Biomass gas purification equipment and process

A biomass gas and purification device technology, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve the problem of complex structure of gas buffer device and filter device, large installation and maintenance workload, and unsatisfactory gasification effect. and other problems, to achieve the effect of compact structure, convenient installation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

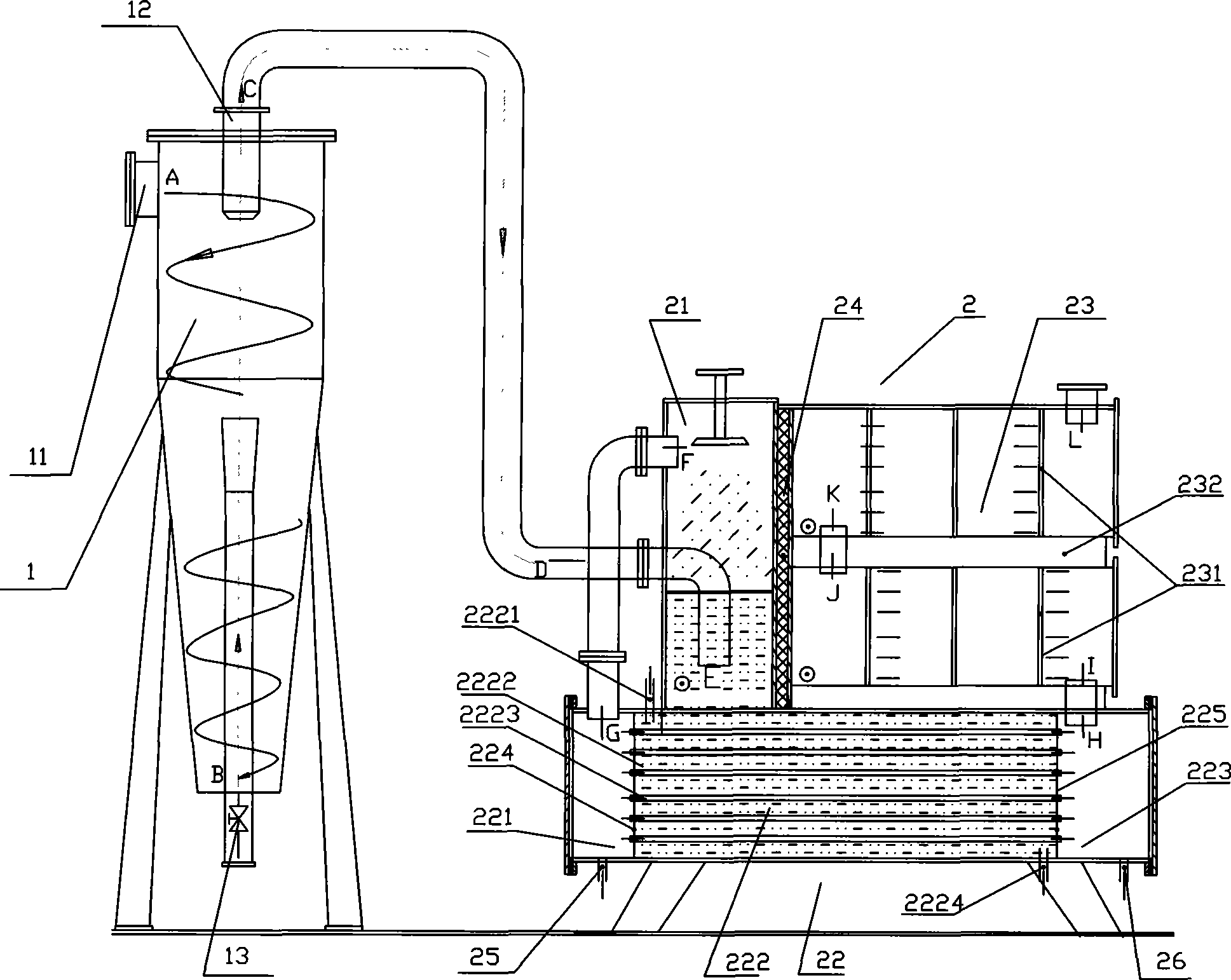

[0047] Biomass gas purification device, such as figure 1 As shown, it includes a cyclone separator 1 and a composite filter device 2, and the bottoms of the two are respectively provided with blowdown valves 13, 25, 26;

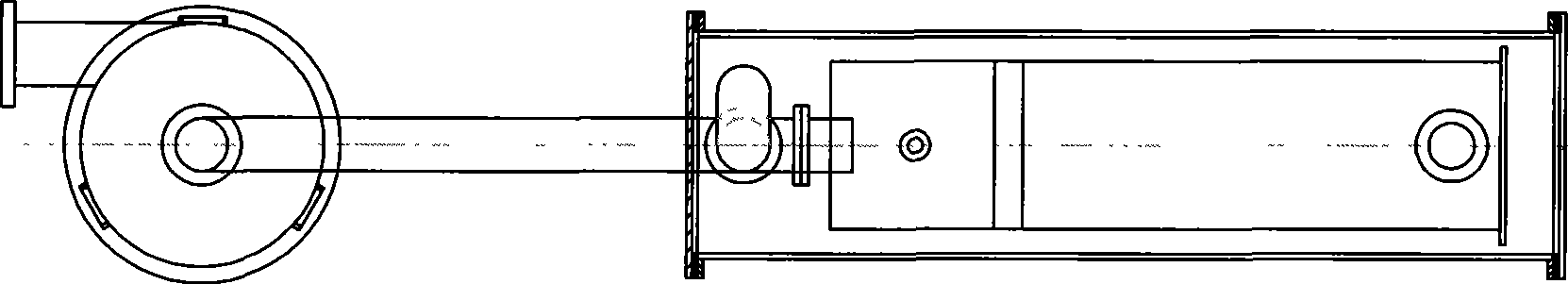

[0048] The cyclone separator 1 is a hollow rotary structure with a thick top and a thin bottom, including two parts connected up and down. The upper part is a hollow cylinder, and the lower part is a hollow rounded table body. The diameter of the top circle is equal to the diameter of the cylinder, and the upper and lower parts are welded into one.

[0049] The top of cyclone separator 1 offers air inlet 11 and air outlet 12 respectively, and described air inlet 11 offers along the tangential direction of described revolving body wall, and described air outlet is located at the center of described revolving body top, as figure 2 shown;

[0050] The composite filtering device 2 is an integrated composite structure comprising a water bath shower 21, a heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com