Gas-liquid phase vinyl chloride production process and equipment

A production process, vinyl chloride technology, applied in the reaction of liquid and gas under the catalytic active body, the chemical method of reacting liquid and gas medium, the disproportionation separation/purification of halogenated hydrocarbons, etc., can solve the problem of carbon deposition, catalytic Low efficiency, overheating surface and other problems, to achieve the effect of improving catalytic efficiency, improving safety, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] As an embodiment of the vinyl chloride production process provided by the present invention, the liquid catalyst is one of imidazole hydrochloride, nitrogen methylpyrrolidone hydrochloride, choline chloride or quaternary phosphonium salt; The active component of the liquid catalyst is one of cupric chloride, cuprous chloride, tin chloride and ruthenium trichloride.

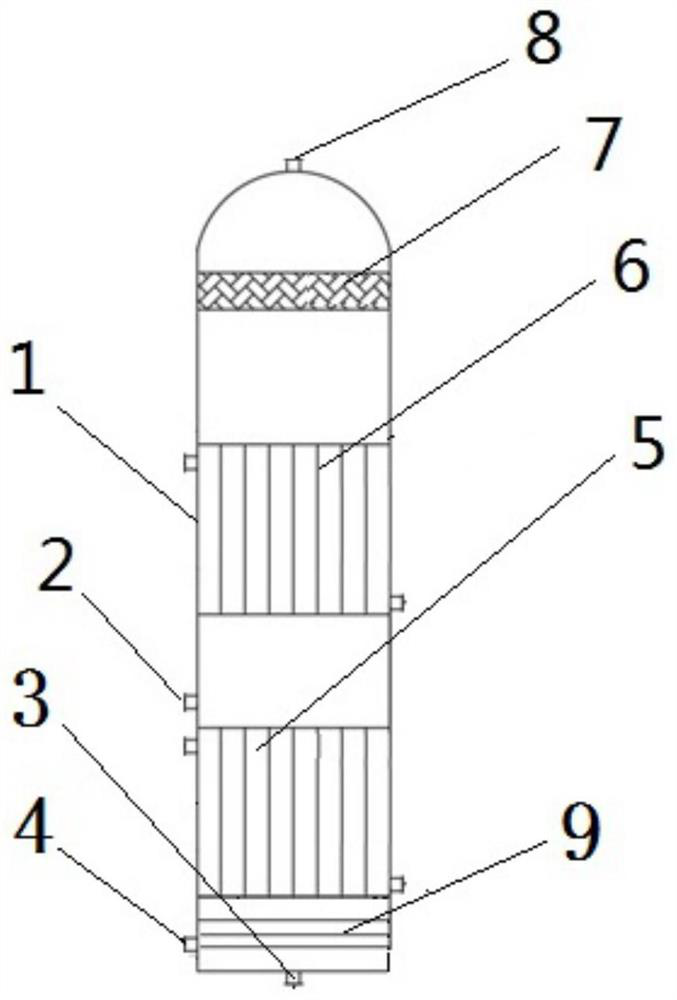

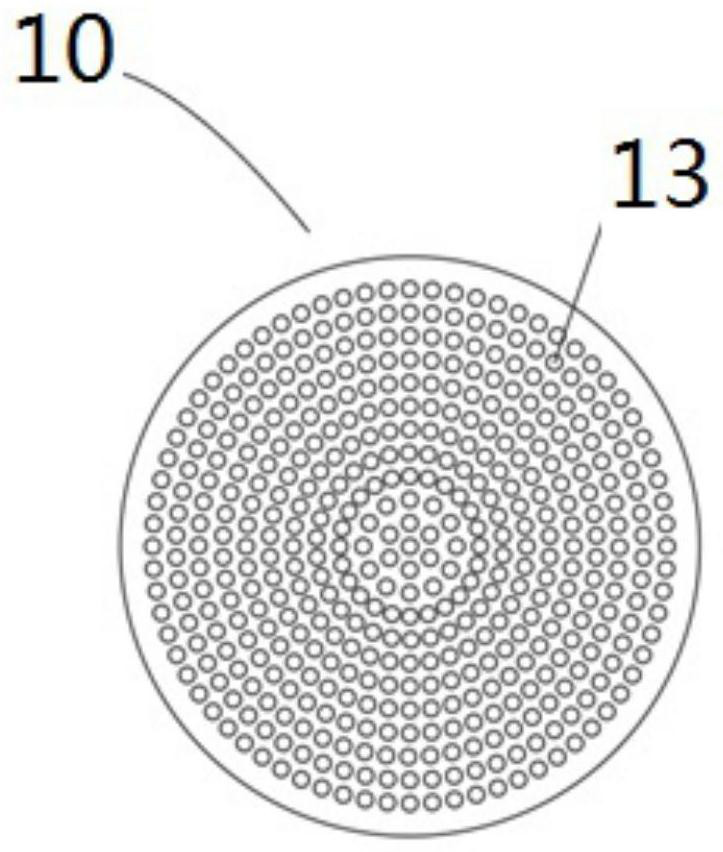

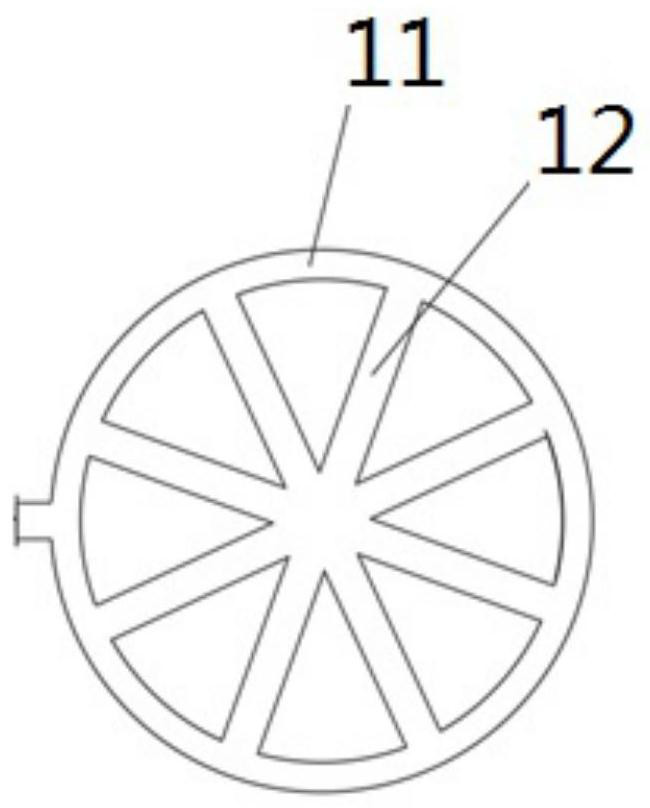

[0052]In this embodiment, the liquid catalyst is heated to 100-120°C, and is fed into the reaction kettle 1 from the middle and lower part through the liquid catalyst pipeline until the liquid catalyst inlet 2 position; the hydrogen chloride gas and acetylene gas are dehydrated and impurity-removed and then mixed from the reaction kettle 1 The bottom is fed into the reaction kettle 1 through the mixed gas pipeline through the gas distributor 9; the liquid catalyst is a mercury-free catalyst; the molar ratio of acetylene gas to hydrogen chloride gas is 1.0-1.2:1.

[0053] In the reactor 1, under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com