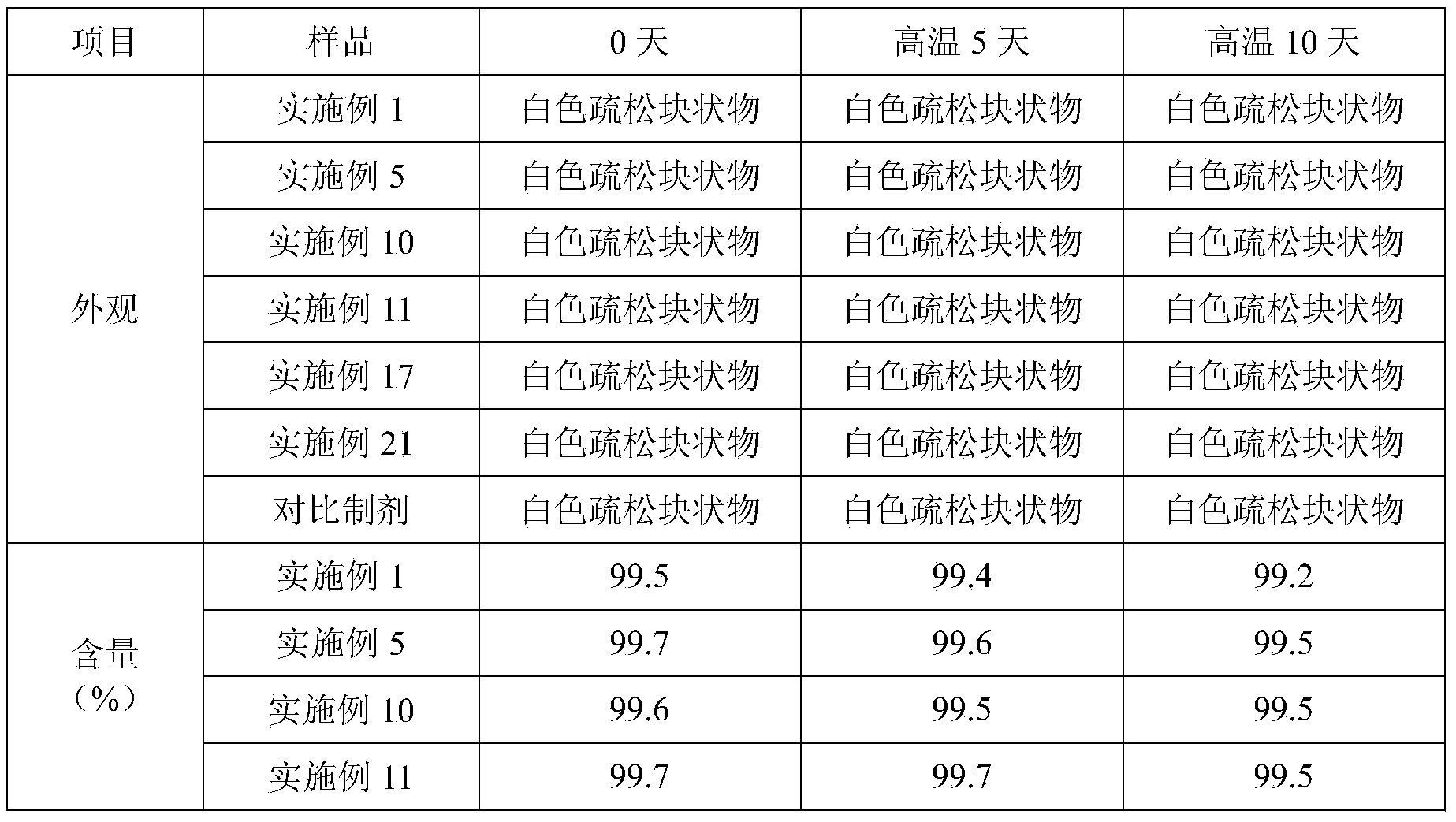

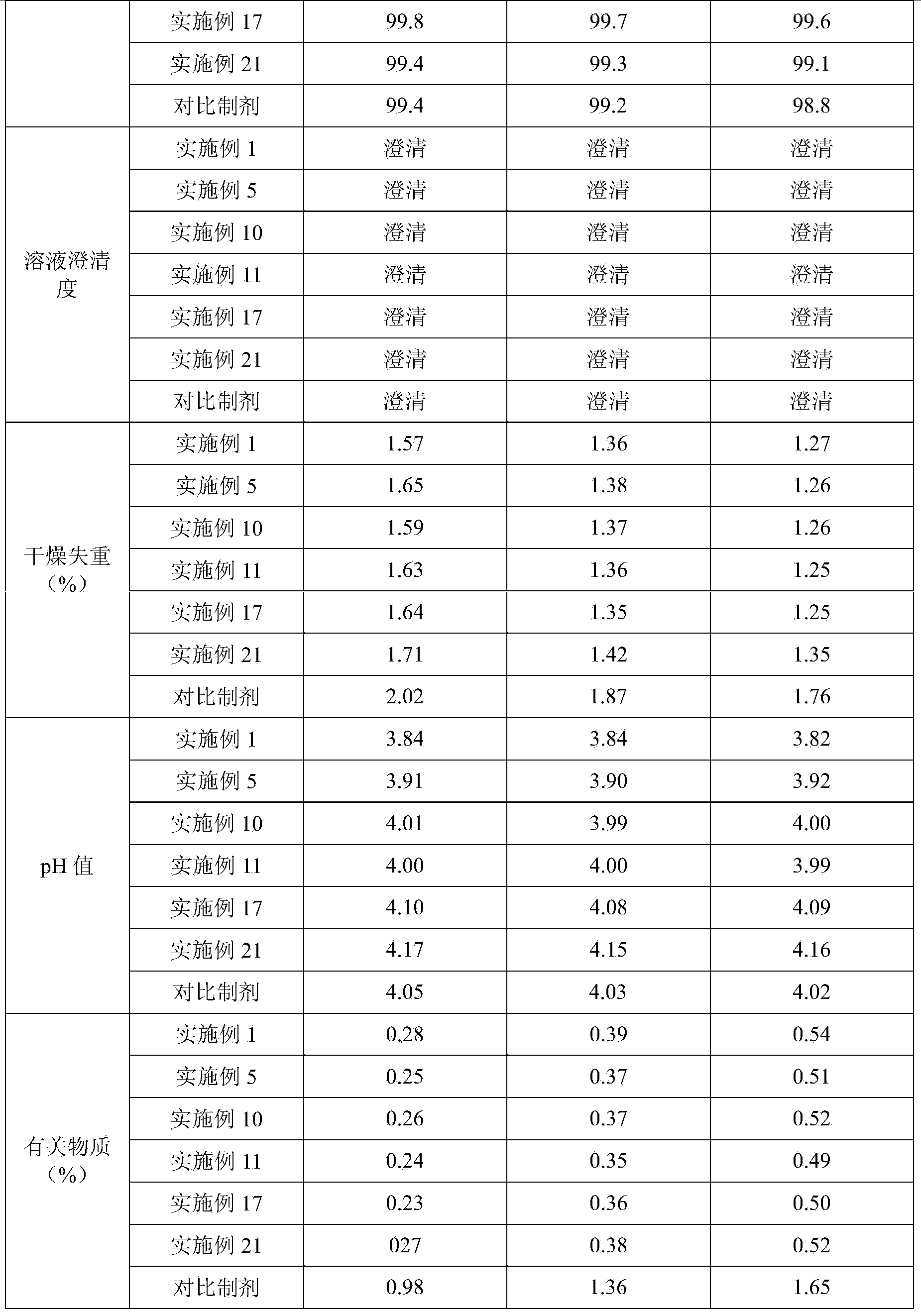

Vecuronium bromide pharmaceutical composition for injection and preparation method thereof

ActiveCN103877032AAvoid intoleranceReduce the risk of reactionsOrganic active ingredientsPowder deliveryMANNITOL/SORBITOLVecuronium bromide

The invention relates to a vecuronium bromide pharmaceutical composition for injection and a preparation method thereof. The vecuronium bromide pharmaceutical composition is characterized in that the pharmaceutical composition consists of vecuronium bromide, citric acid and disodium hydrogen phosphate. In the prescription of the vecuronium bromide pharmaceutical composition, amino acid, lactose, and the like are not used as excipients, so that a risk that the amino acid possibly reacts with the main drug is lowered, and safety risk caused by adding lactose is eliminated at the same time, and therefore, safety is better; and moreover, technical prejudice that product outline is kept by adding excipients such as mannitol, and the like in the prior art are overcome. The vecuronium bromide pharmaceutical composition disclosed by the invention is simple in prescription, lowers production cost to a certain extent, and is more suitable for industrial production.

Owner:CHENGDU EASTON BIOPHARMACEUTICALS CO LTD

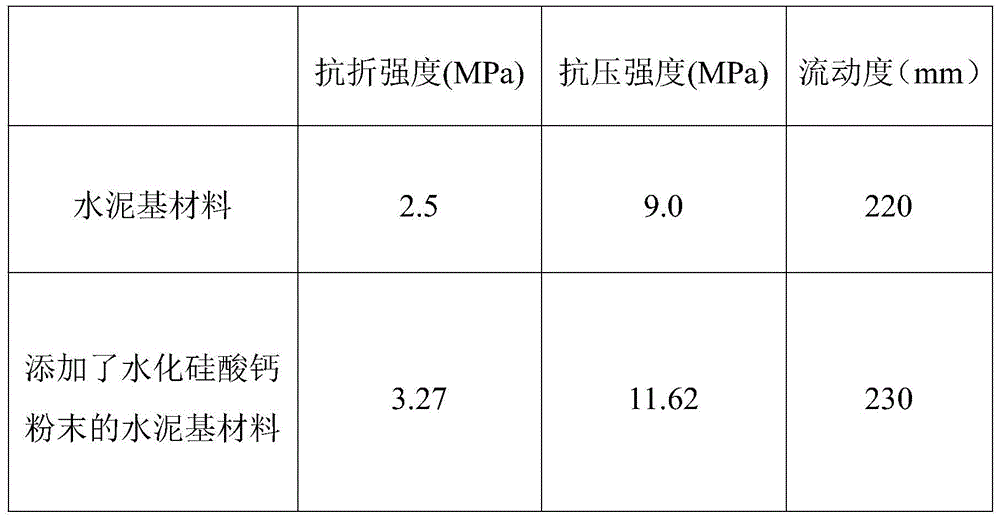

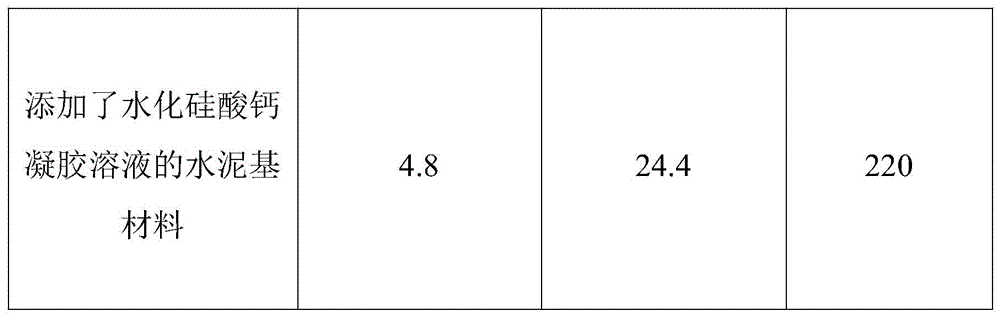

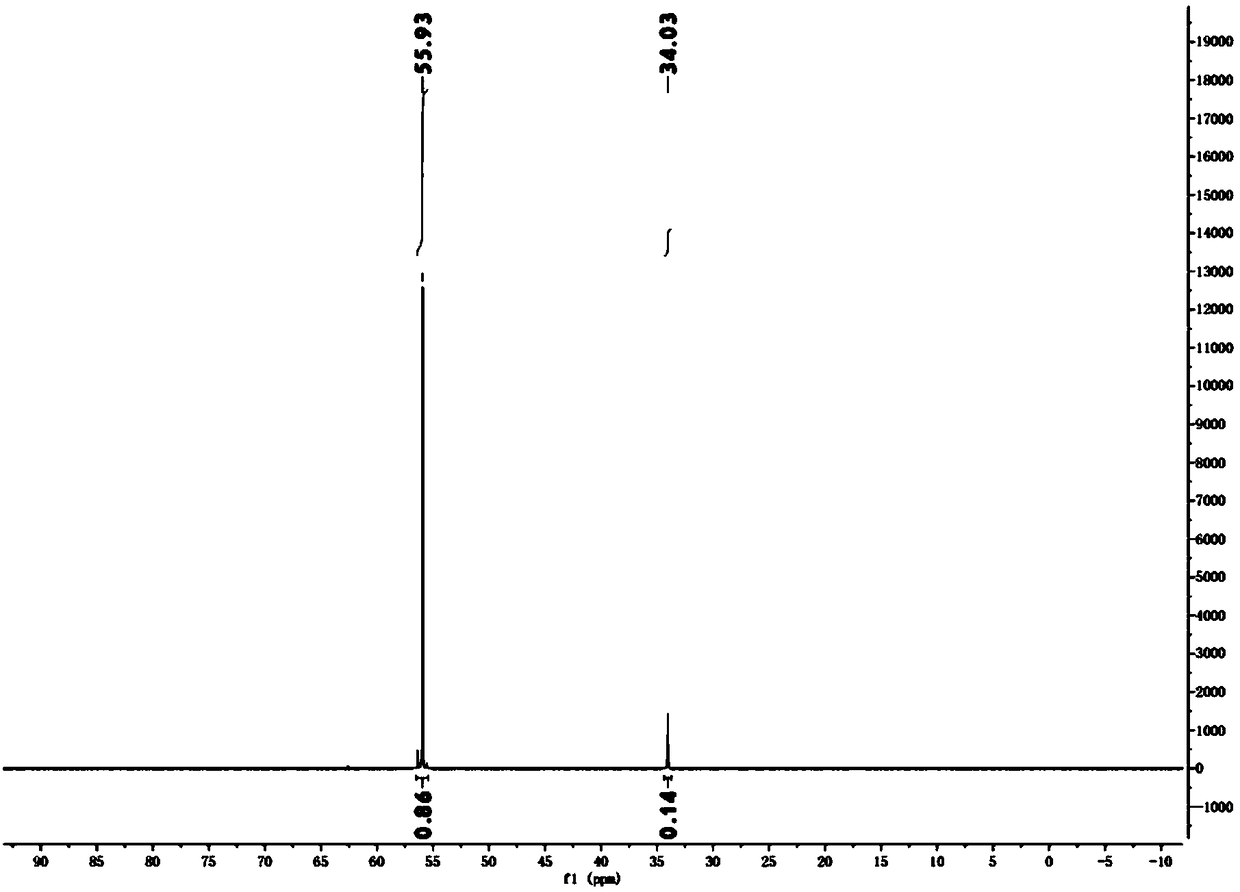

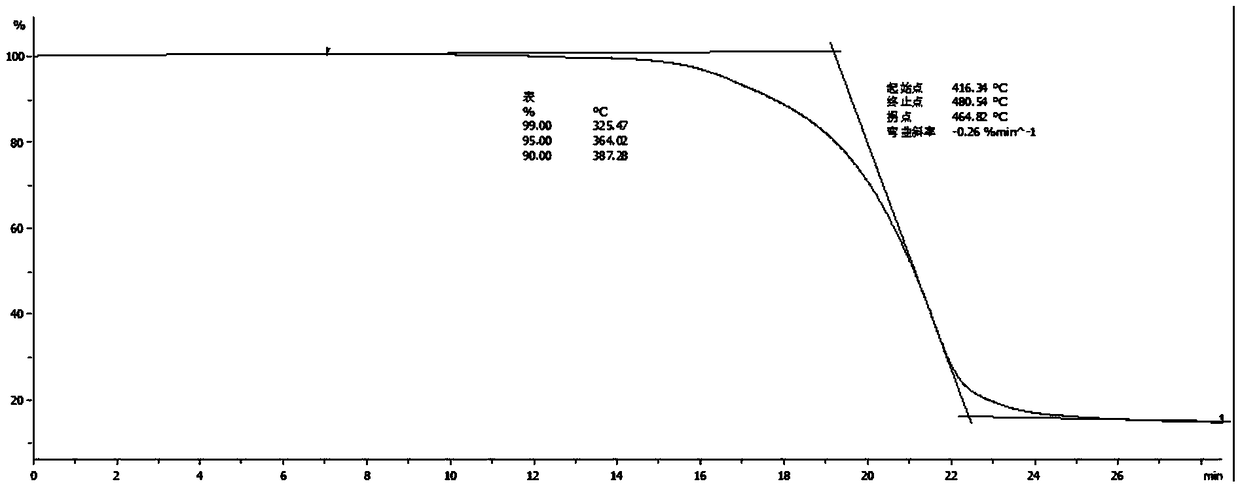

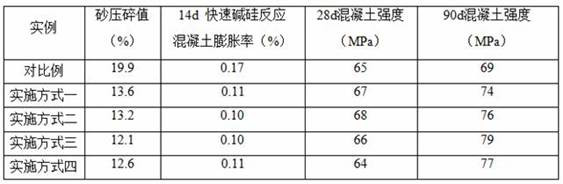

A kind of early strengthening agent of calcium silicate hydrate gel solution and its preparation method by suction filtration

