Direct carbon fuel cell anode with dual electric catalytic functions

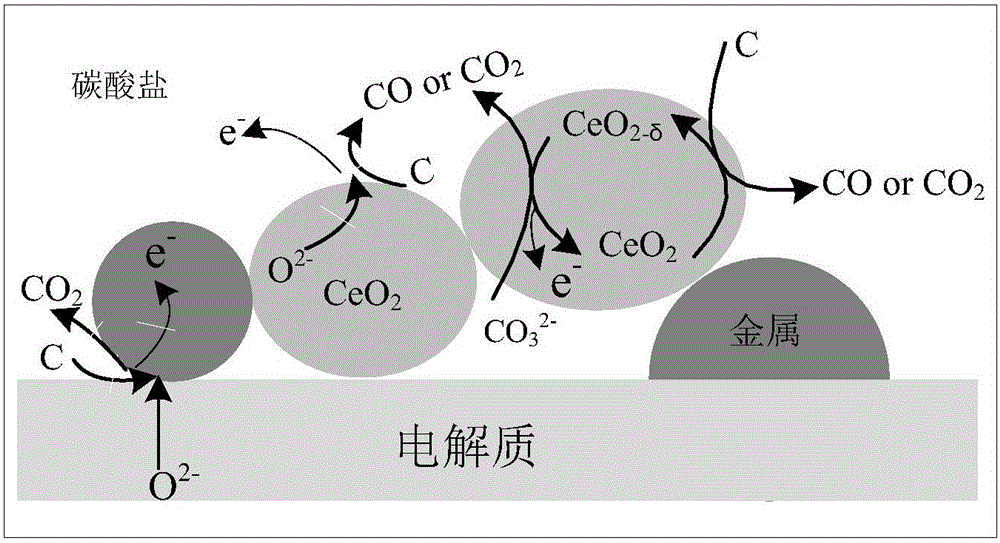

A dual electrocatalysis and fuel cell technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as corrosion of electrolytes, impact on battery performance and life, increase electrode reaction active sites, prolong battery life, and avoid corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

