Patents

Literature

223 results about "Fuel gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

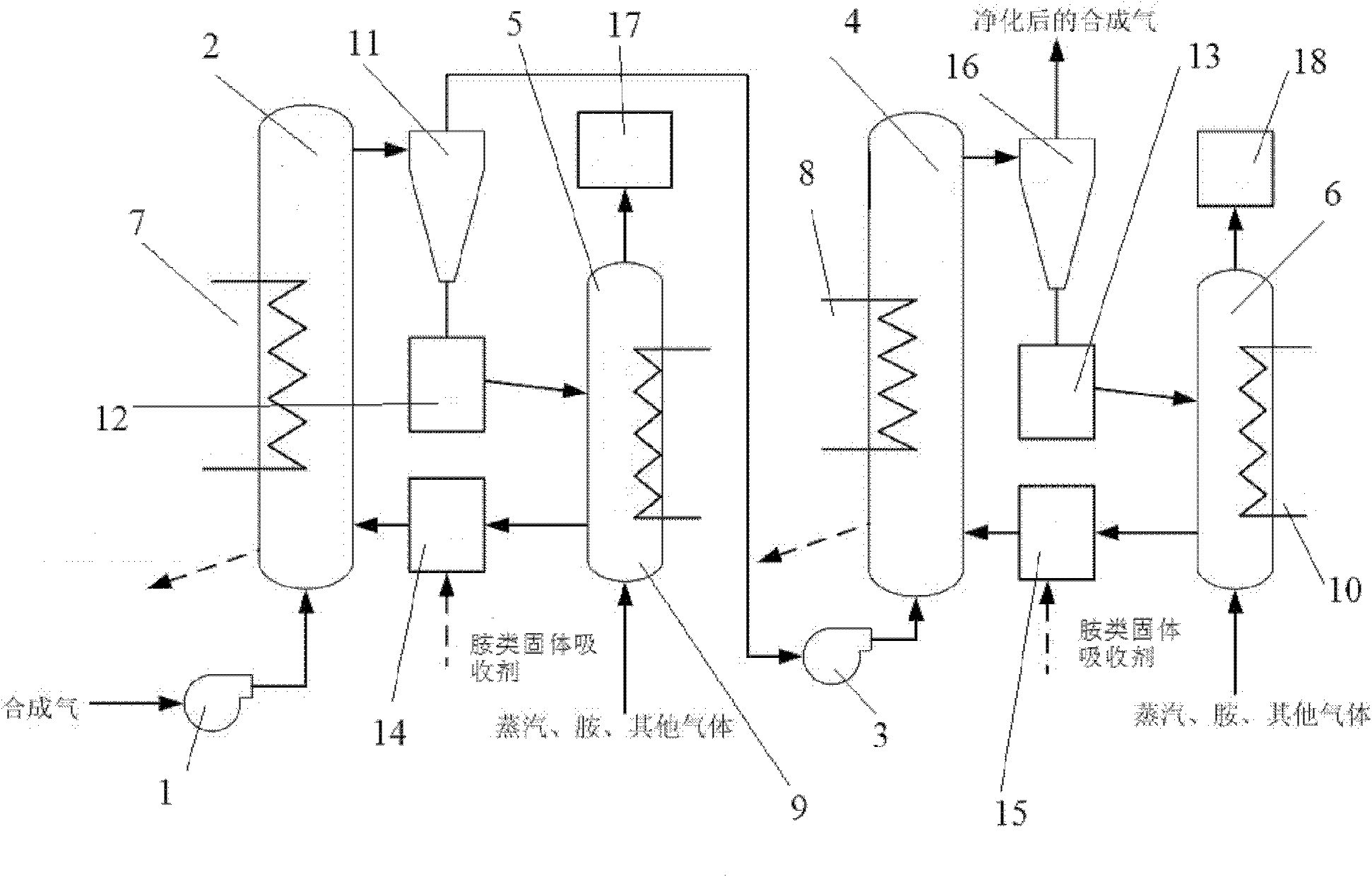

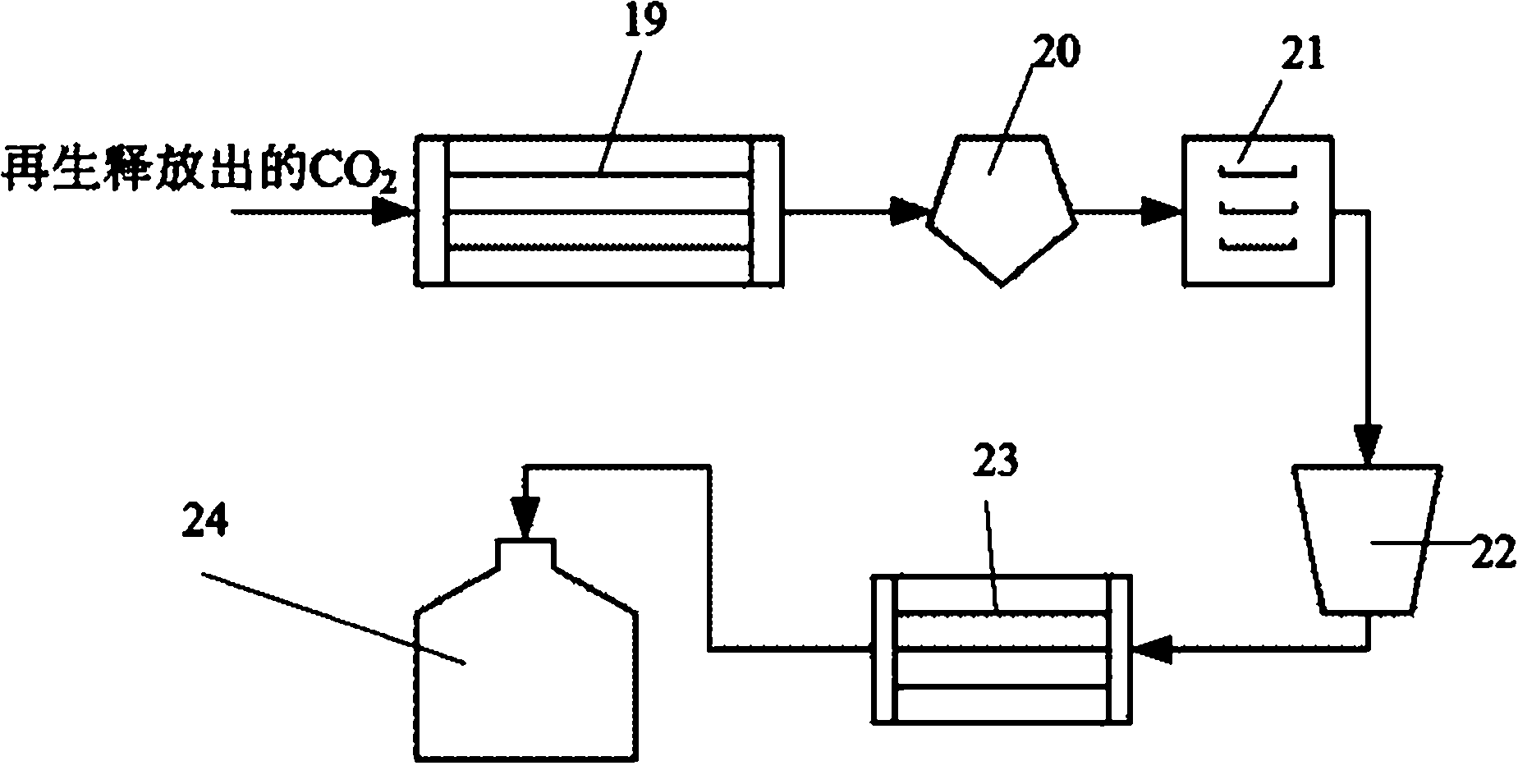

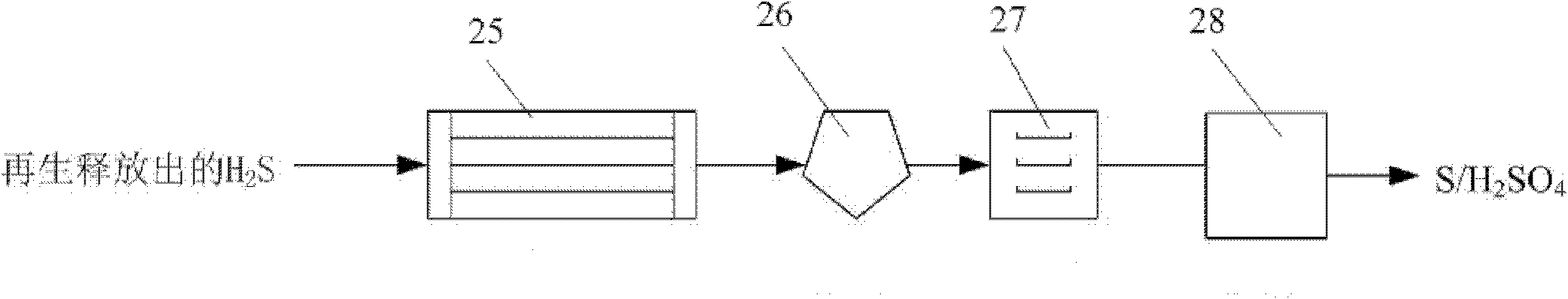

Method for removing CO2 and H2S out of synthesis gas by utilizing amine-type solid absorbent

InactiveCN102585952AReduce heatRealize combined desulfurization and decarbonizatioGaseous fuelsDispersed particle separationSyngasPorous medium

The invention discloses a method for removing CO2 and H2S out of synthesis gas by utilizing an amine-type solid absorbent, belonging to the technical field of environment protection. The method is a technical progress of removing CO2 and H2S out of synthesis gas and biomass generated in coal gasification production or gasified products of other fuels, natural gas and the like by utilizing amine-type solid absorbent prepared from an organic amine loaded porous medium, wherein CO2 and H2S can be removed stage by stage to respectively obtain high-purity CO2 and high-purity H2S and also can be removed in a same reactor. The method has the advantages that process and equipment are simple and compact in integrated design, investment and operation cost is low, and operation is stable and reliable, and CO2 and H2S in the synthesis gas can be separated efficiently with low cost.

Owner:TSINGHUA UNIV

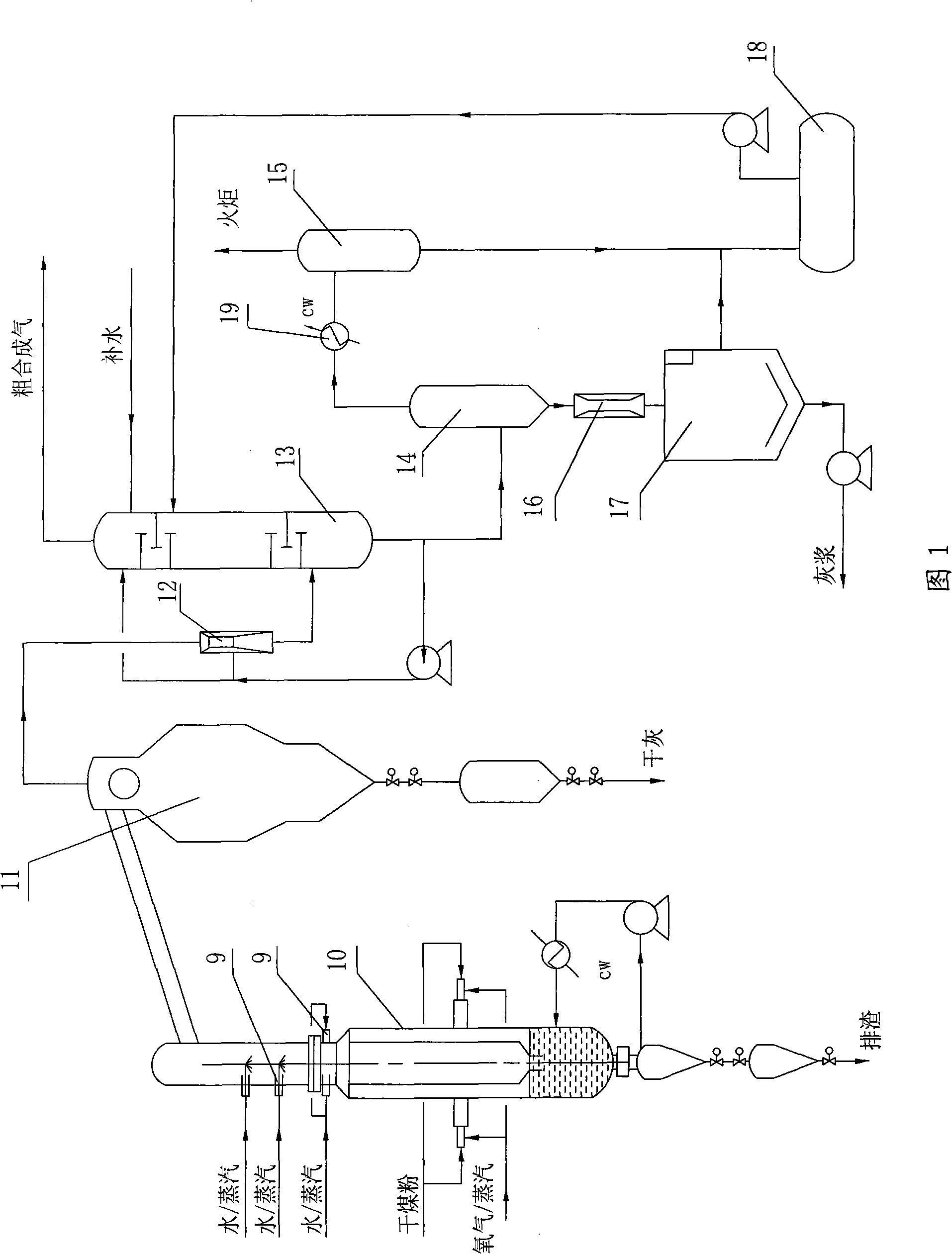

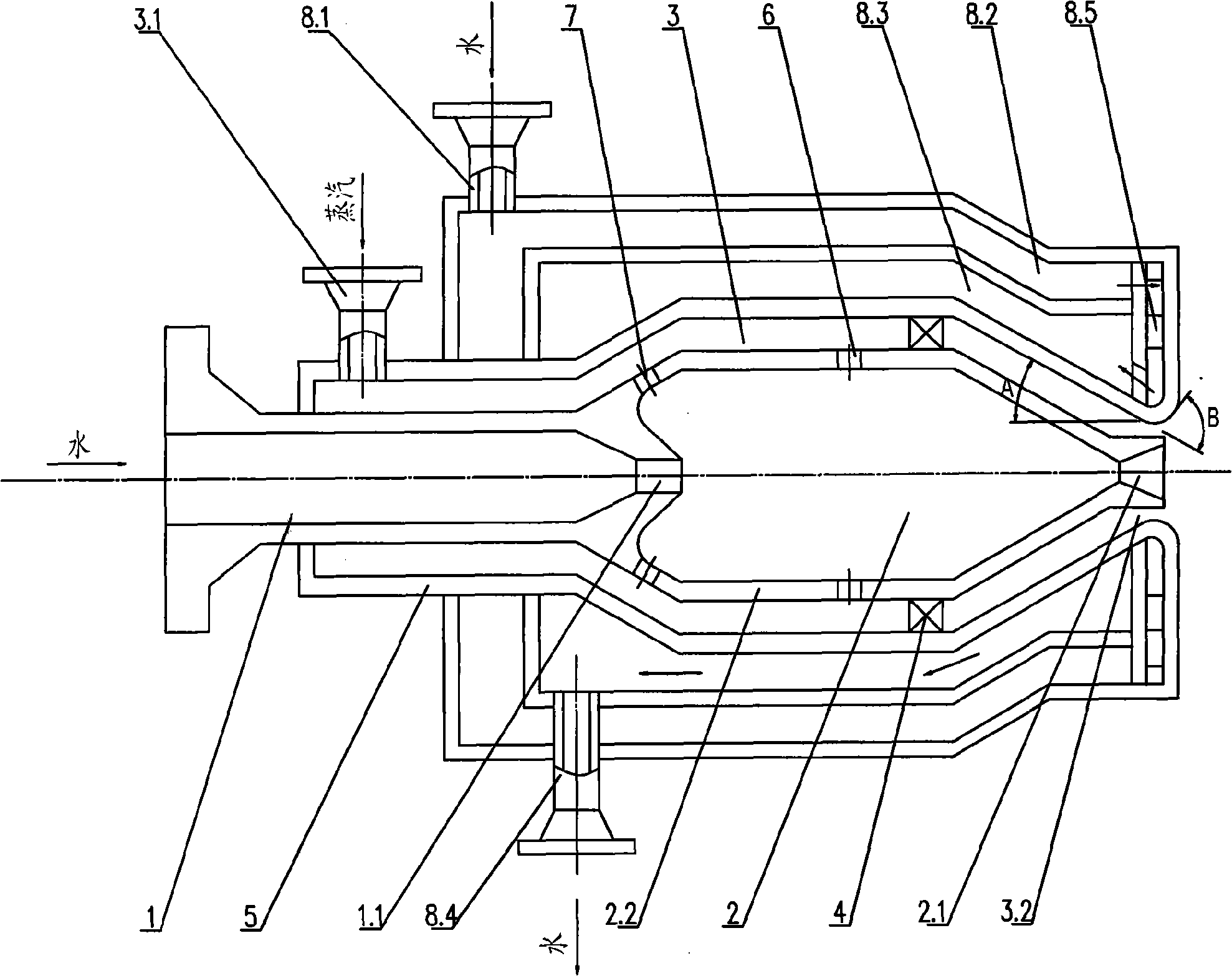

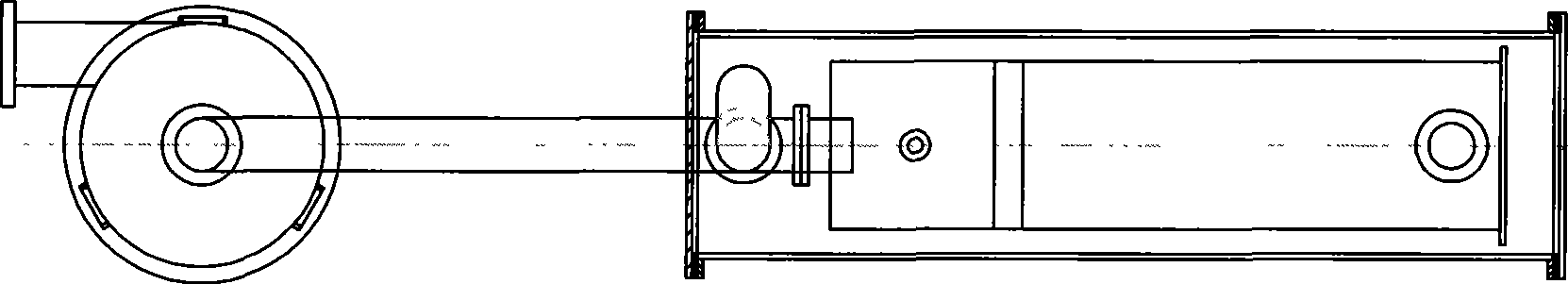

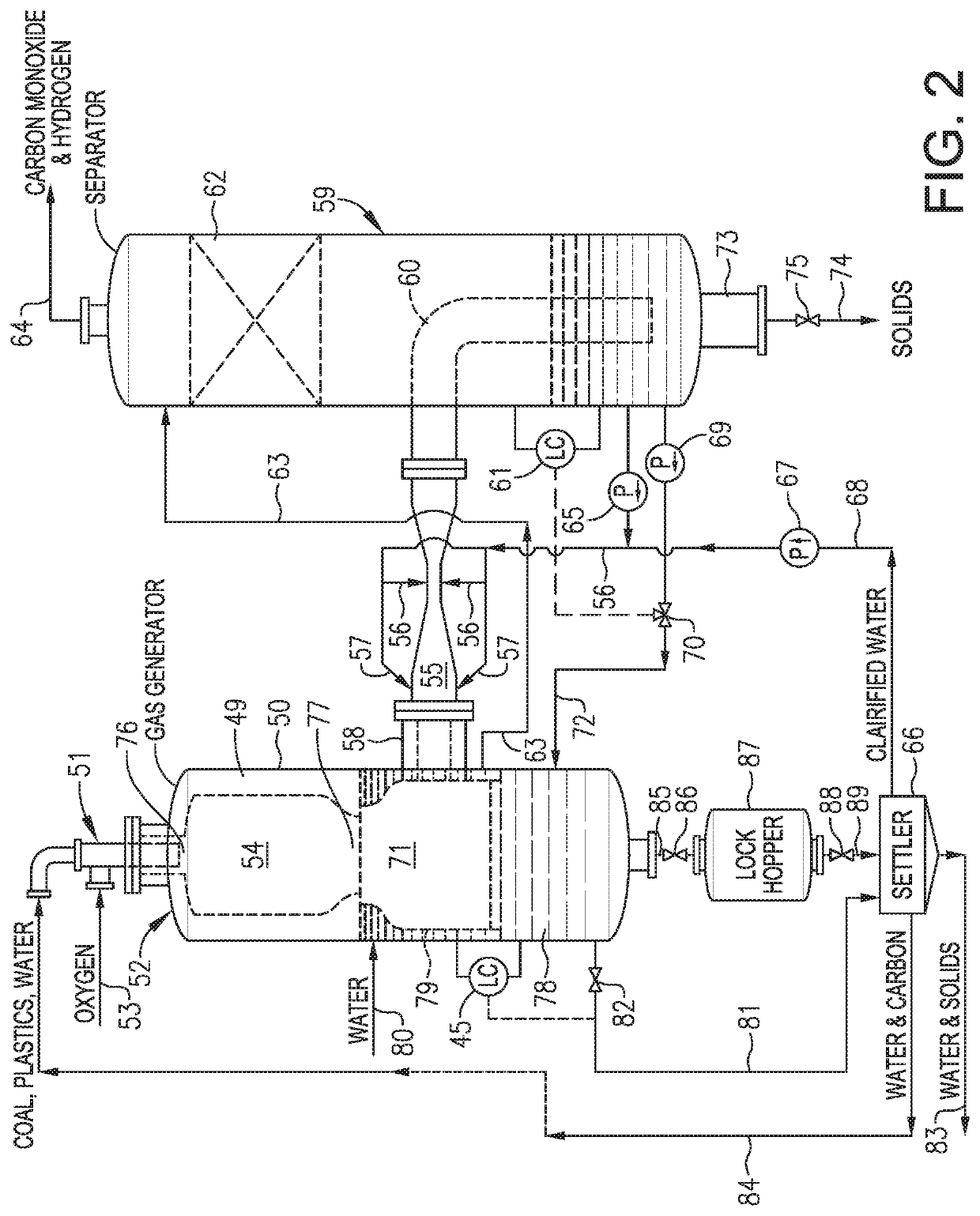

Gasification process of water/gas mixed partial-chilled dry powder fuel and device

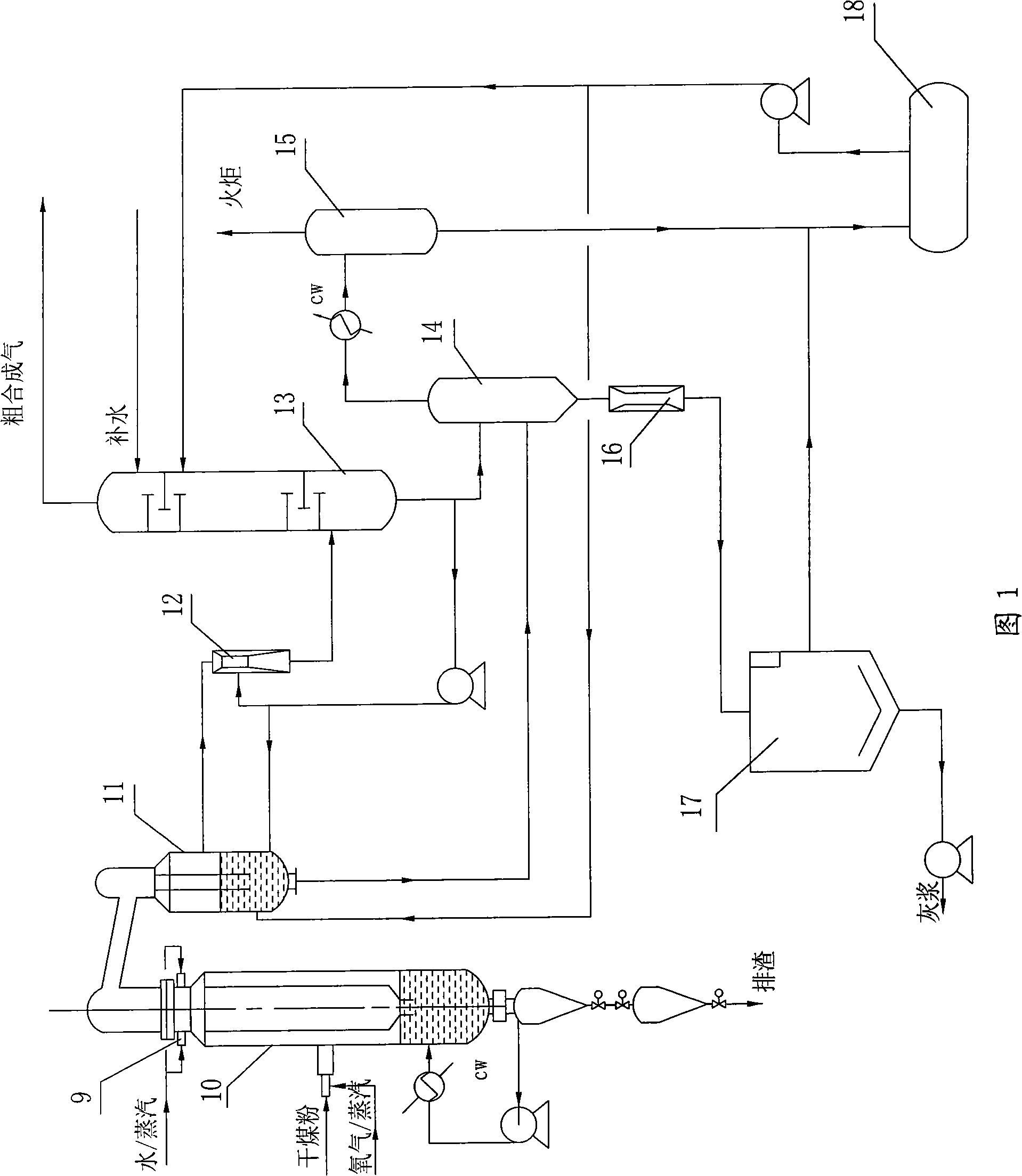

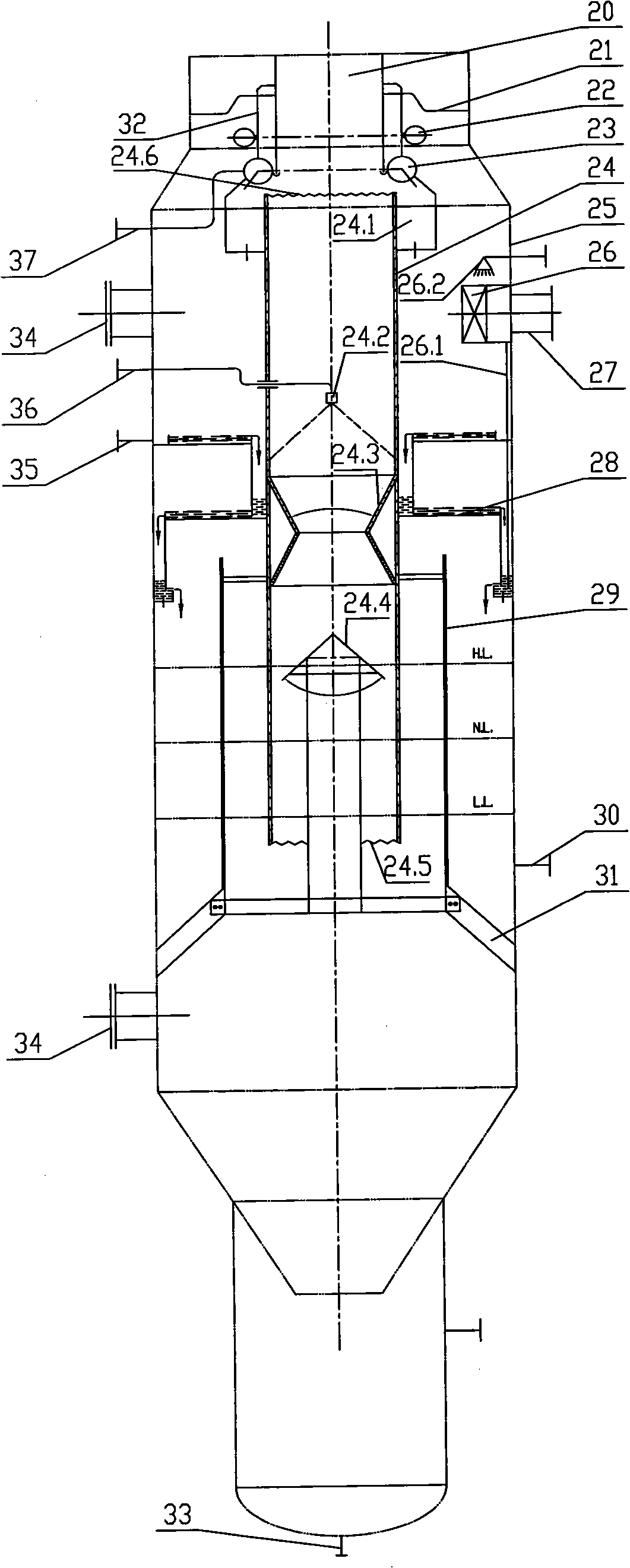

ActiveCN101285006AReduce metal wall temperatureIncrease flow rateGranular/pulverulent flues gasificationWater treatment systemFuel gasification

The invention relates to a process for gasifying water / gas mixed type partial chilling dry powder fuel and a special chiller thereof. The process resolves problems of poor cooling effect caused by only using water to chill high-temperature crude synthetic gases, no high-temperature resistance of spray throwers and easy corrosion and block of nozzles and pipes existing in dry powder fuel gasification process. Flammable dry powders are used as raw materials and undergo pressurized gasification, chilling and dust removal and cleaning; the crude synthetic gases at a temperature of between 180 and 260 DEG C, which are used for downstream operating processes, are obtained; and the cleaning ash water obtained enters an ash water treatment system; chilling steps are as follows: when gasified crude synthetic gases at a temperature of between 1400 and 1700 DEG C rise to the middle part and / or upper part of a gasifier, crude synthetic gases are partially chilled by water / gas mixed fog liquids as the temperature drops to between 400 and 500 DEG C, and then undergo the next step for dust removal and cleaning and simultaneously temperature dropping, and the cure synthetic gases at a temperature of between 180 and 260 DEG C are obtained. The process has the advantages of simple process, good temperature drop effect, abrasion resistance of a chilling device under the condition of high temperature, no ashes collection in nozzles and pipes and long-time effective operation, and can avoid safety accidents.

