Patents

Literature

51results about How to "Increase saturation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing ethylene tar

The invention discloses a method for processing ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid and carbon residue in the ethylene tar. The light fraction passes through a hydrogenation protection reaction zone, a hydrofining reaction zone and a hydrocracking reaction zone sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction is used as a universal type carbon fiber asphalt stock. The method for processing the ethylene tar makes full use of the total fraction of the ethylene tar and increases the additional value of the ethylene tar. In addition, the method enables the arene after hydrostturation in the ethylene tar to open ring, crack moderately and / or isomerize by selecting two types of hydrocracking catalysts to perform grading loading so as to obtain the diesel oil fraction with condensation point less than -40 DEG C in high yield and obtain a side product high-octane gasoline fraction at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

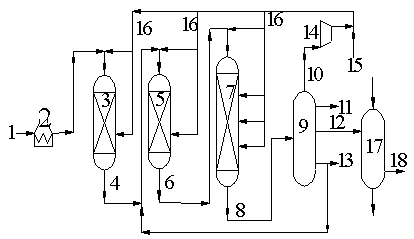

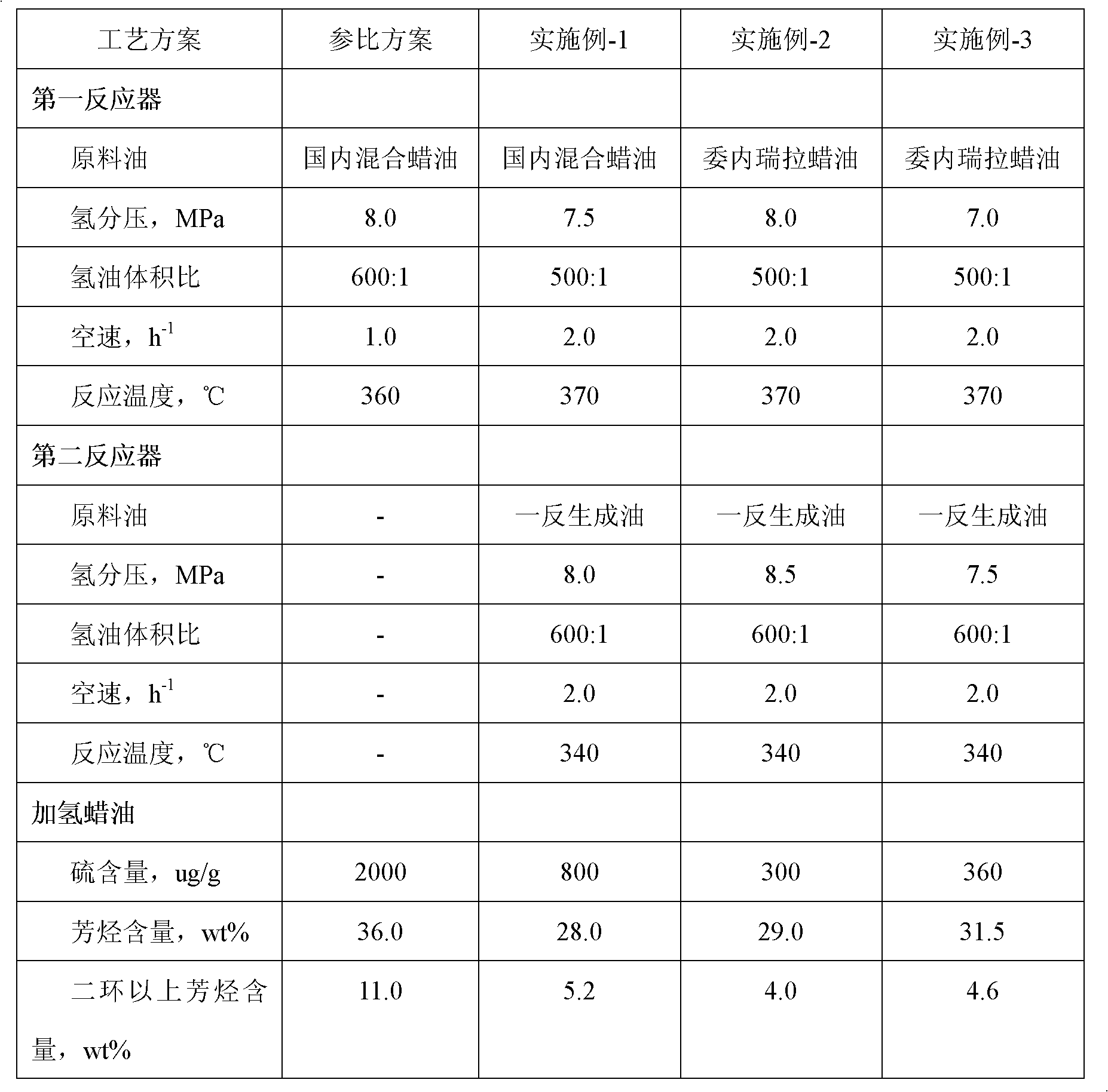

Method for producing the clean diean diesel oil with low sulfur and low arene

InactiveCN1415706AExpand sourceImprove adaptabilityTreatment with hydrotreatment processesSulfurImpurity

A process for preparing low-sulfur low-arylhydrocarbon clean diesel oil includes such steps as hydrorefining / hydrocracking raw hydrocarbon to obtain intermediate fraction oil, catalytic stripping to separate light fraction from heavy fraction, hydrorefining the light fraction to remove residual S and impurities, and catalytic stripping of heavy fraction for removing sulfure and arylhydrocarbon to obtain final product. Its advantage is cyclic use of two reactino segments for low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

