Fuel gasification system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

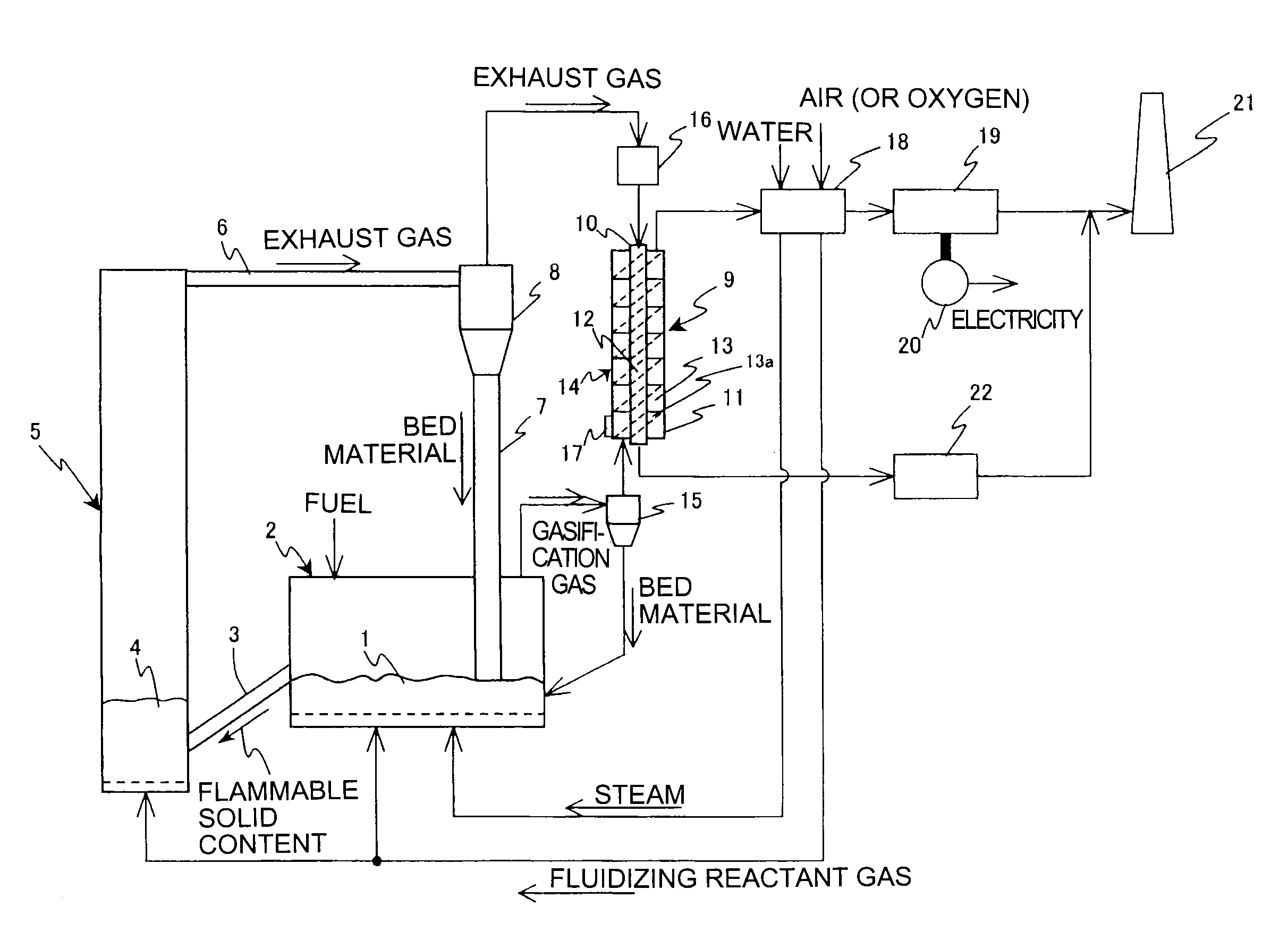

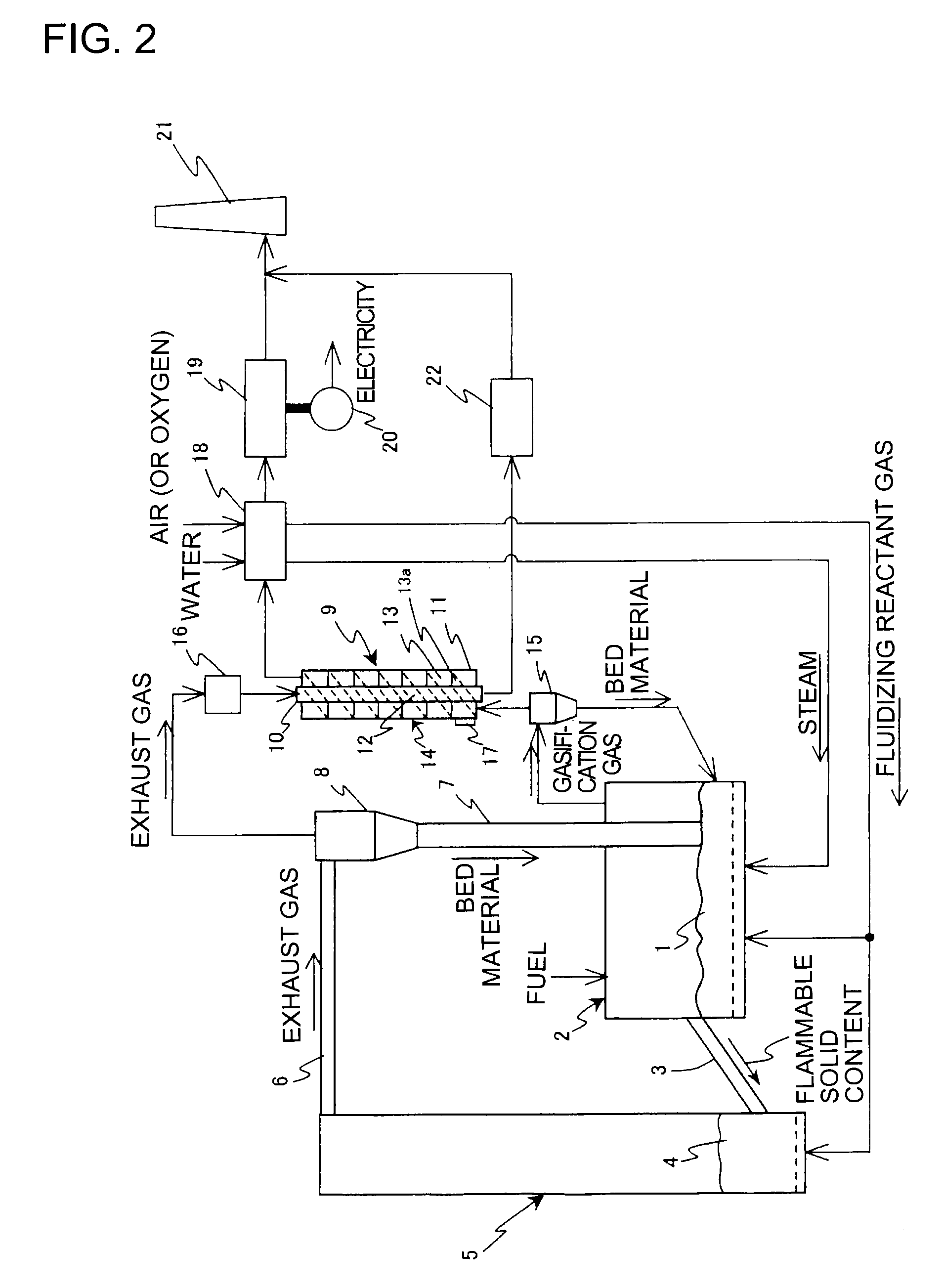

[0055]FIG. 2 shows a first embodiment a fuel gasification system according to the invention which comprises a gasification furnace 2 with a fluidized bed 1 formed therein through steam and fluidizing reactant gas such as air or oxygen so as to gasify charged fuel such as coal, biomass, waste plastic or various wet wastes into gasification gas and flammable solid content; a combustion furnace 5 into which the flammable solid content produced in the gasification furnace 2 is introduced via an introduction pipe 3 together with bed material and in which a fluidized bed 4 is formed by the fluidizing reactant gas to burn the flammable solid content; and a material separator 8 such as hot cyclone into which the exhaust gas is introduced from the combustion furnace 5 via an exhaust gas pipe 6 to be separated from the bed material which in turn is fed via a downcorner 7 into the gasification furnace 2, the fuel gasification system being provided with tar decomposing means 9 which heats the g...

embodiment 2

[0066]FIG. 3 shows a second embodiment of the invention in which parts identical with those shown in FIG. 2 are represented by the same reference characters, its fundamental structure being similar to that shown in FIG. 2. The present embodiment is characteristic as shown in FIG. 3 in that tar decomposing means 9 is constituted by a heat exchanger 23 which heats, by heat of a combustion furnace 5, gasification gas introduced into a gasification