ActiveCN104402009BLong term storageGood dispersionAlkaline-earth metal silicatesCalcium silicateCalcium in biology

The invention discloses a calcium silicate hydrate gel solution early strength agent and a preparation method thereof, and relates to the technical field of construction material production. The early strength agent and the method are used for solving problems of complicated preparation process, high cost, storage difficulty, and poor early strength effect of traditional calcium silicate hydrate powder. The calcium silicate hydrate gel solution early strength agent comprises a calcareous material, a siliceous material, a gel dispersant, and water. A weight ratio of the calcareous material to the siliceous material is 0.3-3:1. A weight ratio of water to the total of the calcareous material and the siliceous material is 5-30:1. The mass percentage of the gel dispersant is 0.1-2.0%. The preparation method of the early strength agent comprises the following steps: reaction materials are weighed; a sodium silicate water solution and a calcium nitrate water solution are respectively prepared; the two are mixed and are subjected to a reaction, such that a gel mixture solution is obtained; suction filtration is carried out; and water and the dispersant are added for re-dispersion. The early strength agent is uniform and stable, and is convenient to store. The early strength agent is highly convenient to use, and has a good early strength effect. With the early strength agent, an alkali-aggregate reaction risk can be effectively reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

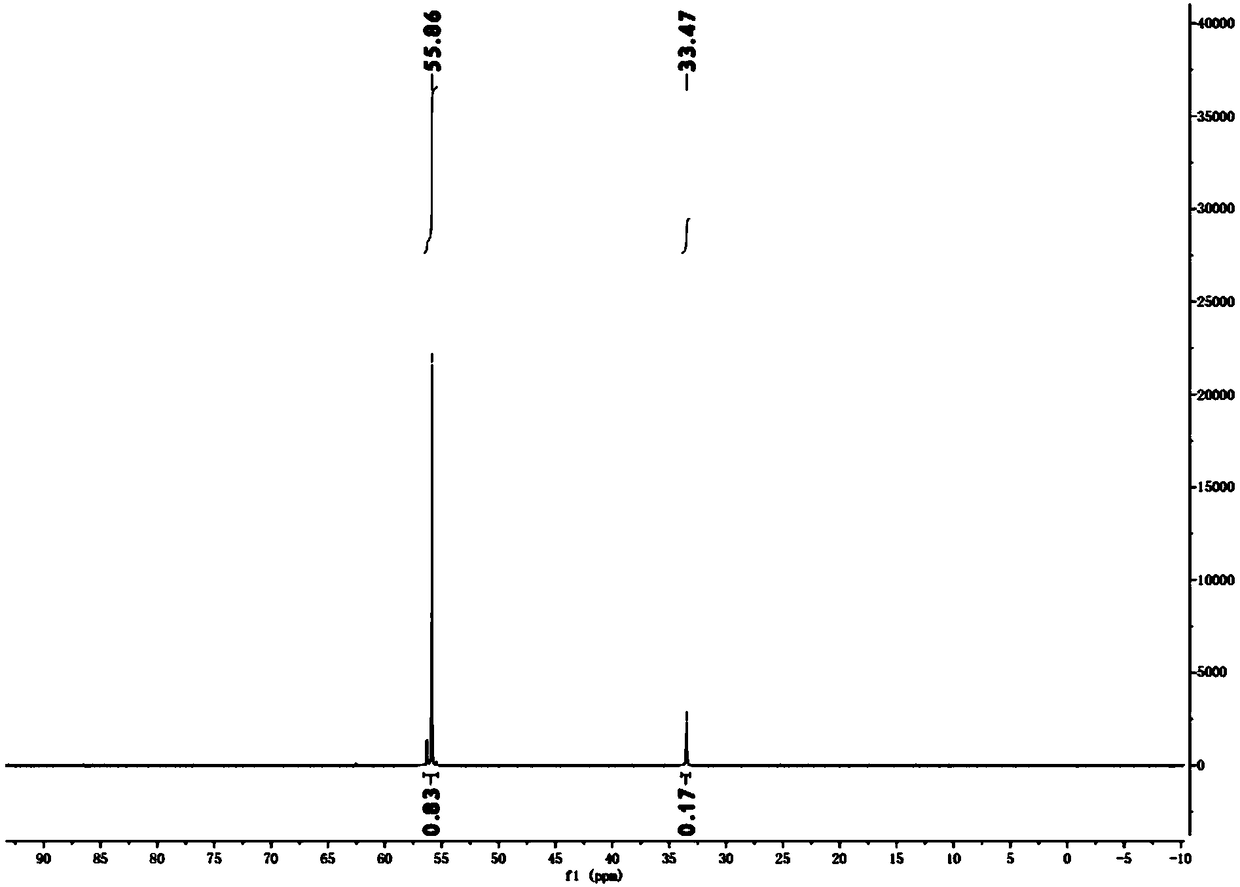

Synthesis method of alkyl phosphinic acid and aluminium salt thereof under normal-pressure mild condition

InactiveCN108864182AAvoid concentrationSimple and fast operationGroup 5/15 element organic compoundsSynthesis methodsPhosphoric acid

The invention discloses a synthesis method of alkyl phosphinic acid and aluminium salt thereof under a normal-pressure mild condition. A hypophosphorous acid solution and alcohol are adopted as raw materials, by means of an organic solvent which has an azeotropy point with water, through in-situ reaction of olefin, the alkyl phosphinic acid is synthesized, after reaction is completed, the pH is adjusted, an aluminium salt solution is added, and alkyl aluminum hypophosphite precipitates as a white precipitate. According to the synthesis method of the alkyl phosphinic acid and the aluminium saltthereof under the normal-pressure mild condition, operation is simple and convenient, concentration of the hypophosphorous acid solution is avoided, energy consumption is reduced, and the efficiencyis improved; the alcohol not only can be used as the raw material for in-situ reaction of the olefin, but also can promote homogeneous system generation of the reaction, so that inconvenience of easyauto-agglutination brought by using acetic acid as a solvent and using olefin as an oligomer is eliminated; by using the solvent co-boiling with water, the purposes of solvent recovery and recycle areachieved, and it is easier to obtain the high-quality salt-forming product; the method is implemented under the normal-pressure mild condition, a security coefficient is high, the reaction risk is small, a synthesis technology is more energy-saving, environmentally friendly and efficient, and industrial production is easier to achieve.

Owner:JINAN TAIXING FINE CHEM

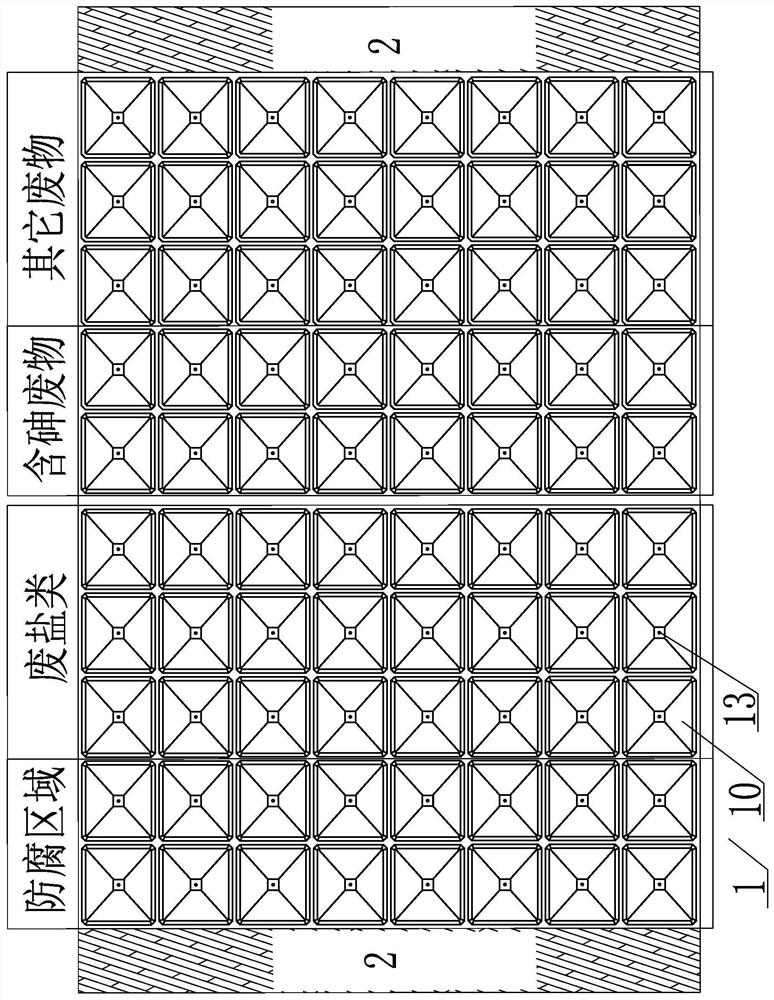

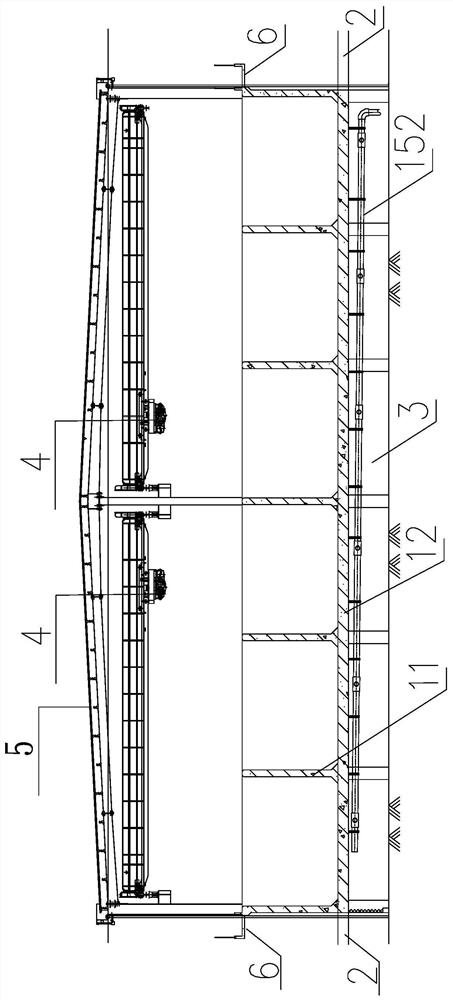

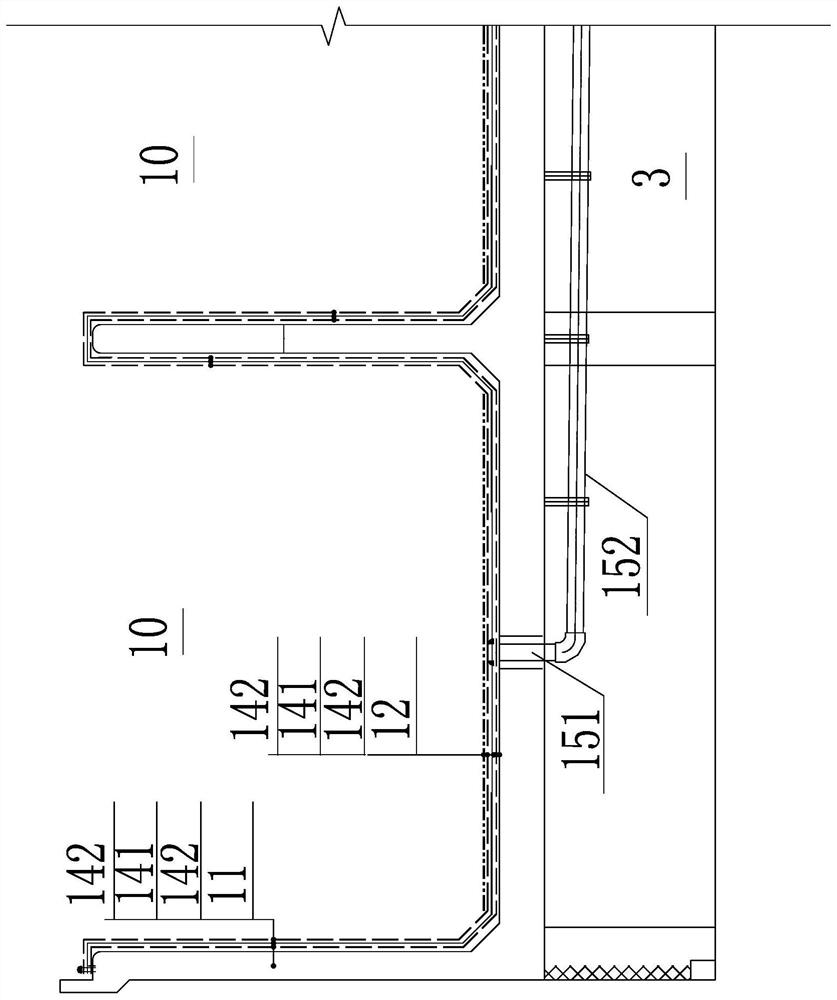

Retrievable hazardous waste rigid landfill system and operation method

PendingCN112974461AReduce workloadReduce productionArtificial islandsSolid waste disposalRebarGantry crane