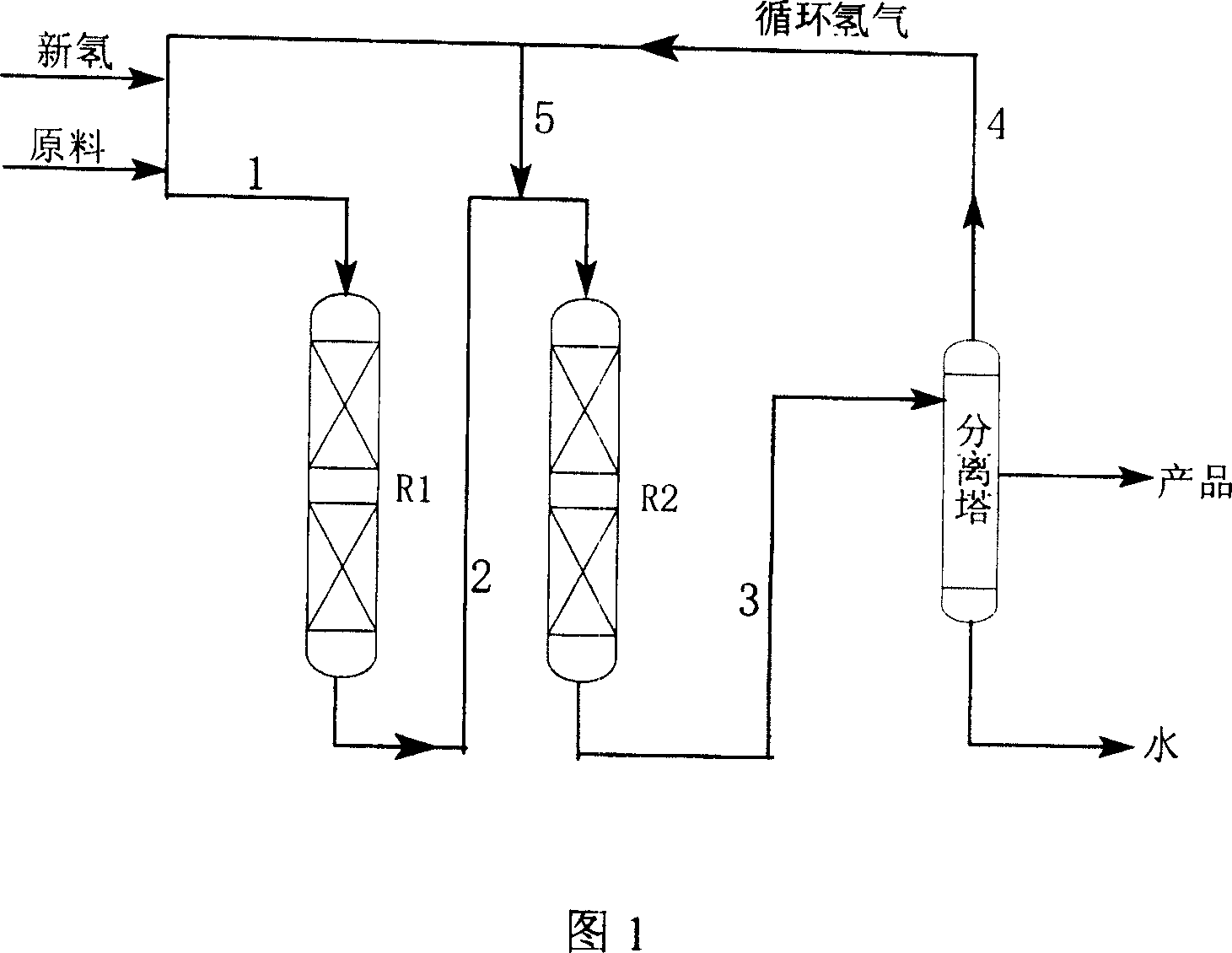

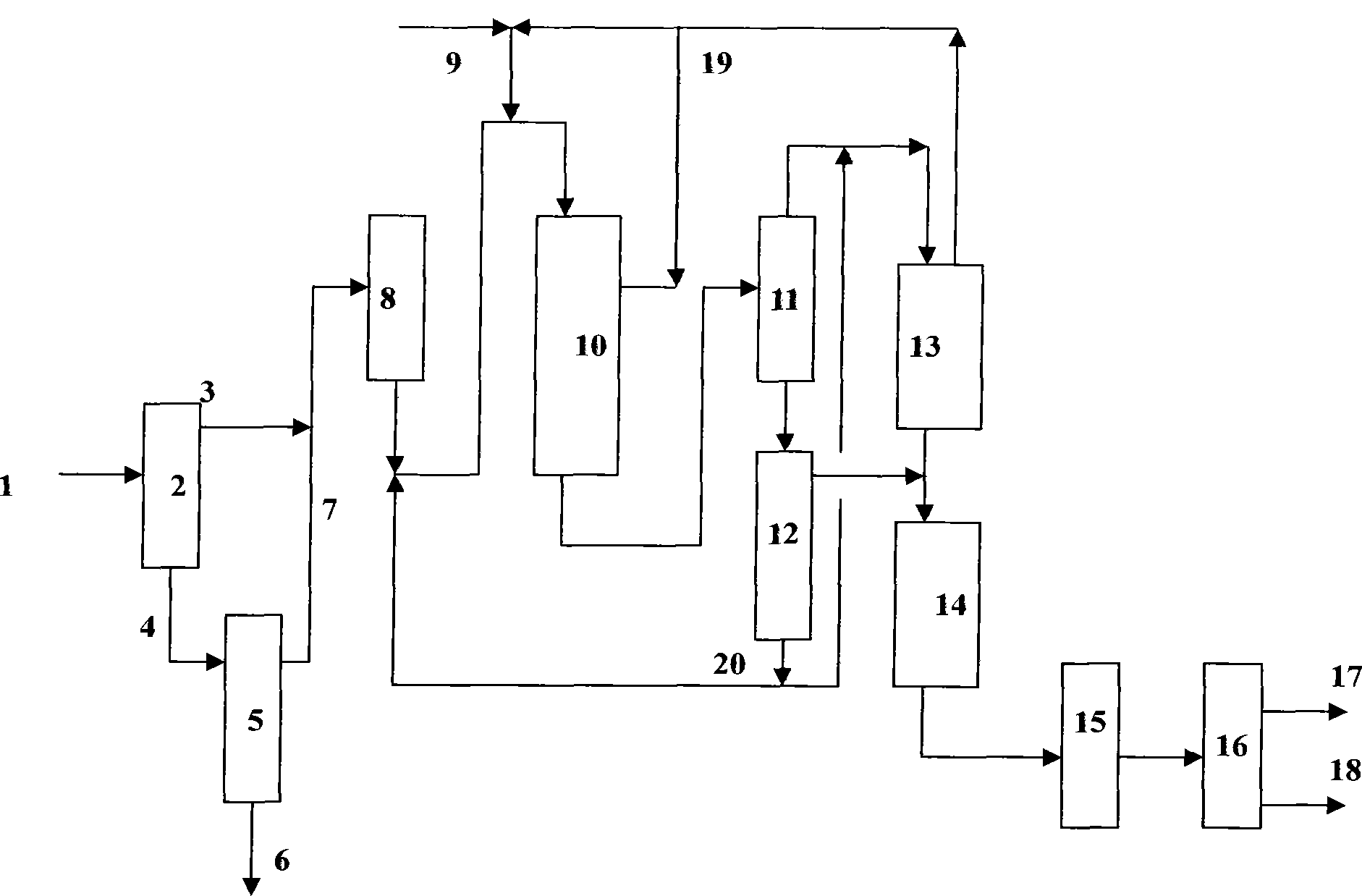

