Patents

Literature

733 results about "Carbon monoxide gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Often called the invisible killer, carbon monoxide is an odorless, colorless gas created when fuels (such as gasoline, wood, coal, natural gas, propane, oil, and methane) burn incompletely. In the home, heating and cooking equipment that burn fuel are potential sources of carbon monoxide.

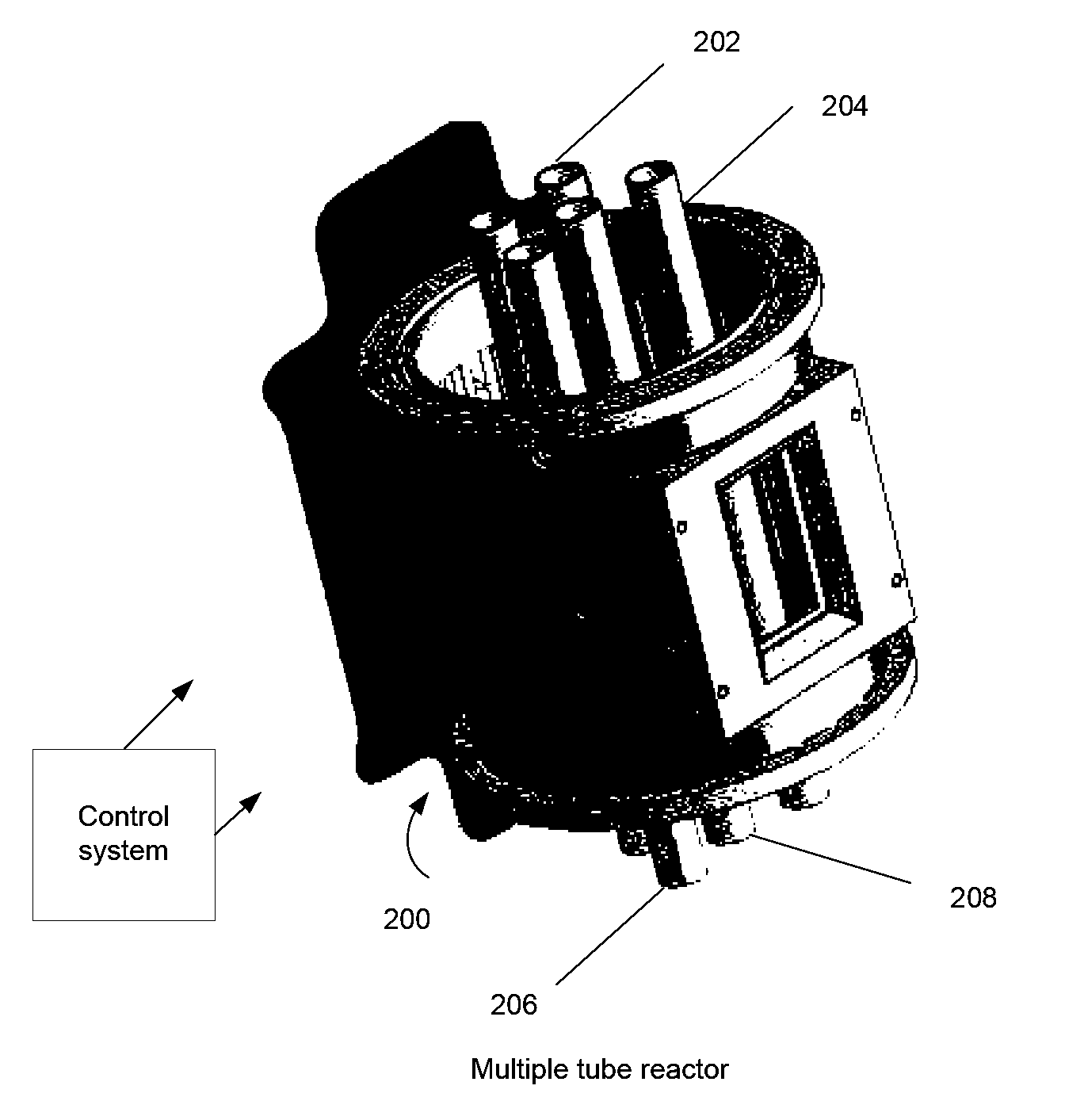

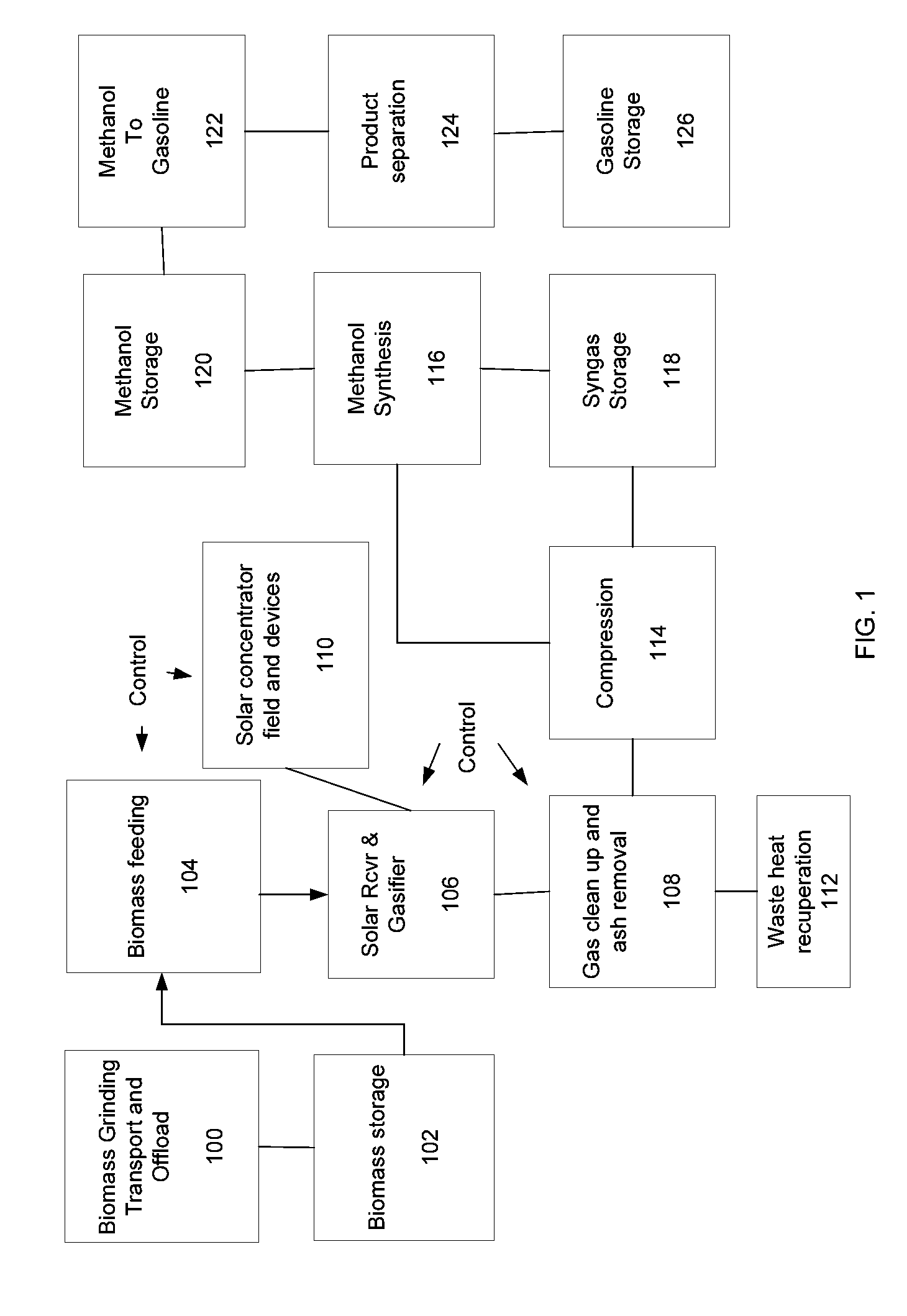

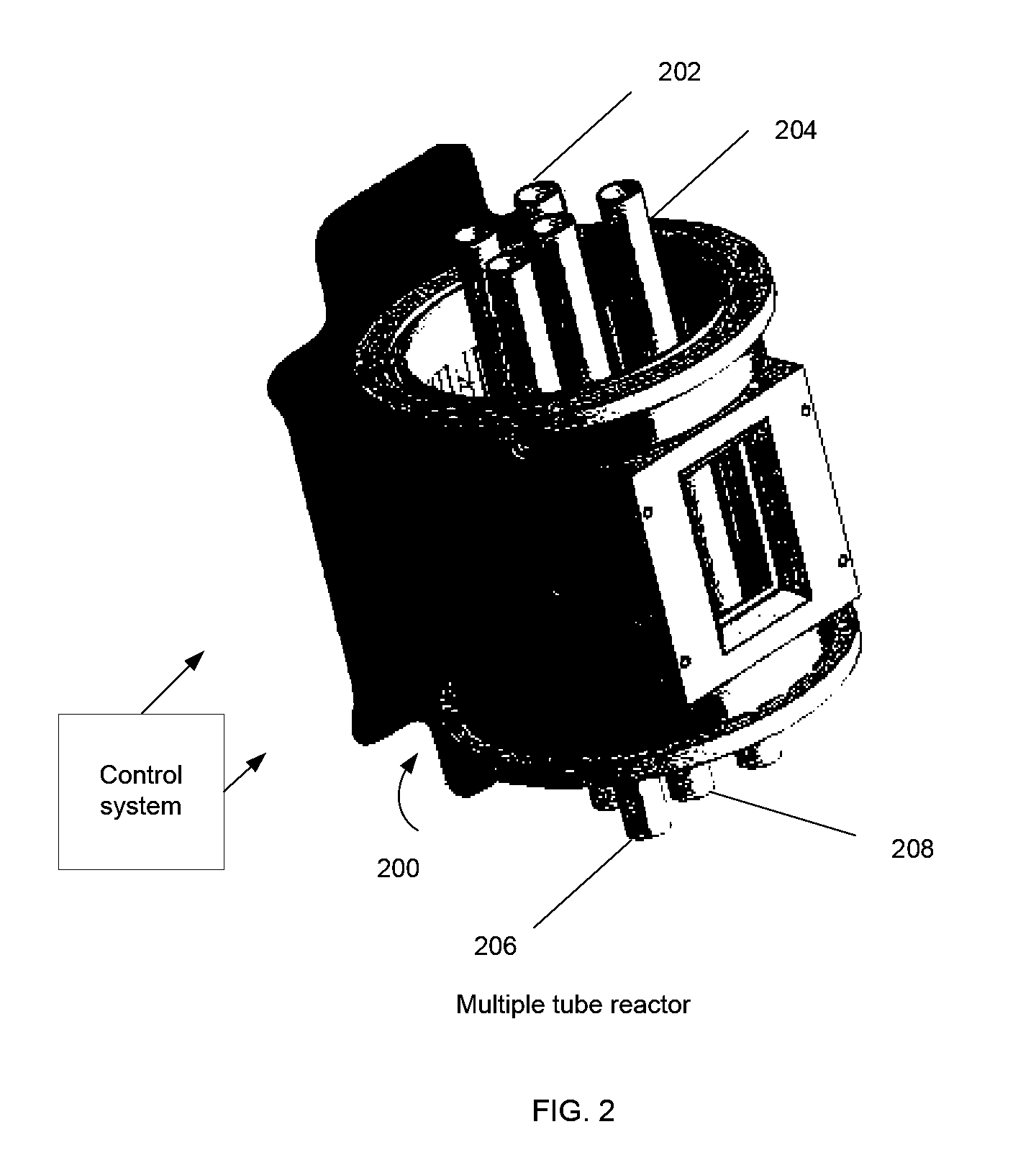

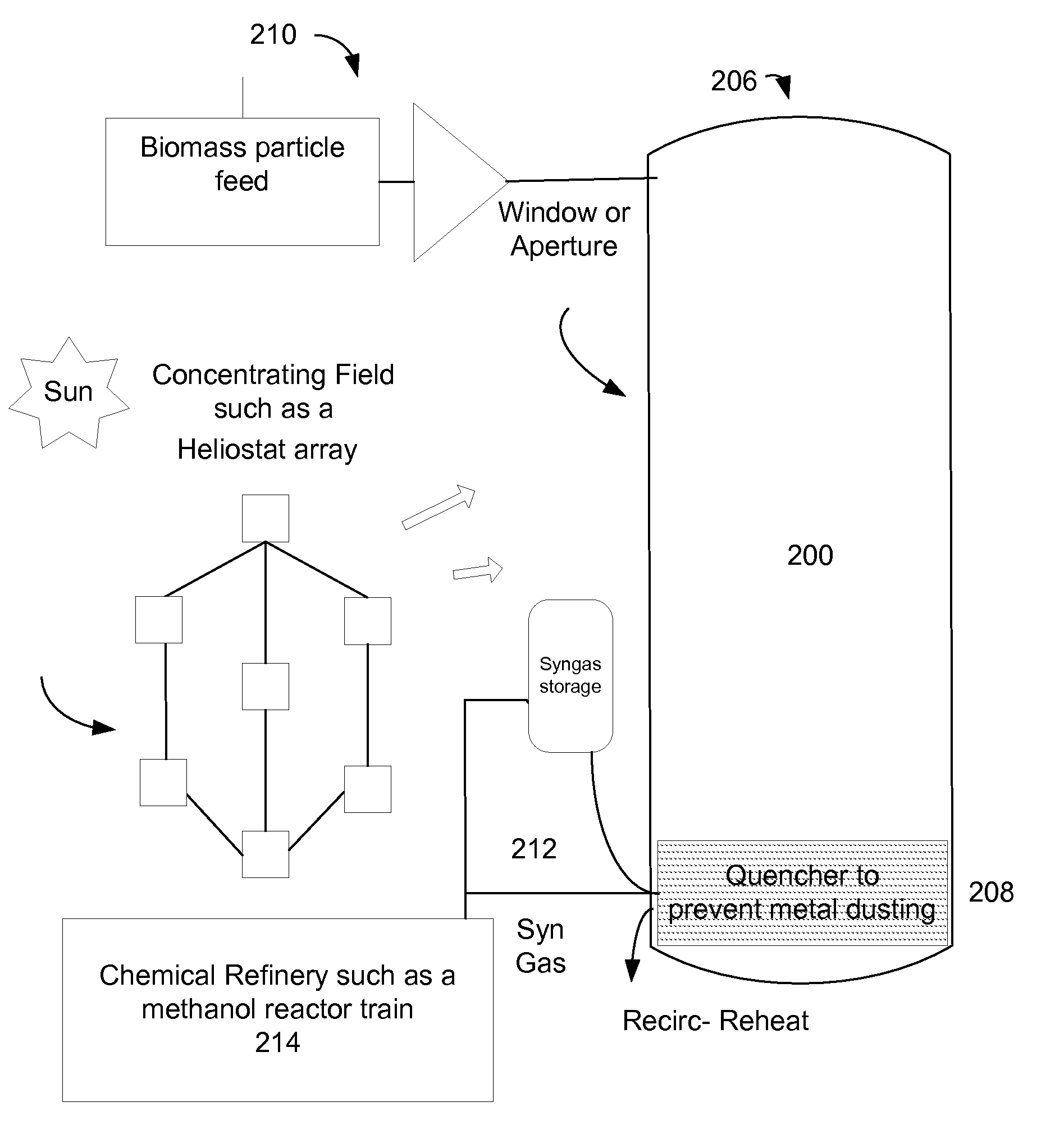

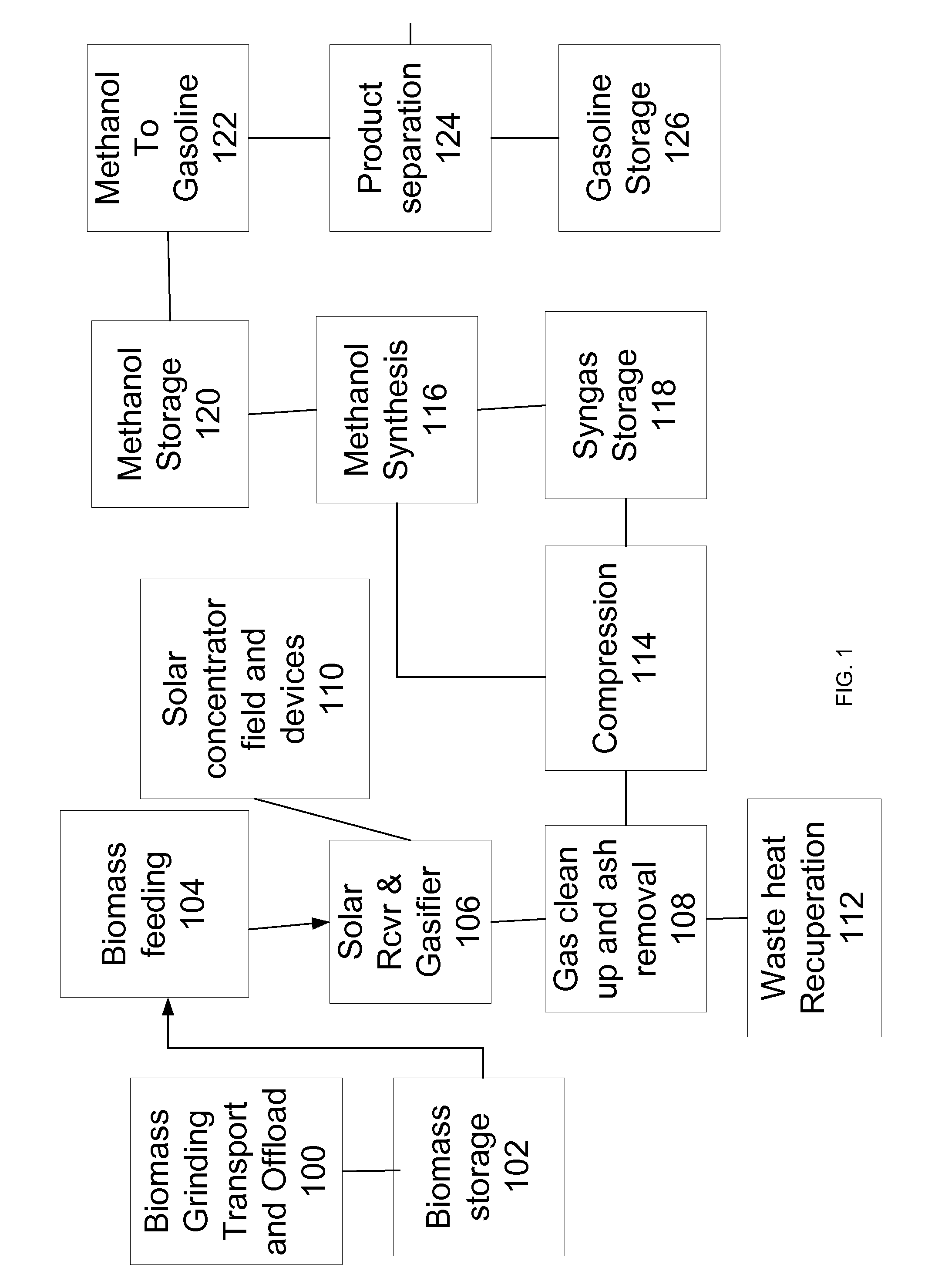

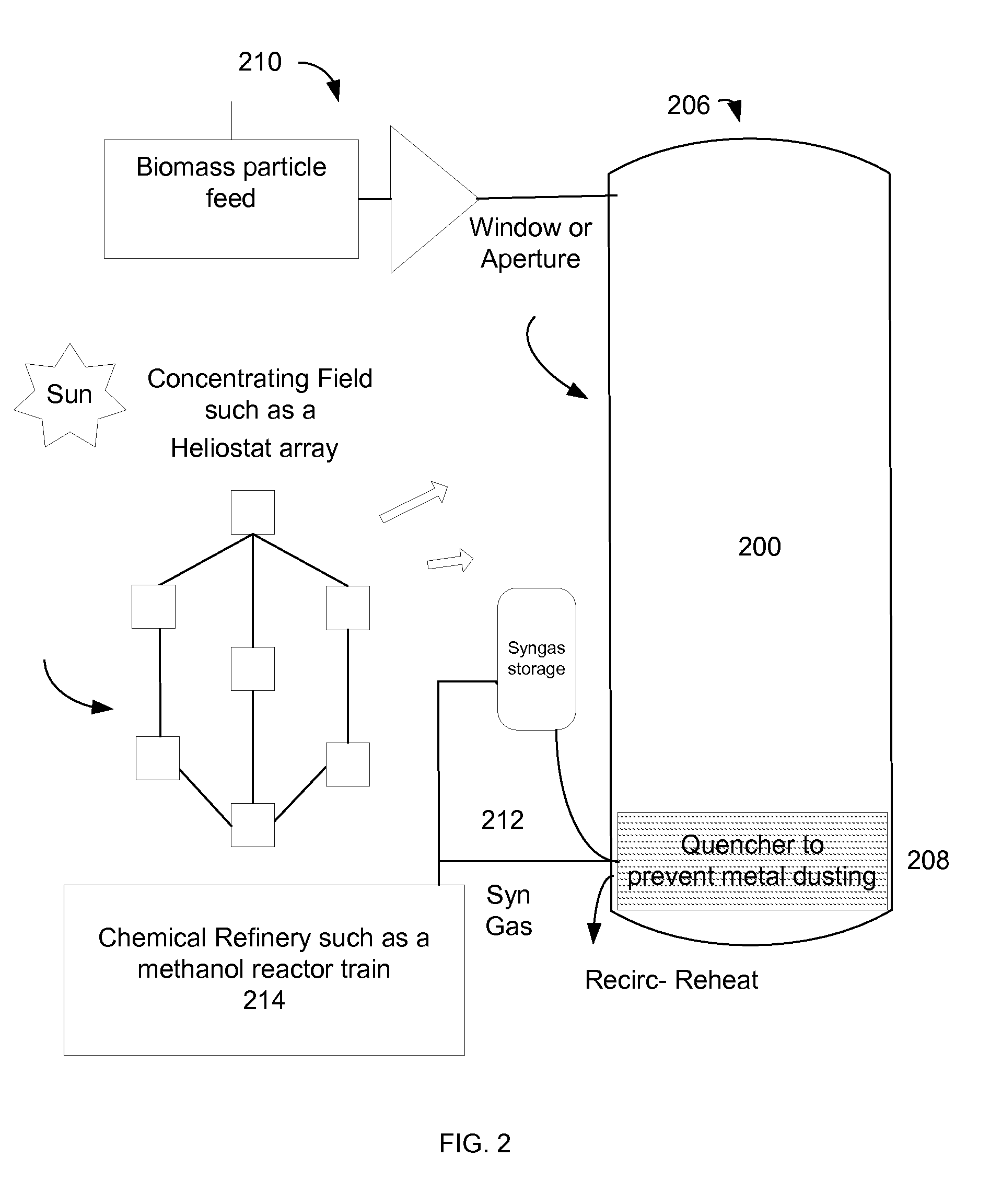

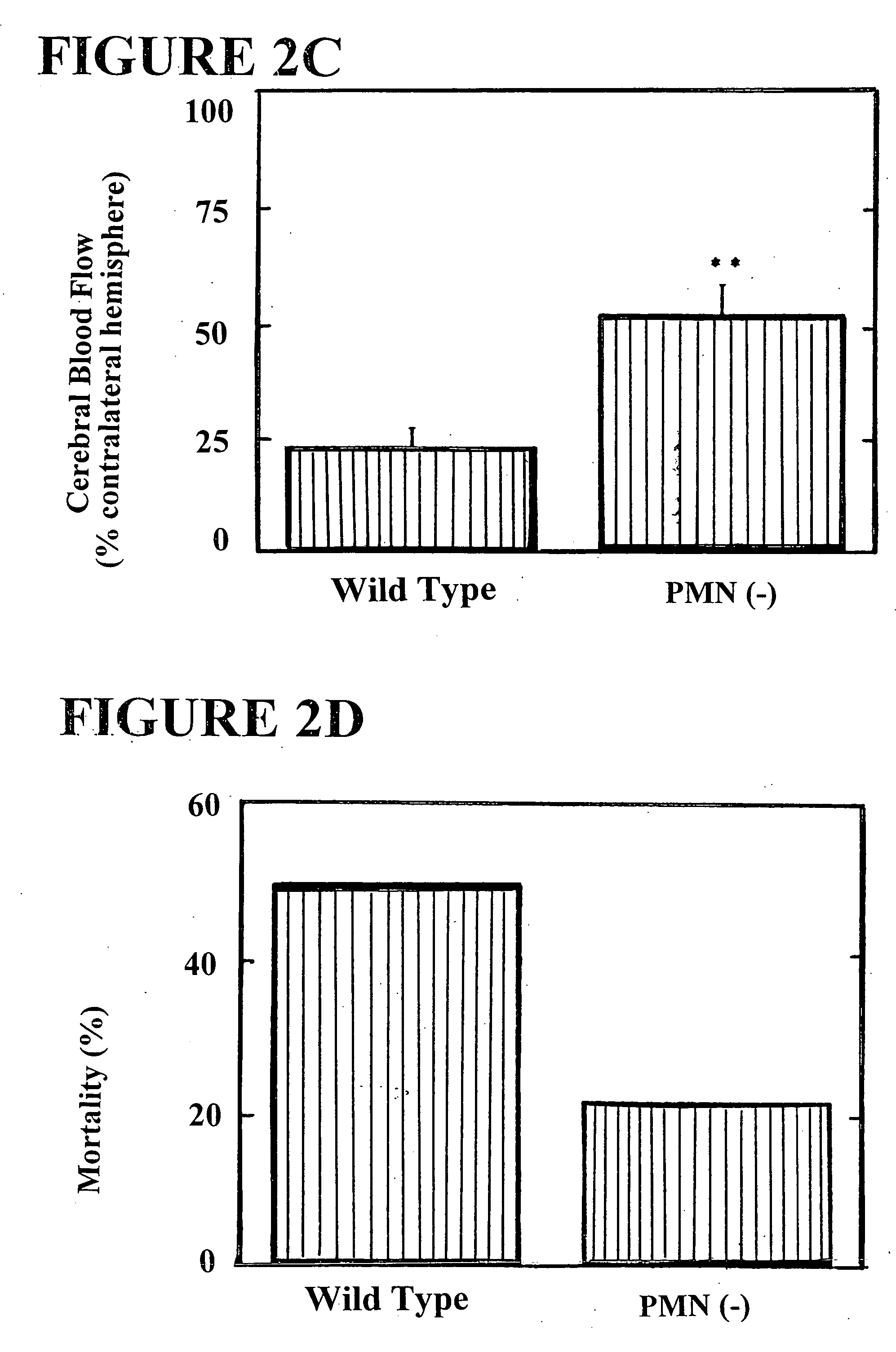

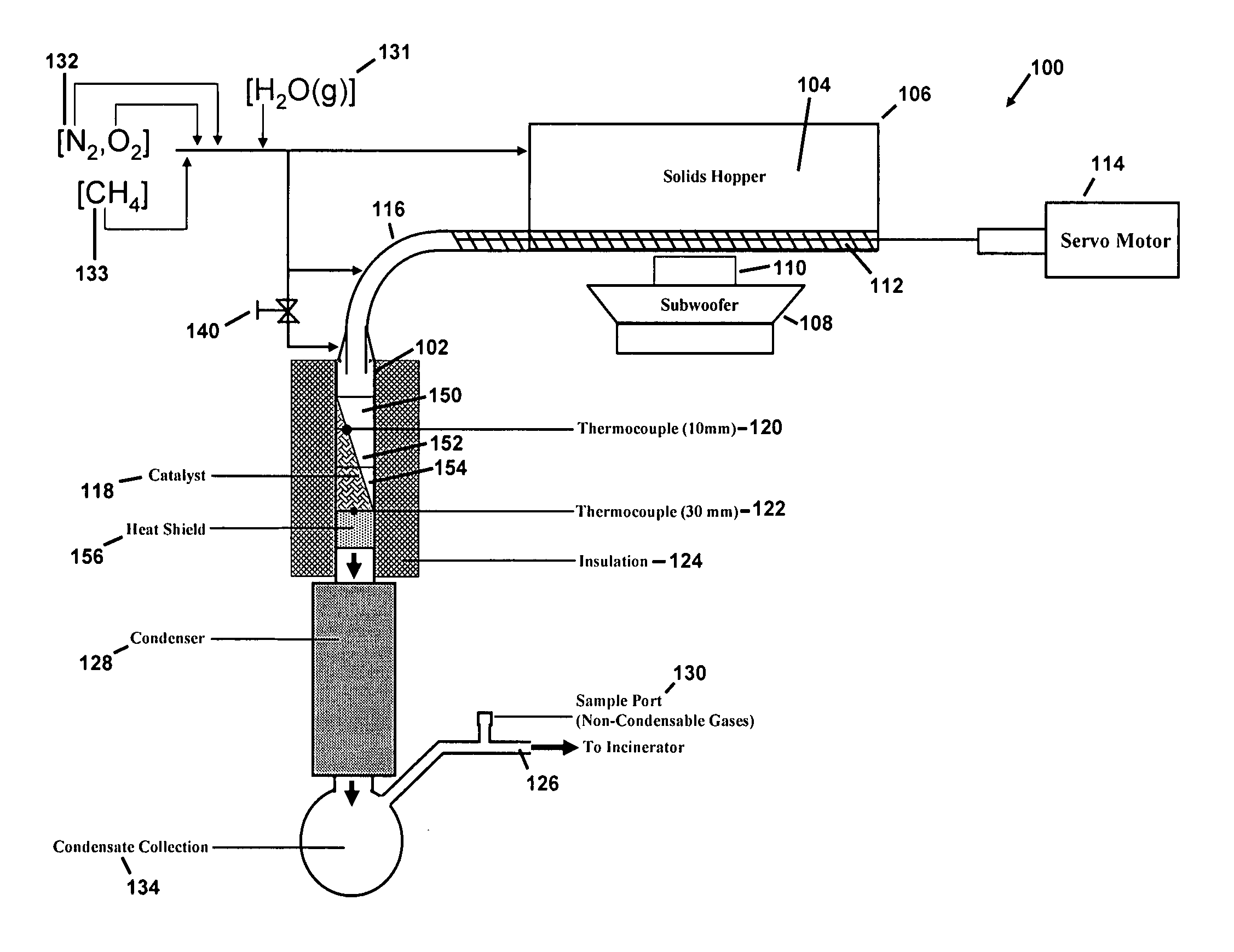

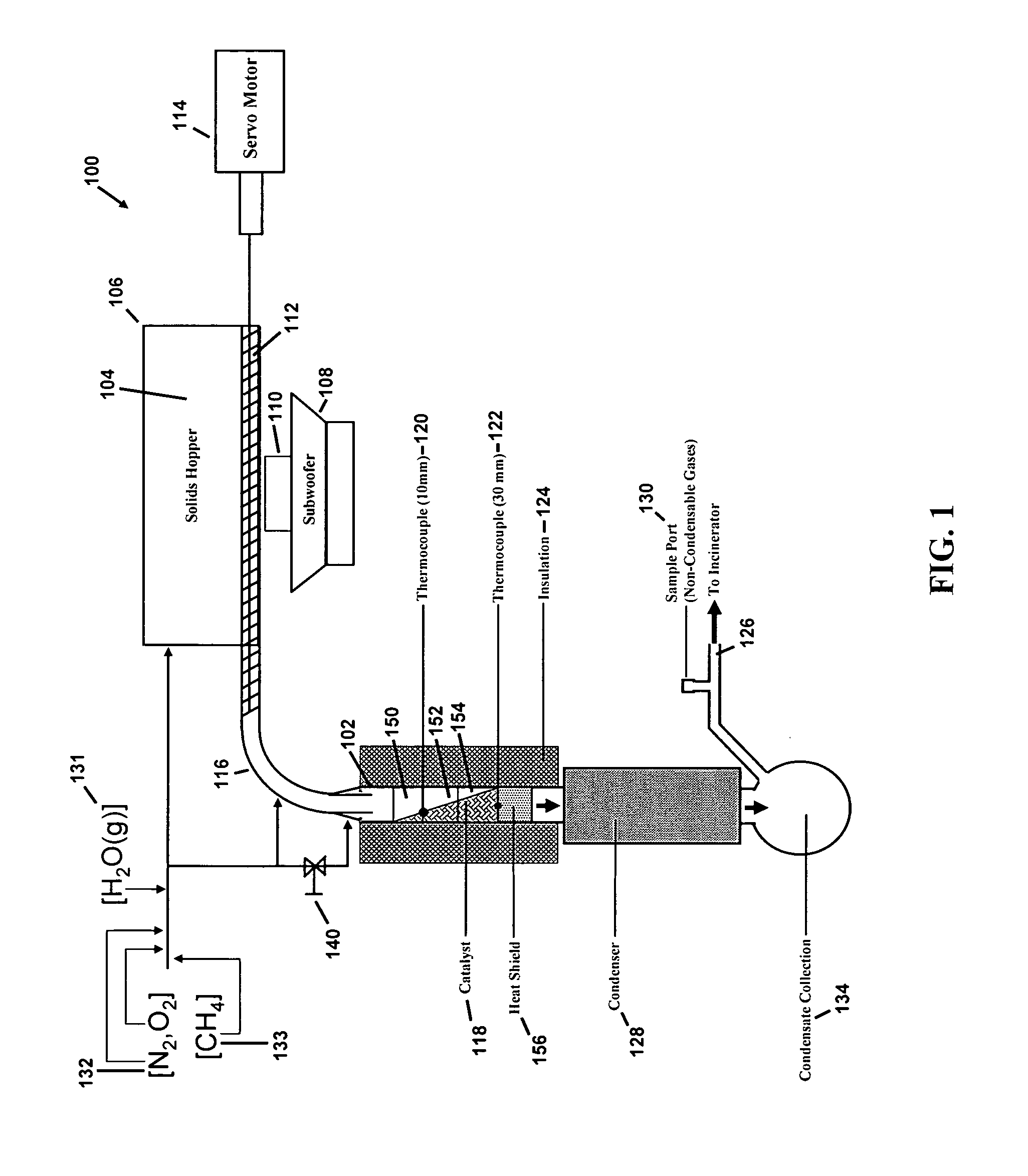

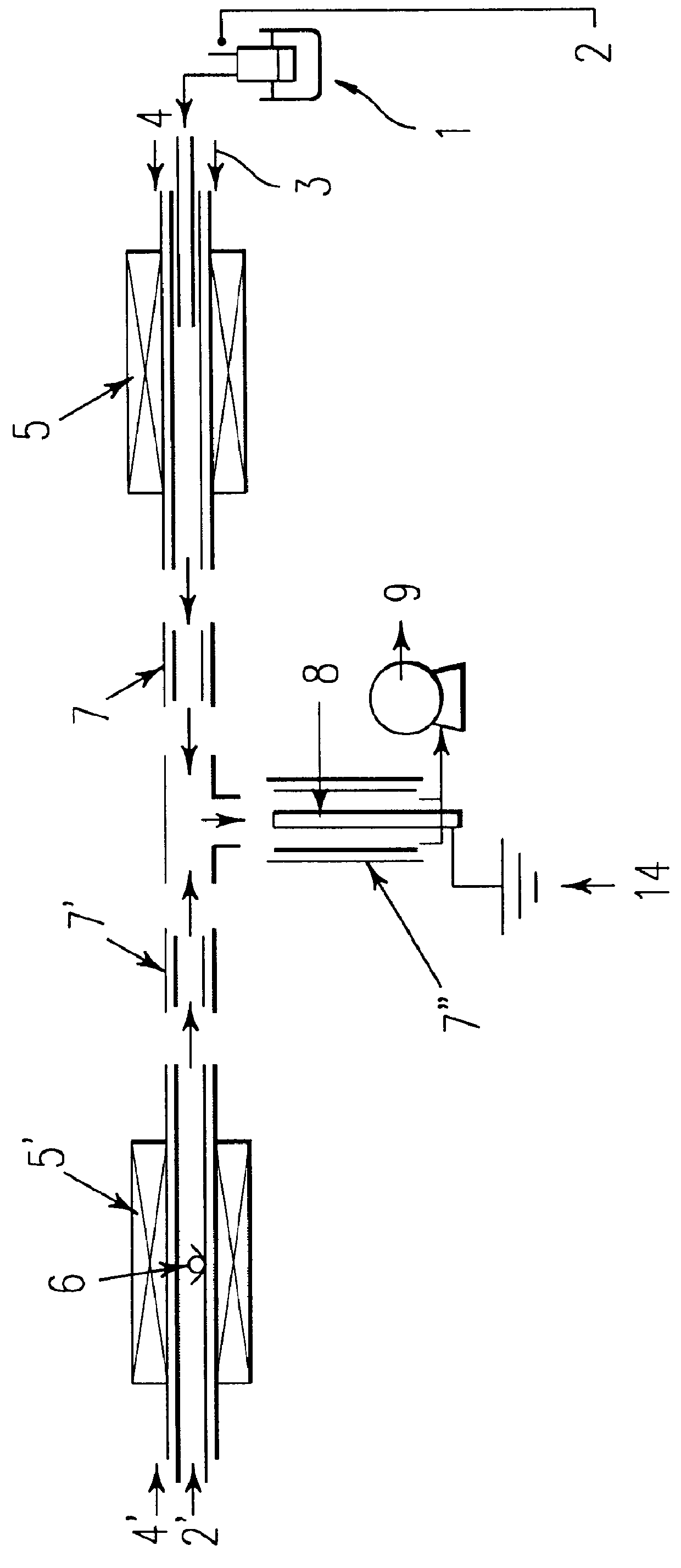

Systems and methods for solar-thermal gasification of biomass

InactiveUS20100237291A1Process control/regulationSolar heating energySteam reformingChemical reaction

A method, apparatus, and system for a solar-driven chemical plant that may include a solar thermal receiver having a cavity with an inner wall, where the solar thermal receiver is aligned to absorb concentrated solar energy from one or more of 1) an array of heliostats, 2) solar concentrating dishes, and 3) any combination of the two. Some embodiments may include a solar-driven chemical reactor having multiple reactor tubes located inside the cavity of solar thermal receiver, wherein a chemical reaction driven by radiant heat occurs in the multiple reactor tubes, and wherein particles of biomass are gasified in the presence of a steam (H2O) carrier gas and methane (CH4) in a simultaneous steam reformation and steam biomass gasification reaction to produce reaction products that include hydrogen and carbon monoxide gas using the solar thermal energy from the absorbed concentrated solar energy in the multiple reactor tubes.

