Patents

Literature

30results about How to "Mitigate carbon formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

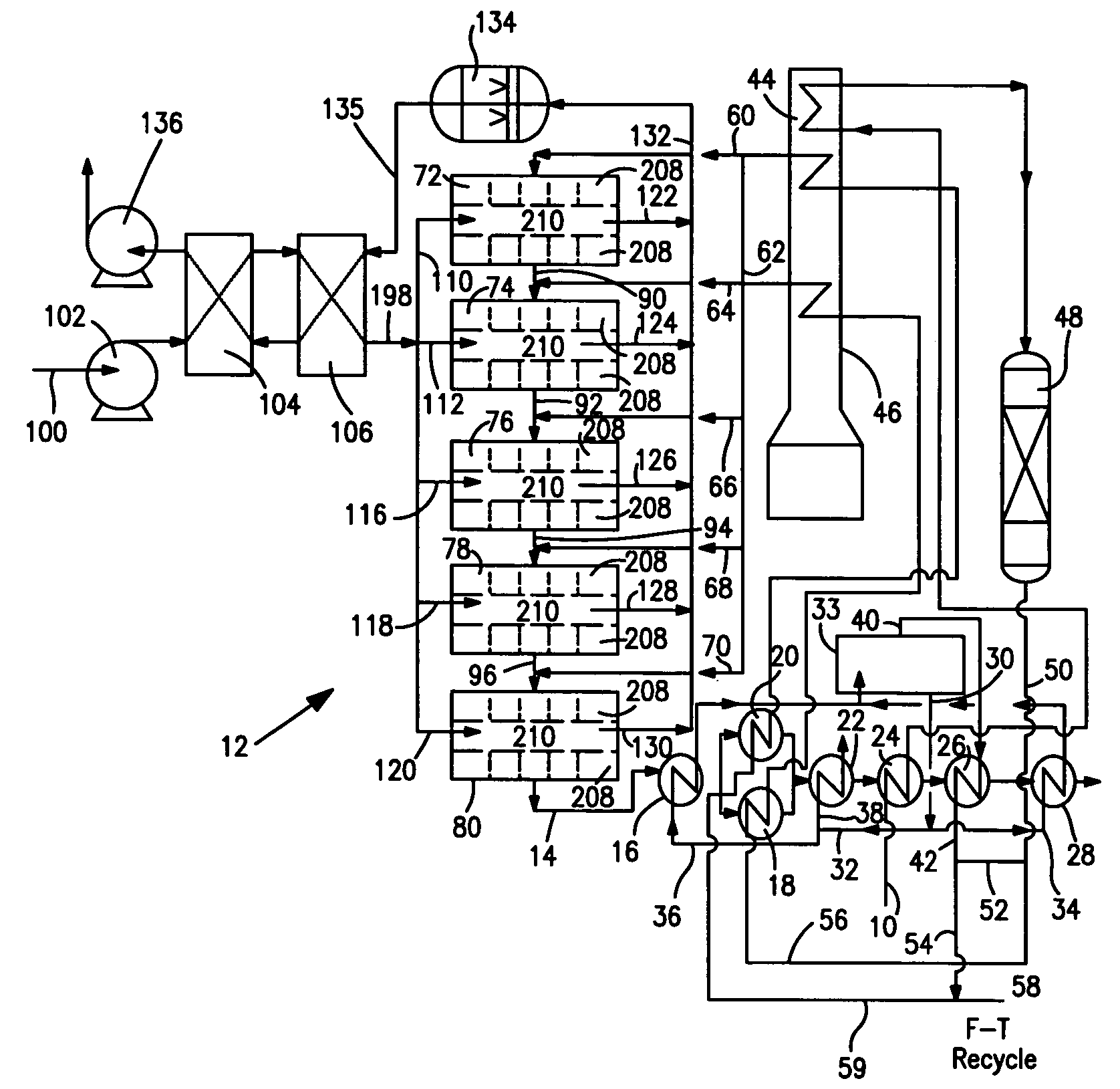

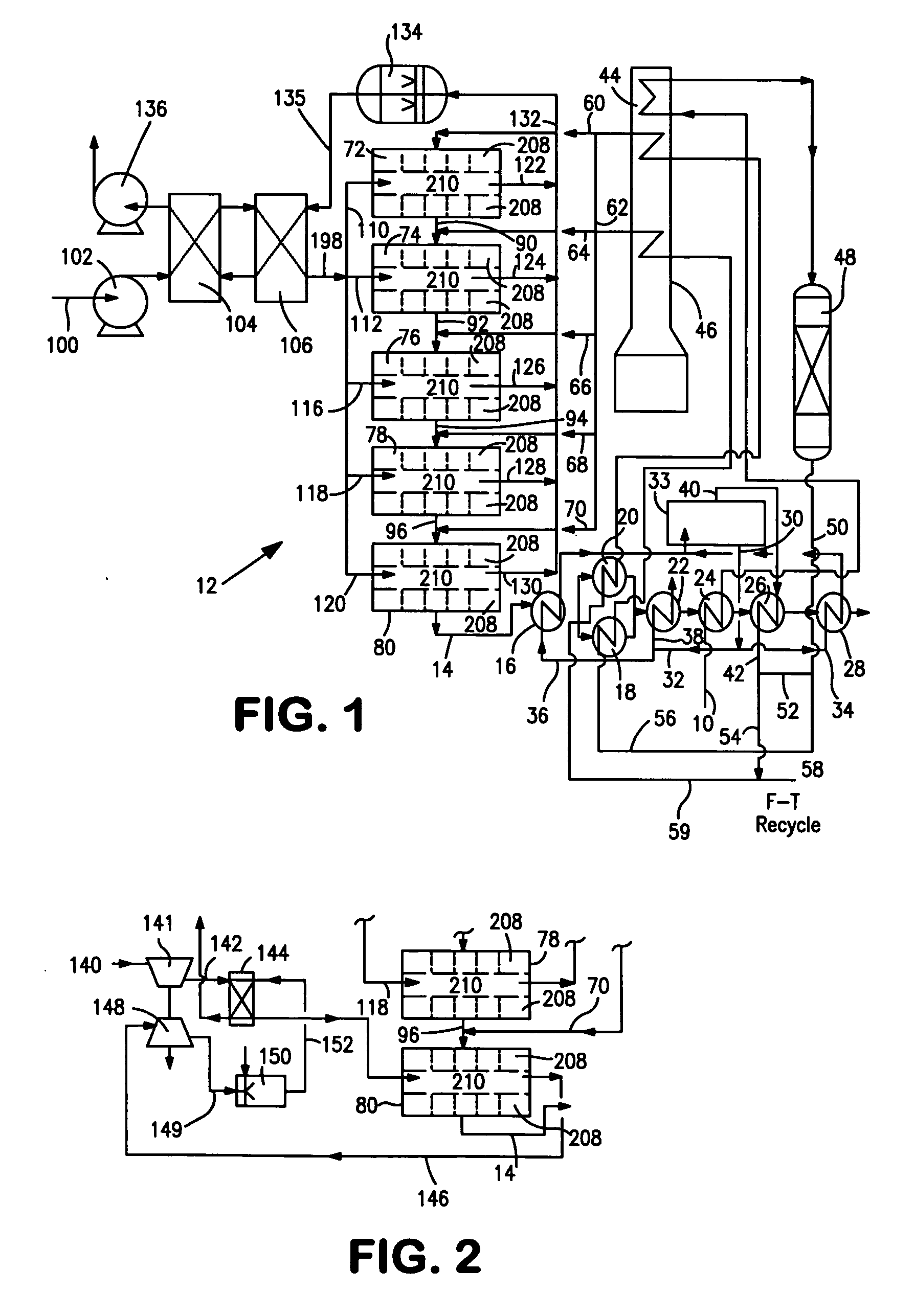

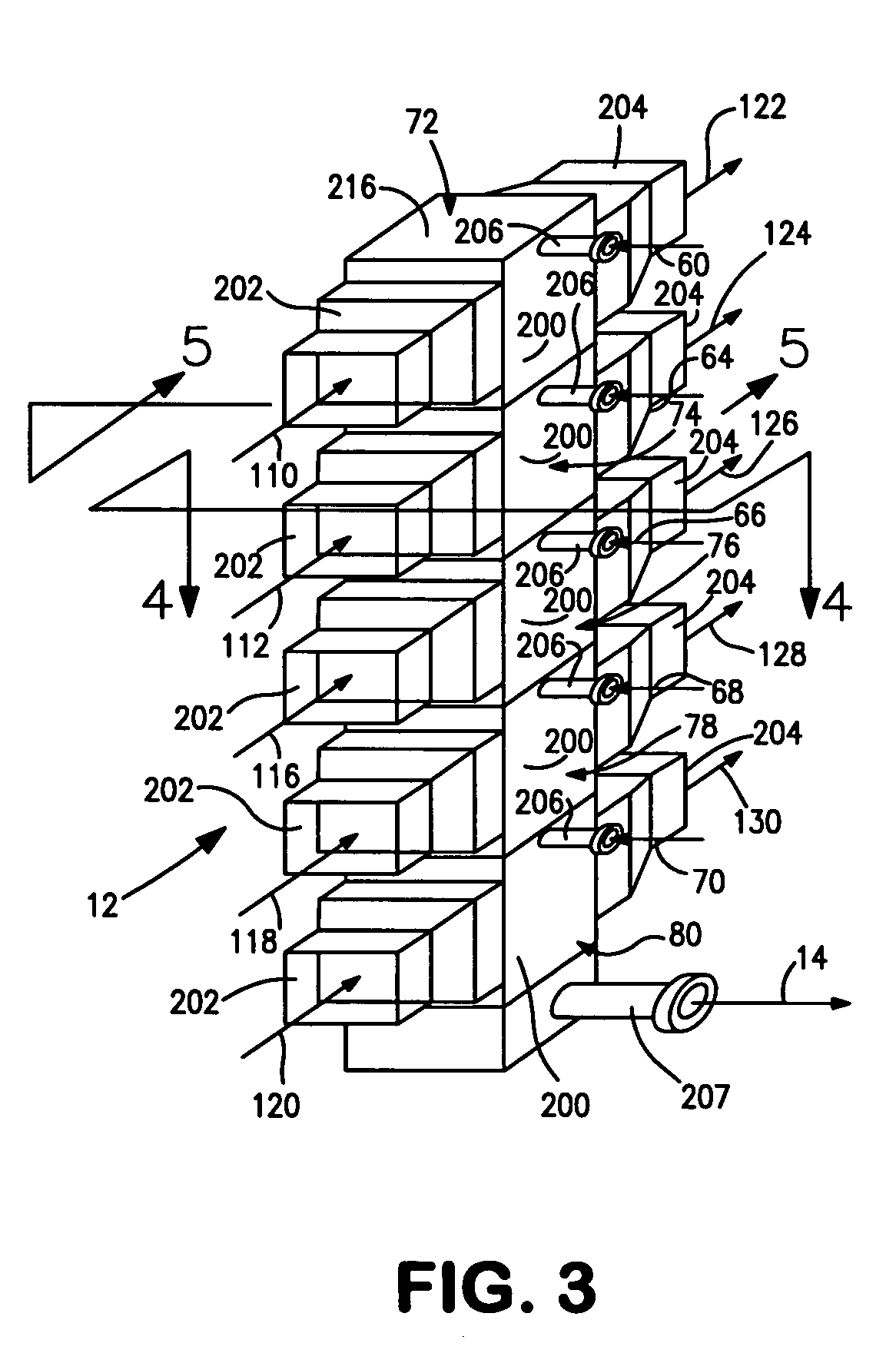

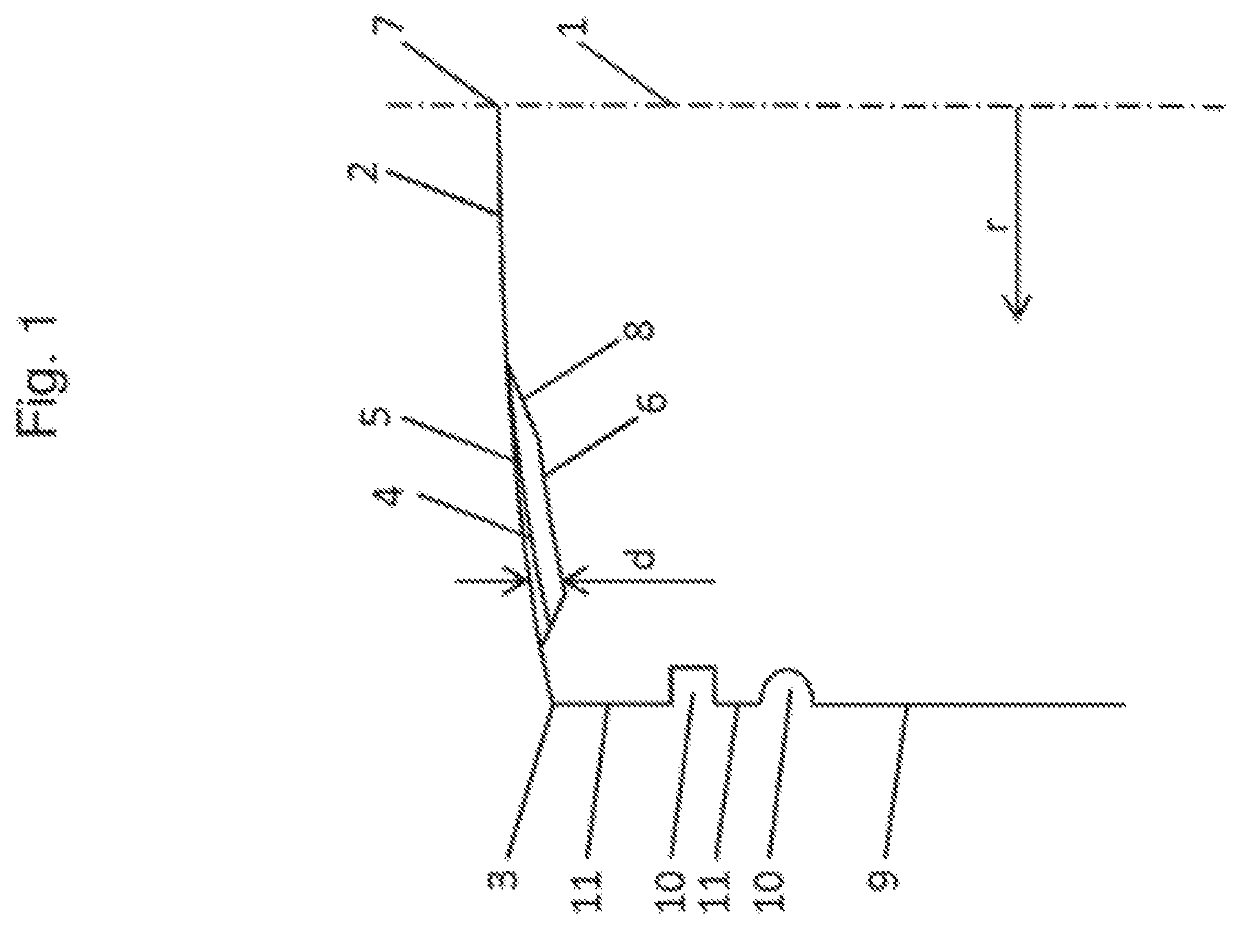

Synthesis gas production method and reactor

InactiveUS20070292342A1Mitigate carbon formationReduce possible catalyst poisoningCombination devicesHydrogenChemistryPartial oxidation

A method of producing a synthesis gas from a hydrocarbon containing gaseous feed in which the hydrocarbon containing gaseous feed is reacted in an autothermal reactor having separated reaction stages in which partial oxidation and steam methane reforming reactions occur. Each of the reaction stages has alternating separation zones and catalytic reaction zones. Oxygen separated by oxygen ion transport in the separation zone supports the partial oxidation reactions occurring in the catalytic reaction zones. Reactants are separately metered to the reaction stages to control temperatures within the reaction stages so that use of expensive high temperature materials is confined to one or more final reaction stages. Reaction stages can incorporate perforated planar members with regions of oxygen ion transport membrane material in registry with such perforated regions form the separation zones and the catalytic reaction zones.