Hydrocracking method for blending ethylene tar

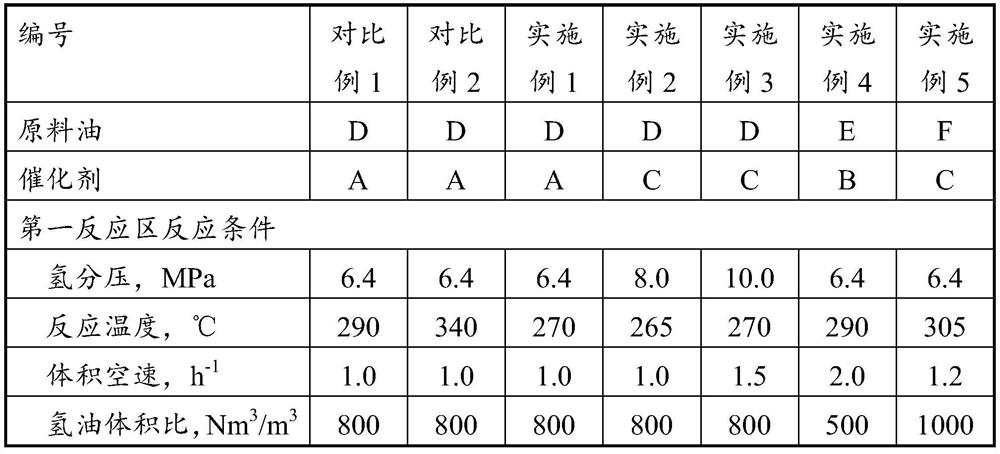

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