The invention provides a retrievable hazardous waste rigid landfill system and an operation method. The retrievable hazardous waste rigid landfill system comprises a hazardous waste landfill reservoir area, a discharging channel, an overhauling interlayer, a portal crane, a steel-structured canopy and a personnel operation walkway plate. The hazardous waste landfill reservoir area is erected on the overhauling interlayer and composed of a plurality of landfill units. Each landfill unit comprises a reinforced concrete retaining wall and a bottom plate and is provided with a bottom plate anti-seepage system, a retaining wall anti-seepage system and a leachate collecting pipe, wherein pipe walking lines of the leachate collecting pipes are mainly located in the overhauling interlayer. The overhauling interlayer is an overhead layer and located below the hazardous waste landfill reservoir area. The portal crane is located above the landfill reservoir area. The steel-structured canopy is located on the upper portion of a crane. Personnel walkways are arranged on the periphery or / and in the landfill reservoir area. The retrievable hazardous waste rigid landfill system has more reliable safety, operable retrievable landfill is achieved, and management and maintenance are facilitated.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

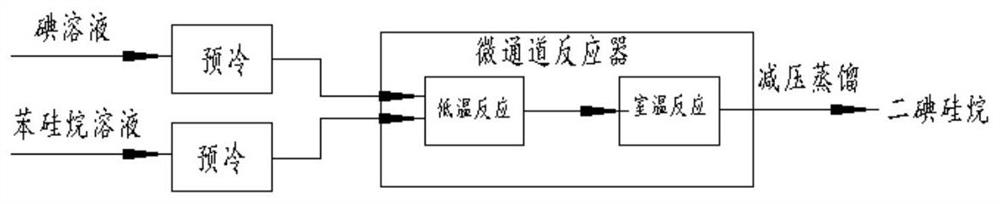

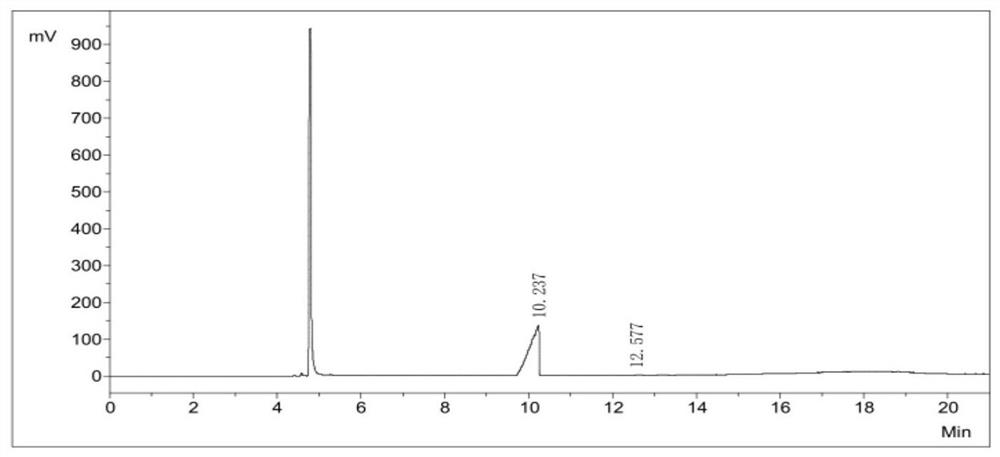

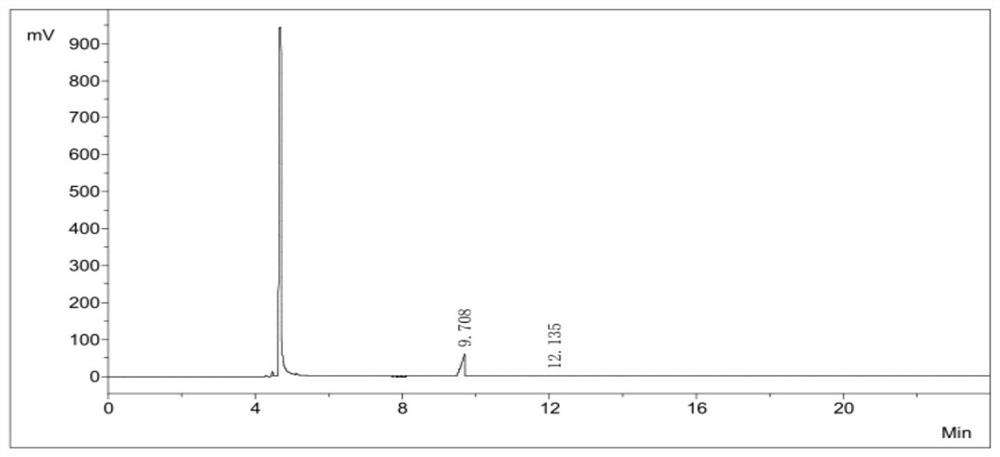

Preparation method and device of diiodosilane

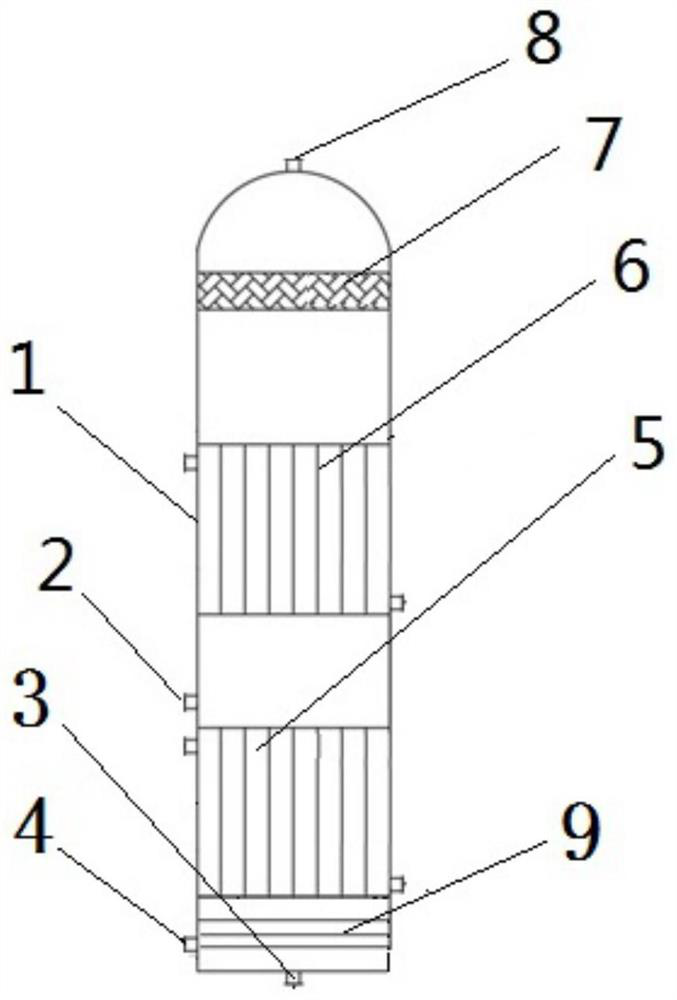

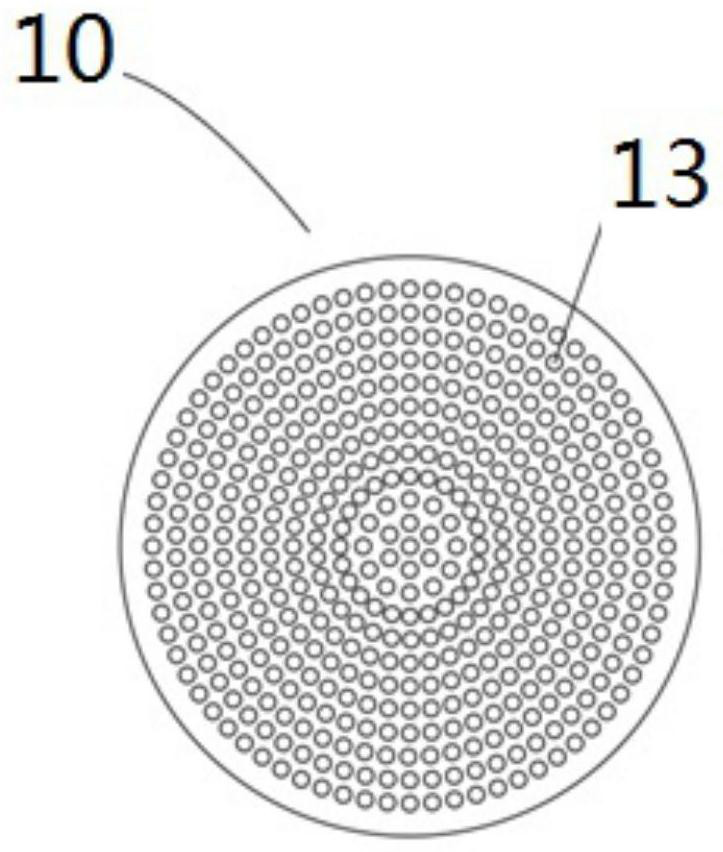

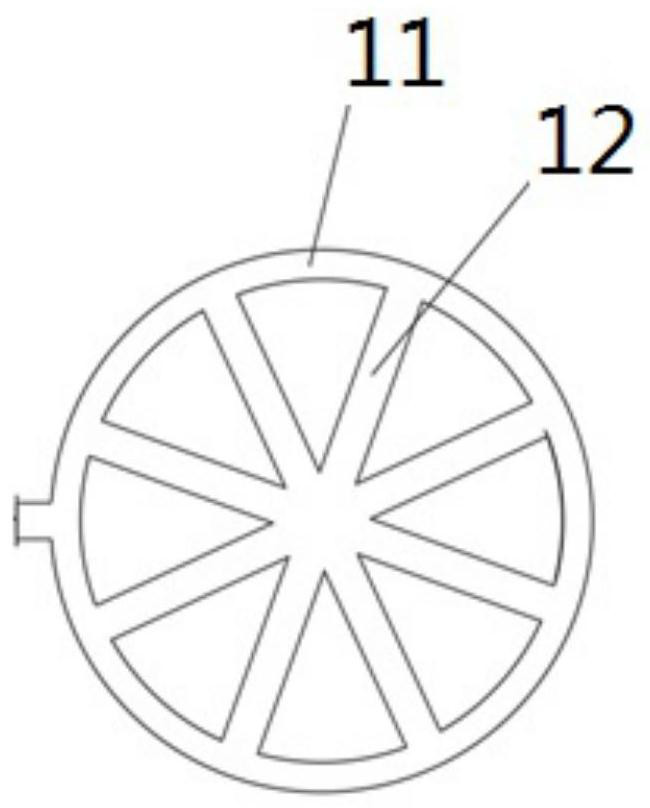

PendingCN114835126AImprove heat transfer efficiencyHigh product contentChemical/physical/physico-chemical microreactorsHalogenated silanesSemiconductor materialsEthyl acetate

The invention relates to a preparation method and device of diiodosilane, and relates to the field of synthesis methods of semiconductor materials, the preparation method comprises the following steps: 1, mixing and dissolving iodine with at least one of chloroform, dichloromethane and dichloroethane according to a volume ratio of 1: (2-5); the phenylsilane is mixed with at least one of ethyl acetate, tert-butyl acetate and butyl acetate according to the mass ratio of 100: (1-5); pre-cooling the iodine solution and the phenylsilane solution at-40 to 0 DEG C; then pumping the mixture into a microchannel reactor, carrying out mixed reaction for 100-300 seconds in a low-temperature microchannel at-40-10 DEG C, and then introducing the mixture into a room-temperature microchannel at 20-30 DEG C to react for 100-400 seconds, so as to obtain a reaction mixture; and 2, carrying out vacuum rectification on the reaction mixture obtained in the step 1, and collecting the product with the fraction temperature of 35-40 DEG C under 20 + / -3 mmHg to obtain the high-purity diiodosilane. The diiodosilane is synthesized through the microchannel reactor, the original synthesis period can be shortened to be within 700 seconds, and the obtained mixture product is high in content and low in impurity metal ion content.