Owner:STATOIL ASA PETRO SA (NO) +1

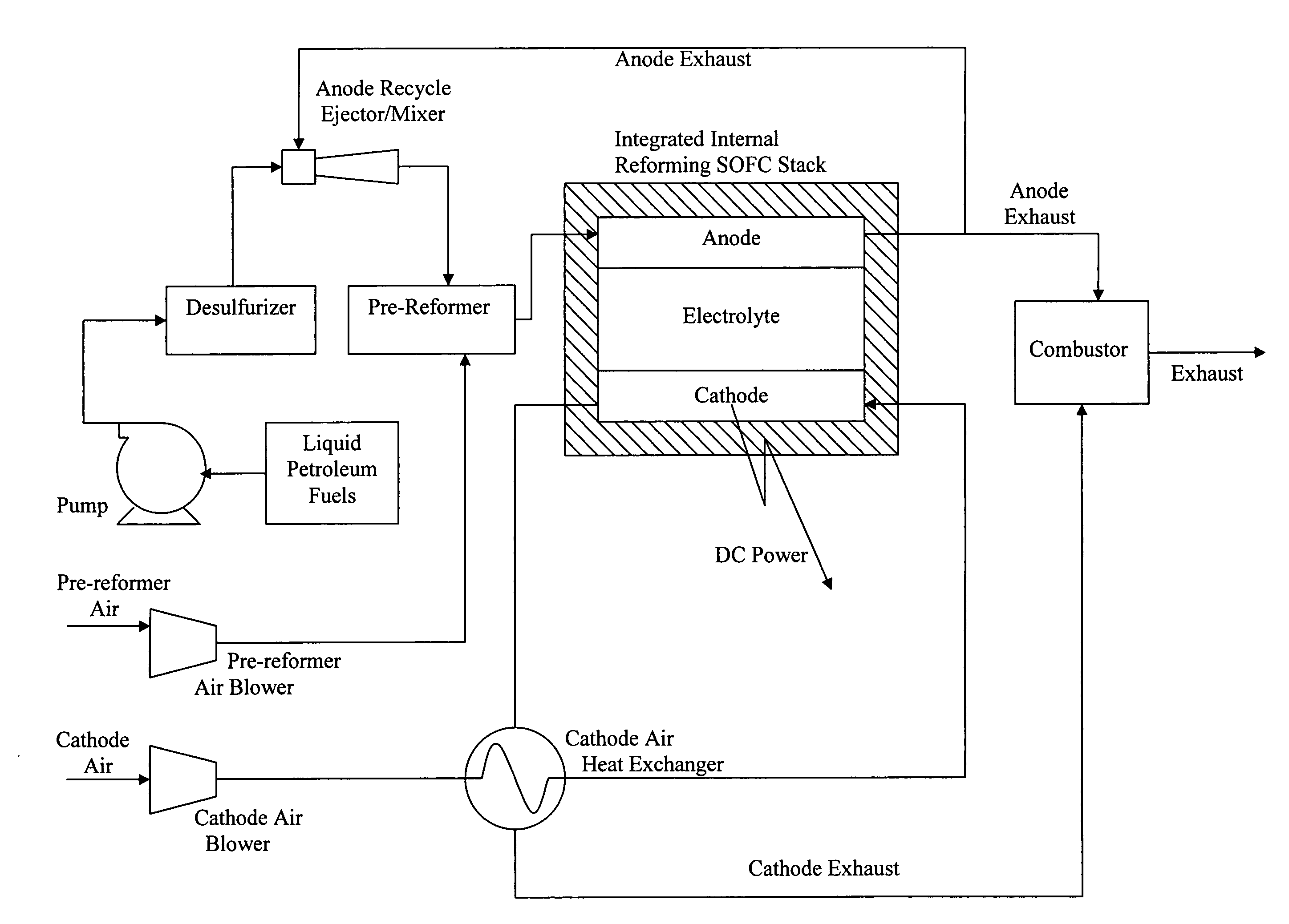

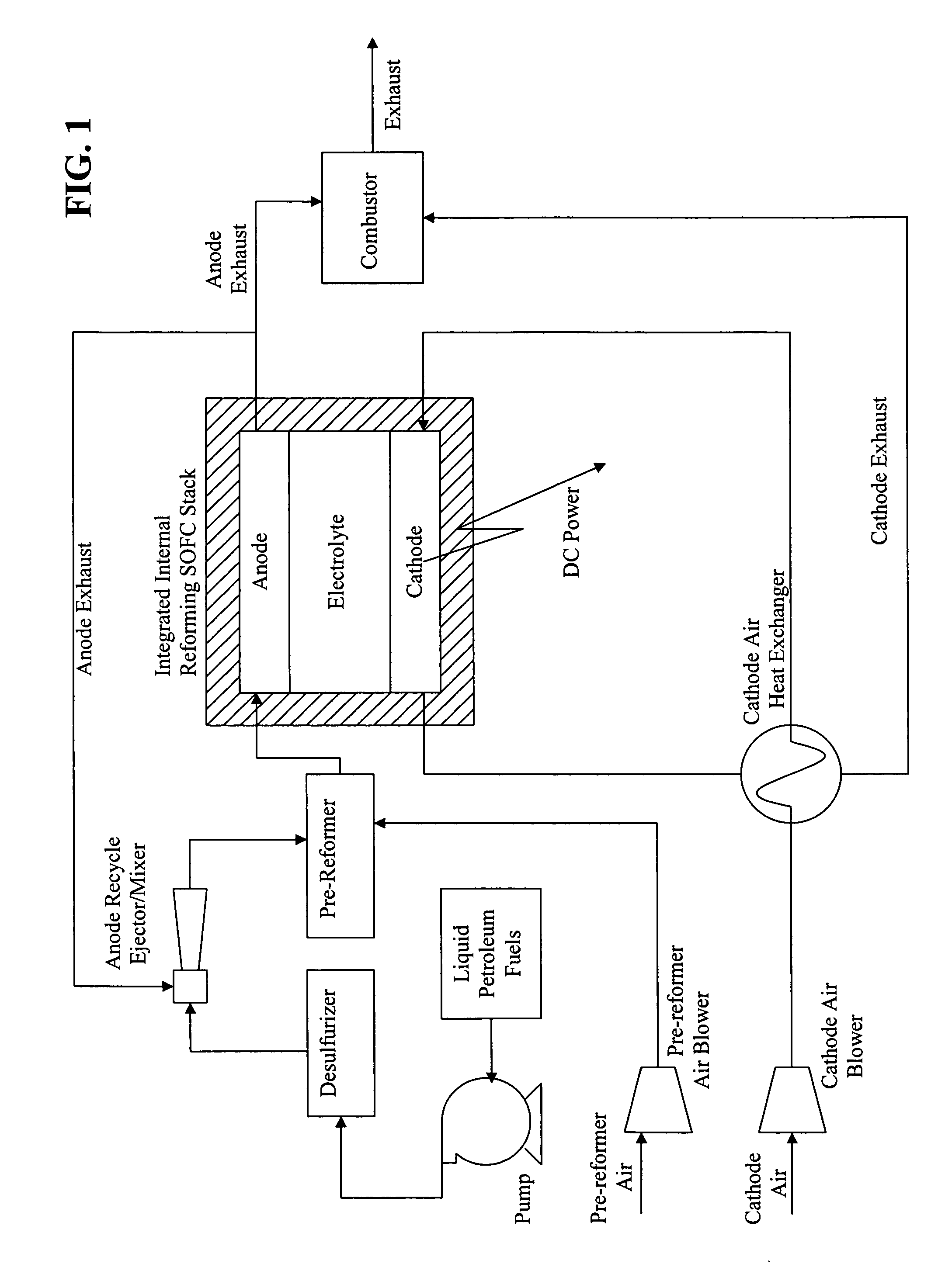

Process for the conversion of oil-based liquid fuels to a fuel mixture suitable for use in solid oxide fuel cell applications

ActiveUS20080107932A1Stable internal performanceMitigate carbon formationHydrogenEnergy inputElectricityFuel cells

Processes for generating electricity using a solid oxide fuel cell are disclosed. The processes are controlled by adjusting the hourly spaced velocity of the hydrocarbon feed through the solid oxide fuel cell. Hydrocarbon fuel is transported at an hourly spaced velocity through a pre-reformer having a catalyst. The hydrocarbon fuel is contacted with the catalyst for a residence time and at a temperature such that a catalyzed hydrocarbon fuel is formed. The hourly spaced velocity determines the residence time of the hydrocarbon fuel in the pre-reformer. The resultant catalyzed hydrocarbon fuel contains at least one gas including one or more of hydrogen gas, methane gas, carbon monoxide gas, or combinations thereof The catalyzed hydrocarbon fuel is then contacted with an anode of a solid oxide fuel cell for a residence time to produce electricity.

Owner:SAUDI ARABIAN OIL CO

Method for reducing coking in a hydrogen generation reactor chamber

ActiveUS7662435B2Mitigate carbon formationEnvelopes/bags making machineryHydrogen/synthetic gas productionPhysical chemistryHydrogen production

Owner:AMOGY INC

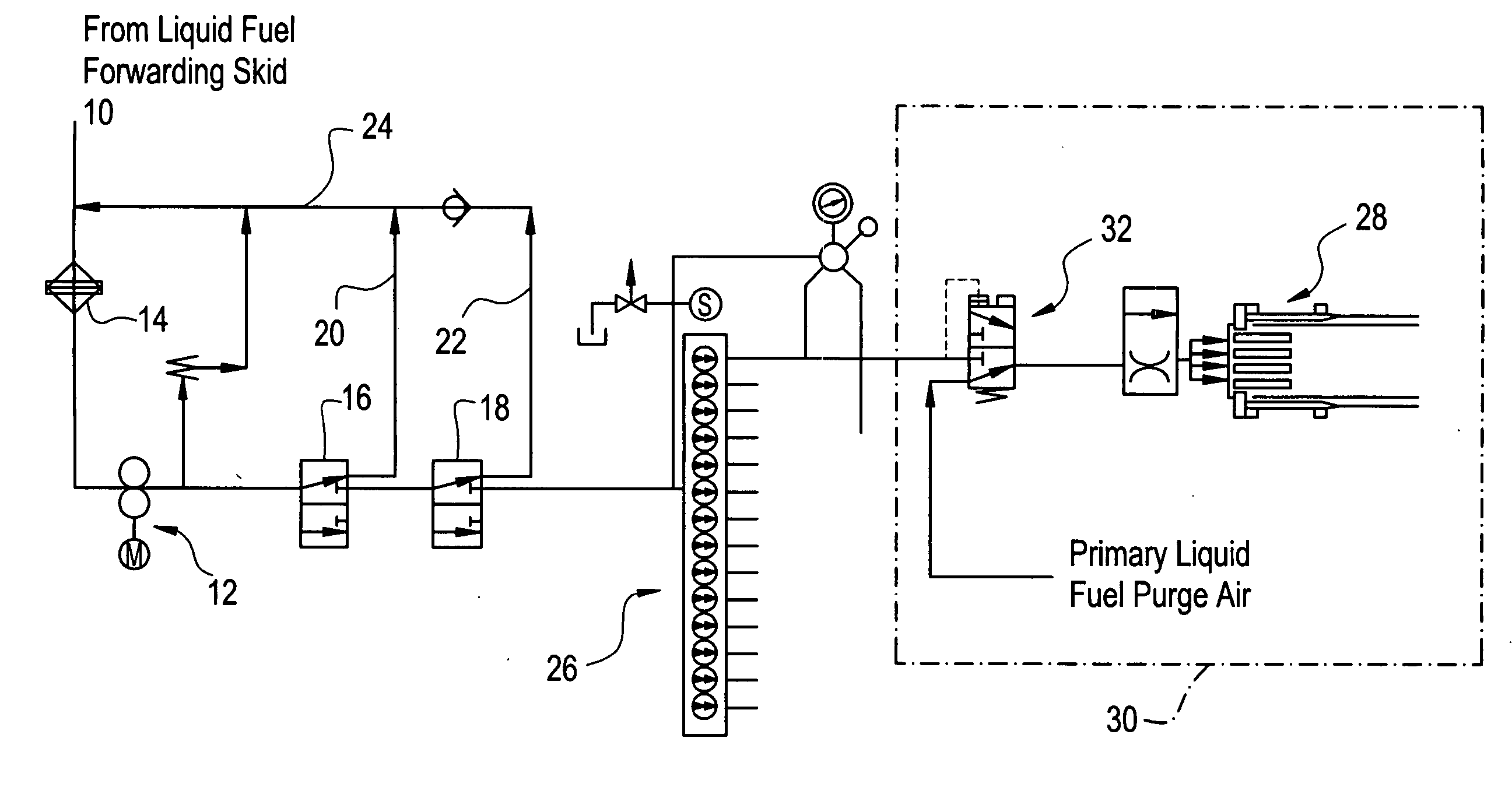

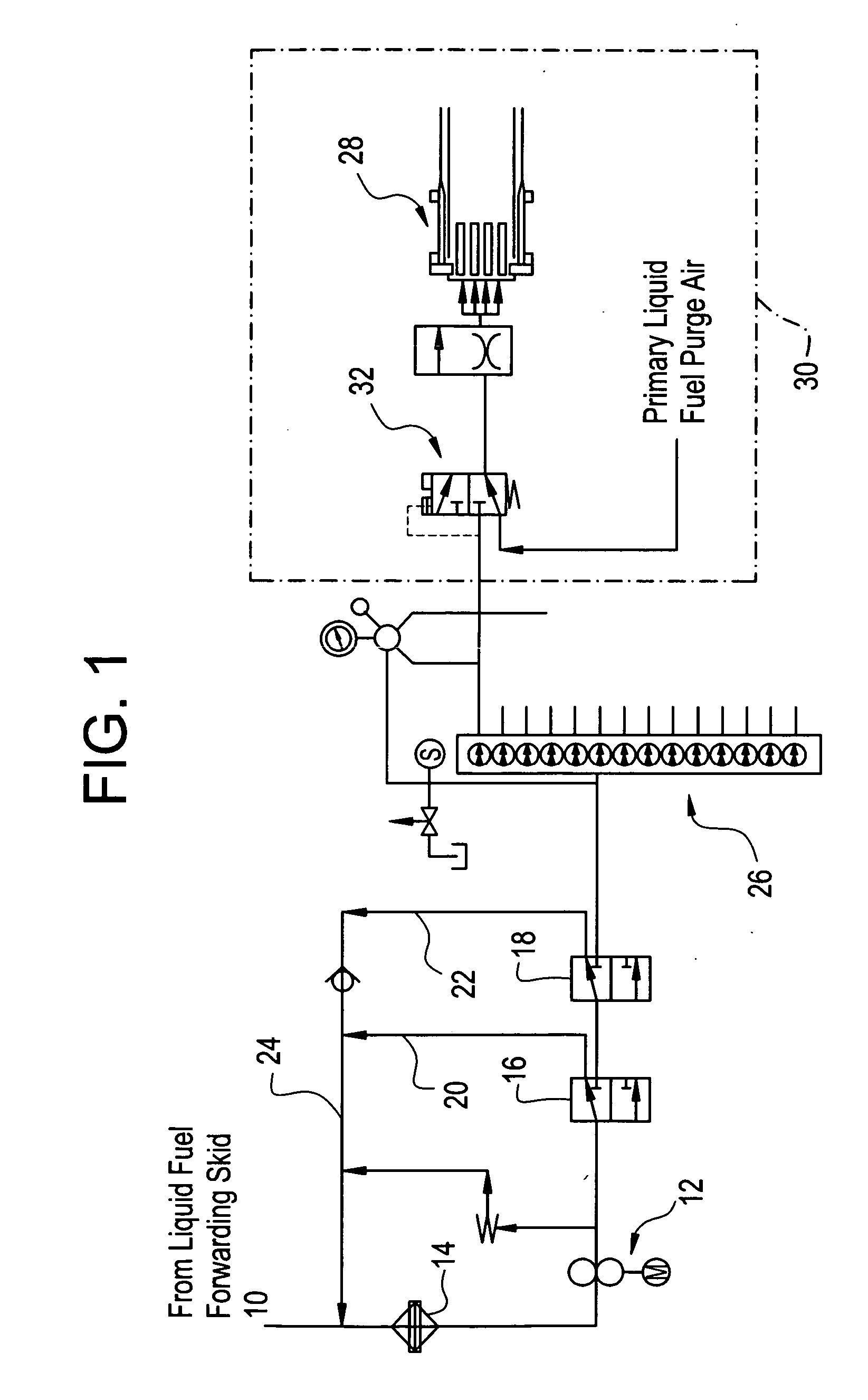

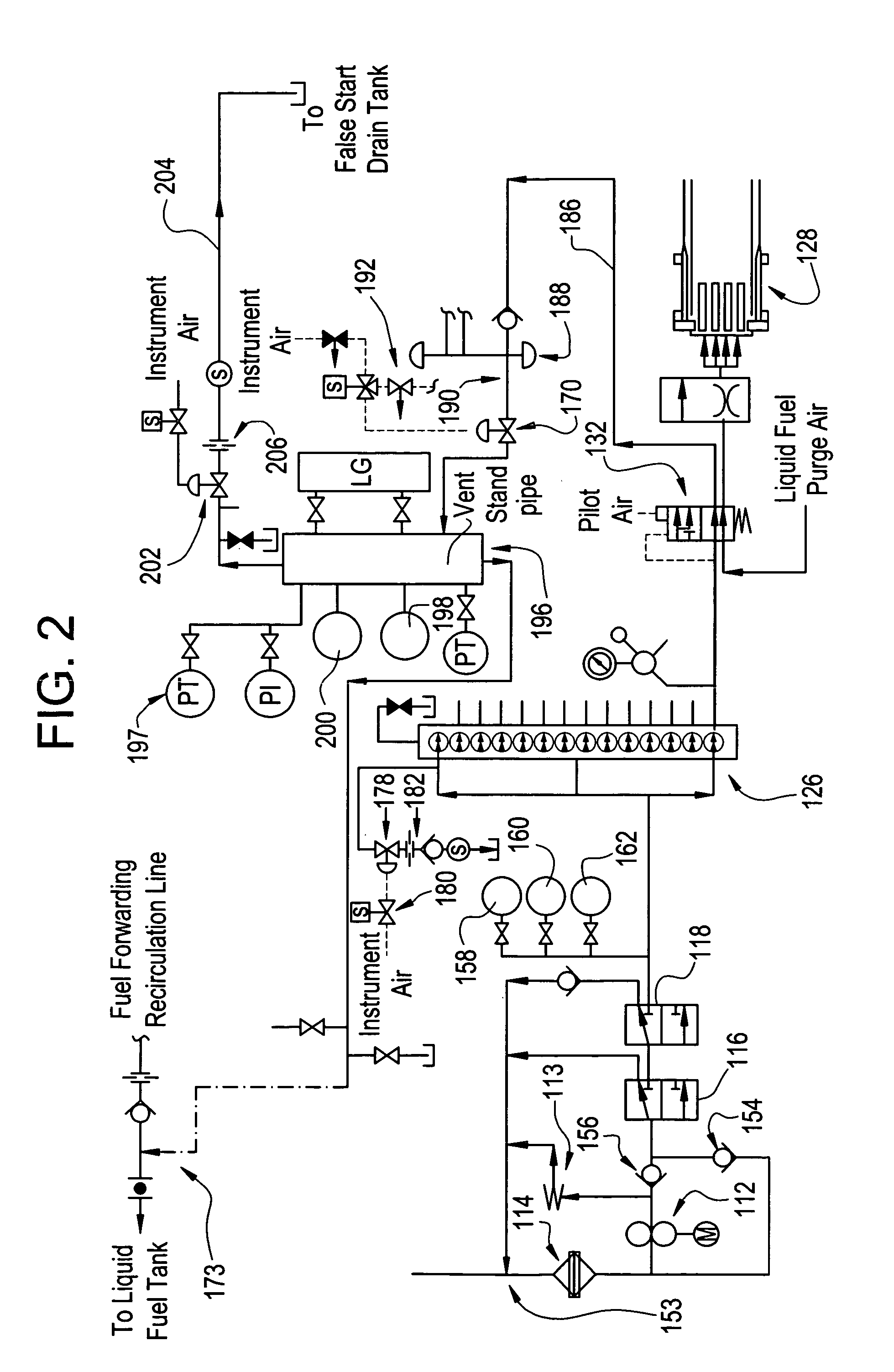

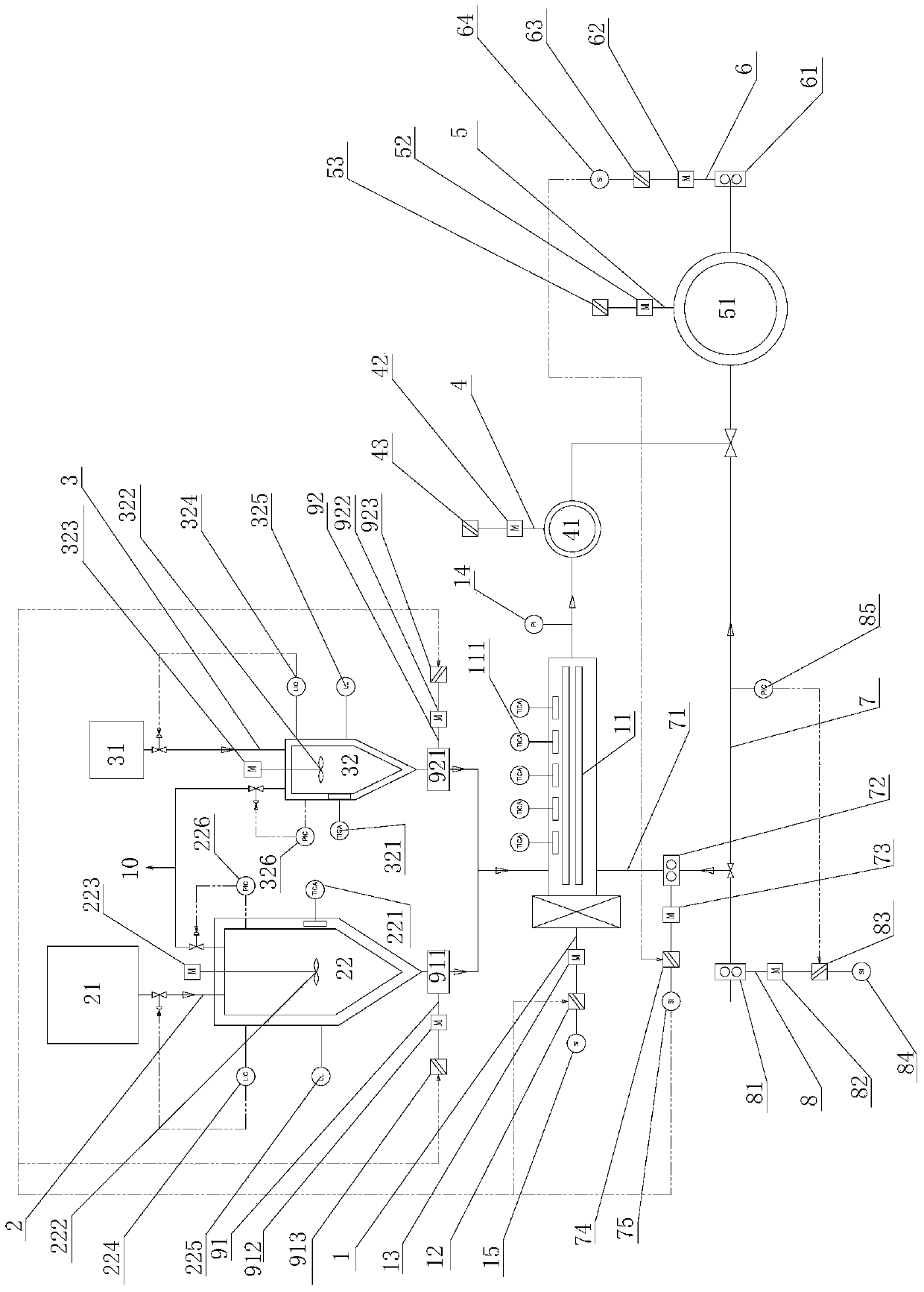

Liquid fuel recirculation system and method

InactiveUS20060150631A1Reduce and eliminate distillate carbon formationReduce and eliminate carbon formationTurbine/propulsion fuel supply systemsGas turbine plantsLiquid fuelStorage tank

A recirculation system for circulating distillate during gas fuel operation so as to reduce or eliminate distillate carbon formation. The recirculation system keeps the distillate's temperature below the carbon formation limit by circulating the distillate back to a storage tank to cool the distillate due to a volume of the storage tank compared to the volume of the recirculation system. The recirculating flow also exercises the flow dividers' gears without having to perform fuel transfers. Further, the system evacuates air from the liquid fuel lines to further decrease the likelihood of carbonaceous residue forming on any interior surfaces that are actually exposed to distillate.

