Processing treatment method of catalytic diesel oil

A technology for catalyzing diesel oil and diesel oil, which is used in hydrotreating process, hydrocarbon oil treatment products, petroleum industry and other directions, can solve the problems of high chemical hydrogen consumption, small amount of catalytic diesel oil, small catalytic diesel oil, etc. The effect of improved thermal system and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

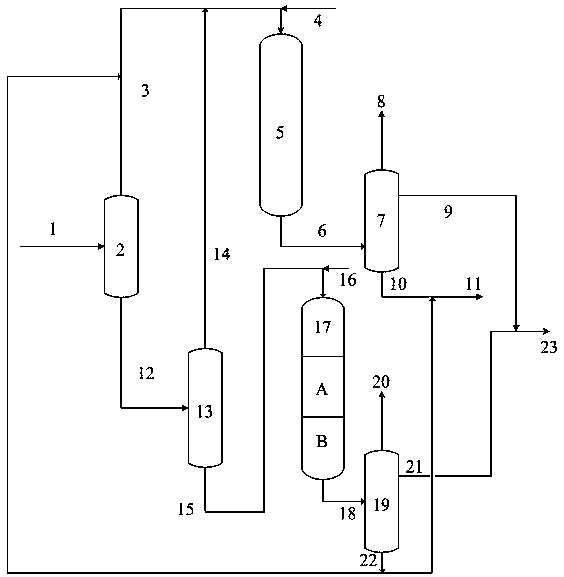

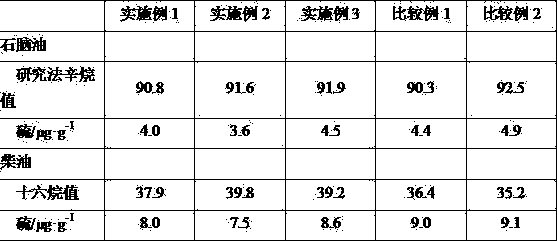

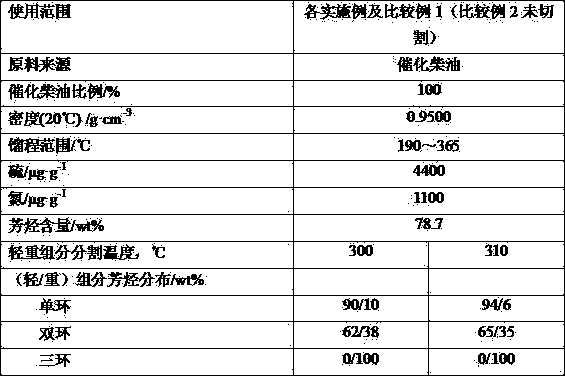

[0043] use figure 1 In the combined process flow shown, catalytic diesel is selected as raw material for hydrogenation production, the cut point of light and heavy components is selected as 290°C, the furfural refining unit is selected for the separation of heavy aromatics, and the target products are high-quality gasoline and diesel. The catalysts used in the examples are commercial catalyst FF-36 hydrotreating catalyst, 3963 hydrogenation upgrading catalyst and the special hydroconversion catalyst A and B of this technology (except metal oxide and Y-type molecular sieve in the catalyst composition, the balance for alumina).

[0044] Next, the combined process method of the present invention will be further described through specific examples.

[0045] Example 1

[0046] use figure 1 In the process flow shown, catalytic diesel is selected as raw material for hydrogenation production, the cut point of light and heavy components is selected as 300°C, and the target products ...

Embodiment 2

[0048] use figure 1 In the combined process flow shown, catalytic diesel is selected as raw material for hydrogenation production, the cut point of light and heavy components is selected as 300°C, and the target products are high-quality gasoline and diesel. The catalysts used in the examples are the commercial catalyst FF-36 hydrotreating catalyst, the 3963 hydroupgrading catalyst and the special hydroconversion catalysts A and B of this technology.

Embodiment 3

[0050] use figure 1In the process flow shown, catalytic diesel is selected as raw material for hydrogenation production, the cut point of light and heavy components is selected as 310°C, and the target products are high-quality gasoline and diesel. The catalysts used in the examples are commercial catalysts FF-36 hydrotreating catalyst, 3963 hydroupgrading catalyst, and hydroconversion catalysts A and B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com