Owner:SUNDROP IP HLDG LLC

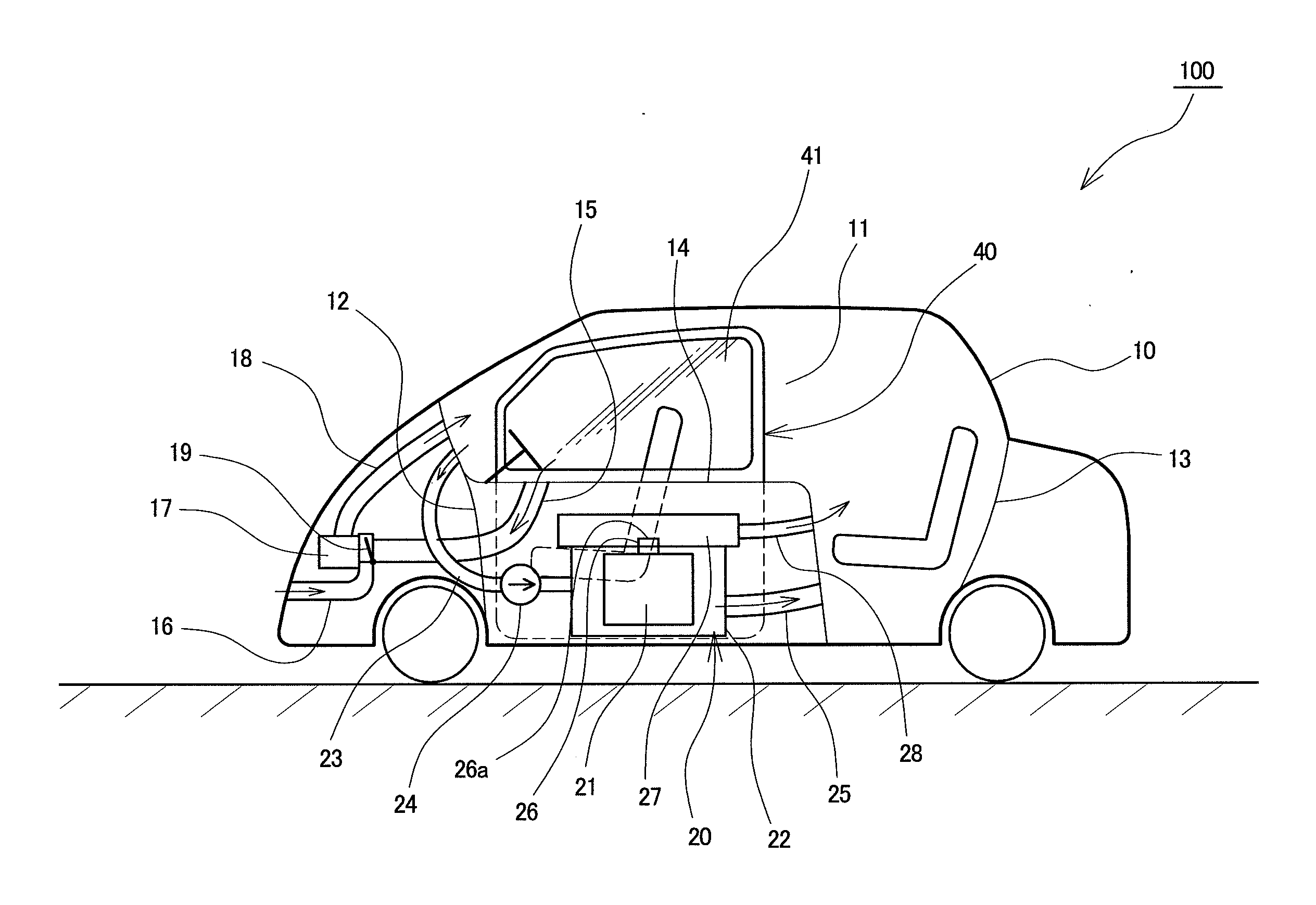

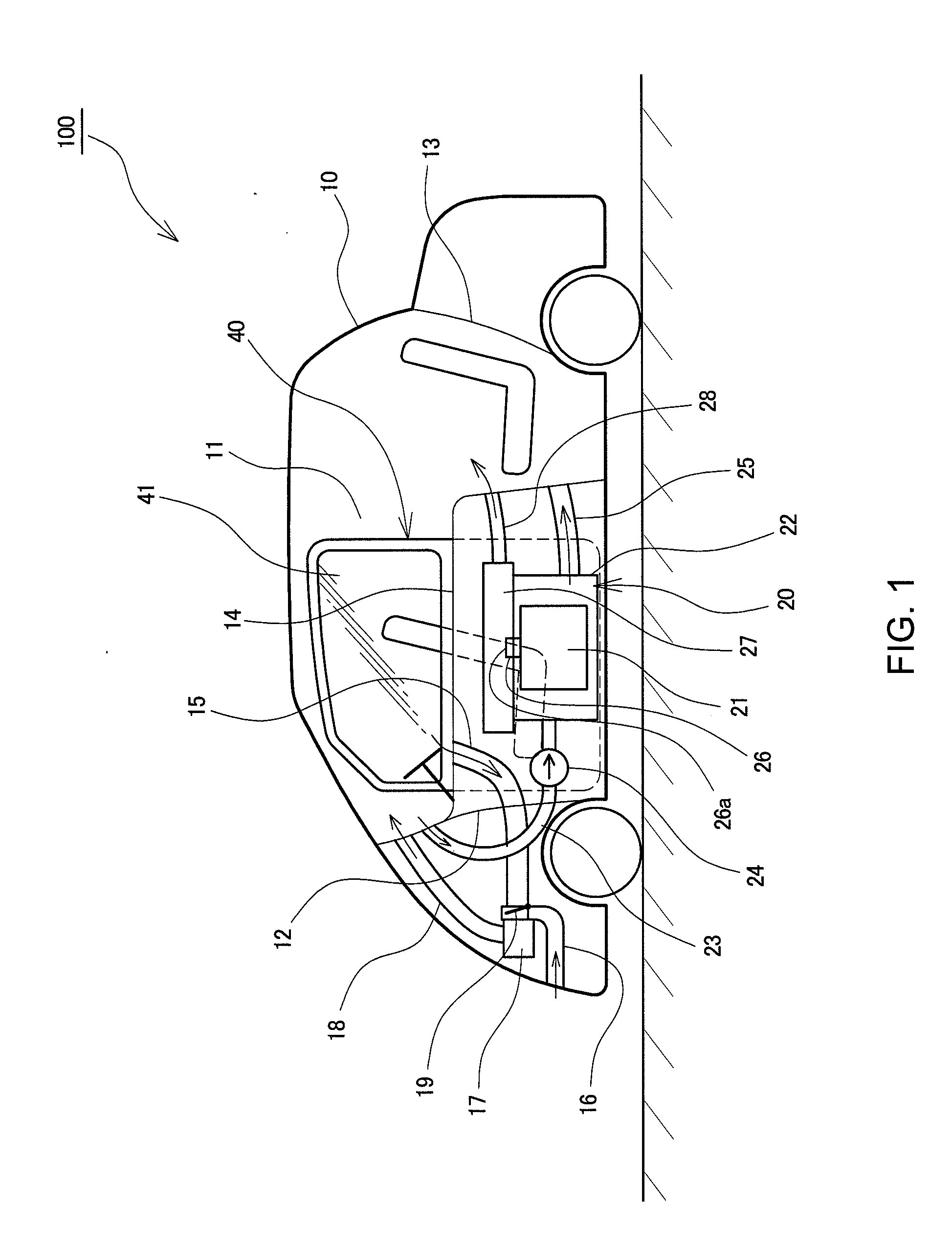

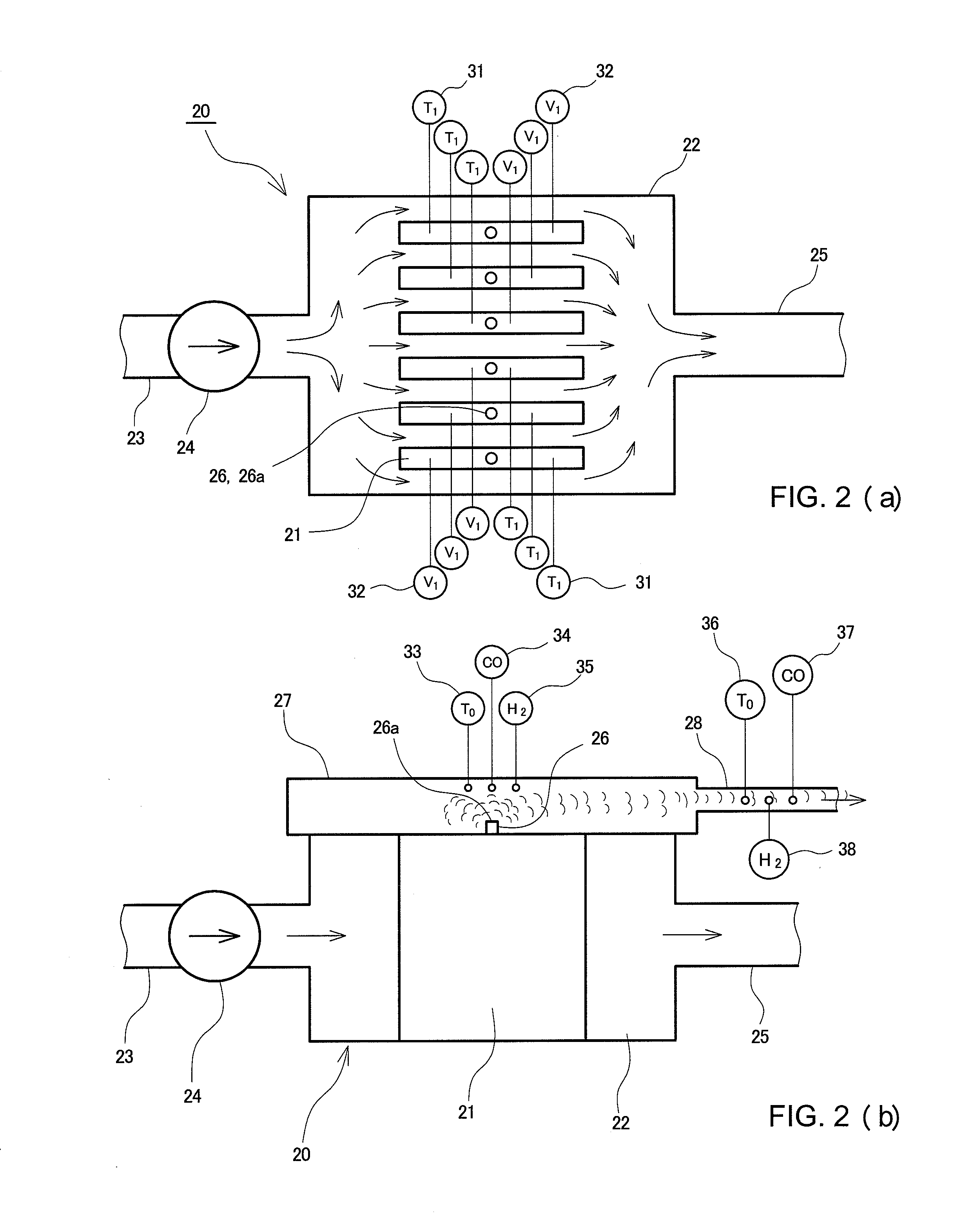

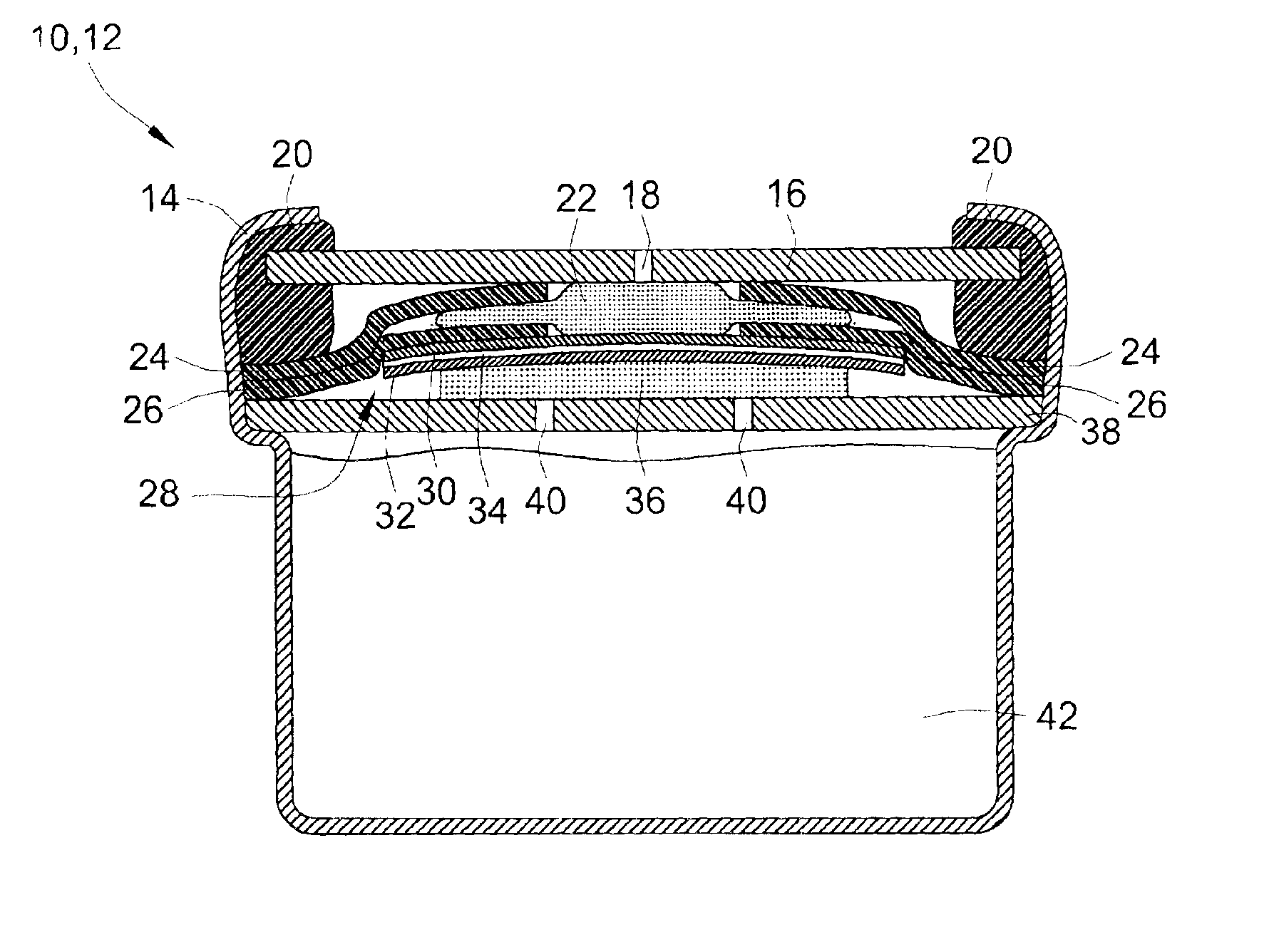

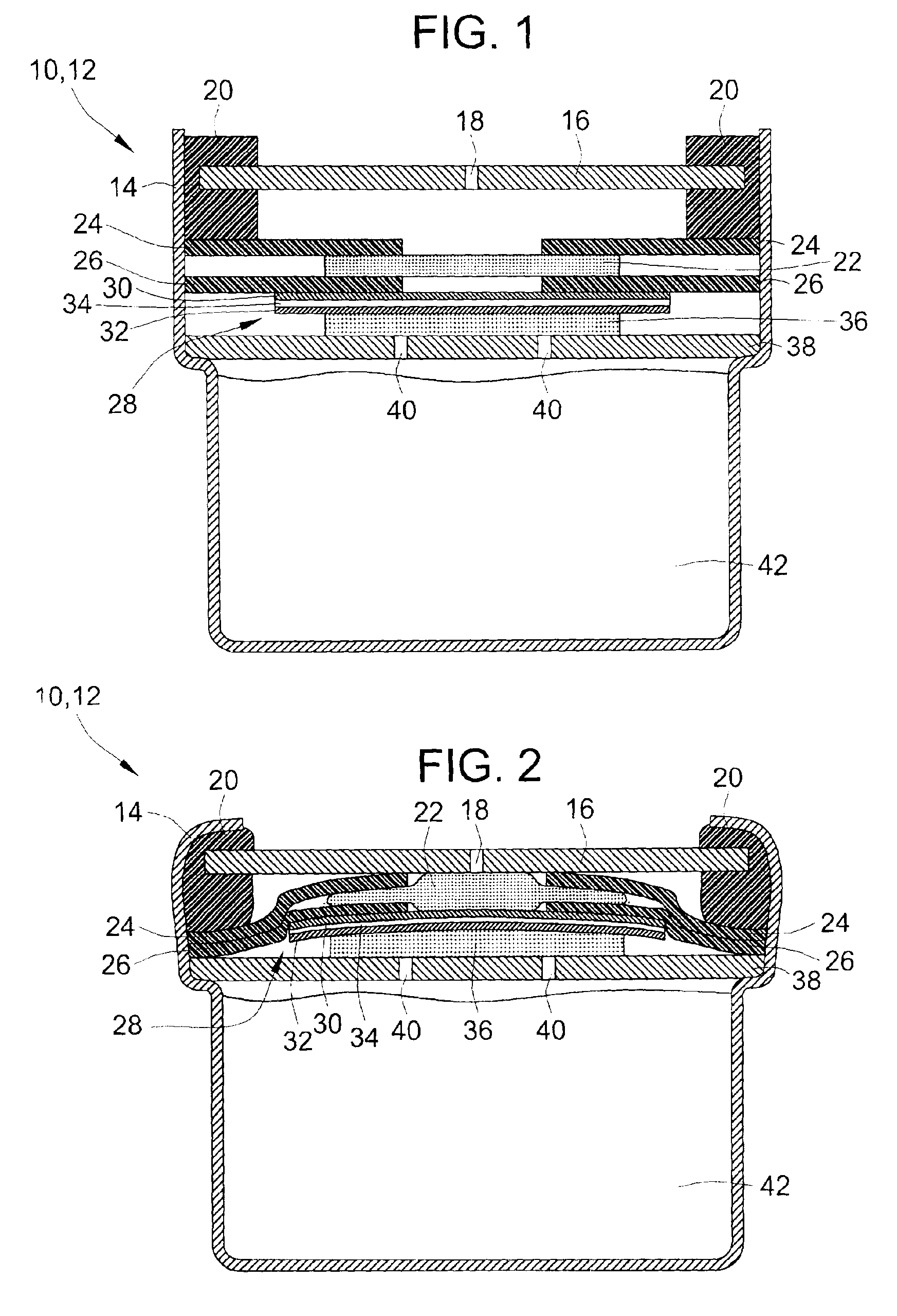

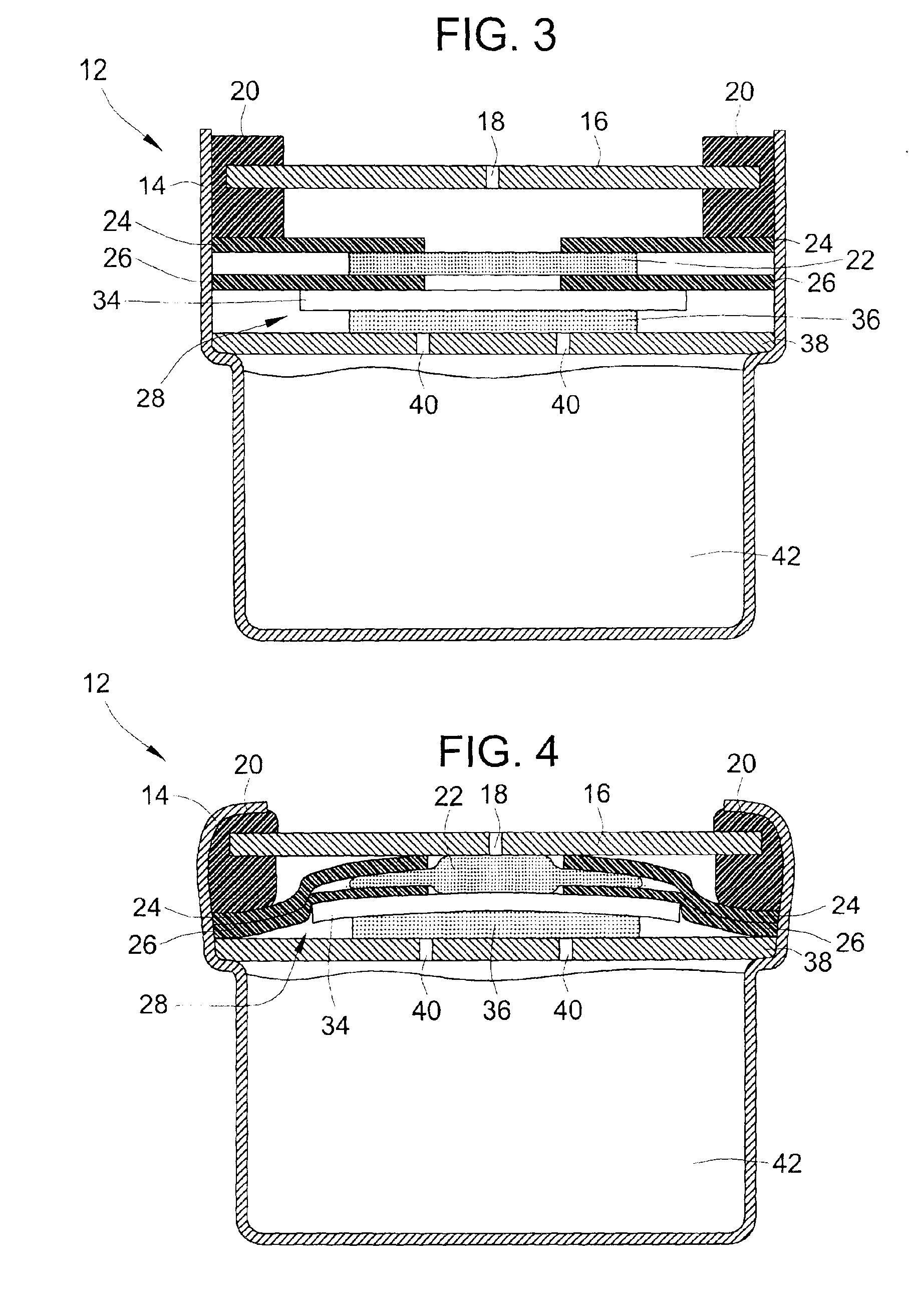

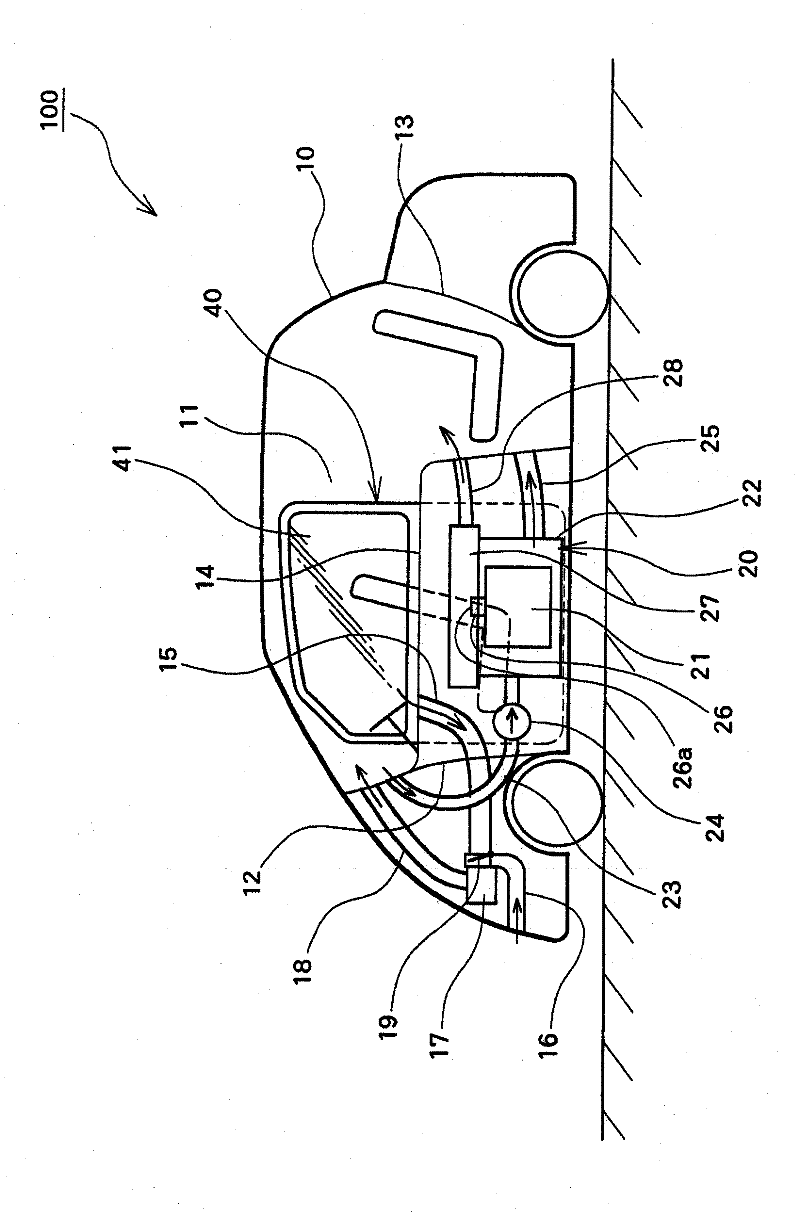

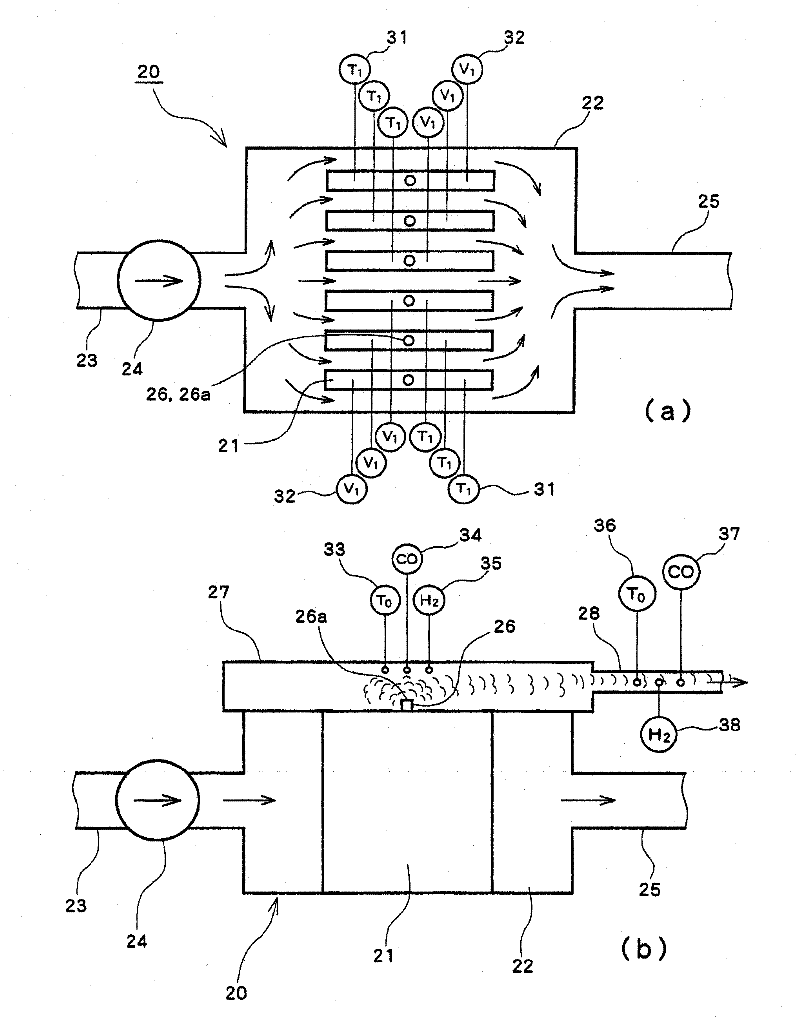

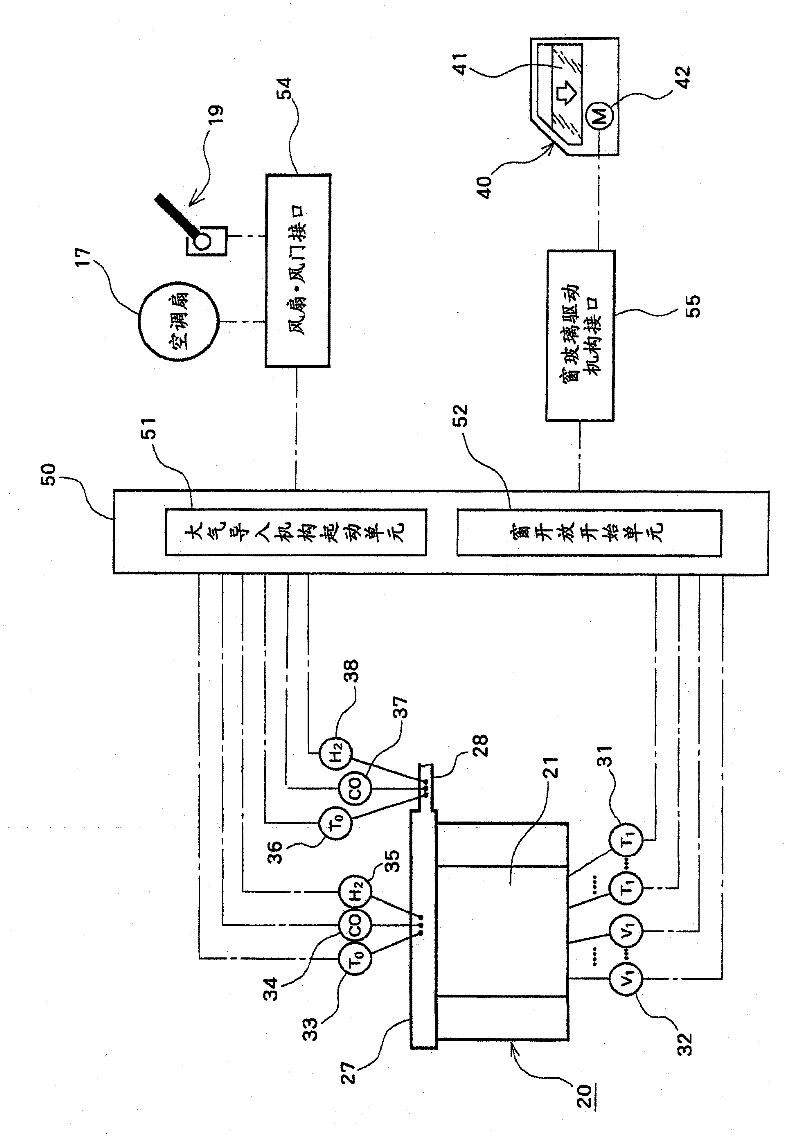

Electric vehicle

An electric vehicle is provided with a cell voltage sensor (32) and a cell temperature sensor (31) which are mounted to each of a plurality of cells (21); a gas temperature sensor (33), a carbon monoxide gas sensor (34), and a hydrogen gas sensor (35) which are mounted to a chamber (27); a gas temperature sensor (36), a carbon monoxide gas sensor (37), and a hydrogen gas sensor (38) which are mounted to a gas exhaust passage (28); and an air-conditioning fan (17), a channel-switching damper (19), and a driving motor (42) which lowers a window glass (41). When battery state values detected by the sensors (31) to (38) exceed predetermined thresholds, a battery pack (20) is judged to be abnormal. Then, the channel-switching damper (19) and the air-conditioning fan (17) are started and the window glass (41) is lowered to ventilate the vehicle interior. This speedily exhausts smoke generated from a lithium ion battery.

Owner:TOYOTA JIDOSHA KK

Self-calibrating carbon monoxide detector and method

InactiveUS6948352B2Analysing fluids using sonic/ultrasonic/infrasonic wavesSamplingHydrogenCalibration gas

The self-calibrating carbon monoxide detector and method of the present invention utilize the gas for which the detector was designed to detect as the calibration gas. Specifically, a carbon monoxide gas generator is included in the detector assembly, and is controller to produce a known amount of CO. The sensor response to the quantity of CO generated is monitored, and the calibration thereof adjusted as necessary. The operation of the gas generator is also monitored, and any failures are flagged for user attention. The gas generator specifically suppresses the generation of hydrogen through the materials used in its construction. Temperature effects may also be compensated either through control of gas generation control parameters or compensation of the sensor output in view of the generator temperature effects.

Owner:WALTER KIDDE PORTABLE EQUIP

Method of plasma etching transition metals and their compounds

InactiveUS20070010100A1Efficient removalSolid-state devicesSemiconductor/solid-state device manufacturingCompound aMetal carbonyl