Owner:安徽敦茂新材料科技有限公司

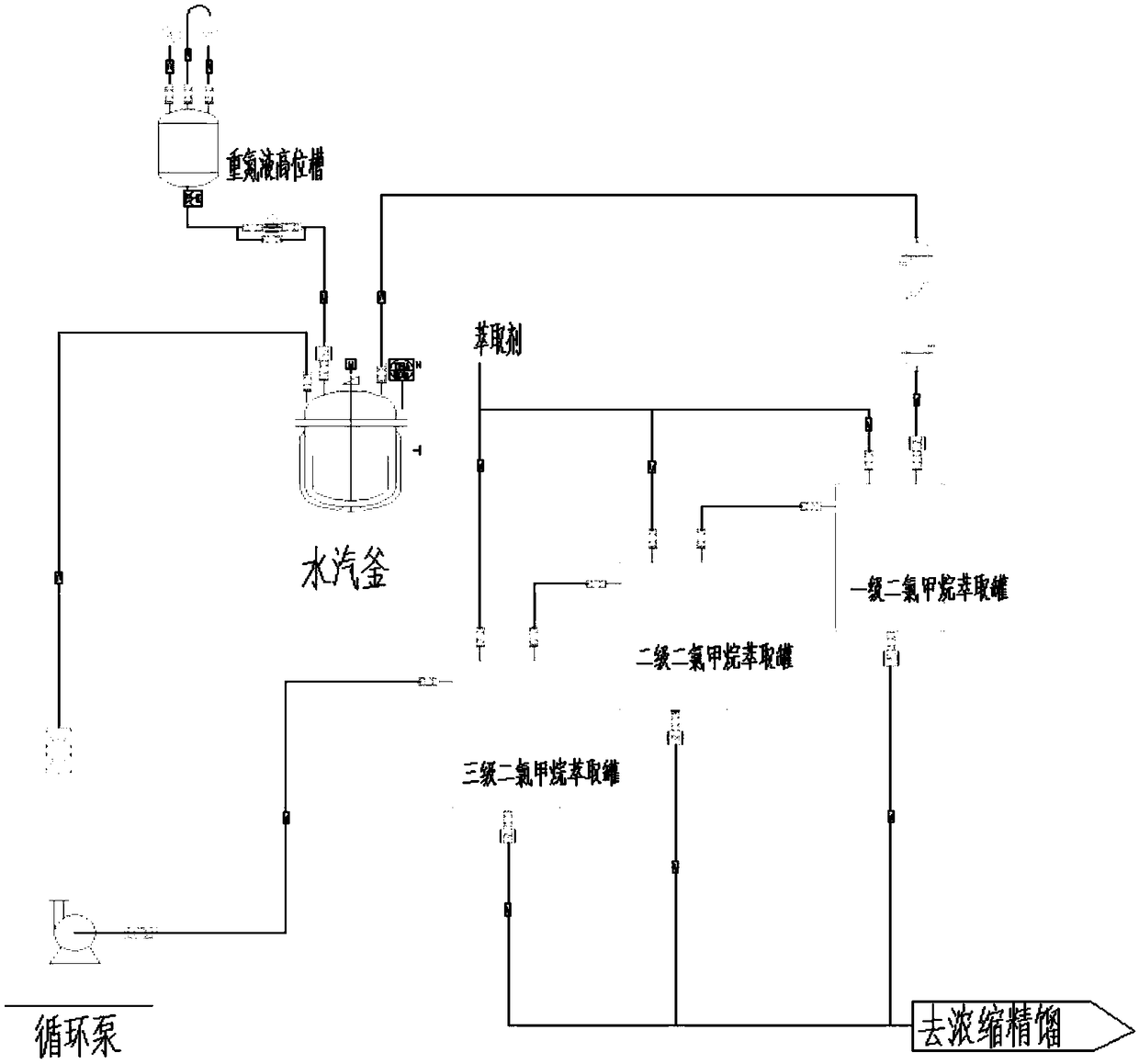

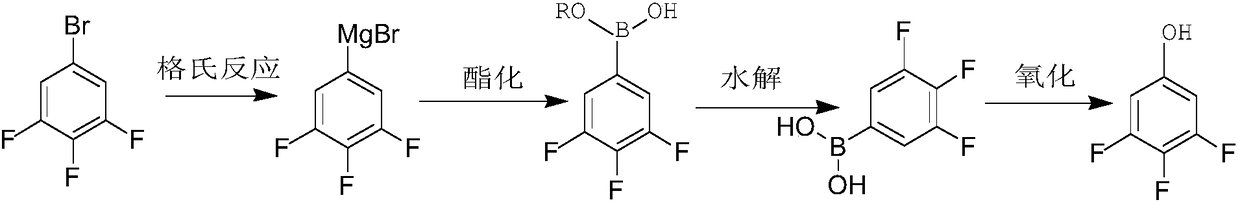

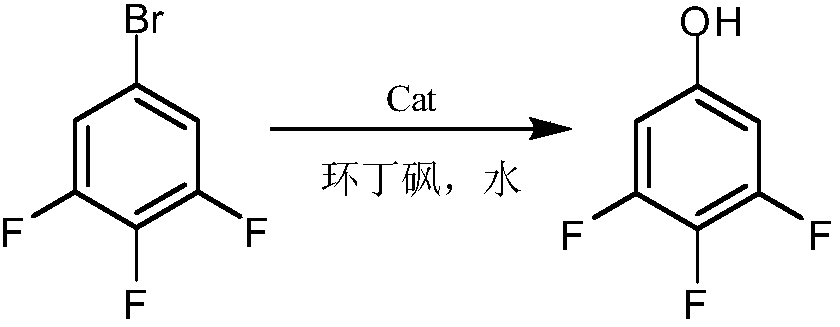

Synthesis method of 3, 4, 5-trifluorophenol

InactiveCN109456150ALow costSimple processOrganic compound preparationAmino compound preparationNitrosylsulfuric acidThree stage

The invention discloses a synthesis method of 3, 4, 5-trifluorophenol. The synthesis method includes following steps: taking 3, 4, 5-trifluorobromobenzene as a raw material, adding a certain volume ofammonia water and cuprous complexing catalyst, allowing heat-insulating reaction in a high-pressure kettle, and performing aftertreatment to obtain 3, 4, 5-trifluoroaniline; allowing 3, 4, 5-trifluoroaniline to be salified with sulfuric acid, being in diazotization reaction with nitroso-sulfuric acid, and hydrolyzing under copper salt catalysis to obtain 3, 4, 5-trifluorophenol. A hydrolysis device is introduced into a three-stage dichloromethane extraction device. Sulfuric acid concentration of a system is ensured to be constant, so that reaction yield is increased substantially. The synthesis method is easy-to-obtain in raw material and simple in process; the catalyst and the sulfuric acid are used for several times, so that raw material cost is low; the synthesis method is easy for industrialization and has good application prospect.

Owner:ZHEJIANG LINJIANG CHEM

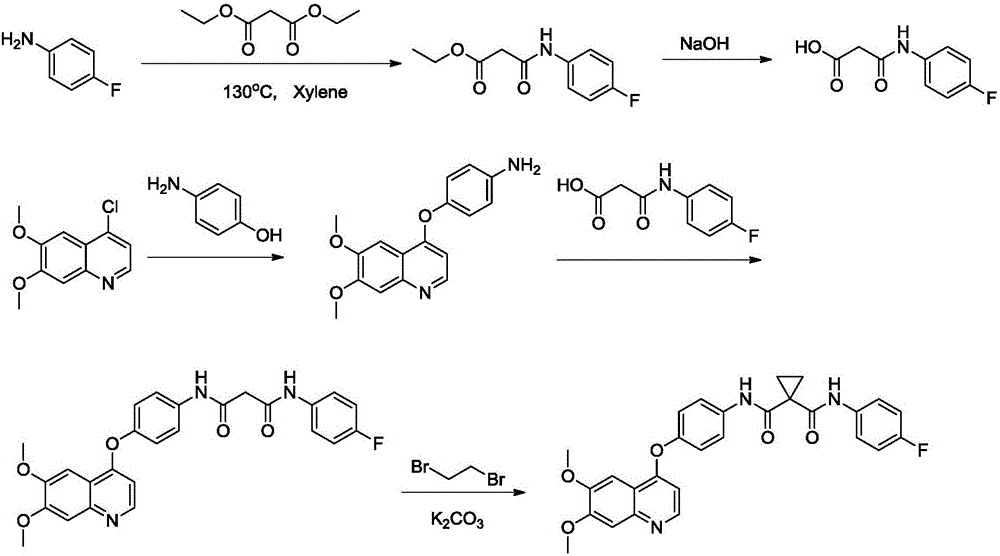

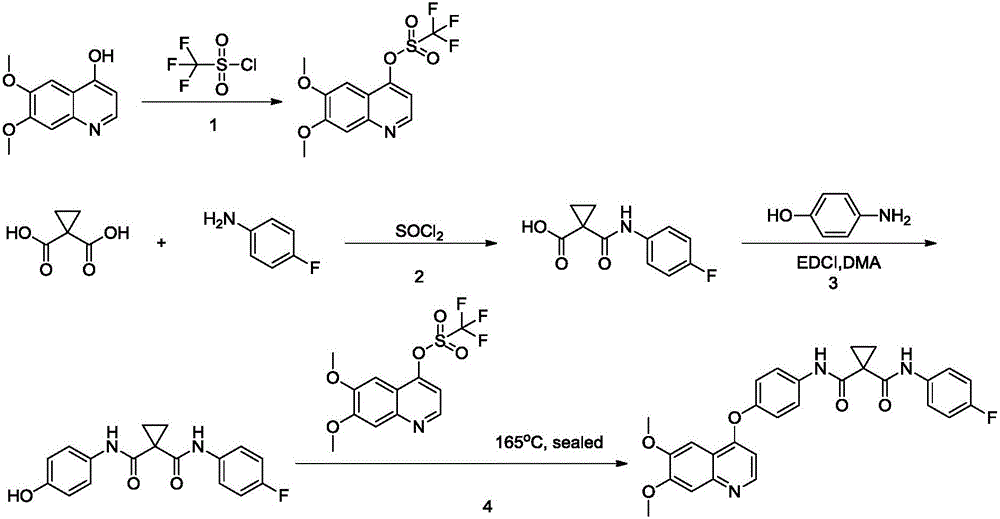

Cabozantinib preparation method

ActiveCN106632028AReduce manufacturing costReduce usageOrganic chemistryEthylene DibromideCabozantinib

The invention discloses a cabozantinib preparation method. The target product cabozantinib is prepared by performing five-step reaction on diethyl malonate, 4-fluoroaniline, 4-chloro-6,7-dimethoxyquinoline, 4-aminophenol, 1,2-dibromoethane and the like used as raw materials. The preparation method is simple to operate and friendly to environment; the comprehensive yield is more than 50% and is obviously increased in comparison with the yield of 20% in the prior art; and the preparation method greatly lowers the existing medicine production cost, and is suitable for industrial large-scale production.

Owner:SHANGHAI ZAIQI BIO TECH

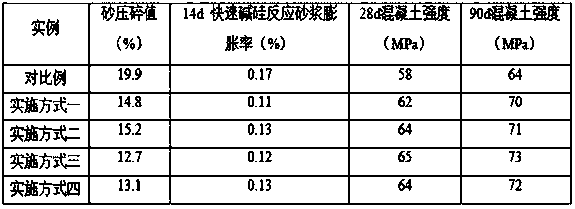

Ferronickel slag aggregate treatment method

The invention discloses a ferronickel slag aggregate treatment method. The ferronickel slag aggregate treatment method comprises the steps of: (1) soaking ferronickel slag aggregate in a mixed aqueoussolution of sodium hydroxide and water glass; (2) adjusting the temperature of the mixed solution obtained in the step (1) to 40-60 DEG C, and keeping the temperature for 1-6 hours; (3) after the heat preservation is finished, quickly stirring the solution for 10-60 seconds; (4) adding sodium carbonate and cement powder, and performing uniform stirring; (5) standing and precipitating the solutionfor 1-2 hours, and performing separating to obtain precipitate and clarified liquid; and (6) screening out ferronickel slag aggregate with the particle size of more than 5mm in the precipitate, naturally air-drying the ferronickel slag aggregate to be used as concrete aggregate, drying and grinding the part with the particle size of less than 5mm in the precipitate to be used as a concrete admixture, and using the clarified liquid as alkali-activated material mixing water. Through treatment of the method, air holes and active ingredients on the surface of the ferronickel slag aggregate are destroyed, and the problems that the ferronickel slag aggregate is high in crushing value and has potential alkali aggregate reaction are solved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

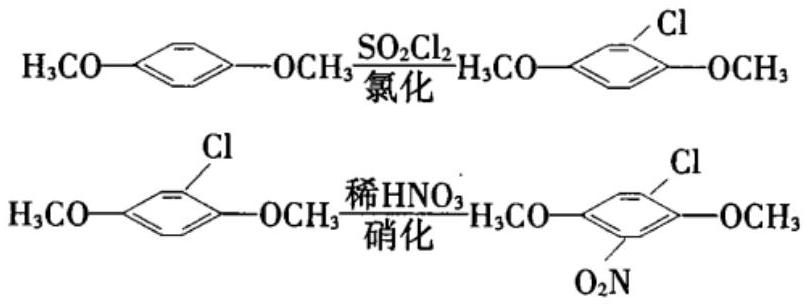

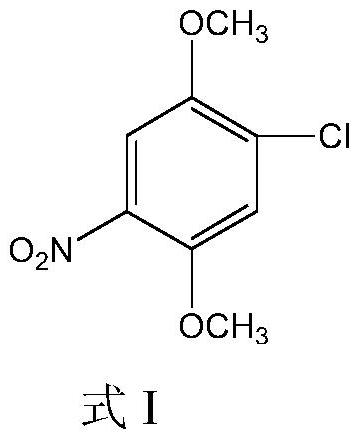

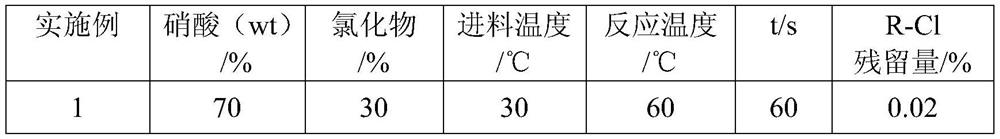

Method for synthesizing 4-chloro-2, 5-dimethoxynitrobenzene by using microreactor

PendingCN111960947AReduce dosageSmall liquid holding capacityChemical/physical/physico-chemical microreactorsNitro compound preparationChlorobenzenePhysical chemistry

The invention relates to a method for synthesizing 4-chloro-2, 3, 5-tetramethylpiperidine by using a microreactor. According to the method, intermediate 2, 5-dimethoxychlorobenzene of 4-chloro-2, 5-dimethoxynitrobenzene and nitric acid are used as raw materials, 4-chloro-2, 5-dimethoxynitrobenzene is synthesized through the microreactor, in the reaction process, the mass fraction of nitric acid is50%-95%, and the mass fraction of a 2, 5-dimethoxychlorobenzene solution is 15%-50%; the feeding molar ratio of nitric acid to 2, 5-dimethoxychlorobenzene is (1.0-1.5): 1, the reaction temperature is50-85 DEG C, the feeding temperature is not higher than 50 DEG C, and the reaction retention time is 30-120 seconds. According to the method, on one hand, the process conditions such as the materialratio and the reaction temperature are accurately controlled, the dosage of nitric acid is reduced, the method is environmentally friendly, the conversion rate of 2, 5-dimethoxychlorobenzene reaches 99.98%, and the yield of 4-chloro-2, 5-dimethoxynitrobenzene reaches 99.5% or above; on the other hand, the key problems of corrosivity of nitric acid, difficulty in controlling the reaction temperature, poor mass and heat transfer effect, poor safety and the like in the conventional synthesis process are solved, and the reaction risk is low; strong operability.

Owner:LILY GRP CO LTD

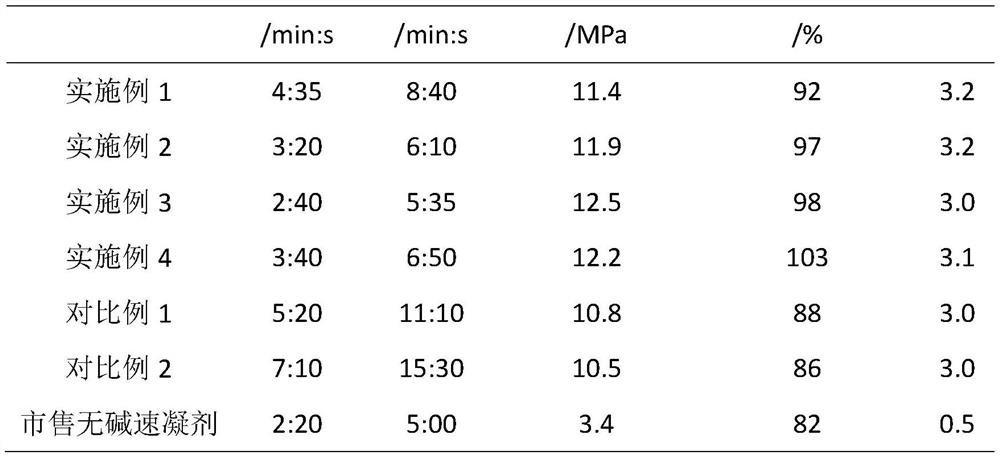

A kind of alkali-free liquid accelerator based on synthetic polyaluminum sulfate

ActiveCN105271867BLow alkali contentReduce the risk of alkali-aggregate reactionAlkali freeAluminium hydroxide

The invention discloses a method for synthesizing polyaluminum sulfate, and discloses a preparation method for an alkali-free liquid quick-setting agent based on synthesizing polyaluminum sulfate. The alkali-free quick-setting agent is prepared by neutralizing aluminum sulfate solution in ammonia water to obtain active aluminum hydroxide gel, and the active aluminum hydroxide is filtered, dried, and ground into powder, and then added to aluminum sulfate solution to obtain polyaluminum sulfate . The proportion of this alkali-free quick-setting agent is: 45%-55% of polyaluminum sulfate, 0-5% of inorganic acid, 0-2% of stabilizer, 0-2% of organic early strength agent, 0-2% of organic tackifier %, the balance is water. In the case of a low dosage of the accelerator, the setting time of cement and the strength of mortar can meet the requirements of JC 477-2005 first-class accelerator for sprayed concrete, and the accelerator is an alkali-free liquid accelerator that can Effectively avoid the adverse effects caused by excessive alkali content. The cement variety of the accelerator has good adaptability.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