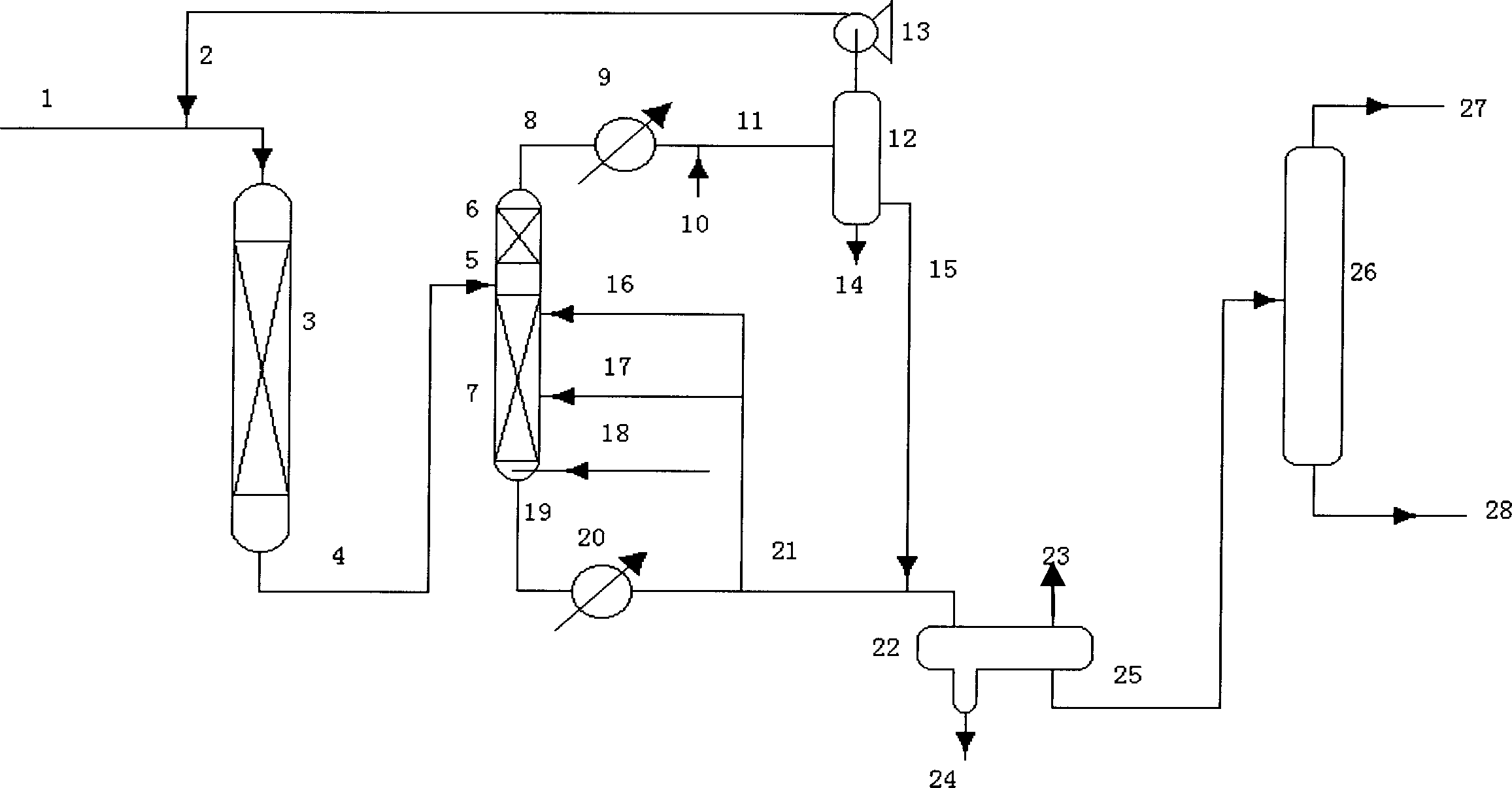

