A kind of ferronickel slag aggregate concrete

A nickel-iron slag and concrete technology, applied in the field of nickel-iron slag aggregate concrete, can solve the problems of high crushing value of nickel-iron slag aggregate, limited utilization of nickel-iron slag, alkali aggregate reaction, etc. Risk-reducing, hydration-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

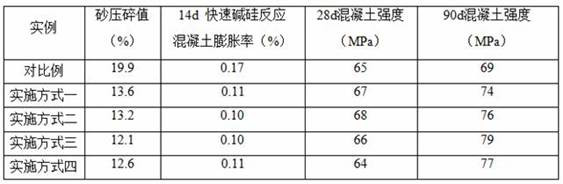

Examples

Embodiment 1

[0019] Ferronickel slag aggregate modification:

[0020] 1) Pre-crushing the coarse nickel-iron slag ore, and then sieving the broken aggregate into two parts larger than 5mm and smaller than 5mm, and grinding the part smaller than 5mm until the specific surface area is greater than 450m 2 / kg, used as concrete admixture;

[0021] 2) Soak the part larger than 5mm in 0.5% hydrochloric acid solution for 10 hours;

[0022] 3) Calcium hydroxide is added to the solution in step 2), and the pH value of the solution is adjusted to be greater than 7;

[0023] 4) Sieve and dry the aggregate larger than 5mm, and use it as concrete coarse aggregate;

[0024] 5) Dry the sediment less than 5mm and grind it until the specific surface area is greater than 450m 2 / kg, used as concrete admixture;

[0025] 6) Keep the soaking solution.

[0026] Preparation of ferronickel slag aggregate concrete:

[0027] Take 30% of the 1.2mm~5mm ferronickel slag fine aggregate, 20% of the machine-made sa...

Embodiment approach 2

[0033] Ferronickel slag aggregate modification:

[0034] 1) Pre-crushing the coarse nickel-iron slag ore, and then sieving the broken aggregate into two parts larger than 5mm and smaller than 5mm, and grinding the part smaller than 5mm until the specific surface area is greater than 450m 2 / kg, used as concrete admixture;

[0035] 2) Soak the part larger than 5mm in 1.5% sulfuric acid solution for 3 hours;

[0036] 3) Calcium hydroxide is added to the solution in step 2), and the pH value of the solution is adjusted to be greater than 7;

[0037] 4) Sieve and dry the aggregate larger than 5mm, and use it as concrete coarse aggregate;

[0038] 5) Dry the sediment less than 5mm and grind it until the specific surface area is greater than 450m 2 / kg, used as concrete admixture;

[0039] 6) Keep the soaking solution.

[0040] Preparation of ferronickel slag aggregate concrete:

[0041] Take 10% of 1.2mm~5mm ferronickel slag fine aggregate, 20% of machine-made sand fine aggre...

Embodiment approach 3

[0047] Ferronickel slag aggregate modification:

[0048] 1) Pre-crushing the coarse nickel-iron slag ore, and then sieving the broken aggregate into two parts larger than 5mm and smaller than 5mm, and grinding the part smaller than 5mm until the specific surface area is greater than 450m 2 / kg, used as concrete admixture;

[0049] 2) Soak the part larger than 5mm in 1.5% formic acid solution for 3 hours;

[0050] 3) Calcium hydroxide is added to the solution in step 2), and the pH value of the solution is adjusted to be greater than 7;

[0051] 4) Sieve and dry the aggregate larger than 5mm, and use it as concrete coarse aggregate;

[0052]5) Dry the sediment less than 5mm and grind it until the specific surface area is greater than 450m 2 / kg, used as concrete admixture;

[0053] 6) Keep the soaking solution.

[0054] Preparation of ferronickel slag aggregate concrete:

[0055] Take 10% of 1.2mm~5mm ferronickel slag fine aggregate, 10% of machine-made sand fine aggregat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com