Gas sensitive material, carbon monoxide gas sensitive element adopting gas sensitive material and preparation method of carbon monoxide gas sensitive element

A technology of gas-sensitive materials and gas-sensitive elements, applied in the field of preparation of resistive semiconductor gas-sensitive elements, which can solve the problems of poor sensitivity, high cost, and low lifespan, and achieve high sensitivity, reduced volume, and long lifespan long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the present embodiment carbon monoxide gas sensor is as follows:

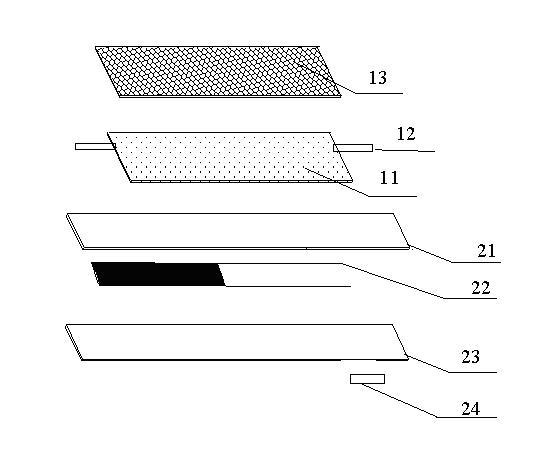

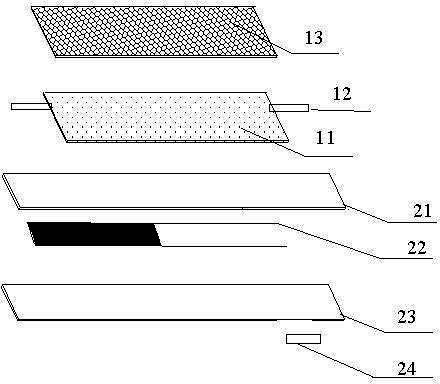

[0036] (1) Preparation of heating body

[0037] The upper ceramic substrate (21) and the lower ceramic substrate (23) are prepared by tape casting, coating, and pressing forming techniques, and then printed with chromic acid on the green substrate of the upper ceramic substrate (21) by screen printing. The heating electrode (3) and the heating electrode lead (24) with lanthanum as the main body are laminated with the green body of the lower ceramic substrate (23) at a temperature of 90°C and a pressure of 16MPa, and sintered at 1500°C for 2 hours to prepare out of the heater.

[0038] (2) Preparation of the slurry used in the gas-sensitive layer

[0039] ① Weigh the inorganic powder for the gas-sensitive layer according to the mass percentage in Table 1:

[0040] Table 1

[0041] Inorganic components SnO 2 Sb 2 o 3 Pt PD CaO SiO 2 Content (%) ...

Embodiment 2

[0052] The inorganic powder used in the gas-sensitive layer of this embodiment is shown in Table 2 by mass percentage:

[0053] Table 2

[0054] Inorganic components SnO 2 Sb 2 o 3 Pt PD CaO SiO 2 Content (%) 88 5 2 3 1 1 Particle size (nm) ≤100 ≤100 Median diameter (nm) ≤50 ≤50

[0055] Other preparation steps and methods are the same as in Example 1, and will not be repeated here.

[0056] The technical index of the carbon monoxide gas sensor that present embodiment makes is as follows:

[0057] project Technical Parameters Detection rangeppm 10-3000 Working temperature °C 120-160 SensitivityuA / ppm 0.01±0.03uA / ppm Gas sensor response time S <10 Device recovery time S <40 zero drift Stability ( / year) <3%

Embodiment 3

[0059] The inorganic powder used in the gas-sensitive layer of this embodiment is shown in Table 3 by mass percentage:

[0060] table 3

[0061] Inorganic components SnO 2 Sb 2 o 3 Pt PD MgO SiO 2 Content (%) 94 1 1 / 2 2 Particle size (nm) ≤200 ≤100 Median diameter (nm) ≤100 ≤50

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com