Owner:WUHUAN ENG

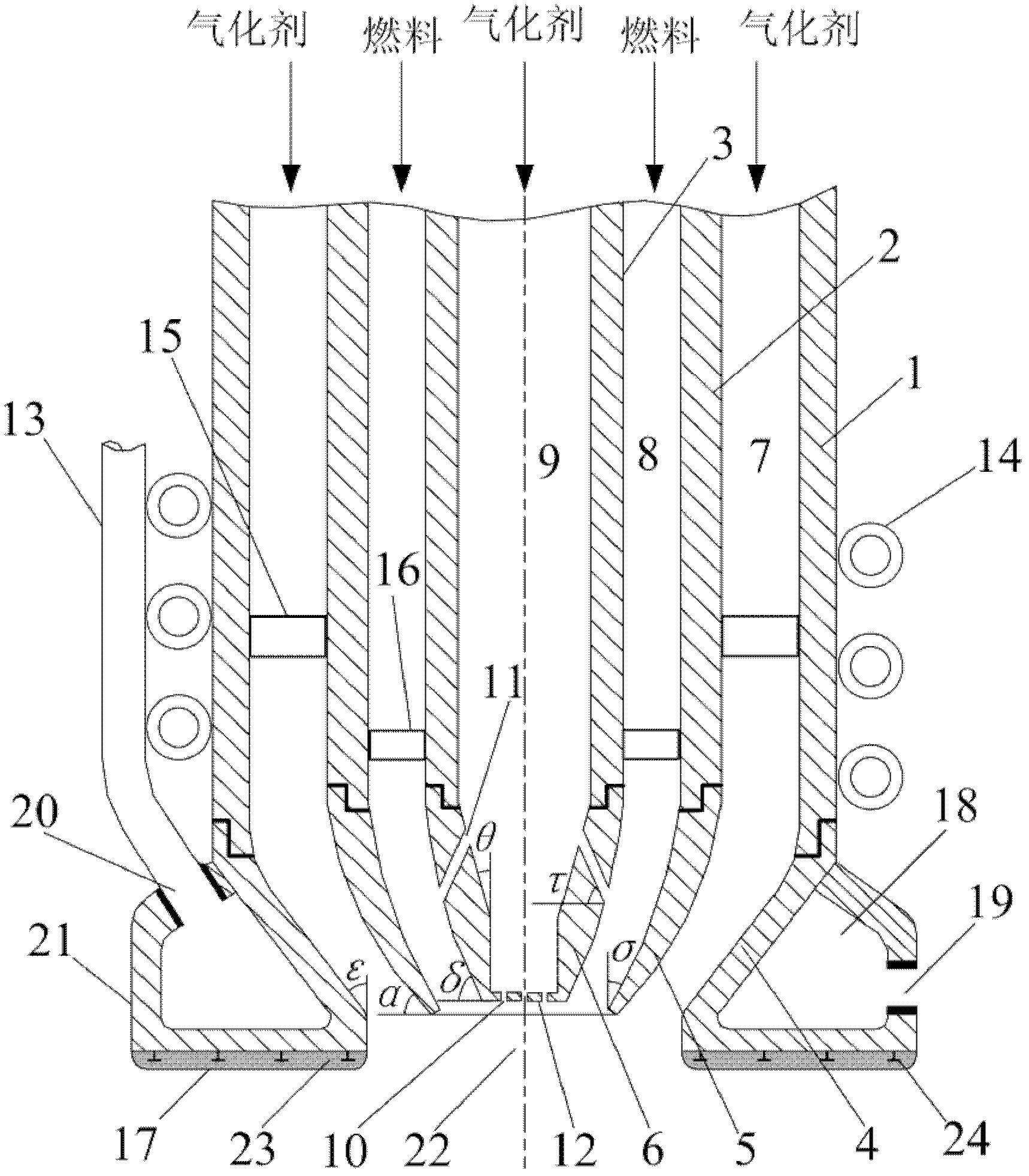

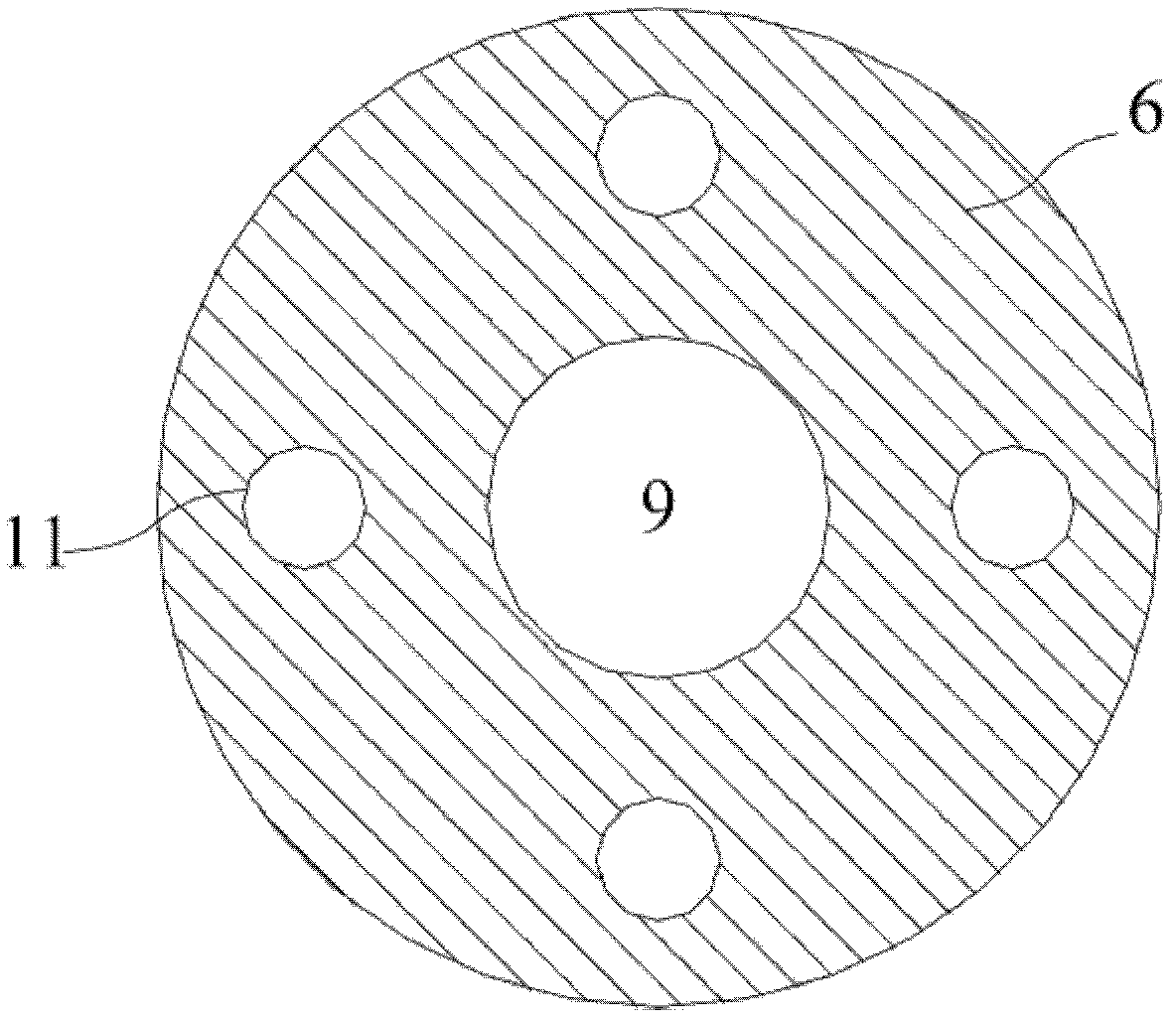

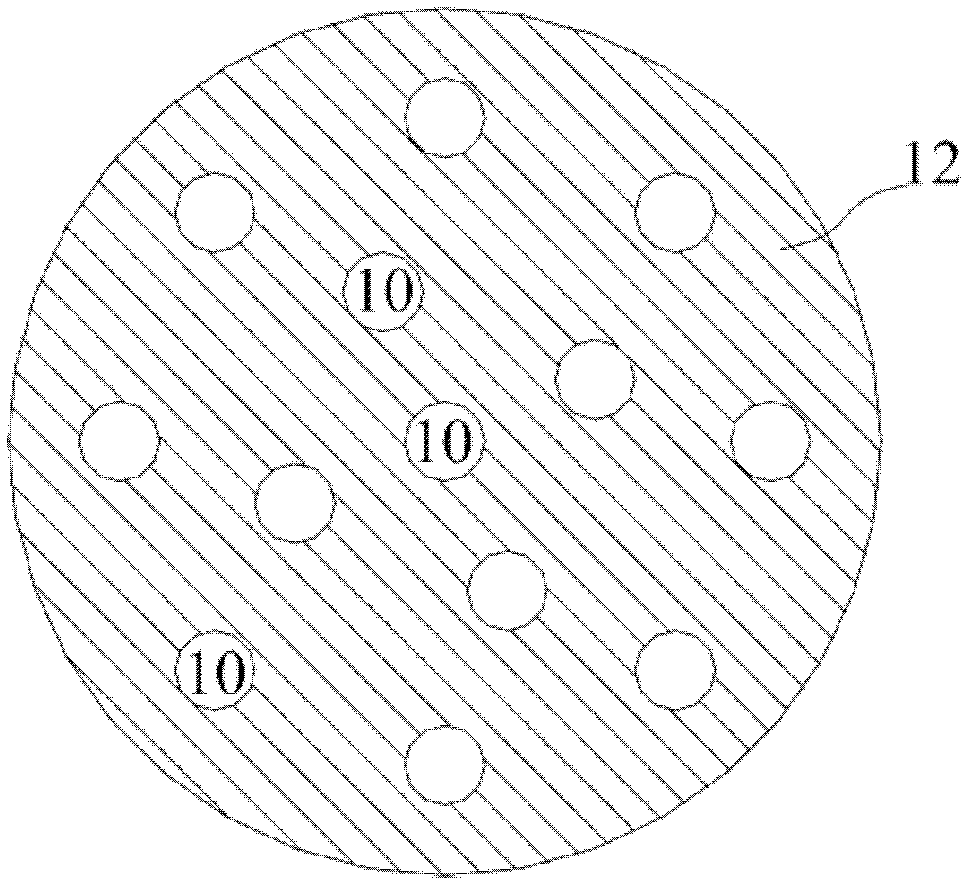

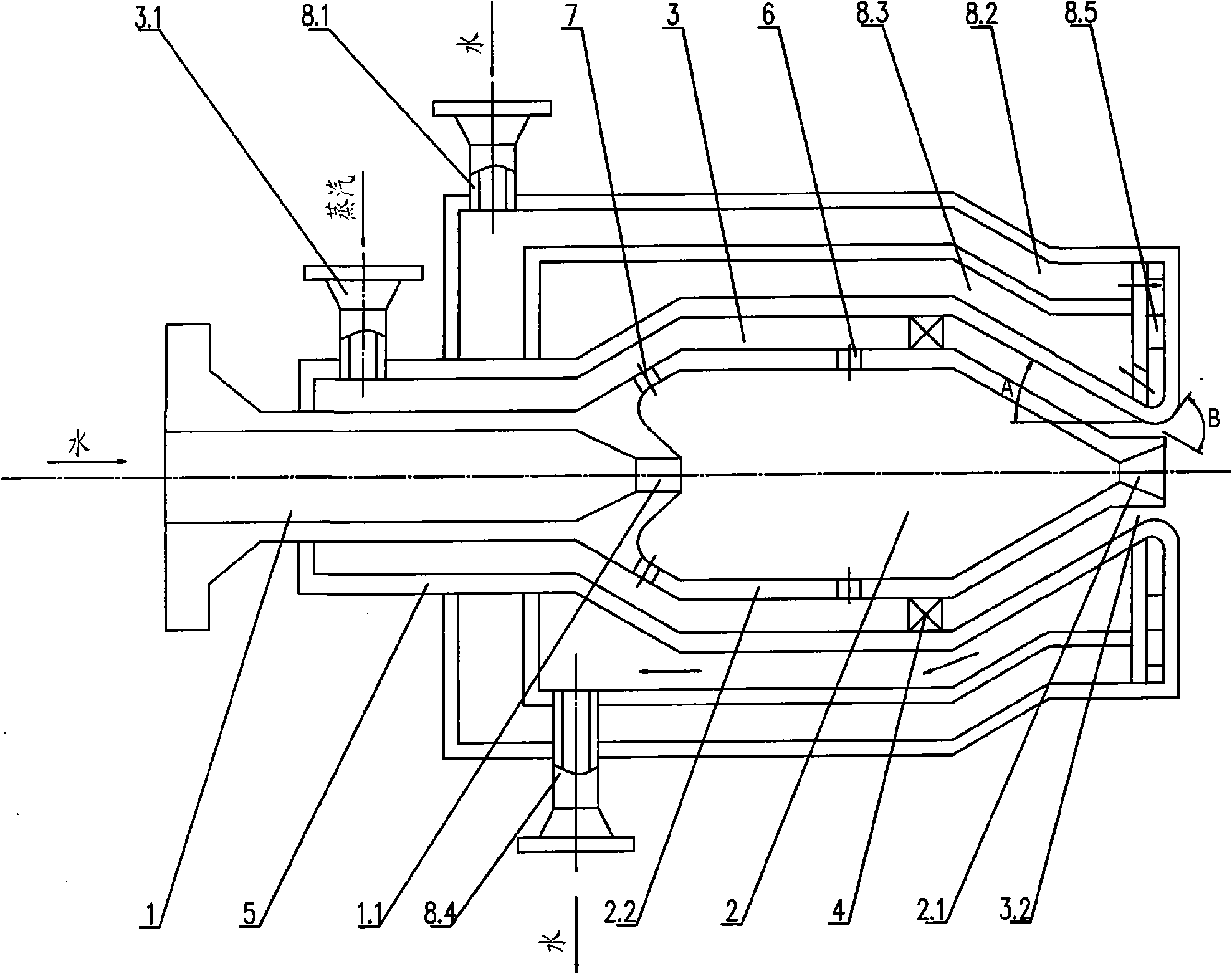

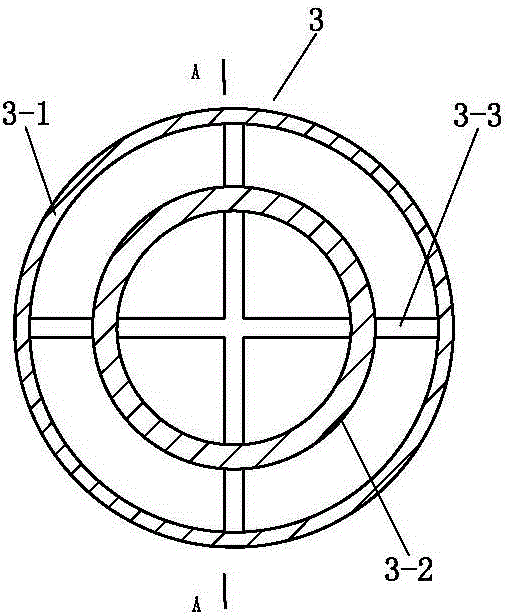

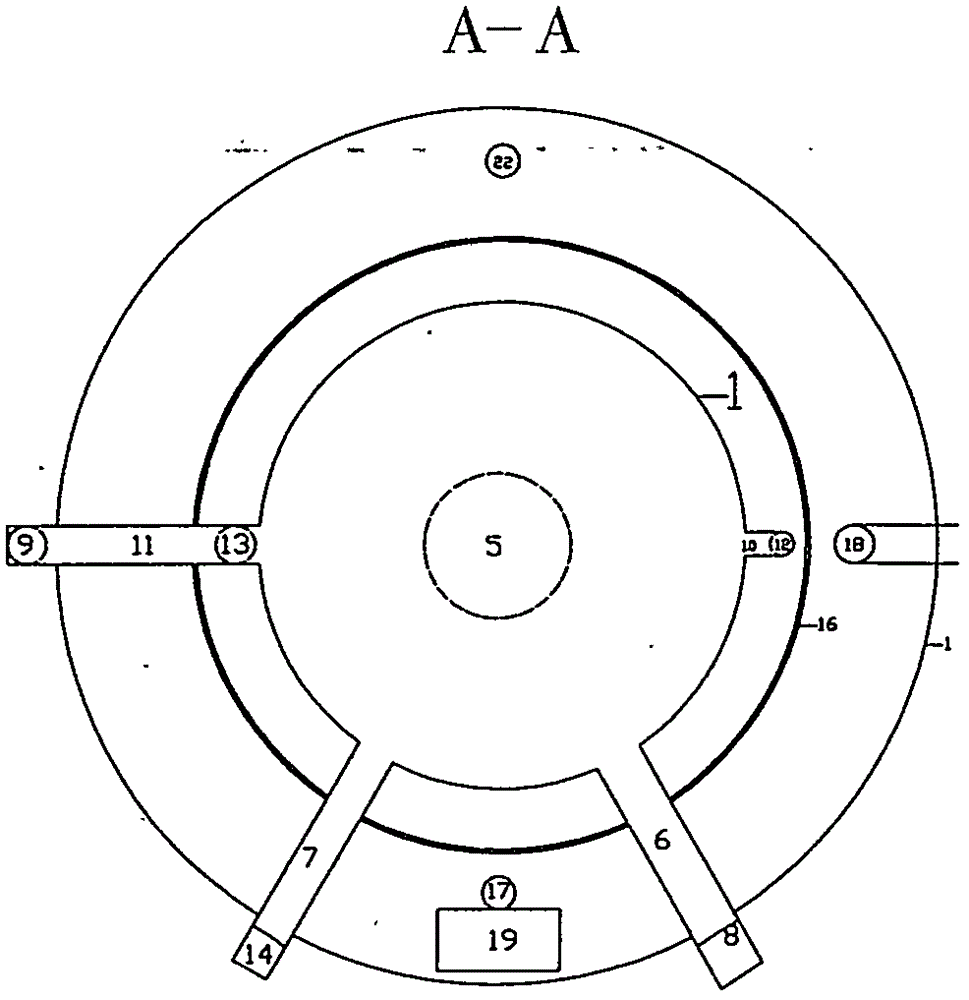

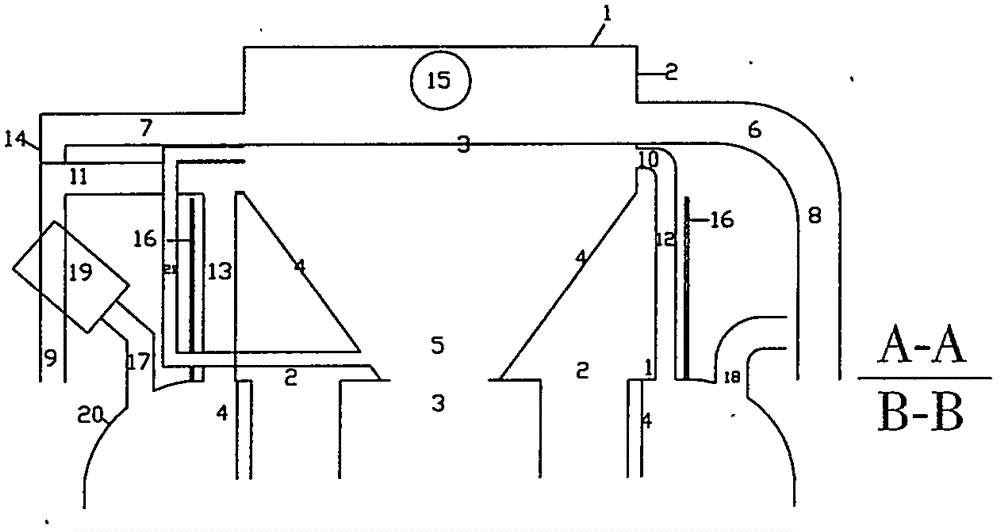

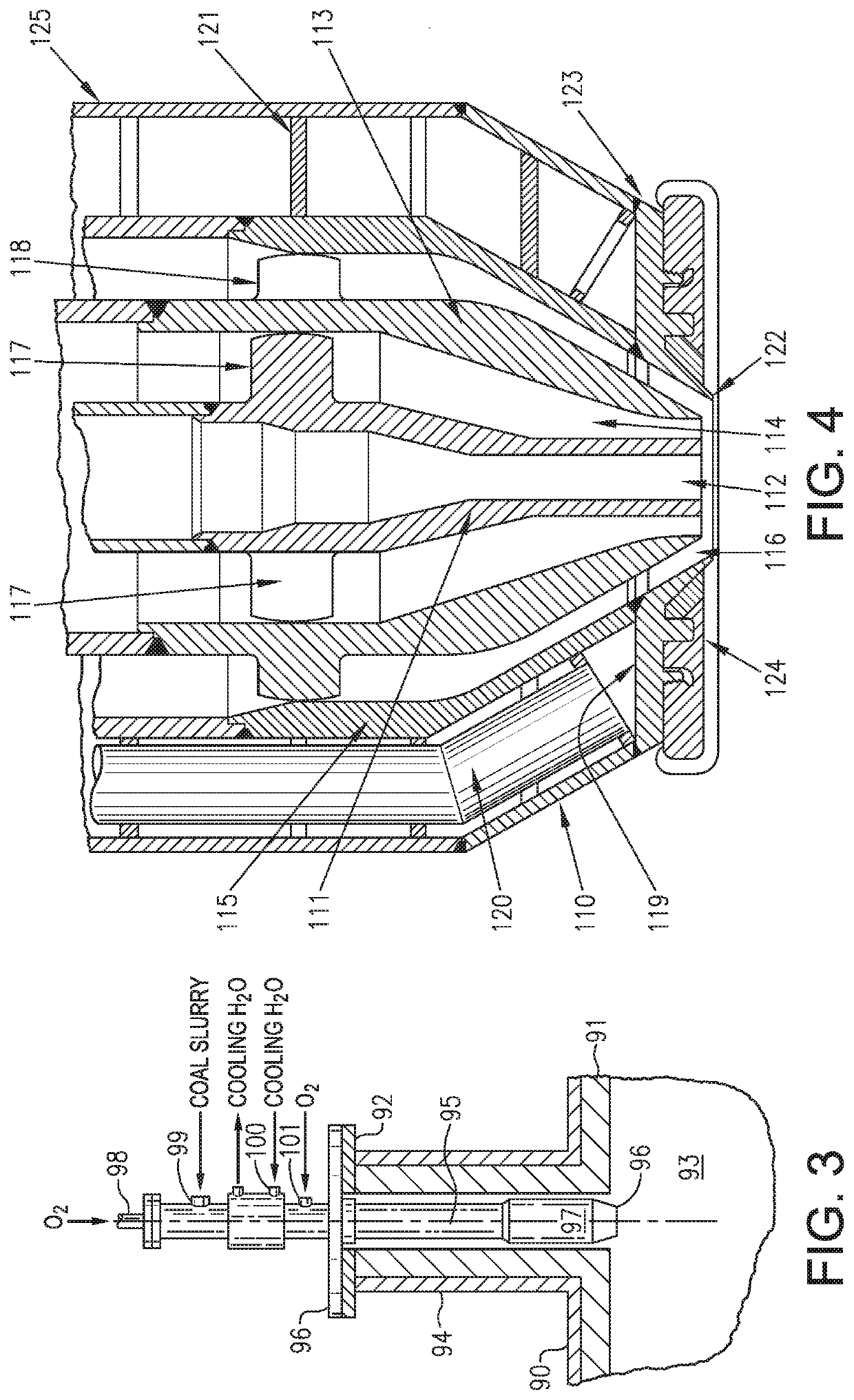

Three-channel slurry fuel gasification burner

ActiveCN102492479ASimple structureEasy to manufacture and maintainCombined combustion mitigationGranular/pulverulent flues gasificationFuel gasificationSlurry

The invention discloses a three-channel slurry fuel gasification burner, which comprises an outer ring channel jet pipe, a middle ring channel jet pipe, a center channel jet pipe, an outer ring nozzle, a middle ring nozzle and a center nozzle that are coaxial. A slurry fuel enters a gasification furnace from a middle ring channel, and a gasification agent enters the gasification furnace from a center channel and an outer ring channel in two parts. The lateral sides of the center nozzle are provided with a lateral gasification agent jet orifice, along which the gasification agent can enter a middle ring channel from the center channel. The end face of the center nozzle is provided with an end face gasification agent jet orifice. At the center nozzle, the gasification agent is divided into a plurality of material flows, which are respectively jetted from the lateral gasification agent jet orifice and the end face gasification agent jet orifice of the center nozzle. The gasification agent jetted from the lateral gasification agent jet orifice contacts with the slurry fuel of the middle ring channel inside the head of the burner. And the slurry fuel also mixes with the gasification agent of the center channel and the outer ring channel at the outlet area of the burner, thus achieving a good atomization effect.

Owner:SHANGHAI BOILER WORKS

Gasification process of water/gas mixed full-chilled dry powder fuel and device

ActiveCN101285005AGuaranteed qualified qualityLess investmentGasification processes detailsCombustible gas purificationWater bathsCooling effect

The invention relates to a process for gasifying water / gas mixed type full chilling dry powder fuel and a special chiller thereof. The process resolves problems of poor cooling effect caused by only using water to chill high-temperature crude synthetic gases, no high-temperature resistance of spray throwers and easy corrosion and block of nozzles and pipes existing in dry powder fuel gasification process. Flammable dry powders are used as raw materials and undergo pressurized gasification, chilling and dust removal and cleaning; crude synthetic gases at a temperature of between 180 and 260 DEG C, which are used for downstream operating processes, are obtained, and the cleaning ash water obtained enters an ash water treatment system; chilling steps are as follows: when gasified crude synthetic gases at a temperature of between 1400 and 1700 DEG C rise to the middle part or the upper part of a gasifier, crude synthetic gases are partially chilled by water / gas mixed fog liquids as the temperature drops to between 800 and 900 DEG C, and then are sent to a water bath type chiller by a pipe for soaking, dust removal and chilling; when the temperature drops to between 180 and 260 DEG C, the cure synthetic gases undergo next step for dust removal and cleaning. The process has the advantages of simple process, good temperature drop effect, abrasion resistance of the chilling device under the condition of high temperature, no ashes collection in nozzles and pipes and long-time effective operation, and can avoid safety accidents.

