Method for preparing high-purity chloropinacolone through photocatalysis

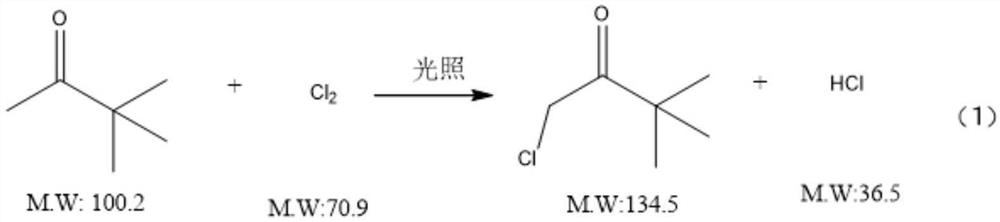

A high-purity technology for pinatonone, which is applied in the efficient preparation of high-purity monochloropinatone and in the field of safety, can solve the problems of high impurity content of dichloropinatone, affecting the production of downstream products, and difficulty in solvent rectification and recovery. Achieve the effect of reducing the content of by-products, reducing costs and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

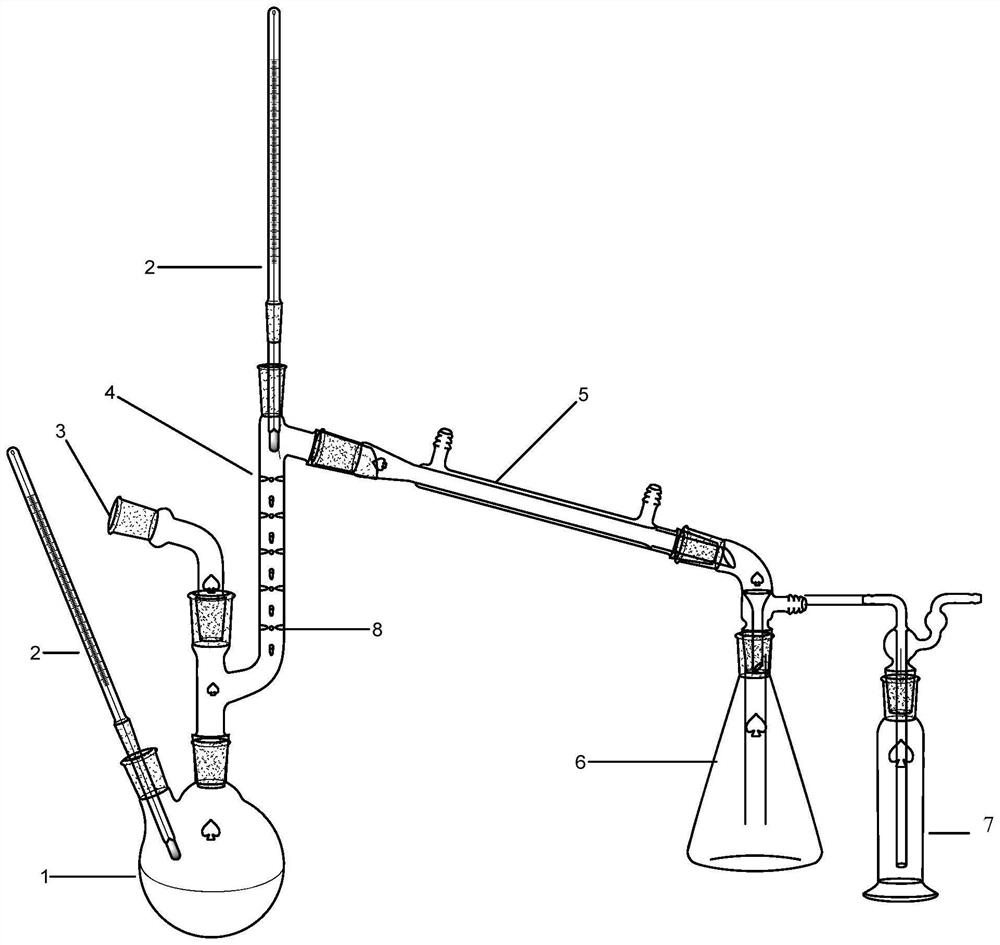

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: drop into 200g pinatone in clean 500ml gasification kettle. Turn on the stirring, turn on the light source: yellow light, the light intensity is 4000lux; when the system is heated to 105-108°C, open the chlorine valve of the reactor, let the chlorine gas into the reactor, and control the rate of the chlorine gas to be 2.1-3.4 g / min, the feed time is 6h; tail gas feeds into the tail gas treatment system: secondary absorption, the first level uses clear water to absorb, and the second level uses liquid caustic soda to absorb; Sampling detection, raw material peak pinazone is less than 1%, and the reaction ends; The system was cooled to room temperature to obtain 258.3 g of a chloropinatone product.

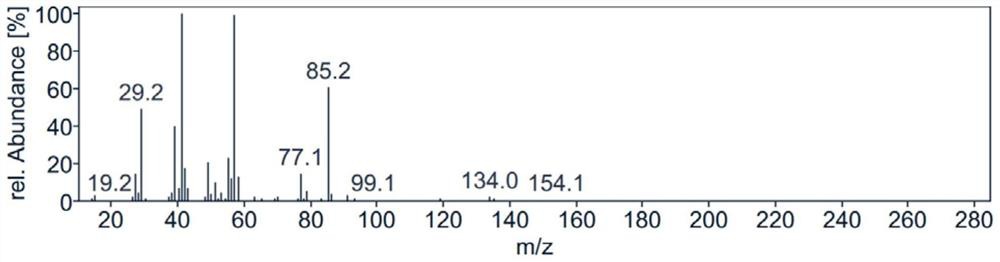

[0023] figure 2 For the mass spectrogram of the product obtained in this embodiment, wherein: the molecular ion peak of chloropinacolone is 134, and it itself also has a carbonyl group, and both sides of the carbonyl carbon can be split; each peak position is ...

Embodiment 2

