Fuel gasification combustion equipment and fuel gasification combustion method

A technology of combustion equipment and combustion method, which is applied in the fields of fuel gasification combustion equipment and fuel gasification combustion, can solve the problem of not being able to achieve pressure-boosting and load-shifting regulation in the gasification process, affecting the benefit of the device, and long-term stable operation and high cost. problems such as financial resources and time, to achieve the effect of reducing mixing and ignition time, improving flammability rate and burnout rate, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

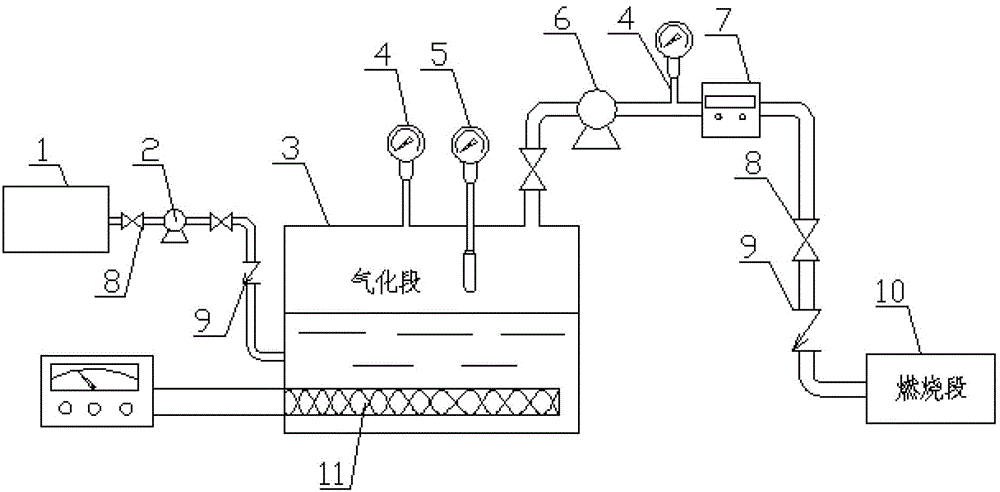

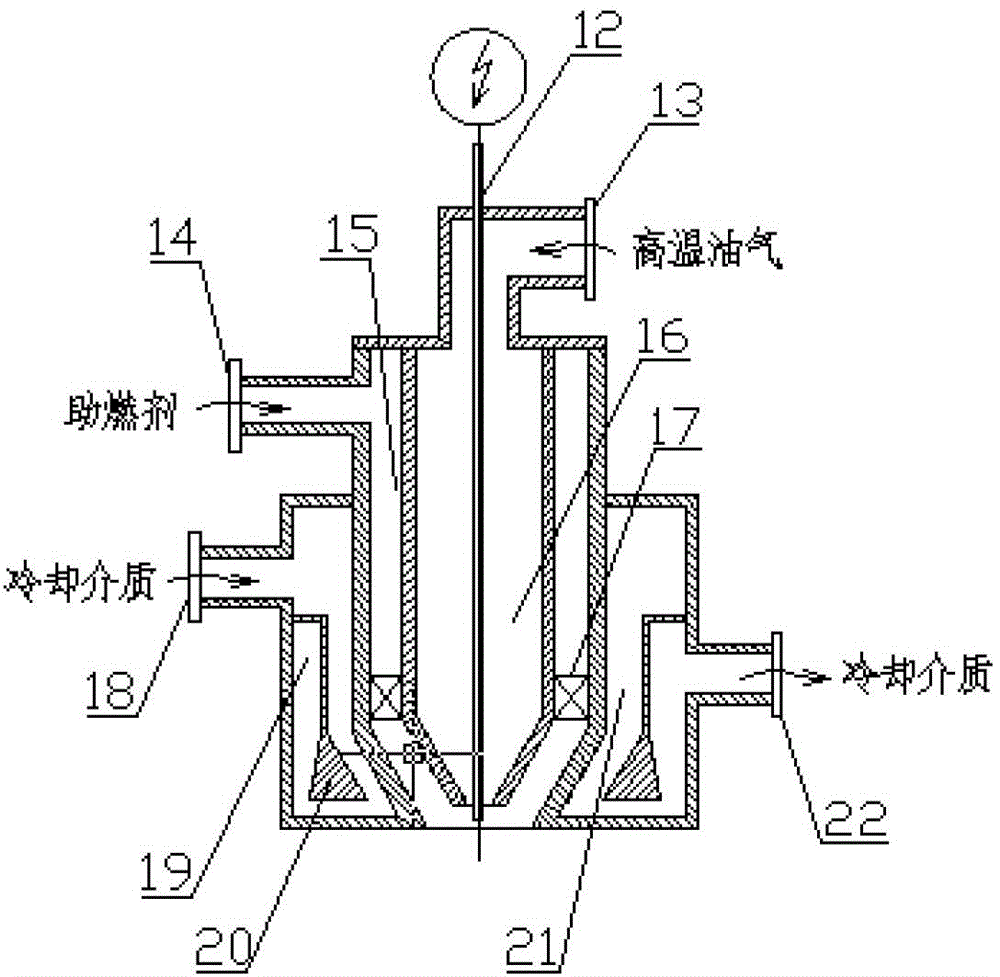

[0030] like figure 1 , figure 2 As shown, a fuel oil gasification combustion equipment and fuel gasification combustion method can realize high-efficiency combustion with back pressure in which liquid fuel gas is first gasified and then burned, and is mainly composed of two parts: a gasification section and a combustion section. The gasification section consists of three processes: liquid fuel storage, high-temperature gasification of fuel, and gaseous fuel transportation. Pressure pump 6, flow meter 7, cut-off valve 8, flame arrester 9, and electric heater 11, among which the cut-off valve 8, high-pressure oil pump 2 and flame arrester 9 are arranged at the outlet of fuel storage tank 1 to realize Timing and quantitative supply of fuel oil, while preventing downstream high-pressure oil and gas backflow; electric heater 11 is equipped with a voltage regulator and a temperature control switch, which can control the gas production range of high-temperature oil and gas by adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com