Owner:GENERAL ELECTRIC CO

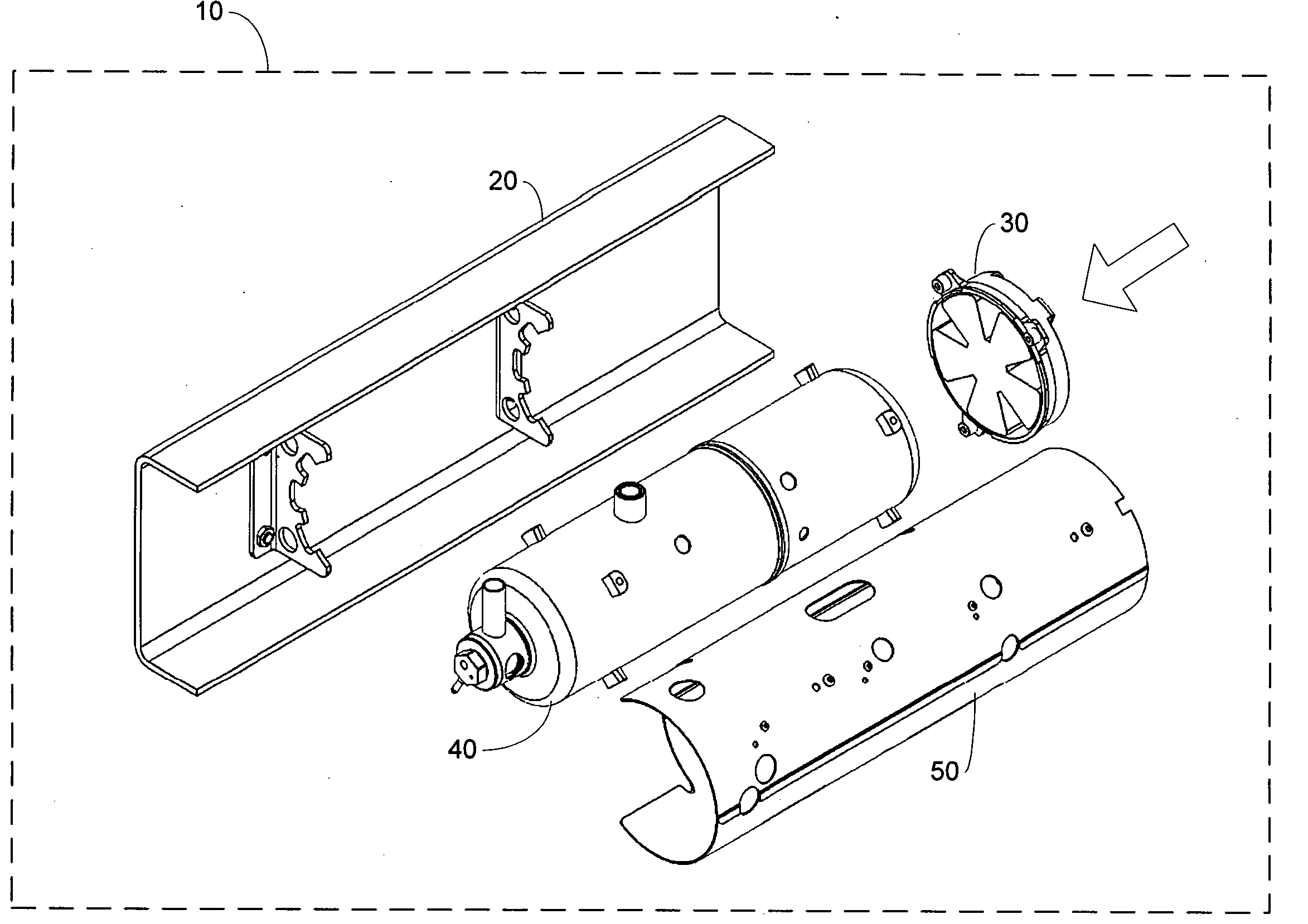

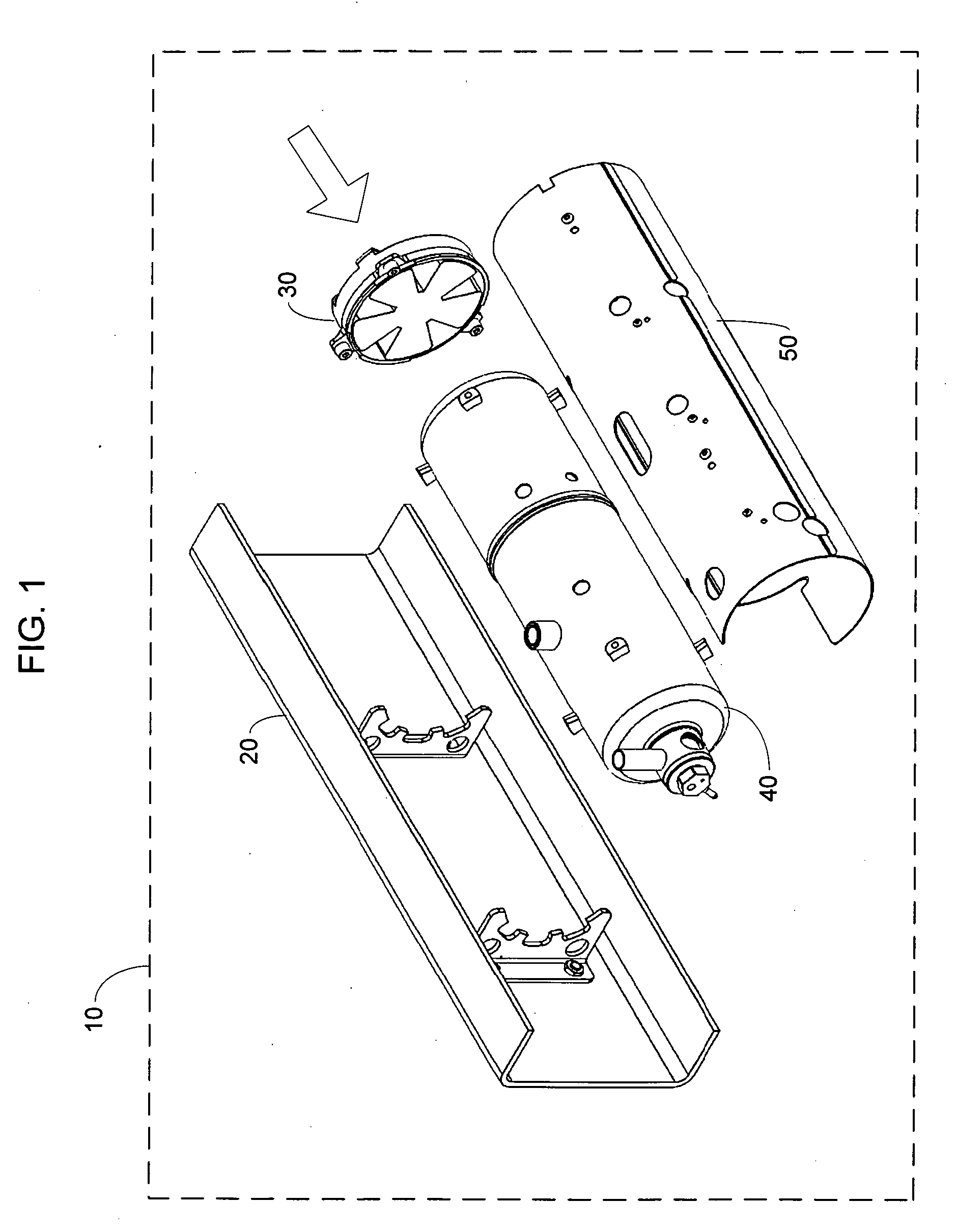

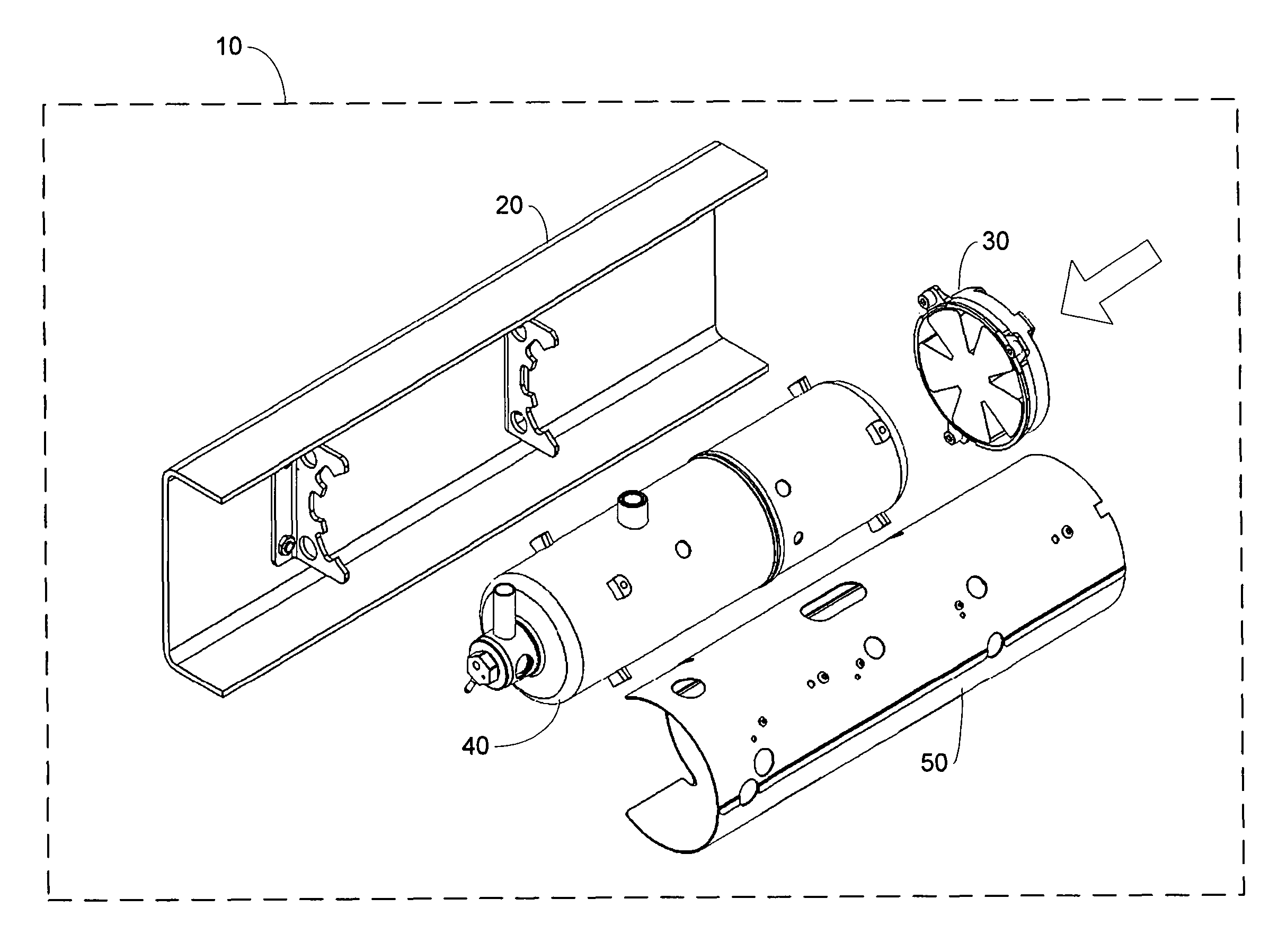

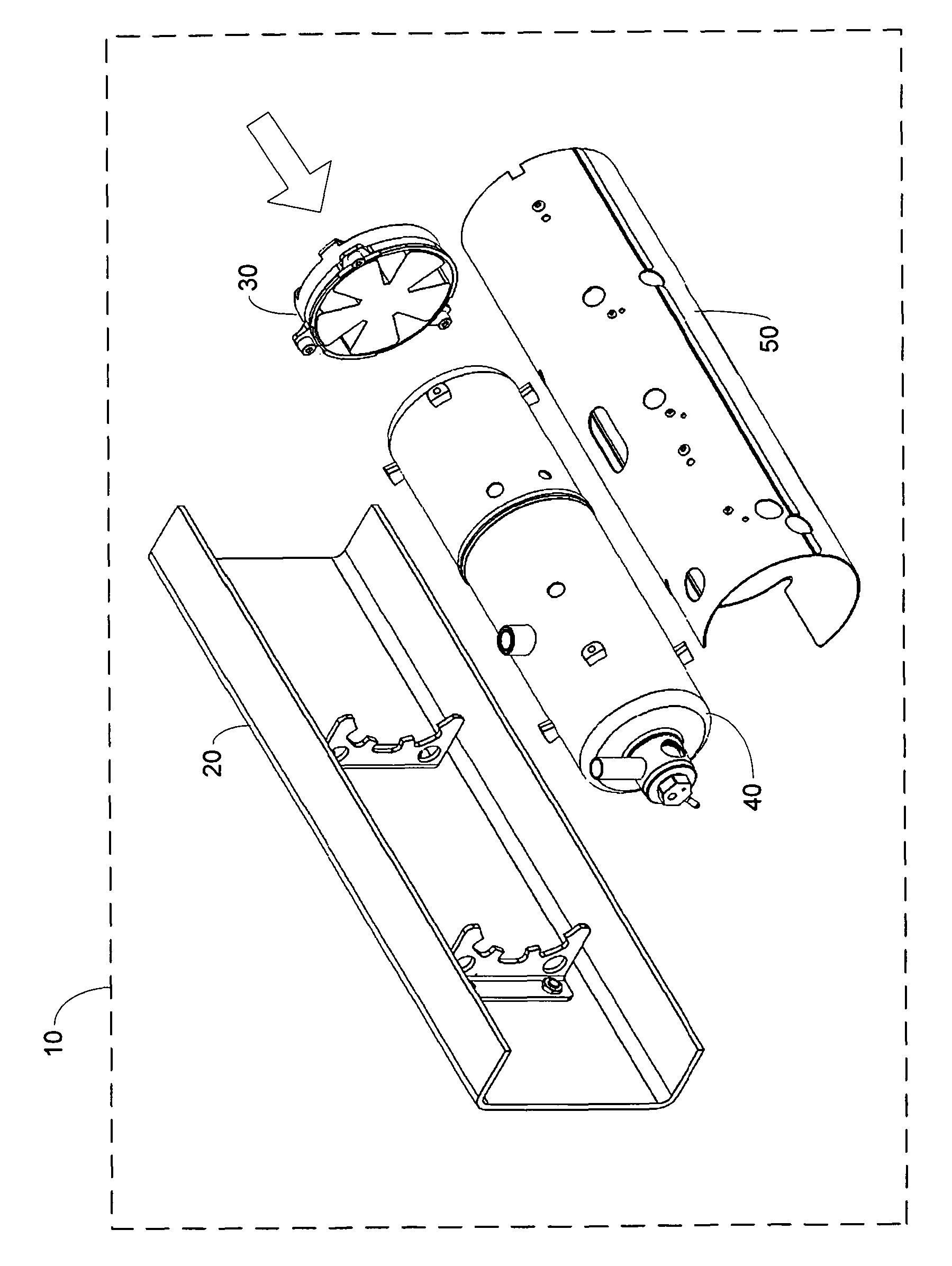

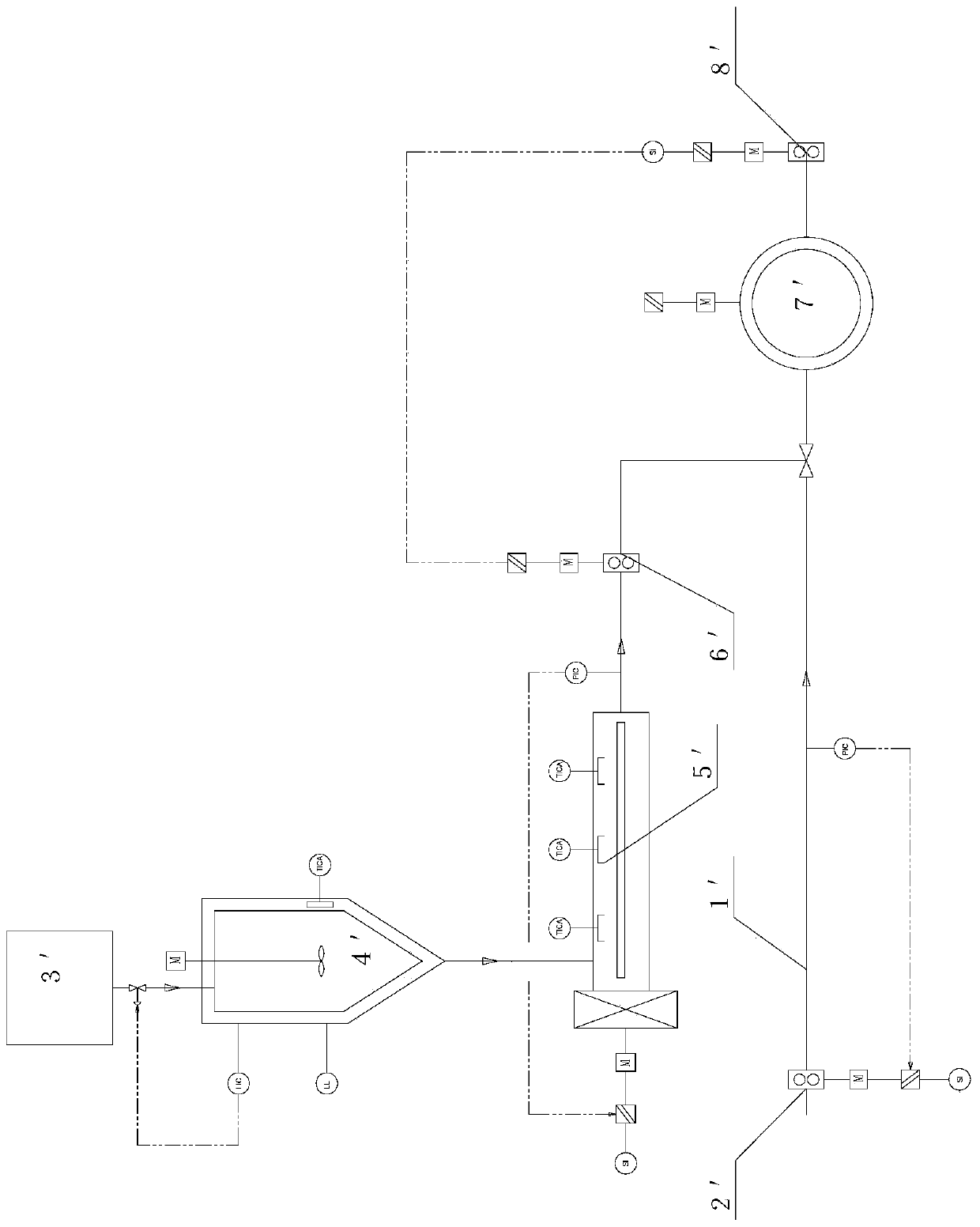

Actively Cooled Fuel Processor

InactiveUS20090235585A1Accelerates the rate of heat lossIncrease heat loss rateCarburetting by solid carbonaceous material pyrolysisGas generation devicesHydrogenActive cooling

A fuel processor for producing a hydrogen-containing product stream from a fuel stream and an oxidant stream is actively-cooled by a gaseous or liquid coolant which is directed to flow in contact with at least a portion of the outer shell of the fuel processor. Active cooling can improve the operating characteristics of the fuel processor as well as allowing for the use of compact fuel processor designs that would otherwise tend to have insufficient heat loss capability.