Owner:WUHUAN ENG

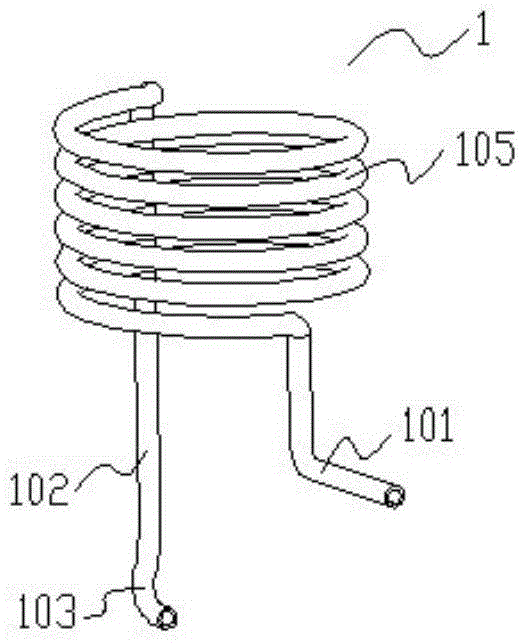

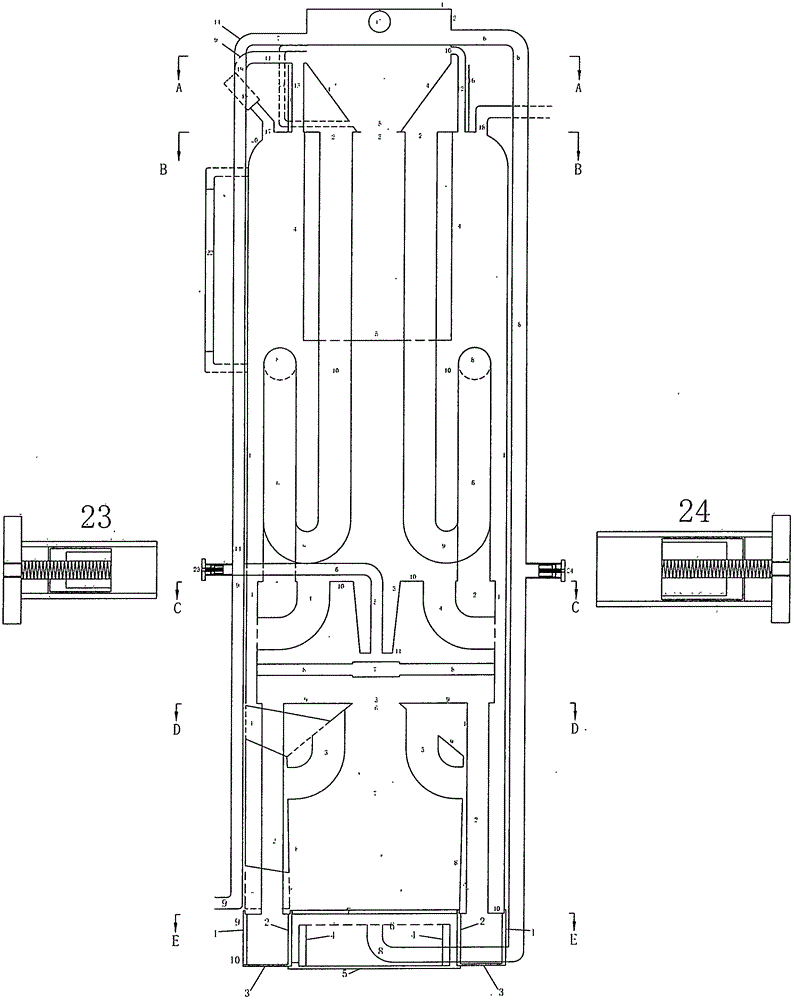

Alcohol group liquid fuel vaporizing combustor

The invention discloses an alcohol group liquid fuel vaporizing combustor, and belongs to the field of heating equipment. The alcohol group liquid fuel vaporizing combustor comprises a fire distributor and a vaporizing pipe connected with the fire distributor, wherein the fire distributor is arranged in a combustion barrel, the vaporizing pipe is of a multi-coil densely arranged columnar structure formed by a metal pipe spirally and is arranged over the fire distributor, and a feeding pipe of the vaporizing pipe is located at the lowest position of the spiral and spirals upwards from the position of the fire distributor; a gas transmitting pipe of the vaporizing pipe vertically falls down from the highest position and is connected with the bottom of the fire distributor through a spraying nozzle connector; an ignition basin is arranged under the fire distributor; the fire distributor is composed of a fire distribution cover on the upper portion, a mixer in the middle and a base cover on the lower portion, the center of the fire distribution cover is sealed, and a plurality of gas spraying holes are formed in the periphery of the surface of the fire distribution cover. The alcohol group liquid fuel vaporizing combustor is automatically heated in the combustion process without a power source or other heat resources, the vaporizing process is uniform, combustion is stable, fire is large, the heating effect is good, no fuel flies out, blockage of the vaporizing pipe is avoided, and the alcohol group liquid fuel vaporizing combustor is convenient to use and popularize.

Owner:广东你好智能科技有限公司

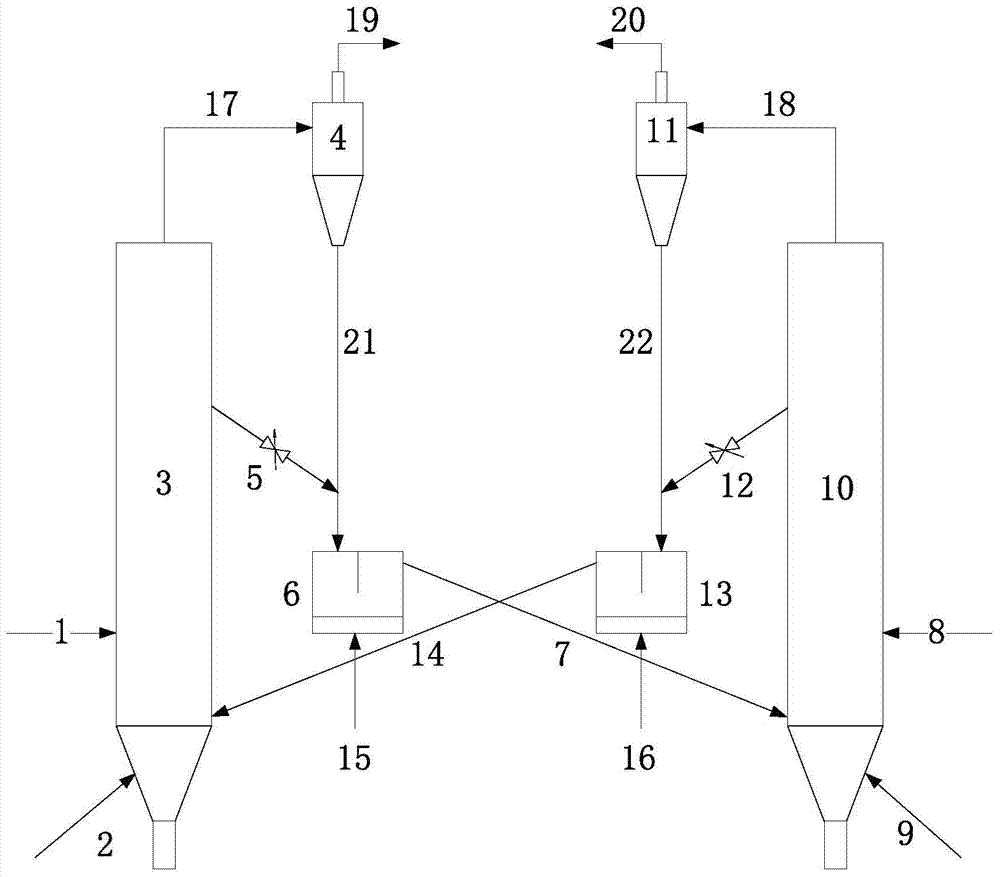

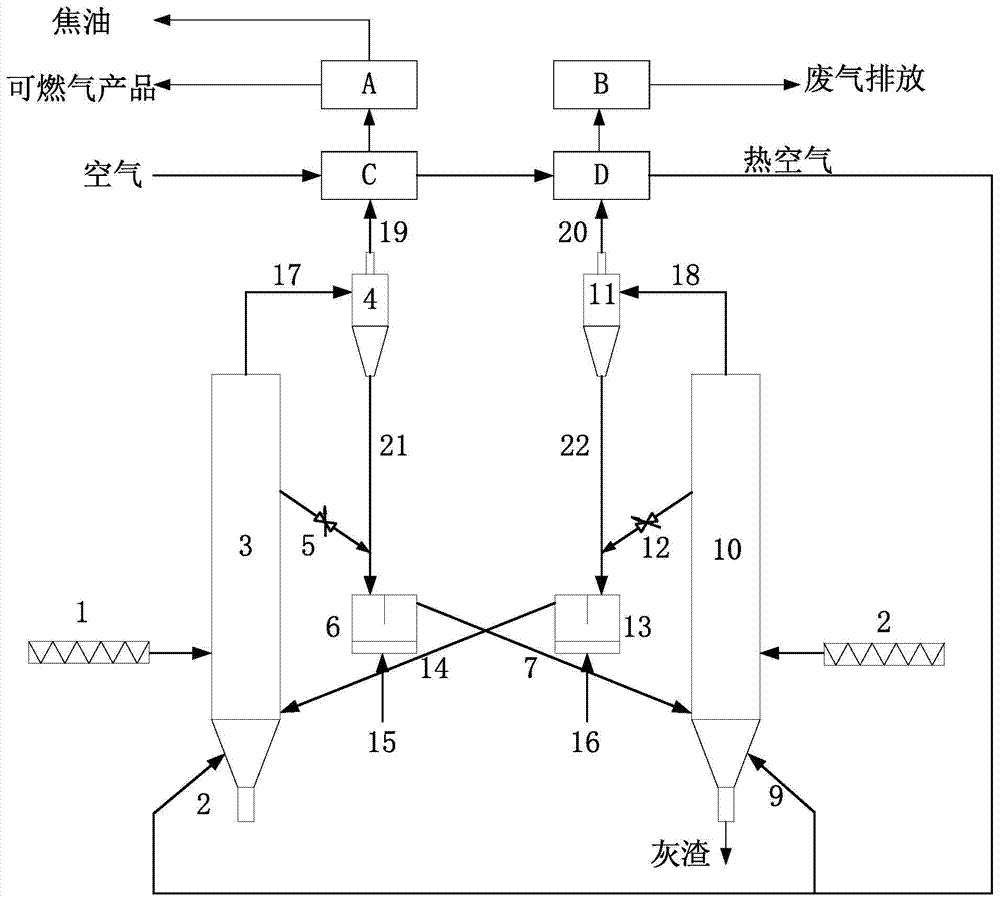

Interactive cyclic solid fuel gasification device with double fluidized beds and method

ActiveCN103756731AImprove operational efficiencyGood adaptabilityGranular/pulverulent flues gasificationProcess engineeringPyrolysis

The invention relates to a mutually-cyclical solid fuel gasification device with double fluidized beds and a solid fuel gasification method. The method comprises the following steps: performing a pyrolysis gasification reaction between a solid fuel and a gas for fluidizations and reactions in a fluidized bed gasification reactor so as to generate a combustible gas, as well as solid coke and semicoke which are not subjected to incomplete pyrolysis gasification reaction, wherein the heat required by the pyrolysis reaction is obtained from high-temperature heat-carrying circulating bed materials; feeding the solid coke / the semicoke and the heat-carrying circulating bed materials with heat discharge into a pneumatic back-feeder through a cyclone separator or an overflow device according to a running state in the reactor; controllably sending the solid coke / the semicoke and the heat-carrying circulating bed materials into a combustion reactor; reheating the heat-carrying circulating bed materials due to the combustion of the solid coke / the semicoke in the combustion reactor; and refeeding the heated heat-carrying circulating bed materials into the gasification reactor through a back-feeding device so as to provide the heat for the pyrolysis gasification reaction. Thus, the device is gasified while the running parameters of the bubbling fluidization and the fast fluidization are adapted. As a result, the solid fuel gasification device provided by the invention has the good adaptability for various combustible solids; and the high running efficiency of the whole device is realized.

Owner:SOUTHEAST UNIV

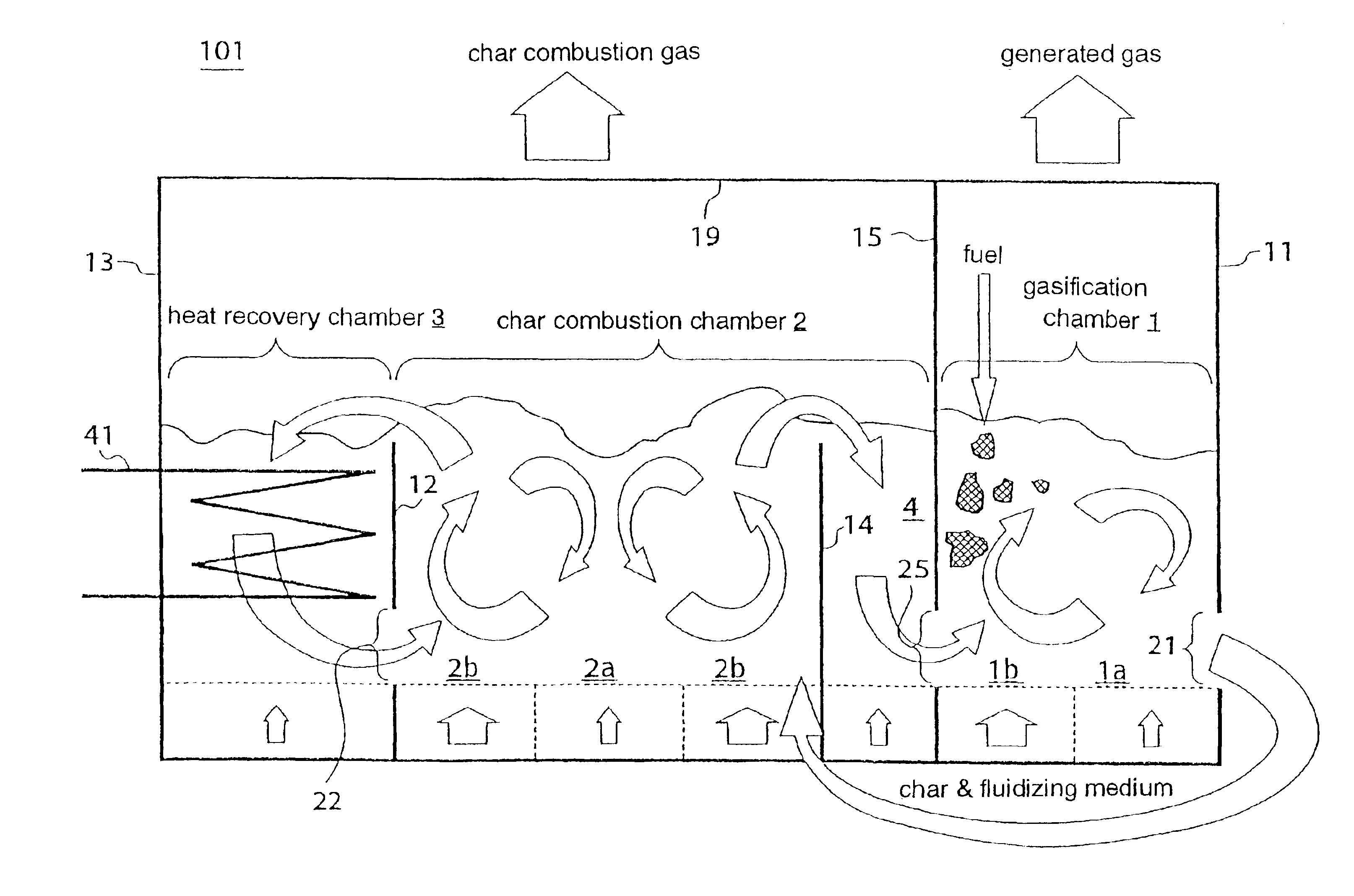

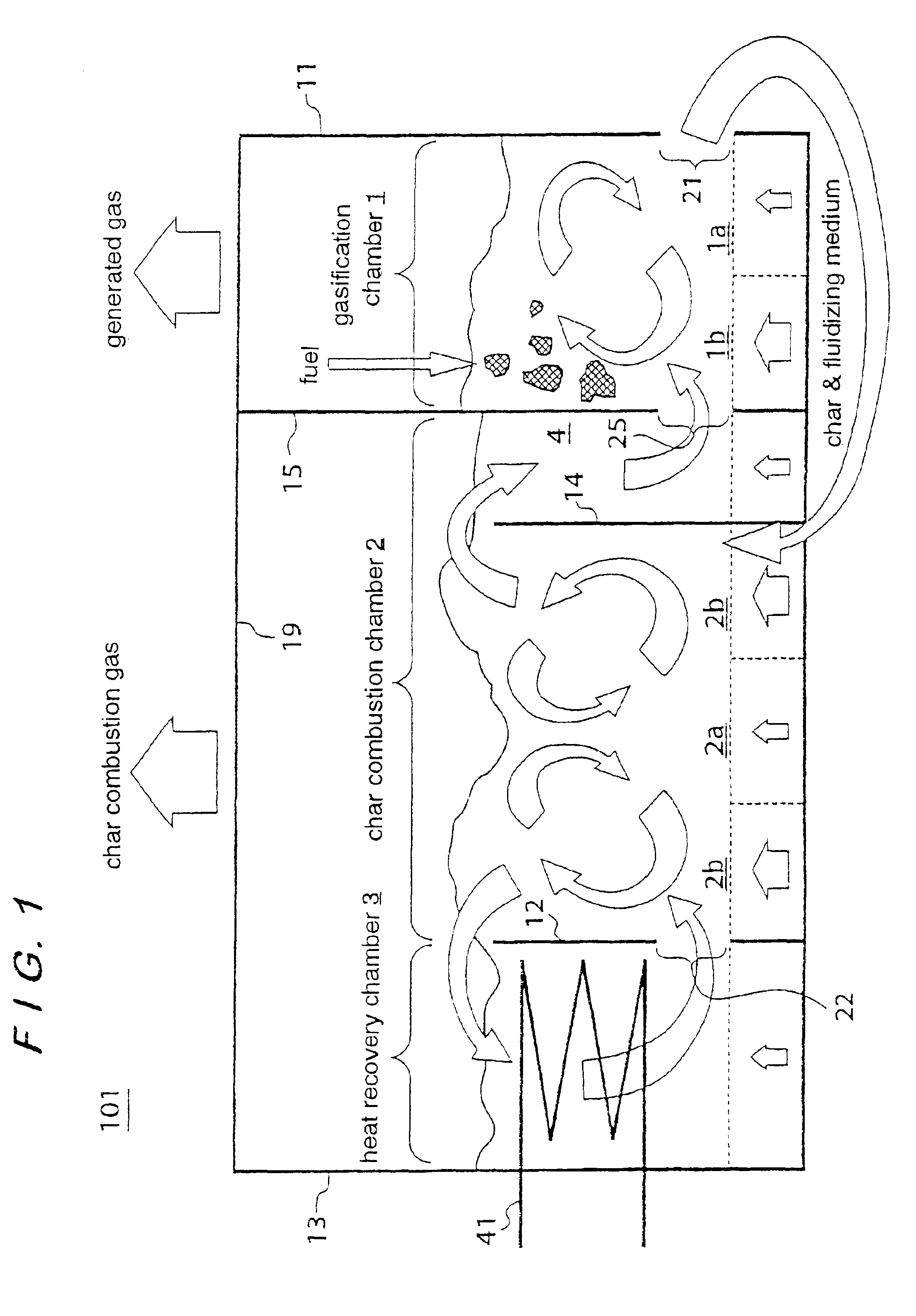

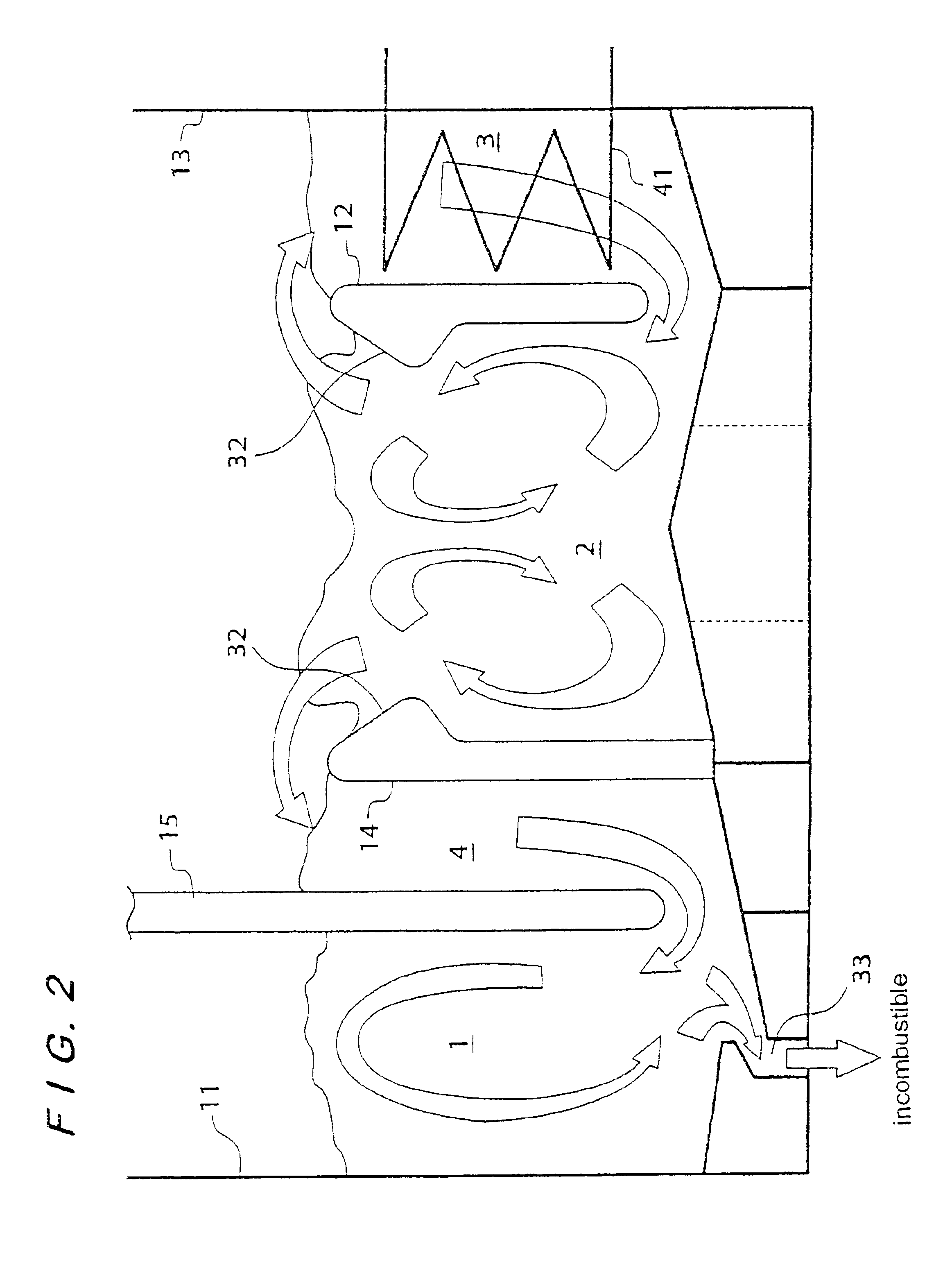

Fuel gasification system

InactiveUS6949224B1Get stableReduce corrosionEnergy inputGasification processes detailsCombustion chamberFuel gasification

The present invention provides a fuel gasification furnace including a gasification chamber (1) for fluidizing a high-temperature fluidizing medium therein to form a gasification chamber fluidized bed having an interface, and for gasifying a fuel in the gasification chamber fluidized bed, a char combustion chamber (2) for fluidizing a high-temperature fluidizing medium therein to form a char combustion chamber fluidized bed having an interface, and for combusting char generated by gasification in the gasification chamber (1) in the char combustion chamber fluidized bed to heat the fluidizing medium, and a first energy recovery device (109) for using gases generated by the gasification chamber (1) as a fuel. The gasification chamber (1) and the char combustion chamber (2) are integrated with each other. The gasification chamber (1) and the char combustion chamber (2) are divided from each other by a first partition wall (15) for preventing gases from flowing therebetween, and which extends vertically upward from the interfaces of the respective fluidized beds. The first partition wall (15) has a first opening (25) provided in a lower portion thereof, and the first opening (25) serves as a communication between the gasification chamber (1) and the char combustion chamber (2), for allowing the fluidizing medium heated in the char combustion chamber (2) to move from the char combustion chamber (2) via the first opening (25) into the gasification chamber (1).