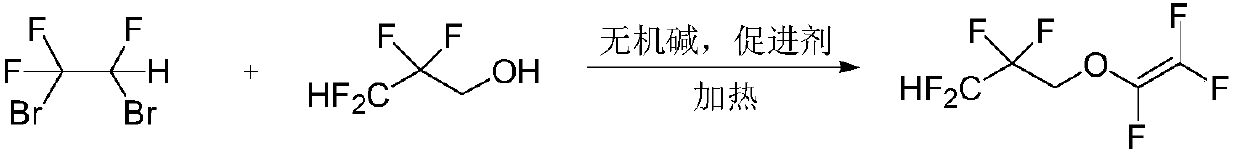

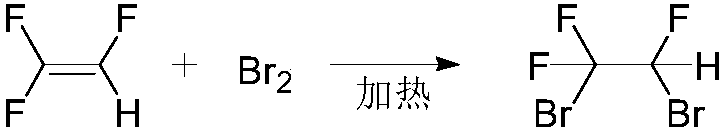

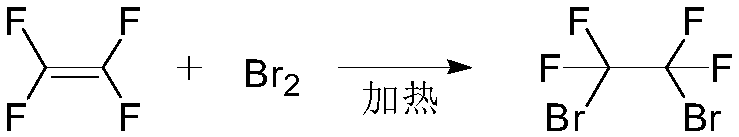

Synthesis method of tetrafluoropropyl trifluoroethylene ether

ActiveCN111018679ASimple response typeMild conditionsOrganic compound preparationPreparation by halogen additionPropanolEther

The invention relates to a preparation method of tetrafluoropropyl trifluoroethylene ether. The preparation method comprises the following main steps: in an alkaline environment, under the condition of heating, carrying out substitution and elimination on tetrafluoropropanol and 1,2-dibromo-1,1,2-trifluoroethane to obtain the tetrafluoropropyl trifluoroethylene ether. Compared with the existing reaction, the method provided by the invention has the advantages of simple reaction type, mild reaction conditions, strong operability, no use of organic solvents, environmental protection, fast reaction rate and high product yield, overcomes the difficulty of using metallic sodium and organic solvents in the prior art, reduces the reaction risk, and is suitable for industrial production.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

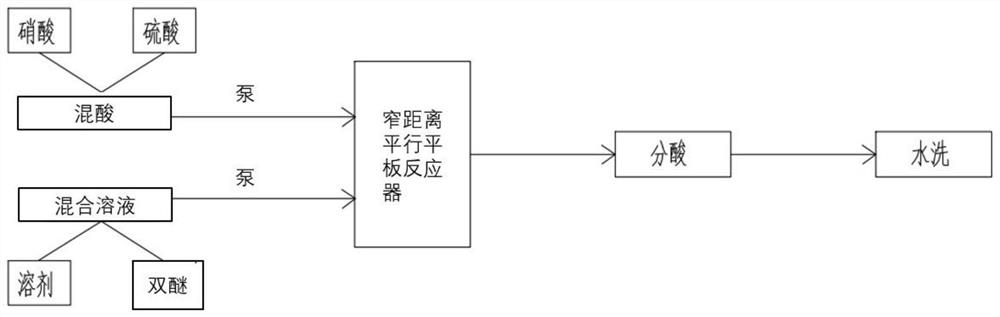

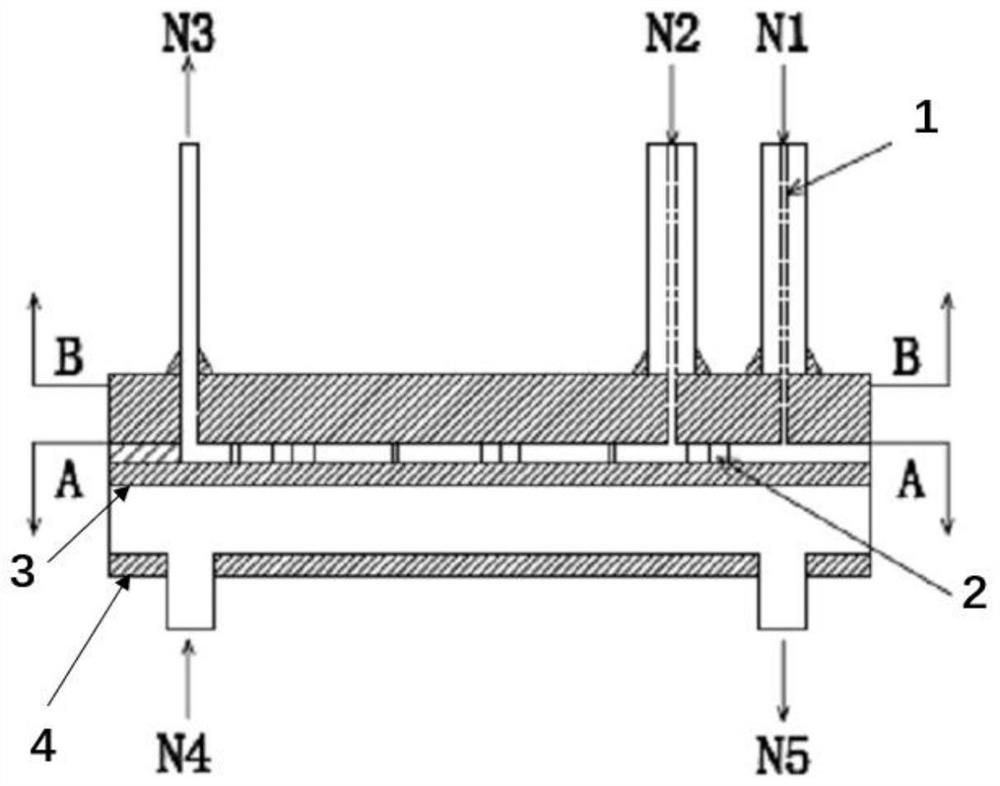

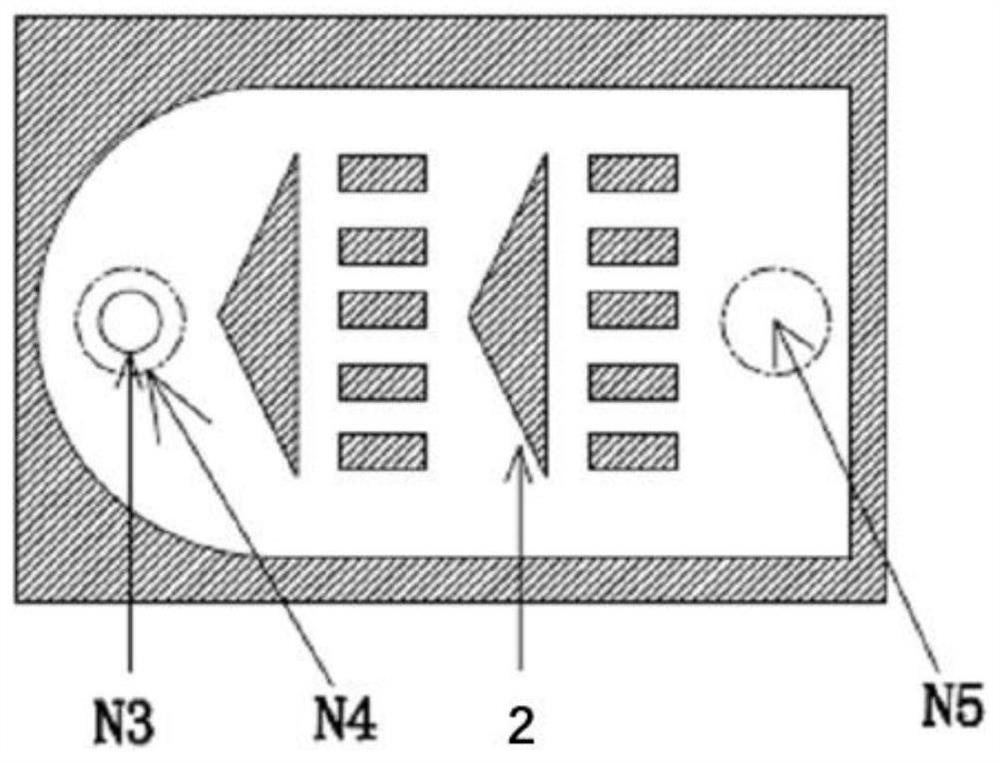

Process for synthesizing nitro diether by adopting narrow-distance parallel plate reactor

PendingCN112174826AEasy to removeShort reaction timeChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsMeth-Parallel plate

The invention belongs to the technical field of chemical engineering, and discloses a process for synthesizing an intermediate nitrodiether of oxyfluorfen by adopting a narrow-distance parallel platereactor, which comprises the following steps: by using 3, 4-dichlorobenzotrifluoride and resorcinol as raw materials, condensing to obtain 1, 3-bis[2-chloro-4-(trifluoromethyl)phenoxy]benzene, and carrying out a nitration reaction process on 1, 3-bis[2-chloro-4-(trifluoromethyl)phenoxy]benzene and a nitrating agent in a narrow-distance parallel plate reactor, so that nitro diether is prepared. Thecontinuous narrow-distance parallel plate reaction is adopted, so that huge heat generated by the reaction can be quickly removed, the reaction temperature can be controlled at 50-95 DEG C, the reaction time is greatly shortened, and the molar equivalent of reaction substances in the reaction process is extremely small, so that the reaction is intrinsically safe, the reaction risk is reduced, andthe process safety is improved.

Owner:西安本清化学技术有限公司

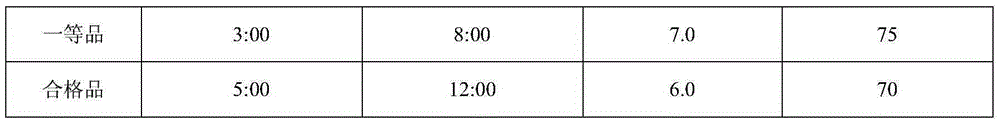

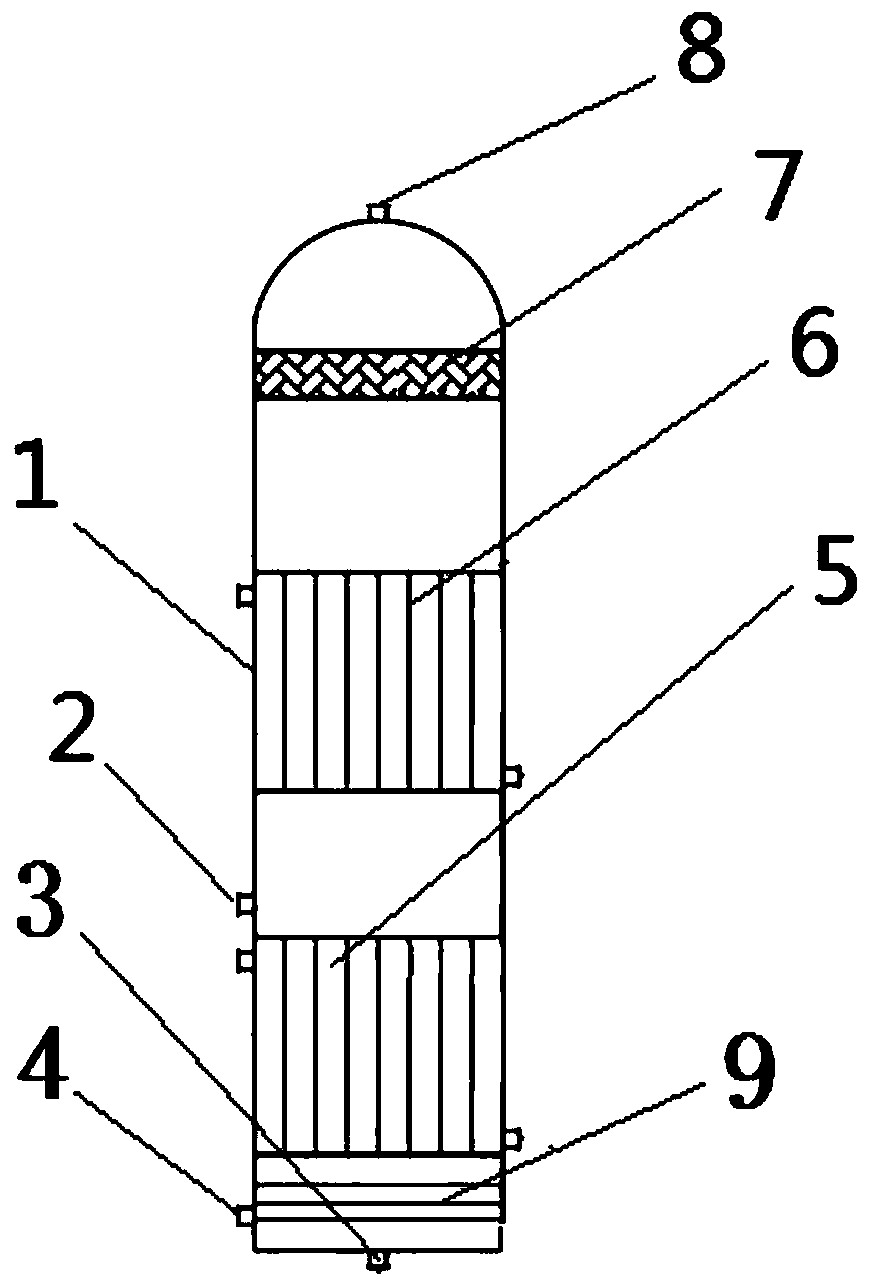

Accelerating agent as well as preparation method and application thereof

The invention belongs to the field of building materials, and particularly relates to an accelerator as well as a preparation method and an application thereof. The accelerator is mainly prepared by mixing water and the following raw materials in parts by mass: 35-50 parts of aluminum salt, 1-3 parts of silicate, 3-10 parts of fluoride salt, 5-10 parts of a neutralizer and 5-10 parts of a stabilizer. The aluminum salt, the silicate, the fluoride salt, the neutralizer and the stabilizer are introduced into the accelerator, so that the accelerating effect is remarkable, and the stability of the accelerator can be obviously enhanced.