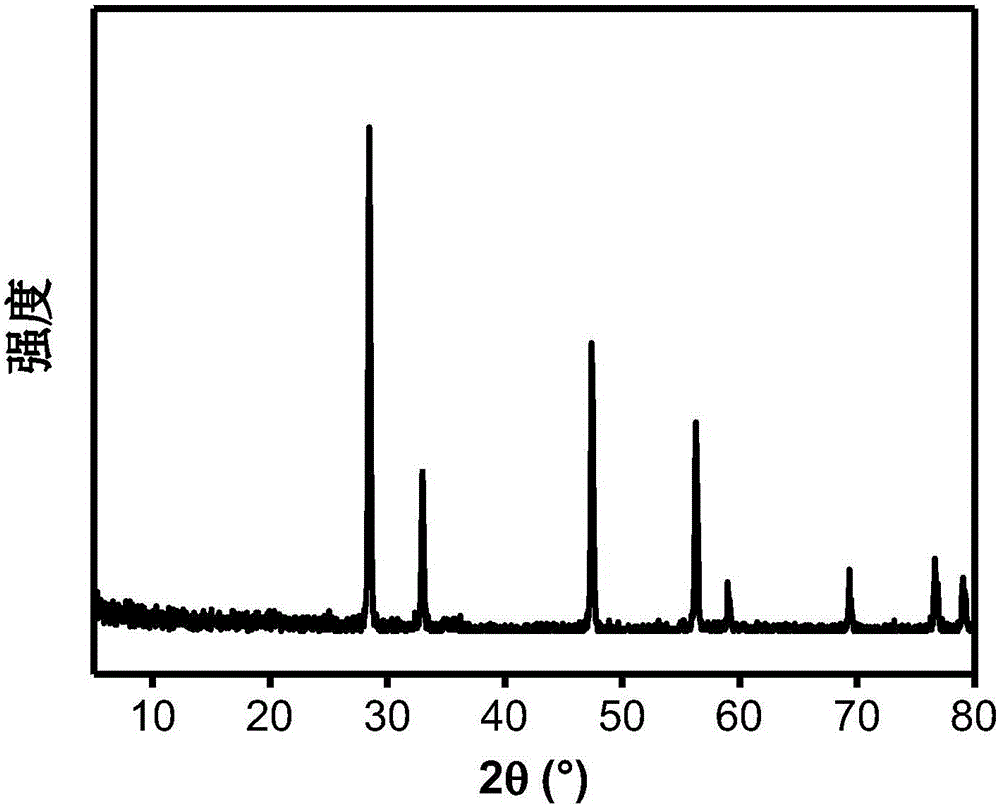

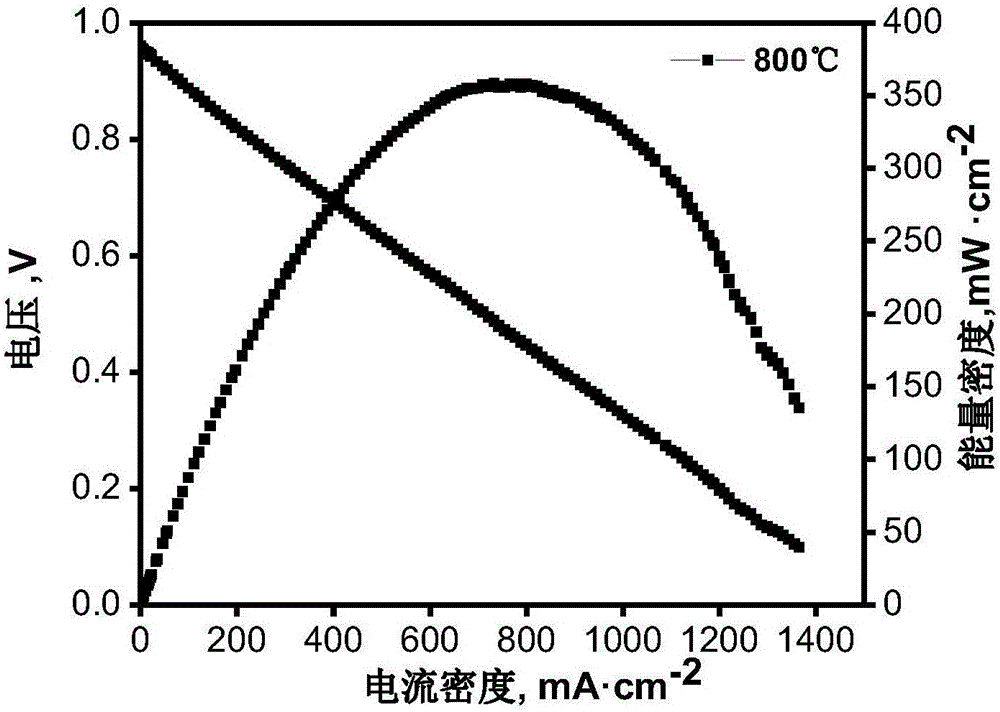

[0032] Dissolve 2.6504g of cerium nitrate, 0.7530g of manganese nitrate, and 0.404g of ferric nitrate in deionized water, then add 10g of glycine and 10g of citric acid to the solution, place in a water bath at 80°C and evaporate to dryness for 12h to a gel state, and then place Burn at 250°C to get the precursor; roast the precursor at 1000°C for 6h to get manganese and iron co-doped CeO 2 Structural skeleton Ce of composite oxide 0.6 mn 0.3 Fe 0.1 o 2 (CMF). XRD analysis shows that the prepared composite oxide completely corresponds to the standard peak of cerium oxide (such as figure 2 shown), indicating that manganese and iron were co-doped into the cerium oxide lattice. The CMF-NiO anode material with double electrocatalytic activity was prepared by mechanical mixing method with CMF and nickel oxide according to the mass fraction of 50% and 50%. The prepared composite anode material was screen-printed on the surface of the electrolyte and assembled into a SO-DCFC. ...

Embodiment 2

[0034] Dissolve 1.35g of PVP in 7.5ml of DMF solvent and stir at room temperature for 4h until completely dissolved. Then, 0.4997g of cerium nitrate and 0.1003g of samarium oxide were added to the solution, stirred for 12 hours until completely dissolved, and left to stand for 12 hours to obtain a gel. The gel was electrospun to obtain the composite fiber precursor, and the prepared precursor was calcined at 800°C for 2 hours to obtain one-dimensional SDC nanofibers. SEM image (such as Figure 4 ) analysis shows that the prepared nanofibers can still maintain their fiber morphology after calcination, and there are a large number of porous structures, which is conducive to the metal impregnation inside the skeleton. Copper nitrate was impregnated into the SDC porous framework to obtain a CuSDC anode material with dual catalytic activity. The prepared composite anode material with a mass ratio of 1:1 was screen-printed on the surface of the electrolyte, assembled into a SO-DCF...

Embodiment 3

[0036] Add 1.737g of cerium nitrate and 0.0937g of gallium oxide into deionized water, react at a high temperature of 200°C for 24h, hydrothermally synthesize the spherical structure of GDC, and obtain spherical GDC powder after roasting in an inert gas atmosphere at 600°C. The FeGDC anode material was obtained by compounding GDC powder and ferric nitrate at a mass ratio of 3:2 and calcining at 450°C. The prepared FeGDC composite anode material was screen-printed on the surface of the electrolyte, assembled into SO-DCFC, and solid carbon black was blended with lithium carbonate, potassium carbonate, and sodium carbonate at a mass ratio of 70%, 15%, 9%, and 6%. Placed in the anode cavity, with 10ml / minCO 2 It is the anode carrier gas, 50ml / min oxygen is the oxidant, and the working temperature of the battery is 900°C. When the mass fraction of Fe in the composite anode material is 40%, the maximum output power density of the battery is 234mW / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com