A method of plasma etching comprises using a primary etchant of carbon monoxide gas to etch a transition metal or transition metal compound and to form a volatile by-product of metal carbonyl.

Owner:SANDISK TECH LLC

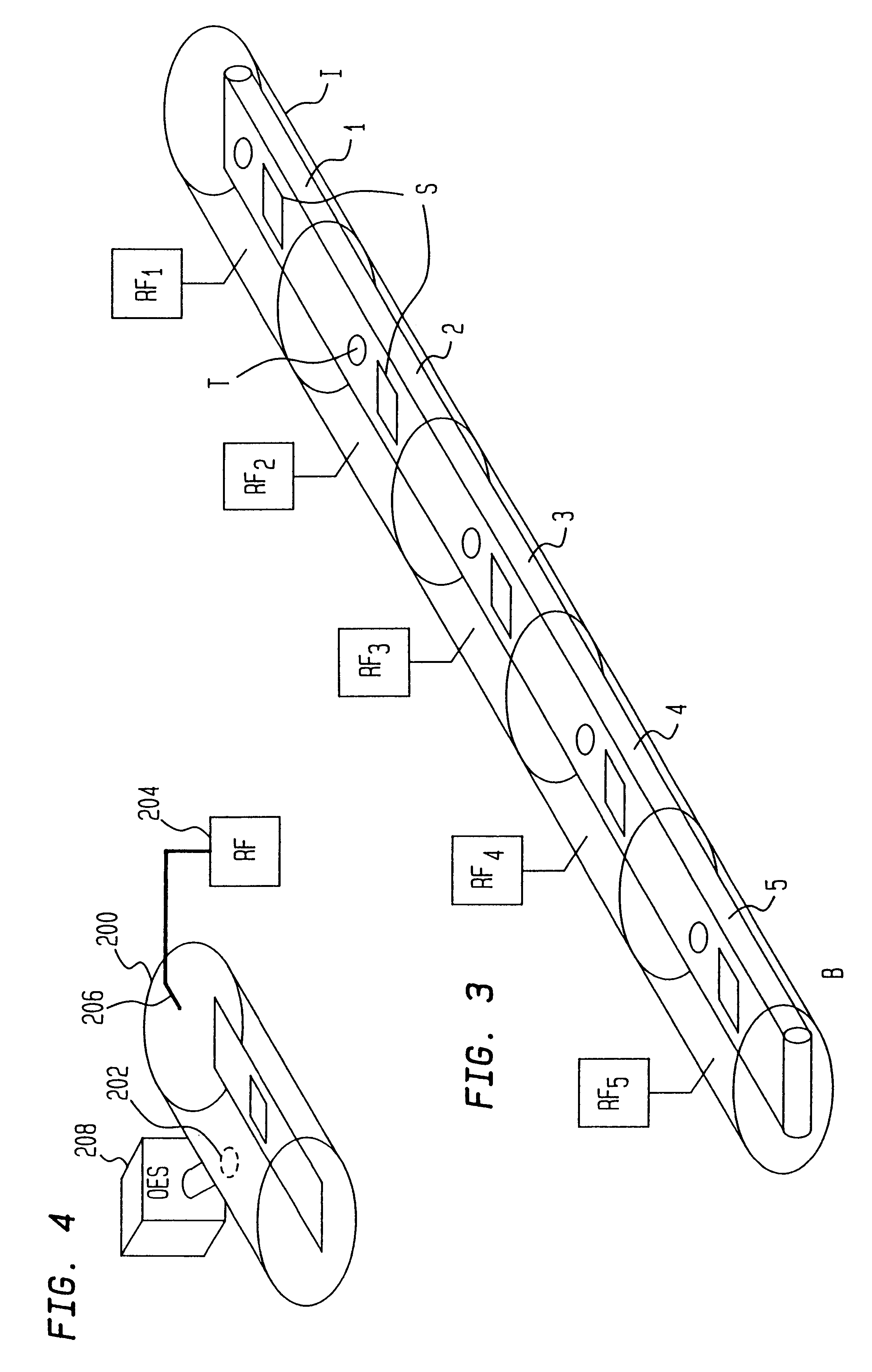

Systems and methods for quenching, gas clean up, and ash removal

A method, apparatus, and system for a solar-driven chemical plant are disclosed. An embodiment may include a solar thermal receiver aligned to absorb concentrated solar energy from one or more solar energy concentrating fields. A solar driven chemical reactor may include multiple reactor tubes located inside the solar thermal receiver. The multiple reactor tubes can be used to gasify particles of biomass in the presence of a carrier gas. The gasification reaction may produce reaction products that include hydrogen and carbon monoxide gas having an exit temperature from the tubes exceeding 1000 degrees C. An embodiment can include a quench zone immediately downstream of an exit of the chemical reactor. The quench zone may immediately quench via rapid cooling of at least the hydrogen and carbon monoxide reaction products within 0.1-10 seconds of exiting the chemical reactor to a temperature of 800 degrees C. or less.

Owner:SUNDROP IP HLDG LLC

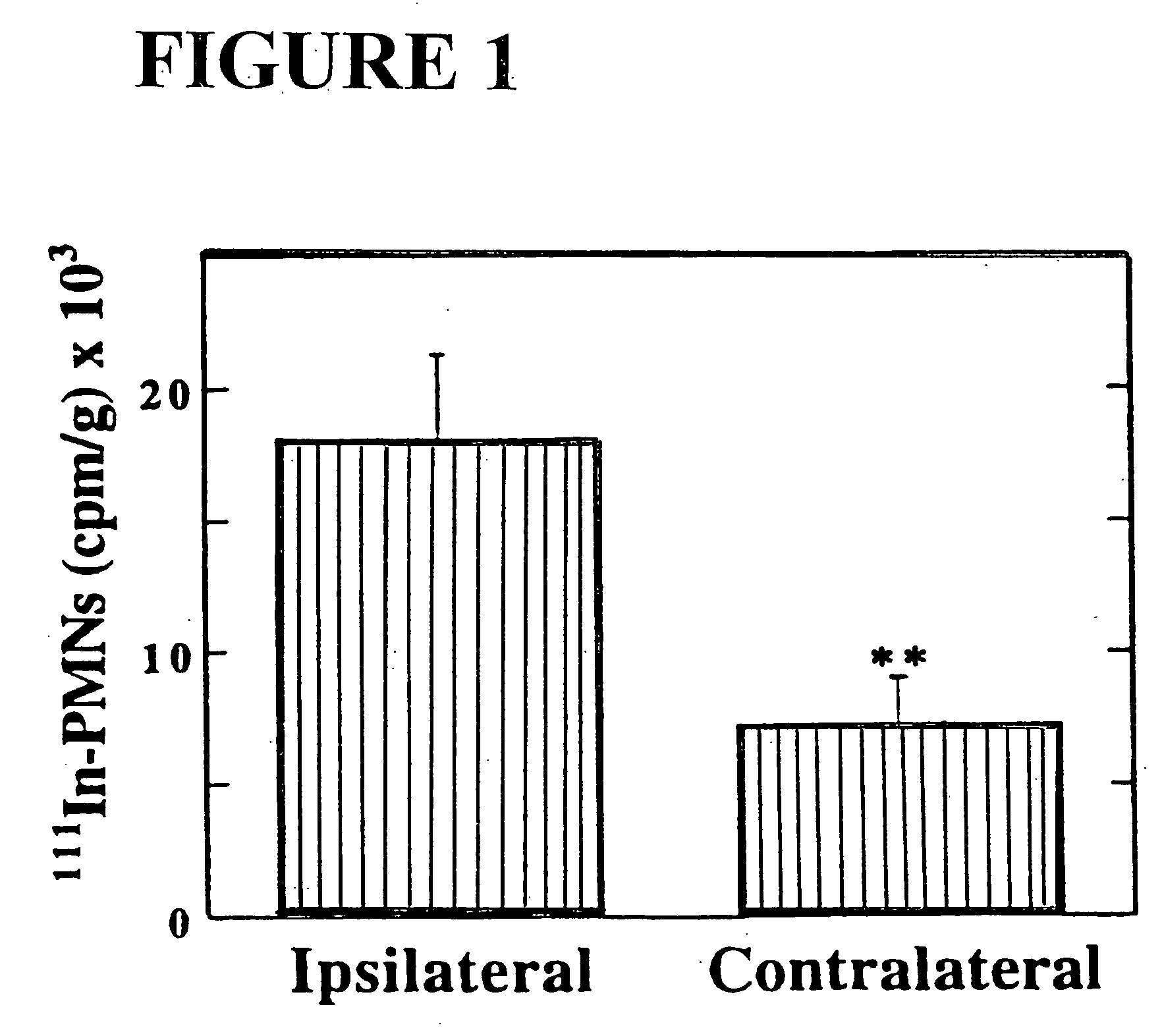

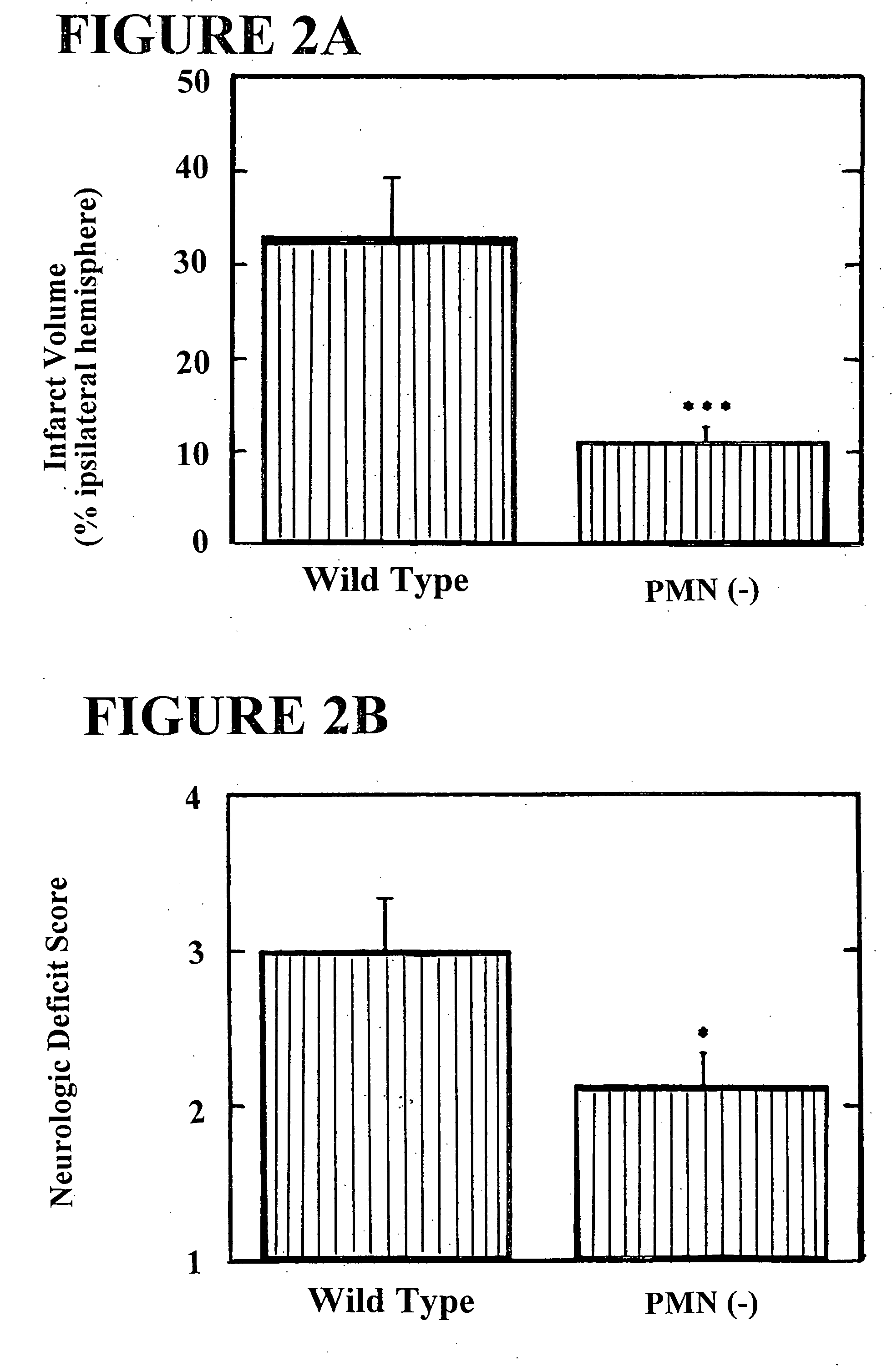

Methods for treating ischemic disorders using carbon monoxide

InactiveUS20050048133A1Avoid accumulationBiocidePeptide/protein ingredientsGynecologySufficient time

The present invention provides for a method for treating an ischemic disorder in a subject which comprises administering to the subject a pharmaceutically acceptable form of a selectin antagonist in a sufficient amount over a sufficient time period to prevent white blood cell accumulation so as to treat the ischemic disorder in the subject. The invention further provides a method for treating an ischemic disorder in a subject which comprises administering to the subject carbon monoxide gas in a sufficient amount over a sufficient period of time thereby treating the ischemic disorder in the subject. The invention further provides a method for treating an ischemic disorder in a subject which comprises administering to the subject a pharmaceutically acceptable form of inactivated Factor IX in a sufficient amount over a sufficient period of time to inhibit coagulation so as to treat the ischemic disorder in the subject.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

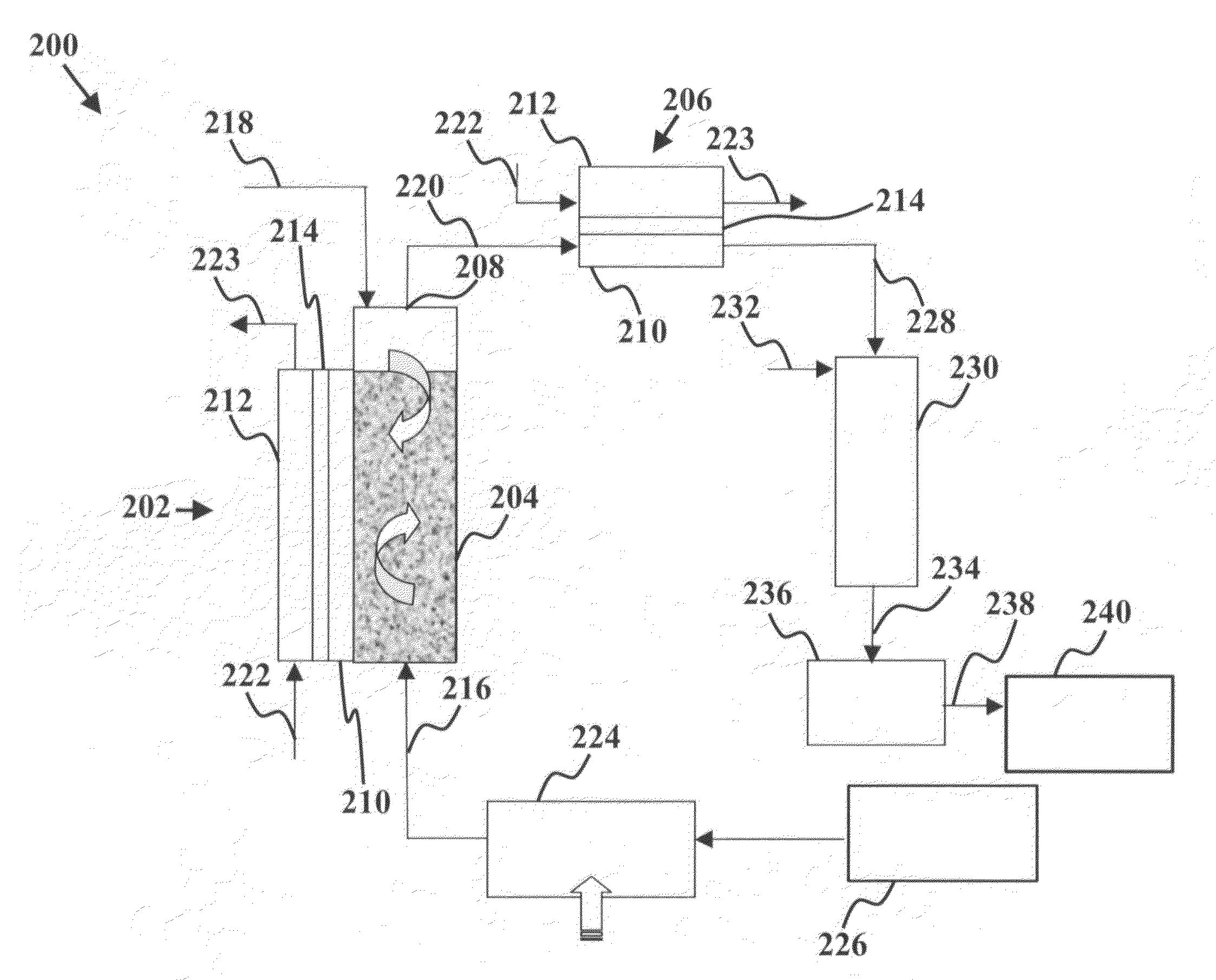

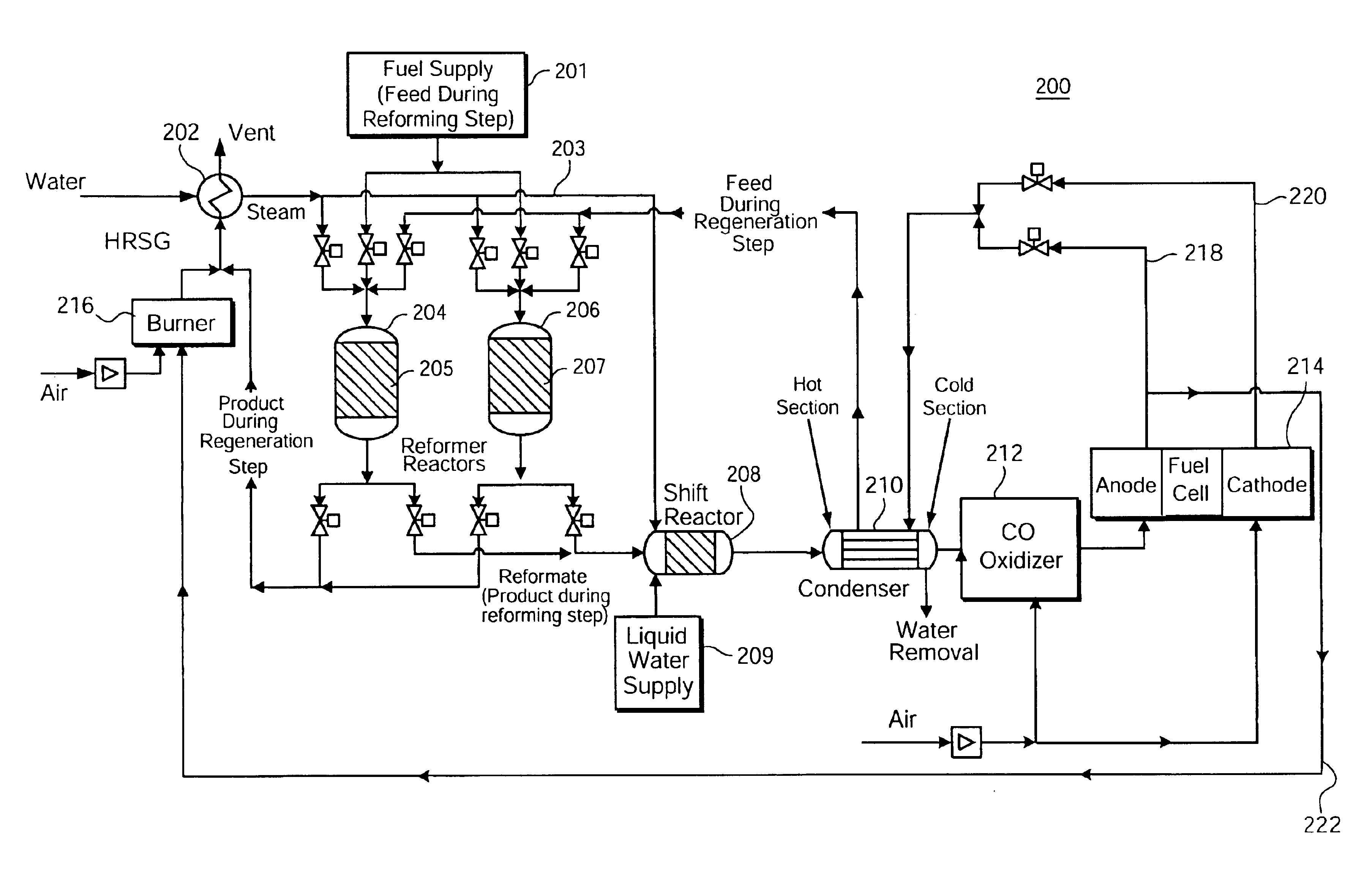

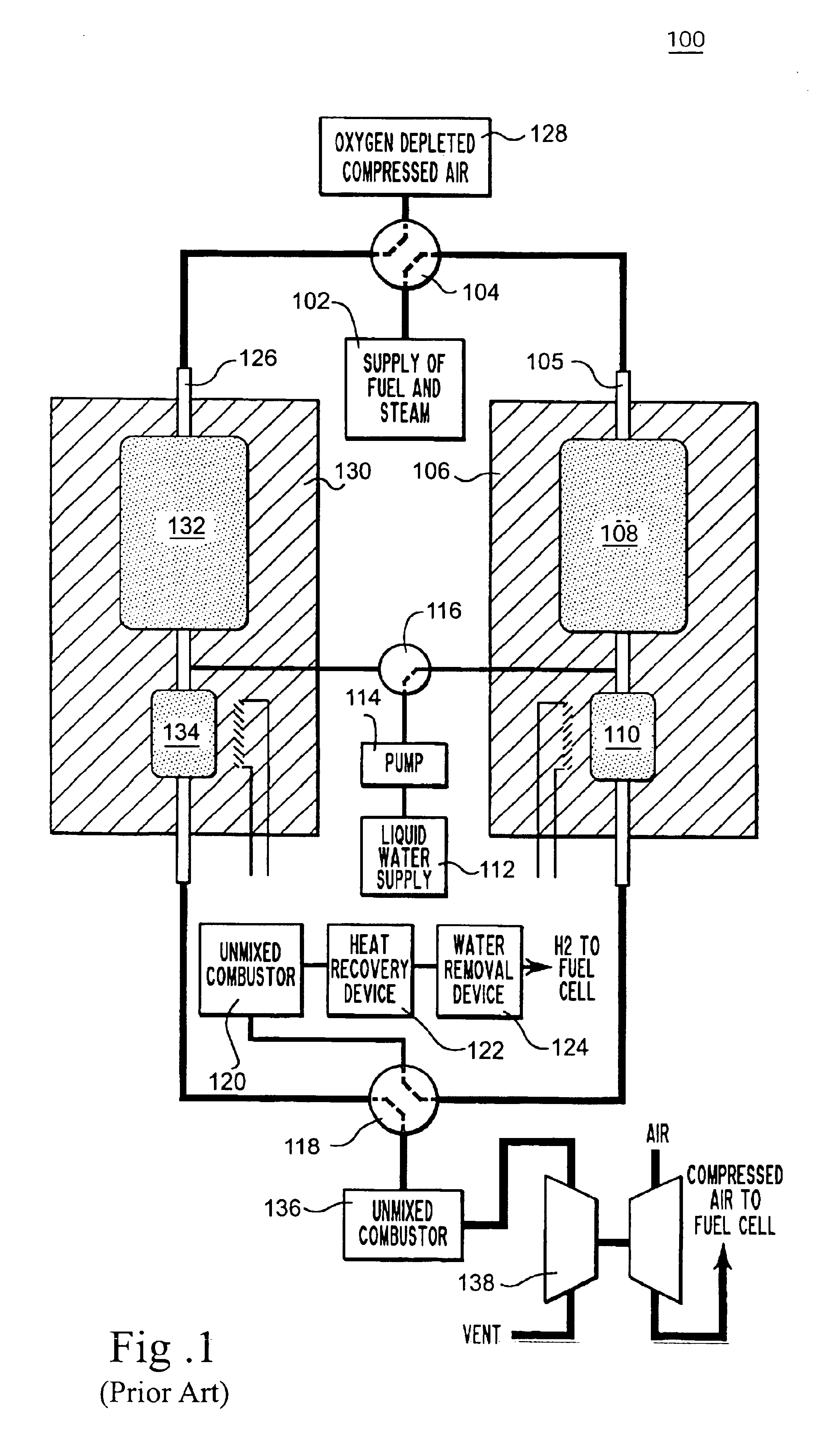

Integrated dry gasification fuel cell system for conversion of soild carbonaceous fuels