Owner:EBARA CORP

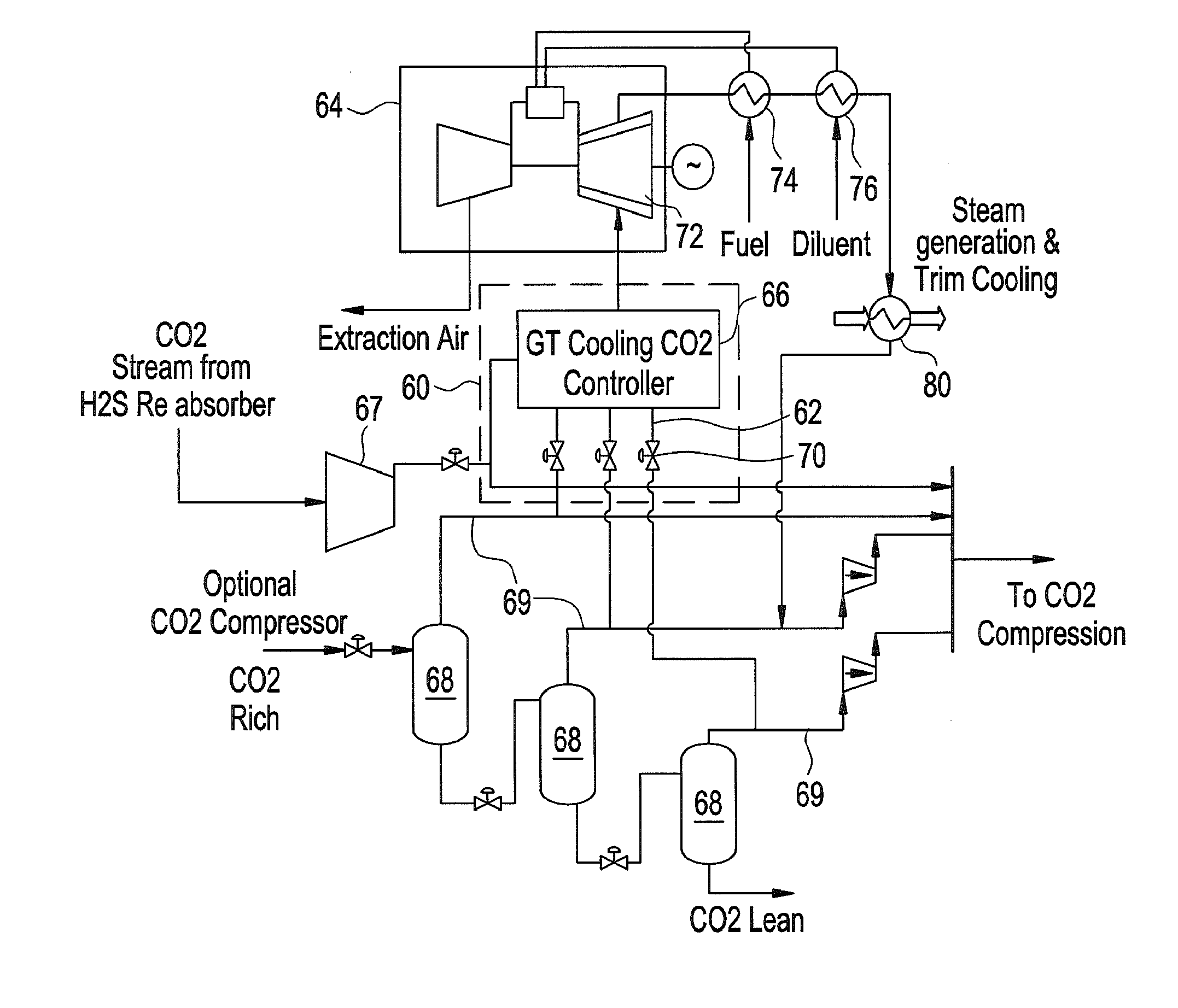

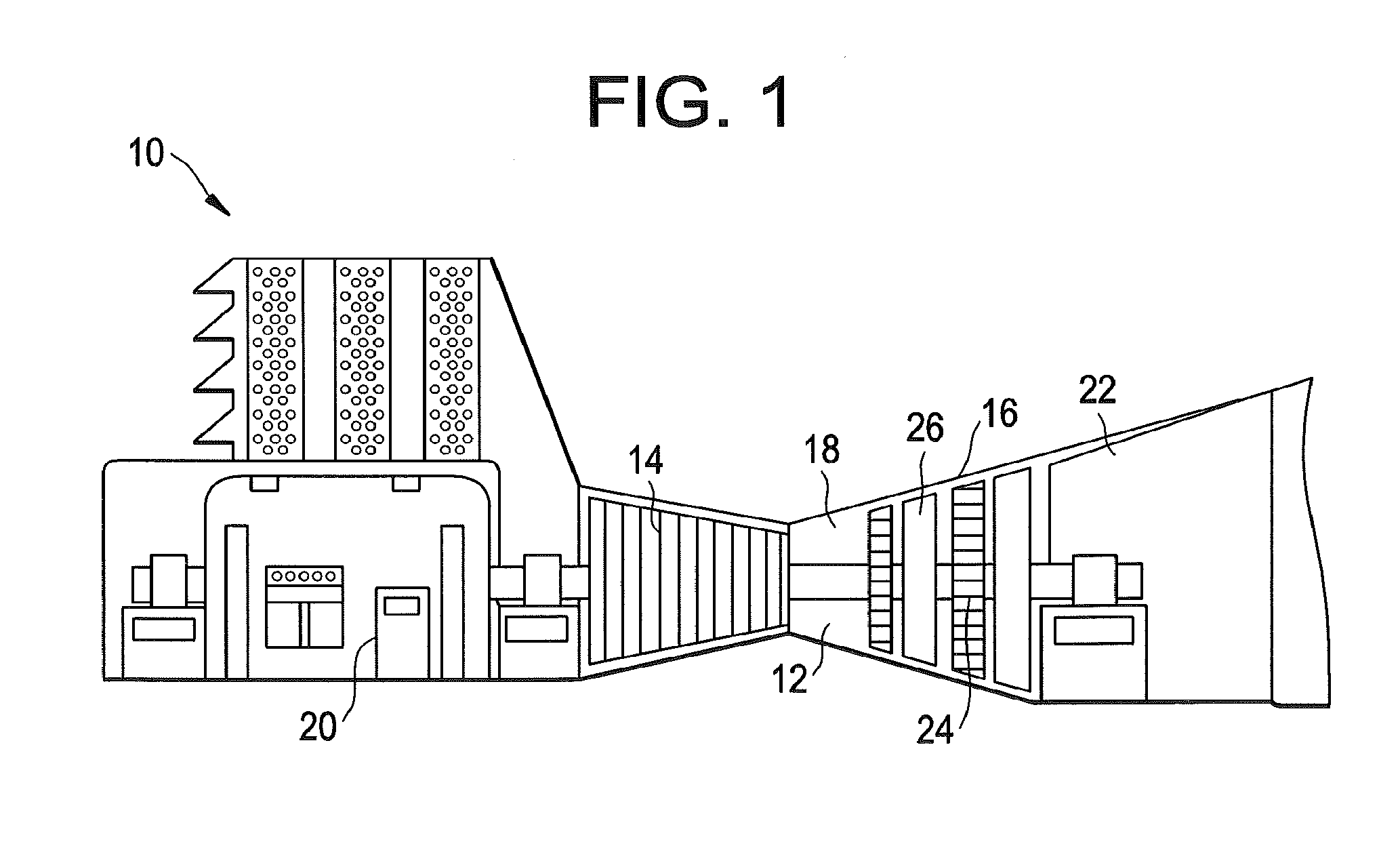

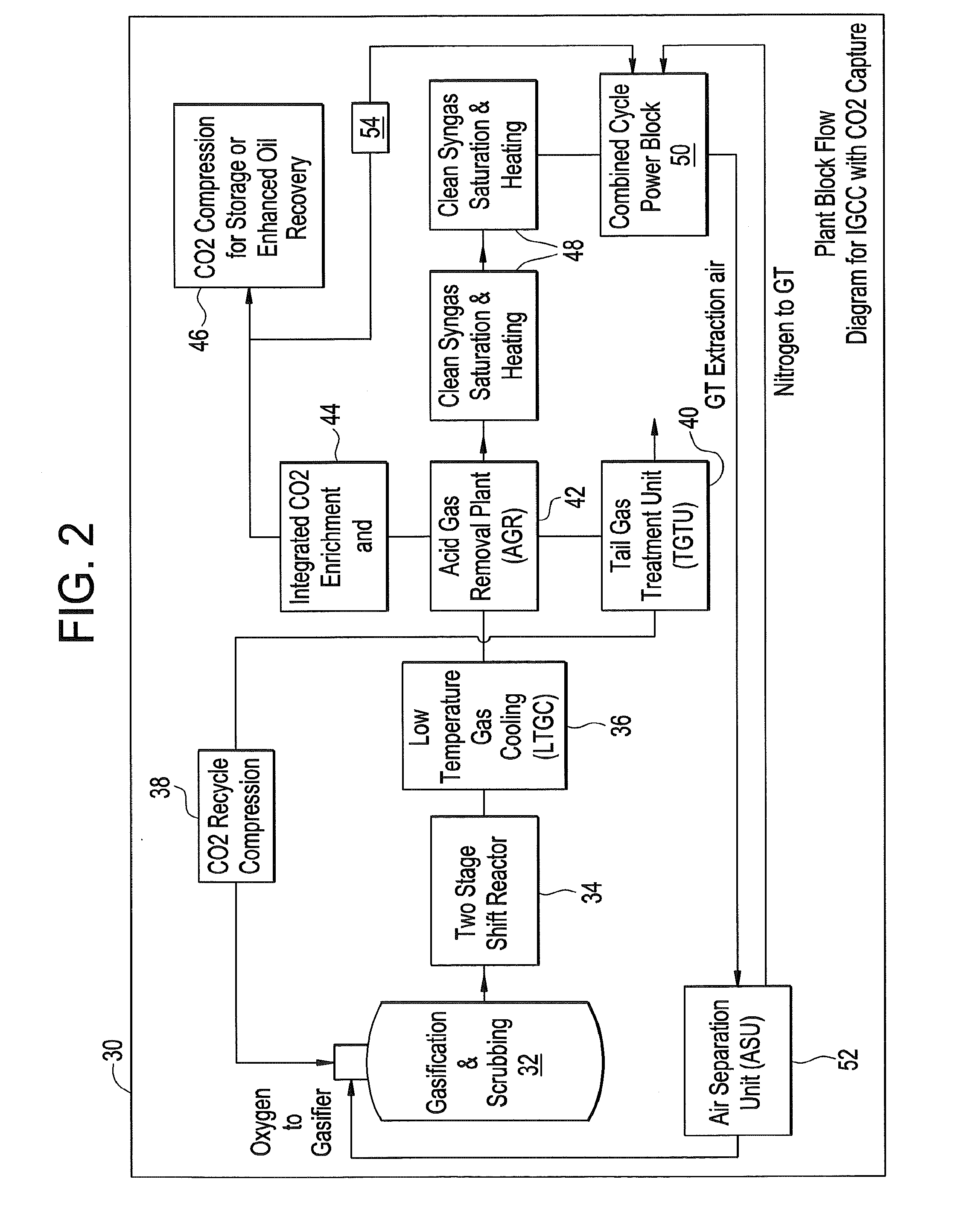

System and method for cooling gas turbine components

A system for cooling components of a turbine includes: at least one input in fluid communication with a source of carbon dioxide gas, the carbon dioxide gas removed from synthesis gas produced by a gasification unit from hydrocarbon fuel; and at least one first conduit in fluid communication with the at least one input and configured to divert a portion of the carbon dioxide gas from the source of carbon dioxide gas to at least one component of the turbine, the turbine configured to combust the synthesis gas.

Owner:GENERAL ELECTRIC CO

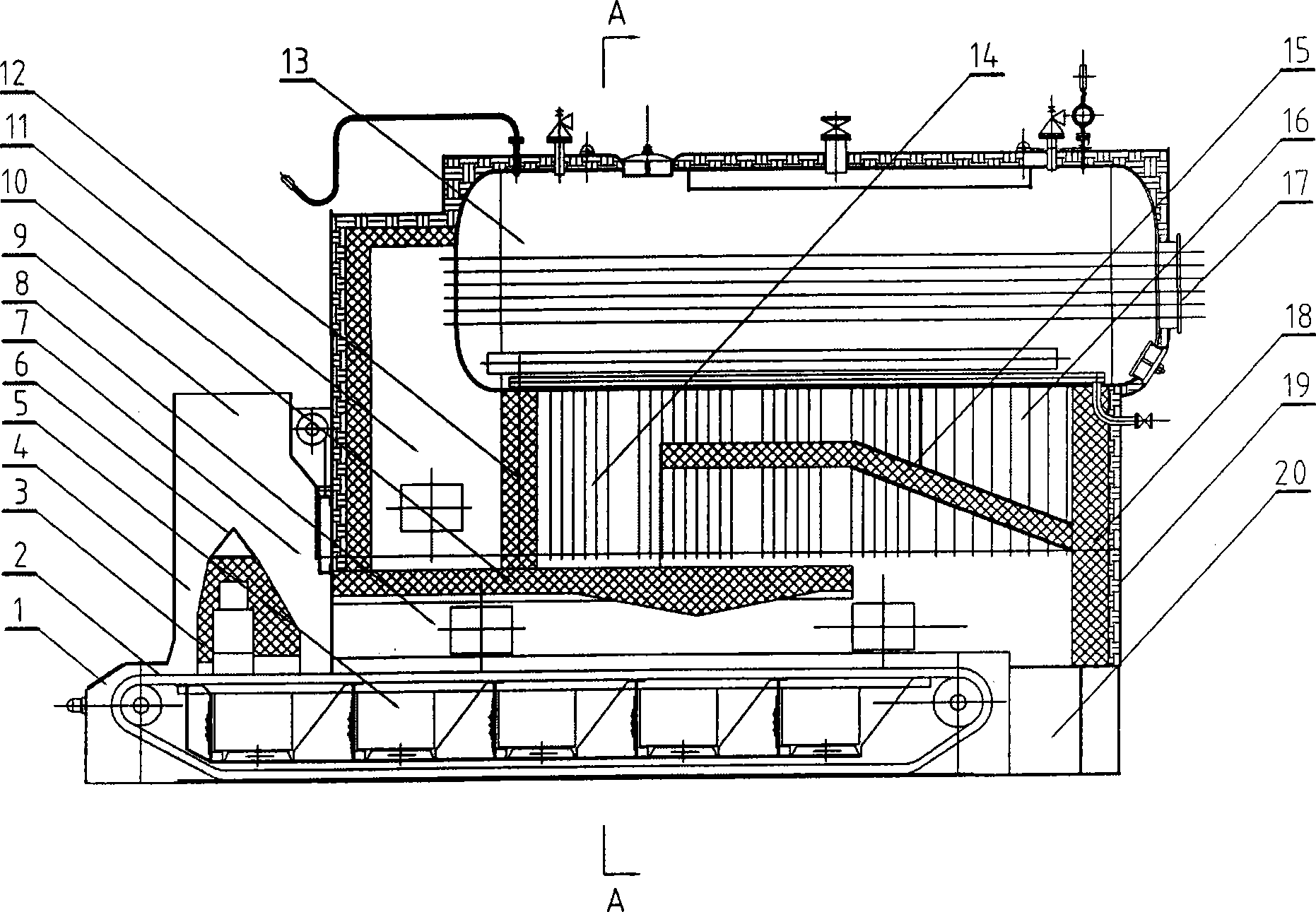

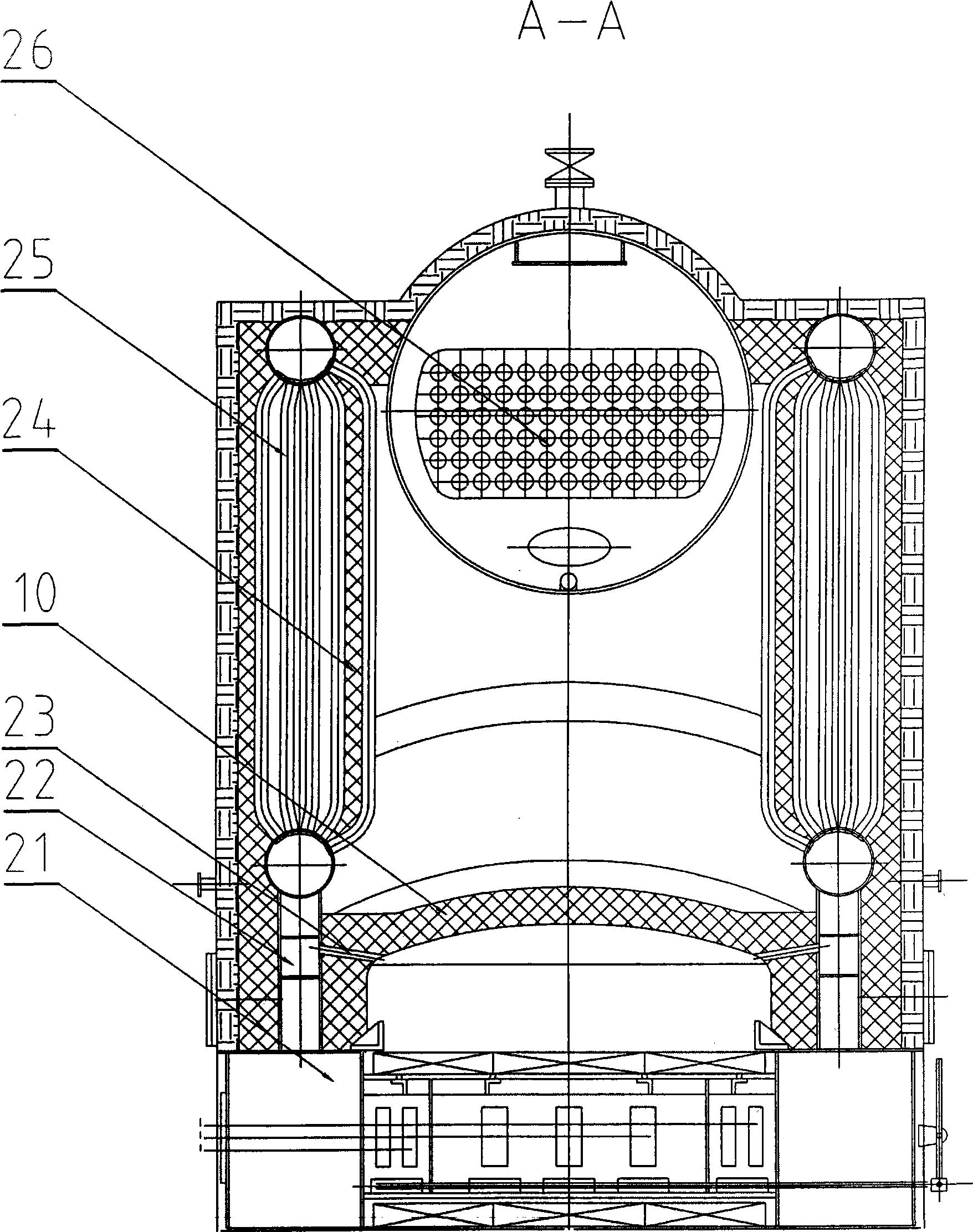

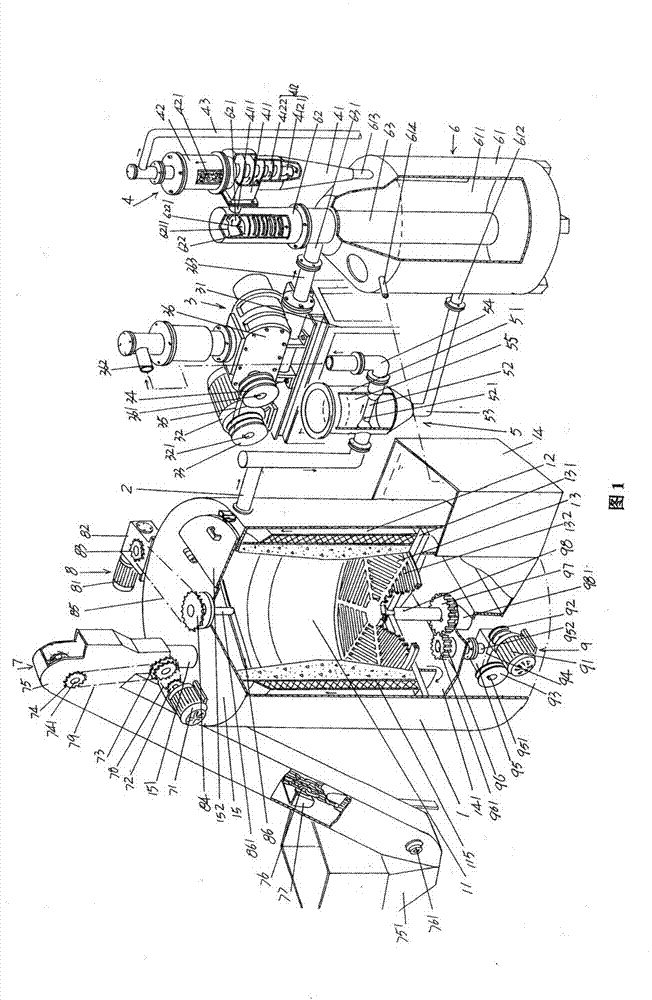

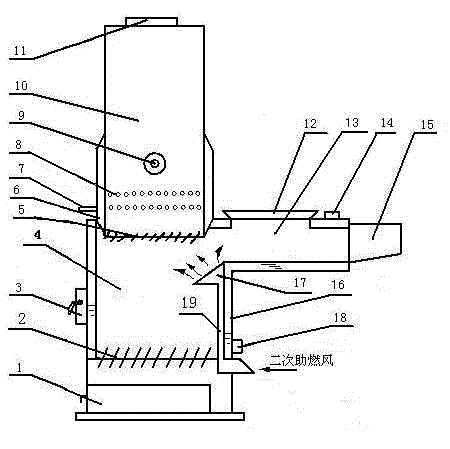

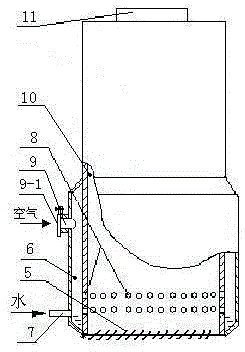

Biomass molding fuel gasification combustion boiler with mechanical travelling grate

ActiveCN101476772ABurn out in timeIncrease temperatureSolid fuel combustionWater heatersBoiler furnaceFuel gasification

The invention relates to a mechanism movable grate biomass molded fuel gasification burning boiler. The boiler comprises a grate base, a grate and a primary air chamber. Two sides of the upper part of the grate base are provided with convective heat exchange tube bundles. A boiler barrel is arranged in the middle of the upper part of the boiler and the convective heat exchange tube bundles are arranged at the two sides of the boiler barrel. A fuel hopper arranged in the front part of the grate is provided with a fuel distributor which divides the lower part of the fuel hopper into a front fuel feeding channel and a rear fuel feeding channel, and a precombustion chamber is arranged between the front fuel feeding channel and the rear fuel feeding channel. The upper part of the grate is provided with a downward convex front arch and a curved rear arch, and the outlet of the downward convex front arch is positioned on the rear part of a lower boiler furnace. The curved rear arch is higher than the downward convex front arch. Walls on the two sides of the lower boiler furnace are provided with a row of secondary air blast pipes which are communicated with a secondary air duct. The boiler is suitable for burning biomass molded fuel, low in operation cost, high in thermal efficiency, low in exhaust dust concentration, and favorable for conservation and environmental protection.

Owner:哈尔滨工大格瑞环保能源科技有限公司

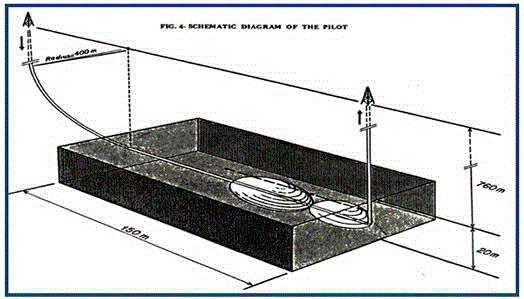

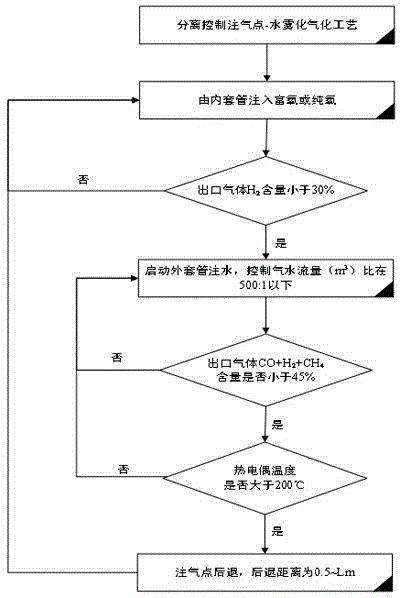

Underground fuel gasification method, gasifying agent delivery pipe and underground fuel gasification system

ActiveCN104895545AAchieve normalAchieve stabilizationConstructionsCoal gasificationWater vaporFuel gasification

The invention discloses an underground fuel gasification method, a gasifying agent delivery pipe and an underground fuel gasification system. The underground fuel gasification method comprises the steps of respectively and continuously delivering water and combustion-supporting gas to an underground fuel gasification reaction zone, atomizing the water delivered to the underground fuel gasification reaction zone by using pressure potential energy of water from the ground to the underground, mixing water vapor produced after atomization with the combustion-supporting gas delivered to the underground fuel gasification reaction zone to form mist gasifying agent, and producing fuel gas through gasification reaction between the mist gasifying agent and the underground fuel in the underground fuel gasification reaction zone by combustion and heating. The gasifying agent delivery pipe comprises a water delivery pipe and a gas delivery pipe. The underground fuel gasification system comprises an underground gasification furnace, the gasifying agent delivery pipe and an atomizing and mixing nozzle. The water and combustion-supporting gas can be mixed in the underground fuel gasification reaction zone to form the mist gasifying agent without using heat, the normalization and stabilization of the underground gasification process are realized, and the production cost is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

