Interactive cyclic solid fuel gasification device with double fluidized beds and method

A technology of fluidized bed gasification and solid fuel, which is applied in the direction of granular/powder fuel gasification, etc. It can solve the problems of not being able to fully adapt to practical applications, poor response to changes in material composition and size, etc., and achieve high-efficiency utilization, Improved combustion and gasification efficiency, large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

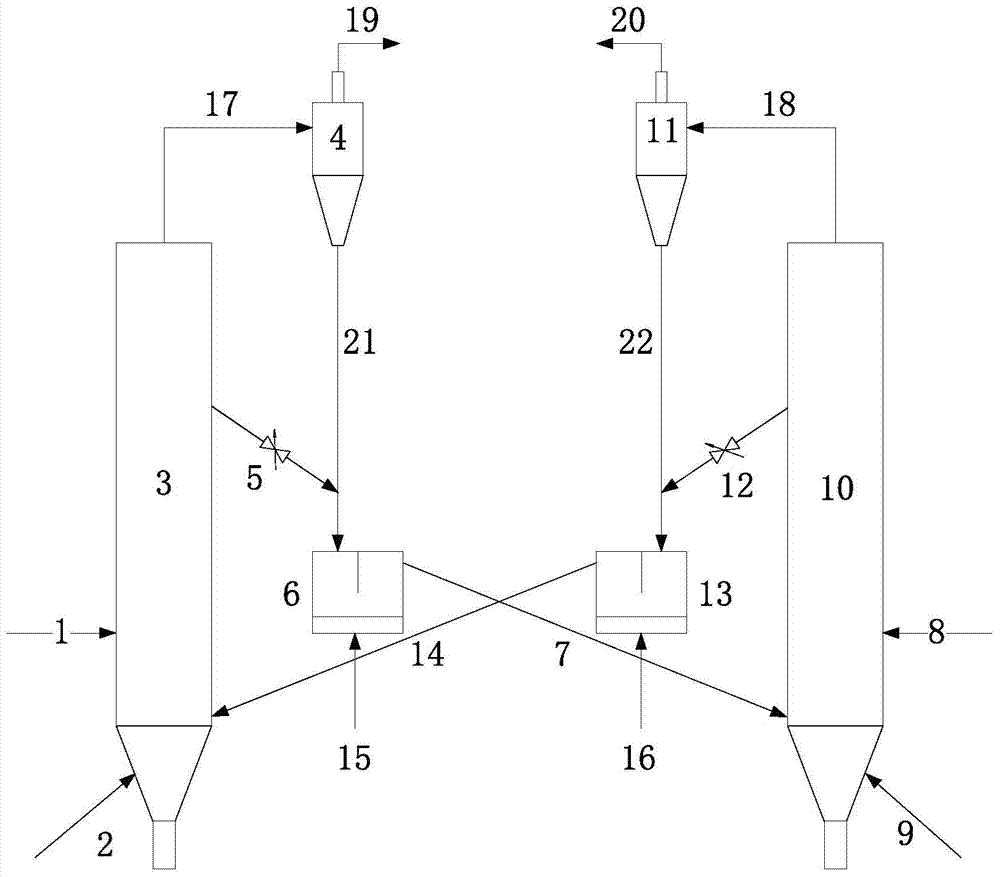

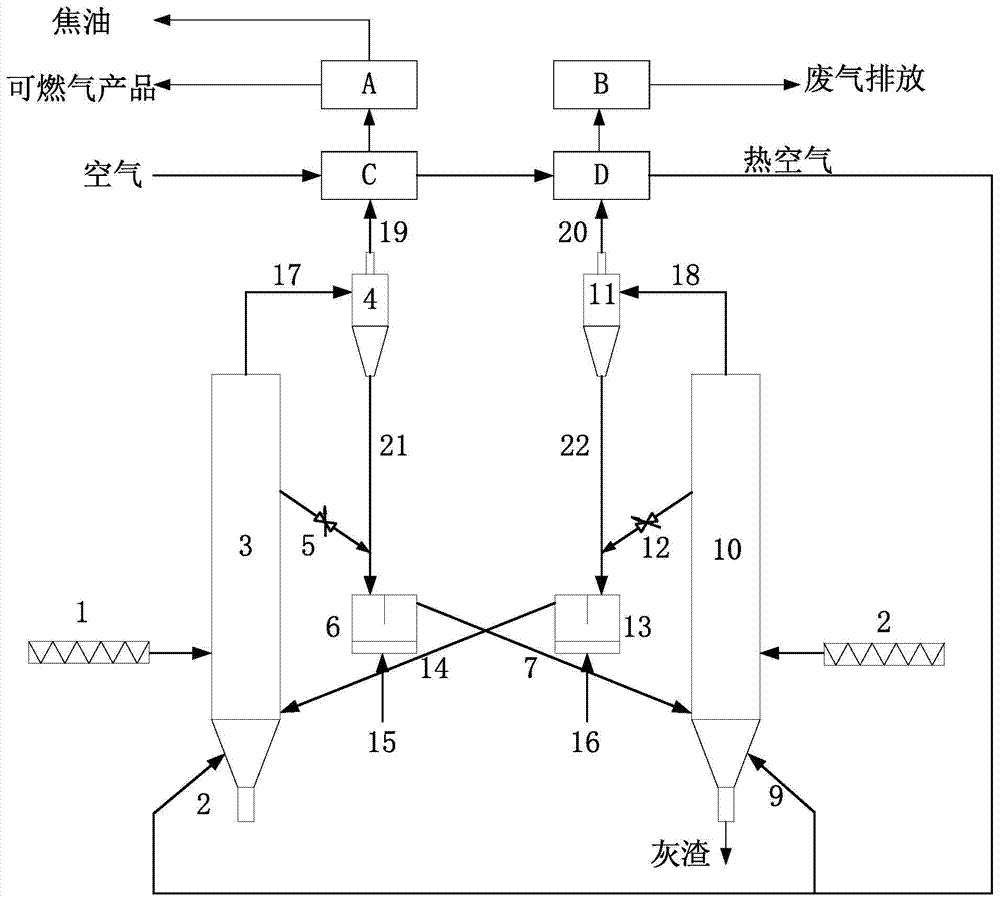

[0026] see Figure 1-2 , the alternating circulation double fluidized bed solid fuel gasification device provided by the present invention comprises a fluidized bed gasification reactor 3 and a fluidized bed combustion reactor 10; the upper outlet 17 of the fluidized bed gasification reactor and the gasification reactor The cyclone separator 4 is connected to each other, and then connected to the upper side of the gasification reactor feeder 6 through the return downcomer 21; the middle part of the fluidized bed gasification reactor is provided with an overflow inclined pipe 5 and a return downcomer 21 The gasification reactor pneumatic feeder 6 is connected with the fluidized bed combustion reactor through the combustion reactor feeding inclined pipe 7; the upper outlet 18 of the fluidized bed combustion reactor is connected with the combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com