InactiveUS20090004529A1Increase power generation rateFuel cell heat exchangeRegenerative fuel cellsFuel cellsOxygen

An integrated dry gas fuel cell (IDG-FC) is provided. The IDG-FC includes at least one solid oxide fuel cell having an anode, a cathode and an electrolyte membrane disposed between the anode and the cathode. The IDG-FC further includes a conversion bed, where carbon dioxide gas is provided to the conversion bed to convert carbon monoxide gas from the carbon dioxide gas. Solid carbonaceous fuel is provided to the conversion bed to promote the gas conversion. The carbon monoxide is provided as fuel to the anode, and air is supplied to the cathode to provide oxygen for oxidation of the carbon monoxide at the anode to generate electric power. This new process does not require water, and supplies the oxygen required for the oxidation reaction through an ionically selective solid oxide electrolyte membrane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

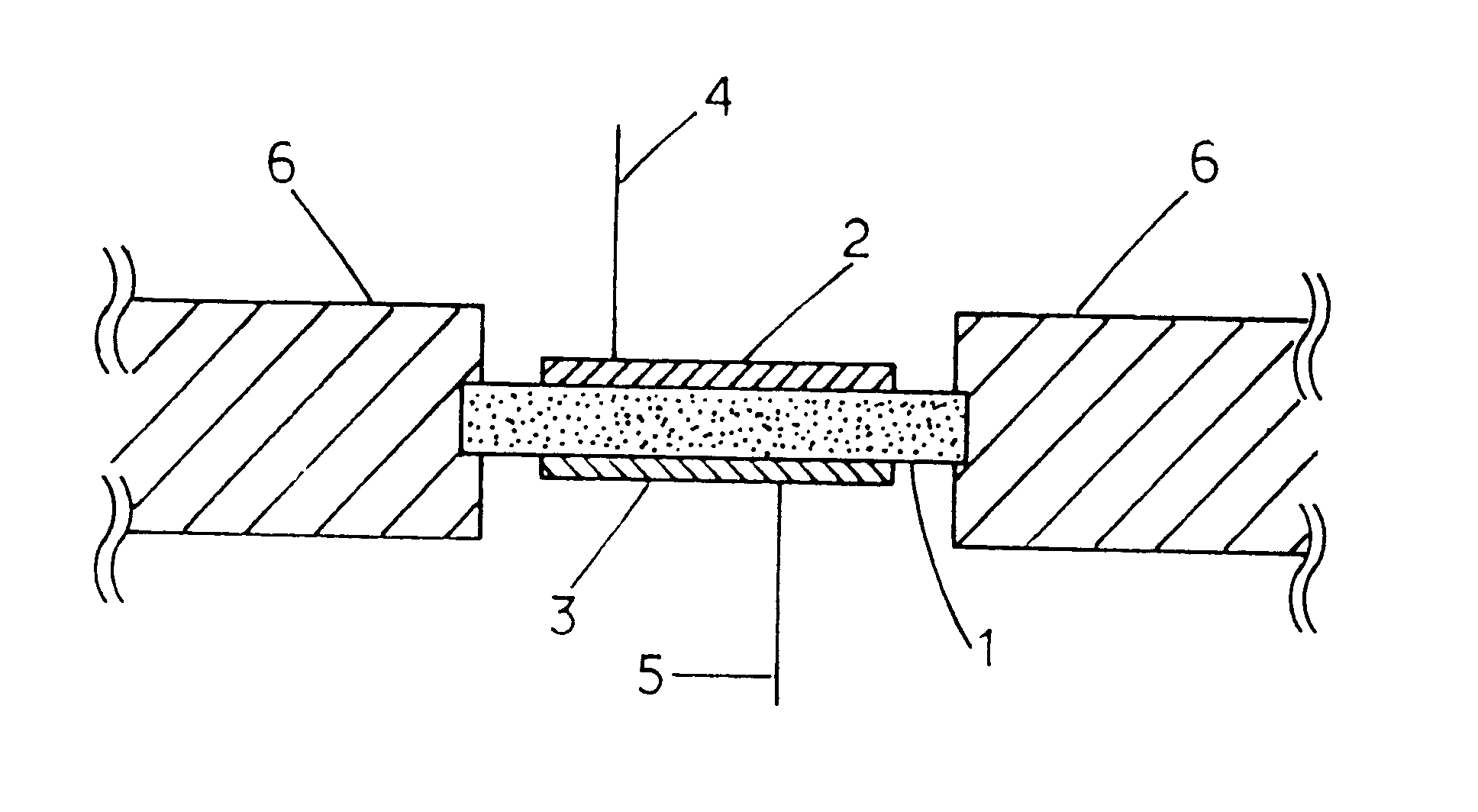

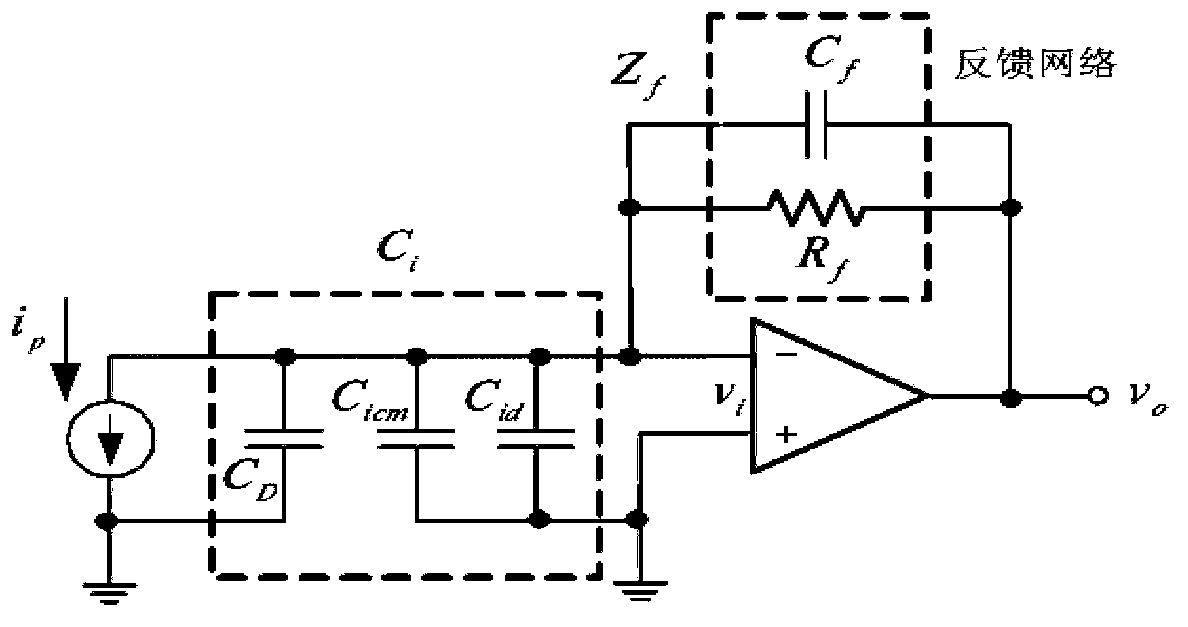

Carbon monoxide gas sensor and measuring device using the same sensor

InactiveUS6254749B1High selectivityHigh sensitivityWeather/light/corrosion resistanceVolume/mass flow measurementElectricityMeasurement device

In a CO gas sensor composed of a CO gas sensing electrode 3 being made of Au or an Au alloy and a reference electrode 2 electrically connected to at least part of a surface of a solid electrolyte having an oxygen ion transfer property, which is superior in CO gas selectivity, in particular, reducing the affect of the co-existing oxygen to CO, and which works with a high precision at a high temperature, and in a CO gas measuring device using the gas sensor, the gas sensor being capable of determining a CO gas concentration by measuring a electromotive force change due to adsorption / oxidization of the carbon monoxide gas in the sensing electrode 3 when a constant current is caused to flow between the reference electrode 2 and the sensing electrode 3 or a current value caused by the oxidizing reaction of the carbon monoxide gas in the sensing electrode when a voltage is kept constant between the reference electrode 2 and the sensing electrode 3.

Owner:NGK INSULATORS LTD

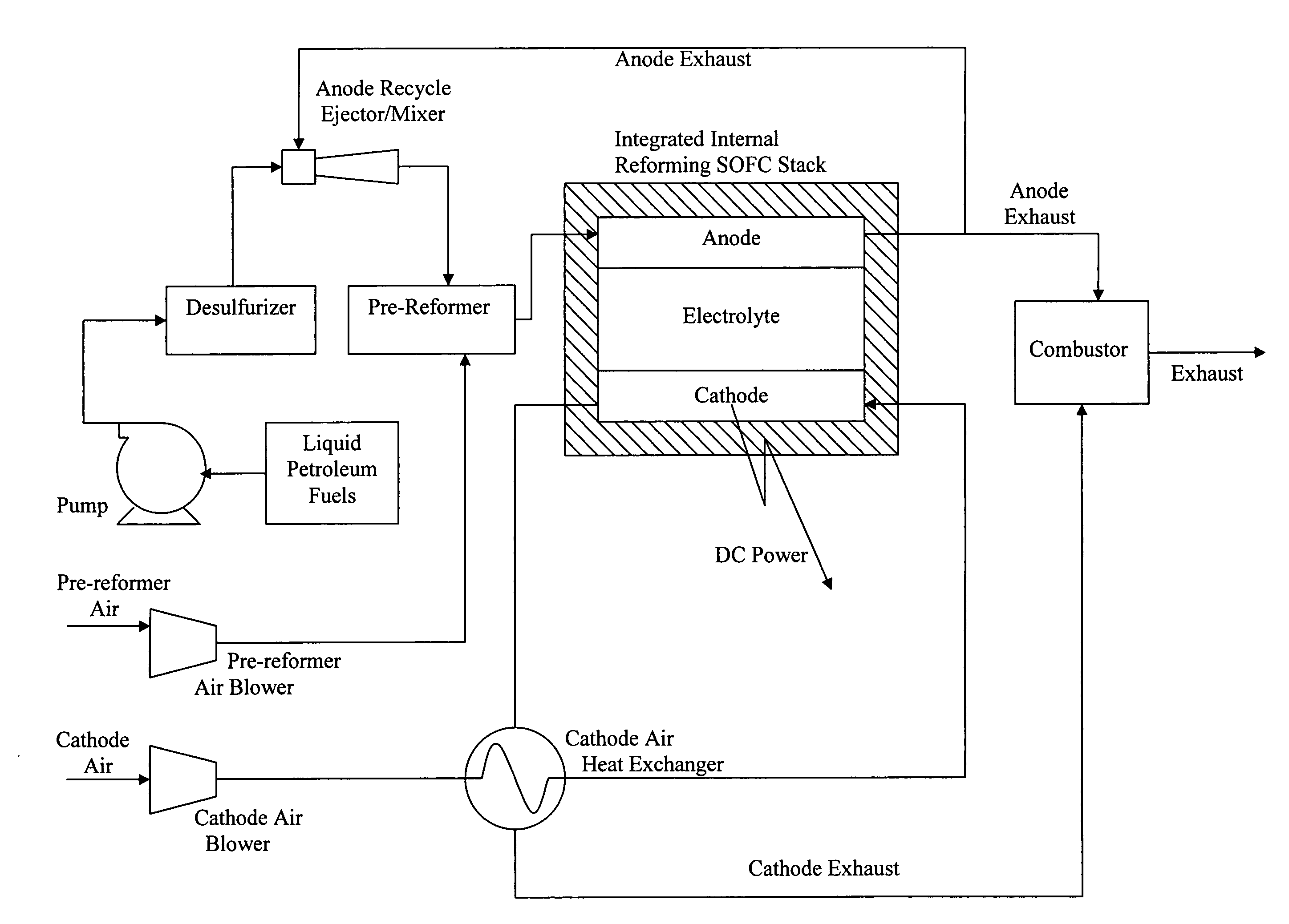

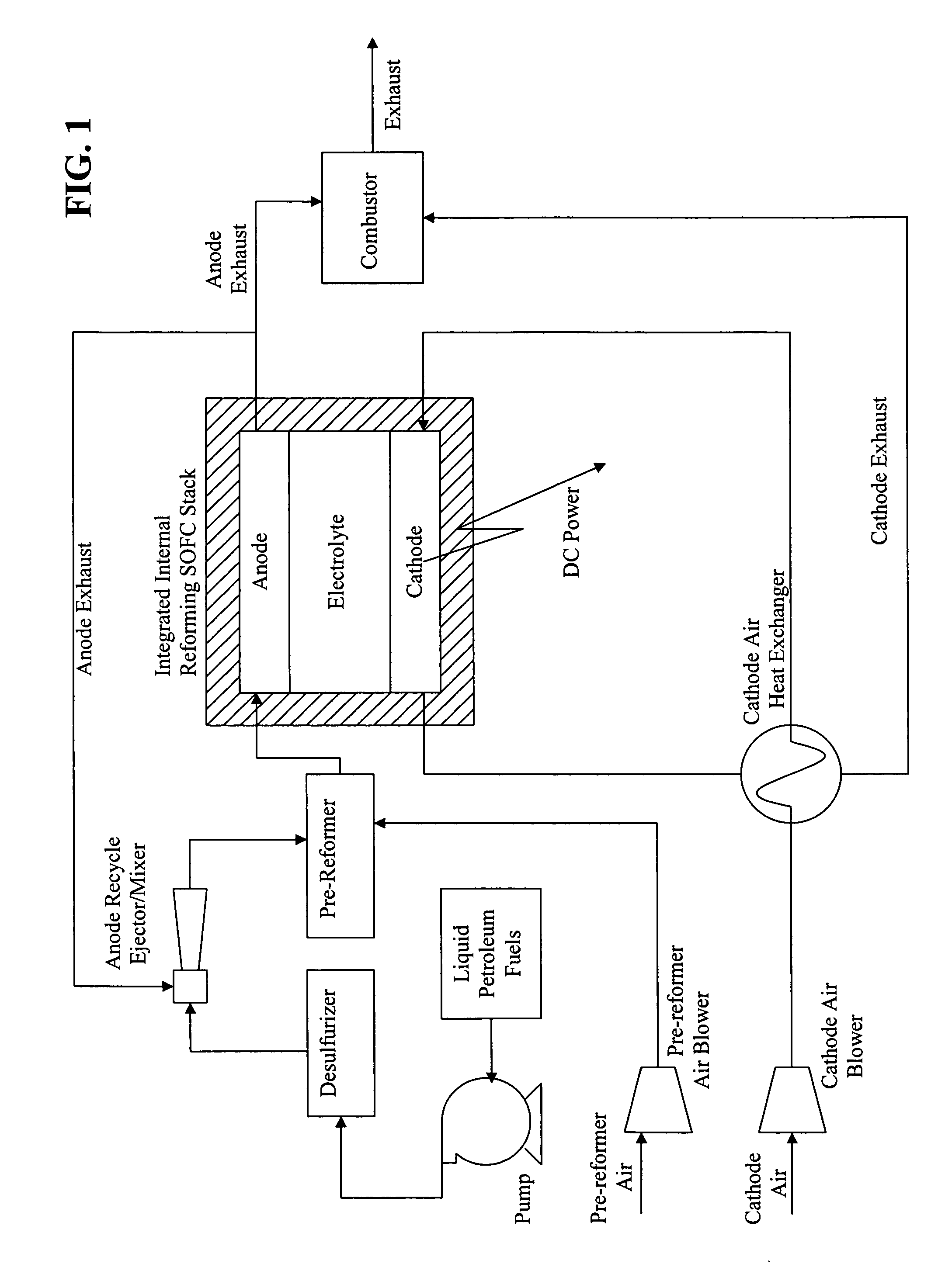

Process for the conversion of oil-based liquid fuels to a fuel mixture suitable for use in solid oxide fuel cell applications

ActiveUS20080107932A1Stable internal performanceMitigate carbon formationHydrogenEnergy inputElectricityFuel cells

Processes for generating electricity using a solid oxide fuel cell are disclosed. The processes are controlled by adjusting the hourly spaced velocity of the hydrocarbon feed through the solid oxide fuel cell. Hydrocarbon fuel is transported at an hourly spaced velocity through a pre-reformer having a catalyst. The hydrocarbon fuel is contacted with the catalyst for a residence time and at a temperature such that a catalyzed hydrocarbon fuel is formed. The hourly spaced velocity determines the residence time of the hydrocarbon fuel in the pre-reformer. The resultant catalyzed hydrocarbon fuel contains at least one gas including one or more of hydrogen gas, methane gas, carbon monoxide gas, or combinations thereof The catalyzed hydrocarbon fuel is then contacted with an anode of a solid oxide fuel cell for a residence time to produce electricity.

Owner:SAUDI ARABIAN OIL CO

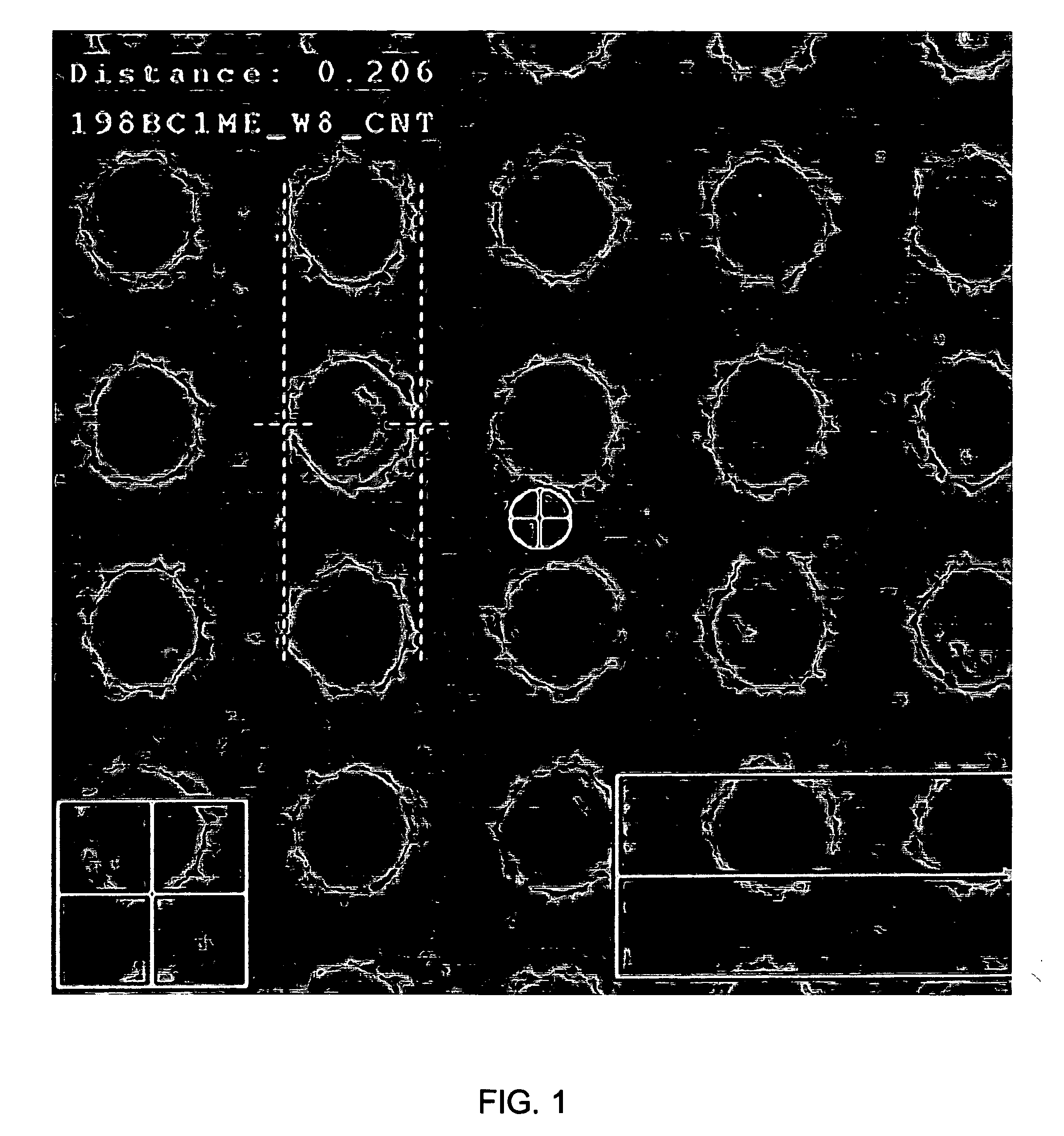

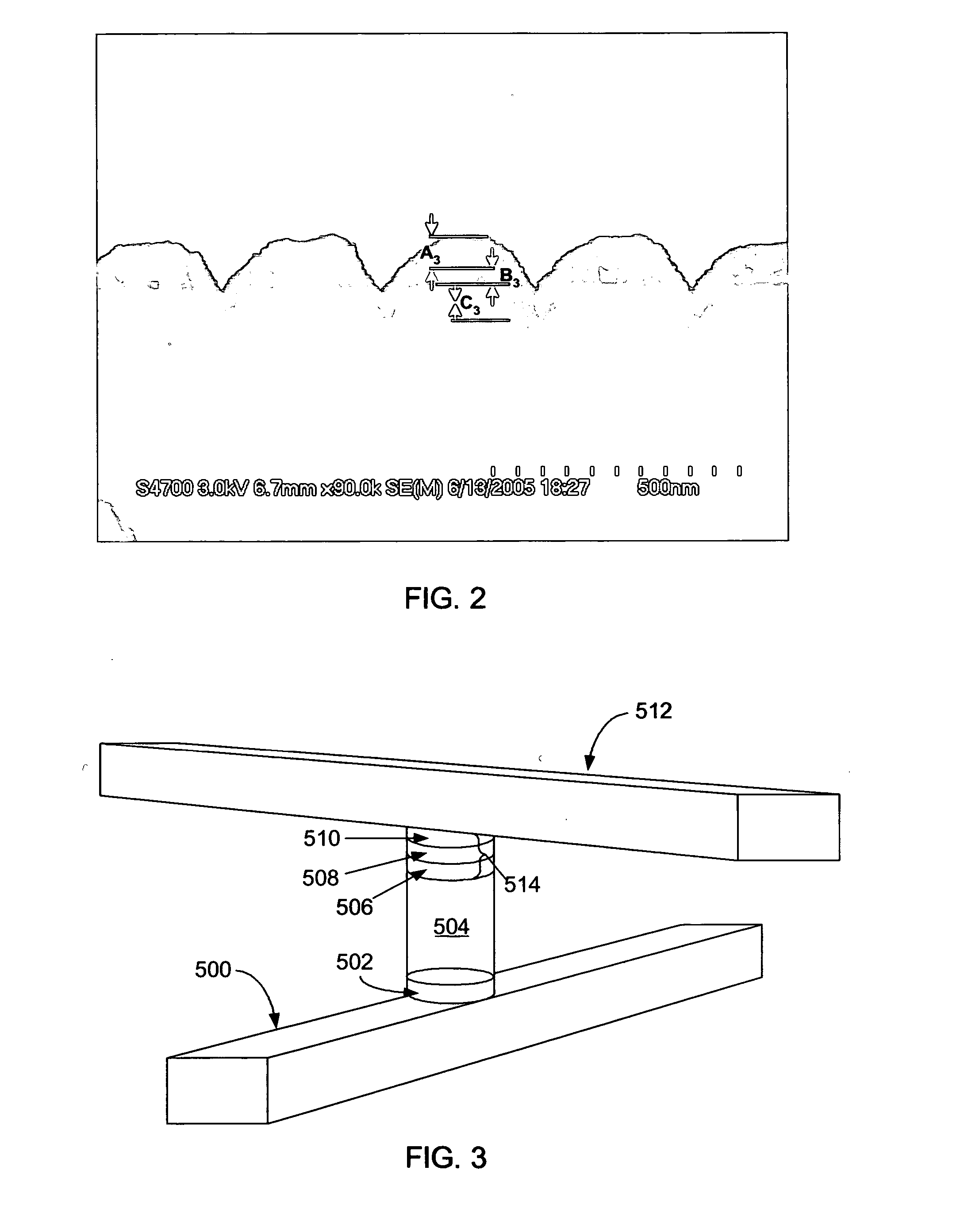

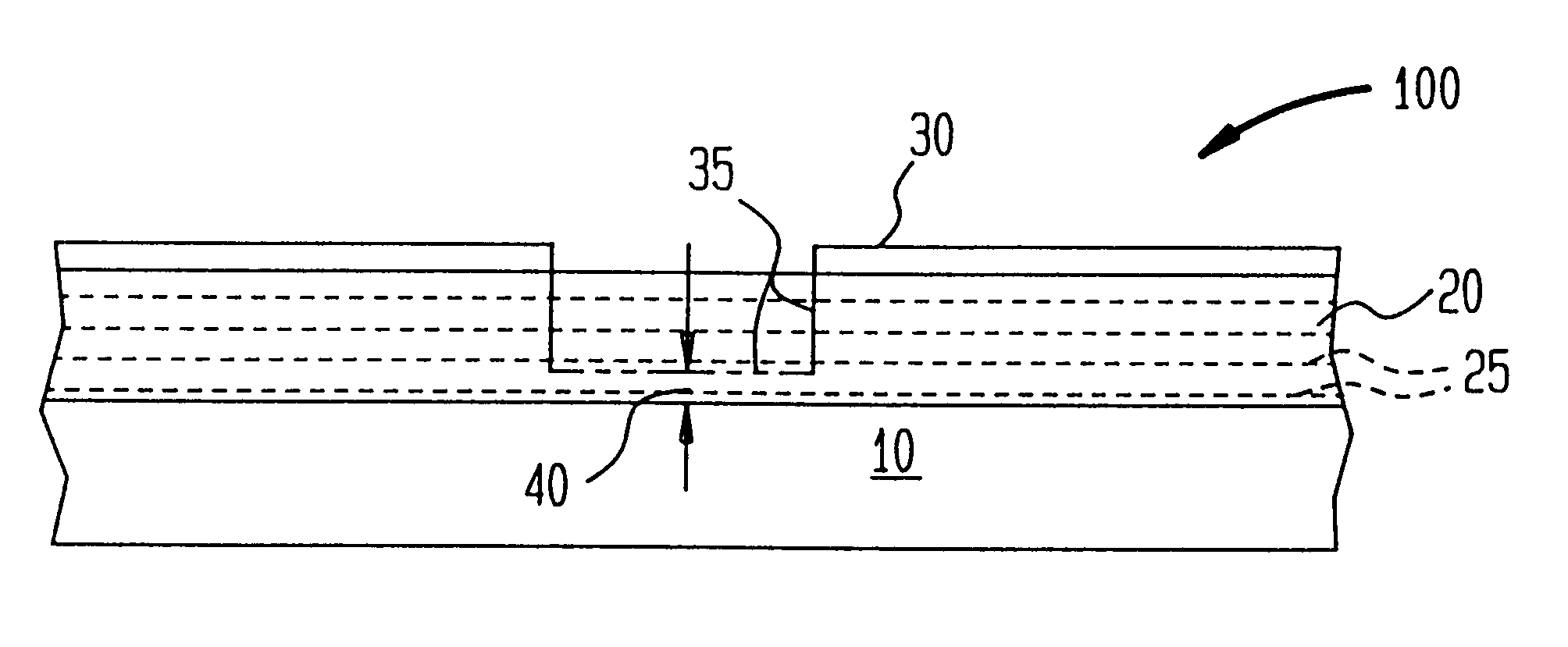

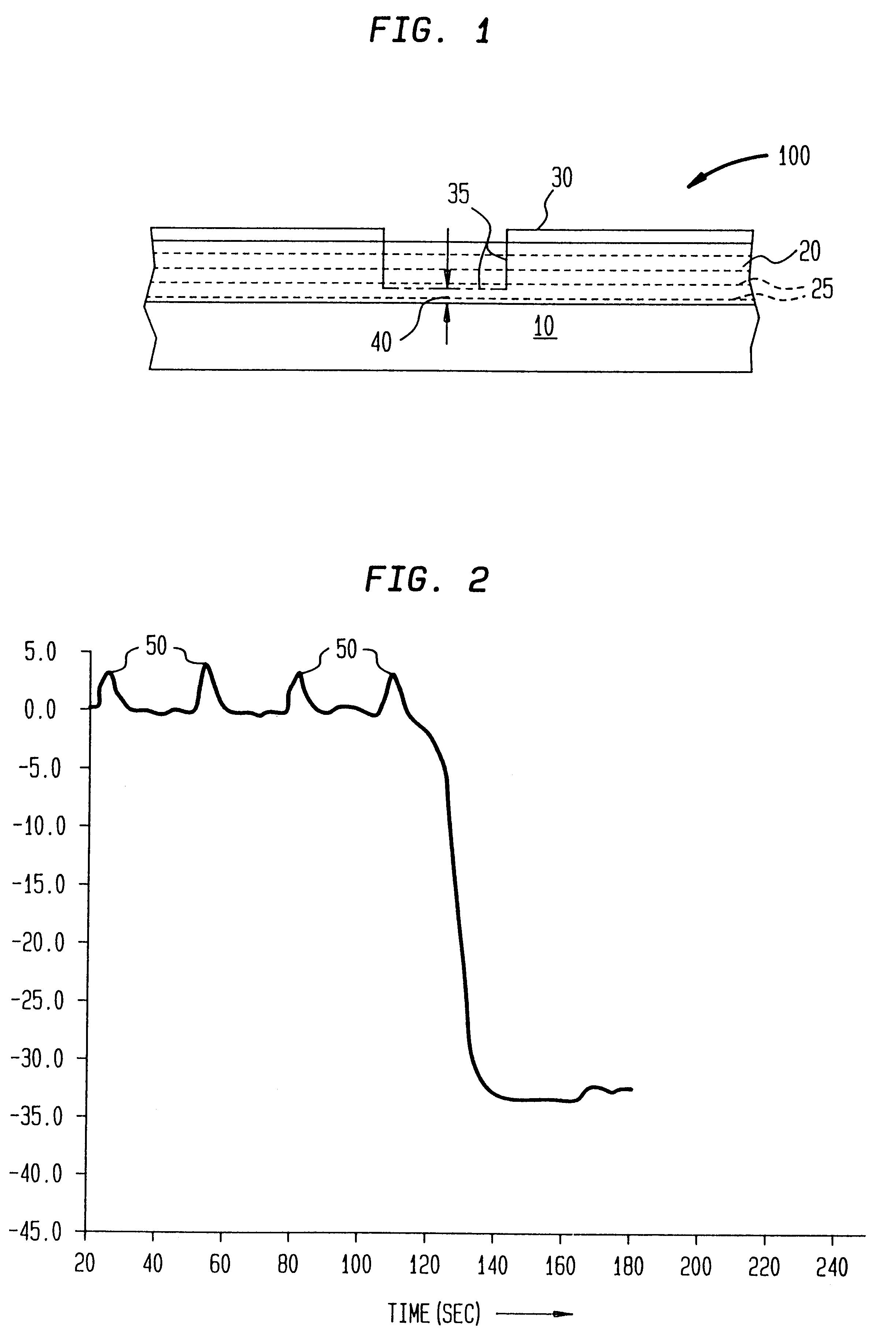

Precise endpoint detection for etching processes

InactiveUS6258497B1Electric discharge tubesVacuum gauge using ionisation effectsGas phaseDislocation

A homogeneous marker is formed, possibly by the adsorption of trace amounts of an ambient material such as carbon monoxide gas, at a surface of a deposited material when the plasma in momentarily interrupted during plasma enhanced chemical vapor deposition or other deposition processes involving the presence of a plasma. When the deposited material is etched, the resulting crystal dislocations or adsorbed gas is detected as a marker by optical emission spectroscopy techniques. The accuracy of an end point determination of the etching process can be increased by providing a sequence of such markers within the bulk or volume of the deposited material. The markers, being merely an interface such as a slight crystal dislocation in otherwise homogeneous material, do not affect the electrical, chemical or optical properties of the remainder of the predetermined deposited material and thus the homogeneity of the deposited material is not significantly affected.