Owner:DO FLUORIDE CHEM CO LTD

A kind of green high-early-strength low-alkali liquid accelerator and preparation method thereof

The invention discloses a green high-early-strength low-alkali liquid accelerator. The components include: aluminum sulfate: (30-60%), sodium fluoride: (5-20%), alcohol Aluminum: (4‑10%), stabilizer: (3‑10%), suspending agent: (1‑5%), defoamer: (0‑1%), and the rest is water. A low-alkali liquid quick-setting agent for shotcrete of the present invention has the advantages of low alkali, no chlorine, no corrosion to human body and machines, no irritating smell, high early strength, high late strength retention rate, good durability, etc. , can greatly reduce the risk of concrete alkali-aggregate reaction and the erosion of reinforced concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

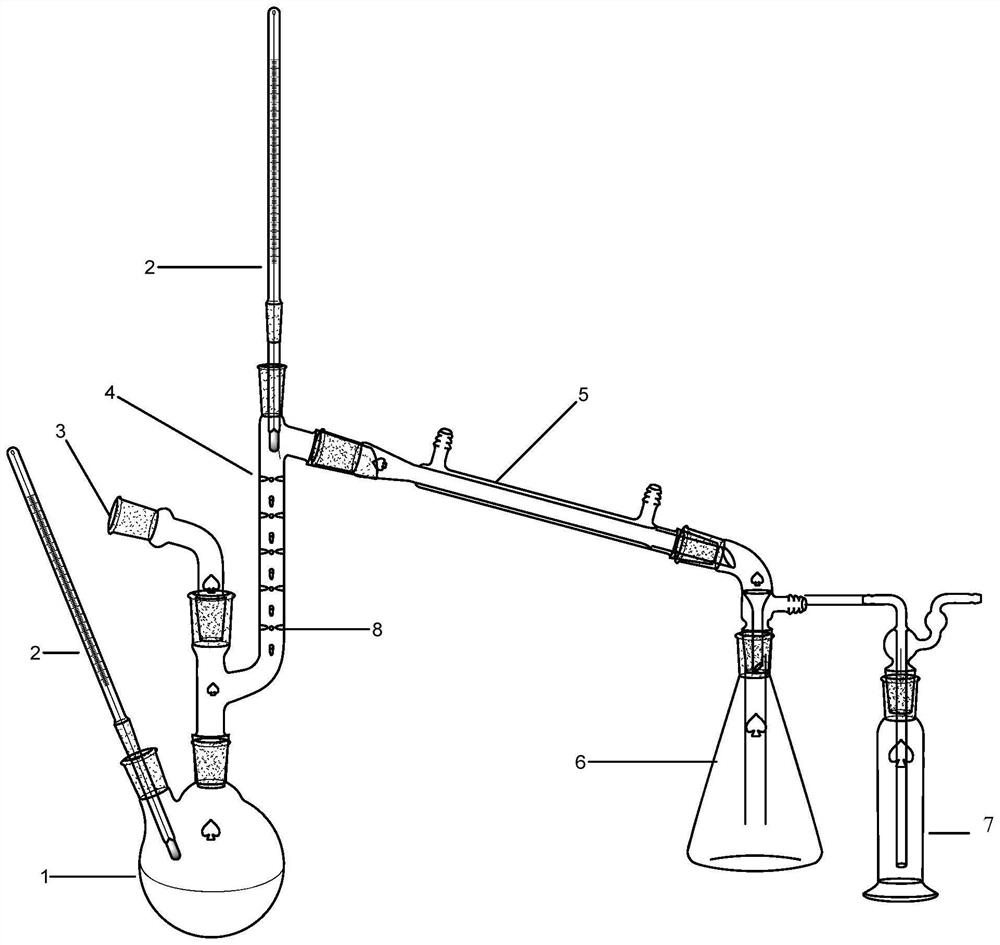

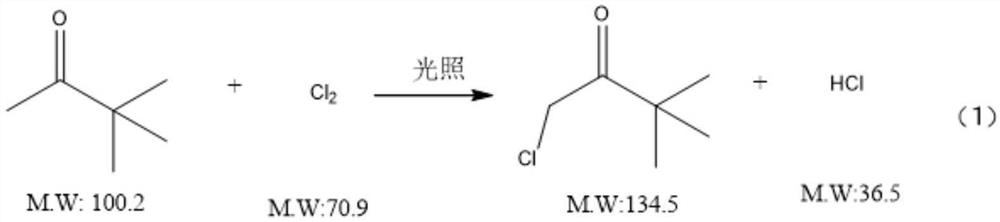

Method for preparing high-purity chloropinacolone through photocatalysis

PendingCN114409516ALow costReduce contentOrganic compound preparationDispersed particle separationProcess engineeringHydrogen chloride

The invention discloses a method for efficiently preparing high-purity chloropinacolone, which comprises the following steps: adding quantitative pinacolone into a clean gasification kettle, and starting stirring; when the system is heated to 105-108 DEG C, pinacolone is gasified and enters the reactor, illumination is started, and chlorine is introduced into the reactor; the method comprises the following steps: reacting pinacolone with chlorine under an illumination condition to generate chloropinacolone; the outlet temperature of the reactor is ensured to be lower than 100 DEG C, pinacolone and chloropinacolone are liquefied and flow back into the gasification kettle, and hydrogen chloride gas generated by reaction can be discharged in time. According to the method disclosed by the invention, photocatalysis and gasification reaction are jointly applied to synthesis of the monochloropinacolone for the first time, and the obtained monochloropinacolone is high in yield, high in purity and low in byproduct content, and the quality of the monochloropinacolone is far higher than that of a product prepared by an existing process.

Owner:JIANGSU SWORD AGROCHEM +1

Vaccine and combination medicine for preventing tuberculosis, method for preparing vaccine and application

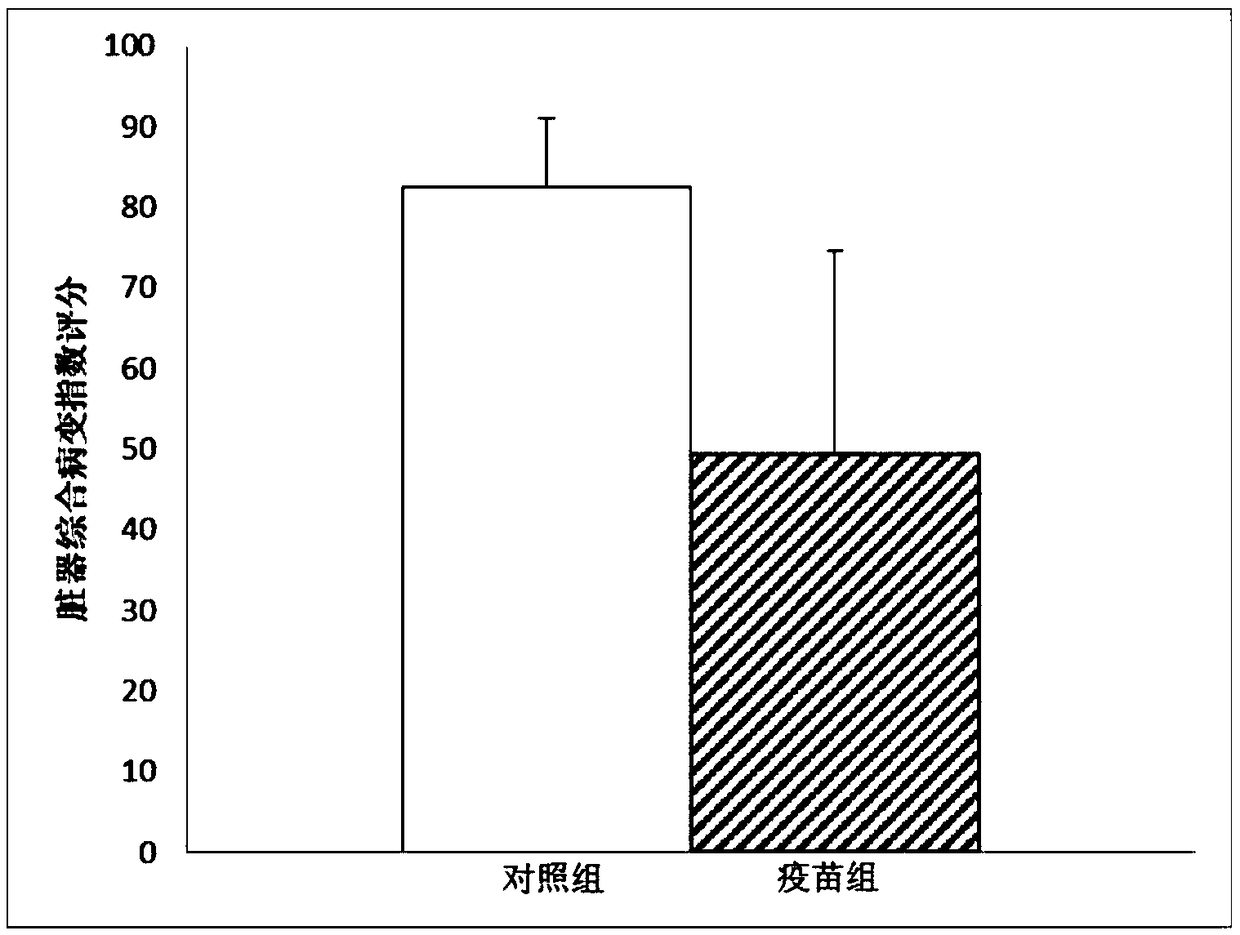

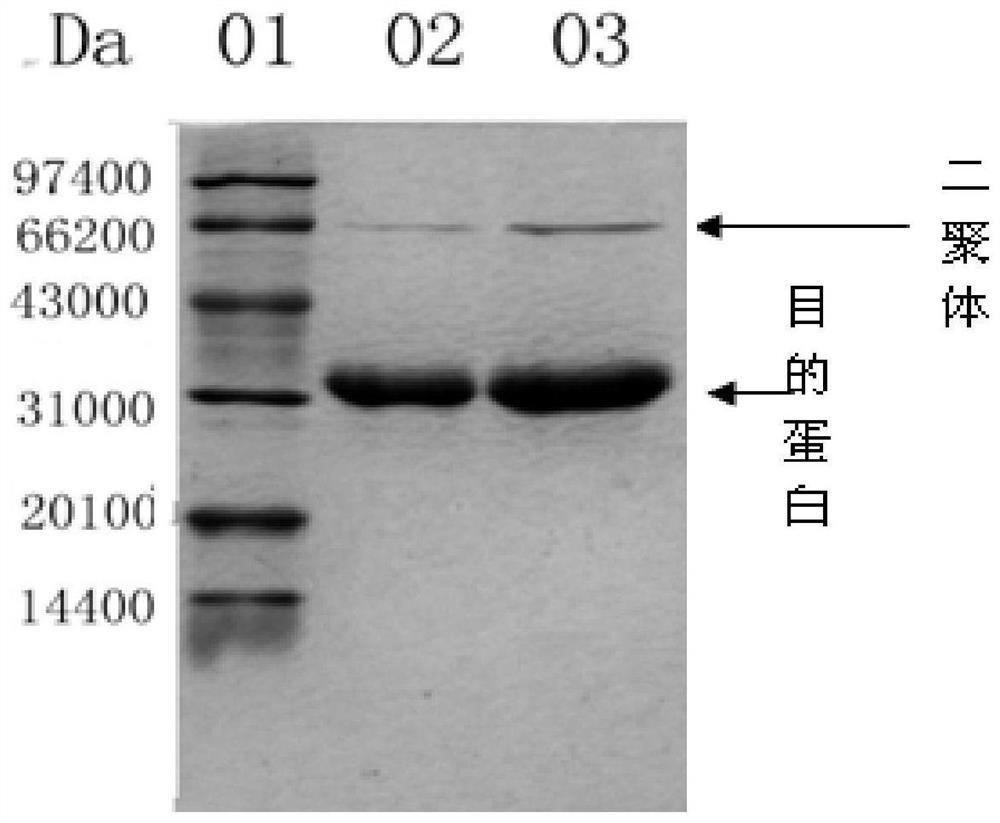

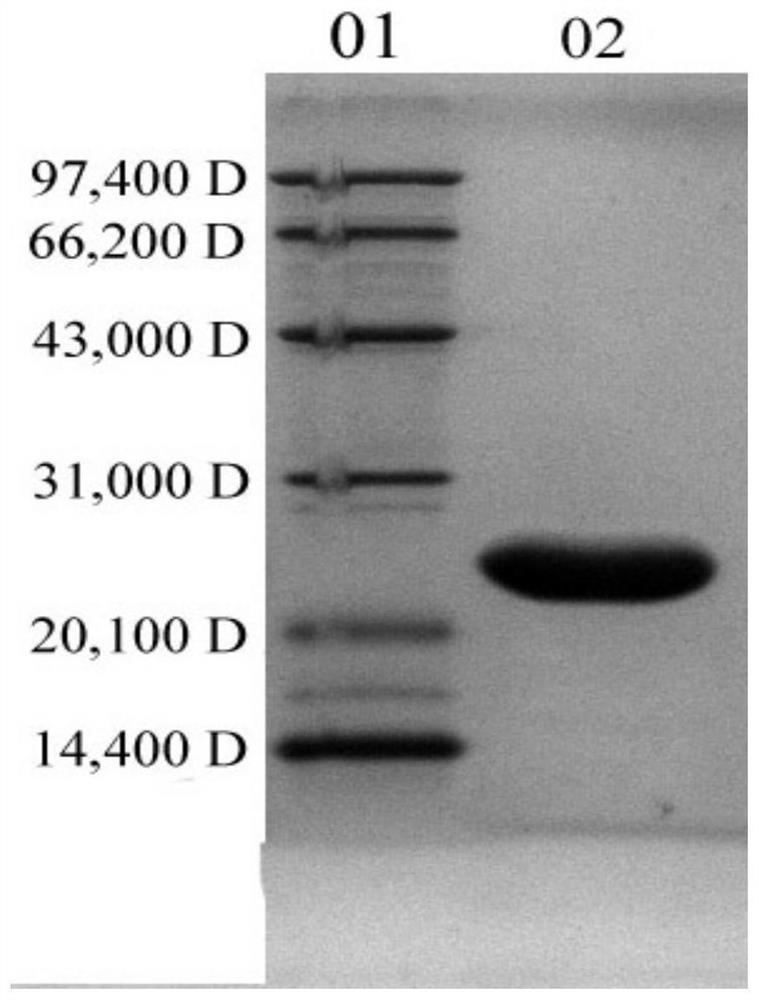

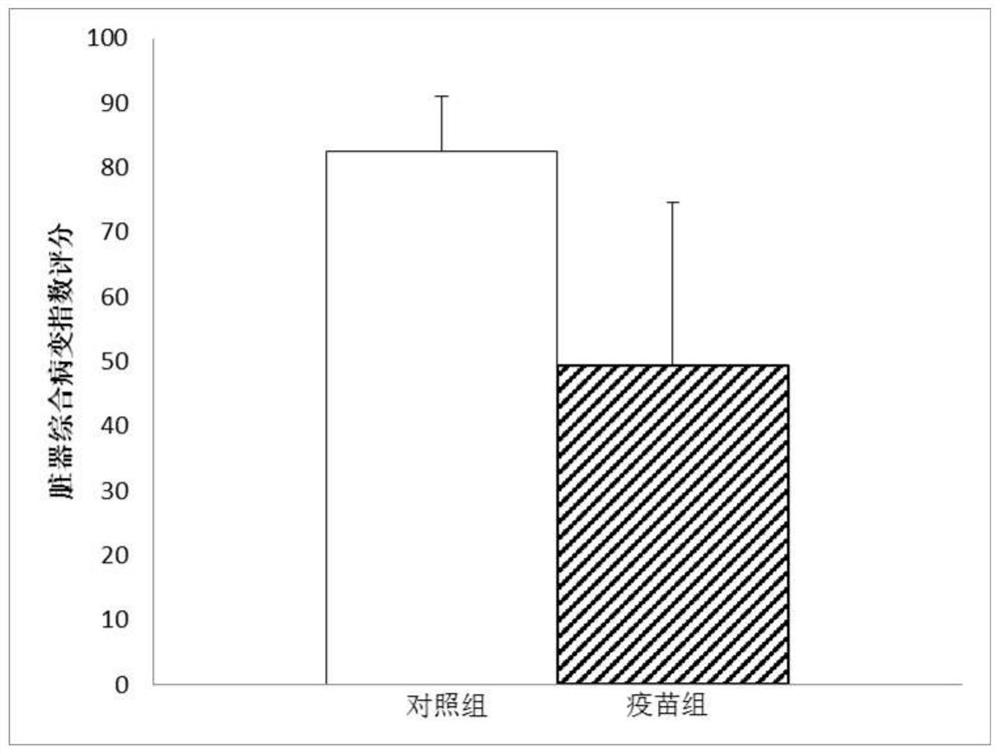

ActiveCN109078177AStrong ability to eradicate Mycobacterium tuberculosisImproving immunogenicityAntibacterial agentsBacterial antigen ingredientsAdjuvantSingle type

The invention discloses vaccine and a combination medicine for preventing tuberculosis, a method for preparing the vaccine and application, and belongs to the field of medicines for treating tuberculosis latent infection. By the aid of the vaccine with mycobacterium microbial compound adjuvants for preventing the tuberculosis, the problems of ineffectiveness or poor effects of existing subunit vaccine for treating tubercle bacillus latent infected population, diversified adjuvants, hypersensitivity and Koch reaction risks can be pertinently solved. The vaccine with mycobacterium microbial compound adjuvants for preventing the tuberculosis comprises Ag85b proteins, ESAT6-CFP10 proteins and mycobacterium vaccae thallus extract. The vaccine, the combination medicine, the method and the application have the advantages that the vaccine with the mycobacterium microbial compound adjuvants for preventing the tuberculosis is used for treating latent tuberculosis infection, and obvious effects can be realized; the vaccine only comprises a single type of adjuvants, and accordingly hypersensitivity and Koch reaction risks can be prevented.