[0025] Embodiment 2: drop into 200g pinatone in clean 500ml gasification kettle. Turn on the stirring, turn on the light source: purple light, the light intensity is 5000lux; when the system is heated to 105-108°C, open the chlorine gas valve of the reactor, let the chlorine gas into the reactor, and control the rate of chlorine gas introduction to 2.1-3.4g / min, the feeding time is 5h; tail gas feeds into the tail gas treatment system: secondary absorption, the first level uses clear water absorption, and the second level uses liquid caustic soda absorption; sampling detection, raw material peak pinazone is less than 1%, and the reaction is over; the system Cool down to room temperature to obtain 257.9 g of a chloropinatone product.

[0026] After testing, the yield of chloropinatone is 98.4%, and the tested quality is as follows: 98.3% of chloropinatone, 0.7% of chloropinatone, and 0.8% of dichloropinatone. As shown in Table 1.

Embodiment 3

[0027] Embodiment 3: drop into 200g pinatone in clean 500ml gasification kettle. Turn on the stirring, turn on the light source: red light, the light intensity is 4000lux; when the system is heated to 105-108°C, open the chlorine valve of the reactor, pass the chlorine gas into the reactor, and control the speed of introducing chlorine gas to 2.1-3.4 g / min, the feeding time is 5.5h; the tail gas is passed into the tail gas treatment system: secondary absorption, the primary use of clear water absorption, the secondary use of liquid alkali absorption; sampling detection, raw material peak pinazone is less than 1%, and the reaction is over; The system was lowered to room temperature to obtain 258.7 g of a chloropinatone product.

[0028] After testing, the yield of chloropinatone was 95.1%, and the tested quality was as follows: 95.2% of chloropinatone, 0.6% of chloropinatone, and 2.5% of dichloropinatone. As shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com