Owner:IBM CORP

Method for producing low-sulfur molten iron in one step by smelting and reducing copper slag

InactiveCN101824505ALower oxygen potentialReduce sulfur contentFluidised-bed furnacesMelting tankCyclone

The invention discloses a method for producing low-sulfur molten iron in one step by melting and reducing copper slag. The method is characterized in that the method includes the following processing steps that: the high-temperature molten copper slag is first reduced by reducing agent in a high-temperature reduction furnace, wherein, when the reduction reaction of iron is nearly finished, a certain amount of additive, which is theoretically calculated, is added in a melting bath based on the existing slag system in the reduction furnace, a jet gun is inserted into a slag-iron interface to blow carbon monoxide into the melting bath when the additive is completely molten, the blowing time is 30min to 40min, and desulphurization reaction is almost finished. The melting bath is kept still, and when slag and iron are completely separated, the high-temperature low-sulfur molten iron and the slag are respectively discharged out of a tap hole and a slag hole. In addition, after high-temperature flue gas passes through a secondary combustion chamber, a residual heat boiler recovers residual heat from the flue gas, dust is collected from the flue gas by cyclone, and the flue gas is washed. By sufficiently utilizing the high desulphurization of the refined slag and blowing the carbon monoxide, the invention solves the defect that the content of sulfur in the molten iron produced by melting and reducing the copper slag for ironmaking is high; the processing flow is short, the emission of pollutant is less, and moreover, the applicability is high.

Owner:KUNMING UNIV OF SCI & TECH

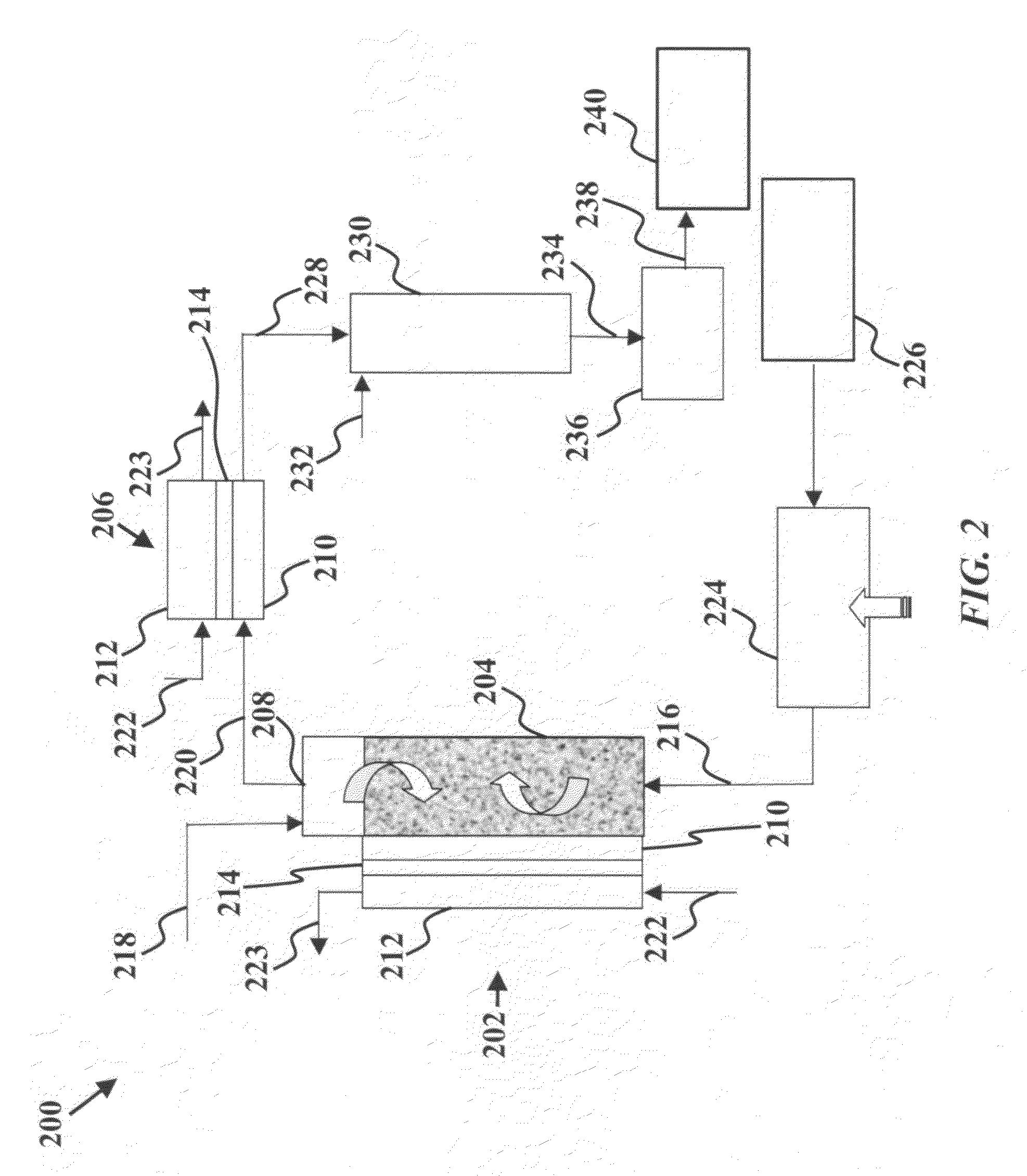

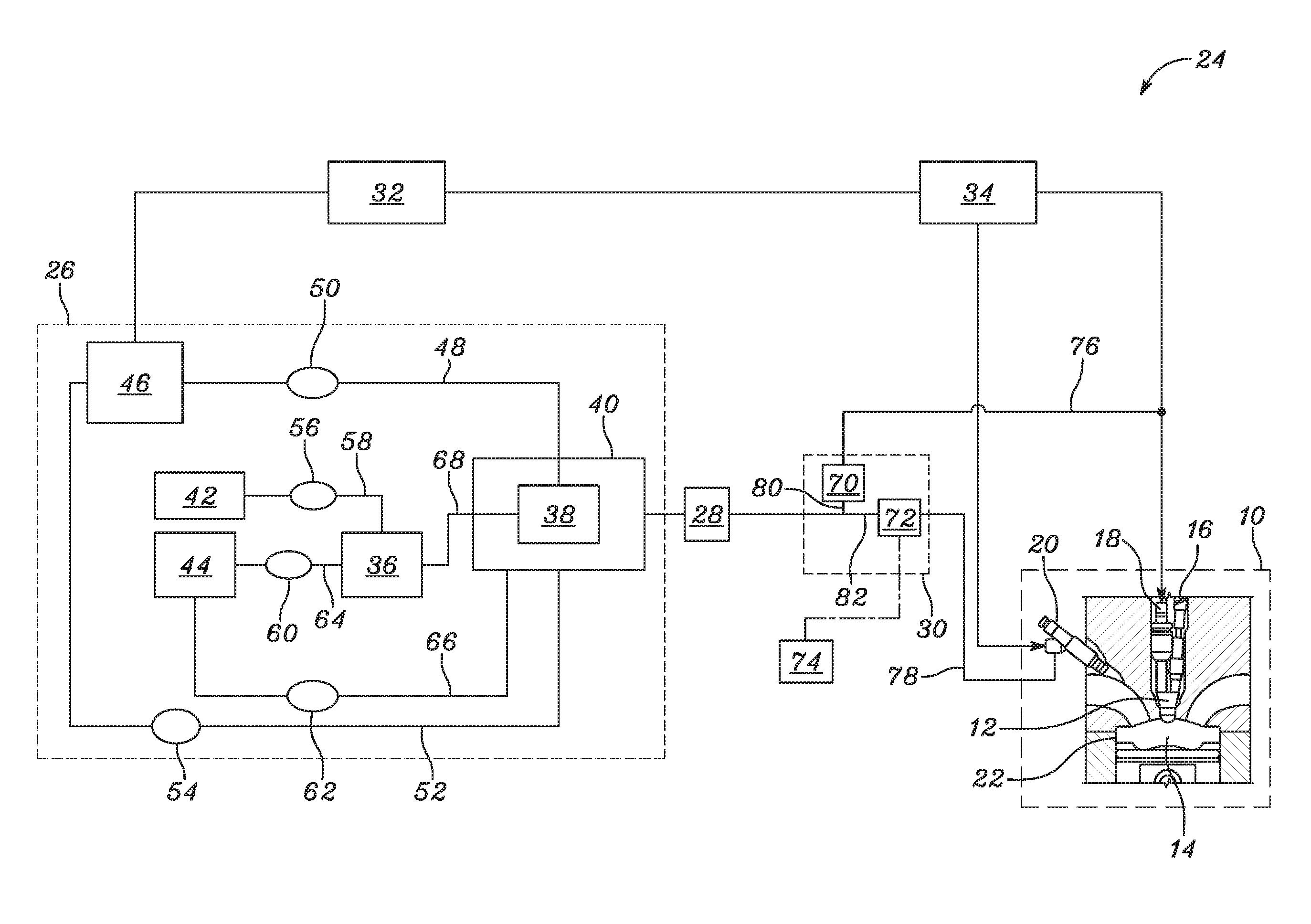

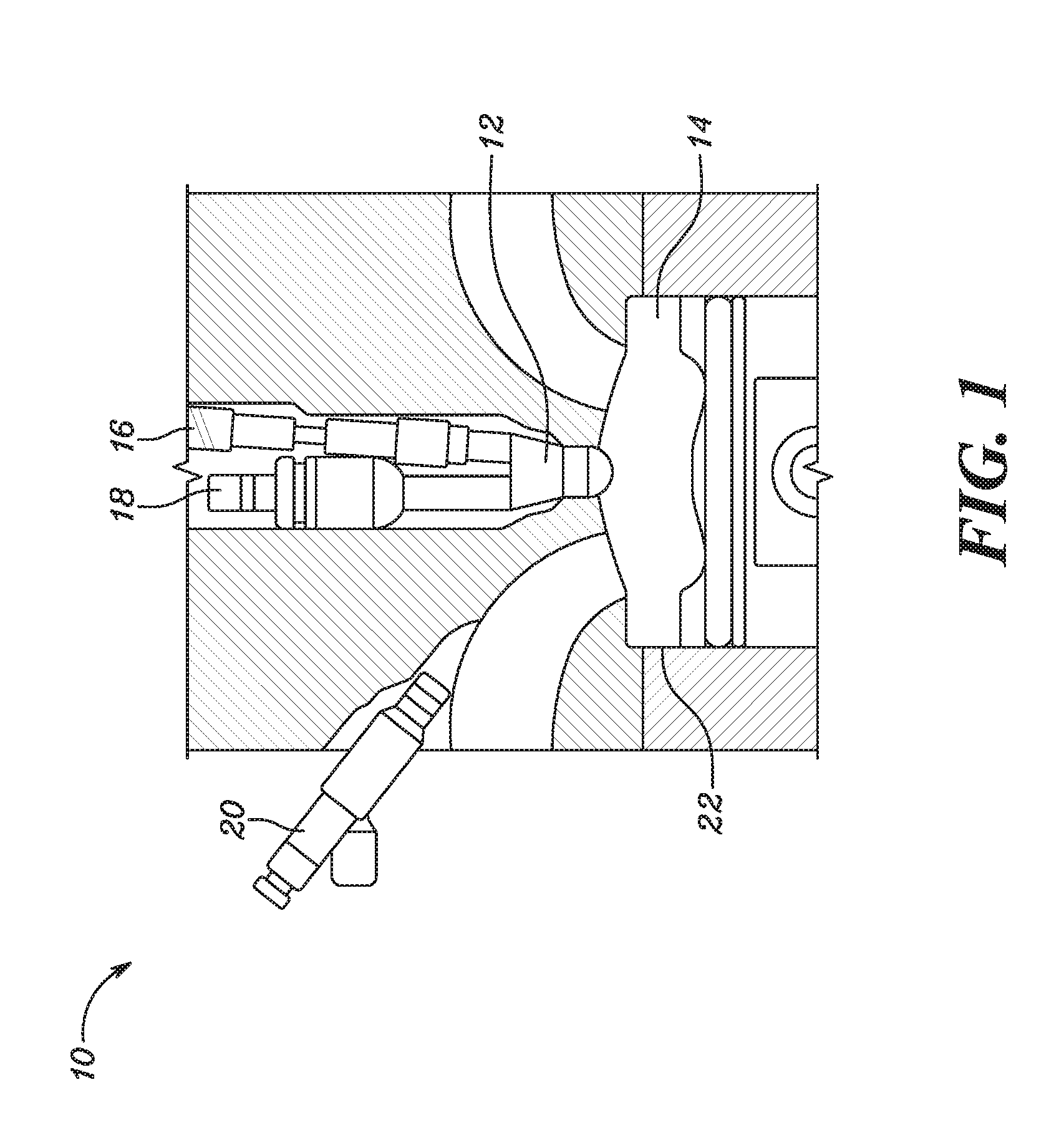

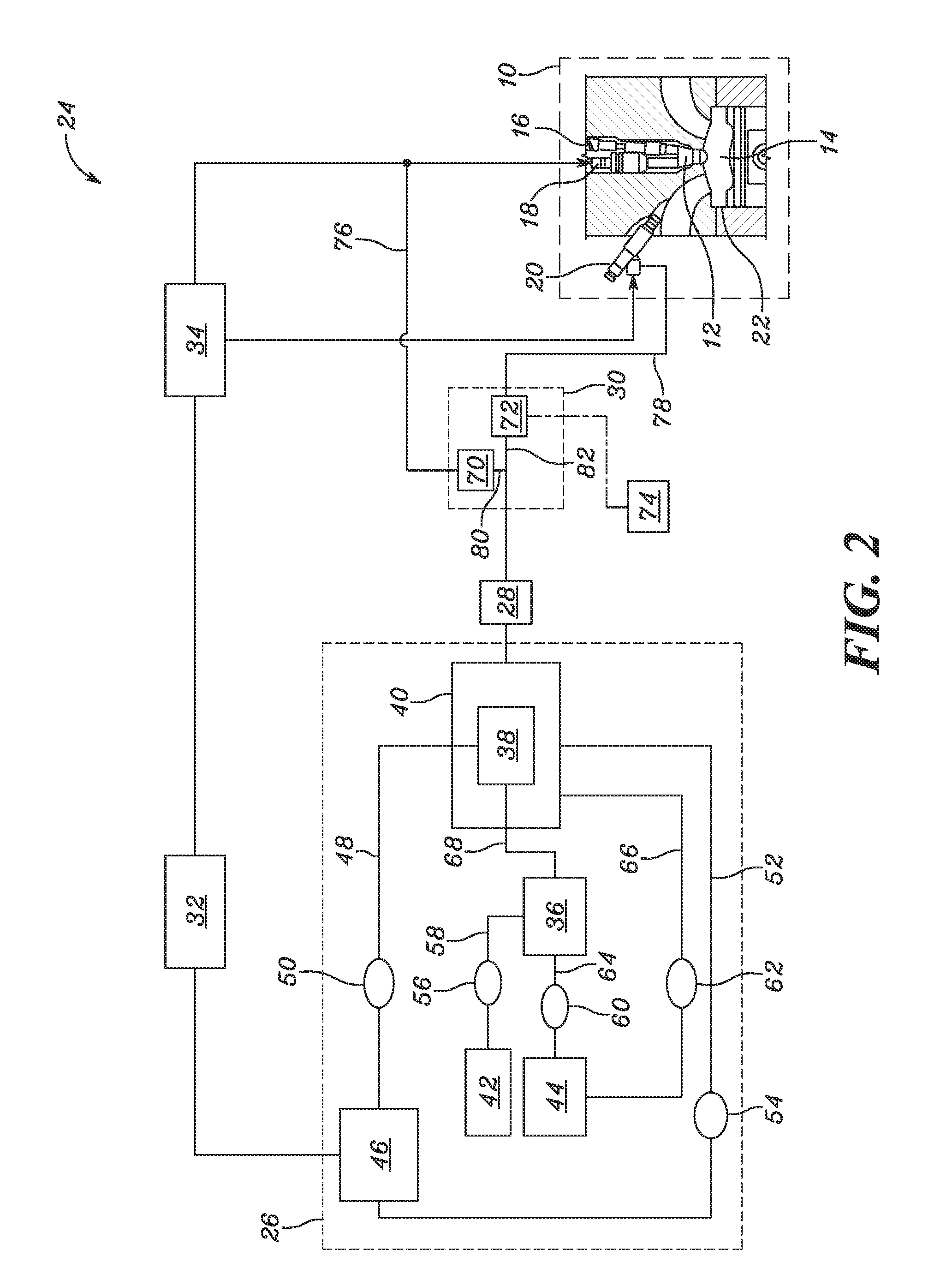

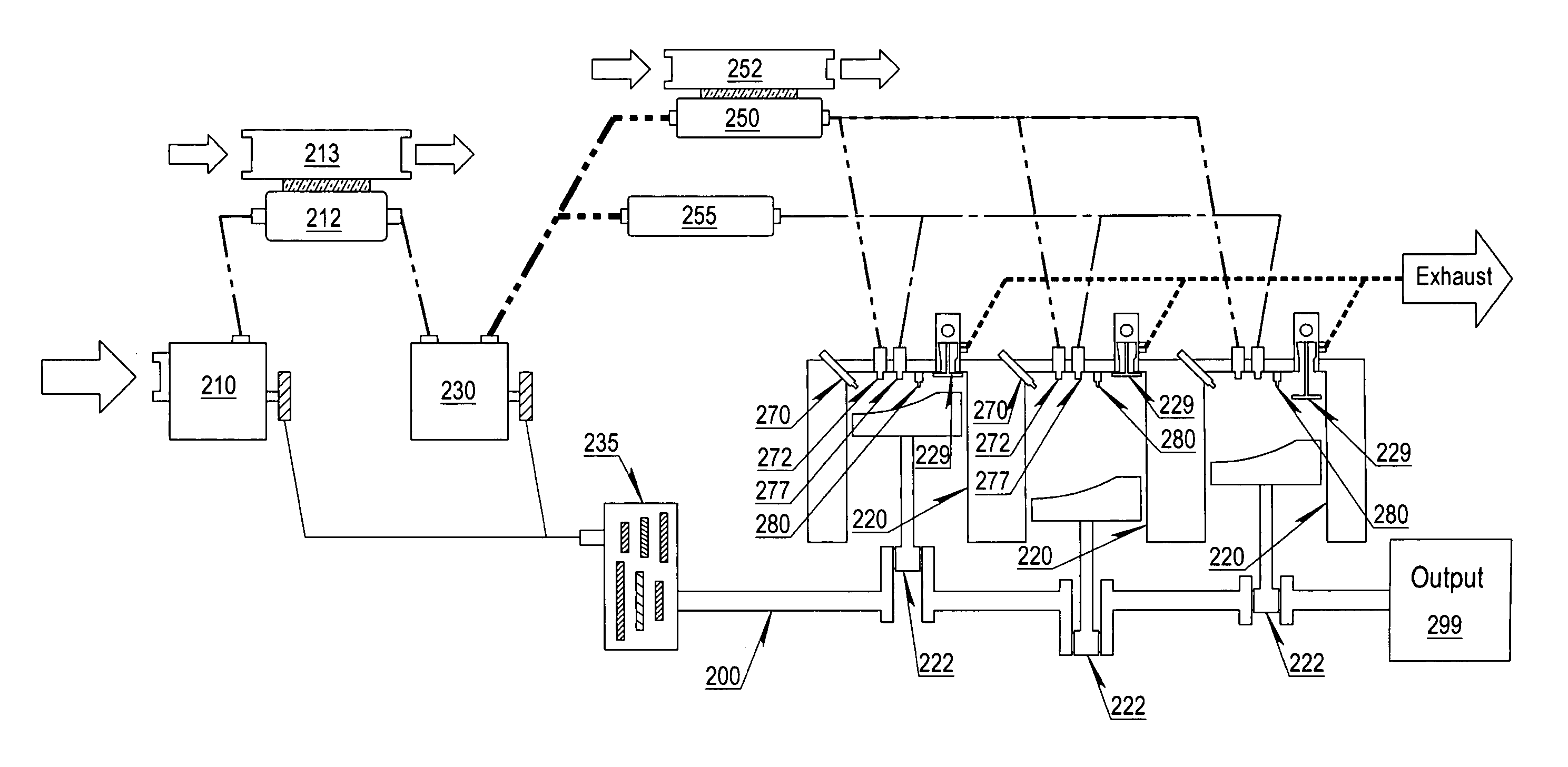

Fuel reformer system for multiple combustion chambers

A system for controlling a flow of a gas stream into a plurality of combustion chambers of an engine is provided. The system comprises a fuel reformer module configured to provide the flow of the gas stream containing hydrogen gas and carbon monoxide gas, a cooler module positioned downstream of the fuel reformer module with respect to the flow of the gas stream. The cooler module is configured to control a temperature of the gas stream. A flow control assembly is positioned downstream of the cooler module and upstream of the plurality of combustion chambers with respect to the flow of the gas stream. The flow control assembly is configured to supply a first effluent stream to a pre-chamber of the plurality of combustion chambers. The flow control assembly also supplies a second effluent stream to a main chamber of the plurality of combustion chambers.

Owner:CATERPILLAR INC

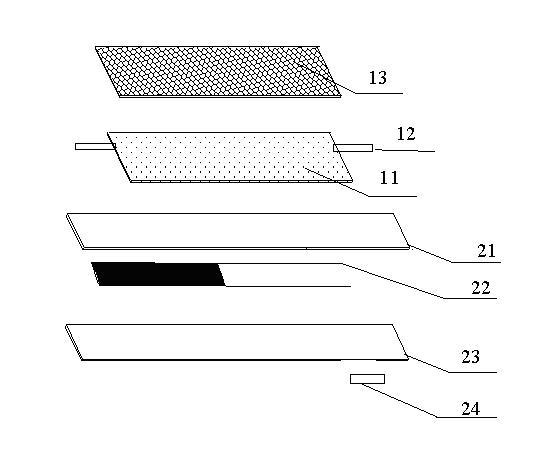

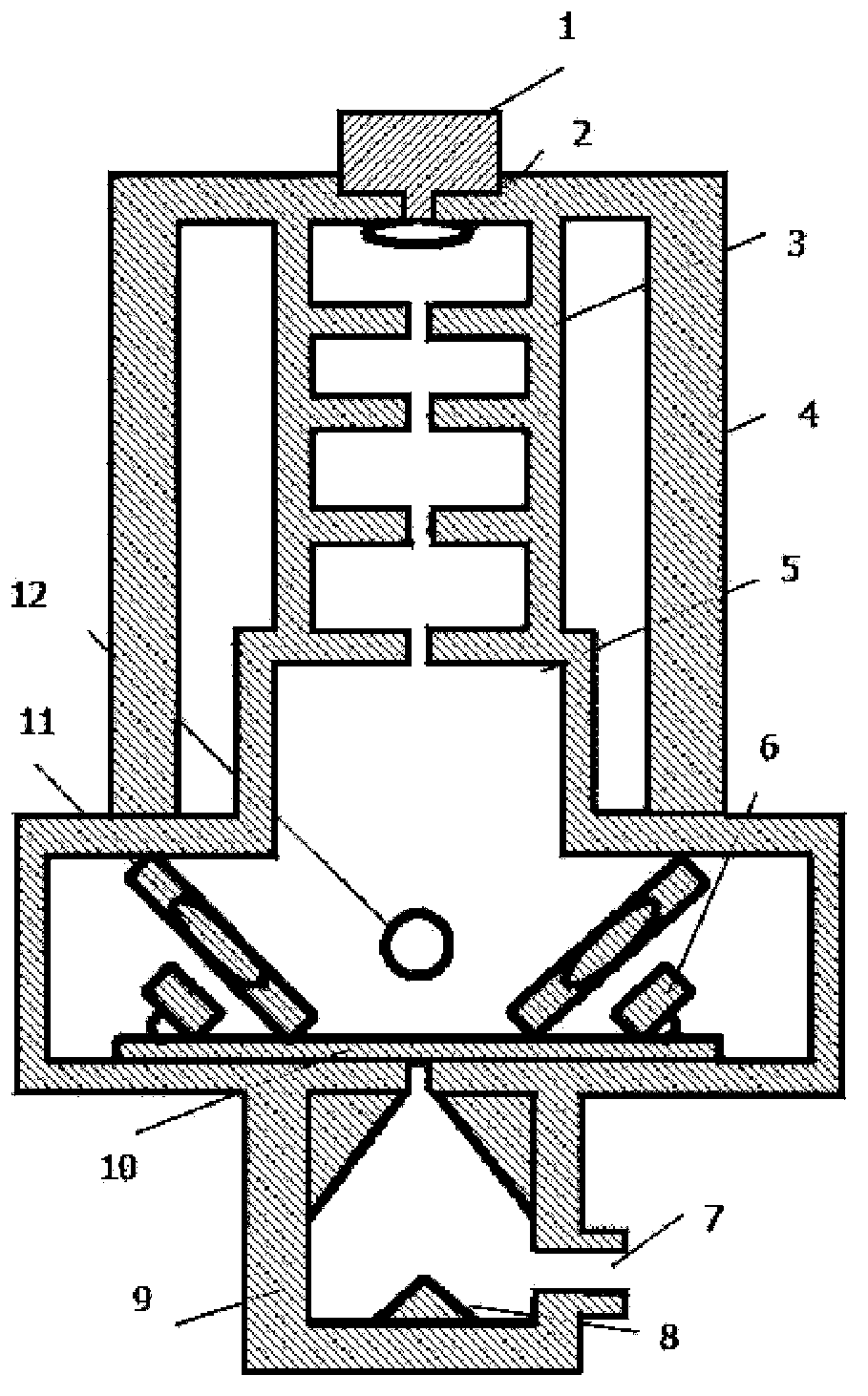

Gas sensitive material, carbon monoxide gas sensitive element adopting gas sensitive material and preparation method of carbon monoxide gas sensitive element

InactiveCN102692437AHigh sensitivityQuick responseMaterial electrochemical variablesMolecular sieveTin dioxide

The invention belongs to the field of gas sensors and relates to a novel tin dioxide gas sensitive material, a gas sensitive element adopting the novel tin dioxide gas sensitive material and a preparation method of the gas sensitive element. The tin oxide gas sensitive material consists of the following substances in percentage by mass: 88 to 94 percent of tin dioxide, 1 to 5 percent of antimony trioxide, 0.5 to 5 percent of noble metal, 0.5 to 4 percent of metallic oxides and 0.5 to 4 percent of silicon dioxide. A carbon monoxide gas sensitive element adopting the tin dioxide gas sensitive material is structurally characterized in that a bottom layer is a heating body, a gas sensitive layer made of the tin dioxide gas sensitive material is covered on the heating body, the gas sensitive layer is connected with a lead wire, and a ceramic molecular sieve is covered on the gas sensitive layer. The carbon monoxide gas sensitive element adopting the tin dioxide gas sensitive material has the advantages that the sensitivity is high, the response is fast, the measuring range is wide, the size is small, the service life is long, and the cost is low.

Owner:惠州市富济电子材料有限公司

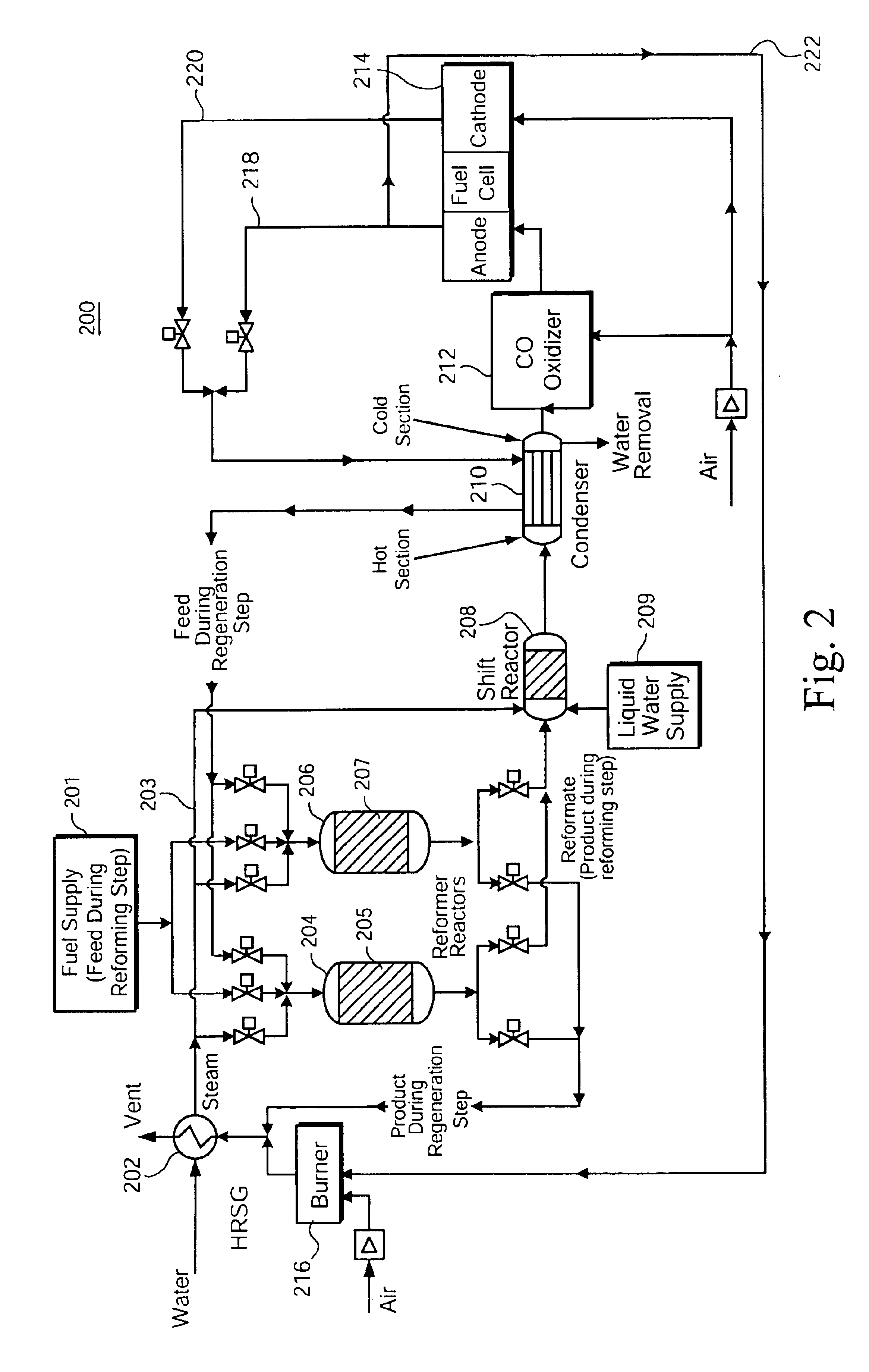

Fuel processor apparatus and method based on autothermal cyclic reforming

InactiveUS6878362B2Improve efficiencyLower cost of capitalHydrogenHydrocarbon from carbon oxidesElectrochemical responseEngineering

In a fuel processor based on autothermal cyclic reforming process, the fuel processor having a reformer, the reformer having two reactors with integrated heat exchangers, the two reactors cycling between a reforming step and a regeneration step, a method of generating hydrogen gas includes receiving a mixture of fuel and steam in the reformer reactor operating in a reforming step to produce hydrogen-rich reformate gas. The fuel is delivered from a fuel supply and the steam is generated by a heat recovery steam generator (HRSG). The reformate gas is fed to a shift reactor to reduce the concentration of carbon monoxide (CO) gas present in the reformate gas. Product gas generated by the shift reactor is received in a condenser to recover heat from the product gas. In one embodiment output gas stream from the condenser is supplied to a CO oxidizer to further reduce the CO concentration. The output gas stream from the CO oxidizer is supplied to an anode of a fuel cell, the fuel cell including a cathode for receiving ambient air to initiate an electrochemical reaction with the gas stream received by the anode. In another embodiment the output gas stream from the condenser is supplied to a Pressure Swing Adsorber (PSA). The output gas is high-purity hydrogen which can be utilized for industrial hydrogen or hydrogen vehicle refueling applications.