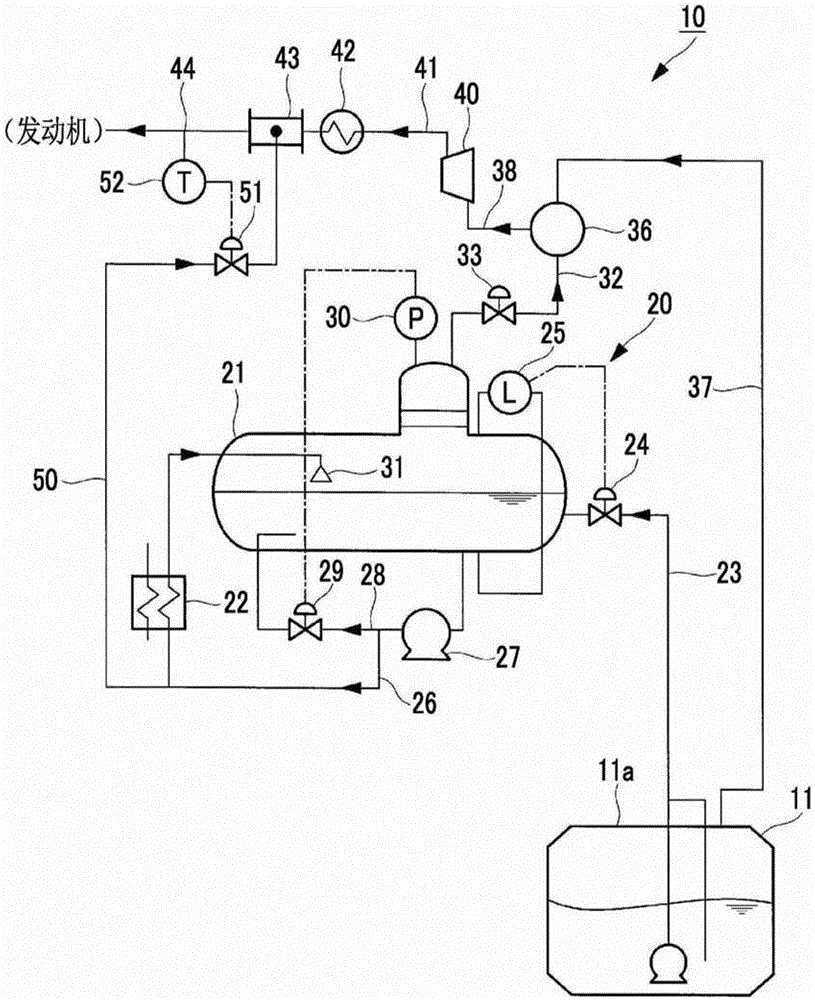

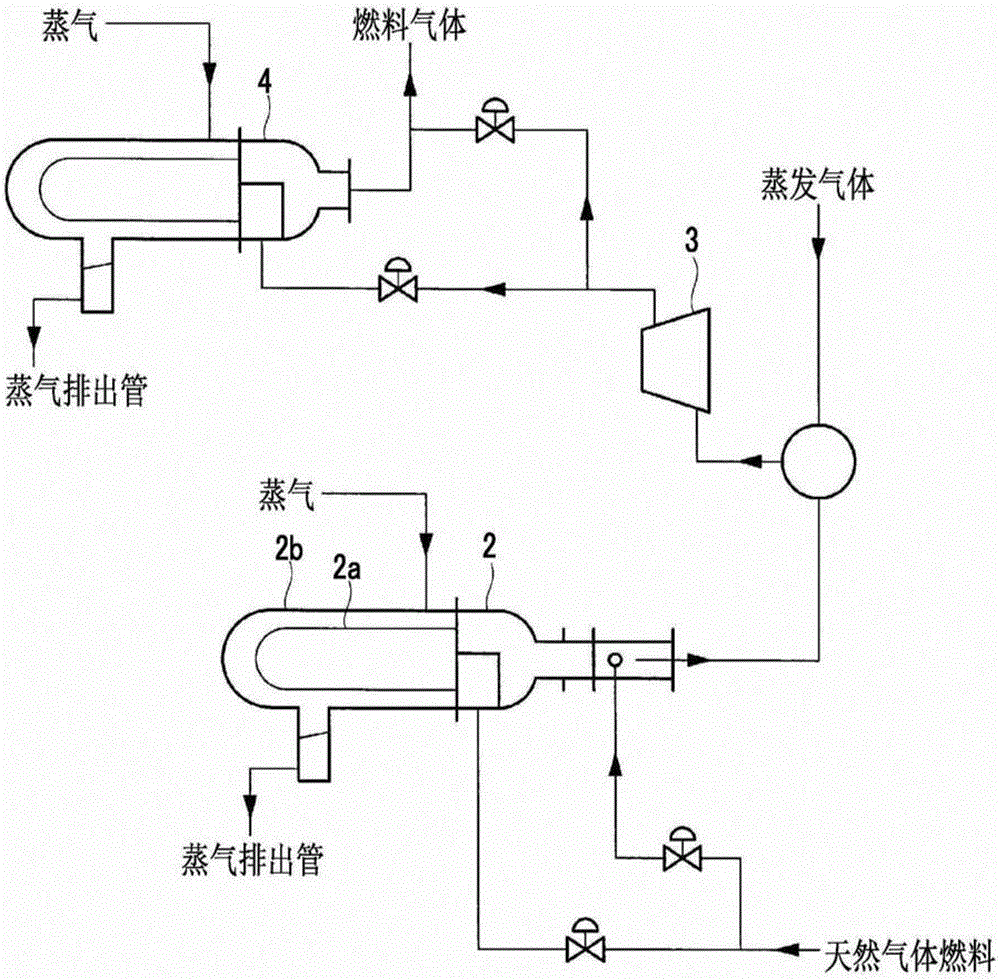

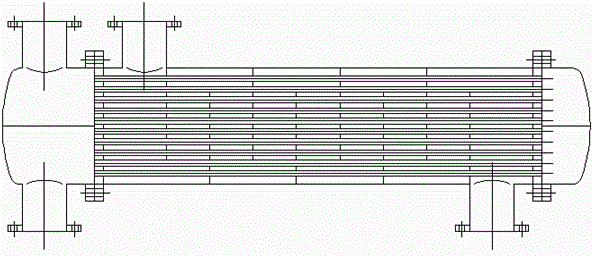

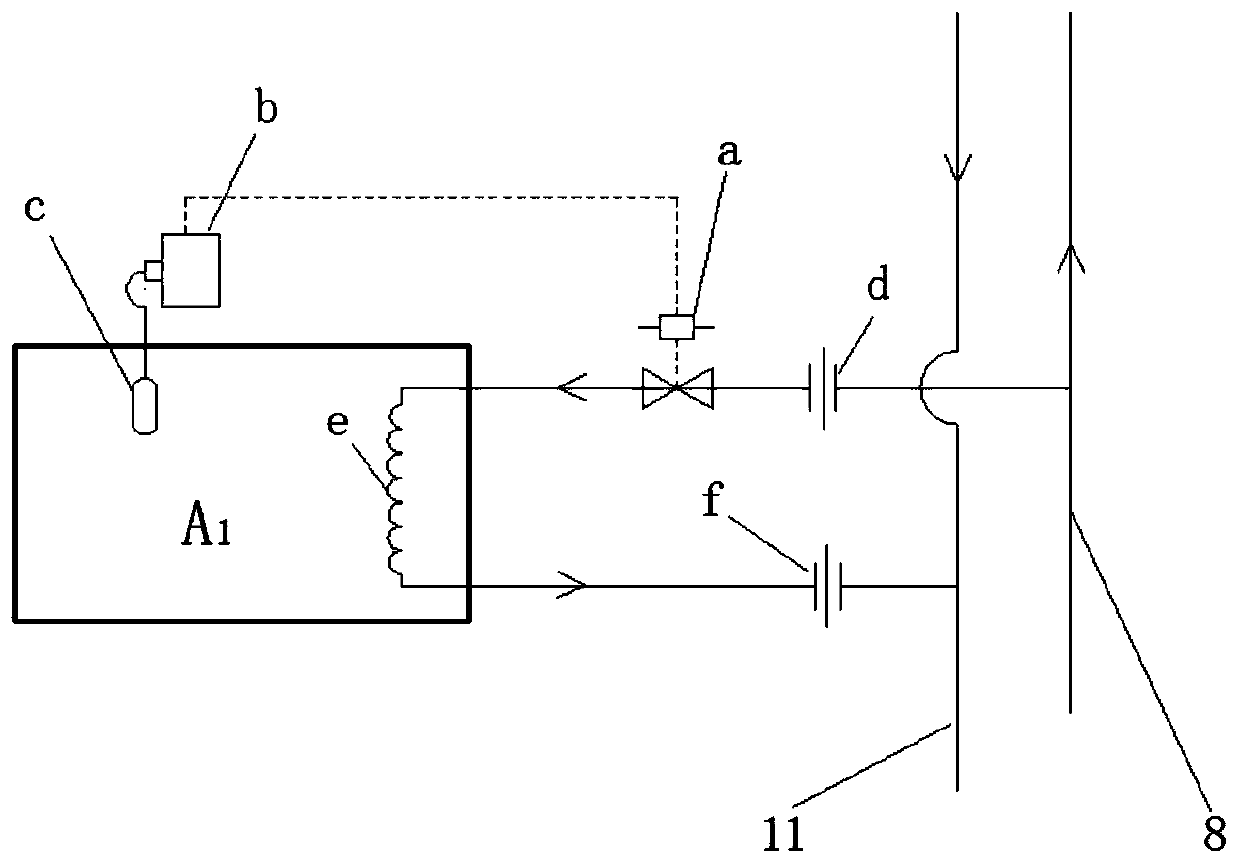

Natural gas fuel evaporator, natural gas fuel supply device, and method for supplying natural gas fuel to ships and motors

ActiveCN104955727ALower gas temperatureCost controlHull interior subdivisionInternal combustion piston enginesFuel gasificationEngineering

The purpose of the present invention is to reduce the cost of fuel gasification equipment for LNG and other liquefied gas. The methane component of LNG liquid inside a holding tank (21) is evaporated, turned into LNG gas, and discharged from the holding tank (21), by: supplying LNG liquid that has been heated by a heating unit (22), putting LNG liquid inside the holding tank (21) into a saturated state, opening a throttle valve (33); and reducing the pressure inside the holding tank (21). In addition, it is preferable that the accumulation of heavy components inside the holding tank is avoided by supplying some of the LNG liquid inside the holding tank (21) to a desuperheater (43), via a branch pipe (50).

Owner:MITSUBISHI SHIPBUILDING CO LTD

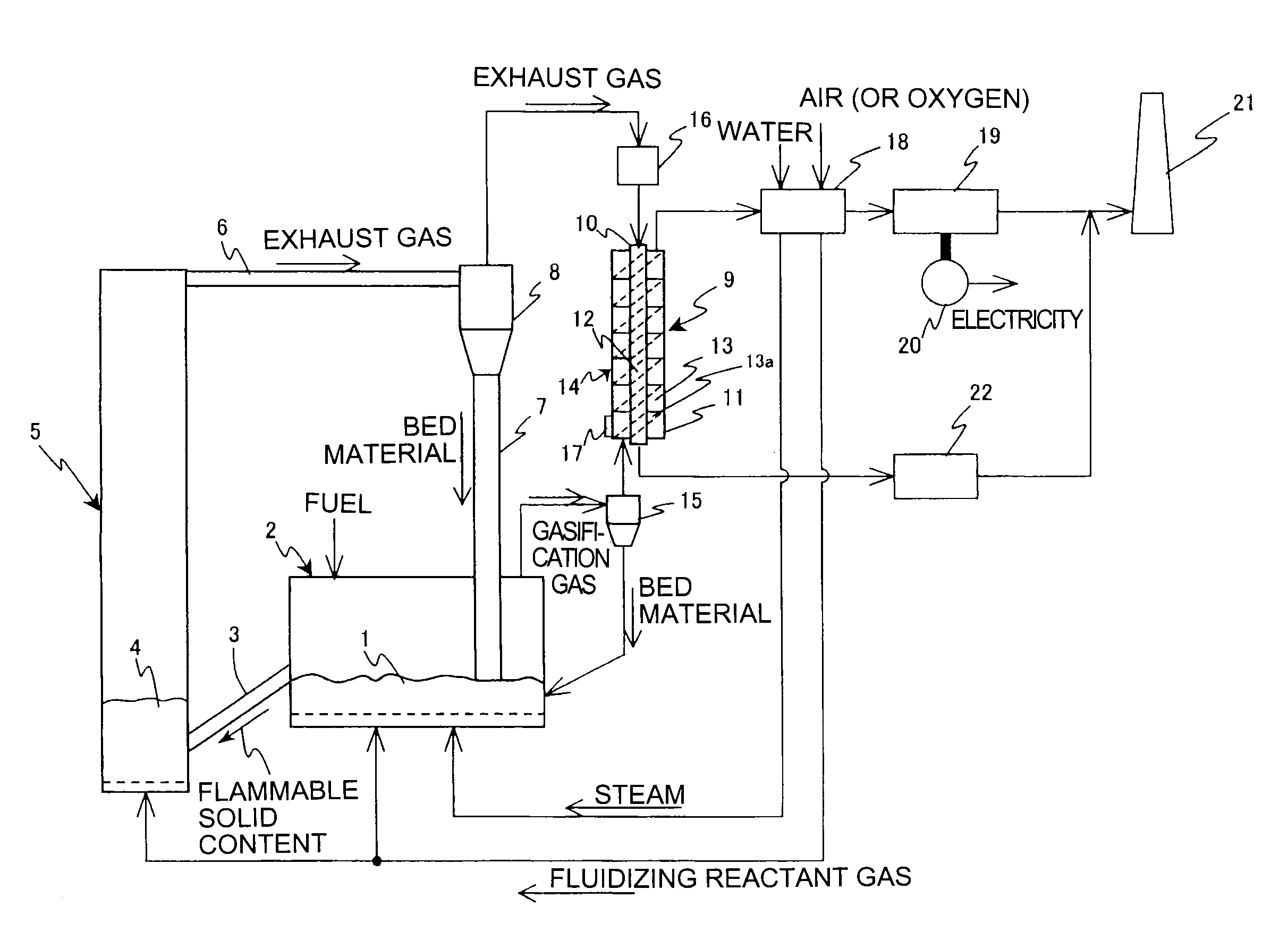

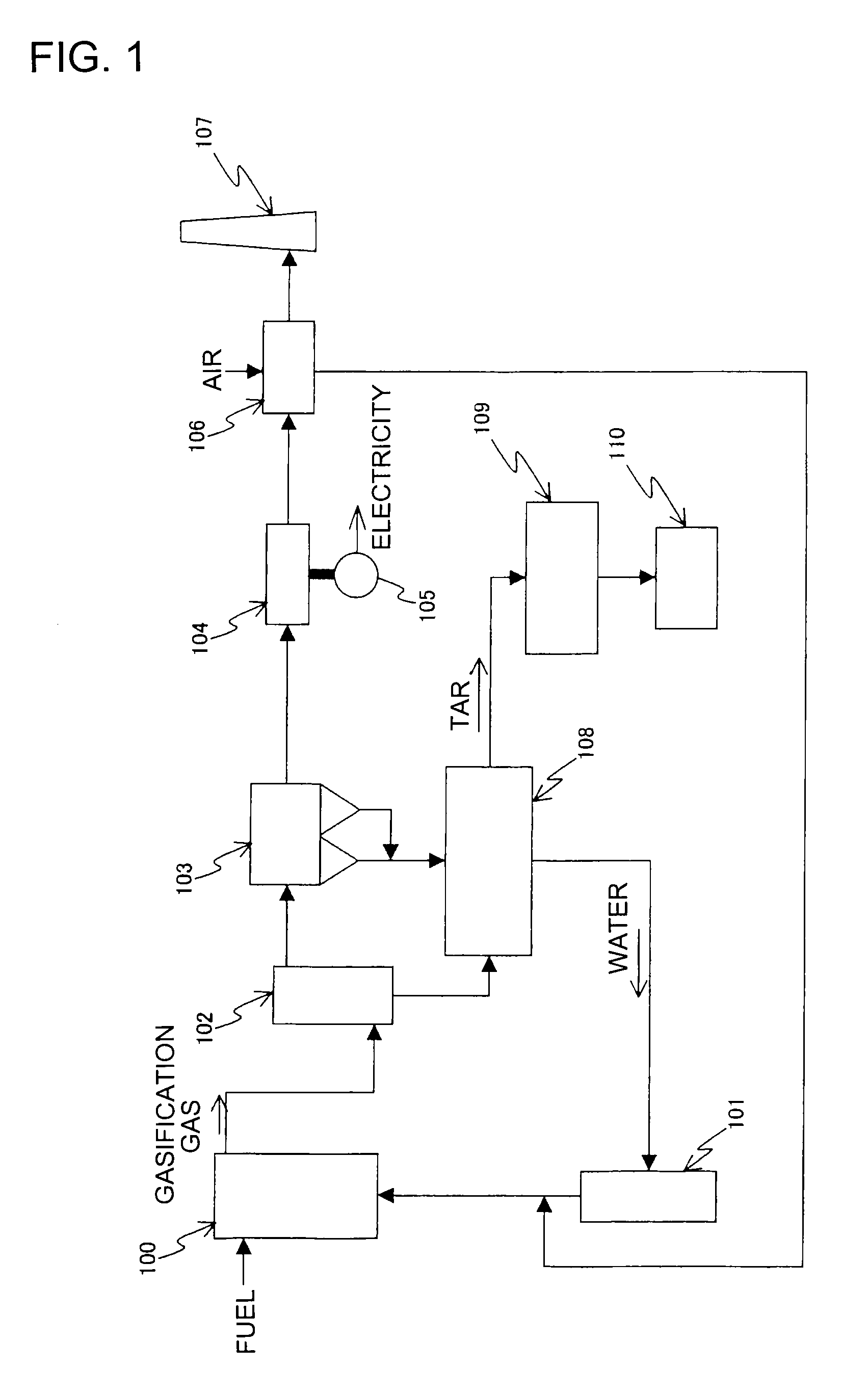

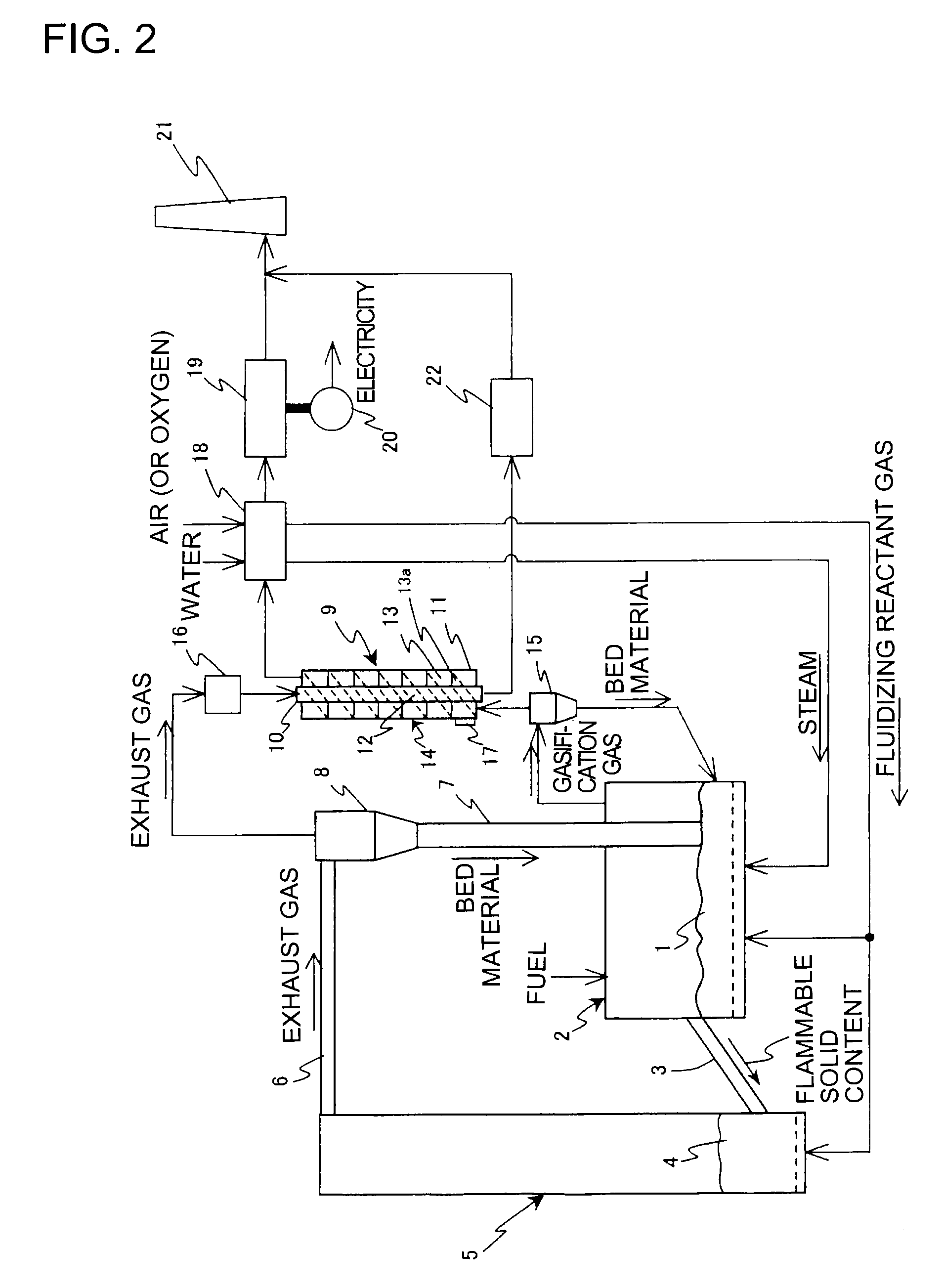

Fuel gasification system

InactiveUS20100050516A1Efficient decompositionGood effectGasification processes detailsFluidised-bed furnacesCycloneSolid component

A fuel gasification system including a gasification furnace including a fluidized bed formed by fluidizing reactant gas for gasifying fuel charged into gasification gas and flammable solid content, a combustion furnace for combustion of the flammable solid content into which the flammable solid content produced in the furnace is introduced together with bed material and that includes a fluidized bed formed by fluidizing reactant gas, a material separator such as hot cyclone that separates bed material from exhaust gas introduced from the combustion furnace, the separated bed material being fed through a downcorner to the gasification furnace, and a tar decomposing mechanism that heats the gasification gas produced in the furnace to decompose tar contained in the gasification gas.

Owner:IHI CORP

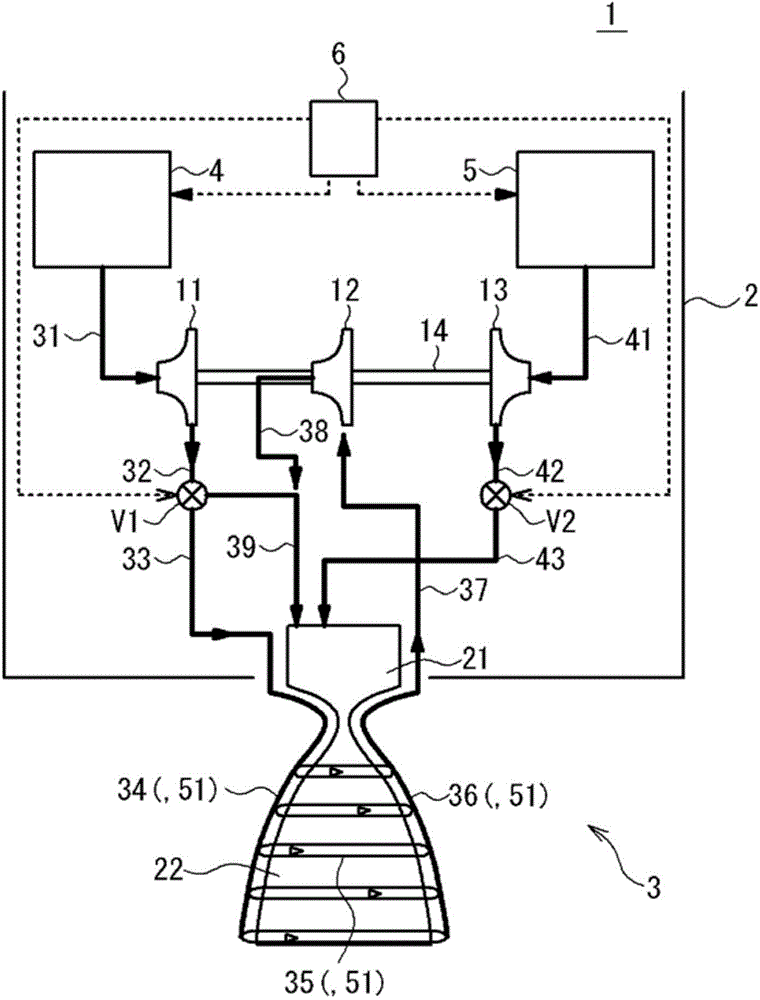

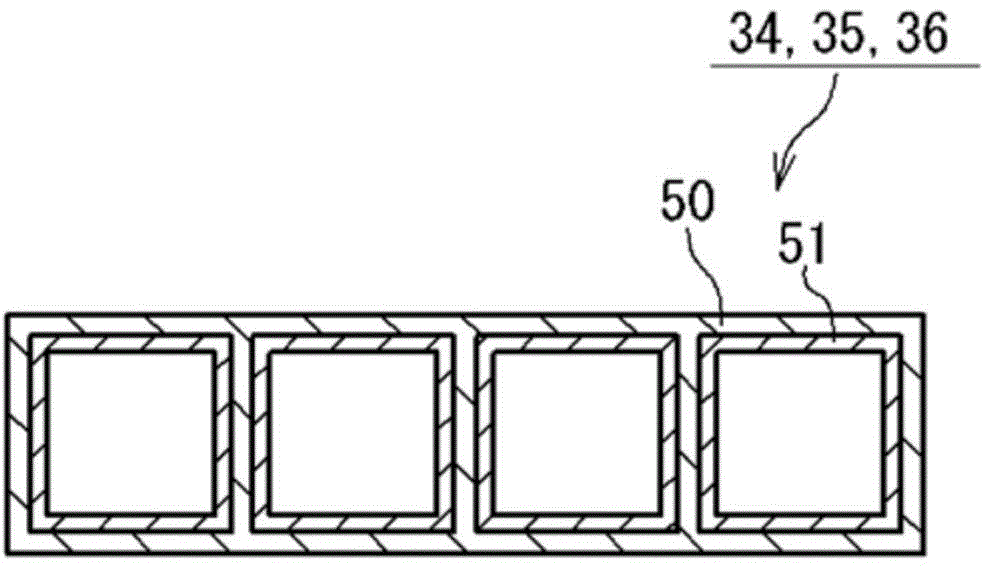

Rocket engine, rocket, and method for starting rocket engine

InactiveCN104919167AReduce lossesWell mixedCosmonautic vehiclesEngine fuctionsCombustion chamberTurbine

A rocket engine is provided with a fuel flow path (31-39), a catalyst part (51), a turbine (12), a first pump (11), a combustion chamber (21), and a nozzle (22). Hydrocarbon-based fuel flows through the fuel flow path (31-39). The catalyst part (51) is provided in the middle of the fuel flow path (31-39), and gasifies the fuel. The turbine (12) is driven by the gasified fuel. The first pump (11) supplies the fuel to the fuel flow path (31-39) by the driving of the turbine (12). The combustion chamber (21) burns the gasified fuel supplied from the fuel flow path (31-39), and an oxidizing agent. The nozzle (22) delivers combustion gas in the combustion chamber (21) and is cooled by heat exchange with part of the fuel flow path (31-39).

Owner:MITSUBISHI HEAVY IND LTD

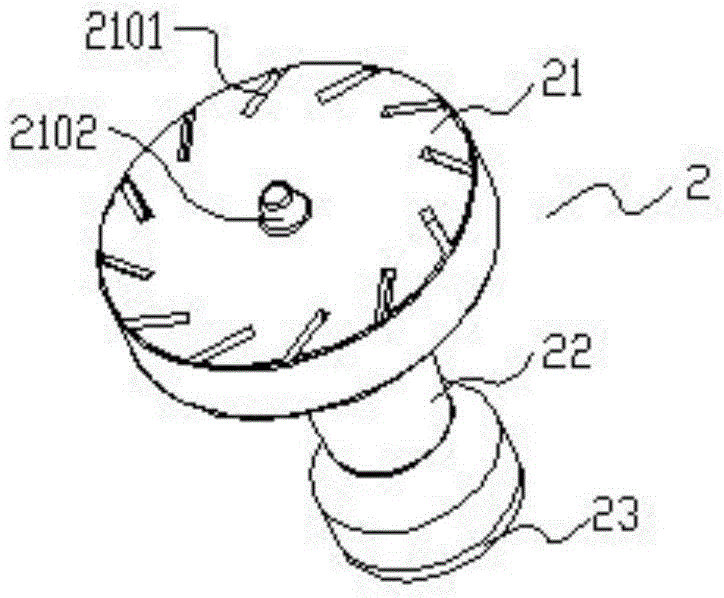

Biomass briquette gasification direct combustion combustor

InactiveCN101660750AEvenly distributedSolve insufficient pile burningChemical industrySolid fuel combustionThermal energyMotor drive

The invention relates to a biomass briquette gasification direct combustion combustor, which comprises a furnace body and a bracket, wherein the furnace body is supported on the bracket; the bottom ofa furnace body is fixedly connected with a bottom support and the middle part of the bottom support is provided with a through hole; a circular fire grate is arranged on the upper part of the bottomsupport; the fire grate is plate-shaped and evenly provided with fire grate air holes and the lower part of the fire grate is connected with a fire grate rotating shaft; and a motor drives the fire grate rotating shaft, the upper part of the furnace body is connected with a cylindrical spray nozzle and the furnace body on the other side opposite to the spray nozzle is provided with a material loading opening. The special combustion mode ensures that biomass fuel is fully gasified and combusted, realizes high-efficiency energy-saving conversion of the biomass and has good energy-saving effect.The biomass briquette gasification direct combustion combustor has compact structure, small volume, great reduction of production cost and obvious environment-friendly effect.