Owner:WESTPORT FUEL SYST CANADA INC

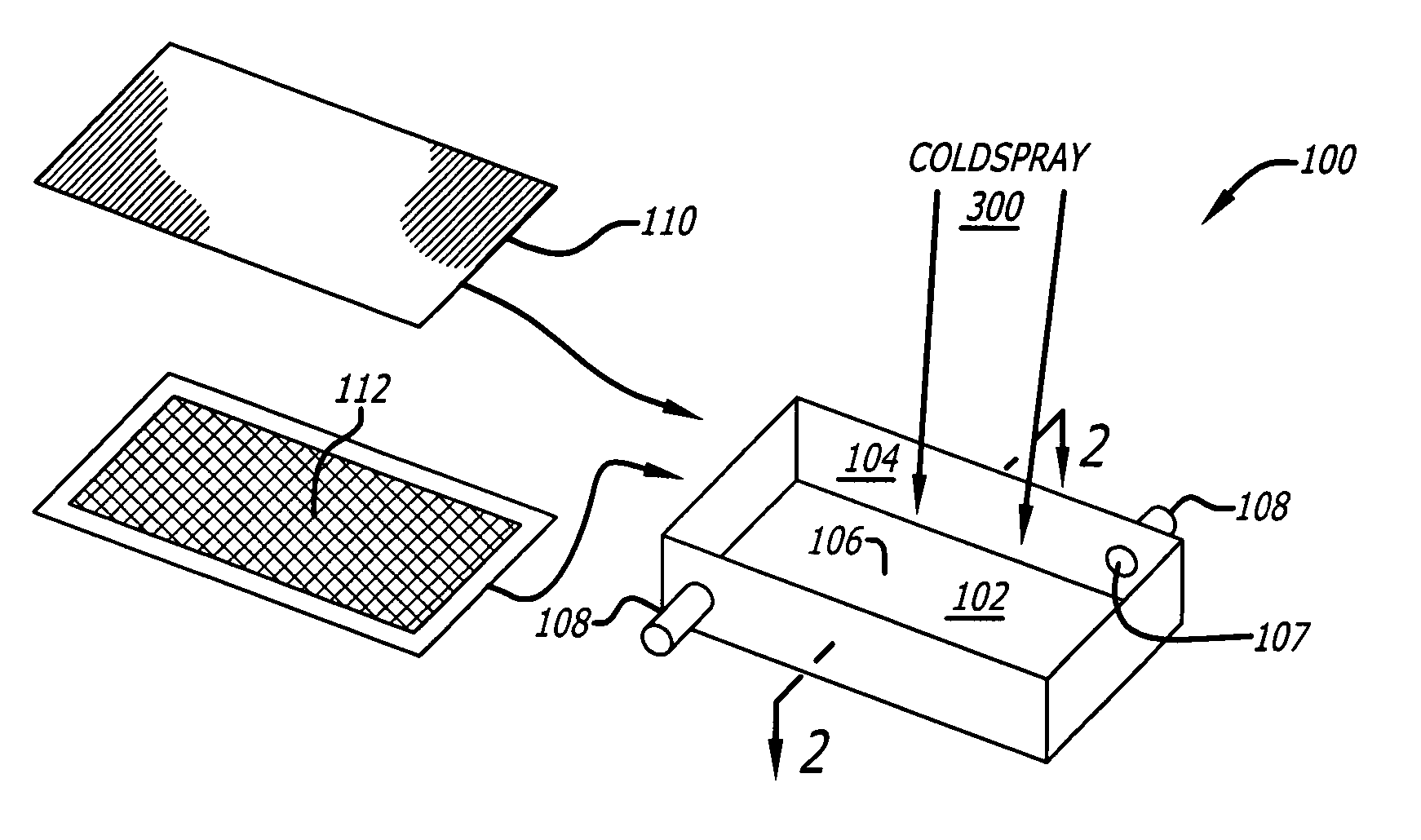

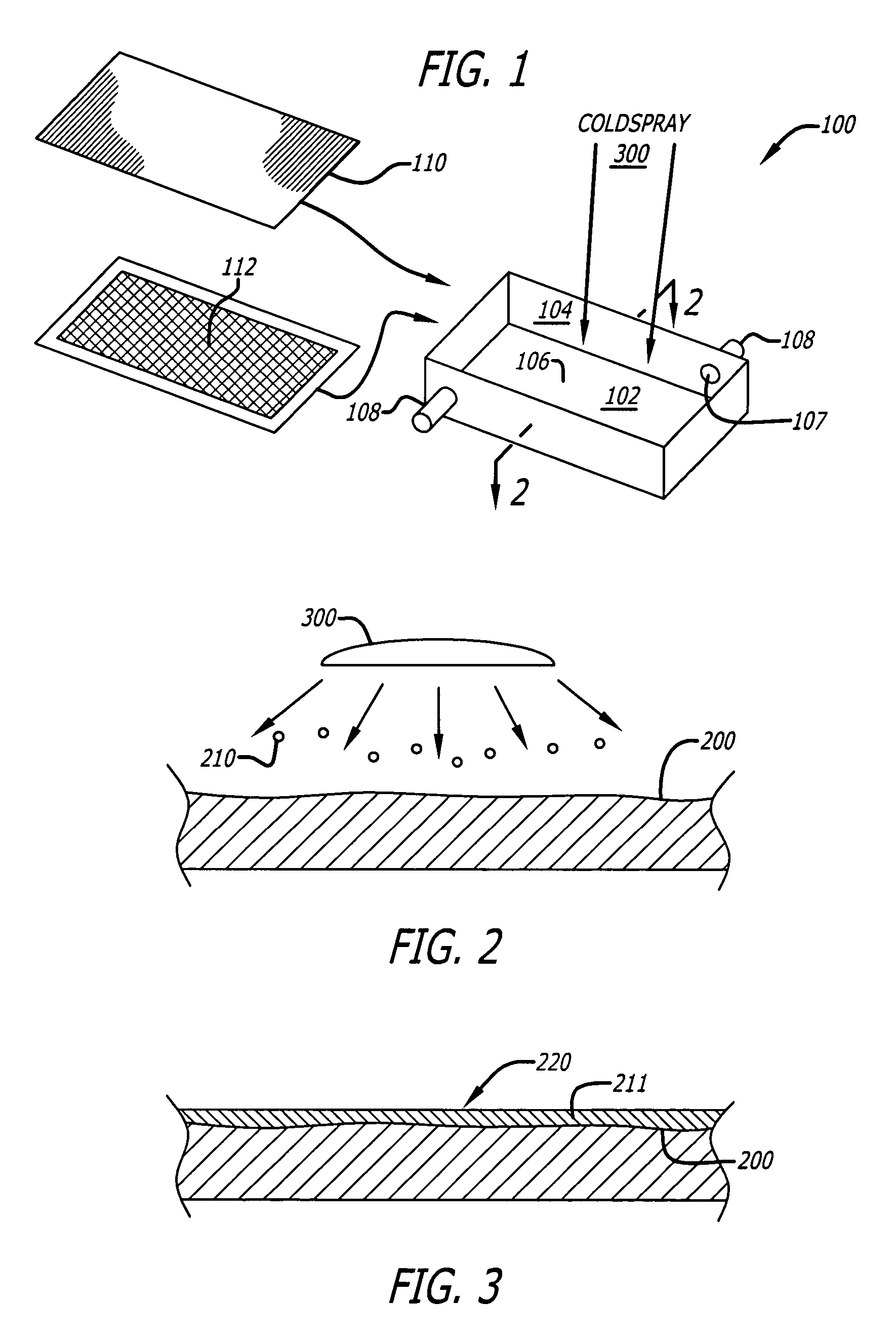

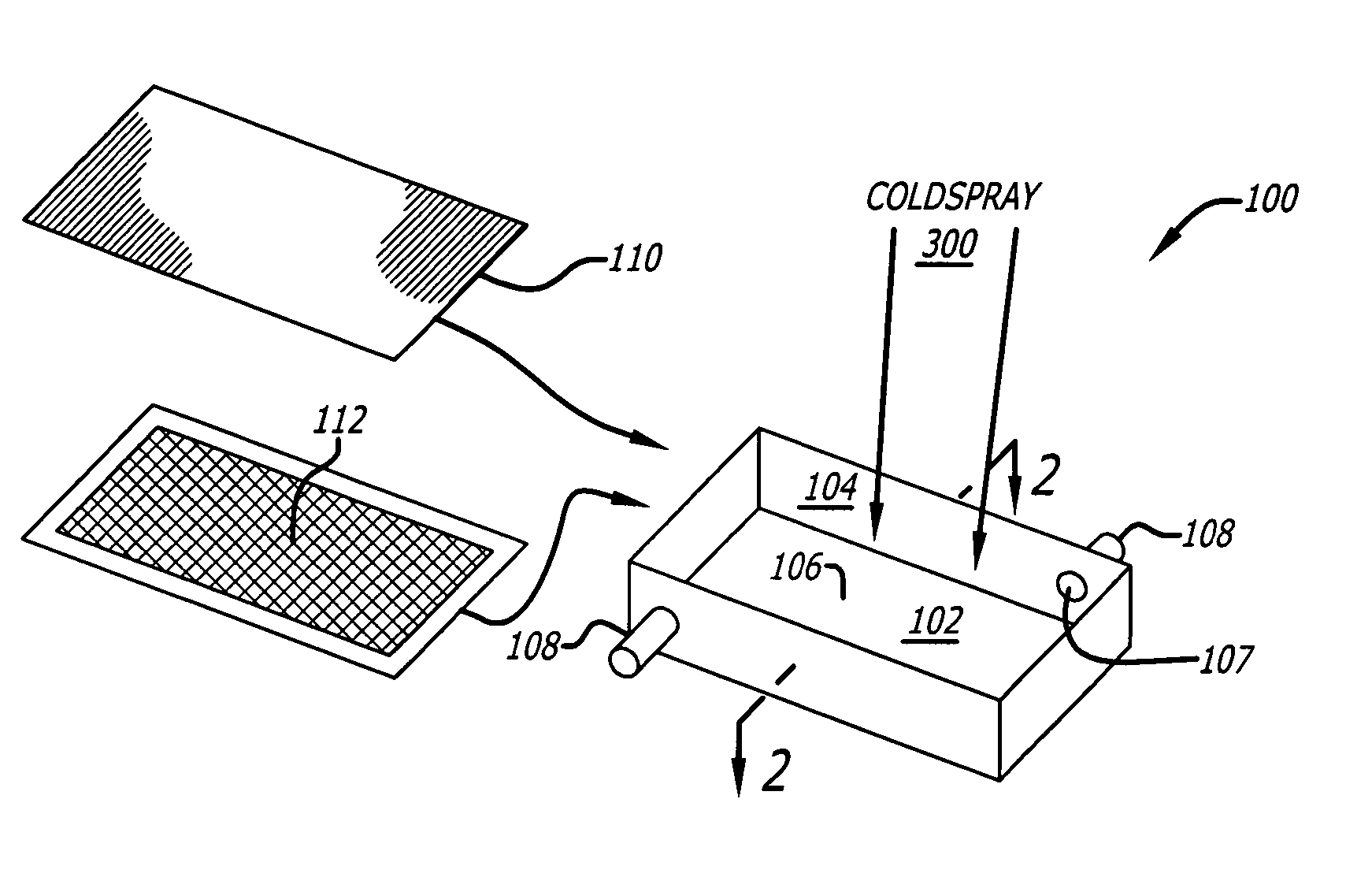

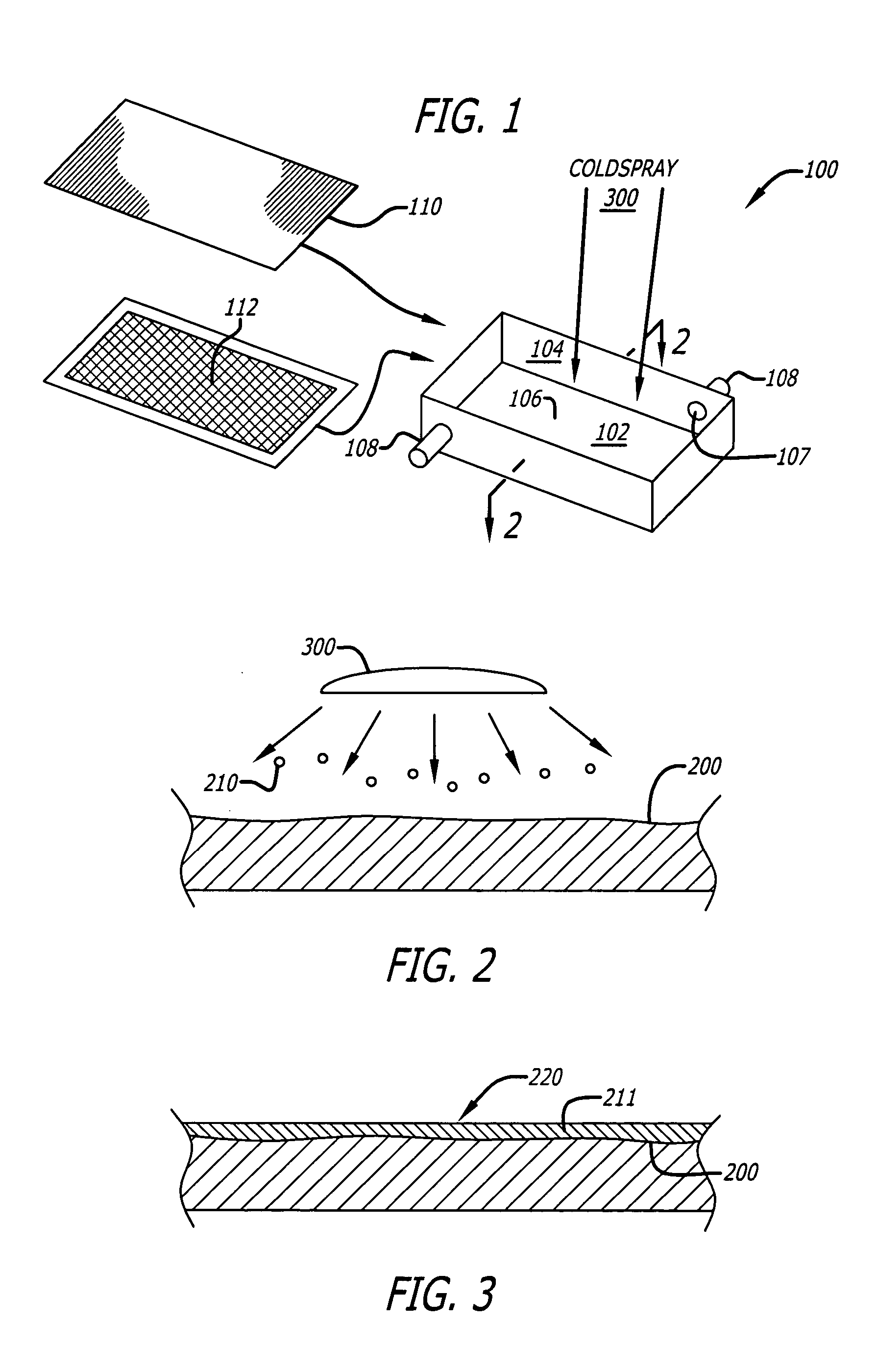

Hydrogen generation reactor chamber with reduced coking

ActiveUS20050100693A1Mitigate carbon formationEnvelopes/bags making machineryHydrogen/synthetic gas productionHydrogenMetal

Owner:AMOGY INC

Method for preparing vinylidene fluoride monomer

ActiveCN104557446AImprove conversion rateHigh selectivityPreparation by hydrogen halide split-offPhysical chemistryReaction temperature

The invention relates to a method for preparing a vinylidene fluoride monomer. The method is characterized by comprising the following steps: preheating and mixing water and 1,1-difluoro-1-chloroethane and feeding the mixture into a cracking tube, quenching reacted cracking gas, removing HCl, drying and feeding the dried gas to a rectifying tower to obtain the high-purity vinylidene fluoride monomer. By the method, the problems of carbon deposition, clogging of a pipeline and the like can be decreased, the selectivity and reaction efficiency can be effectively improved, the reaction temperature is decreased and thus the energy consumption can be reduced, the energy consumption is substantially reduced and the pollution is decreased.

Owner:RUYUAN DONGYANG LIGHT FLUORINE RESIN CO LTD

Process and reactor for the thermoneutral conversion of ethanol to acetic acid

InactiveUS20100130776A1Production of ethanolAvoid the needOrganic compound preparationCarbonyl compound preparationAcetic acidNon oxidative

A process and reactor for the production of acetic acid comprising the steps of: passing a feed stream containing ethanol and water together with a predetermined feed rate of an oxygen containing atmosphere in presence of one or more catalysts being active in simultaneous non-oxidative and oxidative conversion of ethanol to a product stream with acetic acid; recovering from the product stream a stream of acetic acid; optionally recovering reactive derivatives of acetic acid and recycling these to step (a).

Owner:HALDOR TOPSOE AS

Preparation method of ZnO-ZrO2@SAPO-34 core-shell catalyst

InactiveCN108295895AHigh selectivityExtend your lifeMolecular sieve catalystsMolecular sieve catalystMorpholineRoom temperature

The invention discloses a preparation method of a ZnO-ZrO2@SAPO-34 core-shell catalyst. The preparation method comprises the following steps: preparing ZnO-ZrO2 powder; according to a molar ratio of raw materials, namely Al2O3, P2O5, SiO2, MOR (morpholine) and H2O, of 1.0:0.8:0.6:2.5:80, sequentially adding pseudoboehmite, tetraethyl orthosilicate and a templating agent morpholine into an orthophosphoric acid solution while stirring, continuously stirring uniformly, stirring and aging at room temperature for 24h to form a sol system, adding the ZnO-ZrO2 powder into the system according to a core-shell mass ratio of ZnO-ZrO2 to SAPO-34 of 1:4 to 4:1, continuing stirring uniformly, then transferring to a reaction kettle, performing hydrothermal crystallization at 190-210 DEG C for 24-48h, cooling, filtering, washing by using deionized water till a neutral state, drying at 105 DEG C for 6h, and roasting at 500-600 DEG C for 3h to obtain the ZnO-ZrO2@SAPO-34 core-shell catalyst. The catalyst prepared by the preparation method provided by the invention can simultaneously increase the carbon dioxide conversion rate and the low-carbon olefin selectivity in a two-step technology in which the low-carbon olefin is prepared from methanol through CO2 hydrogenation.

Owner:GUIZHOU UNIV

Preparation method of ZnO-ZrO2@Al2O3@SAPO-34 dual-core-shell catalyst

InactiveCN108246356AExtend your lifePromote growthHydrocarbon from carbon oxidesMolecular sieve catalystsMorpholineDual core

The invention discloses a preparation method of a ZnO-ZrO2@Al2O3@SAPO-34 dual-core-shell catalyst. The preparation method comprises the following steps: preparing ZnO-ZrO2@Al2O3 powder; taking Al2O3,P2O5, SiO2, MOR and H2O in a molar ratio of 1.0:0.8:0.6:2.5:80; adding pseudo-boehmite, ethyl orthosilicate and a template agent morpholine to an orthophosphoric acid solution sequentially while stirring, performing uniform stirring continuously, and performing stirring and aging for 24h at room temperature to form a sol system; adding 200-400-mesh ZnO-ZrO2@Al2O3 powder to the system according tothe core-shell mass ratio of ZnO-ZrO2@Al2O3: SAPO-34 of (1:4)-(4:1), performing uniform stirring continuously, and then, transferring the product into a reactor; and performing hydrothermal crystallization for 24-48h at 190-210 DEG C, performing cooling and filtration, performing washing to neutrality with deionized water, performing drying for 6h at 105 DEG C, and performing roasting for 3h at 500-600 DEG C to obtain the catalyst. The catalyst prepared by the preparation method disclosed by the invention can simultaneously improve the conversion rate of carbon dioxide and the selectivity of low-carbon olefin in a two-step process for preparing low-carbon olefin by CO2 hydrogenation through methanol.

