Acetic acid hydrogenation catalyst and its preparation method and application

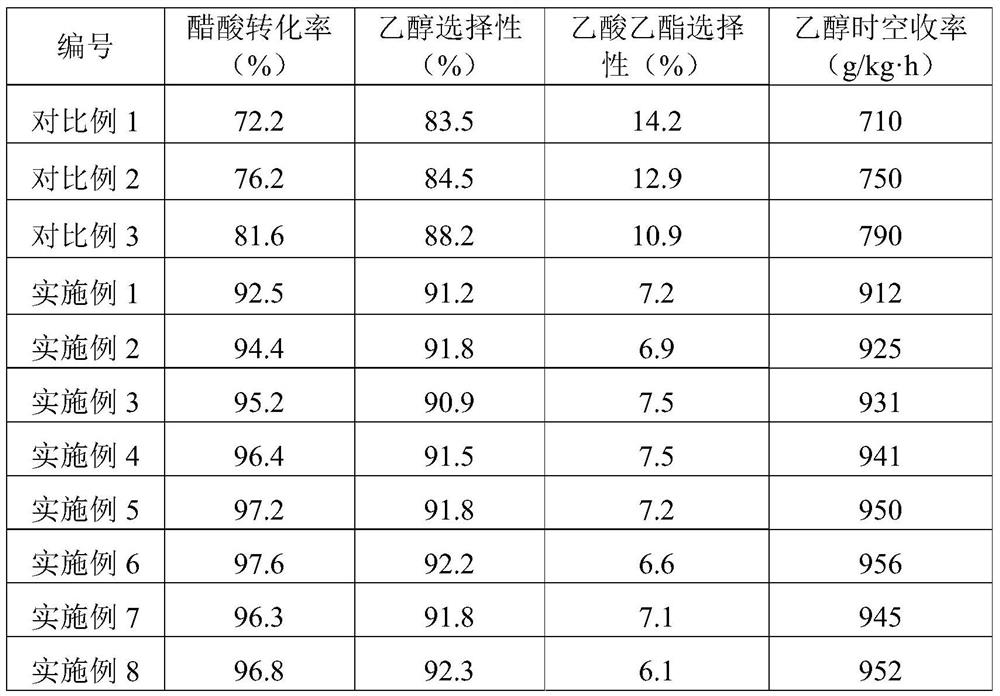

A hydrogenation catalyst, acetic acid technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of increased device load cost, large gas consumption, complicated processes, etc., and achieve high service life and cost. The effect of low and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] According to a second aspect of the present invention, the present invention provides a method for preparing the acetic acid hydrogenation catalyst, the method comprising: loading a soluble salt containing an active component and optionally a soluble salt containing a coagent on the modified catalyst On the carrier, solid-liquid separation, drying and calcination are carried out in sequence.

[0032] In the present invention, according to whether the acetic acid hydrogenation catalyst contains the active assistant and the first modification assistant, the preparation method can be specifically implemented in the following two ways.

Embodiment approach

[0033] When the acetic acid hydrogenation catalyst does not contain the coagent and the first modification aid, according to one embodiment, the method comprises the following steps:

[0034] 1) Preparation of modified carrier

[0035] In the presence of a kneading agent and a binder, kneading magnesia-aluminum spinel or magnesia-aluminum spinel precursor, the second modifying aid and the carrier into a shape, and then drying and calcining in sequence to obtain the modified sexual carrier;

[0036] 2) Load

[0037] The modified carrier is impregnated with an impregnation solution containing a soluble salt of the active component, followed by solid-liquid separation, drying and calcination in sequence.

[0038] When preparing the modified carrier, the kneading agent and the binder and their respective amounts can be selected with reference to the existing kneading method forming carrier technology. For the present invention, preferably, the kneading agent is selected from po...

Embodiment 1

[0087] This example is used to illustrate the acetic acid hydrogenation catalyst of the present invention and its preparation method.

[0088] S1: Add 49.39g of cobalt nitrate, 3.59g of sodium tungstate, 10.49g of 85% phosphoric acid, and 3.65g of potassium nitrate to 100mL of deionized water, continue stirring, and heat and dissolve at 120°C to obtain a Co-W-P-K mixed solution;

[0089] S2: Weigh 70g Al 2 O 3 and 10g MgO, mixed in a ball mill, ground for 2 hours, and then calcined at 1000 ° C for 8 hours to obtain magnesium aluminum spinel;

[0090] S3: 100g SiO 2 After the powder, 6g of succulent powder and 10g of S2 magnesia-aluminum spinel are mixed uniformly, poured into the kneader, slowly added the mixed solution of S1, kneaded and extruded into a 3mm*5mm rod shape, and dried at 120 ° C for 6 hours , and finally calcined at 600 °C for 4 hours to obtain a catalyst carrier;

[0091] S3: Add the catalyst carrier of S3 into 50 mL of ethylene glycol solution dissolved in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com