Owner:刘善华

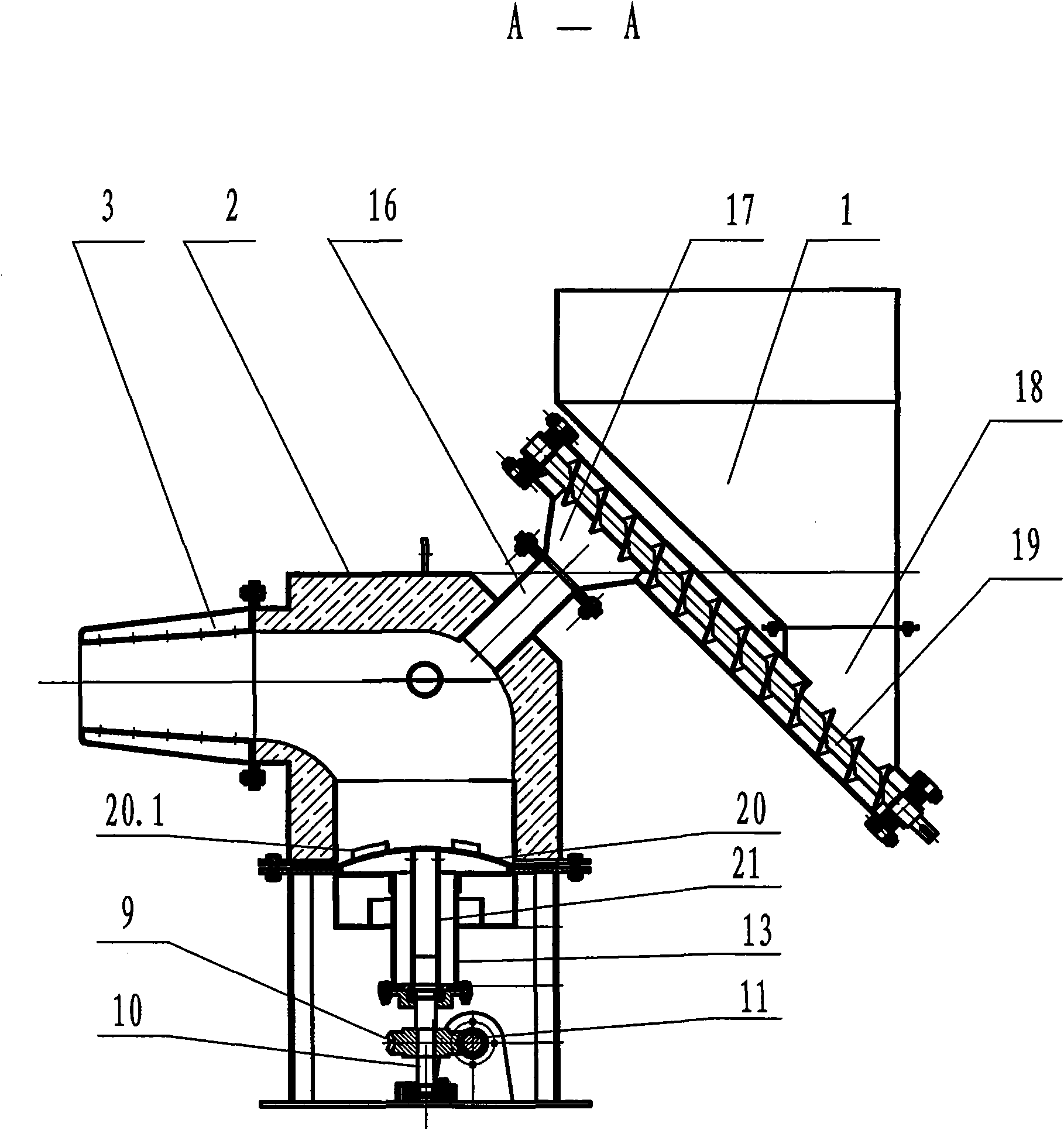

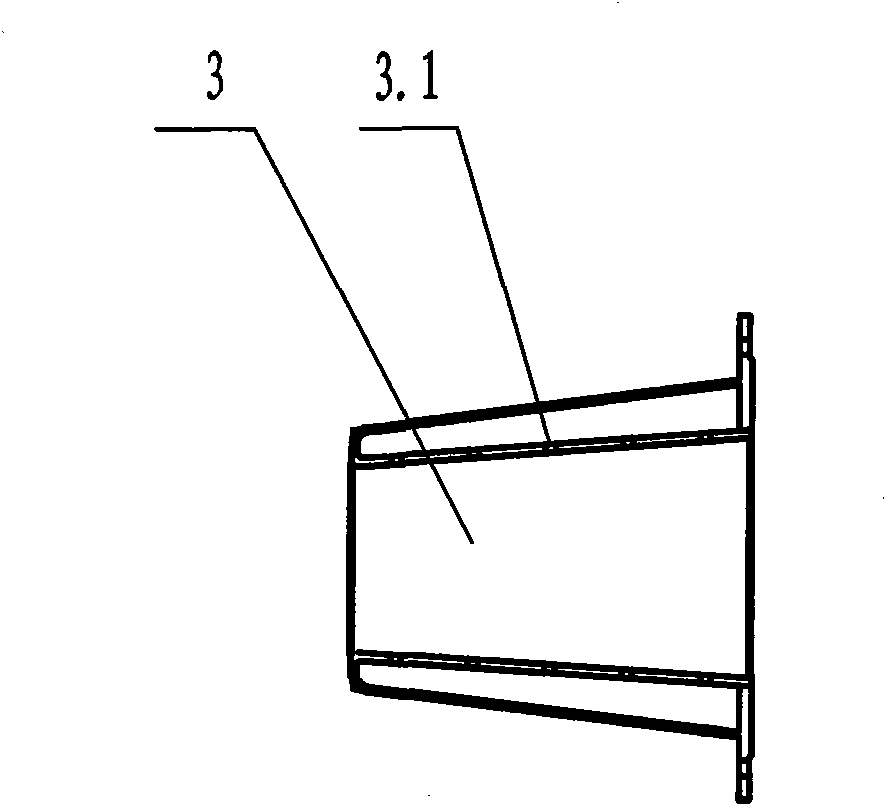

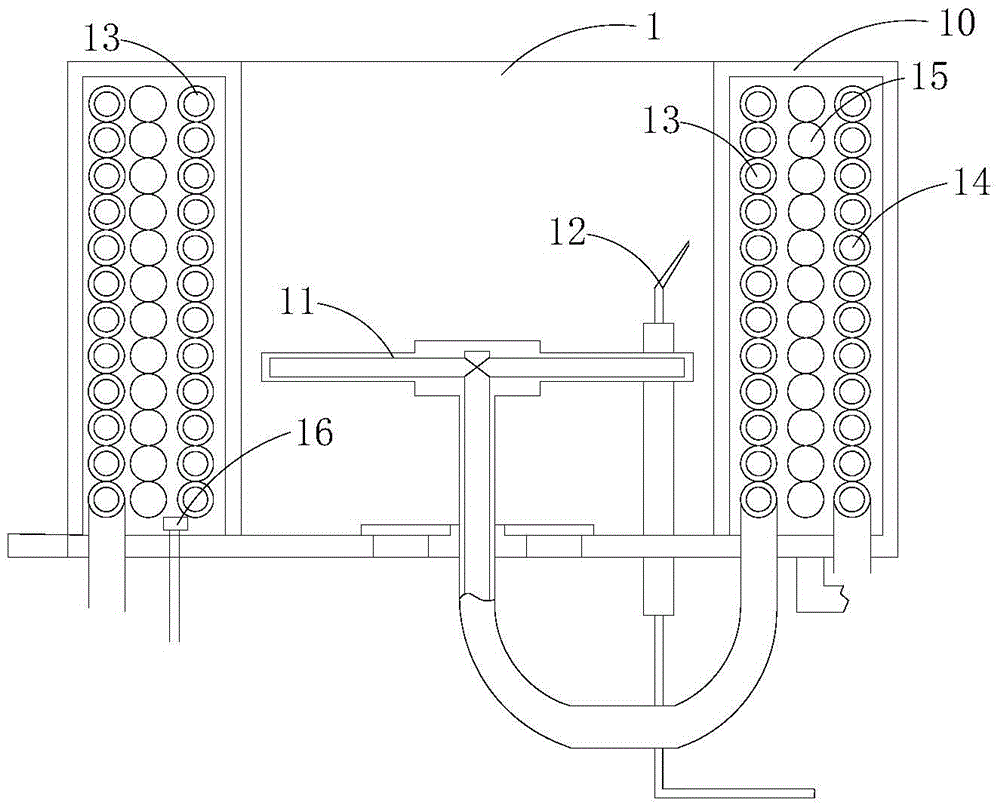

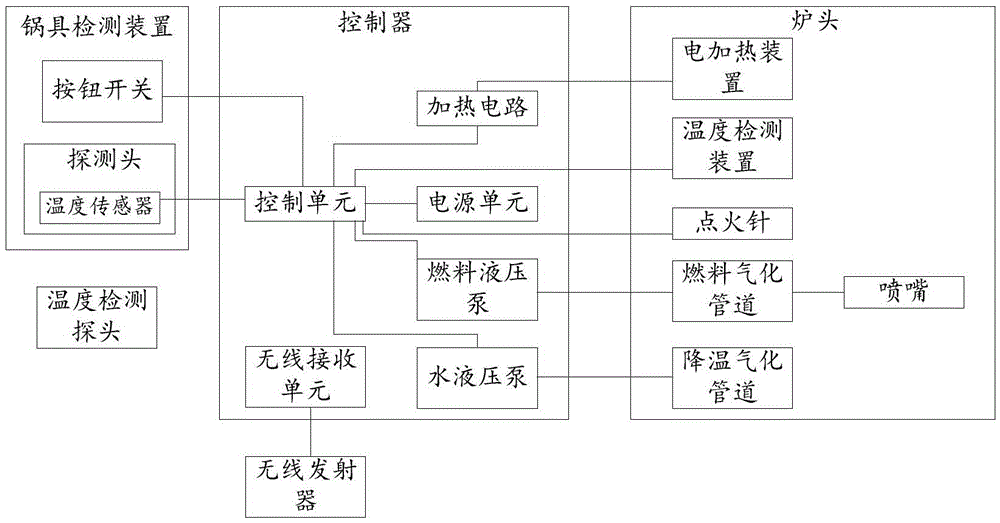

Alcohol-based fuel combustion furnace end and combustor

InactiveCN105546530AReduce the temperatureReduce gasification rateLiquid fuel burnerElectricityCombustor

The invention provides an alcohol-based fuel combustion furnace end and a combustor. The furnace end comprises a hood body, a nozzle, an ignition needle, fuel gasifying pipelines, temperature reduction gasifying pipelines, electric heating devices and a temperature measurement device, wherein the hood body is arranged at the periphery of the ignition needle and the periphery of the nozzle in a sleeving manner; the ignition needle is arranged on one side of the nozzle; the fuel gasifying pipelines, the temperature reduction gasifying pipelines, the electric heating devices and the temperature measurement device are arranged in the hood body; output terminals of the fuel gasifying pipelines are connected with the nozzle, and input terminals of the fuel gasifying pipelines are connected with a fuel supplying device. According to the alcohol-based fuel combustion furnace end and the combustor disclosed by the invention, through the temperature reduction gasifying pipelines, the temperature of the furnace end can be reduced, so that the gasifying speed of alcohol-based fuel is reduced, the speed in spraying gas out of the nozzle is reduced, and the situation that thermal power is reduced due to too fast dissipation of the gas is avoided.

Owner:魏伟

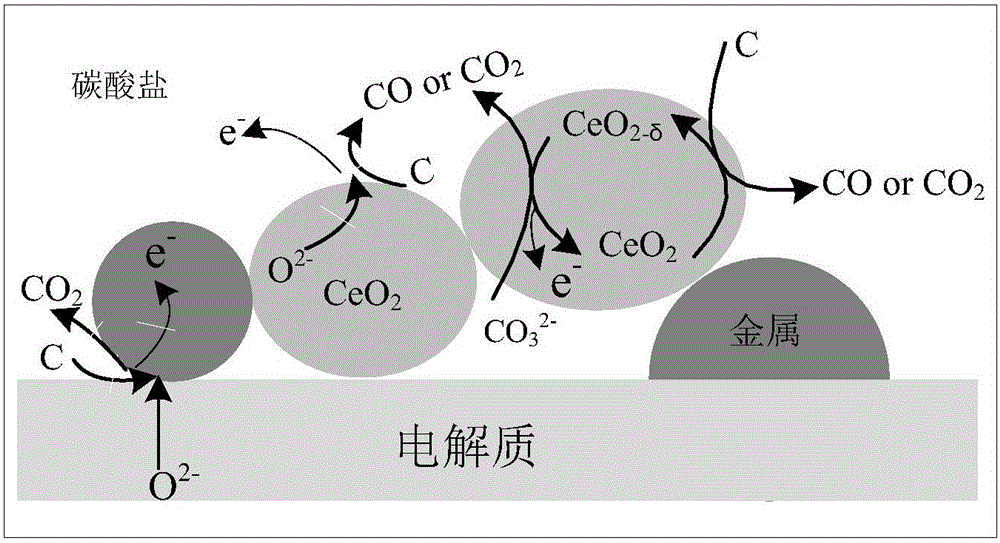

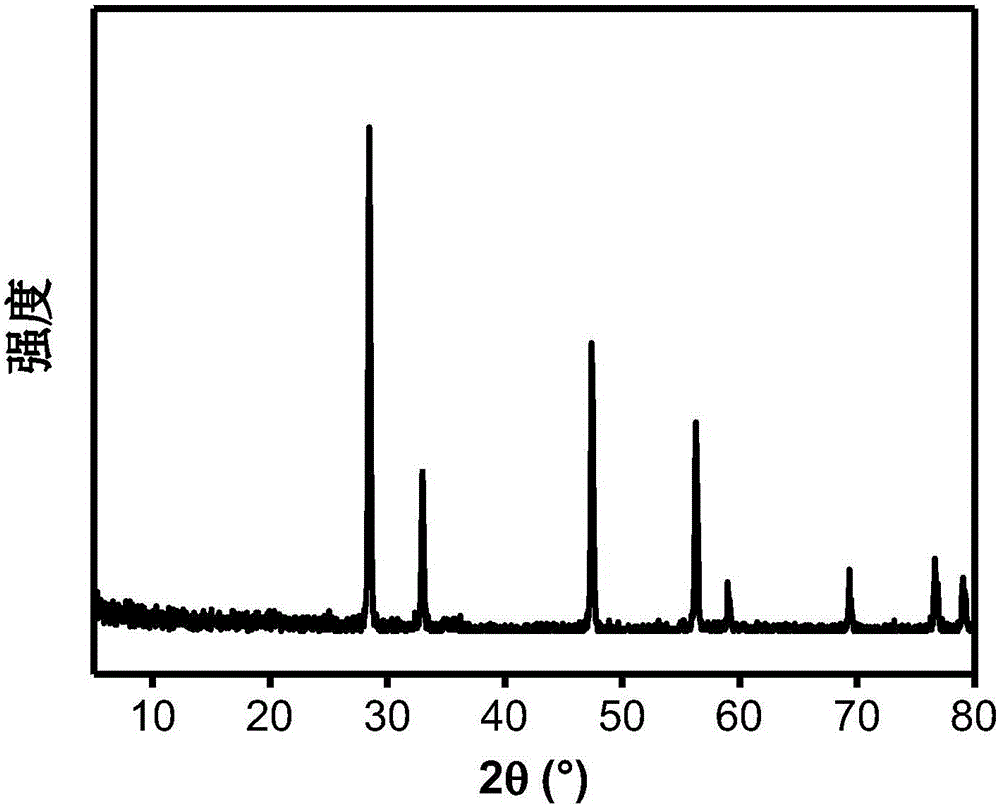

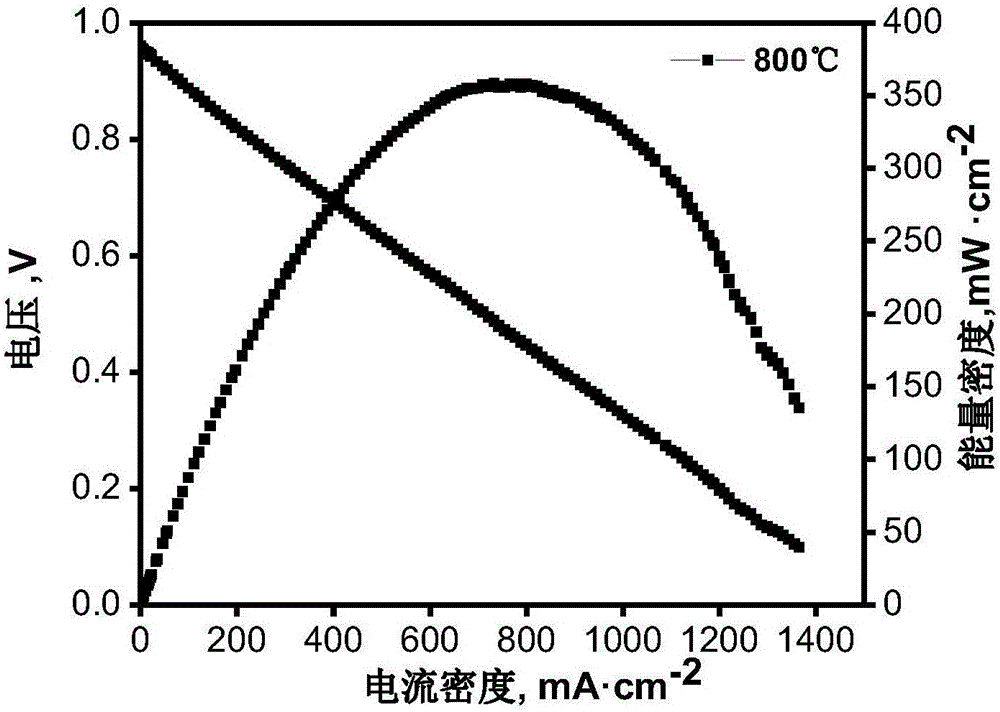

Direct carbon fuel cell anode with dual electric catalytic functions

ActiveCN105742653AImprove output performanceIncreased reactive sitesCell electrodesElectrical conductorReaction rate

The invention relates to a direct carbon fuel cell anode with dual electric catalytic functions, and belongs to the technical field of clean energy. The anode material is prepared by compounding nanoparticle as a conductive phase on the inner and outer parts of transition element-codoped CeO2 as a catalytic active phase of the anode and a porous framework. The prepared anode material has dual electrocatalysis effects on carbon fuel, can be used as an excellent ion conductor, transfers O<2-> generated by a cathode to the electrode surface and increases the electrode reaction active sites; the anode material can be applied to electrochemical oxidation of an intermediate catalytic carbon; and the power output of the cell is improved. The anode material disclosed by the invention is assembled into a direct carbon fuel cell for power generation, so that the three-phase interface length is prolonged; the fuel gasification reaction rate is improved; corrosion of molten carbonate to an electrolyte is avoided; and the lifetime of the cell is prolonged.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

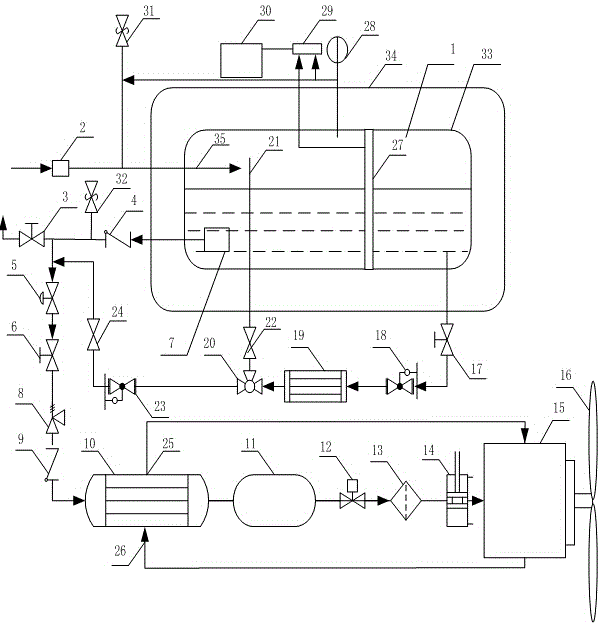

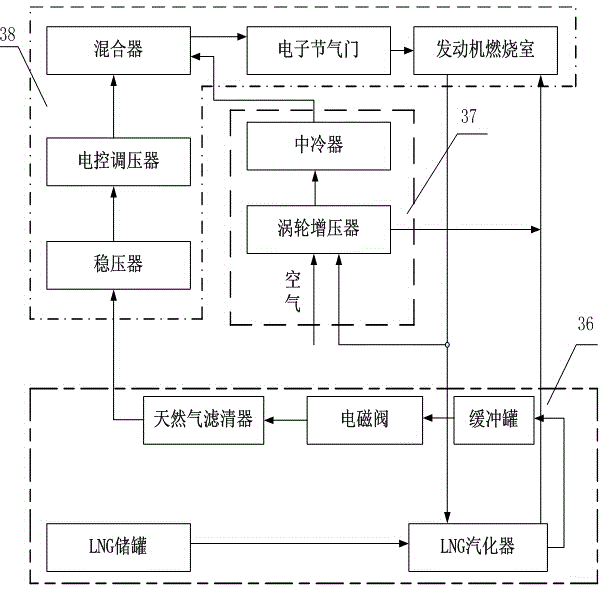

Universal aircraft power system with liquefied natural gas (LNG) as fuel and fuel supply method of universal aircraft power system

InactiveCN105179933AGuaranteed pressureImprove performanceContainer filling methodsPressure vesselsFuel gasificationVaporization

The invention provides a universal aircraft power system with liquefied natural gas (LNG) as fuel and a fuel supply method of the universal aircraft power system. The universal aircraft power system with the LNG as fuel and the fuel supply method of the universal aircraft power system can save energy and are efficient, reasonable in design and easy to achieved, the vaporization of the LNG is guaranteed, and meanwhile the effective utilization of LNG cold energy is achieved; meanwhile, the temperature of cooling liquid of an engine cooling system is reduced, and the performance of an engine is improved. The universal aircraft power system with the LNG as fuel comprises an LNG storage tank, an LNG storage tank self-pressurization system and a low-temperature fuel gasification and gas fuel supply system. The LNG storage tank is used for storing low-temperature LNG fuel, the LNG storage tank self-pressurization system is used for providing pressure required by the LNG transportation process, and the low-temperature fuel gasification and gas fuel supply system is used for converting the LNG output by the LNG storage tank to be in a gas state and transporting the LNG to the engine for combustion. The LNG output end of the LNG storage tank is connected with the input end of the low-temperature fuel gasification and gas fuel supply system. The LNG storage tank is provided with the LNG storage tank self-pressurization system.

Owner:SHENYANG AEROSPACE UNIVERSITY

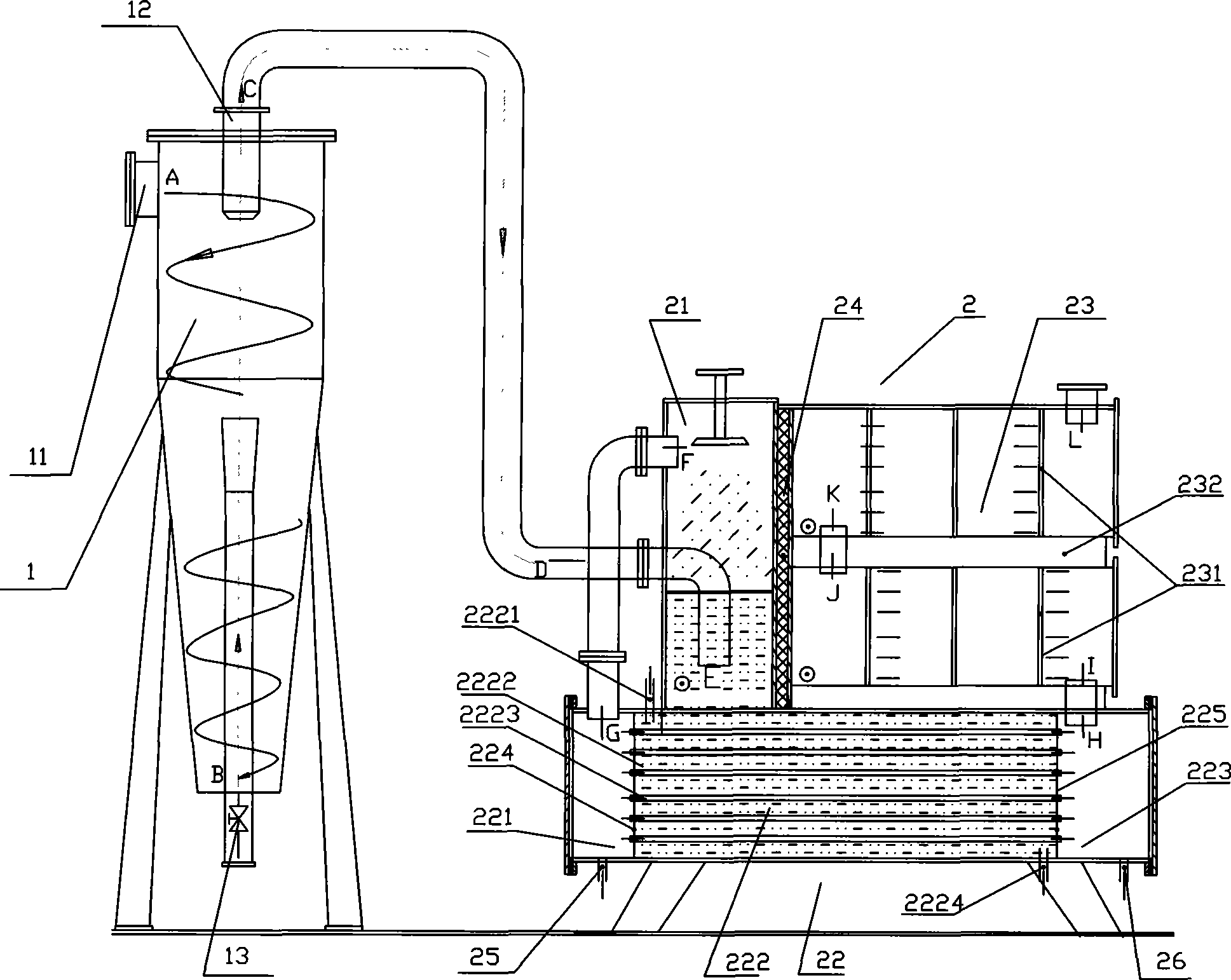

Biomass gas purification equipment and process

InactiveCN101440311ASimple structureDesign scienceGas purification by liquid washingWater bathsFiltration

The invention relates to a biomass fuel gas purification apparatus and a purification process, wherein the purification apparatus comprises a composite filter and is characterized by further comprising a cyclone separator. The cyclone separator is communicated with the composite filter through a gas pipeline; the cyclone separator and the bottom of the composite filter are provided with a sewage outfall respectively; and the composite filter has an integral composite structure comprising a water bath spray thrower, a heat exchanger and a dry-type filter. The biomass fuel gas purification apparatus integrates gas purification and filtration, has the advantages of more reasonable and more compact structure, small occupied area for the apparatus, simple process, scientific design, energy conservation and emission reduction, and in particular achieves fuel gasification and canalization for rural biomass waste materials as soon as possible so that the rural civilians can use clean and convenient fuel gas as urban poeple.

Owner:张建超 +1

Down-draft biomass fuel gasification furnace

InactiveCN102268298BSignificant temperature differenceComplete restorationCombustible gas productionThermodynamicsCombustor

The invention discloses a down-draft biomass fuel gasification furnace which belongs to the technical field of stoves. The down-draft biomass fuel gasification furnace comprises a gasification furnace body which is provided with a hearth and a fire grate at the bottom of the hearth, wherein a gas outlet cavity is formed between the inner wall of the gasification furnace body and the outer wall ofthe hearth; the hearth is provided with a drying region, a cracking region, an oxidation region and a reducing region from top to bottom; a gas outlet pipe, a gas guide mechanism and a carbon monoxide gas filtering mechanism which is used for filtering carbon monoxide gas and guiding the carbon monoxide gas to a combustor for combustion are arranged; one end of the gas outlet pipe is connected with the gasification furnace body and is communicated with the gas outlet cavity, and the other end of the gas outlet pipe is connected with the gas guide mechanism; and the gas guide mechanism is connected with the carbon monoxide gas filtering mechanism through a pipeline. The gasification furnace has the characteristic that: the internal diameter of the hearth is reduced to be less than the internal diameters of both the cracking region and the reducing region on the part corresponding to the oxidation region. The gasification furnace has the advantages of contributing to fully reducing the carbon dioxide gas into carbon monoxide gas, improving the purity of the carbon monoxide gas and preventing the hidden trouble of explosion of the gasification furnace body in case of backfire.