Owner:GUIZHOU UNIV

Method for preparing ZnO-Al2O3@ZSM-5 core-shell structured catalyst

InactiveCN108339565AHigh selectivityExtend your lifeMolecular sieve catalystsMolecular sieve catalystPtru catalystCentrifugation

The invention discloses a method for preparing a ZnO-Al2O3@ZSM-5 core-shell structured catalyst. The method comprises the steps: preparing ZnO-Al2O3 powder; and proportioning raw materials, i.e., n(TEOS), n(NaAlO2), n(TPAOH) and n(H2O) according to a mole ratio of (40 to 360): 1: 19: 4015, sequentially adding NaAlO2, TPAOH and TEOS into deionized water with stirring, carrying out uniform stirringcontinuously, carrying out aging for 3h with stirring at room temperature to form a sol system, adding ZnO-Al2O3 powder into the system according to a core-shell mass ratio, i.e., ZnO-Al2O3: ZSM-5 of(1: 4) to (4: 1), carrying out uniform stirring continuously, carrying out a hydrothermal reaction for 36 to 48 hours at the temperature of 170 DEG C to 190 DEG C in a homogeneous reactor, cooling reacted substances to room temperature, carrying out centrifugation, carrying out washing with deionized water, carrying out washing with anhydrous ethanol, carrying out drying for 12h at the temperature120 DEG C, carrying out roasting for 3h at the temperature 500 DEG C to 600 DEG C, thereby preparing the ZnO-Al2O3@ZSM-5 core-shell structured catalyst. The catalyst prepared by the method can be used for simultaneously improving conversion ratio of carbon dioxide and selectivity of low-carbon olefins in a two-step method process for preparing the low-carbon olefins from methanol through CO2 hydrogenation.

Owner:GUIZHOU UNIV

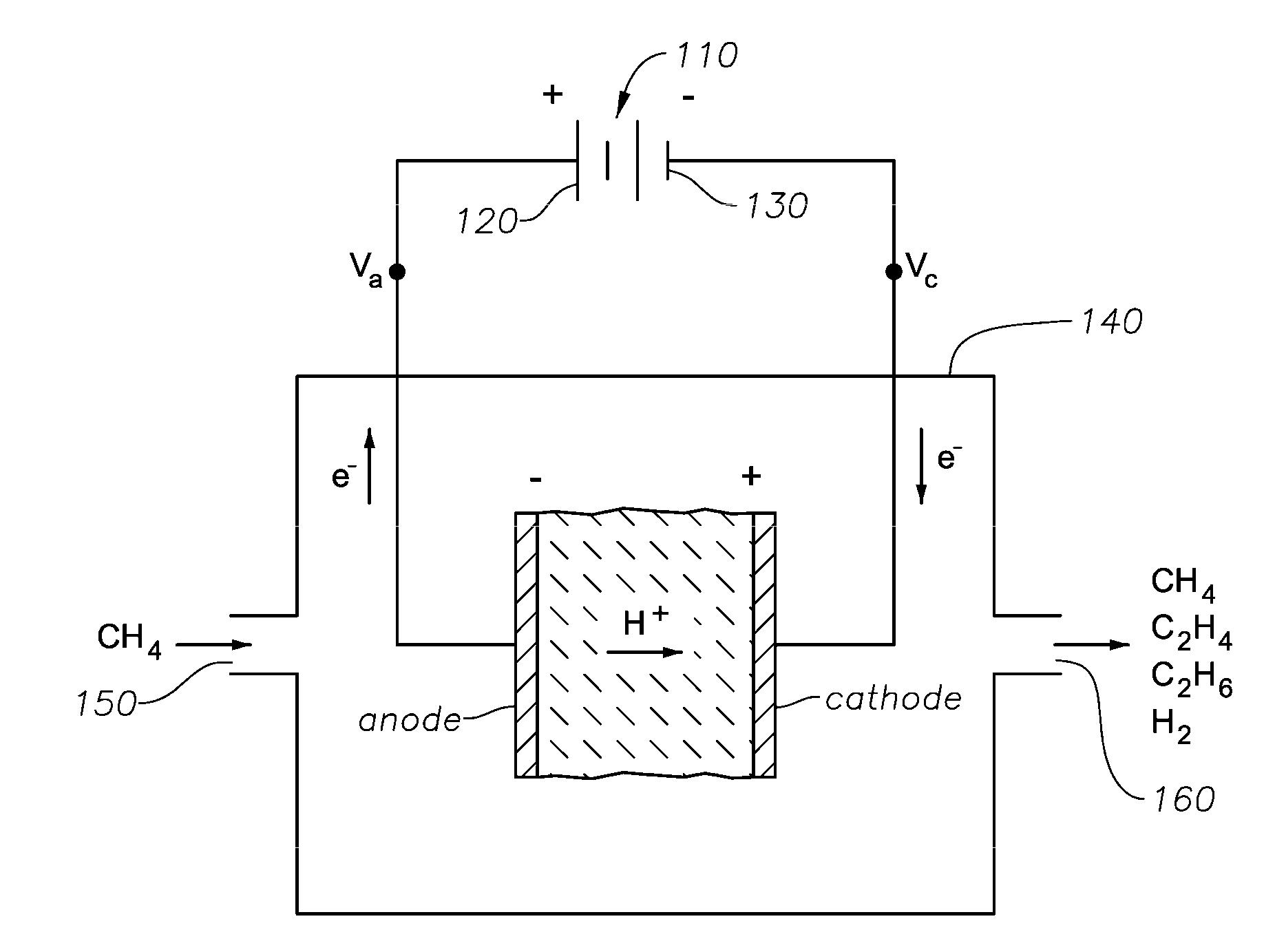

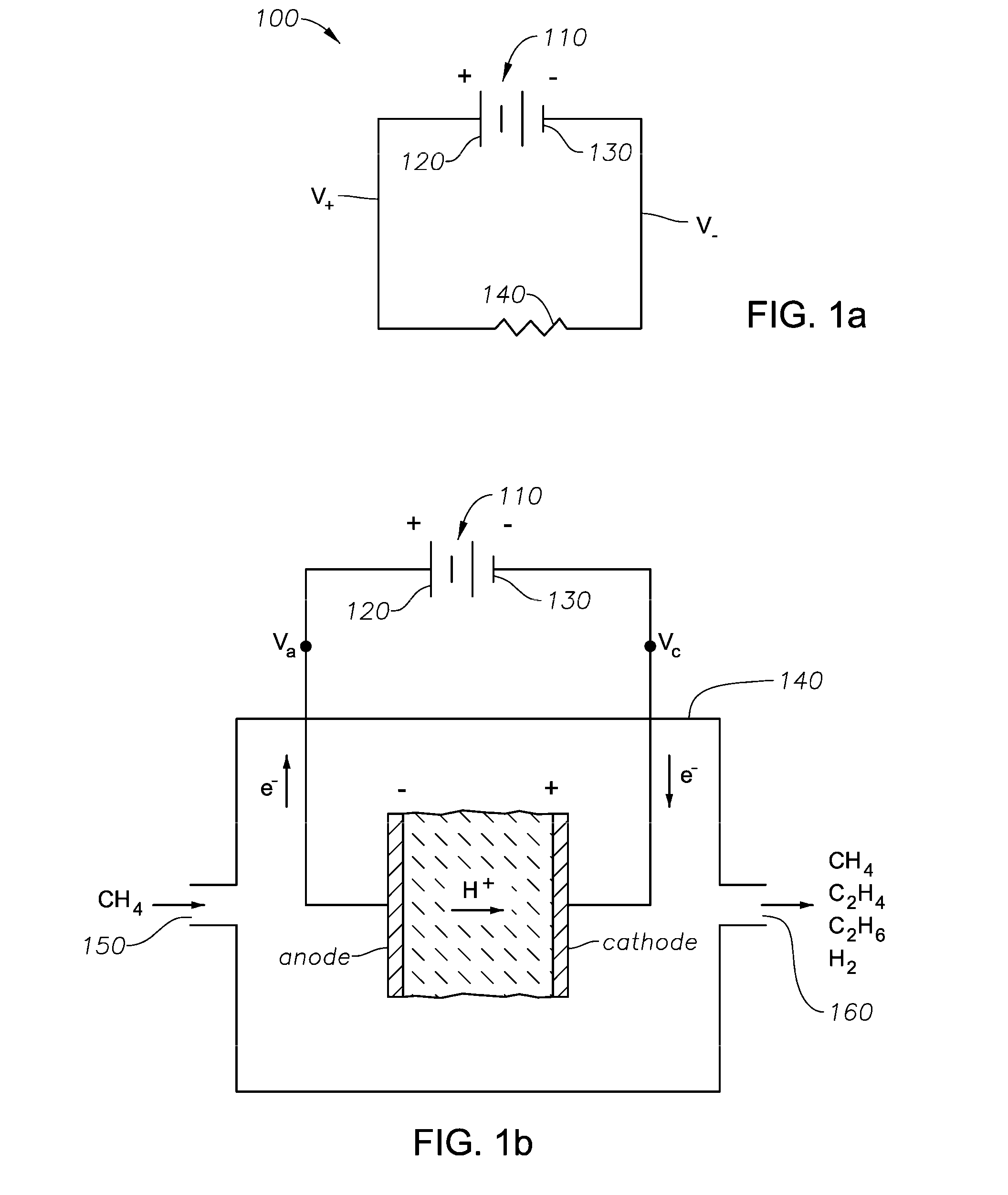

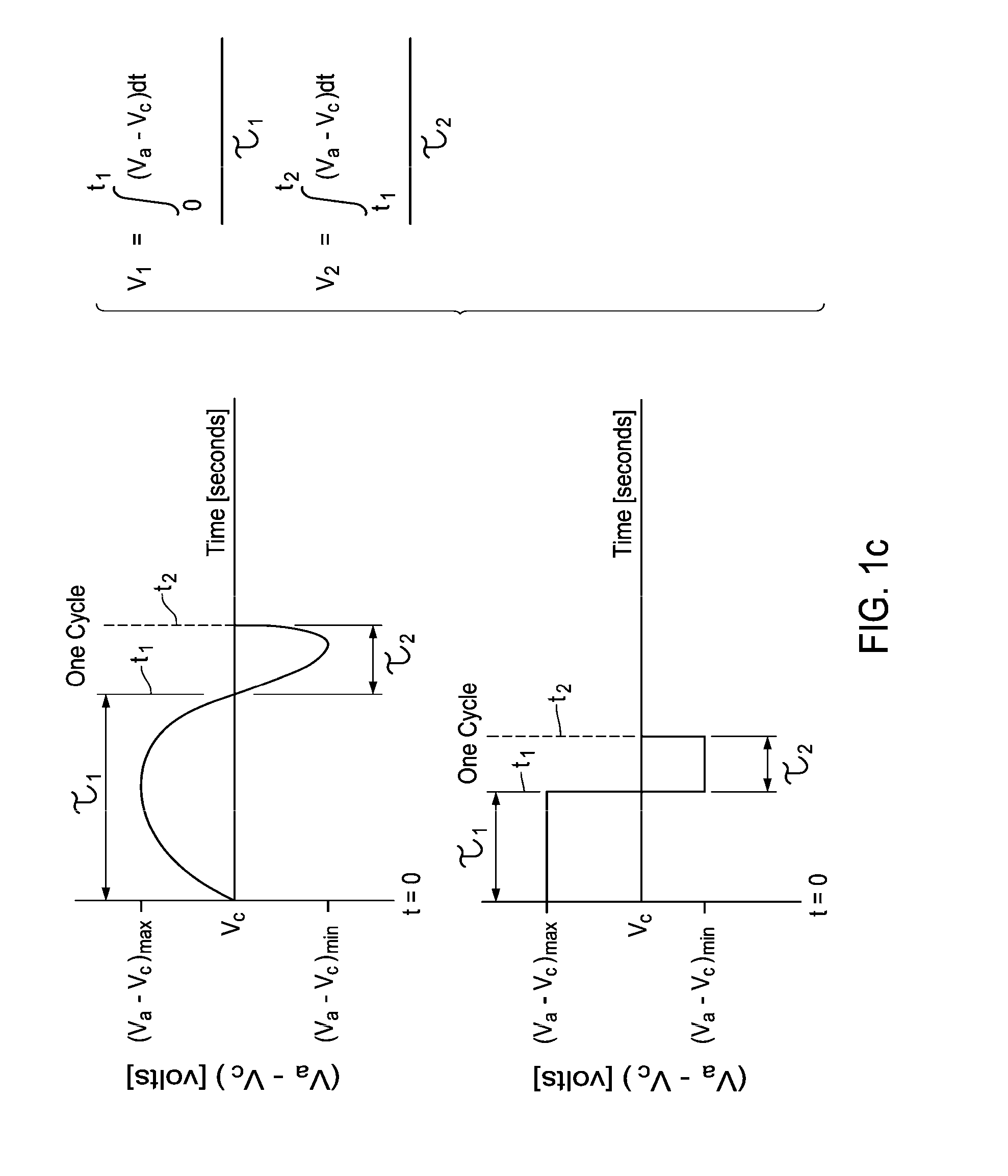

Electrochemical Conversion of Hydrocarbons

ActiveUS20150119542A1Mitigate carbon formationGood choiceGas treatmentElectrolysis componentsHydrocotyle bowlesioidesEngineering

An electrochemical conversion method for converting at least a portion of a first mixture comprising hydrocarbon to C2+ unsaturates by repeatedly applying an electric potential difference, V(τ1), to a first electrode of an electrochemical cell during a first time interval τ1; and reducing the electric potential difference, V(τ1), to a second electric potential difference, V(τ2), for a second time interval τ2, wherein τ2≦τ1. The method is beneficial, among other things, for reducing coke formation in the electrochemical production of C2+ unsaturates in an electrochemical cell. Accordingly, a method of reducing coke formation in the electrochemical conversion of such mixtures and a method for electrochemically converting carbon to C2+ unsaturates as well as an apparatus for such methods are also provided.

