Method for improving refractive index and heat resistance of polyurethane resin optical material

A polyurethane resin and optical material technology, applied in optics, optical components, instruments, etc., can solve the problems of impact toughness, glass transition temperature, anti-yellowing performance reduction, resin refractive index and huge workload, etc., to achieve Improves heat resistance, avoids troublesome problems, and reduces the effect of burning smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

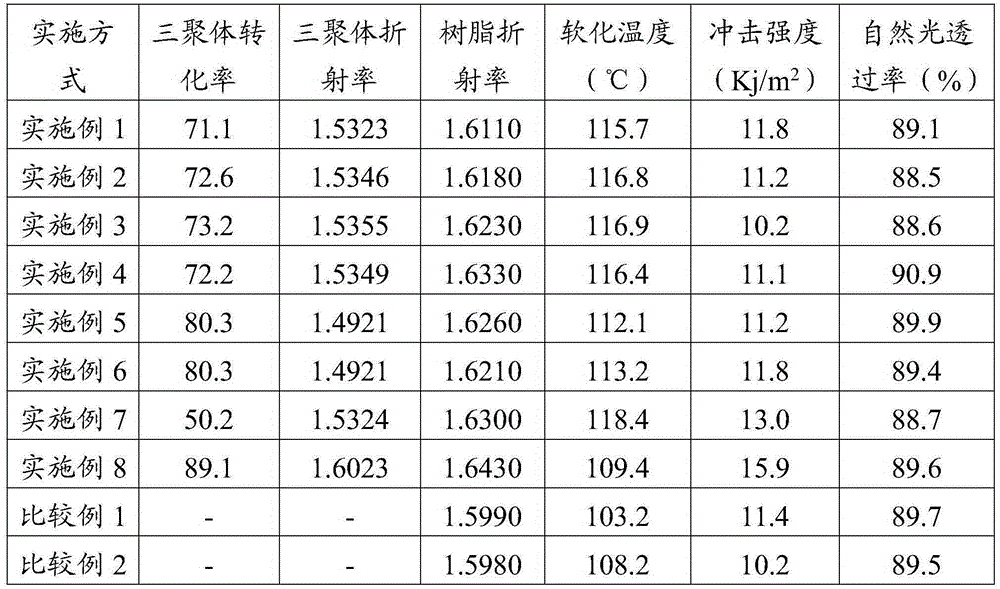

Examples

Embodiment 1

[0055] Isocyanate trimer preparation: Weigh isophorone diisocyanate (20g), add dibutyltin dichloride (0.02g), react at a constant temperature at 60°C for 5h, and test the conversion rate of isophorone diisocyanate trimer It is 71.1%, and the refractive index is 1.5323.

[0056] Polyurethane prepolymer preparation: take the above isophorone diisocyanate trimer (12.0g), and 1,6-diisocyanatohexane (13.4g), dicyclohexylmethane 4,4-diisocyanate (25.0g ), then add pentaerythritol tetrakis(3-mercaptopropionate) (4.8g), 2,3-bis(2-mercaptoethylthio)-3-propane-1-thiol (41.8g), UV-324 (0.4g), UV-327 (0.6g), antioxidant 1010 (0.5g), light stabilizer 770 (0.2g), di-n-butyl phosphate (0.8g), di-n-butyltin dilaurate (1.0g) and purple agent 511 (0.2ppm) were mixed and dissolved to make a uniform solution.

[0057] Its specific curing steps are:

[0058] (1) Take 10 mg of polyurethane optical resin pre-polymerization liquid sample and seal it in a special crucible for differential scanning ...

Embodiment 2

[0072]Preparation of isocyanate trimer: Weigh isophorone diisocyanate (20g), add N,N',N"-tris(dimethylaminopropyl)-hexahydrotriazine (0.05g), at 70°C After constant temperature reaction for 5 hours, it was tested that the conversion rate of isophorone diisocyanate trimer was 72.6%, and the refractive index was 1.5346.

[0073] Polyurethane prepolymer preparation: take the above isophorone diisocyanate trimer (12.0g), and 1,6-diisocyanatohexane (13.4g), dicyclohexylmethane 4,4-diisocyanate (25.0g ), then add pentaerythritol tetrakis(3-mercaptopropionate) (4.8g), 2,3-bis(2-mercaptoethylthio)-3-propane-1-thiol (41.8g), UV-324 (0.4g), UV-327 (0.6g), antioxidant 1010 (0.5g), light stabilizer 770 (0.2g), di-n-butyl phosphate (0.8g), di-n-butyltin dilaurate (1.0g) and purple agent 511 (0.2ppm) were mixed and dissolved to make a uniform solution.

[0074] Its specific curing steps are:

[0075] (1) Take 10 mg of polyurethane optical resin pre-polymerization liquid sample and seal i...

Embodiment 3

[0089] Preparation of isocyanate trimer: Weigh isophorone diisocyanate (20g), add 2,4,6-tris(dimethylaminomethyl)phenol (0.06g), react at constant temperature at 80°C for 5h, test the isophorone Fluorone diisocyanate trimer conversion rate is 73.2%, and the refractive index is 1.5355.

[0090] Polyurethane prepolymer preparation: take the above isophorone diisocyanate trimer (12.0g), and 1,6-diisocyanatohexane (13.4g), dicyclohexylmethane 4,4-diisocyanate (25.0g ), then add pentaerythritol tetrakis(3-mercaptopropionate) (4.8g), 2,3-bis(2-mercaptoethylthio)-3-propane-1-thiol (41.8g), UV-324 (0.4g), UV-327 (0.6g), antioxidant 1010 (0.5g), light stabilizer 770 (0.2g), di-n-butyl phosphate (0.8g), di-n-butyltin dilaurate (1.0g) and purple agent 511 (0.2ppm) were mixed and dissolved to make a uniform solution.

[0091] Its specific curing steps are:

[0092] (1) Take 10 mg of polyurethane optical resin pre-polymerization liquid sample and seal it in a special crucible for differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com