Owner:常熟市多能铆焊厂

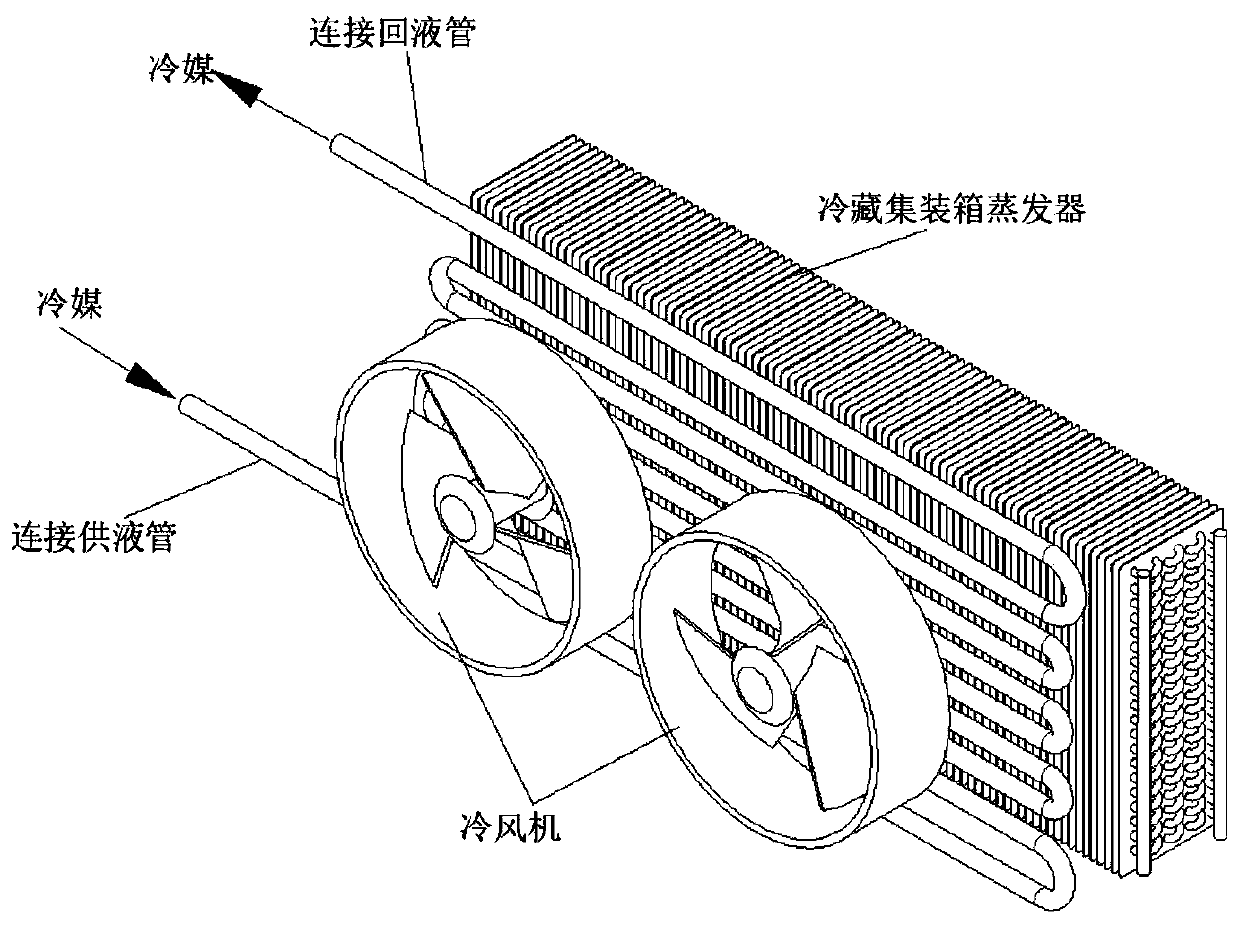

System and method for utilizing ship LNG cold energy by refrigerated container

PendingCN110901870ASave electricitySolve overloadPropulsion based emission reductionAuxillariesGlycol synthesisFuel supply

The invention discloses a system and method for utilizing ship LNG cold energy by a refrigerated container. The system mainly comprises a refrigerated container cold energy utilization system, a supply pipeline system and an LNG fuel supply system. When a ship sails on the sea, LNG fuel is consumed; a 50% ethylene glycol solution is used as a refrigerant to exchange heat with LNG fuel; a refrigerant for obtaining cold energy enters the refrigerated container heat exchanger through the liquid supply pipe, the quick coupling and the electromagnetic valve in sequence to release cold energy for refrigeration, therefore, the cold energy of the ship LNG fuel is used for refrigerating the refrigerated container; the consumption of a heat source in the LNG fuel gasification process can be reduced;the ship power grid load is reduced; the problem that the ship power grid load of a large LNG power container ship is huge due to refrigeration of a refrigerated container is solved; reasonable utilization of energy is achieved, the supply pipeline system and the refrigerated container utilization system are connected through a hose, a quick connector and the like, the problem that a movable refrigerating device cannot utilize LNG cold energy is solved, and the economical efficiency of a ship is greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

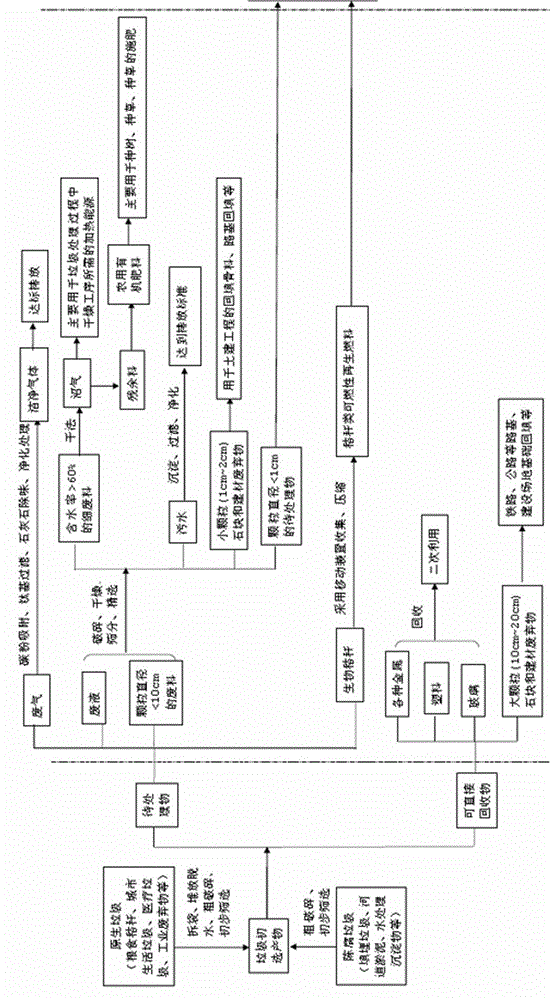

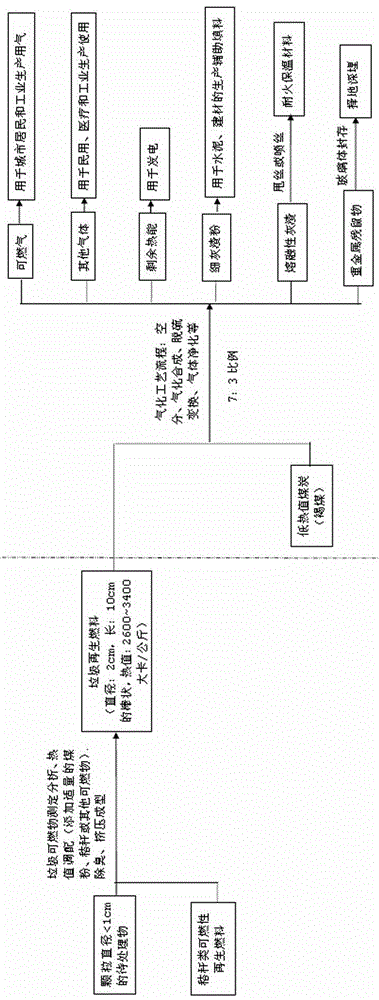

Comprehensive garbage treatment method

ActiveCN104907321AIncrease costLow costWaste processingSolid waste disposalFuel gasificationProcess engineering

The invention provides a comprehensive garbage treatment method comprising the steps of primarily screening, separating, classifying materials to be processed, preparing renewable energy, and gasifying fuel, or the like. Without depending on the treatment manner of classified garbage collection, the provided garbage treatment method focuses on treating the decayed garbage with a massive treatment principle of 'combining a scattered manner with a centralized manner' being applied to the solid waste. The original ecological garbage and the decayed garbage are pre-processed in a small range, so as to generate a flammable renewable fuel; the flammable renewable fuel is collected in a large range, and is then gasified in a massive and centralized manner; the renewable substances and the non-renewable substances generated in the treatment are comprehensively utilized.

Owner:杨先春

Environment-friendly energy-saving efficient gasification boiler

ActiveCN106168373AReasonable designSolve the technical problems of pollutionSolid fuel combustionCombustion apparatusThermal energyMicroparticle

Provided is an environment-friendly energy-saving efficient gasification boiler. No chimney exists on small boilers or big boilers. Due to the fact that for all the boilers, the combustion method is wrong, and chimneys are designed, energy combustion is insufficient, carbonic oxide flue gas and dust microparticles pollute the atmosphere, and fuel is wasted; the boiler adopts a gasification principle, environmental protection design is achieved, no pollution exists, the manufacturing cost is low, and the operating cost is low. Coal, straw, low-grade fuel, garbage and waste combustibles serve as energy sources, and single combustion, mixed combustion and multi mixed combustion are conducted. Conventional energy is changed into efficient fuel through gasification, smoke produced in the gasification process is gas, straw gas and mixed combustible gas, secondary efficient combustion is conducted, thermal energy collection is thorough, water involved hot surface is all covered, the thermal efficiency reaches 99%, and for single use, energy conservation reaches 30% or above. The application is wide and contains livelihoods, industry, national defense and the like.

Owner:SHANG HAI WANG GAN ENVIRONMENTAL PROTECTION TECH GRP CO LTD +5

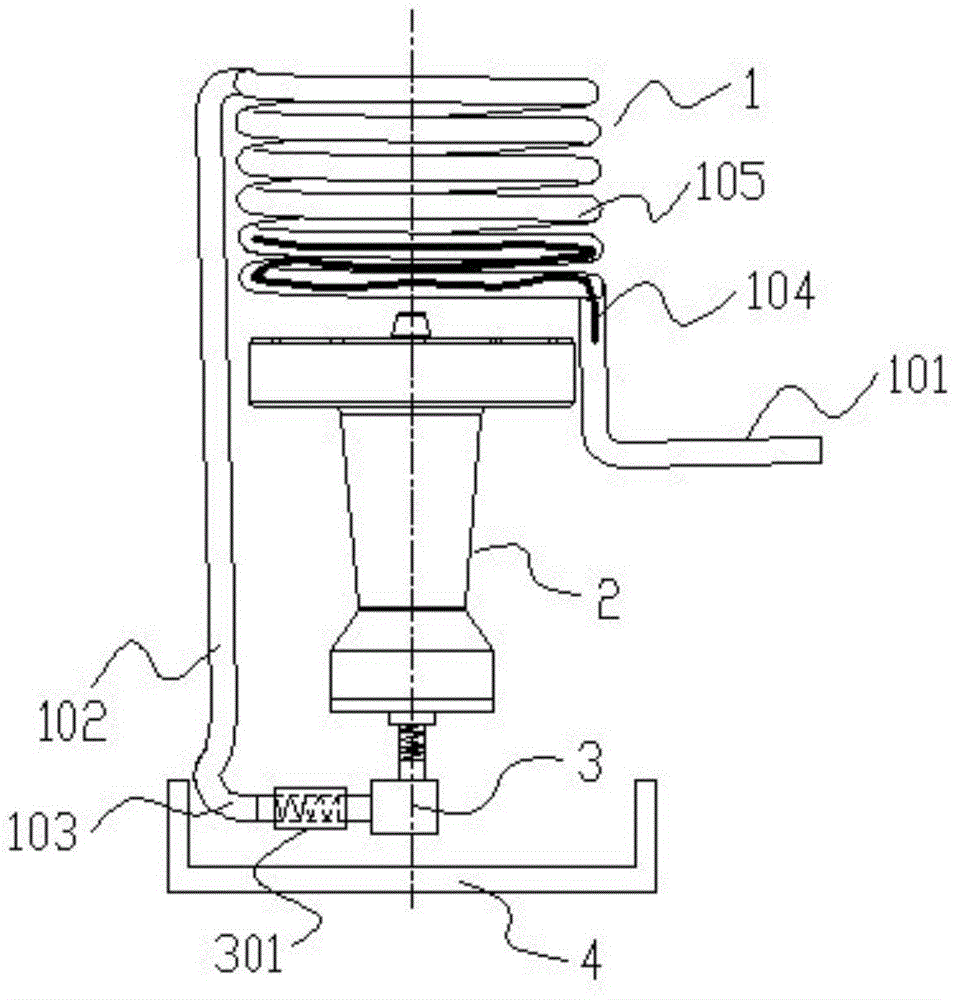

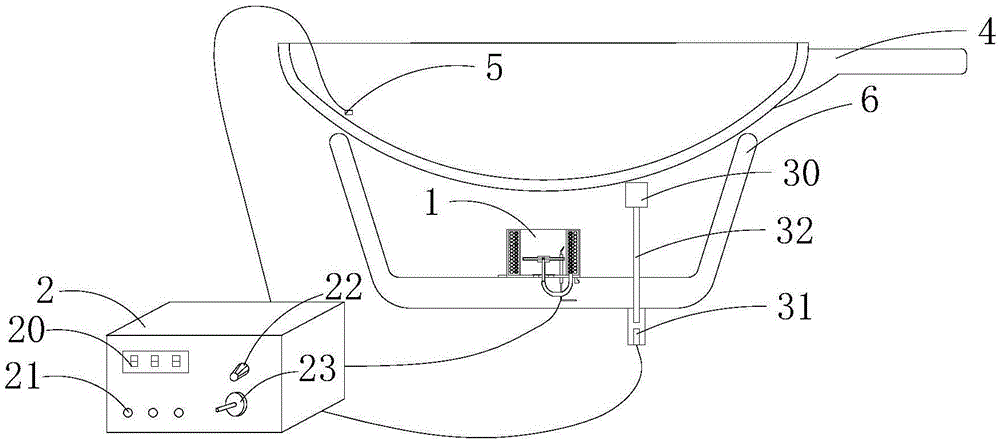

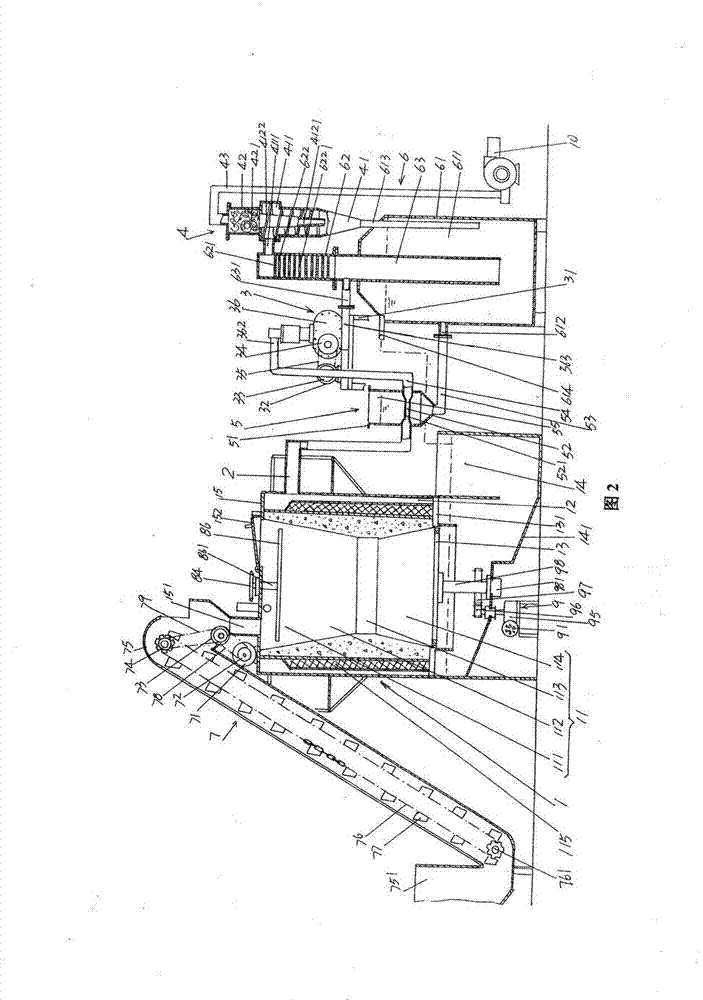

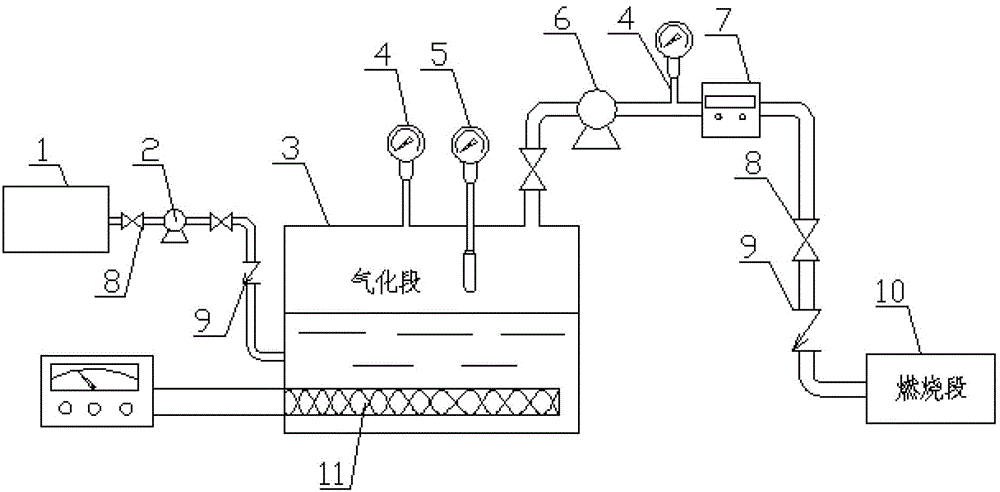

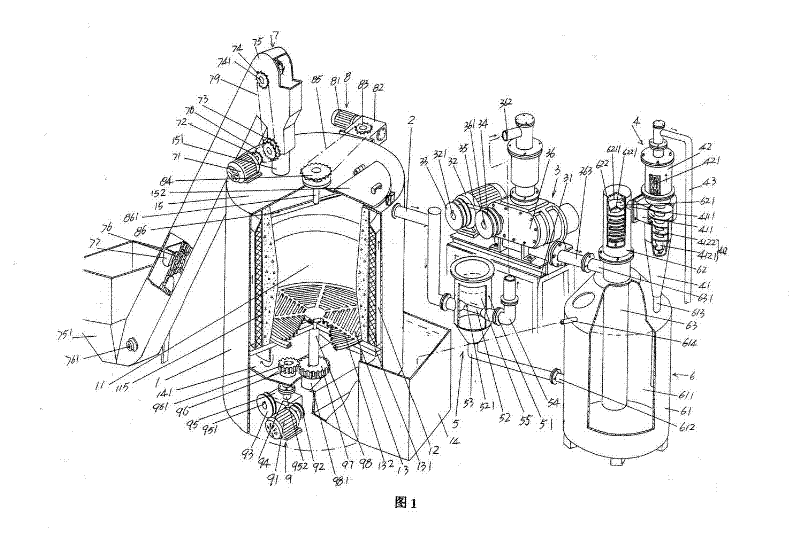

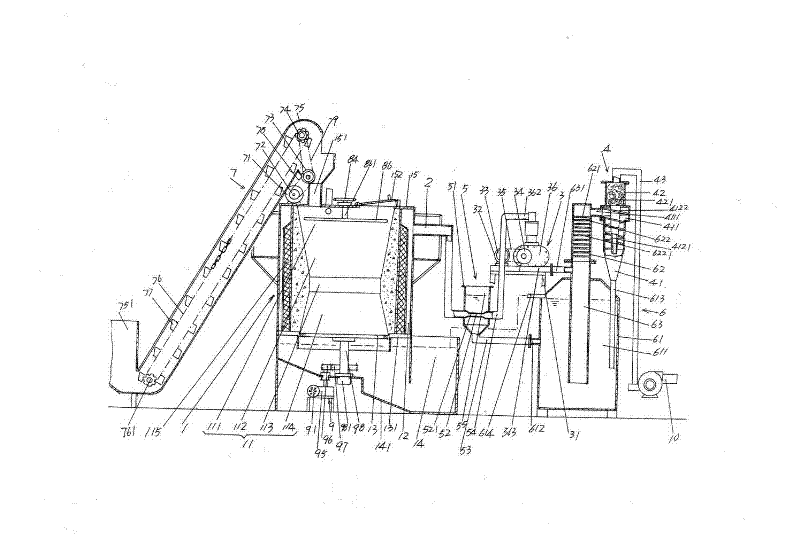

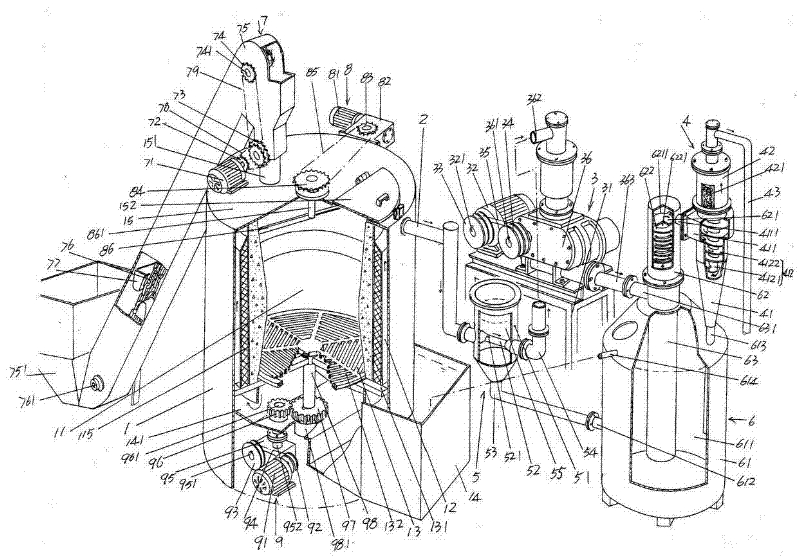

Fuel gasification combustion equipment and fuel gasification combustion method

The invention provides fuel gasification combustion equipment and a fuel gasification combustion method. The fuel gasification combustion equipment comprises a fuel storage tank (1) used for storing a liquid fuel for gasification combustion, a gasifying device used for performing high-temperature gasification and gas-state delivery on the liquid fuel from the fuel storage tank (1), and a combustion device (10) used for combusting the gaseous fuel from the gasifying device. The fuel gasification combustion method comprises the following steps of: delivering the liquid fuel under a certain pressure to the gasifying device, performing high-temperature gasification on the liquid fuel in the gasifying device, and outputting the gaseous fuel resulting from high-temperature gasification under an increased pressure for combustion under a constant pressure or continuously-variable pressure.

Owner:CHANGZHENG ENG

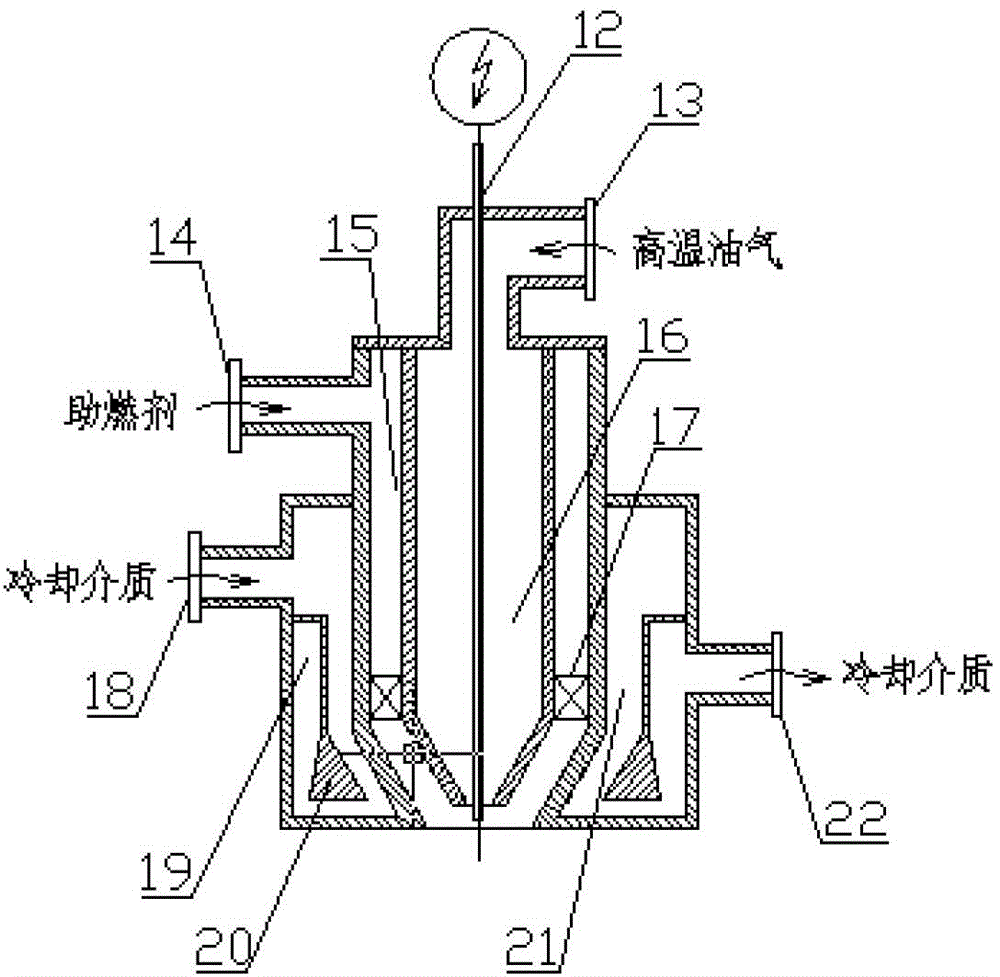

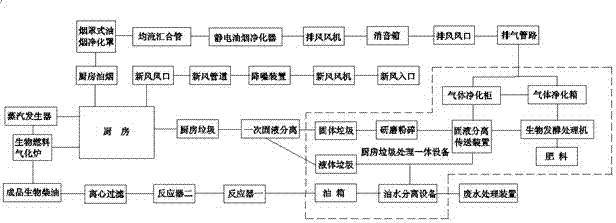

Harmless recycling utilization system for kitchen oil fume and garbage

InactiveCN107345675ASmall footprintImprove recycling ratesBio-organic fraction processingDomestic stoves or rangesOil and greaseBiodiesel

The invention discloses a harmless recycling utilization system for kitchen oil fume and garbage. The harmless recycling utilization system comprises the following steps that (1) the kitchen oil fume is fed into an electrostatic oil fume purifier through a fume cover type fume suction purification cover and a flow equalizing convergence pipe, and then is fed into an exhaust air outlet through an exhaust fan and a silencing box; (2) solid garbage is crushed by a grinding machine, then is extruded into a solid-liquid separation conveying device and is thrown into a biochemical fermentation treatment machine to be made into primary fertilizer, and gas generated in the grinding and crushing process is fed into a gas purification cabinet communicating with an exhaust pipeline; and (3) liquid garbage is thrown into an oil-water separation device, the waste oil is directly collected into an oil tank after oil-water separation, biological diesel oil subjected to the methanol esterification treatment is combusted by a bio-fuel gasification furnace, a boiler is heated through a steam generator, and wastewater is uniformly fed into a wastewater treatment device for treatment. The harmless recycling utilization system is small in occupied area, high in recycling utilization rate, low in operation cost, high in safety and suitable for various places such as hotels, restaurants and mess halls.

Owner:广州宝世洁环保工程技术有限公司 +1

Downdraft Biomass Fuel Gasifier

InactiveCN102268298ASignificant temperature differenceComplete restorationCombustible gas productionThermodynamicsCombustor

The invention discloses a down-draft biomass fuel gasification furnace which belongs to the technical field of stoves. The down-draft biomass fuel gasification furnace comprises a gasification furnace body which is provided with a hearth and a fire grate at the bottom of the hearth, wherein a gas outlet cavity is formed between the inner wall of the gasification furnace body and the outer wall ofthe hearth; the hearth is provided with a drying region, a cracking region, an oxidation region and a reducing region from top to bottom; a gas outlet pipe, a gas guide mechanism and a carbon monoxide gas filtering mechanism which is used for filtering carbon monoxide gas and guiding the carbon monoxide gas to a combustor for combustion are arranged; one end of the gas outlet pipe is connected with the gasification furnace body and is communicated with the gas outlet cavity, and the other end of the gas outlet pipe is connected with the gas guide mechanism; and the gas guide mechanism is connected with the carbon monoxide gas filtering mechanism through a pipeline. The gasification furnace has the characteristic that: the internal diameter of the hearth is reduced to be less than the internal diameters of both the cracking region and the reducing region on the part corresponding to the oxidation region. The gasification furnace has the advantages of contributing to fully reducing the carbon dioxide gas into carbon monoxide gas, improving the purity of the carbon monoxide gas and preventing the hidden trouble of explosion of the gasification furnace body in case of backfire.