Owner:EXXONMOBIL CHEM PAT INC

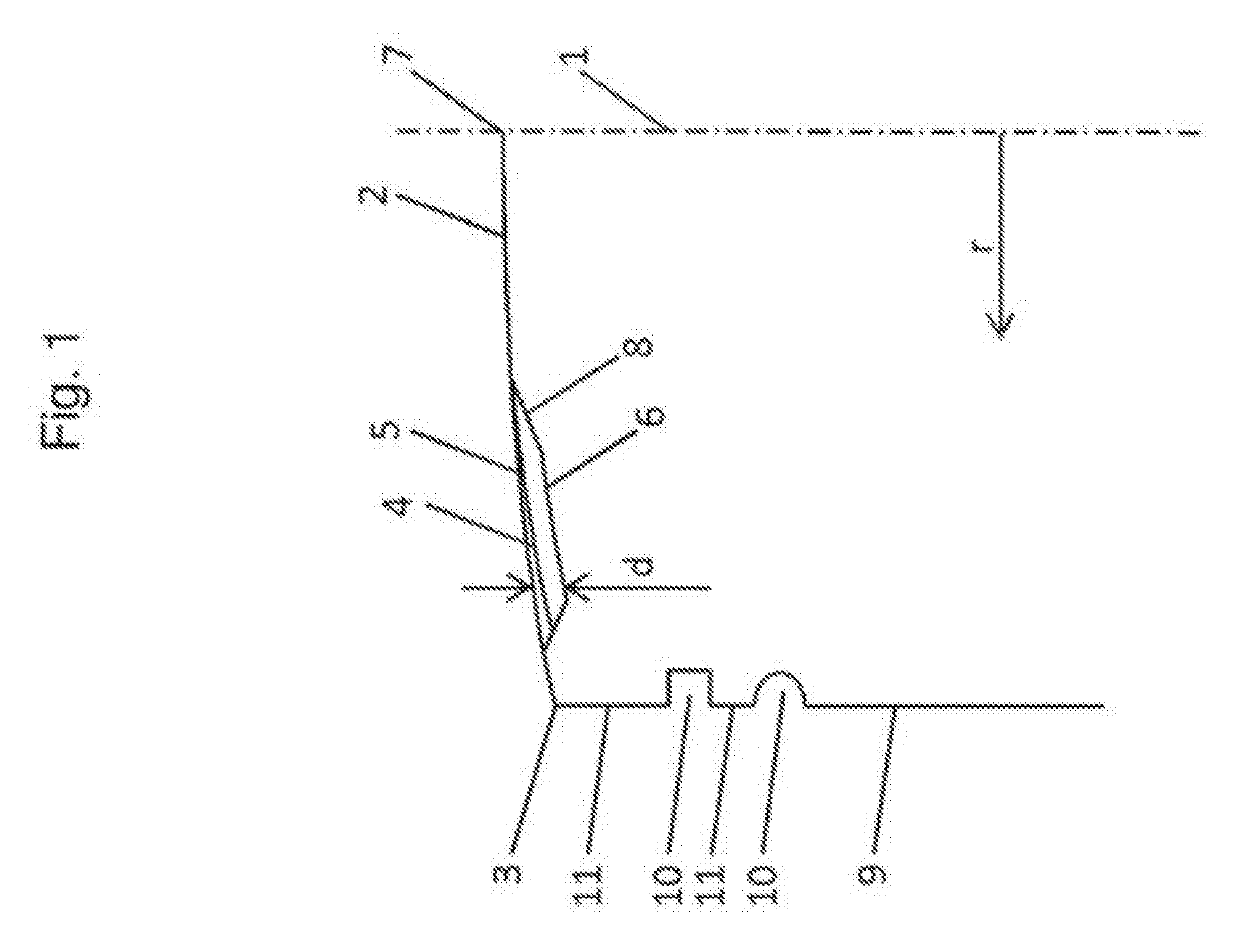

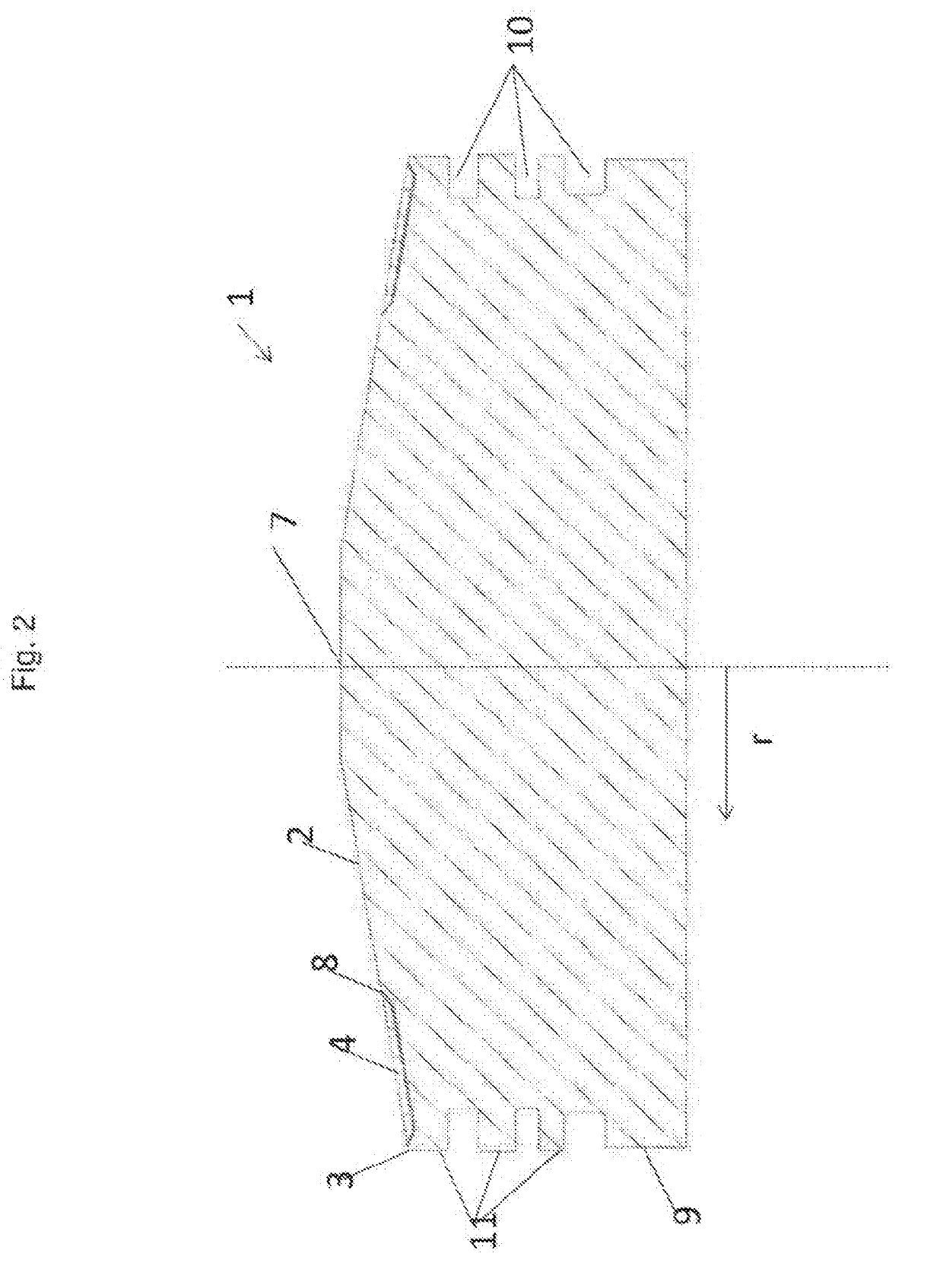

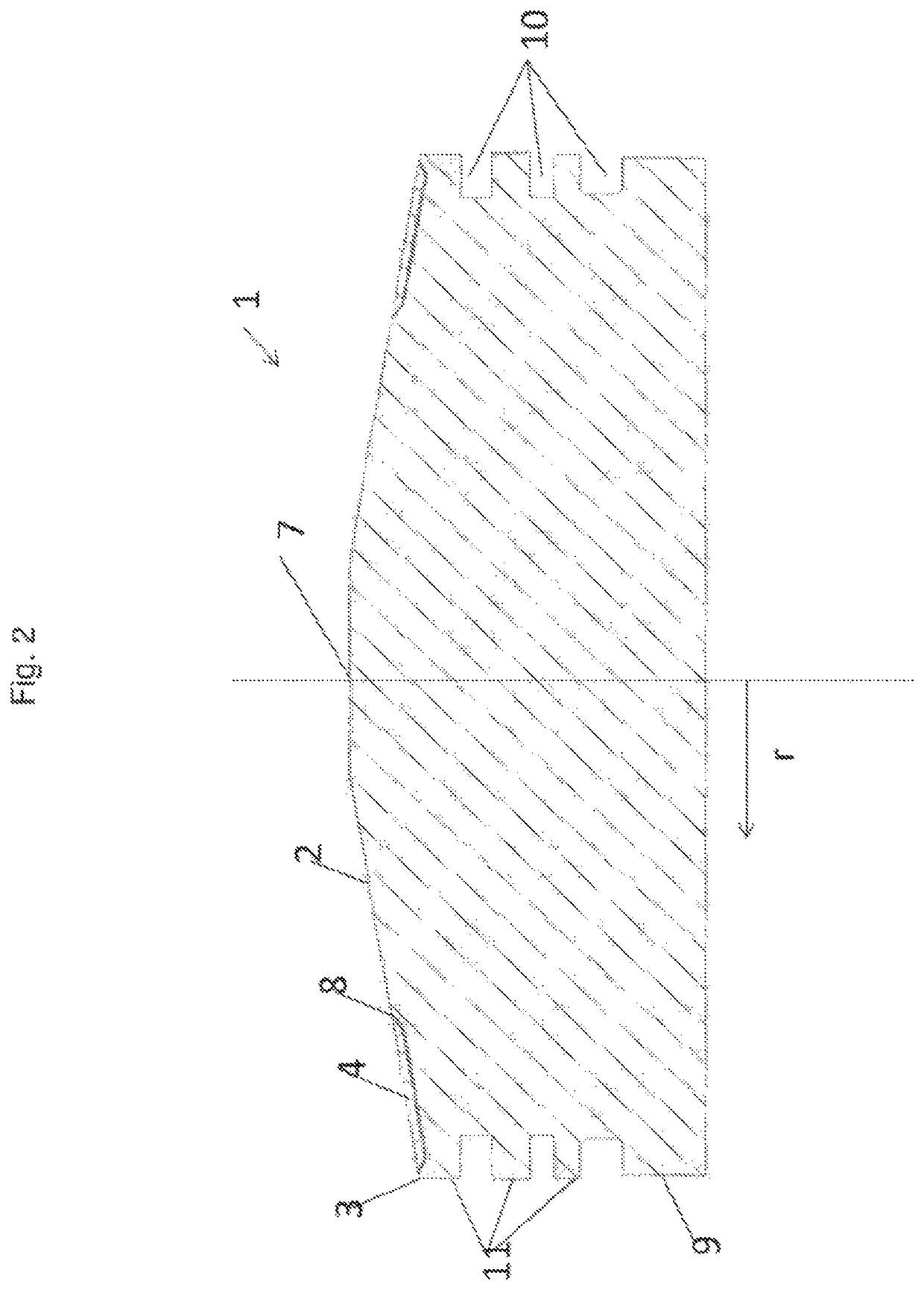

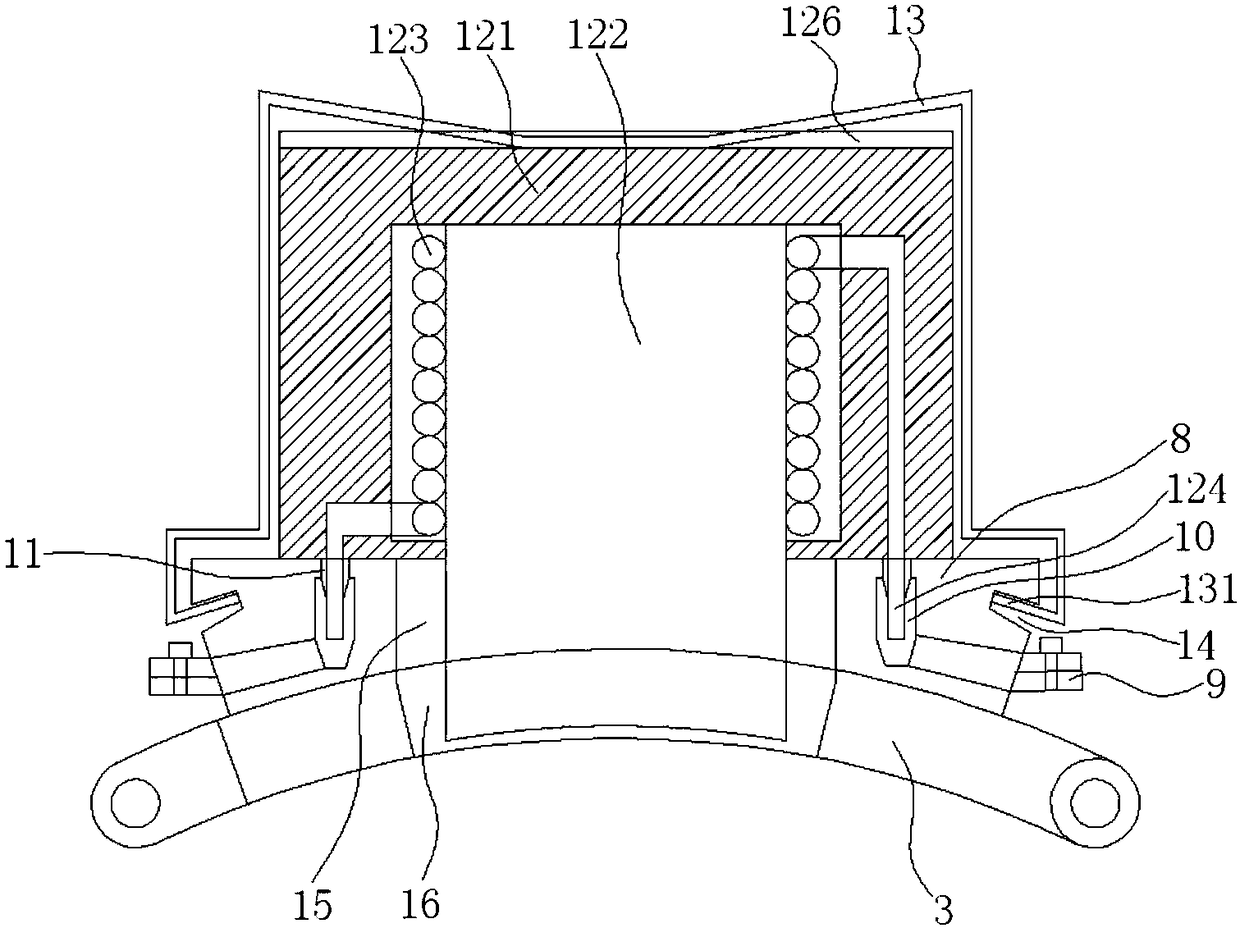

Piston for an internal combustion engine

ActiveUS20190093596A1Mitigate carbon formationReduce stressMachines/enginesPistonsExternal combustion engineInternal combustion engine

A piston for an internal combustion engine with a piston crown and a circumferentially arranged crown edge, whereby, near the periphery of the crown edge, a thermal barrier coating is applied, whereby the thermal barrier coating tapers off before the periphery of the crown edge.

Owner:GE JENBACHER

Preparation method of ZSM-5@t-ZrO2 core-shell catalyst

InactiveCN108295890ALower Diffusion LimitsEnhanced dissociation adsorptionMolecular sieve catalystsThiol preparationRoom temperatureCore shell

The invention discloses a preparation method of a ZSM-5@ t-ZrO2 core-shell catalyst. The preparation method comprises the following steps: preparing a ZSM-5 precursor solution; at room temperature, according to a core-shell mass ratio of t-ZrO2 to ZSM-5 of 4:1 to 8:1, adding the t-ZrO2 powder into the ZSM-5 precursor solution prepared in the step (1), continuing stirring uniformly, then transferring to a reaction kettle, performing hydrothermal crystallization at 180 DEG C for 48h, cooling, filtering, washing by using deionized water till a neutral state, drying at 105 DEG C for 6h, and roasting at 500-600 DEG C for 3h to obtain the ZSM-5@t-ZrO2 core-shell catalyst. The catalyst prepared by the preparation method provided by the invention can simultaneously increase the methanol conversionrate and the methanthiol selectivity and has a long service life.

Owner:GUIZHOU UNIV

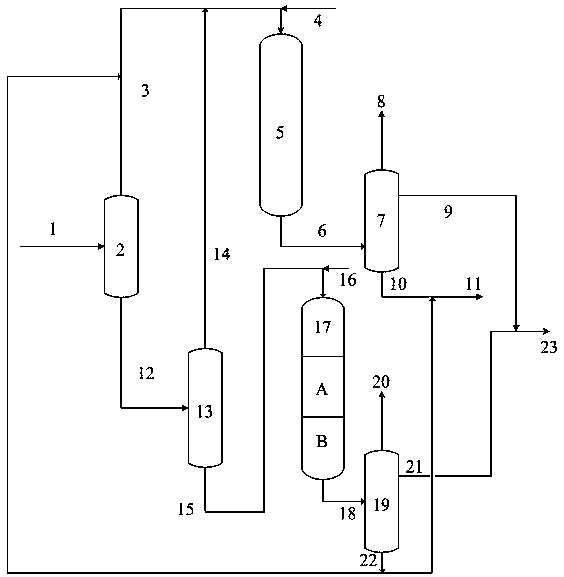

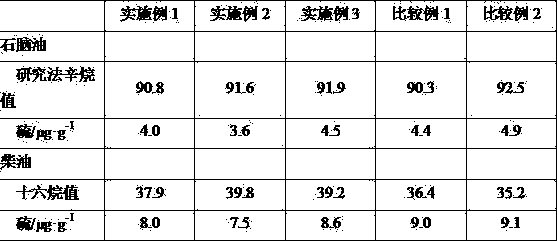

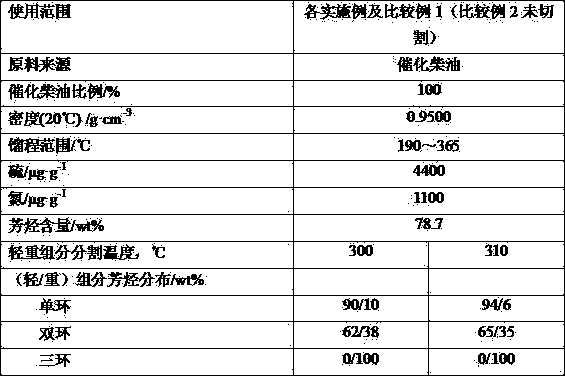

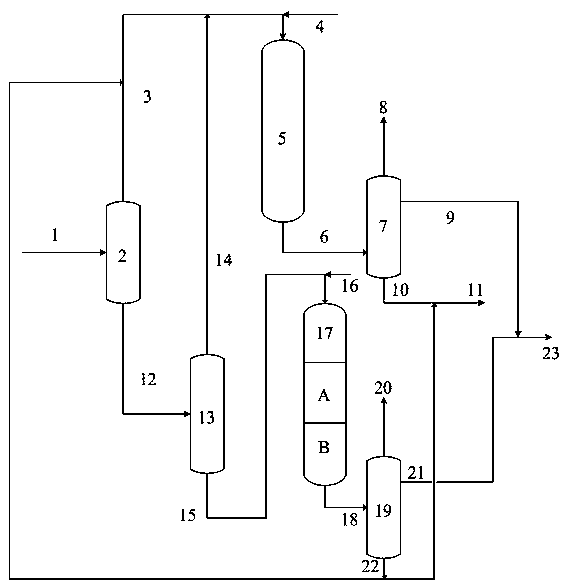

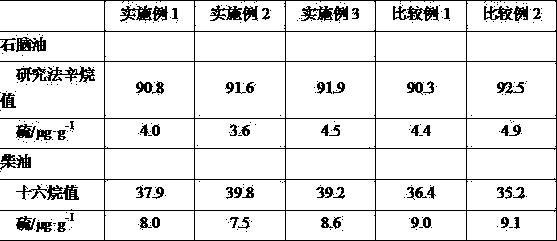

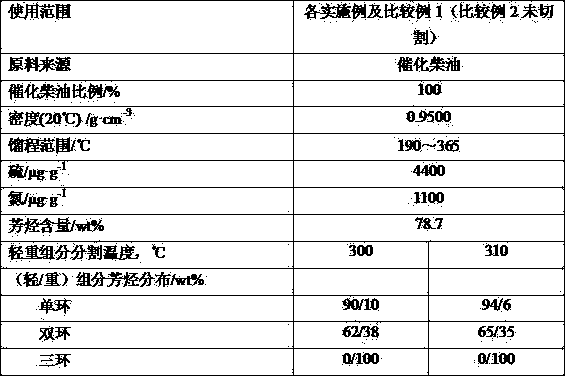

Processing treatment method of catalytic diesel oil

ActiveCN108102703AIdeal comprehensive processing effectLow operating costTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected tohydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is separated, a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained, the obtained triaromatic hydrocarbon component is subjected to hydrofining and hydroconversion, and a gasoline component and a diesel oil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that inferior catalytic cracking diesel oil can be reasonably used to produce qualified gasoline anddiesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Piston for an internal combustion engine

ActiveUS10634090B2Mitigate carbon formationReduce stressMachines/enginesPistonsInternal combustion engineThermal barrier coating

A piston for an internal combustion engine with a piston crown and a circumferentially arranged crown edge, whereby, near the periphery of the crown edge, a thermal barrier coating is applied, whereby the thermal barrier coating tapers off before the periphery of the crown edge.

Owner:GE JENBACHER

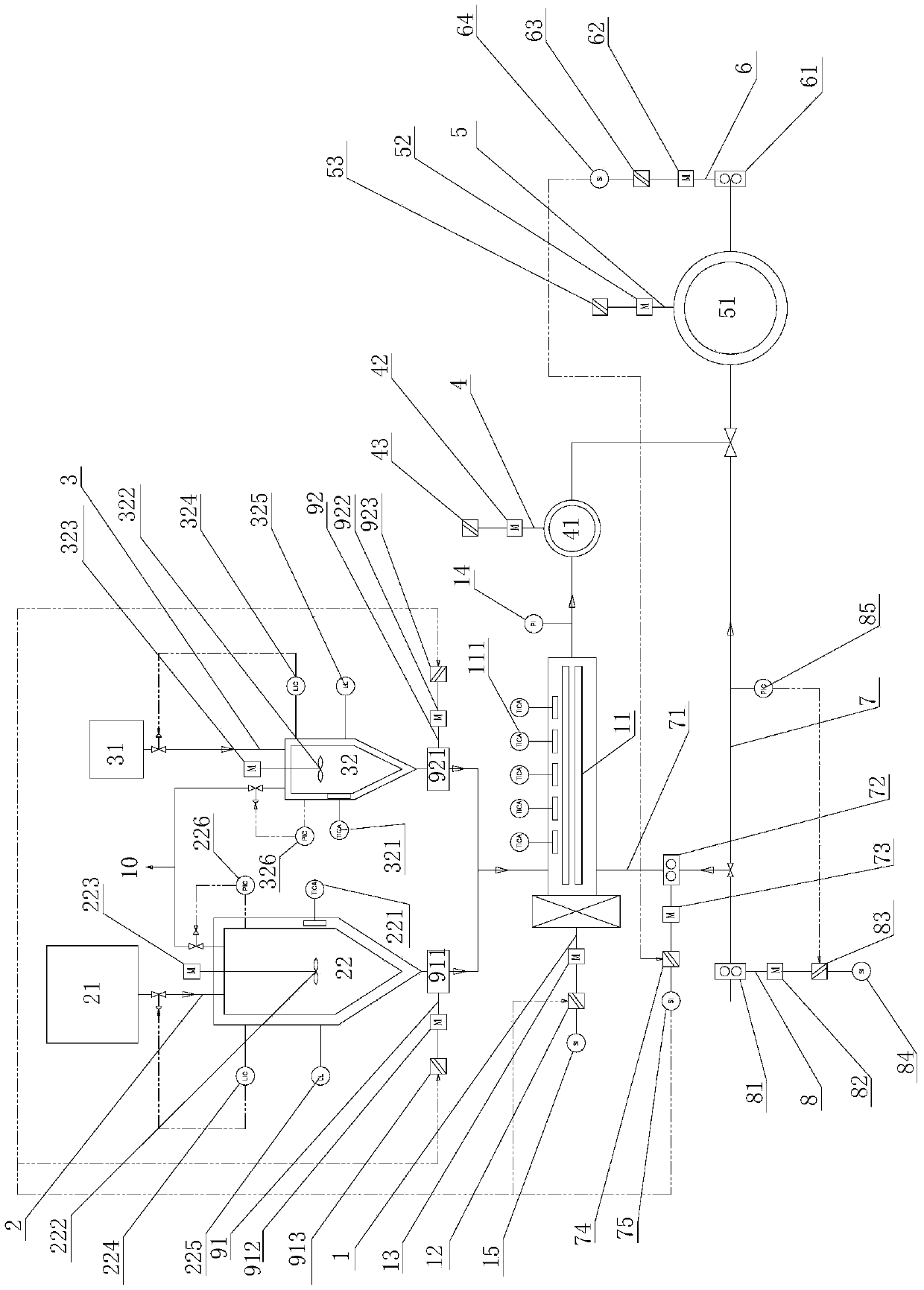

Method for preparing black yarn through direct mixing of PET melt and special equipment of method

ActiveCN105586647AMitigate carbon formationReduce manufacturing costMelt spinning methodsArtifical filament manufactureYarnLow speed

Provided are a method for preparing black yarn through direct mixing of a PET melt and special equipment of the method. The method comprises the steps that a melt is introduced from a main melt pipeline, and then a delustering agent and a dispersing agent are mixed according to a proportion; the mixture enters a double screw extruder under a negative pressure condition to be subjected to low-speed primary mixing, co-blending is conducted through an ultrasonic dynamic mixing machine, and direct spinning is conducted after mixing is conducted through a dynamic mixer. The equipment comprises an extruder assembly, an auxiliary material bin assembly, a dispersing agent bin assembly, an ultrasonic dynamic mixing assembly, a dynamic mixing assembly, a spinning metering assembly and a control box; the main melt pipeline is connected to a material outlet of a material outlet assembly, a material outlet of the ultrasonic dynamic mixing assembly is connected with the main melt pipeline through a tee joint and then communicated with the dynamic mixer, a material outlet of the dynamic mixer is communicated with a material inlet of a spinning metering pump, and a material outlet of the spinning metering pump serves as a spinning assembly connector to be connected with spinning equipment. The method for preparing the black yarn through direct mixing of the PET melt and the special equipment of the method have the advantages that the viscosity is reduced, the quality is stable, the spinnability is good, and the cost is low.