Owner:ANHUI ZHIFEI LONGCOM BIOPHARM CO LTD +3

A kind of vaccine for preventing tuberculosis and combination drug and preparation method and application

ActiveCN109078177BSide effects are rareMinor side effectsAntibacterial agentsBacterial antigen ingredientsAdjuvantLatent tuberculosis

The invention discloses a vaccine for preventing tuberculosis, a combined medicine, a preparation method and an application, and belongs to the field of medicines for treating latent infection of tuberculosis. Aiming at the problems that the existing subunit vaccines are ineffective or poor in treating people with latent tuberculosis infection, many types of adjuvants are used, and there are risks of hypersensitivity reactions and Koch reactions, the present invention provides a prevention method containing a mycobacterial microbial compound adjuvant Tuberculosis vaccine, which comprises Ag85b protein, ESAT6-CFP10 protein and Mycobacterium vaccae cell extract. The tuberculosis prevention vaccine containing the mycobacterial microbial compound adjuvant of the present invention is used for treating latent tuberculosis infection, and the effect is remarkable.

Owner:ANHUI ZHIFEI LONGCOM BIOPHARM CO LTD +3

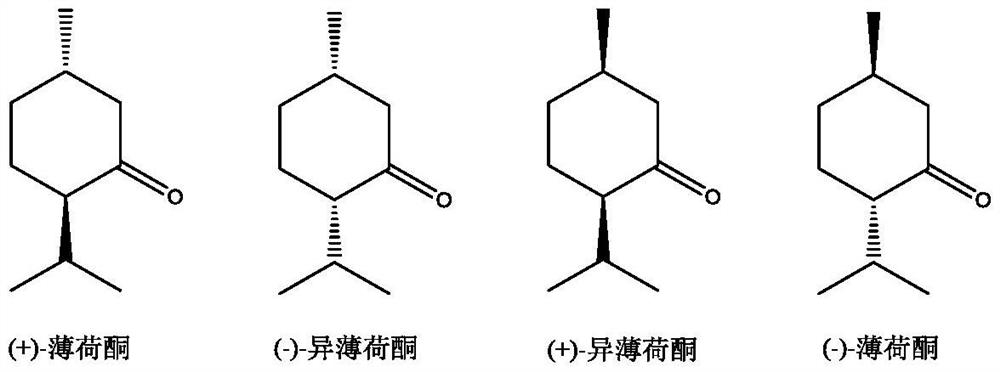

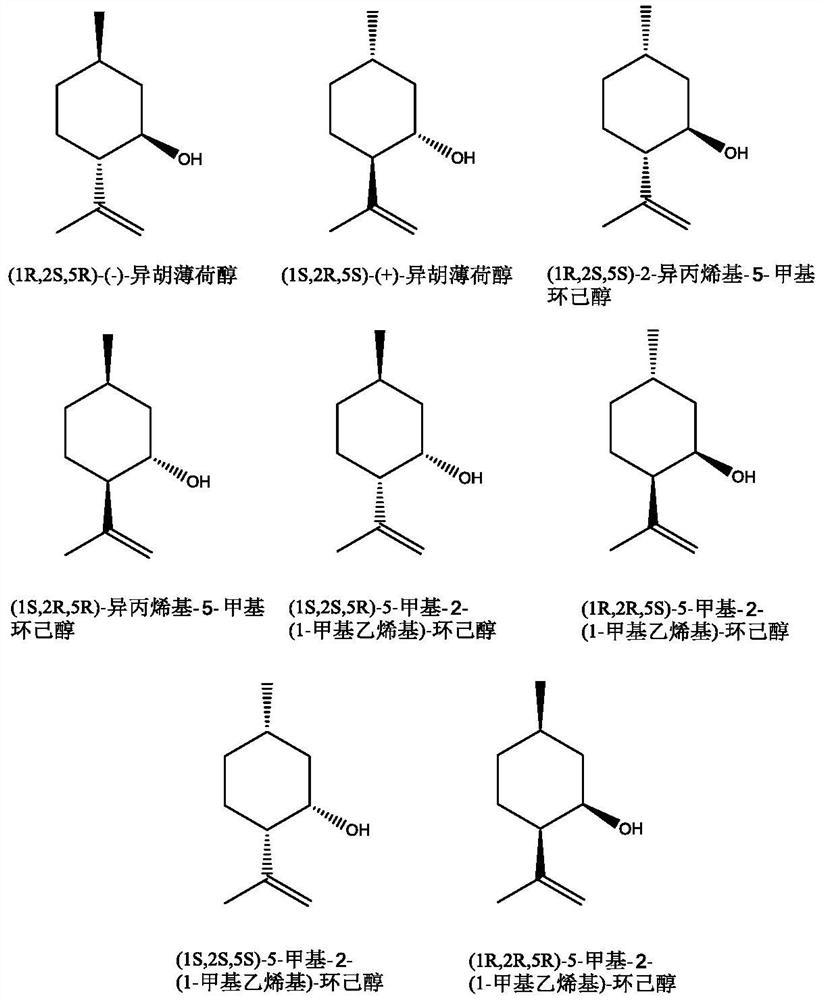

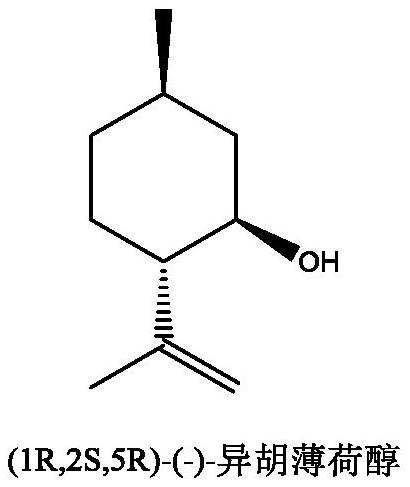

A method for preparing high-purity l-menthone

ActiveCN109438212BHigh purityExcellent electron transfer abilityOrganic chemistry methodsCarbonyl compound preparation by oxidationPtru catalystProcess engineering

Owner:WANHUA CHEM GRP CO LTD

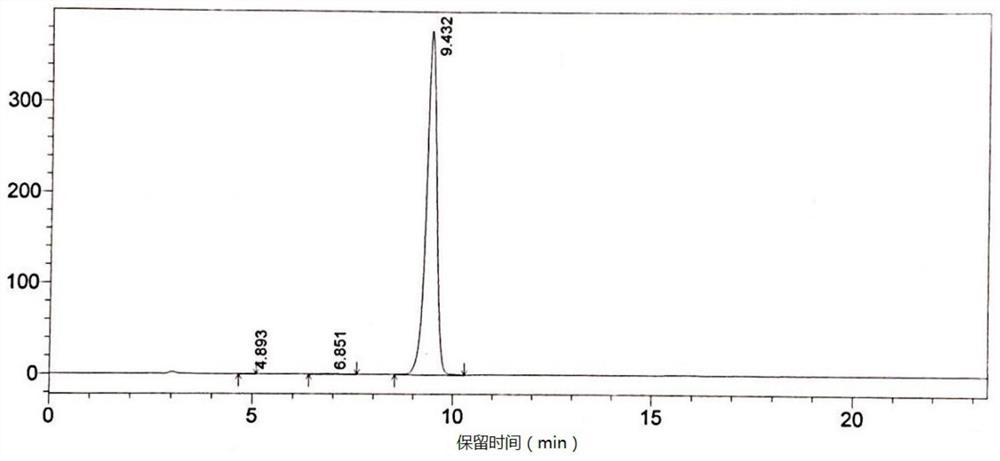

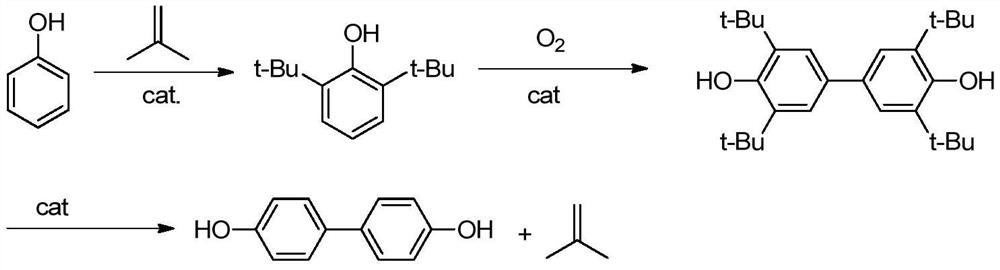

A kind of method adopting loop reactor to synthesize 4,4'-dihydroxybiphenyl

ActiveCN113416119BIncrease mass transfer rateImprove reaction efficiencyOrganic chemistryOrganic compound preparationTert butyl phenolOrganic solvent

Owner:四川圣效科技有限公司 +1

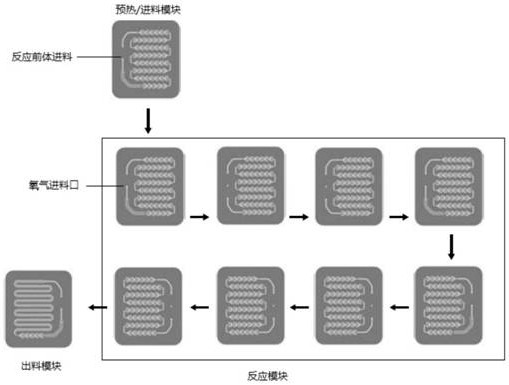

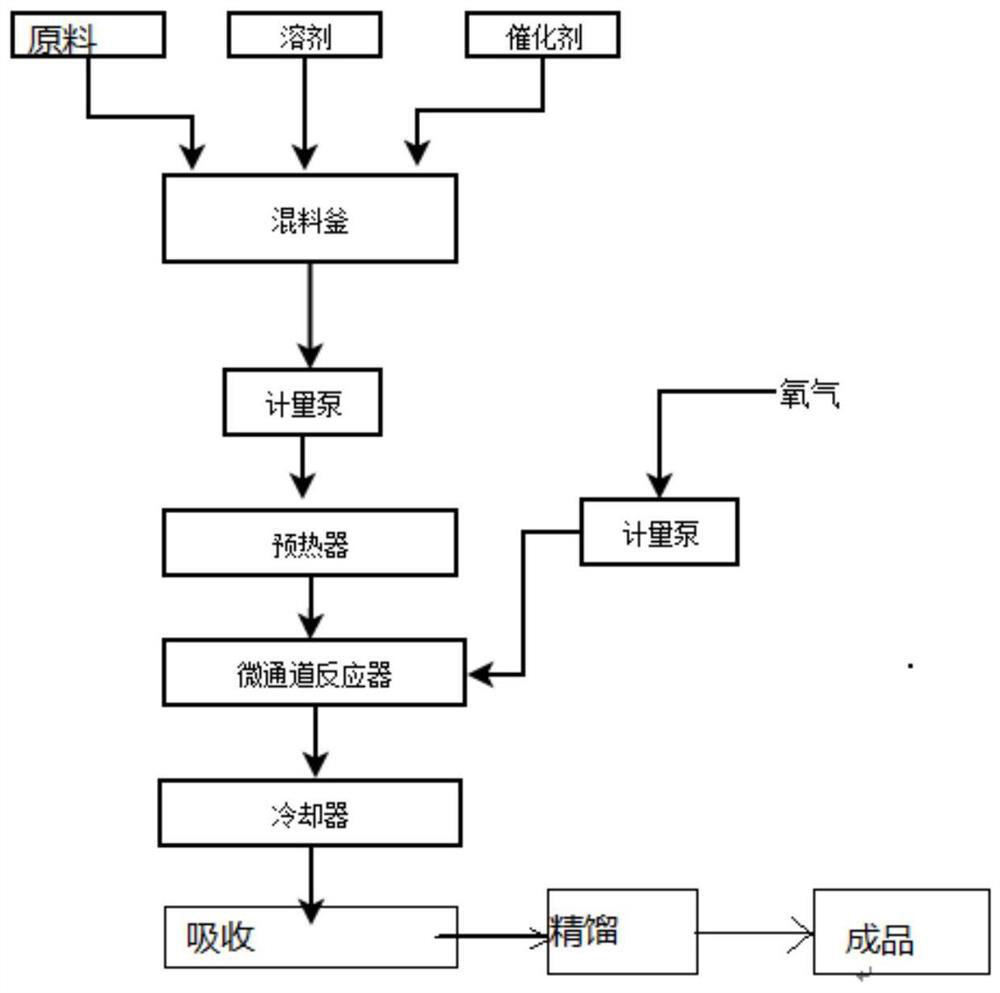

Method for synthesizing biphenyldianhydride in continuous flow microchannel reactor

ActiveCN108610314BImprove consistencyLow costOrganic chemistryChemical recyclingAcetic acidPtru catalyst

The invention discloses a method for synthesizing biphenyl dianhydride in a continuous-flow microchannel reactor: step 1 configures a reaction solution, mixes tetramethylbiphenyl, glacial acetic acid, a catalyst and an accelerator uniformly; step 2 preheats the reaction solution, Then enter the reaction module, and at the same time pass pure oxygen into the reaction module, and the reactants are mixed and reacted in the reaction module; after a certain period of time in step 3, the reaction product enters the receiving tank; in step 4, the acetic acid solvent is recovered, dehydrated, refined and recycled , the remaining product is washed and extracted to obtain biphenyl tetraic acid, and biphenyl dianhydride is obtained through melting and dehydration; step 5 biphenyl dianhydride is further purified to obtain 3,3'-BPDA, 3,4'-BPDA and 4, 4'‑BPDA.

