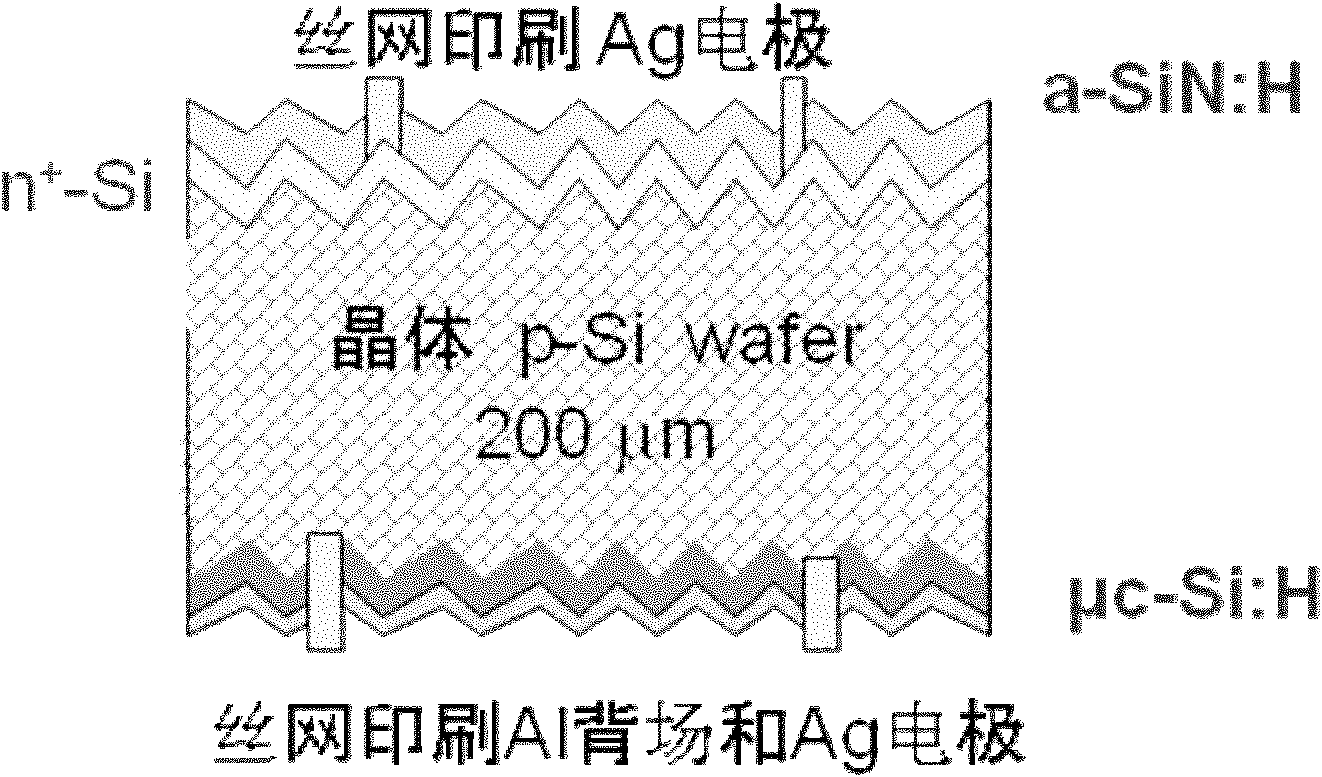

Preparation method of double-sided passivated crystalline silicon solar cell

A solar cell, double-sided passivation technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problem of unsuitable P-type silicon wafer surface passivation, etc., to improve thermal stability, output performance, and process window. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