Owner:新凤鸣集团股份有限公司

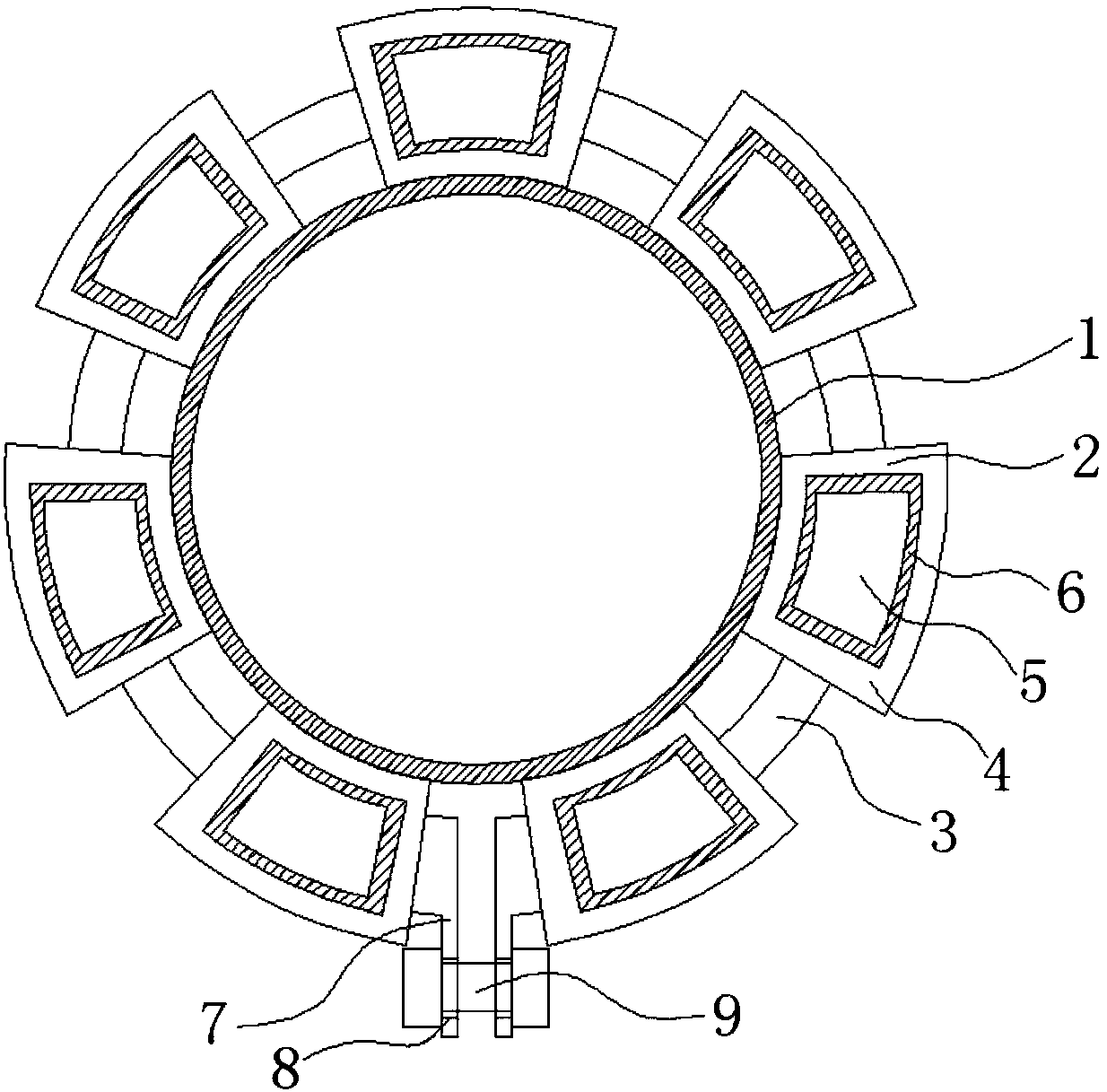

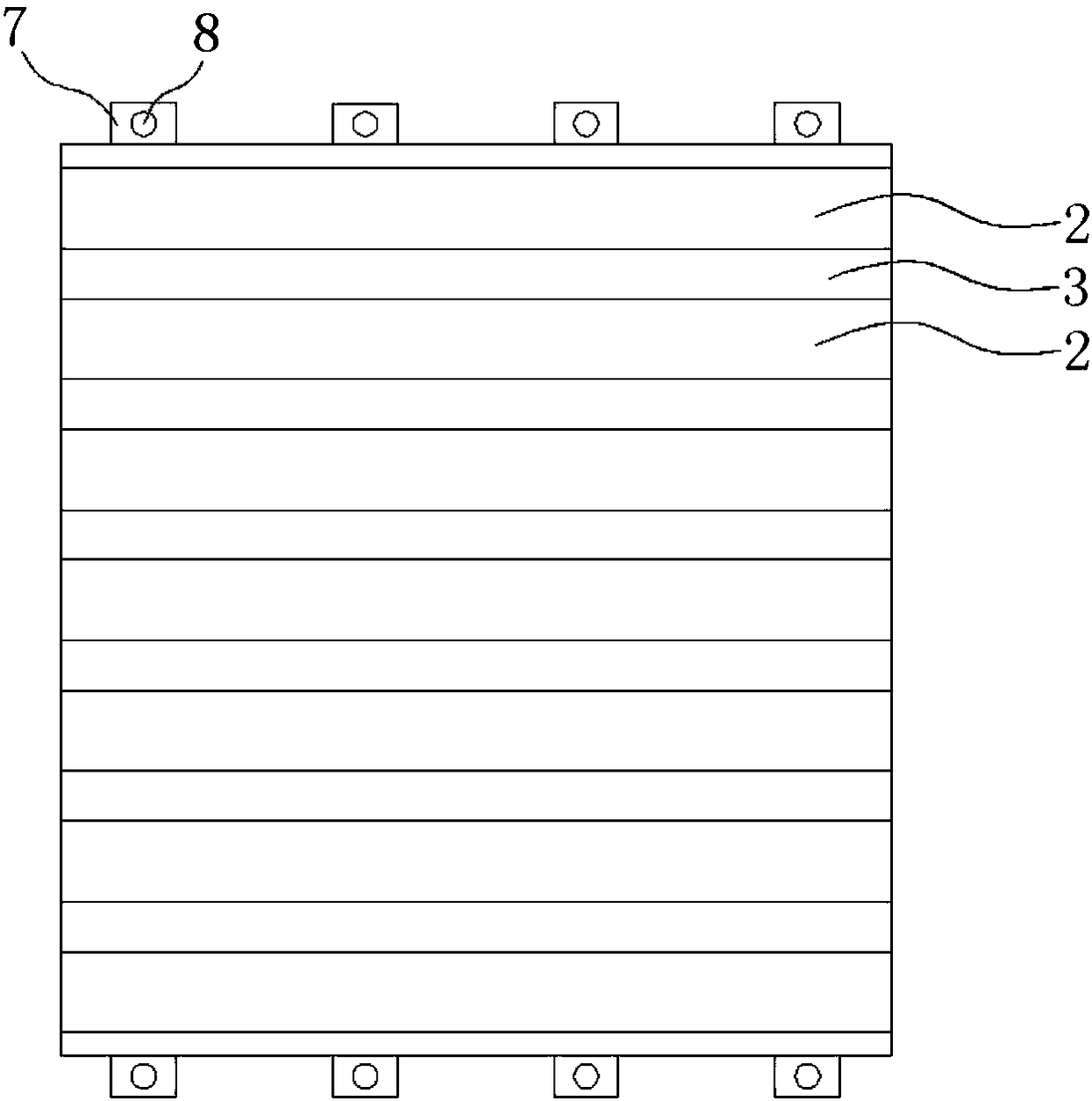

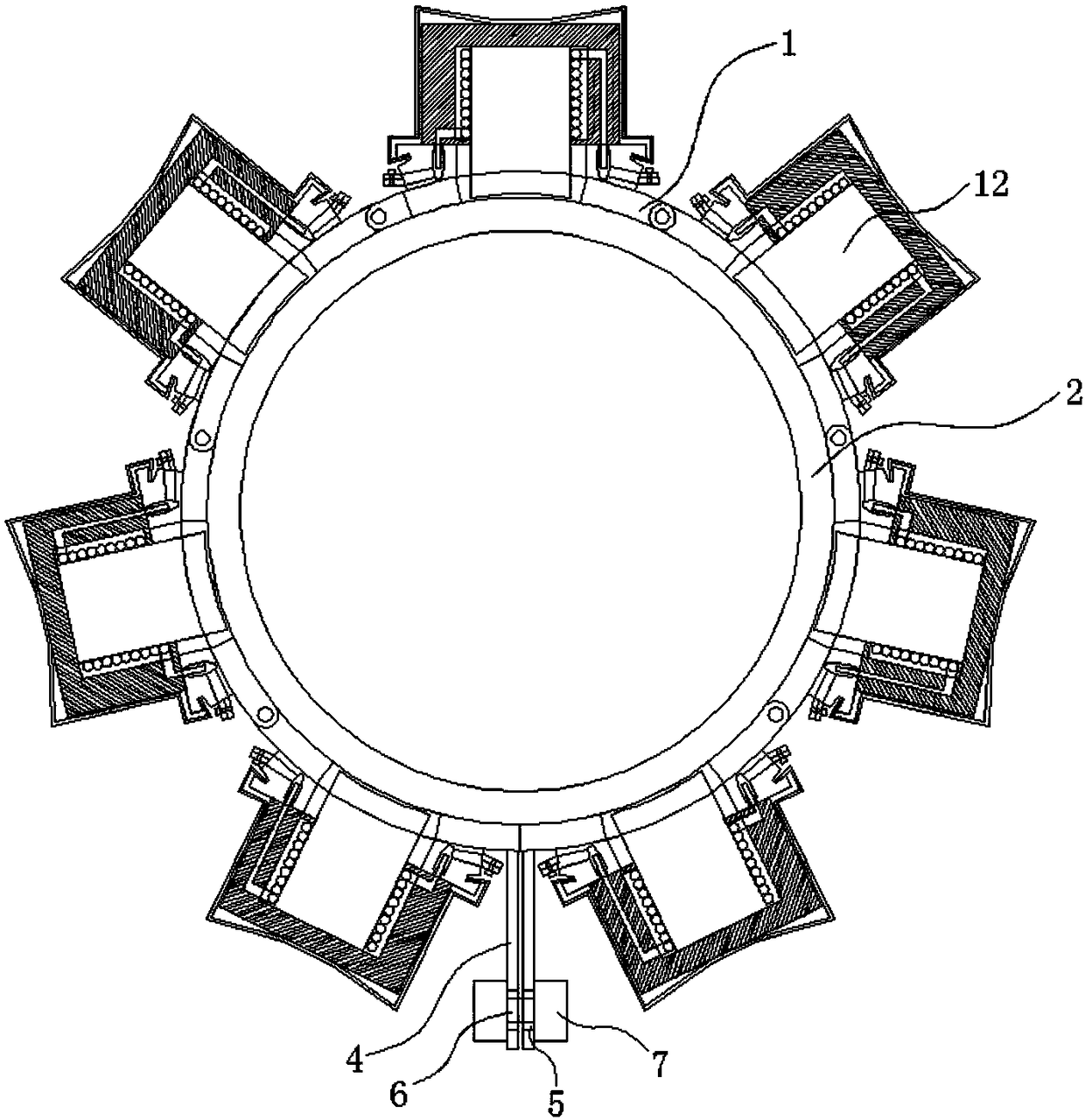

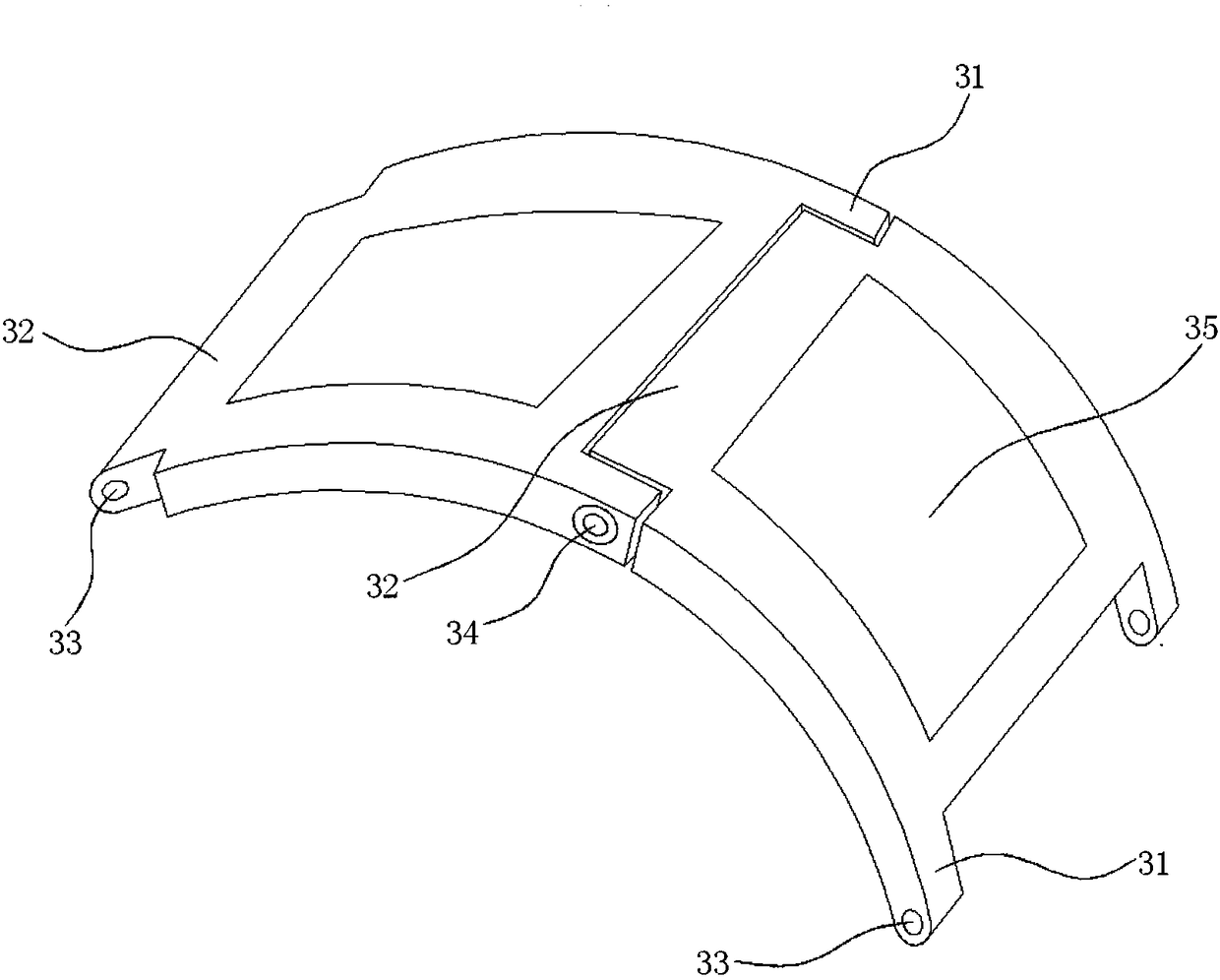

Externally wrapped magnetizer

PendingCN108597724ABurn fullyMitigate carbon formationWater/sewage treatment by magnetic/electric fieldsPermanent magnetsWater qualityEngineering

The invention discloses an externally wrapped magnetizer. The magnetizer comprises a rectangular body, wherein the body comprises a plurality of wrapping bodies which are arranged in sequence; a connecting component is connected between every two adjacent wrapping bodies; an accommodating cavity is formed inside each wrapping body; each accommodating cavity is internally provided with a magnet; and at least one group of fixed component is arranged at two ends of the body oppositely. The magnetizer can sleeve the periphery of a fuel pipeline or a water pipeline, fuel or water inside the pipeline is magnetized, the magnetizer has the effects of sufficiently burning the fuel, reducing the carbon deposition phenomenon of a fuel nozzle and improving the water quality respectively, when the magnetizer is used, the magnetizer directly sleeves an existing pipeline without other modification construction, the operation is convenient, the magnetizer is not in contact with a fluid inside the pipeline, and the magnetizer has the advantages that the fluid is not polluted.

Owner:南京鸣全特科技发展有限公司

A kind of method for preparing vinylidene fluoride monomer

ActiveCN104557446BImprove conversion rateHigh selectivityPreparation by hydrogen halide split-offReaction temperaturePhysical chemistry

The invention relates to a method for preparing a vinylidene fluoride monomer. The method is characterized by comprising the following steps: preheating and mixing water and 1,1-difluoro-1-chloroethane and feeding the mixture into a cracking tube, quenching reacted cracking gas, removing HCl, drying and feeding the dried gas to a rectifying tower to obtain the high-purity vinylidene fluoride monomer. By the method, the problems of carbon deposition, clogging of a pipeline and the like can be decreased, the selectivity and reaction efficiency can be effectively improved, the reaction temperature is decreased and thus the energy consumption can be reduced, the energy consumption is substantially reduced and the pollution is decreased.

Owner:RUYUAN DONGYANG LIGHT FLUORINE RESIN CO LTD

Process and reactor for the thermoneutral conversion of ethanol to acetic acid

InactiveUS8471060B2High yieldMitigate carbon formationOrganic compound preparationCarbonyl compound preparationAcetic acidNon oxidative

Owner:HALDOR TOPSOE AS

Actively cooled fuel processor

InactiveUS8496717B2Increase heat loss rateReduce formationHydrogenCarburetting by solid carbonaceous material pyrolysisHydrogenActive cooling

A fuel processor for producing a hydrogen-containing product stream from a fuel stream and an oxidant stream is actively-cooled by a gaseous or liquid coolant which is directed to flow in contact with at least a portion of the outer shell of the fuel processor. Active cooling can improve the operating characteristics of the fuel processor as well as allowing for the use of compact fuel processor designs that would otherwise tend to have insufficient heat loss capability.

Owner:WESTPORT FUEL SYST CANADA INC

A method for preparing methyl mercaptan by extracting aluminum modified composite catalyst from phosphogypsum

ActiveCN110026232BExtend your lifeConducive to strengthening the restriction effectMolecular sieve catalystsThiol preparationPtru catalystPhysical chemistry

The invention discloses a method for preparing methyl mercaptan by extracting aluminum modified composite catalyst from phosphogypsum, comprising the following steps: acid leaching waste gypsum, separating and purifying aluminum to prepare γ-Al 2 o 3 , with the prepared γ‑Al 2 o 3 The sample was modified on ZSM-5 to obtain a composite catalyst, hydrogen sulfide gas and methanol gas fully contacted and reacted with the catalyst to obtain the product methyl mercaptan. On the one hand, this method removes some impurities in phosphogypsum, realizes the recycling of phosphogypsum solid waste, and at the same time utilizes the properties of the impurities themselves to prepare γ‑Al 2 o 3 The @ZSM‑5 composite catalyst has a long service life, a high selectivity of the product methyl mercaptan, and a lower reaction temperature.

