Synthesis method of tetrafluoropropyl trifluoroethylene ether

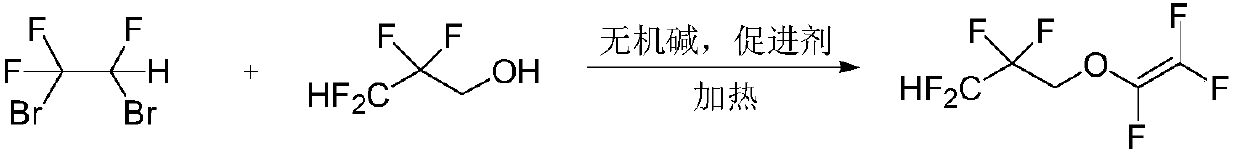

A technology of tetrafluoropropyl trifluorovinyl ether and tetrafluoropropanol, which is applied in the field of compound synthesis, can solve the problems of safety hazards, difficult industrial production, lack of tetrafluoropropyl trifluorovinyl ether, and inability to reflect useful value, and the like, Achieve the effect of reducing reaction risk, reducing reaction steps, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

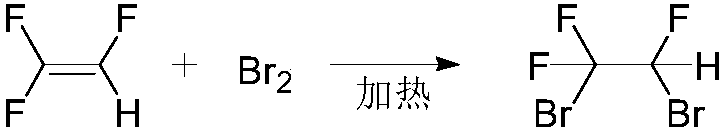

[0045] This example relates to the preparation of 1,2-dibromo-1,1,2-trifluoroethane intermediate, including the following steps:

[0046] Add 176g (1.1mol) of liquid bromine into the reactor, slowly bubble the trifluoroethylene "waste gas" mixed with tetrafluoroethylene produced in the production process of tetrafluoroethylene, and heat to 55°C to start the reaction until the reaction The liquid turns from dark red to clear and transparent liquid, and the mixed gas is stopped.

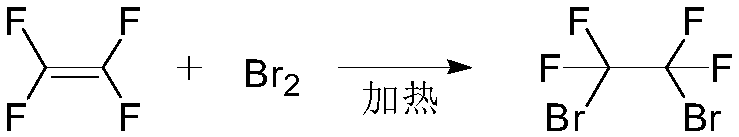

[0047] After the reaction was completed, the reaction product was washed successively with saturated sodium bisulfite solution and saturated brine. After extracting the organic layer, dry it with anhydrous sodium sulfate, and filter it with suction to obtain a crude product. Then, 193.4 g of 1,2-dibromo-1,1,2-trifluoroethane and 51.9 g of 1,2-dibromo-1,1,2,2-tetrafluoroethane were separated by rectification.

Embodiment 2

[0049] This embodiment relates to the preparation of tetrafluoropropyltrifluoroethylene ether, comprising the steps of:

[0050] Add 132g (1.0mol) of tetrafluoropropanol, 140g (2.5mol) of potassium hydroxide, and 300ml of deionized water into the reactor, raise the temperature of the reaction system to 80°C, and slowly add 1,2-dibromo-1 , 193.4g (0.8mol) of 1,2-trifluoroethane, continue to react for 2h after the dropwise addition is completed.

[0051] After the reaction was completed, the system was washed with water, extracted and separated to obtain a crude product, and finally purified by rectification to obtain 12.5 g of the target product tetrafluoropropyltrifluoroethylene ether with a purity of 99.3% and a total yield of 7.4%.

Embodiment 3

[0053] This embodiment relates to the preparation of tetrafluoropropyltrifluoroethylene ether. Compared with Example 2, the main difference is that 0.1mol of the reaction accelerator glyme is added, including the following steps:

[0054] Add 132g (1.0mol) of tetrafluoropropanol, 140g (2.5mol) of potassium hydroxide, and 300ml of deionized water into the reactor, and add 13.4g (0.1mol) of reaction accelerator diglyme at the same time, and the reaction system The temperature was raised to 80°C, and then 193.4 g (0.8 mol) of 1,2-dibromo-1,1,2-trifluoroethane was slowly added dropwise, and the reaction was continued for 2 hours after the dropwise addition was completed.

[0055] After the reaction was completed, the system was washed with water, extracted and separated to obtain a crude product, and finally purified by rectification to obtain 139.1 g of the target product tetrafluoropropyltrifluoroethylene ether with a purity of 99.5% and a total yield of 82%. The 1HNMR informati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com