gas passage 13 which in turn is formed on an inner surface of the furnace 5. It goes without saying that the gasification gas passage 13 on the inner surface of the furnace 5 may be, as needs demand, in the form of spiral passage just like the embodiment of FIG. 2 so as to prolong the dwell time of the gasification gas in the heat exchanger 23.

[0067]In the embodiment shown in FIG. 3, the gasification gas produced in a gasification furnace 2 and separated from the bed material in a material separator 15 is introduced into the gasification gas ...

embodiment 3

[0068]FIG. 4 shows a third embodiment of the invention in which parts identical with those shown in FIG. 2 are presented by the same reference characters, its fundamental structure being similar to that shown in FIG. 2. The present embodiment is characteristic as shown in FIG. 4 in that tar decomposing means 9 is constituted by a heat exchanger 24 which heats, by heat of a combustion furnace 5, gasification gas introduced into a gasification gas passage 13 which in turn is formed on an outer surface of the furnace 5. In the embodiment of FIG. 4, the gasification gas passage 13 formed on the outer surface of the furnace 5 is in the form of a spiral passage 13a with heat storage material (not shown) so that high temperature can be retained while dwell time of the gasification gas in the heat exchanger 24 is secured. An exhaust gas passage 12 is formed on an outer surface of the gasification gas passage 13 of the heat exchanger 24 so as to introduce exhaust gas from the combustion furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com