Owner:中建西部建设贵州有限公司

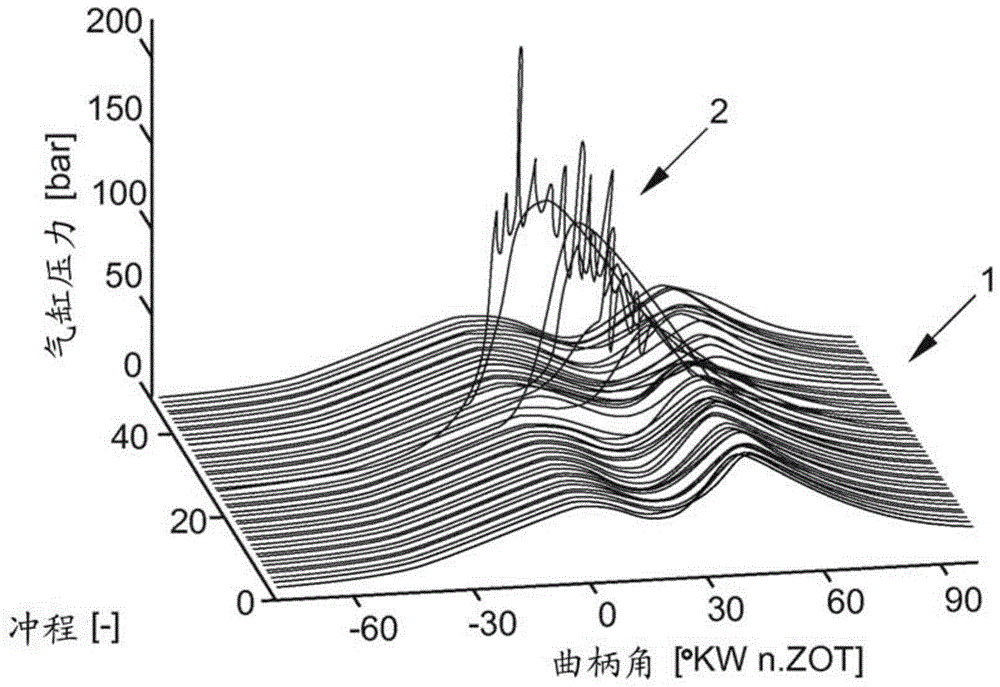

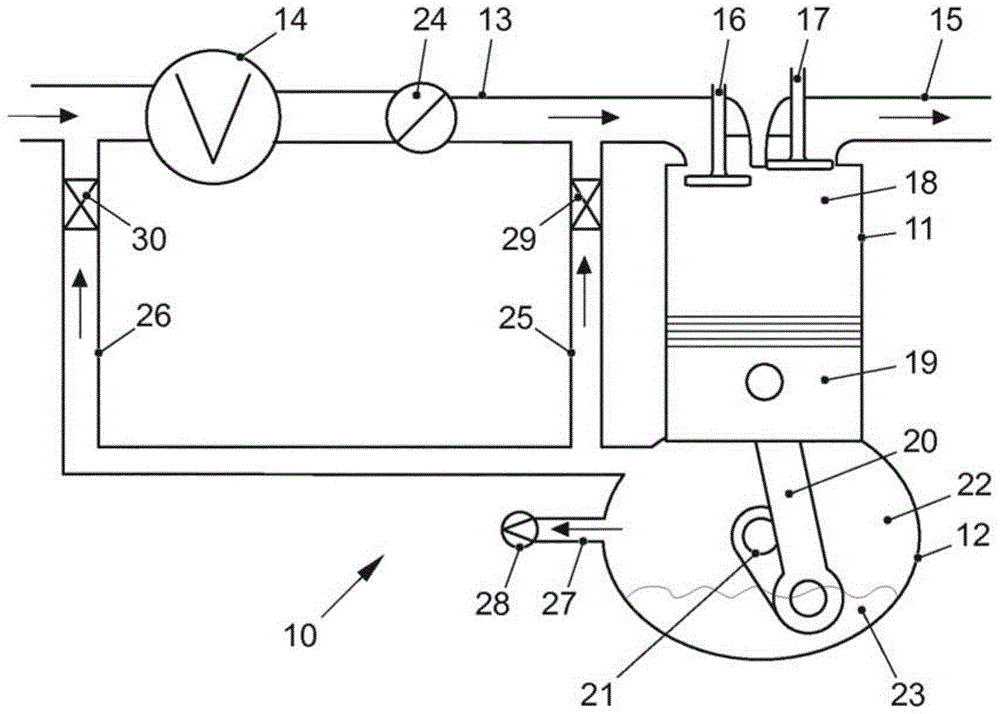

Method for avoiding pre-ignition in internal combustion engine and internal combustion engine and vehicle

ActiveCN104334842BIncreased propensity to pre-igniteMitigate carbon formationInternal combustion piston enginesEngine controllersAutomotive engineeringDetonation

The invention relates to a method for preventing pre-ignition of a cylinder working medium before a planned ignition time in an internal combustion engine. In the method, the pressure in the crankcase (12) of the internal combustion engine (10) is regulated in such a way that combustion through the crankcase (12) and combustion in the cylinders (11) of the internal combustion engine (10) is avoided. The pressure ratio between chambers (18) transfers lubricating oil components from the crankcase (12) to the combustion chambers (18). In another method, the ignition timing for the cylinders (12) of the internal combustion engine (10) is adjusted in certain operating ranges of the internal combustion engine (10) in such a way that the adjusted ignition timing occurs in the cylinder (12) of detonation combustion.

Owner:VOLKSWAGEN AG

Preparation method of t-ZrO2@CuO-ZnO@ZSM-5 double core-shell catalyst

InactiveCN108579798AHigh selectivityExtend your lifeMolecular sieve catalystsOrganic compound preparationAnhydrous ethanolDual core

The invention discloses a preparation method of a t-ZrO2@CuO-ZnO@ZSM-5 double core-shell catalyst, which includes steps of: preparation of t-ZrO2@CuO-ZnO powder: according to molar ratio of n(TEOS):n(NaAlO2):n(TPAOH):n(H2O)=40-360:1:19:4015, successively adding NaAlO2, TPAOH and TEOS to deionized water under stirring, continuously stirring the mixture uniformly, and aging the mixture for 3 h at room temperature under stirring to form a sol system; according to core-shell mass ratio of t-ZrO2@CuO-ZnO:ZSM-5 = 1:2-2:1, adding the t-ZrO2@CuO-ZnO powder to the system, continuously stirring the mixture uniformly, and performing a hydrothermal reaction in a homogeneous reactor at 170-190 DEG C for 24-48 h at rotation speed of 4 rpm; cooling the product to room temperature, centrifuging the product, and washing the product in deionized water and anhydrous ethanol; and drying the product at 120 DEG C for 12 h and roasting the product at 500-600 DEG C for 3 h. The catalyst can simultaneously increase CO2 conversion rate and low-carbon olefin selectivity in a two-step process of producing low-carbon olefin by hydrogenation of CO2 with methanol.

Owner:GUIZHOU UNIV

A method for directly mixing pet melts to produce black silk and its special equipment

ActiveCN105586647BMitigate carbon formationReduce manufacturing costMelt spinning methodsArtifical filament manufactureYarnLow speed

Provided are a method for preparing black yarn through direct mixing of a PET melt and special equipment of the method. The method comprises the steps that a melt is introduced from a main melt pipeline, and then a delustering agent and a dispersing agent are mixed according to a proportion; the mixture enters a double screw extruder under a negative pressure condition to be subjected to low-speed primary mixing, co-blending is conducted through an ultrasonic dynamic mixing machine, and direct spinning is conducted after mixing is conducted through a dynamic mixer. The equipment comprises an extruder assembly, an auxiliary material bin assembly, a dispersing agent bin assembly, an ultrasonic dynamic mixing assembly, a dynamic mixing assembly, a spinning metering assembly and a control box; the main melt pipeline is connected to a material outlet of a material outlet assembly, a material outlet of the ultrasonic dynamic mixing assembly is connected with the main melt pipeline through a tee joint and then communicated with the dynamic mixer, a material outlet of the dynamic mixer is communicated with a material inlet of a spinning metering pump, and a material outlet of the spinning metering pump serves as a spinning assembly connector to be connected with spinning equipment. The method for preparing the black yarn through direct mixing of the PET melt and the special equipment of the method have the advantages that the viscosity is reduced, the quality is stable, the spinnability is good, and the cost is low.

Owner:新凤鸣集团股份有限公司

A kind of processing method of catalytic diesel oil

ActiveCN108102703BIdeal comprehensive processing effectLow operating costTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineProcess engineering

The invention discloses a processing treatment method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected tohydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is separated, a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained, the obtained triaromatic hydrocarbon component is subjected to hydrofining and hydroconversion, and a gasoline component and a diesel oil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that inferior catalytic cracking diesel oil can be reasonably used to produce qualified gasoline anddiesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for preparing propylene by extracting aluminum modified composite catalyst from phosphogypsum

ActiveCN110026233BExtend your lifeImprove the limit effectMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPtru catalystPhysical chemistry

The invention discloses a method for extracting phosphogypsum from an aluminum-modified composite catalyst to prepare propylene, comprising the following steps: acid leaching waste gypsum, separating and purifying aluminum to prepare γ-Al 2 o 3 , with the prepared γ‑Al 2 o 3 The sample is modified on ZSM-5 to obtain a composite catalyst, and now the methanol liquid gasification is fully contacted with the catalyst to obtain the product propylene. On the one hand, this method removes some impurities in phosphogypsum, realizes the recycling of phosphogypsum solid waste, and at the same time utilizes the properties of the impurities themselves to prepare γ‑Al 2 o 3 The @ZSM‑5 composite catalyst has a long service life and a high selectivity to propylene.

Owner:中建西部建设贵州有限公司

Outer-package inserting-connection electromagnetic magnetizer

PendingCN108538538ABurn fullyWon't fall offMagnetic bodiesWater/sewage treatment by magnetic/electric fieldsMagnetizationWater quality

The invention discloses an outer-package inserting-connection electromagnetic magnetizer which comprises a mounting frame. The mounting frame comprises multiple substrates in sequential hinged connection, a base is arranged on the outer sides of the substrates, wiring terminal are arranged on the base, each wiring terminal is connected with a connection seat, an inserting hole is formed in the base on the outer side of each connection seat, an electromagnet is arranged on the outer side of the base, and two inserting needles are arranged on a shell, inserted into the inserting holes and connected with the connection seats. The magnetizer can sleeve on the periphery of a fuel pipeline or a water pipeline, the electromagnet magnetizes fuel or water in the pipeline after being electrified, size of a magnetic field generated by the electromagnet can be adjusted through current to adapt to occasions having different magnetizing strength needs, and the magnetizer has effects of enabling sufficient burning of the fuel, reducing carbon formation of a fuel nozzle and improving water quality; when in use, the magnetizer can be directly mounted on an existing pipeline in a sleeved manner, andother modification construction is not needed; the magnetizer is convenient to operate, does not contact with fluid in the pipeline and has the advantage of avoiding fluid pollution.

Owner:南京鸣全特科技发展有限公司

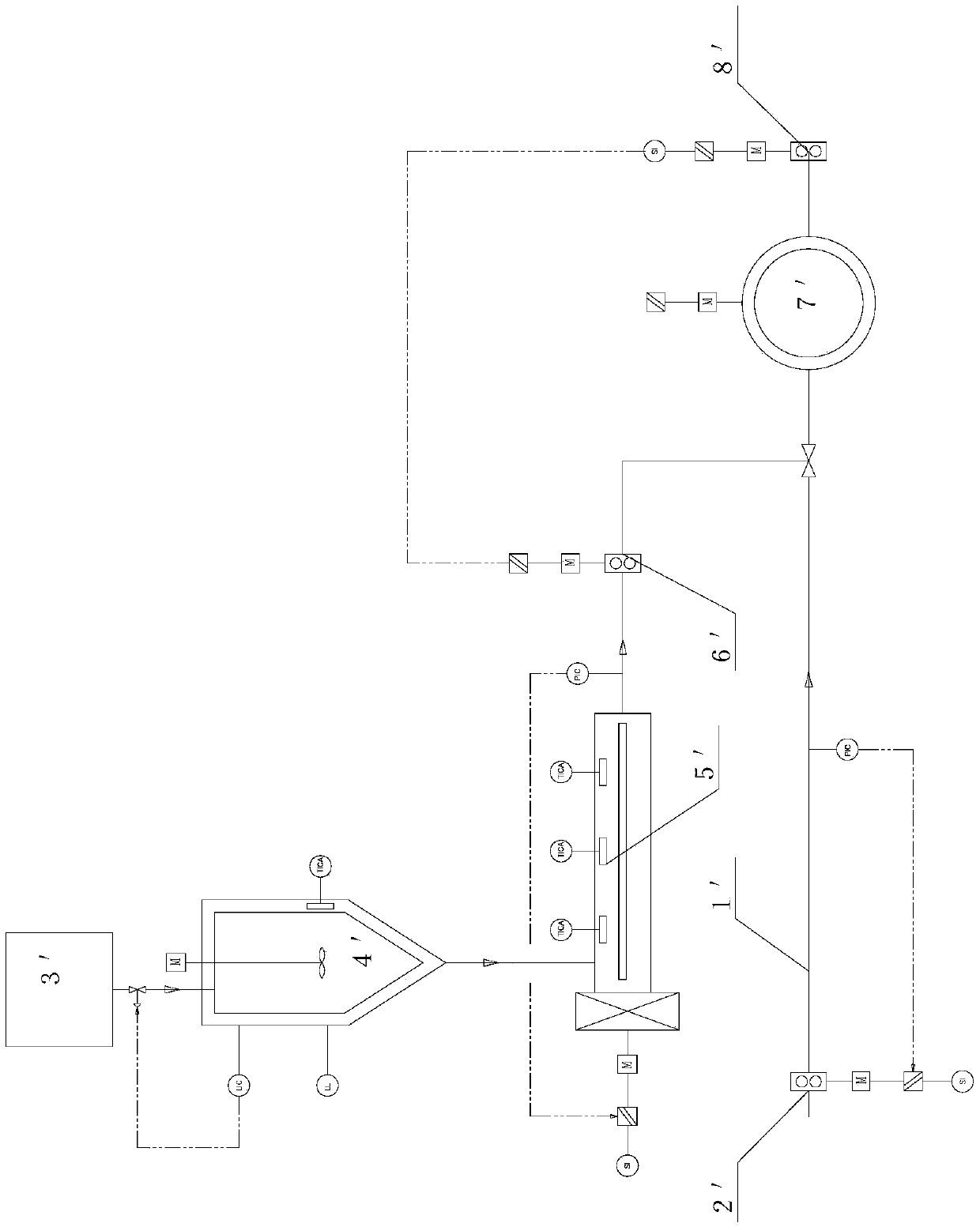

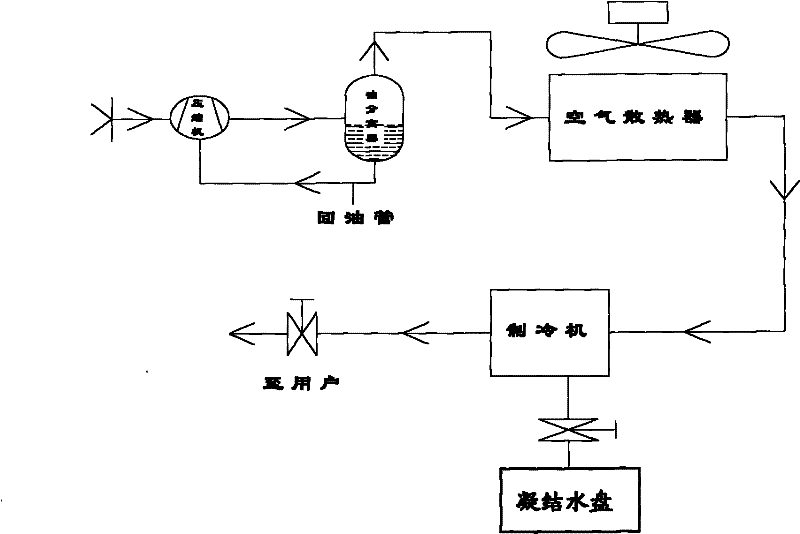

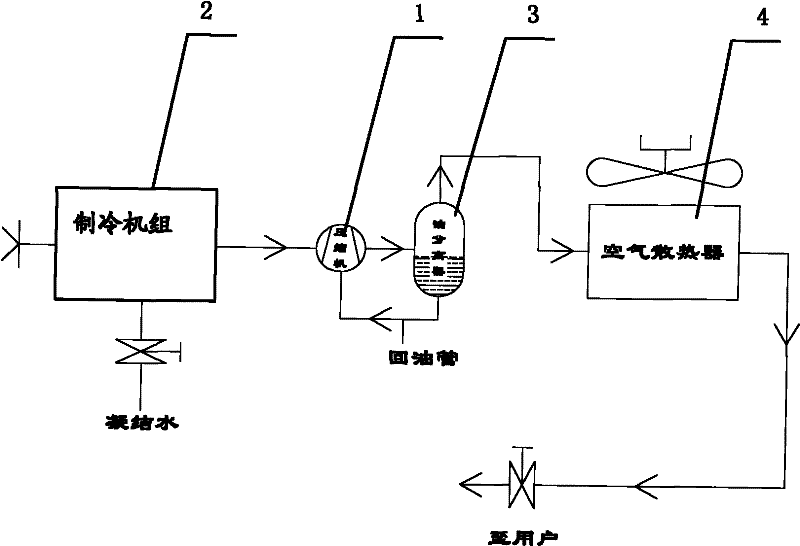

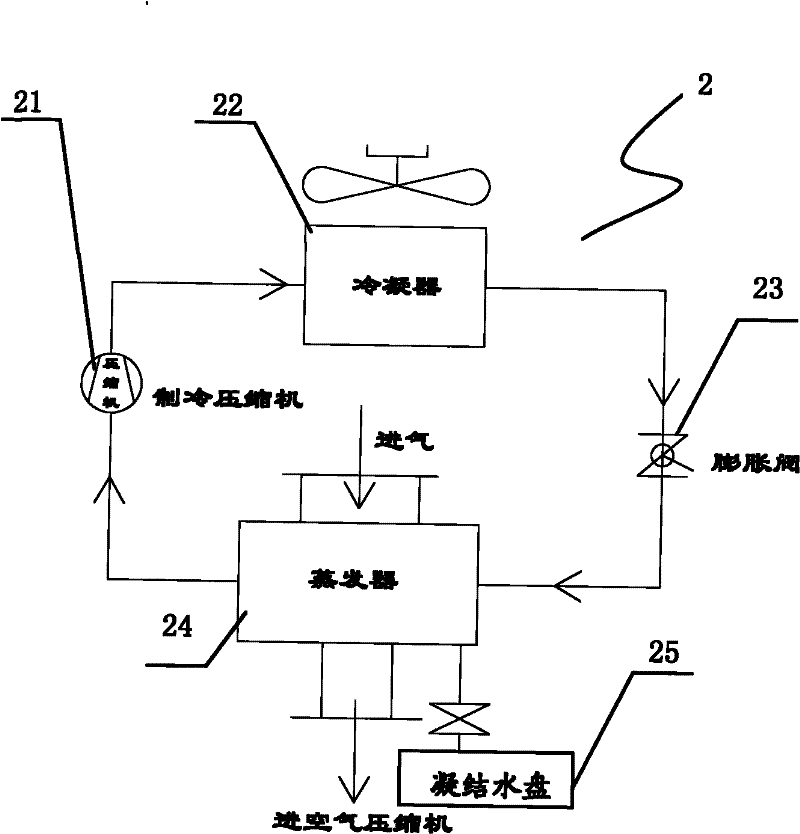

Air compressor set capable of freezing and drying air inflow

InactiveCN101865120BReduce intake air temperatureReduce the temperaturePositive displacement pump componentsPositive-displacement liquid enginesEngineeringAir compressor

The invention belongs to the technical field of air conditioners, in particular disclosing an air compressor set capable of freezing and drying air inflow. The air compressor set comprises an air compressor, wherein a refrigerating unit is connected on the air inlet at the front end of the air compressor; a compressed air output end of the air compressor is successively connected with an oil separator and an air radiator; and the tail end of the air radiator transports dry compressed air to users by connecting tubes. The air compressor firstly dehumidify air therein in advance so that low airinflow temperature is low, air inflow area is large, low compressor energy consumption is low, small noise is small and reliability is greatly improved.

Owner:广州市盈夏机械技术有限公司

Method for preparing composite catalyst by extracting aluminum from phosphogypsum

PendingCN109999894AExtend your lifeConducive to strengthening the restriction effectMolecular sieve catalystsReaction temperaturePhosphogypsum

The invention discloses a method for preparing a composite catalyst by extracting aluminum from phosphogypsum, comprising the following steps: carrying out acid leaching of waste gypsum, separating and purifying aluminum to prepare gamma-Al2O3, and modifying ZSM-5 by using the prepared gamma-Al2O3 sample to obtain the composite catalyst. By the method, part of impurities in phosphogypsum are removed to realize recycling of the phosphogypsum solid waste; and by the utilization of properties of impurities, the prepared gamma-Al2O3(at)ZSM-5 composite catalyst has long life, product selectivity ishigh, and reaction temperature is reduced.

Owner:中建西部建设贵州有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com