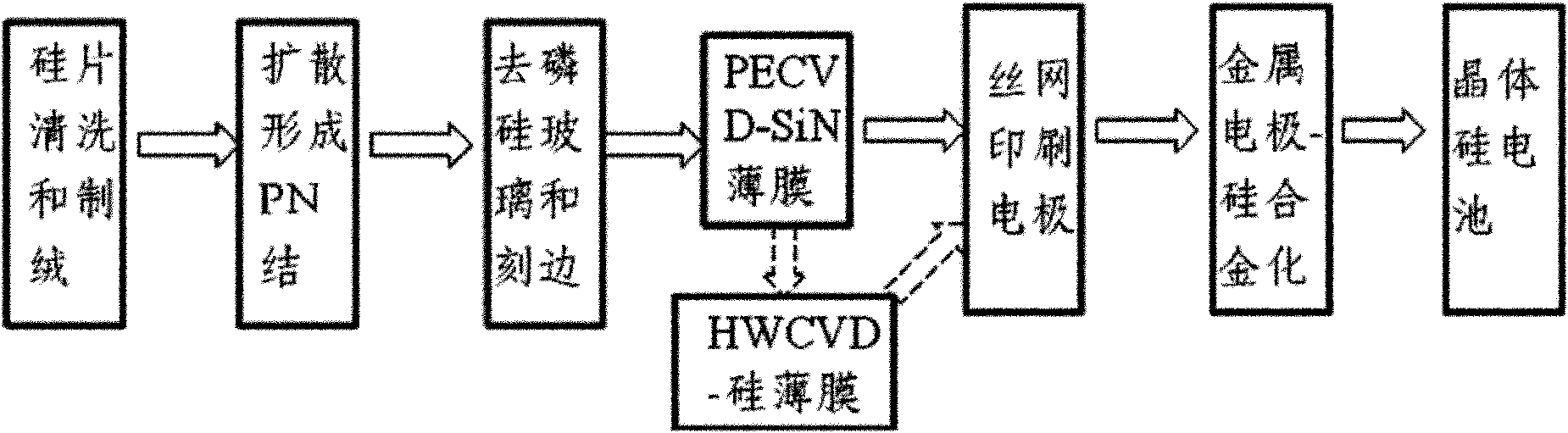

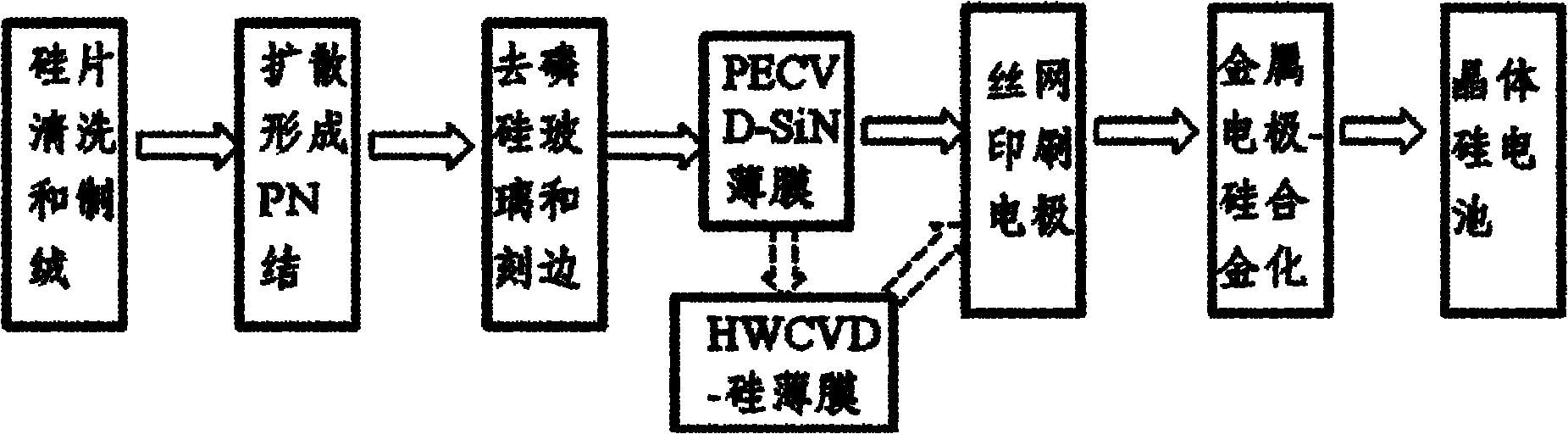

Method used

Image

Examples

Embodiment

[0032] ①The surface of P-type monocrystalline silicon wafer is pre-cleaned and surface textured by semiconductor cleaning process. The thickness of the silicon wafer used is about 200μm, and the area is 125x125mm 2 Quasi-square sheet, resistivity 1Ω·cm, use about 1-5% hydrofluoric acid to remove SiO on the surface of silicon sheet 2 layer. Next, a pyramid-shaped textured surface is prepared on the P-type single crystal silicon wafer in a mixed solution of NaOH and isopropanol (IPA) with a concentration of less than 3% at about 80°C. It was then ultrasonically cleaned with deionized water and blown dry with nitrogen.

[0033] ②Use a tubular diffusion furnace, use phosphorus oxychloride as the diffusion source, and nitrogen as the source gas to diffuse phosphorus on the p-type monocrystalline silicon wafer after texturing to form an N-type emission layer, thereby forming a PN junction, in which the emission Area square resistance 30-80Ω / □.

[0034] ③ Use HF solution with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com