Owner:GENERAL ELECTRIC CO

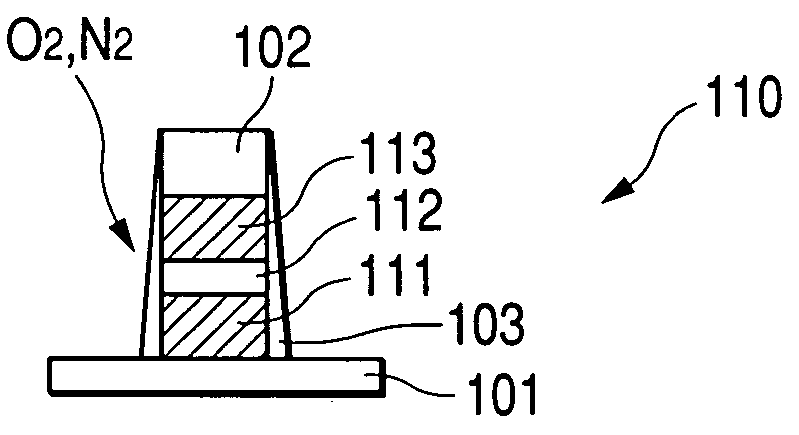

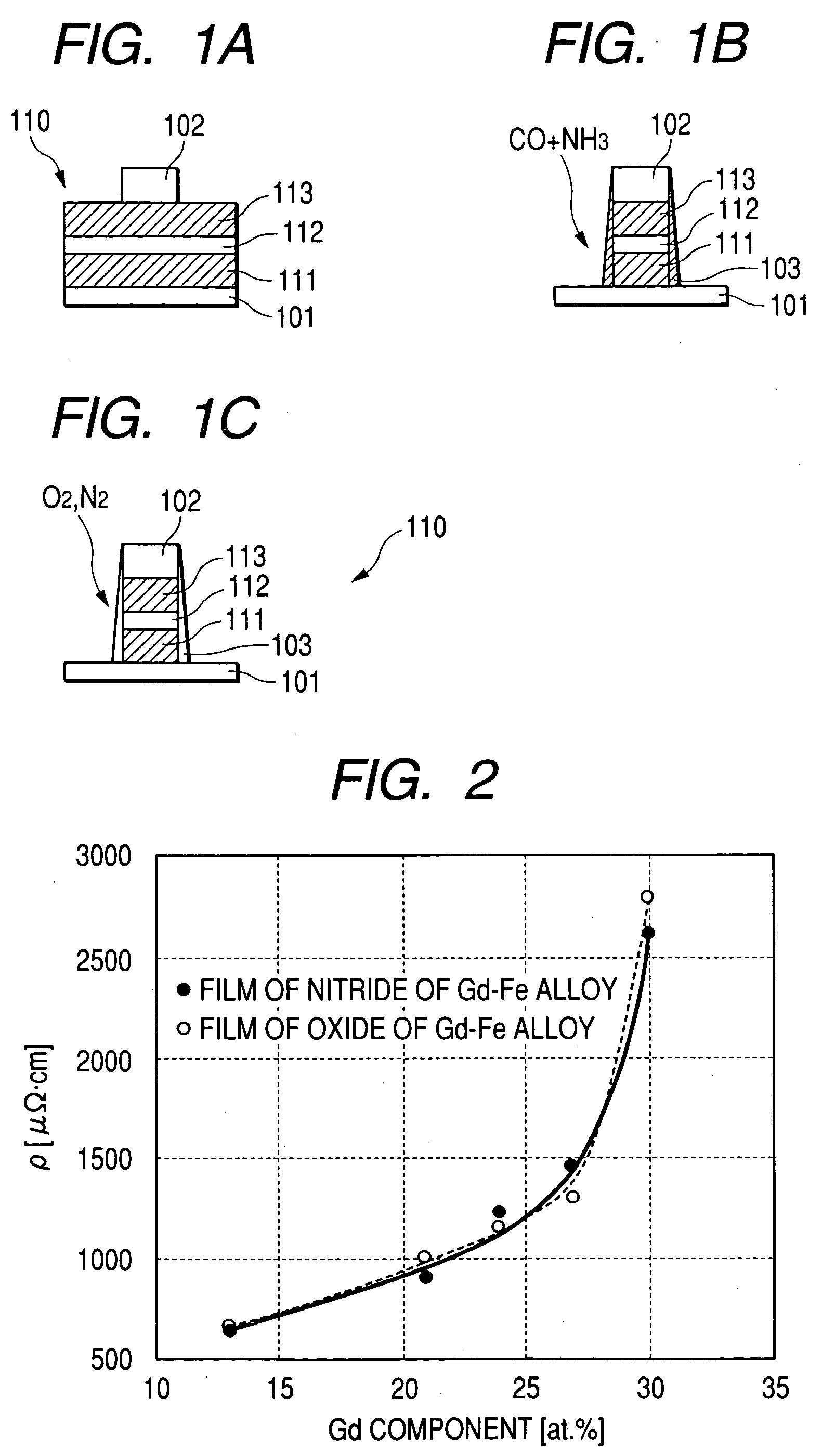

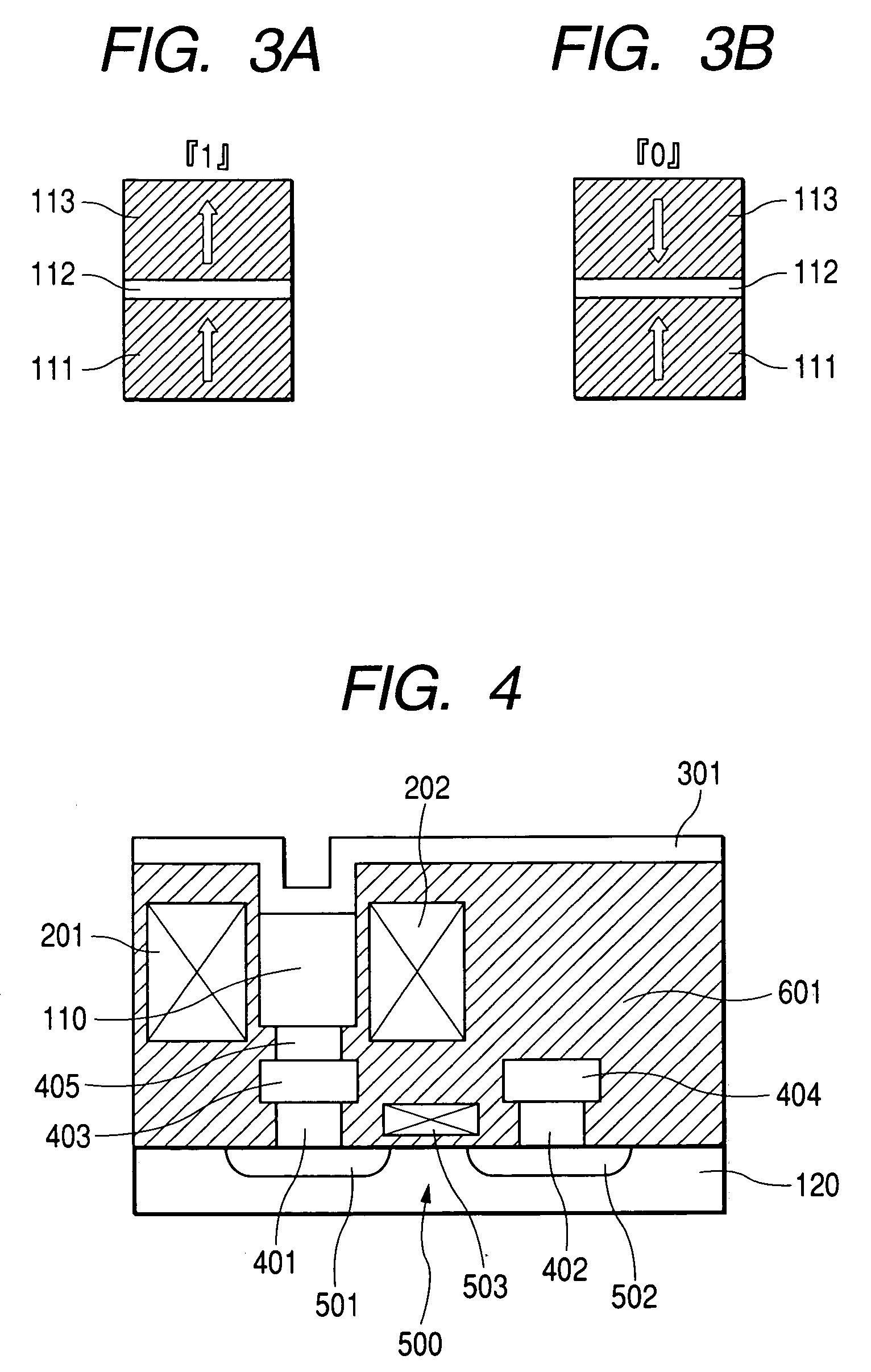

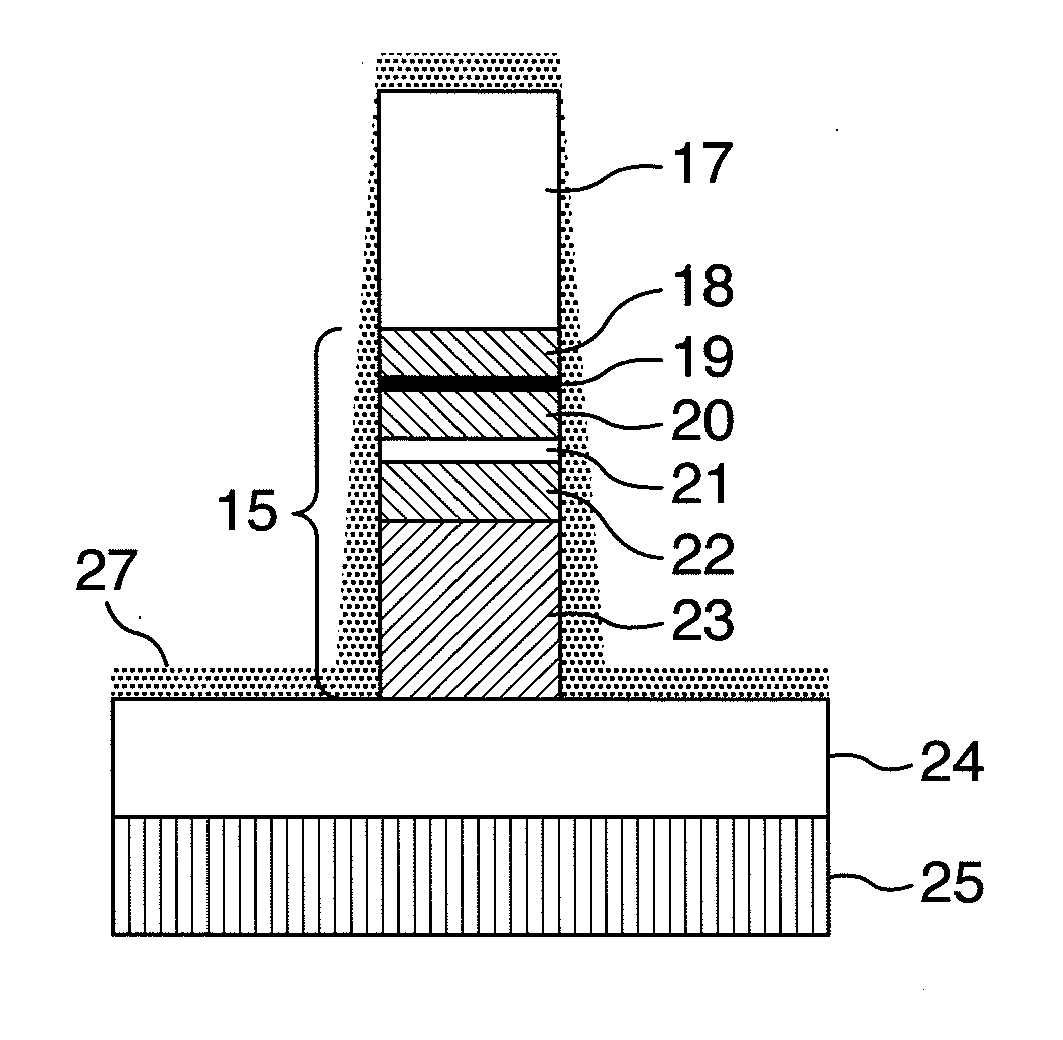

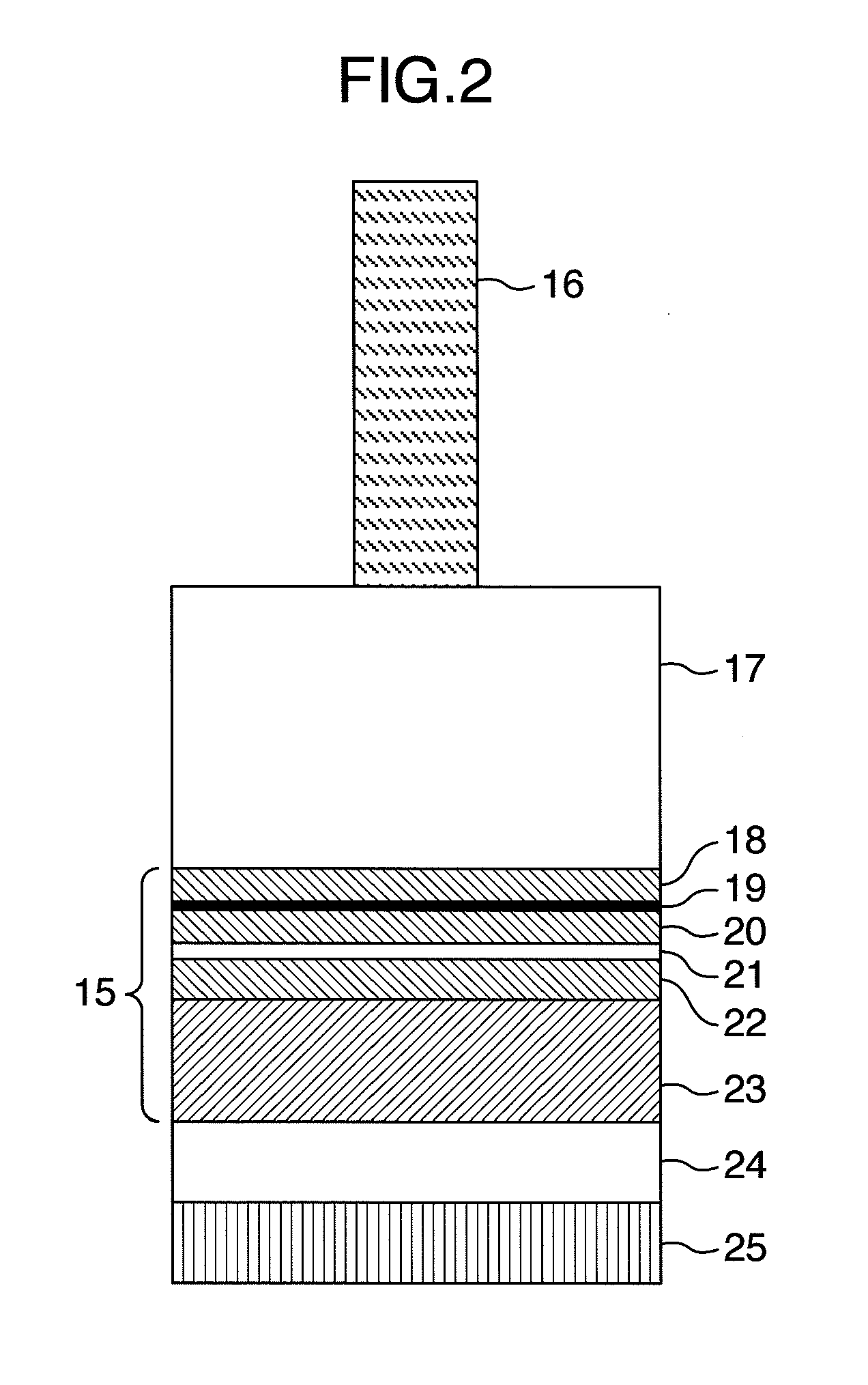

Method of etching magnetic material, magnetoresistive film and magnetic random access memory

ActiveUS20050048675A1Decreases ratio of componentReduce the ratioNanostructure applicationNanomagnetismResistRare earth

Provided are a method of etching a magnetic material which enables a current flowing via a sidewall substance to be suppressed to a greater extent, and the like. A spin tunneling magnetoresistive film 110, which comprises a first magnetic film 111, a tunnel film 112 and a second magnetic film 113, is formed on a substrate 101, and on the top surface of the spin tunneling magnetoresistive film 110 a resist film 102 having a desired shape is formed. The magnetic films 111, 113 are each an alloy film of a rare earth metal-transition metal. The spin tunneling magnetoresistive film 110 is plasma etched by using a mixed gas of carbon monoxide gas and ammonia gas. A sidewall substance 103 adhering to a side surface of the spin tunneling magnetoresistive film 110 is oxidized or nitrided by performing plasma etching by use of oxygen gas or nitrogen gas.

Owner:CANON KK

Electric vehicle

An electric vehicle is provided with a cell voltage sensor (32) and a cell temperature sensor (31) which are mounted to each cell (21); a gas temperature sensor (33), a carbon monoxide gas sensor (34), and a hydrogen gas sensor (35) which are mounted to a chamber (27); a gas temperature sensor (36), a carbon monoxide gas sensor (37), and a hydrogen gas sensor (38) which are mounted to a gas exhaust passage (28); and an air-conditioning fan (17), a channel-switching damper (19), and a driving motor (42) which lowers a window glass (41). When battery state values detected by the sensors (31) to(38) exceed predetermined thresholds, a battery pack (20) is judged to be abnormal. Then, the channel-switching damper (19) and the air-conditioning fan (17) are started and the window glass (41) is lowered to ventilate the vehicle interior. This speedily exhausts smoke generated from a lithium ion battery.

Owner:TOYOTA JIDOSHA KK

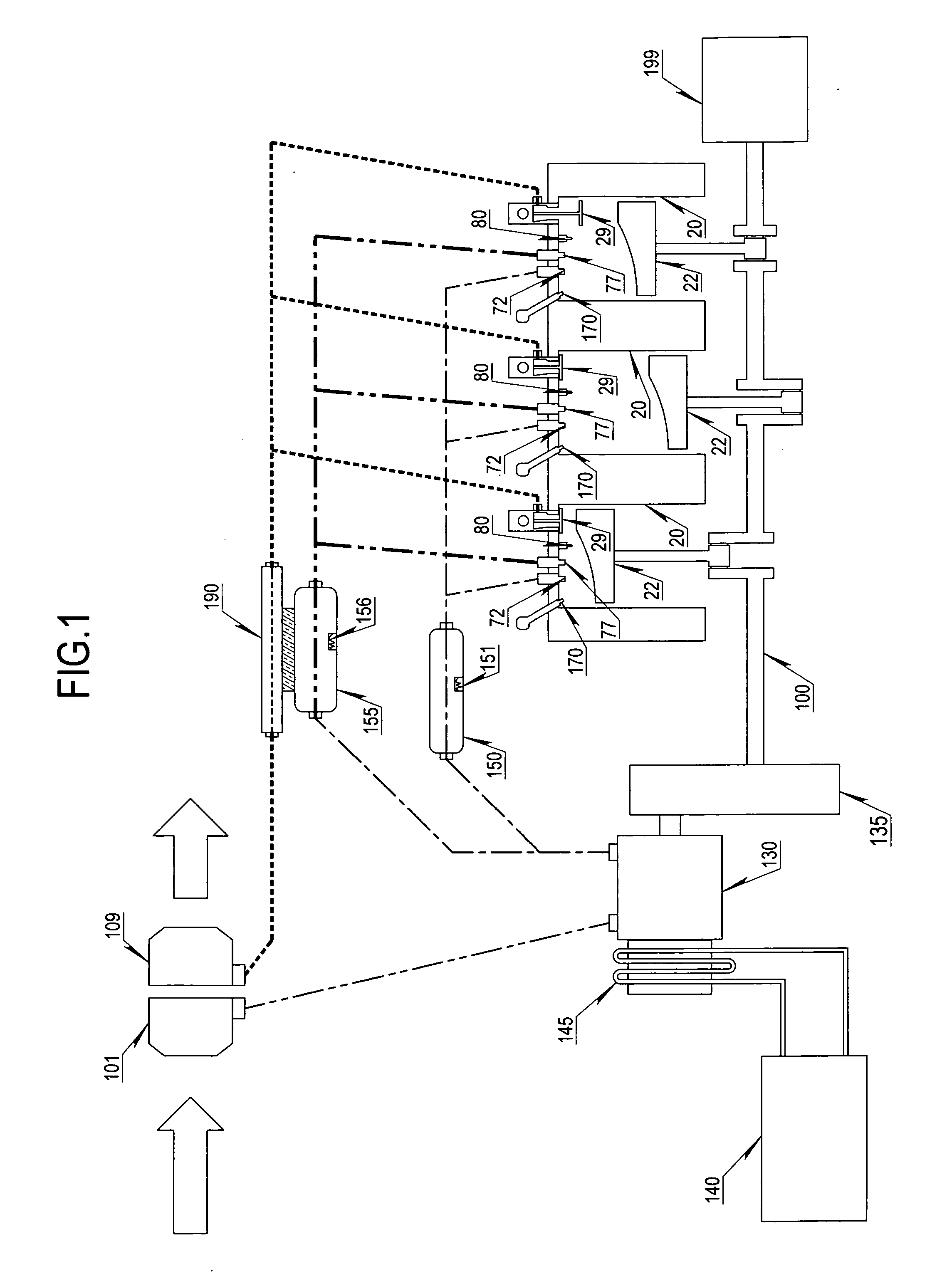

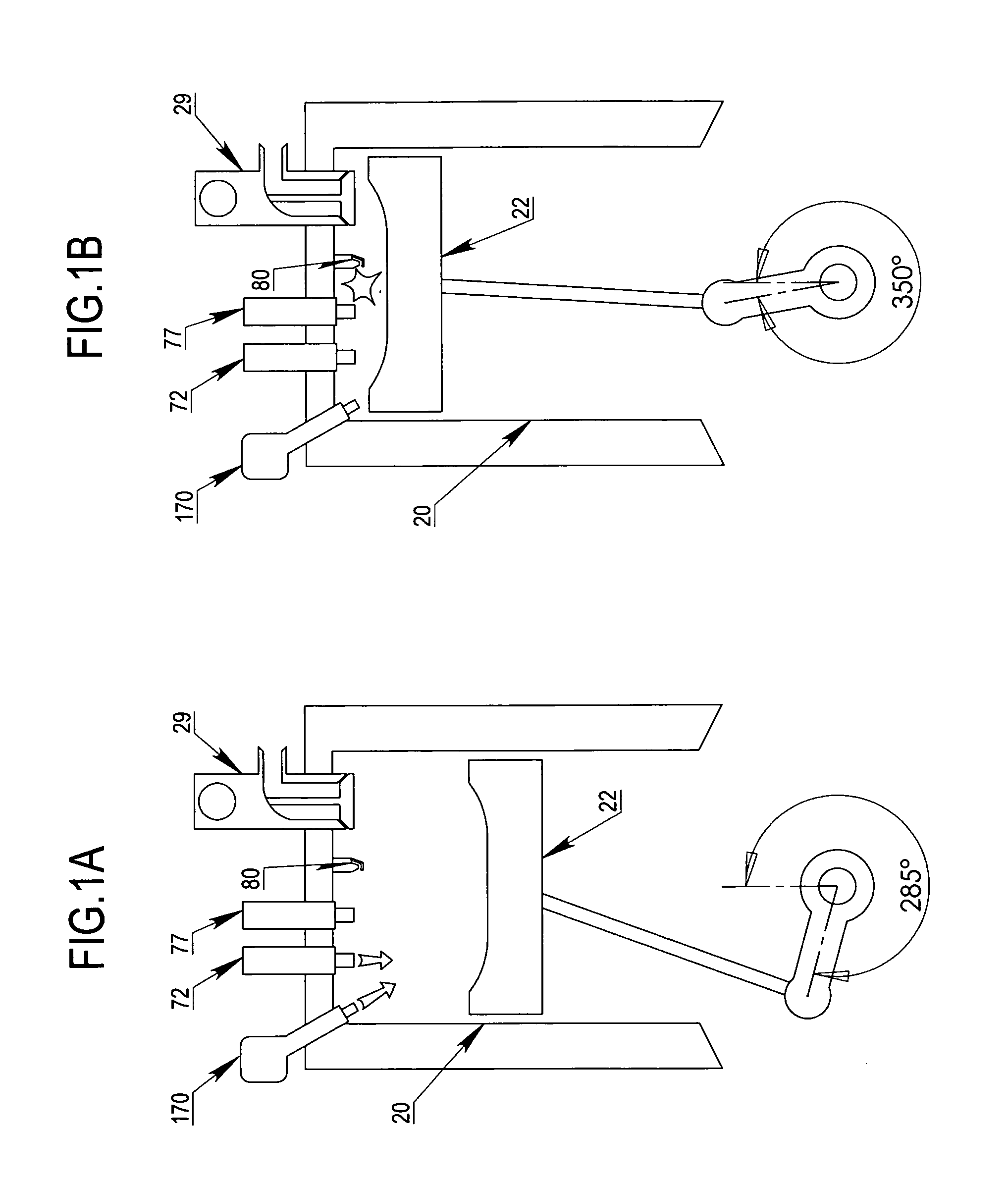

Mackay cold-expansion engine system

InactiveUS20110251743A1Improve expansion efficiencyImprove energy efficiencyElectrical controlInternal combustion piston enginesThermal energyEngineering

The present invention provides an integrated engine system; said integrated engine system includes an air-compression means, an air-buffer-system, a power-management-unit, and at least two cold-expansion-chambers; wherein each of said at least two cold-expansion-chamber includes a spark-ignition means, a fuel-supplying means, a cold-air-injection means, and a reenergize-air-injection means; each cold-expansion-chamber operates in a Mackay Cold-Expansion Cycle, which includes a first-intake-process, a hot-combustion-process, a fuel-cooling-process, a second-intake-process, a cold-expansion-process, and an active-exhaust-process; wherein the fuel-cooling-process may be disabled according to the operation condition.The air-buffer-system buffers a cooled high-boost-air for said cold-air-injection means and a heated high-boost-air for said reenergize-air-injection means; said power-management-unit includes sensor means and computation circuits to drive said fuel-supplying means, said cold-air-injection means, said reenergize-air-injection, and said spark-ignition means in order to maximize the energy efficiency of the Mackay Cold-Expansion Cycle, such that a cold-expansion-medium produces power in a controlled-temperature oxygen-rich condition; wherein the average medium temperature is reduced by 30%-80% to block heat-loss during the second-intake-process, and all the carbon-monoxide-gas of said cold-expansion-medium is spontaneously reacted with an excessive oxygen-gas during the cold-expansion-process, thereby fully releasing the energy of the supplied fuel by an accelerated conversion of carbon-dioxide-gas before the cold-expansion-medium is expelled out of the associated cold-expansion-chamber; wherein, the average temperature of said cold-expansion-medium is regulated within the range of 400-1100 degree Celsius by the power-management-unit, in order to efficiently produce power at a slowly-decreasing expansion pressure with the least heat-loss.Furthermore said air-buffer-system recovers the thermal energy from a heat-transfer-catalytic-converter, which utilizes the thermal energy of the expelled cold-expansion-medium to heat up a high-boost-air for the second-intake-process; thereby the energy efficiency is increased in a heavy load operation by reducing the workload on the air-compression means, and the temperature of the expelled cold-expansion-medium is maintained at an operable temperature of the catalytic-conversion means in a light load operation without comprising the energy efficiency.

