Production equipment for glass microspheres used for road traffic

A technology for glass microspheres and production equipment, which is applied in glass manufacturing equipment, glass molding, glass re-molding and other directions to achieve the effects of high efficiency, accurate laser cutting and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

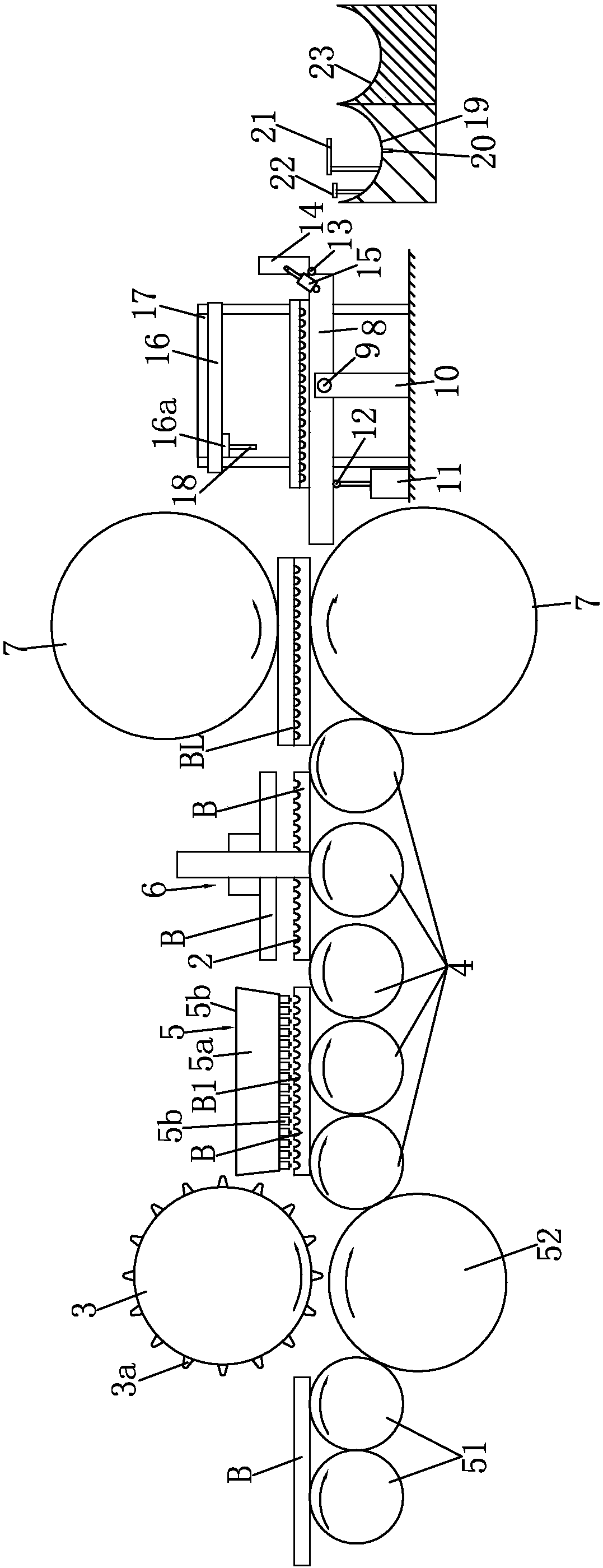

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

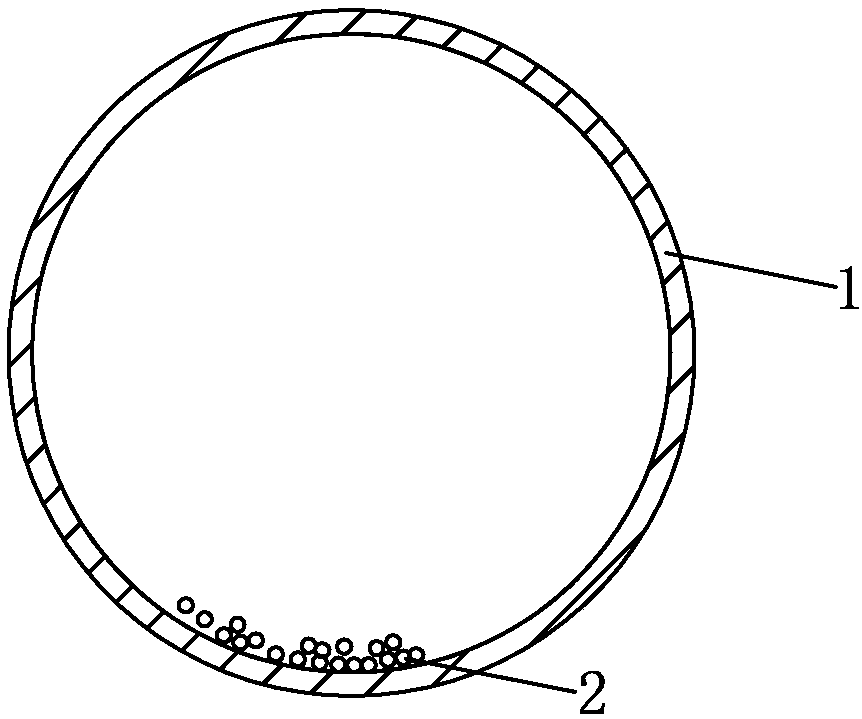

[0030] refer to figure 1 , 2 , and combined with Figure 3-8 It can be seen that a production equipment of glass microspheres for road traffic is mainly composed of the first conveying roller 51 and the turning platform 8 . Wherein, the number of the first conveying rollers 51 is at least two, and these first conveying rollers 51 are arranged side by side, and the glass sheet B is manually placed on the first conveying rollers 51 during operation. These first conveying rollers 51 rotate under the drive of the corresponding driving mechanism, and drive the glass thin plate B to move horizontally to the right.

[0031] The right side of these first conveying rollers 51 is provided with a rotating support roller 52 , the role of the support roller 52 is to support the glass sheet B, and a rotating embossing roller 3 is correspondingly provided directly above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com