Organic/inorganic composite, manufacturing method therefor, organic/inorganic composite film, manufacturing method therefor, photonic crystal, coating material, thermoplastic composition, microstructure, optical material, antireflection member, and optical lens

A technology of inorganic composites and inorganic composite membranes, which can be used in the treatment of dyed high-molecular organic compounds, optical components, and devices for coating liquids on surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0884] According to the ratio in Table 1, the organic-inorganic composite A was produced according to the following steps. The concentration of each component is a numerical value based on the total amount of each component. Table 2 shows the evaluation results of the obtained organic-inorganic composite A.

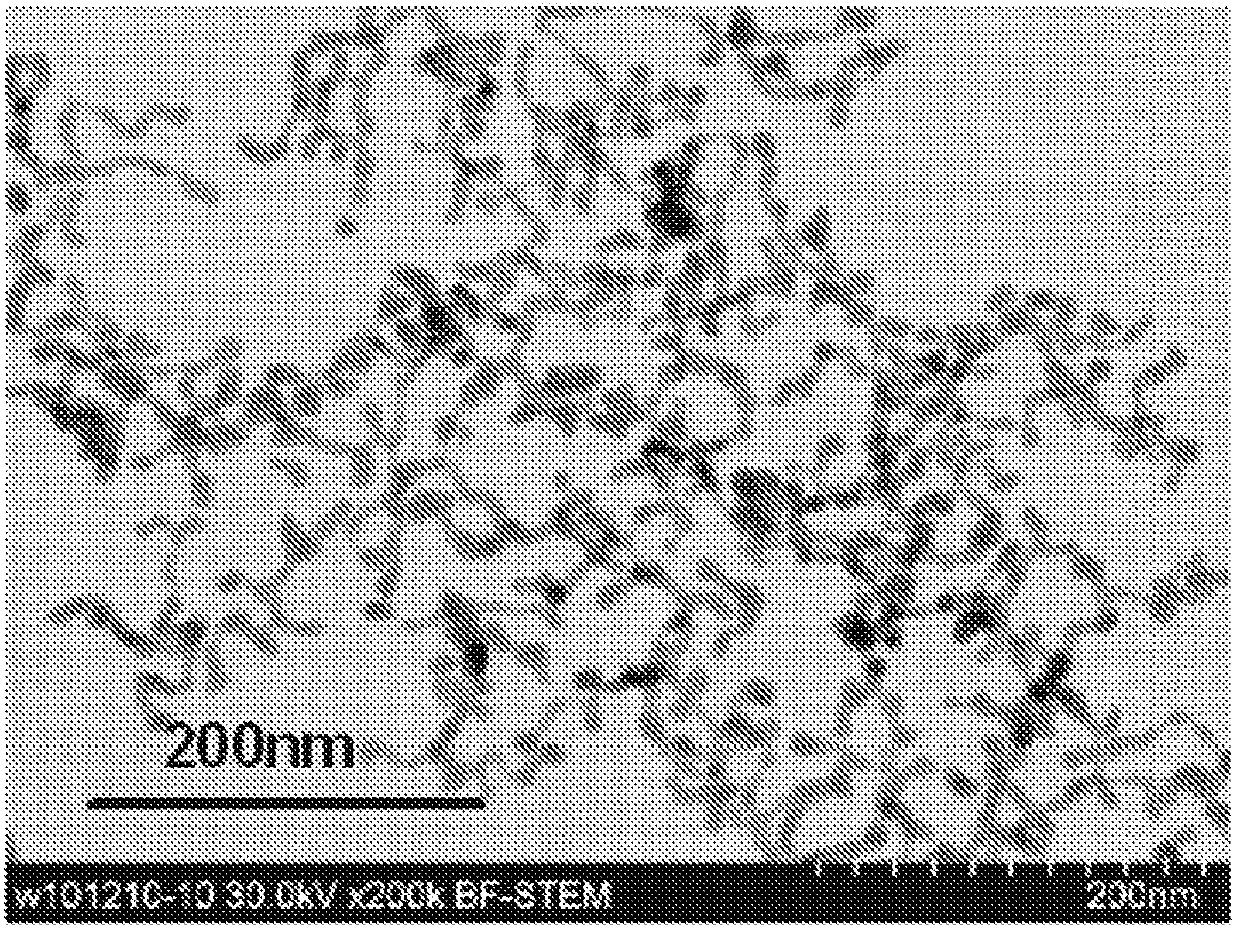

[0885] (1) Add 2.61% by mass of BPS modified ZrO to the Schlenk bottle with rotor 2 Particles, CuBr 0.045% by mass, CuBr 0.007% by mass 2 and 0.288% by mass of dNbpy.

[0886] (2) Connect a cooling tube to the Schlenk flask, vacuum the inside of the flask, and then replace it with nitrogen. Repeat this operation 3 times to deoxygenate the inside of the flask.

[0887] (3) Under nitrogen conditions, 97.05% by mass of MMA was introduced into the flask and stirred to prepare a reaction liquid.

[0888] (4) The flask was immersed in an oil bath at 60° C., and the reaction solution was stirred for 45 minutes to carry out polymerization reaction.

[0889] (5) After immersi...

Embodiment 2

[0918] The organic-inorganic composite B was produced in the same manner as in Example 1 in accordance with the composition in Table 1 except that the conditions of the polymerization reaction were 70° C. and 1 hour. Tables 2-4 show the evaluation results of the obtained organic-inorganic composite B, coating material, organic-inorganic composite film, and molded body.

[0919] MIBK was mixed with the organic-inorganic composite B, and a coating material and an organic-inorganic composite film (coating film) were obtained in the same manner as in Example 1. When the appearance of the obtained organic-inorganic composite film was visually confirmed, aggregation of particles was not seen, and transparency was maintained. When the refractive index of the obtained coating film was measured, it was 1.55, and compared with the pMMA of Comparative Example 1, the refractive index increased by 0.06. From this, it was found that the refractive index of the coating film can be controlle...

Embodiment 3

[0922] The organic-inorganic composite C was produced in the same manner as in Example 1 in accordance with the composition in Table 1 except that the polymerization reaction conditions were 90° C. and 7 hours. The evaluation results of the obtained organic-inorganic composite C, the coating material, the organic-inorganic composite film, and the molded article are shown in Tables 2-4.

[0923] Anisole was mixed with the organic-inorganic composite C, and a coating material was obtained by the above-mentioned method. Using the above coating material, an organic-inorganic composite film (coating film) was obtained in the same manner as in Example 1. When the appearance of the obtained coating film was visually confirmed, aggregation of particles was not seen, and transparency was maintained. When the refractive index of the obtained coating film was measured, it was 1.70, and compared with the pMMA of Comparative Example 1, the refractive index was increased by 0.21. From thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com