Underground fuel gasification method, gasifying agent delivery pipe and underground fuel gasification system

A fuel gasification and conveying pipe technology, which is applied in coal gasification, underground mining, construction, etc., can solve the problems affecting the normal combustion and gasification of the gasifier, and the extinguishment of the gasifier, so as to protect the environment, reduce the negative impact, Avoid the effect of extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

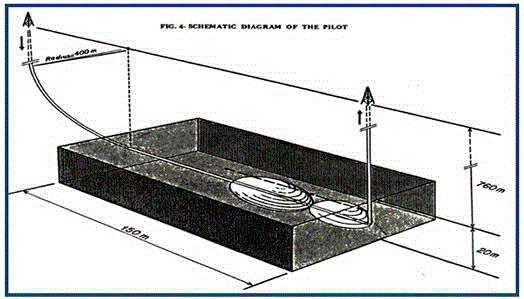

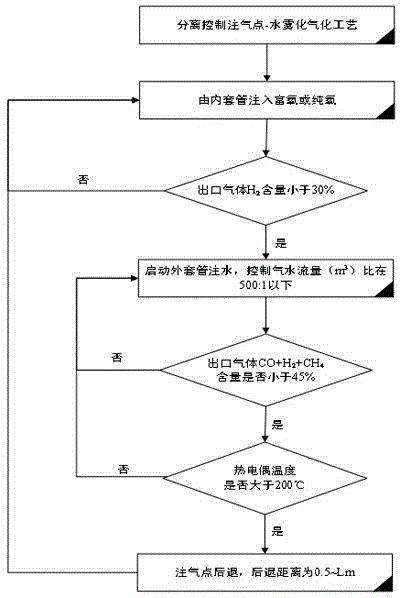

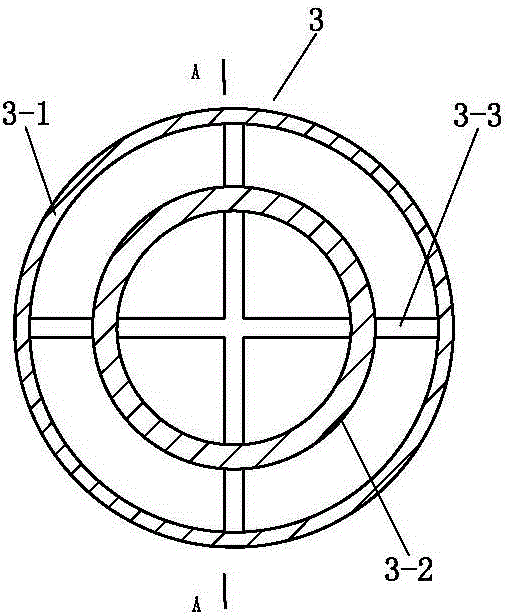

[0091] Such as Figure 8 to Figure 9 As shown, this embodiment provides an underground fuel gasification method, which continuously transports water and supporting gas to the underground fuel gasification reaction zone, and uses the pressure potential energy between the water from the ground to the underground to transport the underground fuel gas The water in the gasification reaction zone is atomized, and the water vapor generated after atomization is mixed with the combustion-supporting gas transported to the underground fuel gasification reaction zone to form a mist gasification agent. The mist gasification agent is in the underground fuel gasification reaction zone The medium and underground fuels undergo gasification reaction through combustion and heating to generate gas, and the generated gas is discharged.

[0092] As a preference, the temperature of the water is between 50°C and 100°C before being transported to the underground fuel gasification reaction zone. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com