Owner:常熟市多能铆焊厂

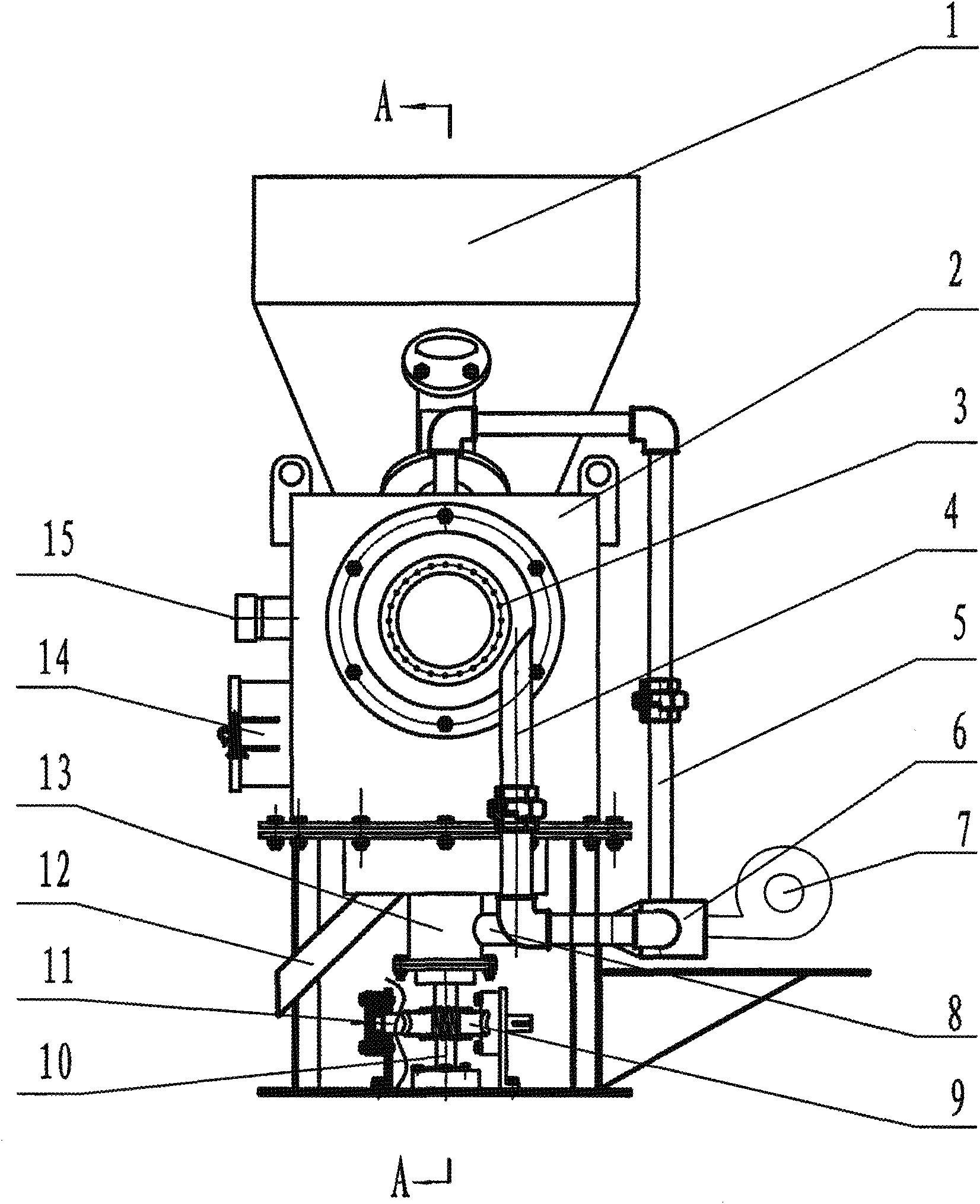

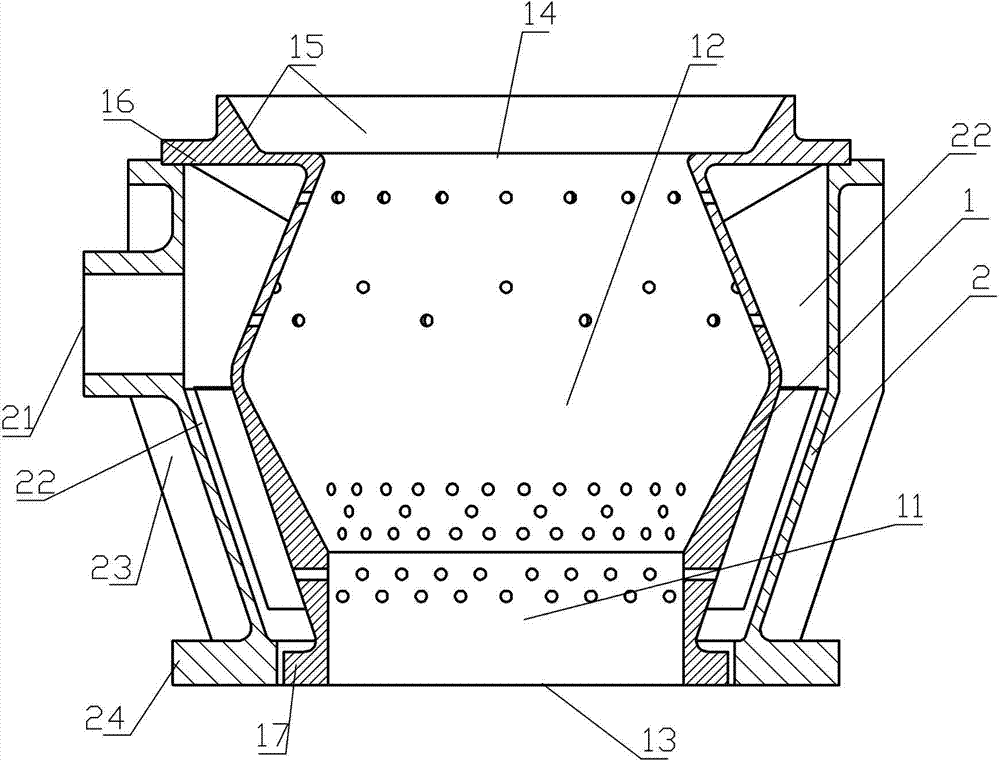

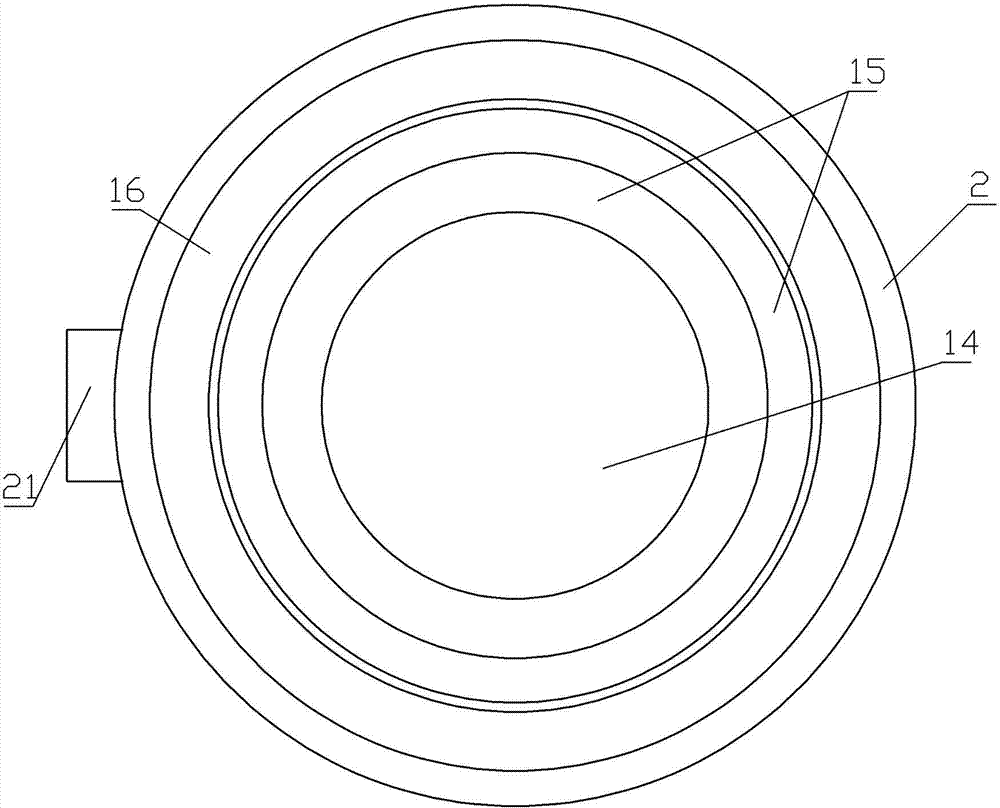

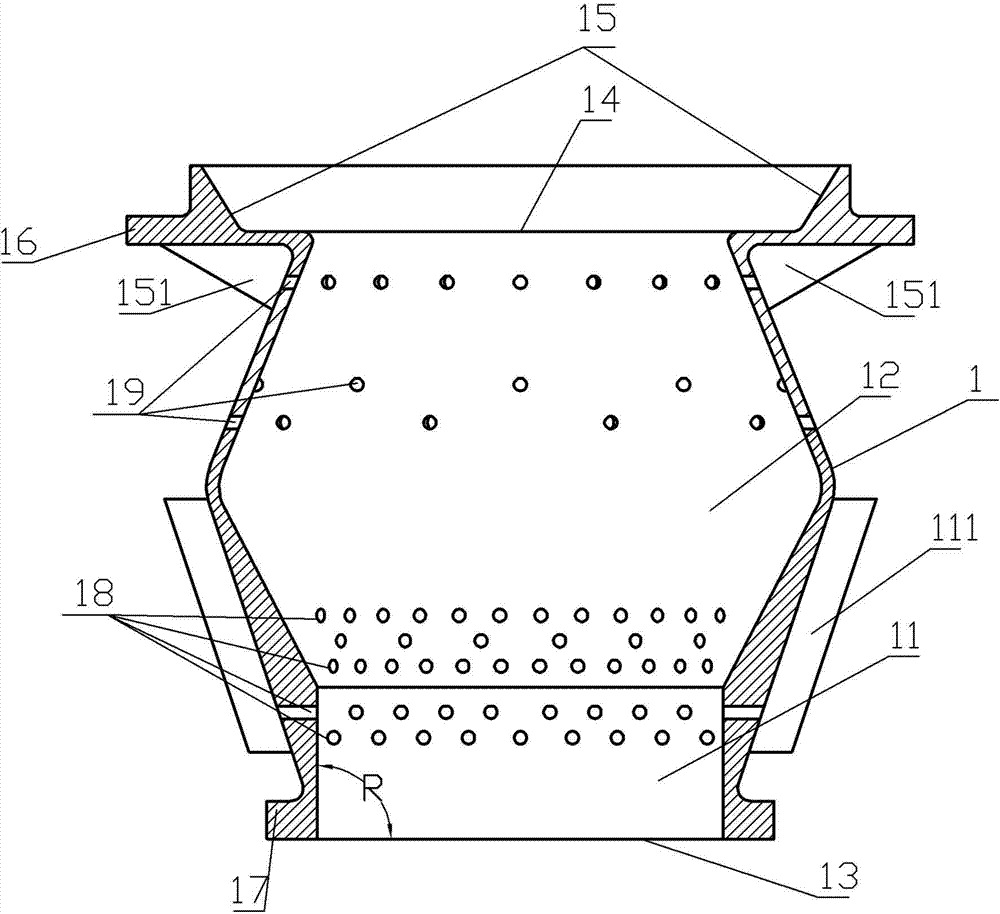

High-efficiency non-coking solid particle fuel gasification combustor

InactiveCN103900113AThere will be no cokingImprove fuel efficiencyDomestic stoves or rangesSolid fuel combustionEnvironmental resistanceCombustion chamber

The invention discloses a high-efficiency non-coking solid particle fuel gasification combustor. The high-efficiency non-coking solid particle fuel gasification combustor comprises a gasification combustion core (1) and a sleeve (2) outside the core. The gasification combustion core (1) is tubular as a whole. A through cavity in the gasification combustion core (1) is divided into a combustion gasification chamber (11) and a fuel gas combustion chamber (12), and an opening in the bottom of the gasification combustion core (1) is an ash outlet (13) and is also a fuel combustion-supporting air inlet. An opening in the upper portion of the gasification combustion core (1) is a flame outlet (14) and is also a solid particle fuel inlet. The sleeve (2) outside the core is tubular as a whole, the gasification combustion core (1) is sleeved with the sleeve (2) outside the core, and an annular interlayer cavity between the gasification combustion core (1) and the sleeve (2) outside the core is an intake air preheating balancing chamber (22). Gas holes are formed in the gasification combustion core (1). Practice repeatedly proves that the problem that because fuel and fuel ash coke and become blocky in a fuel duct, the fuel duct is blocked will not be caused, and the combustor is high in efficiency, capable of saving energy, environmentally friendly and free of smoke.

Owner:广东宏丁节能科技发展有限公司

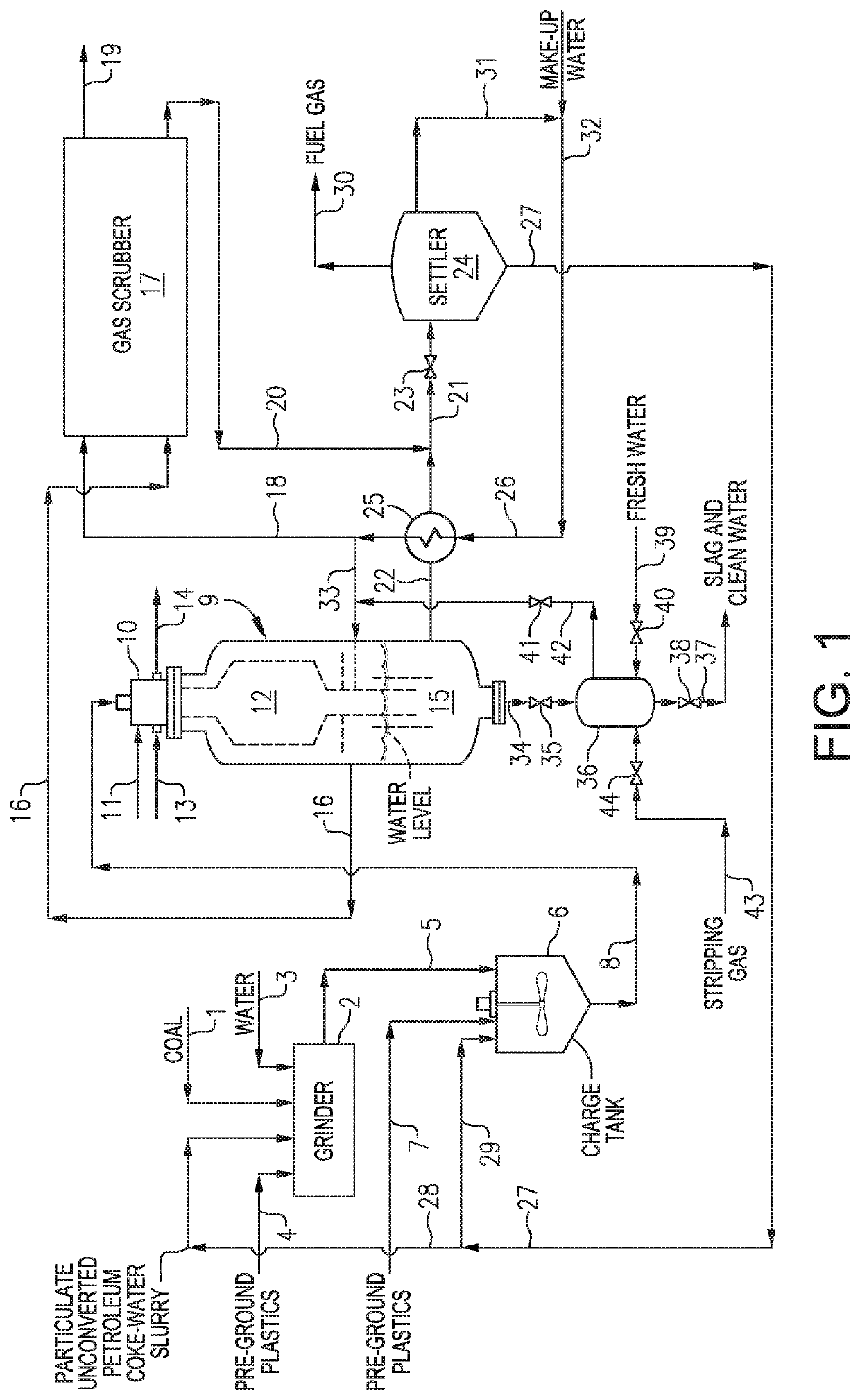

Feed location for gasification of plastics and solid fossil fuels

Pre-ground plastics of small particle size not more than 2 mm are co-fed into a solid fossil fuel fed entrained flow partial oxidation gasifier. A syngas composition can be made by charging an oxidant and a feedstock composition comprising recycle plastics and a solid fossil fuel to a gasification zone within a gasifier; gasifying the feedstock composition together with the oxidant in said gasification zone to produce said syngas composition; and discharging at least a portion of said syngas composition from said gasifier; wherein the recycled plastics are added to a feed point comprising a solid fossil fuel belt feeding a grinder after the solid fossil fuel is loaded on the belt, a solid fossil fuel belt feeding a grinder before the solid fossil fuel is loaded onto the belt, or a solid fossil fuel slurry storage tank containing a slurry of said solid fossil fuel ground to a size as the size fed to the gasification zone.

Owner:EASTMAN CHEM CO

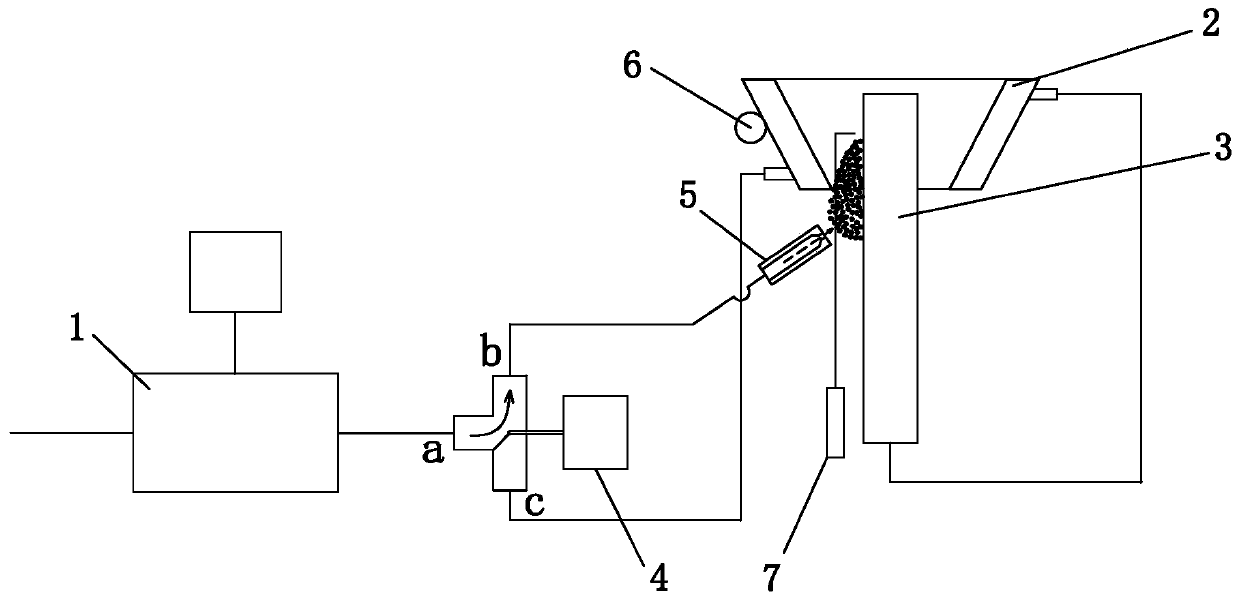

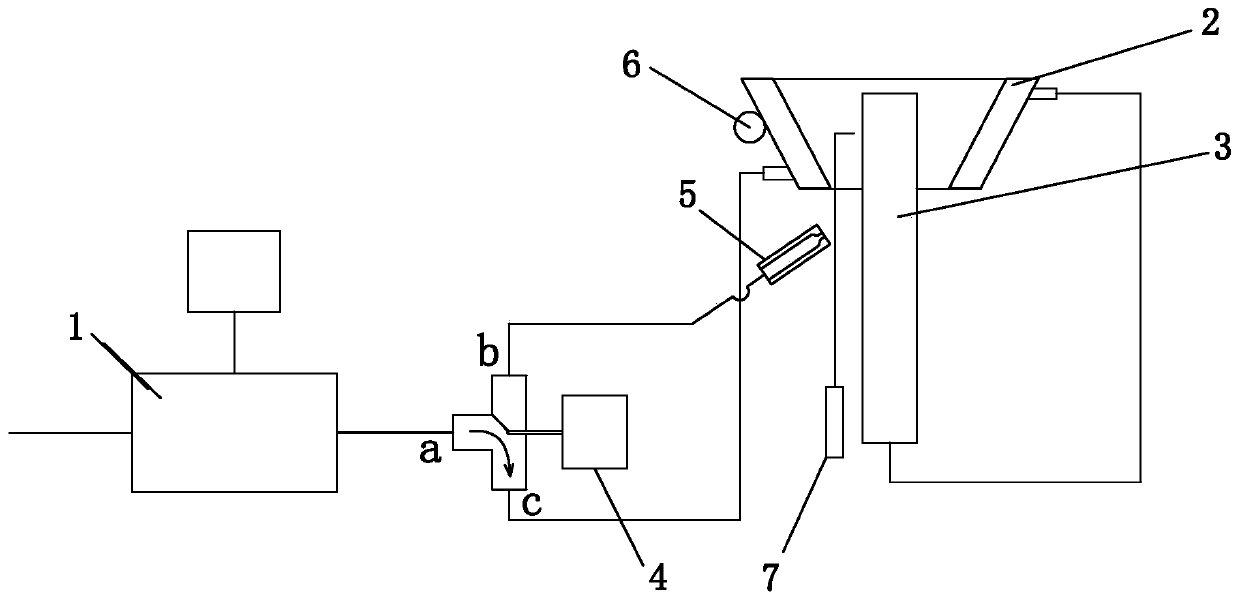

Alcohol combustion stove and cold start ignition method thereof

PendingCN110469877ALow costSimple structureDomestic stoves or rangesLiquid heating fuelFuel gasificationEngineering

The invention relates to an alcohol combustion stove. The alcohol combustion stove comprises a fuel flow adjusting device, a gasification ring and a direct injection pipe which are sequentially connected through pipelines; a three-way switching valve is arranged on the pipeline of the fuel flow adjusting device and the gasification ring, the output end of the fuel flow adjusting device is connected with the end a of the three-way switching valve through the pipeline, the end c of the three-way switching valve is connected with the input end of the gasification ring through the pipeline, the end b of the three-way switching valve is connected with a fuel atomization nozzle, and the fuel ejection direction of the fuel atomization nozzle faces the gasification ring; and a temperature detection device used for detecting the temperature of the gasification ring is arranged on the gasification ring. The alcohol combustion stove further comprises an ignition device used for igniting the fuelsprayed out through the fuel atomization nozzle. The invention further relates to a cold start ignition method of the alcohol combustion stove. The alcohol combustion stove is simple in structure, lowin manufacturing cost and good in fuel gasification effect.

Owner:GUANDDONG JIBAO ELECTRICAL APPLIANCE TECH CO LTD

Civil multi-purpose furnace capable of economizing firewood and saving coal

InactiveCN103335334AIncrease firepowerFull firepowerLighting and heating apparatusChemical industryThermal energyCombustion chamber

The invention relates to a civil multi-purpose furnace capable of economizing firewood and saving coal. A front furnace mouth is formed in the upper portion of a hearth, wherein the upper portion of the hearth extends to one side to form a gasification combustion chamber, a smoke outlet communicated with a heatable brick bed is formed in the gasification combustion chamber, an opening for cooking is formed in the upper portion of the gasification combustion chamber, a biomass fuel storage box is arranged on the front furnace mouth of the hearth, the lower end of the storage box is provided with a furnace grate which is communicated with the hearth, a clamping sleeve is arranged on the storage box, a water supplement opening and an air inlet with the adjustable size are formed in the outer layer of the clamping sleeve, and a plurality of airflow small holes which are communicated with the storage tank are formed in the inner layer of the clamping sleeve. Coal or firewood or mixture of coal and firewood can be combusted in the hearth, the storage box forms a small biomass fuel gasification device, biomass fuel is converted into flammable gas and made to enter the hearth, no black smoke is produced in the combustion process, the thermal efficiency is high, consumed fuel is greatly saved, and the requirements of a peasant household for cooking thermal energy or other life thermal energy can be met at the same time.

Owner:LIAONING HEBAIYI BIOMASS TECH DEV

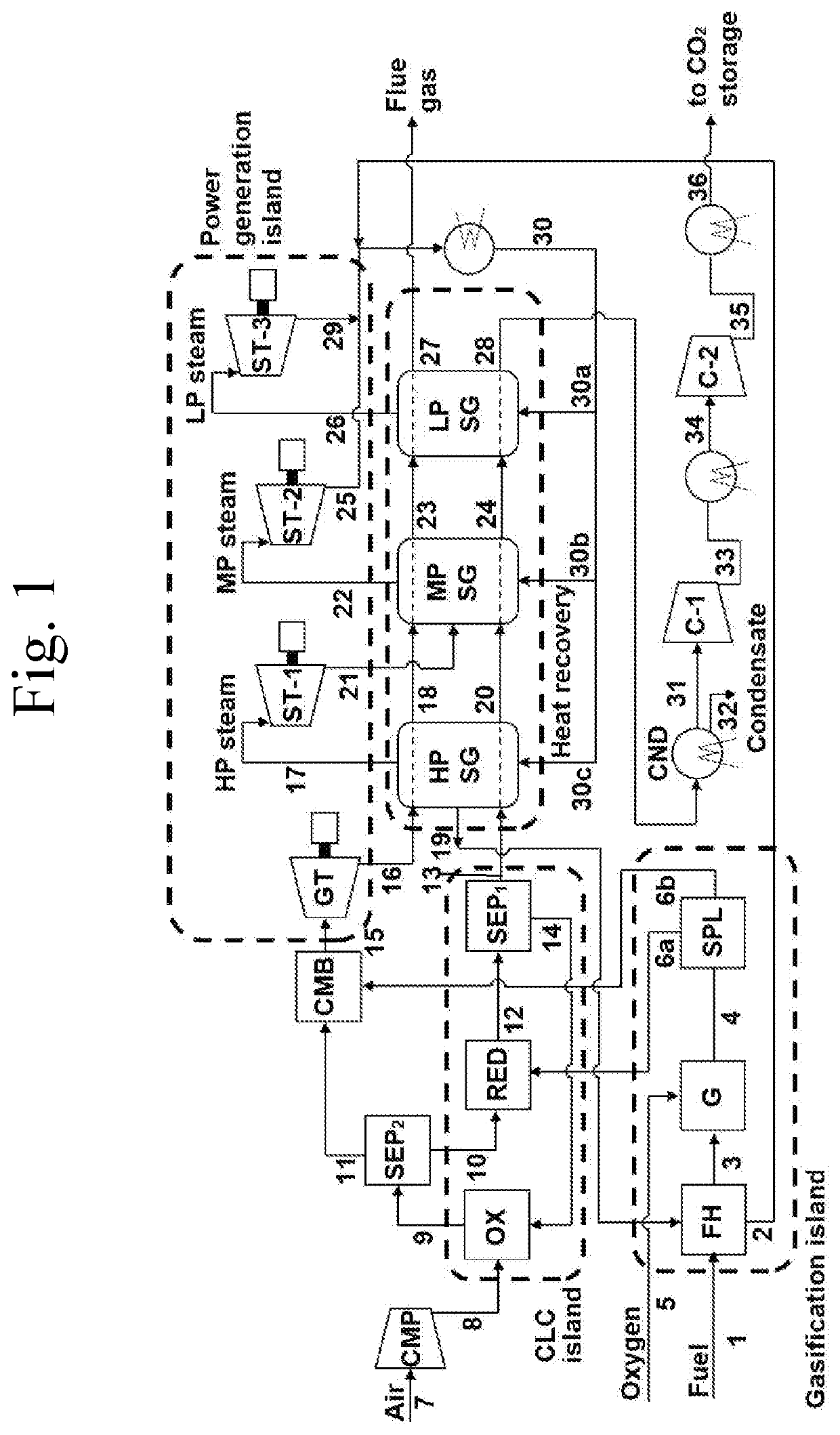

Integrated chemical looping combustion system and method for power generation and carbon dioxide capture

ActiveUS20200095898A1Increase pressureFluidized bed combustionLiquid fuel pretreatmentCombustion chamberLiquid fuel

A chemical looping combustion (CLC) based power generation, particularly using liquid fuel, ensures substantially complete fuel combustion and provides electrical efficiency without exposing metal oxide based oxygen carrier to high temperature redox process. An integrated fuel gasification (reforming)-CLC-followed by power generation model is provided involving (i) a gasification island, (ii) CLC island, (iii) heat recovery unit, and (iv) power generation system. To improve electrical efficiency, a fraction of the gasified fuel may be directly fed, or bypass the CLC, to a combustor upstream of one or more gas turbines. This splitting approach ensures higher temperature (efficiency) in the gas turbine inlet. The inert mass ratio, air flow rate to the oxidation reactor, and pressure of the system may be tailored to affect the performance of the integrated CLC system and process.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com