Owner:SHANDONG GUANSEN POLYMER MATERIAL TECH CO LTD

A kind of ferronickel slag aggregate concrete

The invention discloses a nickel-iron slag aggregate concrete. The concrete is prepared by mixing the following raw materials in parts by mass: 100-150 parts of cement, 100-200 parts of lithium slag powder, 1500-1800 parts of nickel-iron slag aggregate, nickel Iron slag powder 100~300 parts, water reducer 5~20 parts, polymer emulsion 30~50 parts, mixing water 120~150 parts. The invention improves the crushing value of the ferronickel slag aggregate through the pretreatment of the ferronickel slag aggregate, and reduces the risk of potential alkali aggregate reaction of the ferronickel slag aggregate concrete. At the same time, the amount of cement used in the present invention is small, and the alkalinity of lithium slag powder and ferronickel slag powder is low. The combination of the three reduces the overall alkalinity of concrete and also reduces the risk of alkali-aggregate reaction.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

A kind of continuous production method of vulcanization accelerator dpg

ActiveCN108586295BRelieve pressureReduce the risk of reactionsOrganic chemistryOrganic compound preparationPtru catalystOrganic solvent

The invention provides a continuous production method of a vulcanization accelerator DPG. The method comprises the following steps: (1) mixing diphenylthiourea, catalyst, ammonia water and an organic solvent to obtain a reaction raw material mixture; (2) reacting The raw material mixture and the oxidant are oxidized in a continuous flow reactor to obtain a reaction product; (3) post-processing the reaction product to obtain a vulcanization accelerator DPG; wherein the organic solvent in step (1) can dissolve diphenylsulfide Urea and vulcanization accelerator DPG. The method reduces the pressure in the reaction process, improves the utilization rate of raw materials, and while stabilizing the product quality, greatly shortens the reaction time compared with the traditional process, improves the reaction yield, and effectively overcomes the limitations of the traditional kettle-type batch production. shortcoming.

Owner:KEMAI CHEM

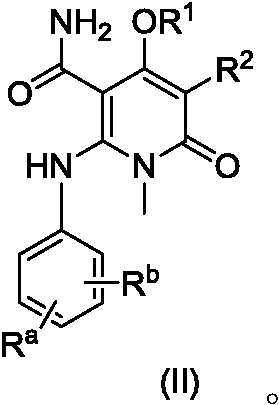

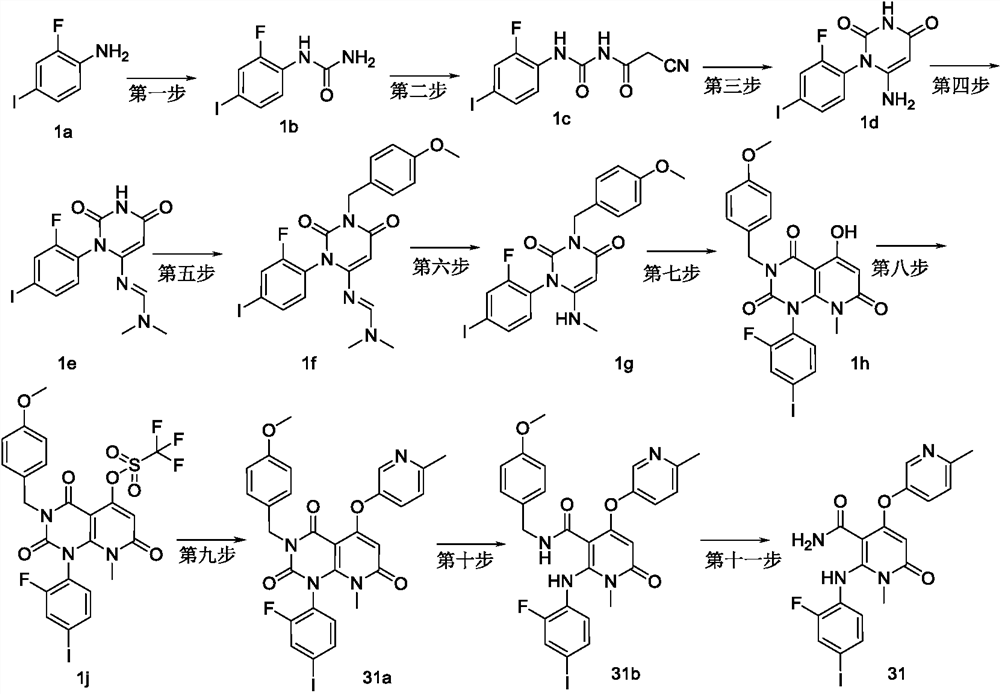

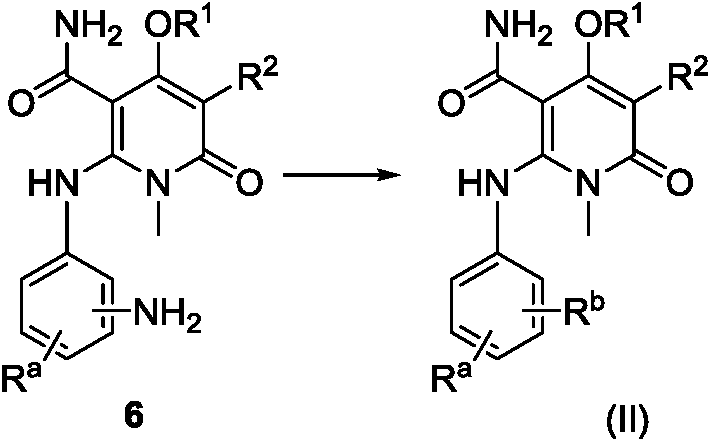

A kind of preparation method of pyridone derivatives and its intermediate

ActiveCN108884048BFew reaction stepsEasy to buyOrganic chemistryCombinatorial chemistryPerylene derivatives

Owner:JIANGSU HENGRUI MEDICINE CO LTD

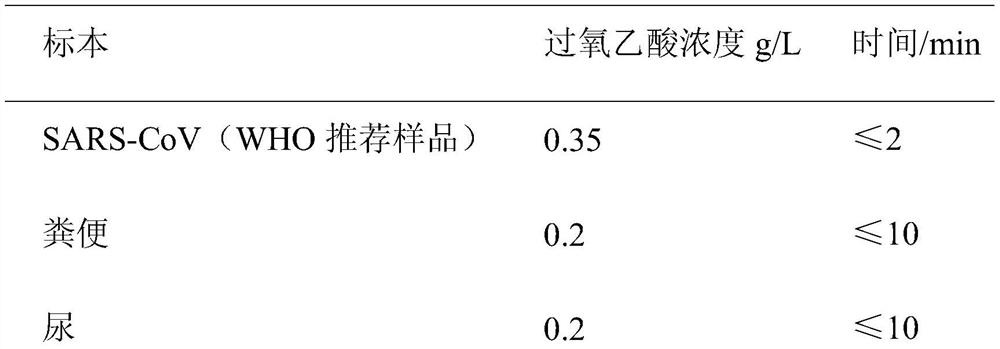

Catalyst for preparing peracetic acid disinfectant and preparation method of disinfectant

PendingCN112958079ASimple process routeImprove stabilityBiocideOrganic compound preparationPlatinumPtru catalyst

The invention provides a catalyst for preparing a peracetic acid disinfectant and a preparation method of the disinfectant, and the catalyst is prepared by the following steps: under certain conditions, uniformly mixing a catalyst precursor and an auxiliary material, and carrying out heat treatment and activation to obtain the catalyst. The catalyst precursor is one or two or more of a metal precursor salt, a metal oxide and a metal elementary substance, and the metal precursor salt is one or two or more of potassium chloroaurate, potassium chloropalladate, potassium chloroplatinate, ruthenium trichloride, silver nitrate and sodium hexachlororhodate; the metal oxide is one or two or more of PtOx, PdOx, RuOx, RhOx, IrOx, AuOx, AgOx and AlOx; and the metal elementary substance is one or two or more of Pt, Pd, Ru, Rh, Ir, Au, Ag and Al. Low-concentration hydrogen peroxide is suitable for peracetic acid synthesis, dependence on a high-concentration hydrogen peroxide production device is avoided, and production popularization can be achieved.

Owner:CHINA TIANCHEN ENG

Gas-liquid phase vinyl chloride production process and equipment

ActiveCN110698319BInhibit surface carbonHigh catalytic efficiencyPreparation by halogen halide additionCatalytic liquid-gas reactionPtru catalystSolid reaction

The invention provides a gas-liquid phase vinyl chloride production process and device, belonging to the technical field of chemical product preparation, comprising the following steps: raw material treatment, the raw material includes a liquid catalyst and a mixed gas composed of hydrogen chloride and acetylene; acetylene hydrochlorination reaction, acetylene React with hydrogen chloride to generate vinyl chloride, and control the reaction temperature through a heat exchanger during the reaction; gas-liquid separation, the generated vinyl chloride gas flows out of the liquid catalyst, and the liquid catalyst cools and liquefies when the vinyl chloride gas passes through the condenser and flows back to The reaction zone acts on the reaction again; the liquid catalyst is recovered, and a small amount of liquid catalyst is separated again by means of a demister; the conversion rate of acetylene is detected. When the conversion rate is lower than 95%, the liquid catalyst is replaced. When the conversion rate is greater than 95%, it is used The original liquid catalyst continues to catalyze, aiming to solve the problems of overheating phenomenon, surface area carbon and low catalytic efficiency caused by gas-solid reaction in the existing process.

Owner:河北美邦工程科技股份有限公司

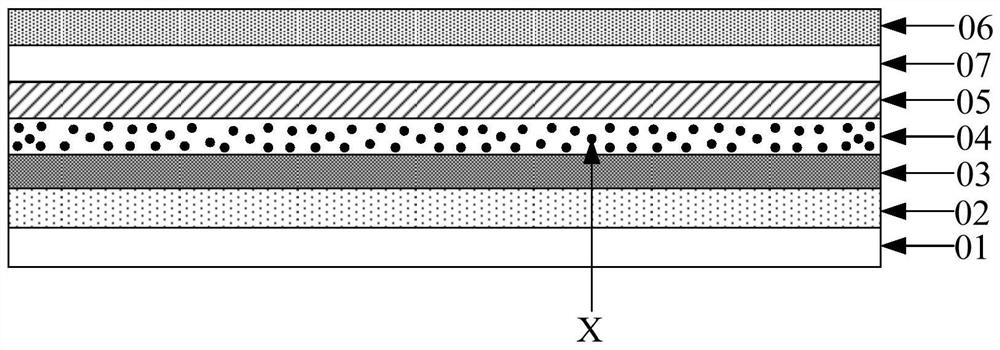

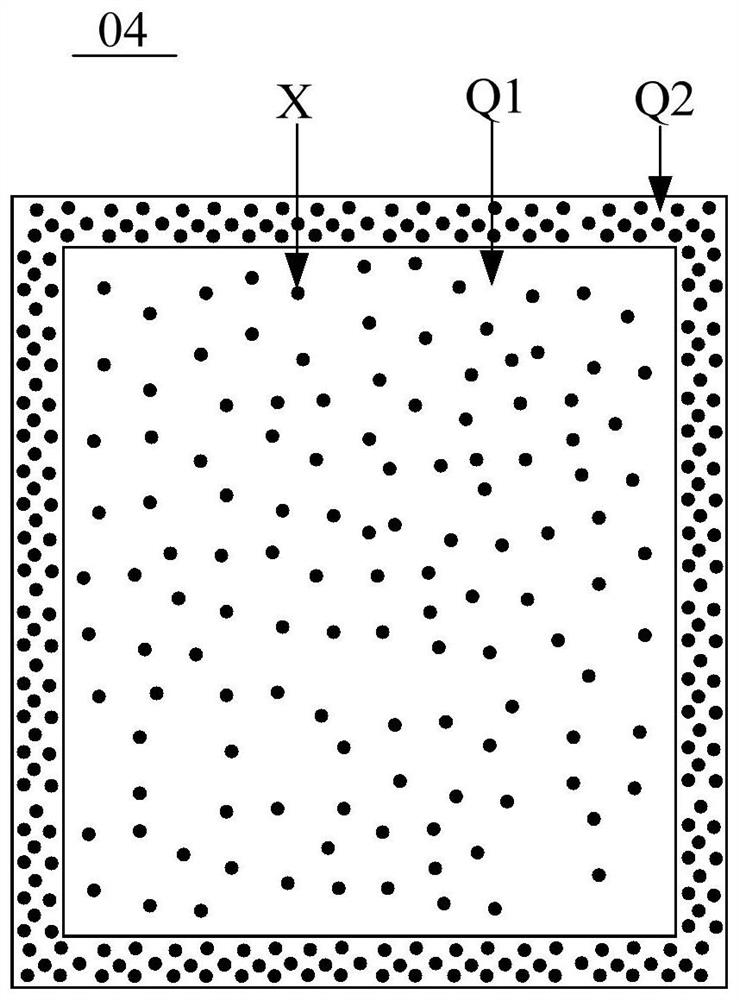

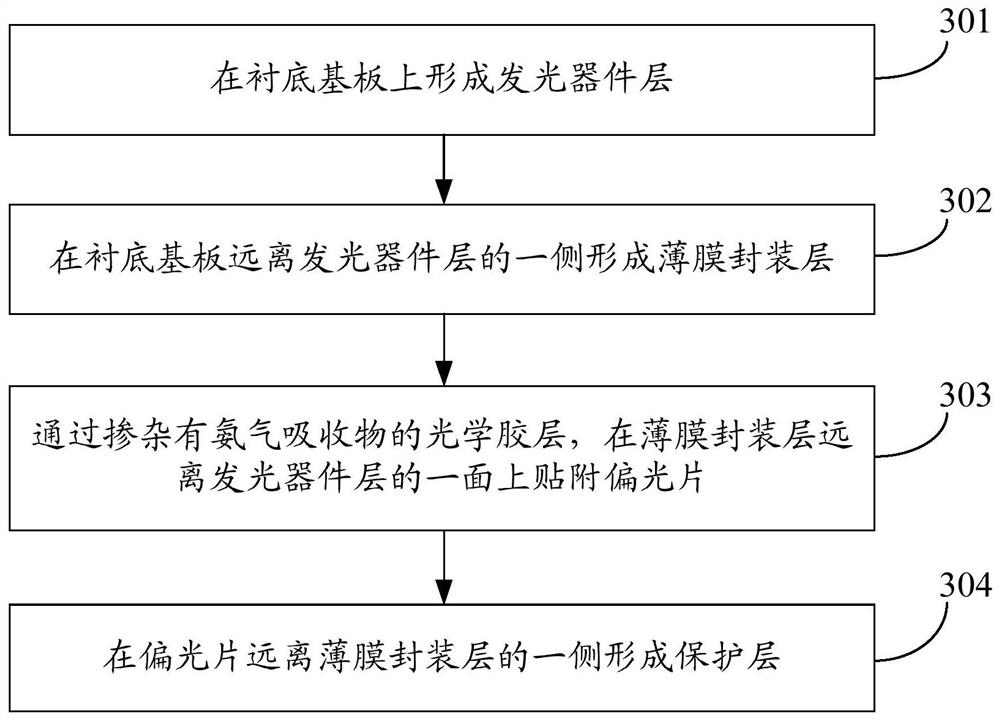

Display substrate, method for manufacturing the same, and display device

ActiveCN109817831BImprove the display effectReduce risk of fadingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The application discloses a display substrate, a manufacturing method thereof, and a display device, which belong to the field of display technology. The display substrate includes a base substrate and a light emitting device layer, a thin film encapsulation layer, an optical adhesive layer and a polarizer disposed on the base substrate in sequence, and the polarizer is attached to the side of the thin film encapsulation layer away from the light emitting device layer through the optical adhesive layer. The optical adhesive layer is doped with ammonia absorber. The present application can reduce the risk of reaction between the ammonia gas overflowing from the thin film encapsulation layer and the polarizer, thereby reducing the risk of fading of the polarizer and improving the display effect of the display device. This application is used to reduce the risk of polarizer fading.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com