Owner:HU LUNG TAN +1

Preparation method of long-afterglow luminescent material zine phosphate

InactiveCN1443827ASimple preparation processVariety of afterglow colorsLuminescent compositionsPhosphateNitrogen gas

The present invention relates to a long afterglow luminous material zinc phosphate. Its preparation method includes the following steps: mixing the carbonates, oxides, phosphates, nitrates, acetaets and sulfates of the above-mentioned elements in the representation formula as raw material to obtain their mixture, grinding said mixture and flux and uniformly mixing them; selecting air, nitrogen gas, carbon, carbon monoxide gas, hydrogen gas or nitrogen-hydrogen mixed gas, presintering at 200-600 deg.C for 2-6 hr., cooling to room temp., secondary grinding and uniformly mixing them, sintering at 500-1100 deg.C for 4-10 hr. so as to obtain said invented product.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

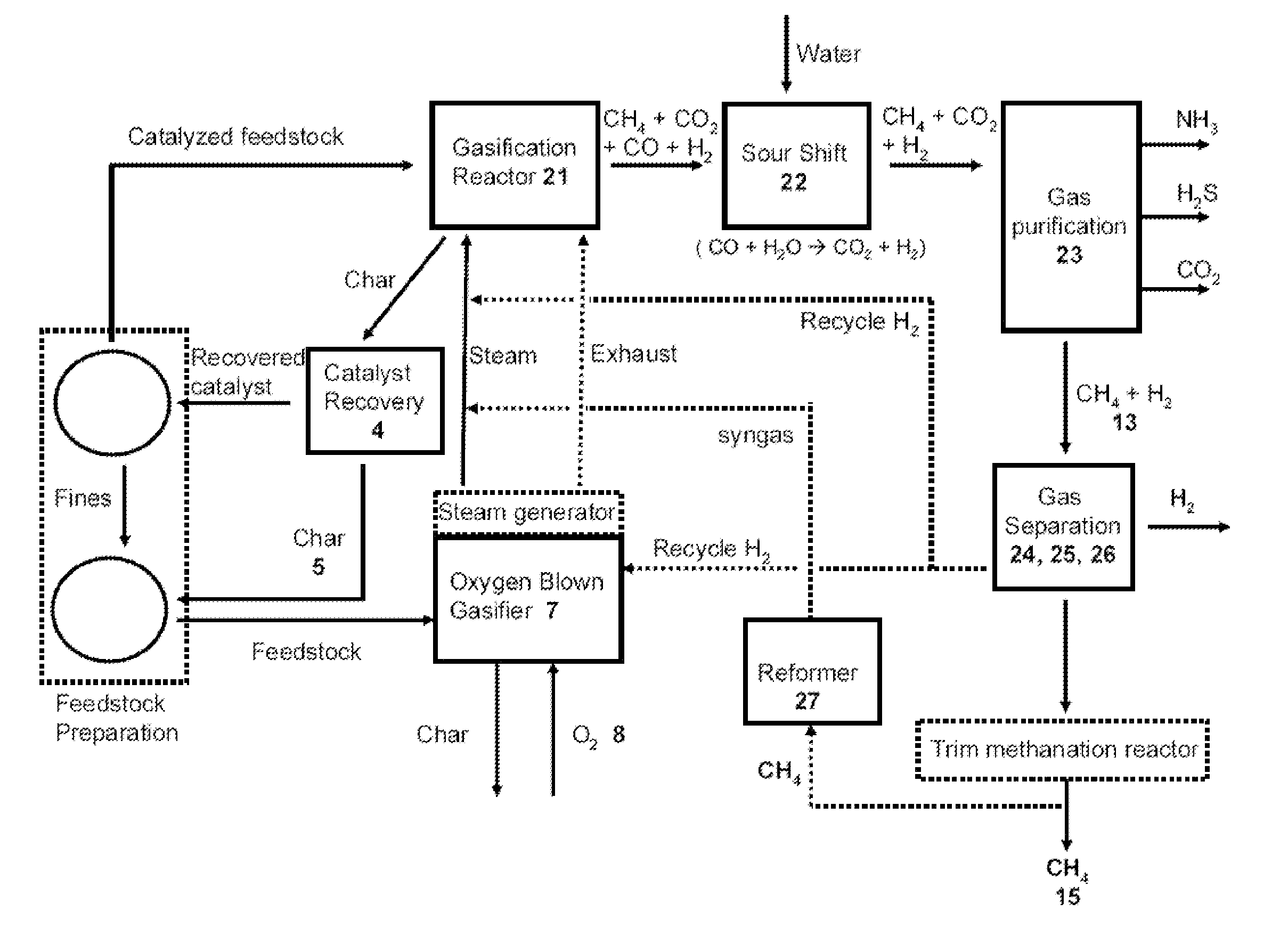

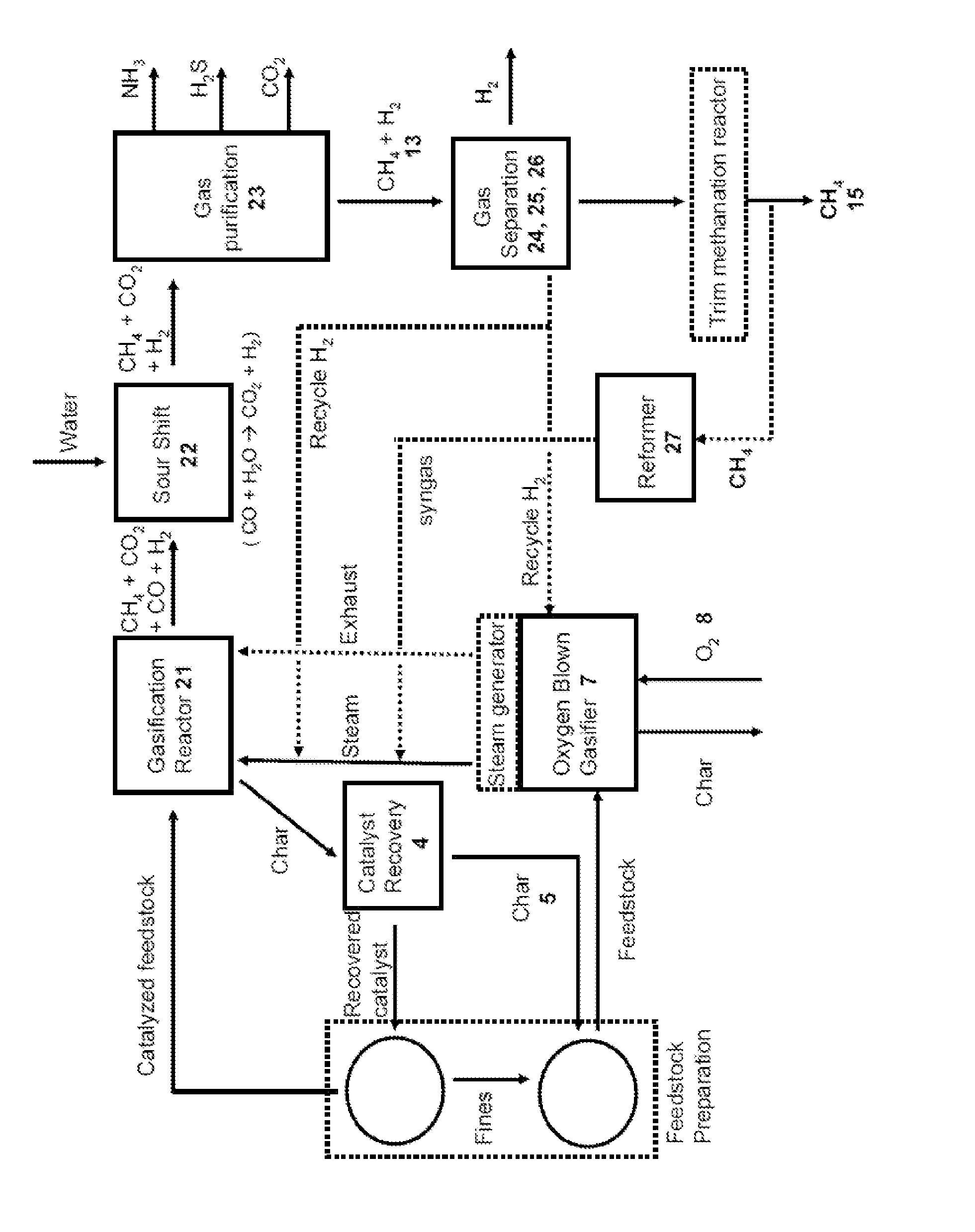

Sour shift process for the removal of carbon monoxide from a gas stream

Processes for the catalytic conversion of a carbonaceous composition into a gas stream comprising methane are provided, where a sour shift reaction is used to remove carbon monoxide gas stream produced by the gasification process. The incorporation of the sour shift reaction provides an efficient and cost-effective means of eliminating carbon monoxide from the gas stream. In addition, the sour shift reaction also generates additional hydrogen, thus increasing the amount of hydrogen produced from the gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

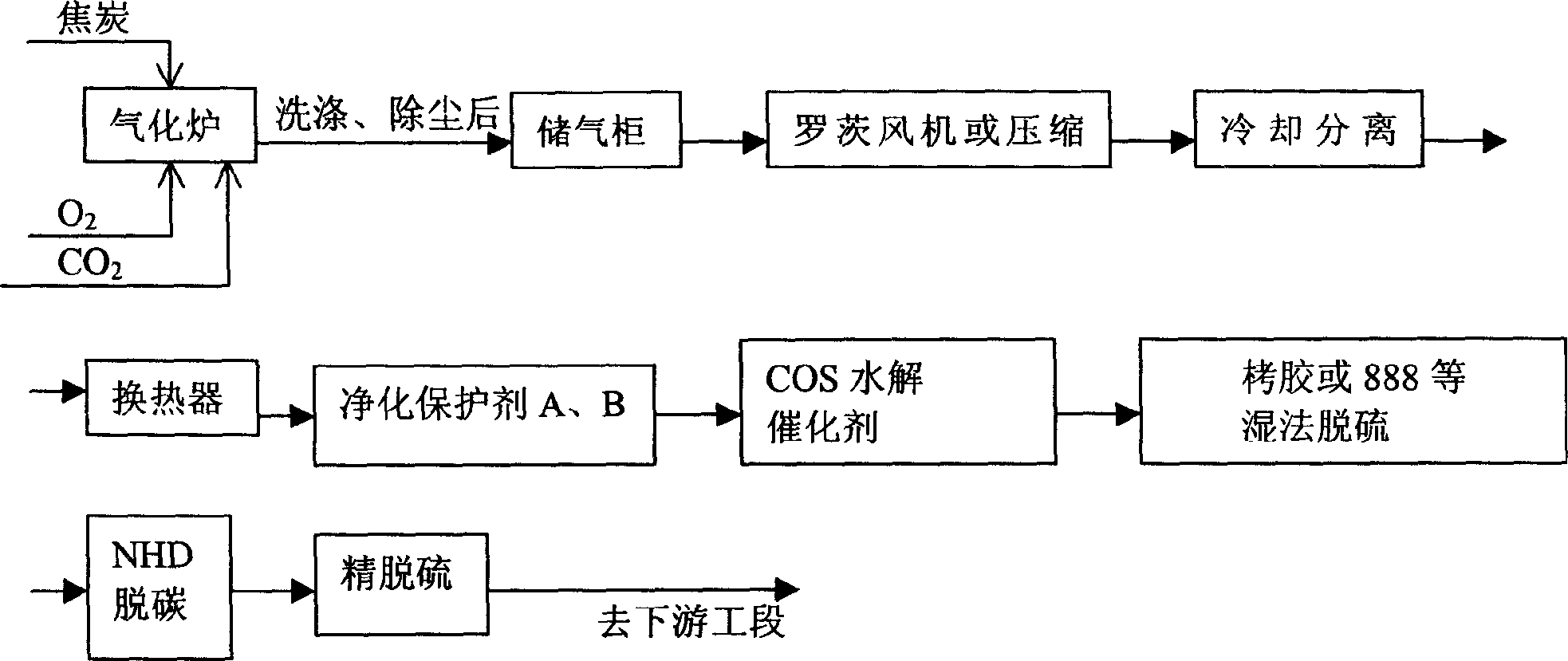

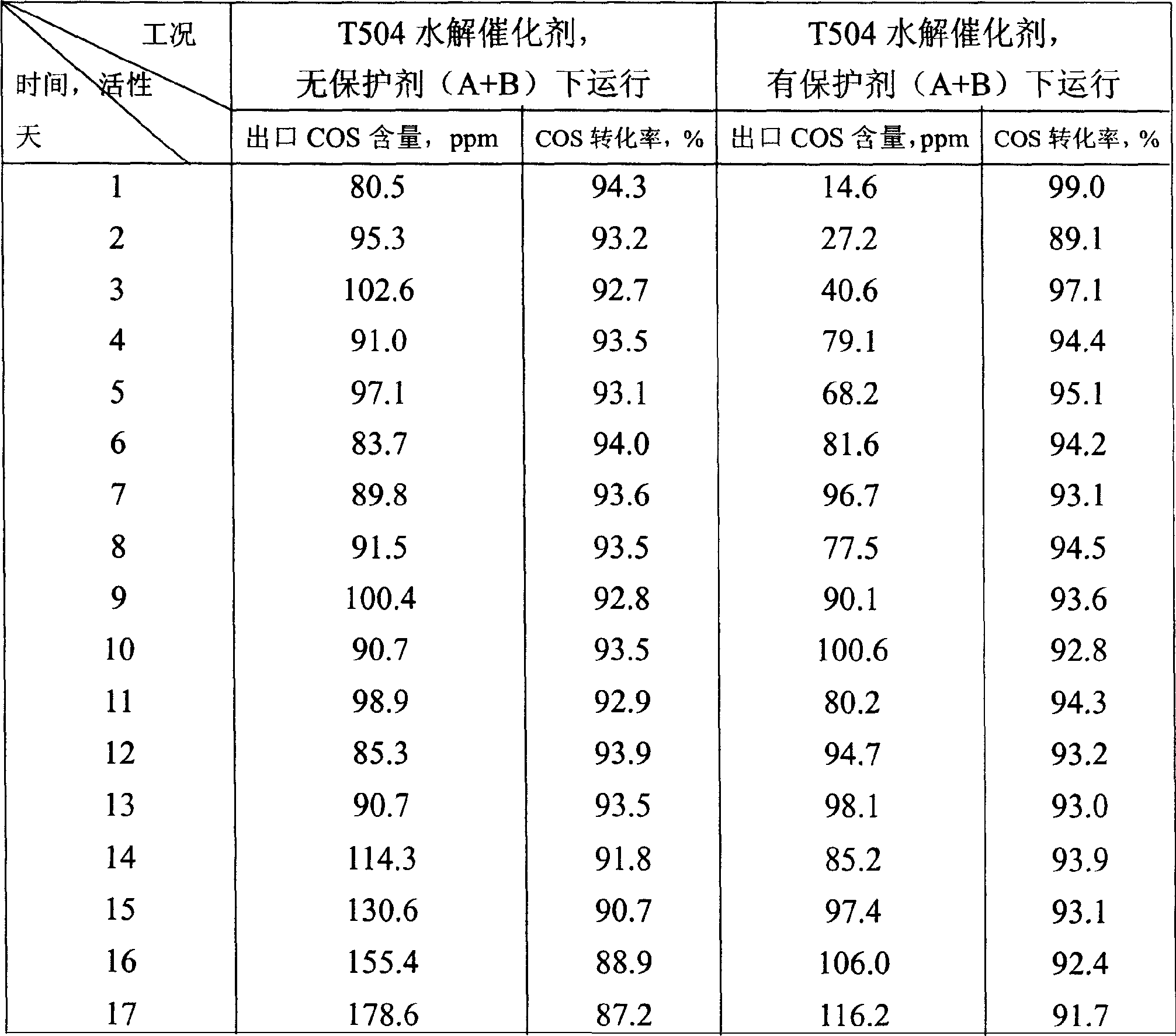

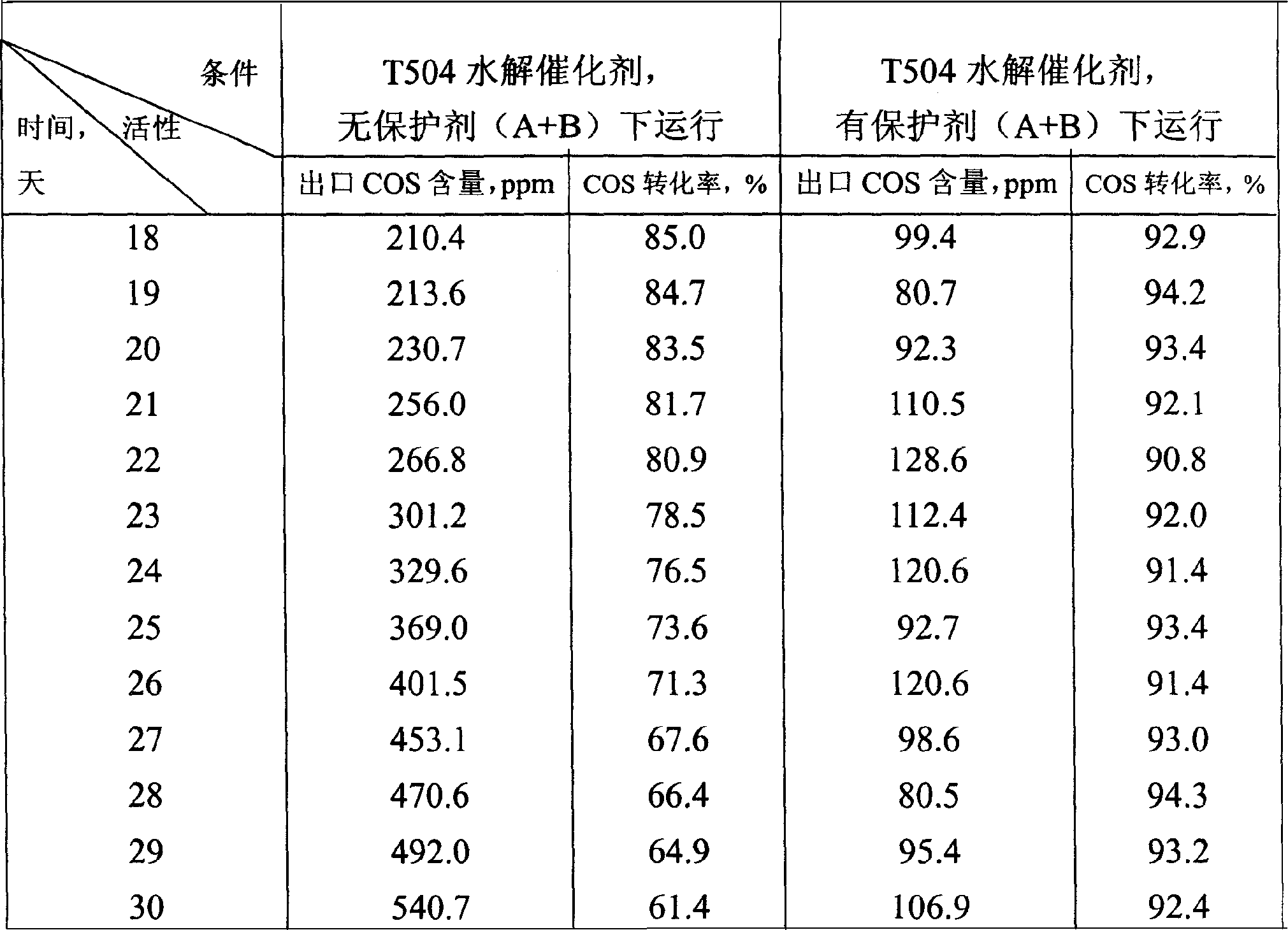

Process for preparing high purity carbon monoxide gas by desulfurization of organic sulfur at low and normal temperature

ActiveCN1844326AAchieve recyclingImprove and protect the ecological environmentCombustible gas purificationPoly(ethylene glycol) dimethyl etherDesorption

The invention relates to a technology for removing organic sulfur at a low or normal temperature to prepare high-purity carbonic oxide gas. The method consists of gasifying the coke with carbon monoxide or carbon dioxide to prepare the raw gases including 10 % -99 % CO, 0.1 %-90 % CO2, 0.001 %-2 % O2, 50-9000ppm COS, 10-10000ppm H2S, through gas storage holder, after pressurization and pyrogenation, entering purification tower filled with puripreservatives of A and B to remove hazardous materials including nitrogen oxide, hydrogen arsenide, hydrogen phosphide, hydrogen chloride, hydrogen nitrile, oxides of sulfur and sulfureted hydrogen, entering tower for removing organic sulfur filled with sulfur carbonyl hydrolyst, hydrolyzing 85%-95% of sulfur carbonyl for conversion into sulfureted hydrogen, at 20-150 DEG C, with a pressure of 0.1-10 MP, in which the refined raw gases can be used by productions of fine chemical industry including downstream acetate, dimethyl formamide,dimethyl ether, toluene diisocyanate or methyl diphenylene diisocyanate. The technology converts 85 %-95 % of sulfur carbonyl into sulfureted hydrogen, can adopt routine wet desulfurization to replace polyethylene glycol dimethyl ether desulfuration,can carry out cycle utilization of carbon dioxide and sulfur carbonyl of decarburized desorption gases of polyethylene glycol dimethyl ether, and can carry out zero discharge of poison material of sulfur carbonyl, which is good for environmental conservation.

Owner:HAISO TECH +1

Catalyst for synthesis of diethyl oxalate employing carbon monoxide gas-phase catalytic coupling and preparation method thereof

InactiveCN101612580AHigh space-time yieldHigh reactivityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsGas phaseDiethyl oxalate

The invention discloses a catalyst for the synthesis of diethyl oxalate employing carbon monoxide gas-phase catalytic coupling and the catalyst adopts metal palladium as active component, alpha-Al2O3 as carrier and transition metal copper as promoter; wherein, the content of metal palladium is 0.1-5.0% of the carrier and the content of transition metal copper is 0.05-3.0%. The catalyst shows higher reactivity and higher time space yield of dimethyl oxalate in the reaction that carbon monoxide and ethyl nitrite are used to synthesize dimethyl oxalate. The invention also discloses a preparation method of the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

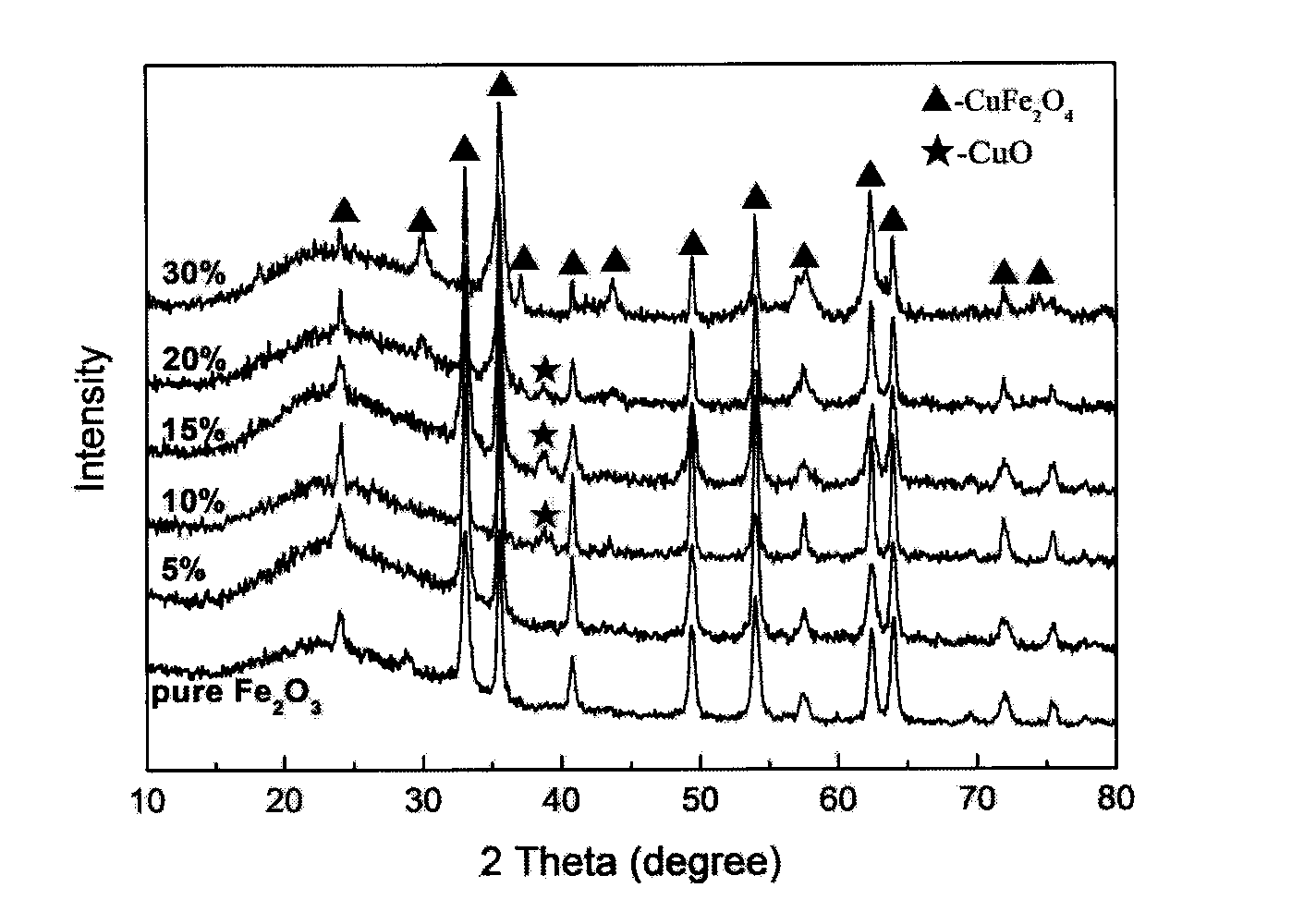

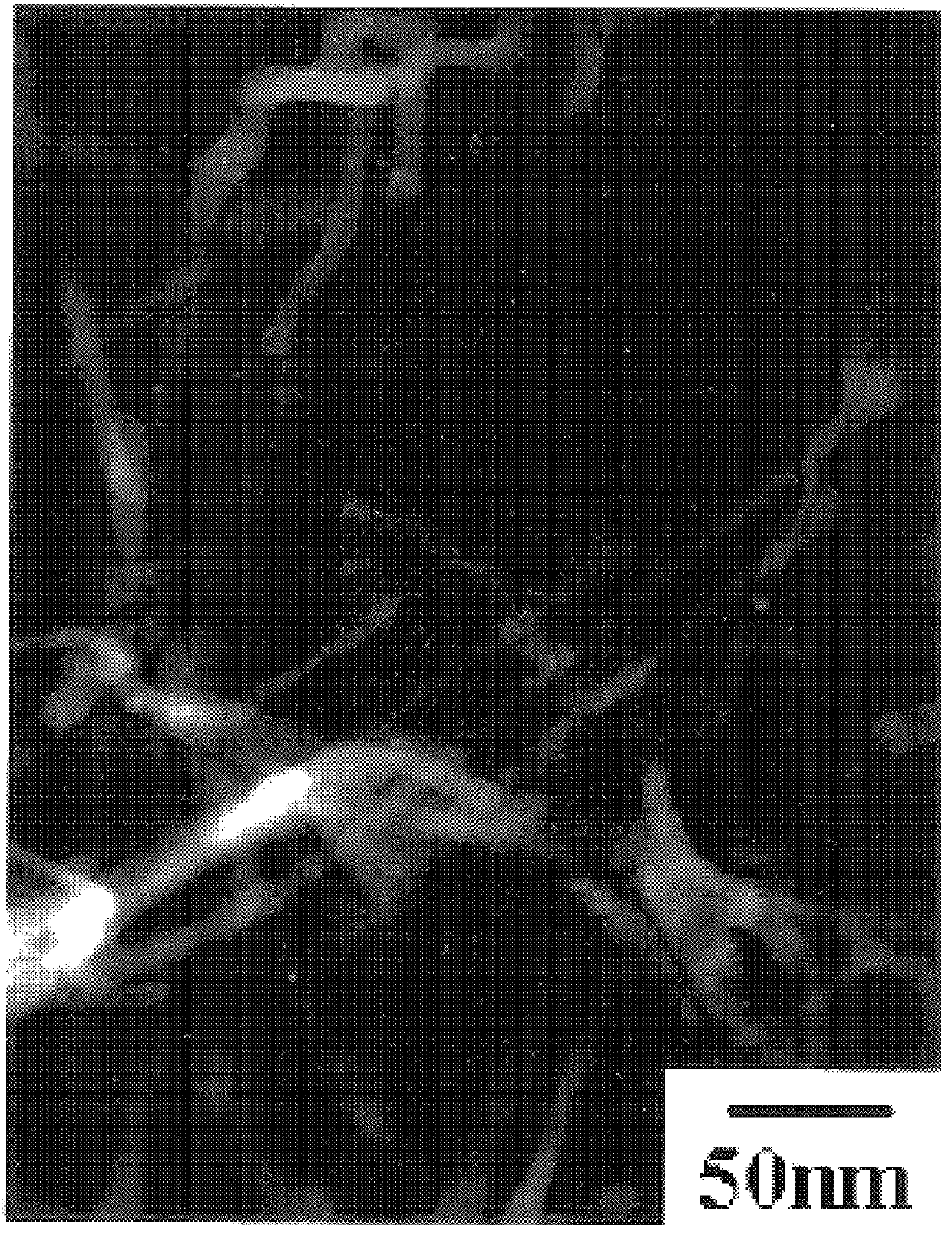

Preparation of p-n type nano CuO/alpha-Fe2O3 composite semiconductor material and application thereof as gas sensitive material

InactiveCN103257158AThe content is easy to controlLow costMaterial nanotechnologyMaterial resistanceDeposition precipitationSemiconductor materials

The invention relates to a preparation method of a p-n type nano CuO / alpha-Fe2O3 composite semiconductor material, and the material is applied to the field of gas sensors. Pure alpha-Fe2O3 is prepared by using a chemical precipitation method; and the nano CuO / alpha-Fe2O3 composite semiconductor material is further prepared by using a deposition-precipitation method. The CuO / alpha-Fe2O3 composite semiconductor gas sensitive material provided by the invention is simple in preparation technique, low in equipment requirement and low in cost; according to the prepared gas sensitive material, along with the increase of the CuO content, Cu atoms gradually enter alpha-Fe2O3 crystal phases, and the particle sizes of special grains range from 10nm to 20nm. By utilizing the prepared material, effective detection on hydrogen sulfide at room temperature is realized, and the material can rapidly respond to carbon monoxide at both 50 DEG C and 100 DEG C, so that the material has large application prospects.

Owner:HENAN POLYTECHNIC UNIV

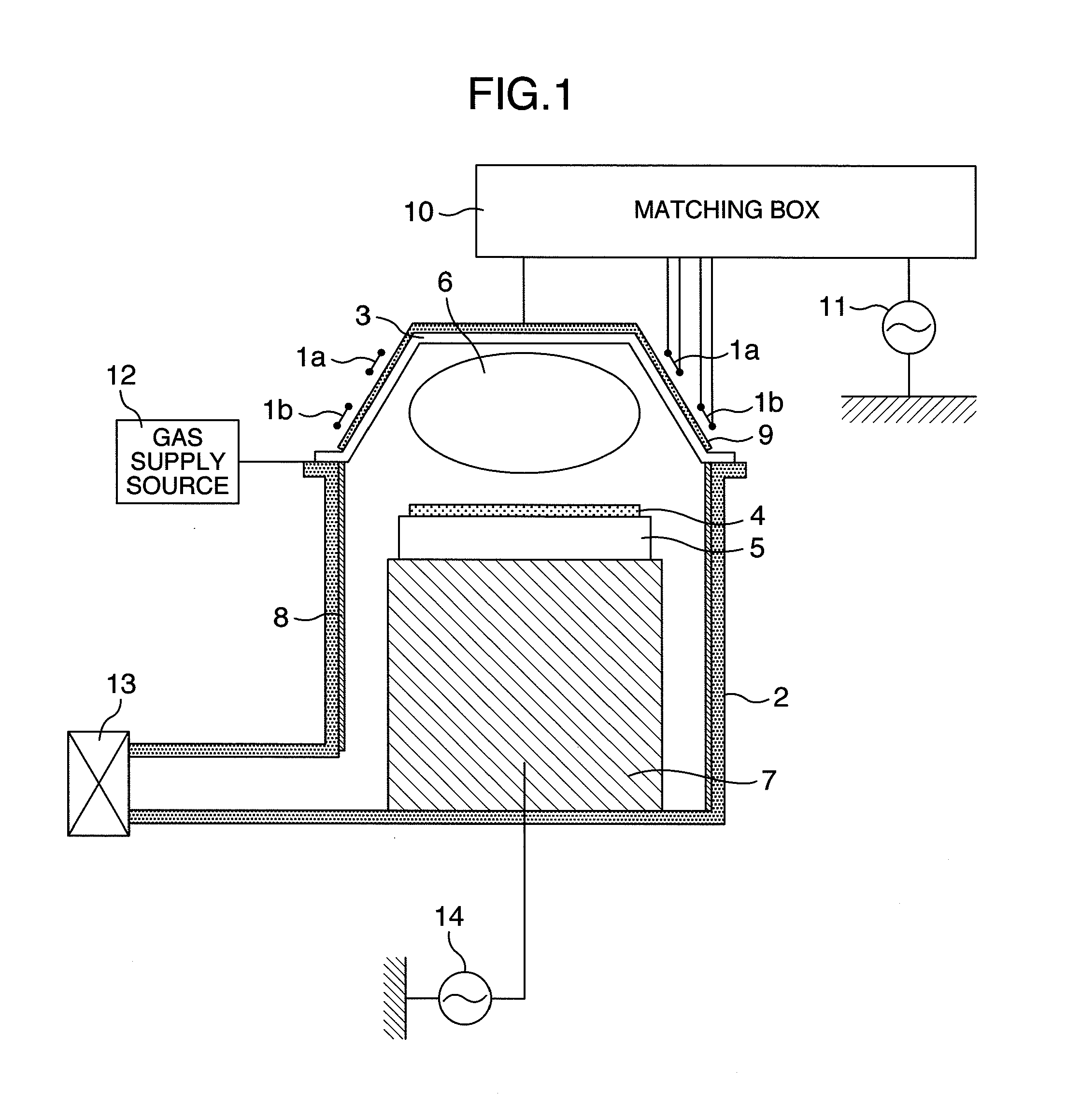

Plasma etching method

ActiveUS20150017741A1Avoid depositionDeposition of byproducts on an etching pattern sidewall can be suppressedSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentCarbon monoxide gasMixed gas

In a plasma etching method of plasma-etching a sample which has a first magnetic film, a second magnetic film disposed above the first magnetic film, a metal oxide film disposed between the first magnetic film and the second magnetic film, a second metal film disposed over the second magnetic film and forming an upper electrode, and a first metal film disposed below the first magnetic film and forming a lower electrode, the plasma etching method includes the steps of: a first process for etching the first magnetic film, the metal oxide film, and the second magnetic film by using carbon monoxide gas; and a second process for etching the sample by using mixed gas of hydrogen gas and inactive gas after the first process. In this case, the first metal film is a film containing therein tantalum.

Owner:HITACHI HIGH-TECH CORP

Method for preparing superfine nickel carbonyl powder by nickel carbonyl thermal decomposition

The invention discloses a method that is used to prepare superfine carbonyl nickel powder by the carbonyl nickel thermal decomposition. The method is that the carbonyl nickel and the carbon monoxide gas are mixed admission the decomposer to mix with the carbon monoxide main heat source gas whose preheating temperature is from two hundred and forty centigrade degree to three hundred twenty centigrade degree to make the carbonyl nickel decompose to from superfine carbonyl nickel powder whose granularity is from twenty nanometer to ten millimeter. The pressure of the decomposer is from 0.02MPa to 0.2MPa in the whole decomposition process. The invention avoids the complicated operation of separating the mixed gas after the decomposition, simplifies the preparation technology, reduces the cost of the production, and greatly reduces the produce of the wall built up.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

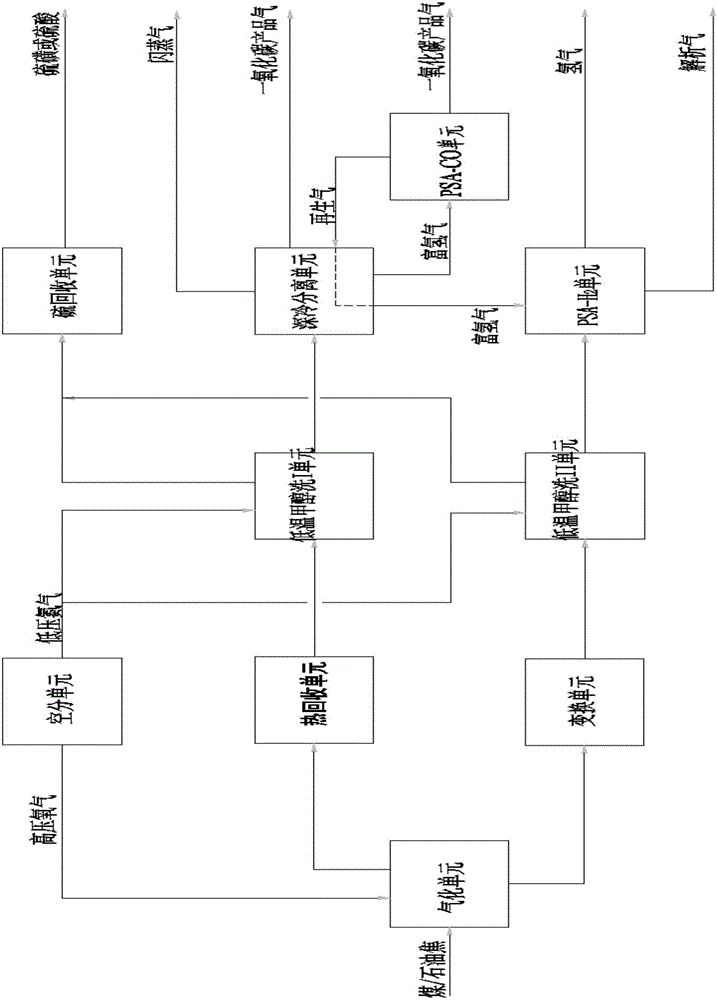

Method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation

ActiveCN105948046AFlexible scale adjustmentHigh recovery rateHydrogen separation by selective and reversible uptakeGas treatmentSyngasPhysical chemistry

The invention discloses a method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation. The crude synthetic gas prepared by the gasification unit is divided into two parts, one part is used for preparing pure carbon monoxide, and the other part is preparing pure hydrogen. The process of preparing pure carbon monoxide is divided into two parts: one part is used for preparing pure carbon monoxide with the crude synthetic gas prepared by gasification by a heat recovery unit, a low temperature methanol washing I unit, and a cryogenic separation unit; and the other part is used for preparing pure carbon monoxide by the hydrogen rich gas from the outlet of the cold box of the cryogenic separation unit sending into a PSA-CO unit. The feedstock of preparing hydrogen is divided into two parts: one part is the converted gas which is purified by a conversion unit and a low temperature methanol washing II unit with the crude synthetic gas prepared by gasification and contains carbon monoxide -1% (mol), and the other part is the hydrogen rich gas from a resurgent TSA device of the cryogenic separation unit, and the two parts of the gas are mixed and sent into the PSA-H2 unit to prepare pure hydrogen. The method has high recovery rates of carbon monoxide and hydrogen, has no desorbed gas circulation and no resurgent gas introduced by environment, has small investment and low energy consumption, and can adjust product gas scale of hydrogen and carbon monoxide flexibly.

Owner:HUALU ENG & TECH

Method for producing high-purity metal chromium by using carbon reduction method

InactiveCN102965526AHigh speedIncrease productivityProcess efficiency improvementImpurityMaterials science

The invention relates to a method for producing high-purity metal chromium by using a carbon reduction method. The method comprises the following steps of: uniformly mixing chromic oxide powder and carbon black powder, adding deionized water or alcohol to form a wet mixed material, carrying out press forming, and drying, thereby obtaining a mixed material block; putting the mixed material block in a vacuum furnace, and enabling chromic oxide to be reduced by carbon black under high-temperature vacuum conditions, thereby obtaining crude chromium; introducing gaseous carbon monoxide, and carrying out heat preservation for 3-8 hours at the temperature of 1,300-1,500 DEG C; introducing gaseous carbon dioxide, and carrying out heat preservation for 3-8 hours at the temperature of 800-1,000 DEG C; and cooling down, and discharging, thereby obtaining a high-purity metal chromium block. According to the method, a gas-solid reduction manner is adopted to remove residual raw materials and non-metallic impurities, so that the production cost is reduced, and the reduction time is shortened; and the produced high-purity metal chromium has the purity of 99.96-99.98%, the oxygen content less than 0.03%, the sulfur content less than 0.01% and the carbon content less than 0.01%, thereby meeting the standards of the high-purity metal chromium.

Owner:JINZHOU NEWROUTE HYPERPURE MATERIAL CO LTD

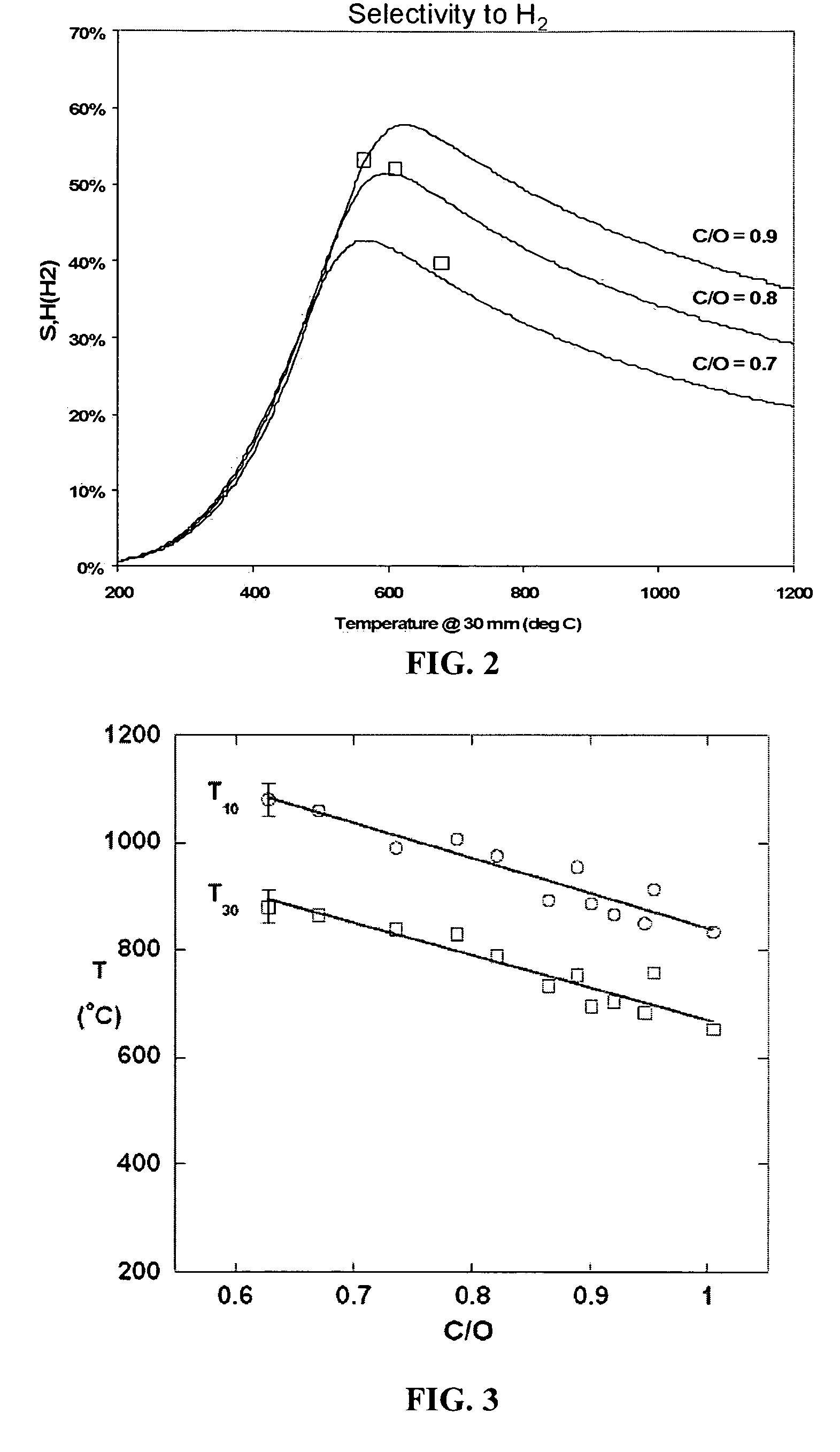

Solid fuel volatilization to produce synthesis gas

A method comprising contacting a carbon and hydrogen-containing solid fuel and a metal-based catalyst in the presence of oxygen to produce hydrogen gas and carbon monoxide gas, wherein the contacting occurs at a temperature sufficiently high to prevent char formation in an amount capable of stopping production of the hydrogen gas and the carbon monoxide gas is provided. In one embodiment, the metal-based catalyst comprises a rhodium-cerium catalyst. Embodiments further include a system for producing syngas. The systems and methods described herein provide shorter residence time and high selectivity for hydrogen and carbon monoxide.

Owner:RGT UNIV OF MINNESOTA

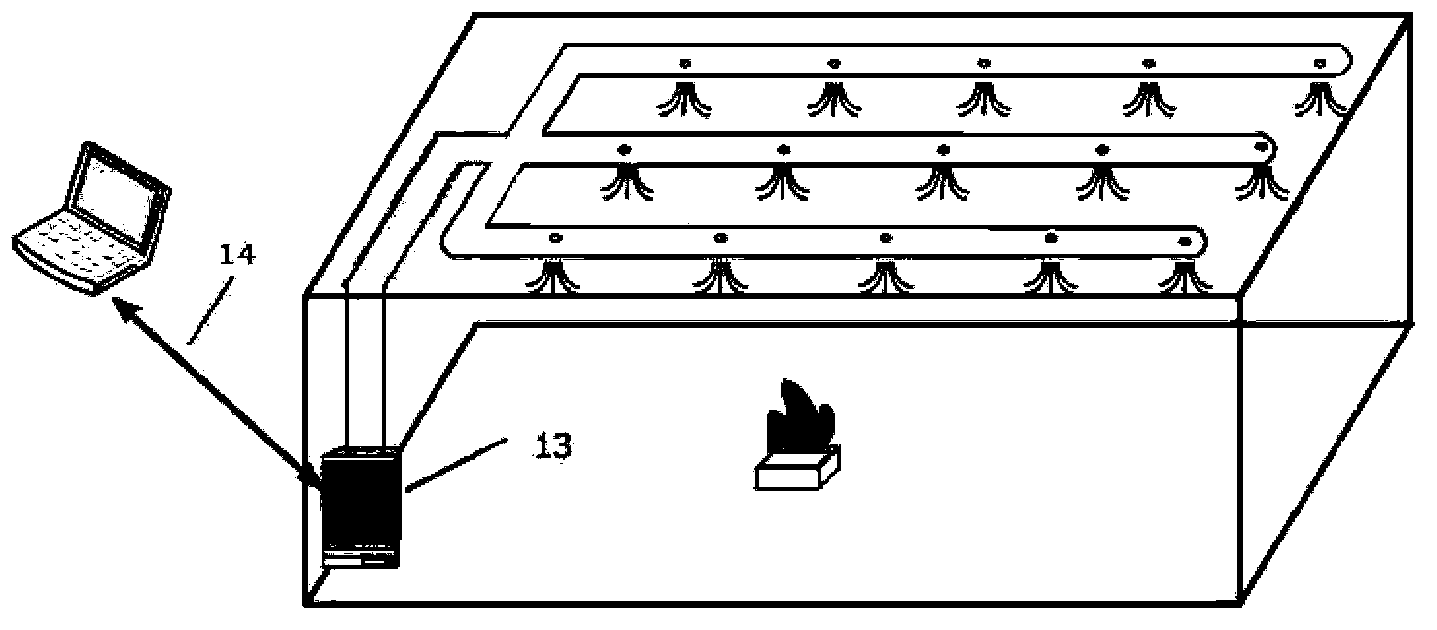

Air-breathing high-sensitivity smoke particle detector and application thereof

ActiveCN103366495AAvoid interferenceEliminate the effects of probing accuracyFire alarmsParticle suspension analysisAir pumpParticle physics

The invention discloses an air-breathing high-sensitivity smoke particle detector and application thereof. The air-breathing high-sensitivity smoke particle detector and application thereof are characterized in that the smoke particle detector is arranged at the tail end of an air pumping pipeline in the monitored area, an air sample is drawn by the air pumping pipeline in a drive mode and filtered, and the smoke particles with the grain diameters of not more than 20 microns in the air sample drawn in the drive mode and filtered are tested through the detector according to a laser particle scattering method. According to the air-breathing high-sensitivity smoke particle detector and application thereof, infinitesimal smoke particles can be detected, and fire characteristic parameters can be effectively detected in the ultra early stage of fire; interferences of passive waiting and delaying and air motion of a protected area are overcome, and the influence on detecting precision due to smoke particle concentration dilution is eliminated; by high-sensitive composite monitoring on the fire characteristic parameters of smoke particle concentration, temperature and carbon monoxide gas in the air sample, the defect that smoke particles are monitored in a single mode through an existing air-breathing high-sensitivity smoke particle detecting system can be overcome, and therefore false alarm rate is effectively lowered.

Owner:HEFEI UNIV OF TECH

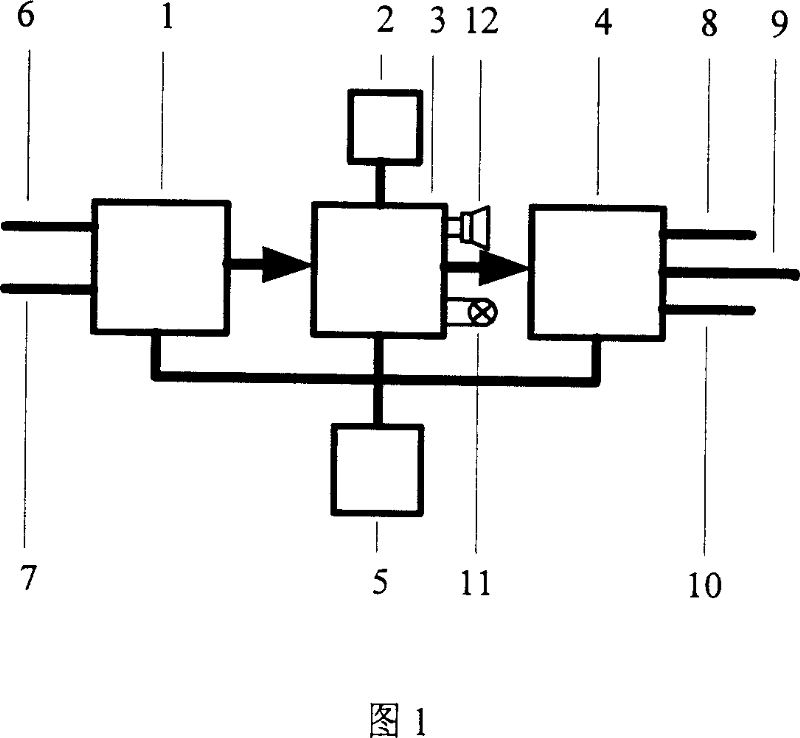

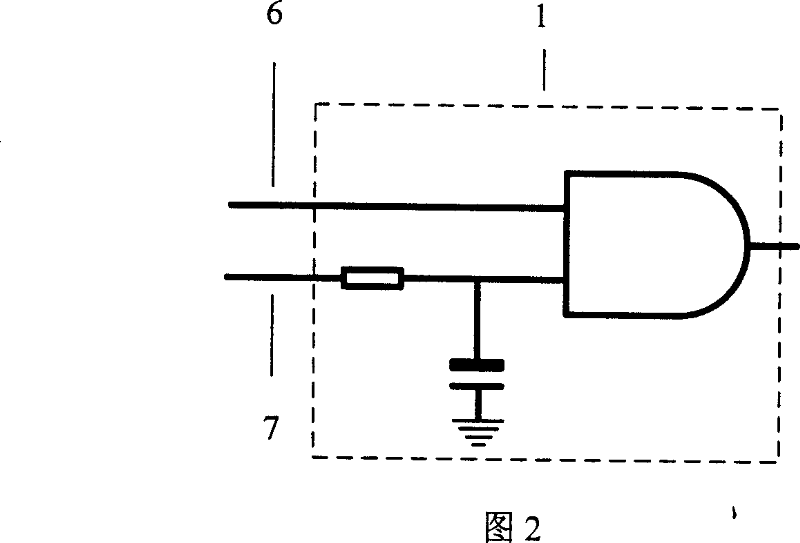

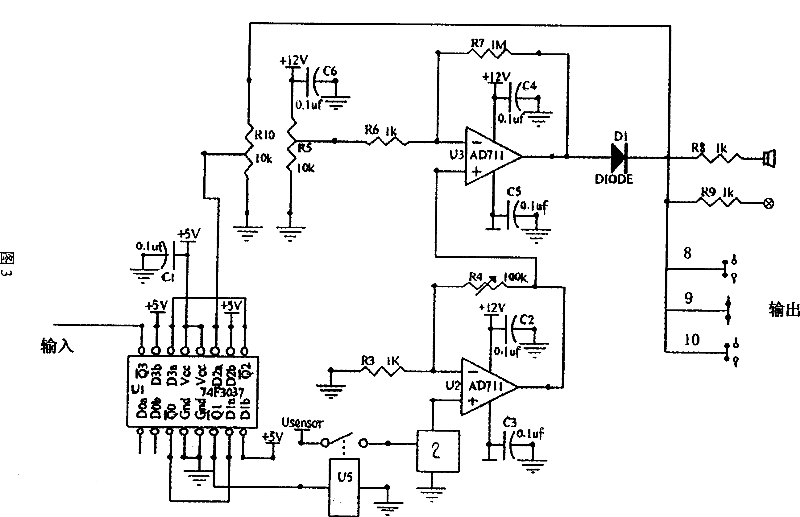

Method and device for detecting and alarming of noxious gas inside automobile

InactiveCN101041332AExtend your lifeLife does not affectTractorsPropulsion unit safety devicesIdle speedCarbon monoxide gas

The invention relates to an inspecting and alarming device for poisonous gas in automobile, comprising gate circuit of delay switch for inspecting if the time when automobile is in idle speed and motion state achieves the setting value. When the time achieves the setting value the signal is emitted and the inspecting circuit is opened. CO sensor is set in the inspecting circuit to collect the concentration signal of CO and transform the signal into voltage signal, which is amplified subsequently. When amplified voltage signal achieves the setting value alarm is started while three signals are outputted. One signal output is used to control car window to open; another signal output is used to control engine to close and the residual signal output is used to open anti-theft alarming device. By adopting the method of opening inspection circuit automatically, the device prolong the using time of sensor greatly while the problem that in the original technology only alarm can be started and the source of poisonous gas can not be cut is conquered. The safety is increased. It is provided with simple structure, strong practicability. It is widely applied in various automobiles.

Owner:林学春 +1

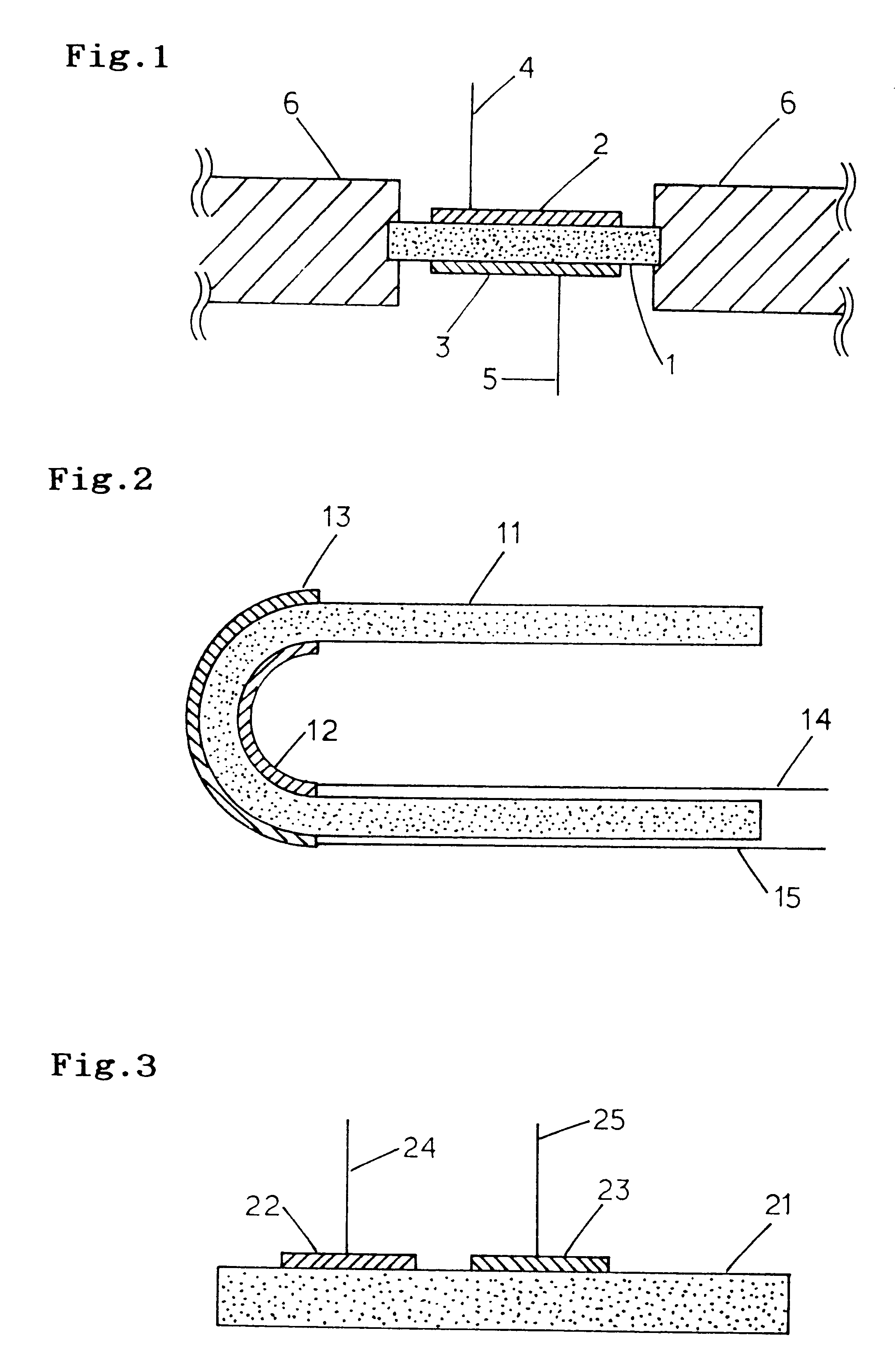

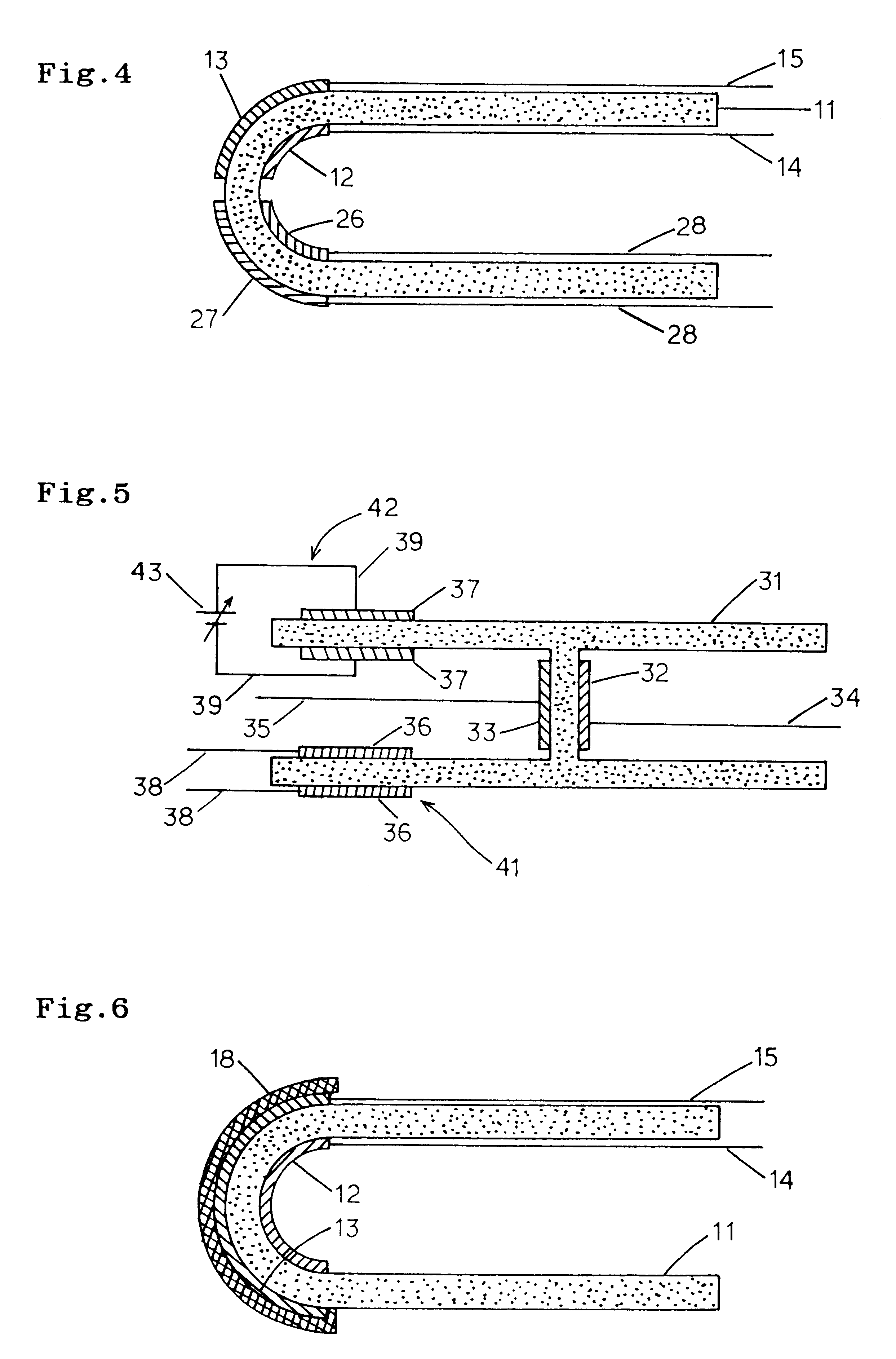

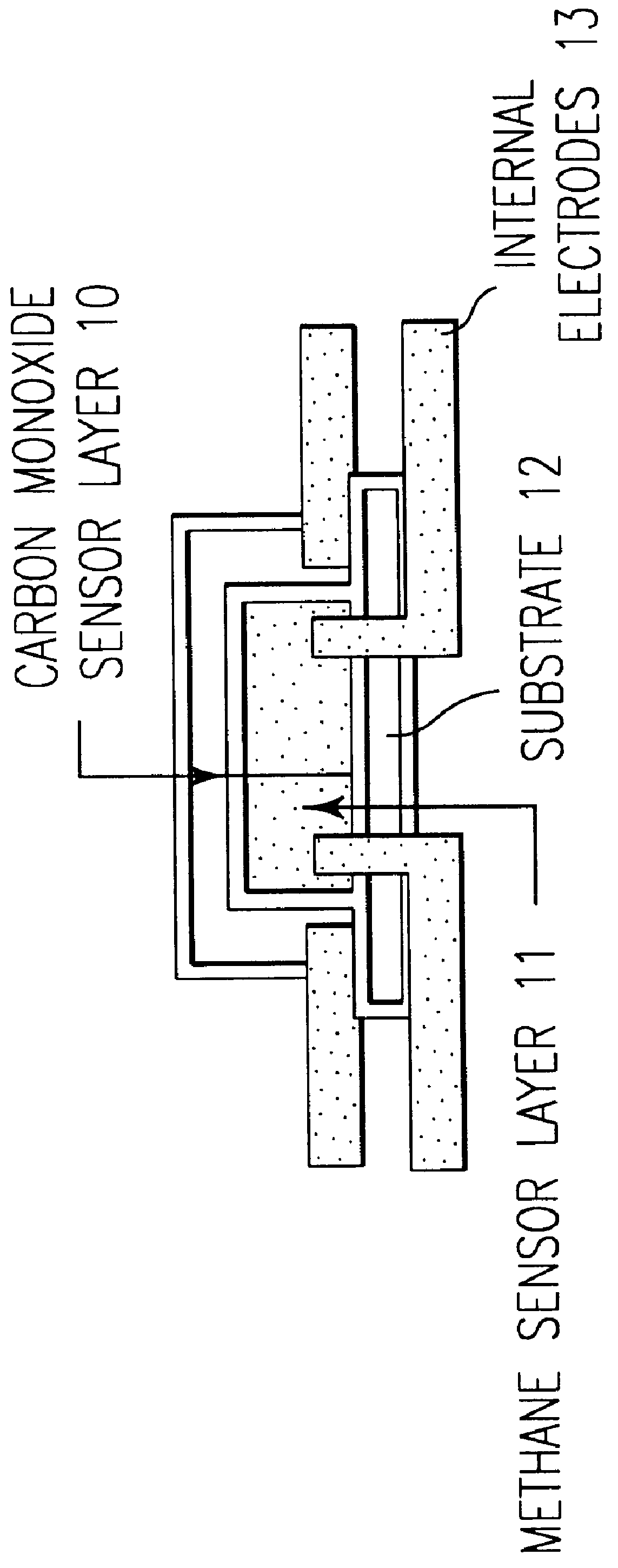

Multilayered gas sensor

InactiveUS6070450AImprove gas selectivityGood choiceAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansGas phaseProduct gas

The present invention provides a gas sensor element having physical, electrical and chemical properties capable of detecting methane and carbon monoxide selectively with 1 intergrated filtering, catalyzing sensor by improving gas selectivity of the semiconductor gas sensor. The present invention relates to a gas sensor element, which has a carbon monoxide sensor layer with an ability to function as a catalyst film that blocks carbon monoxide, which impedes detection of methane, and has a layer-built structure where the surface of a methane sensor is covered with the carbon monoxide gas sensor which can be obtained by a gas-phase method.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com