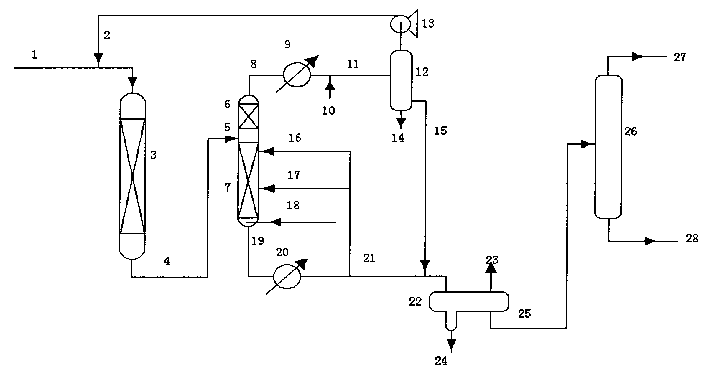

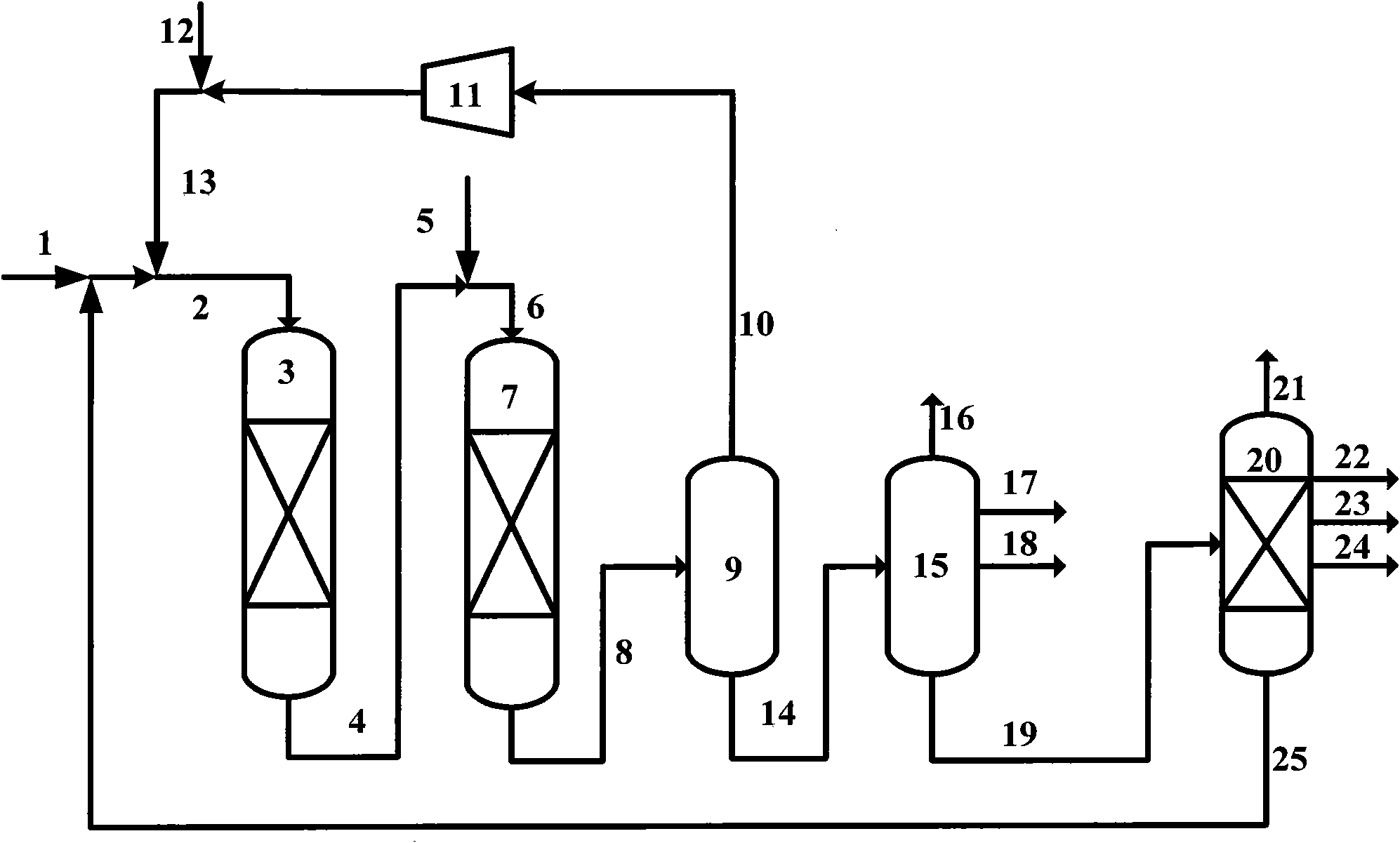

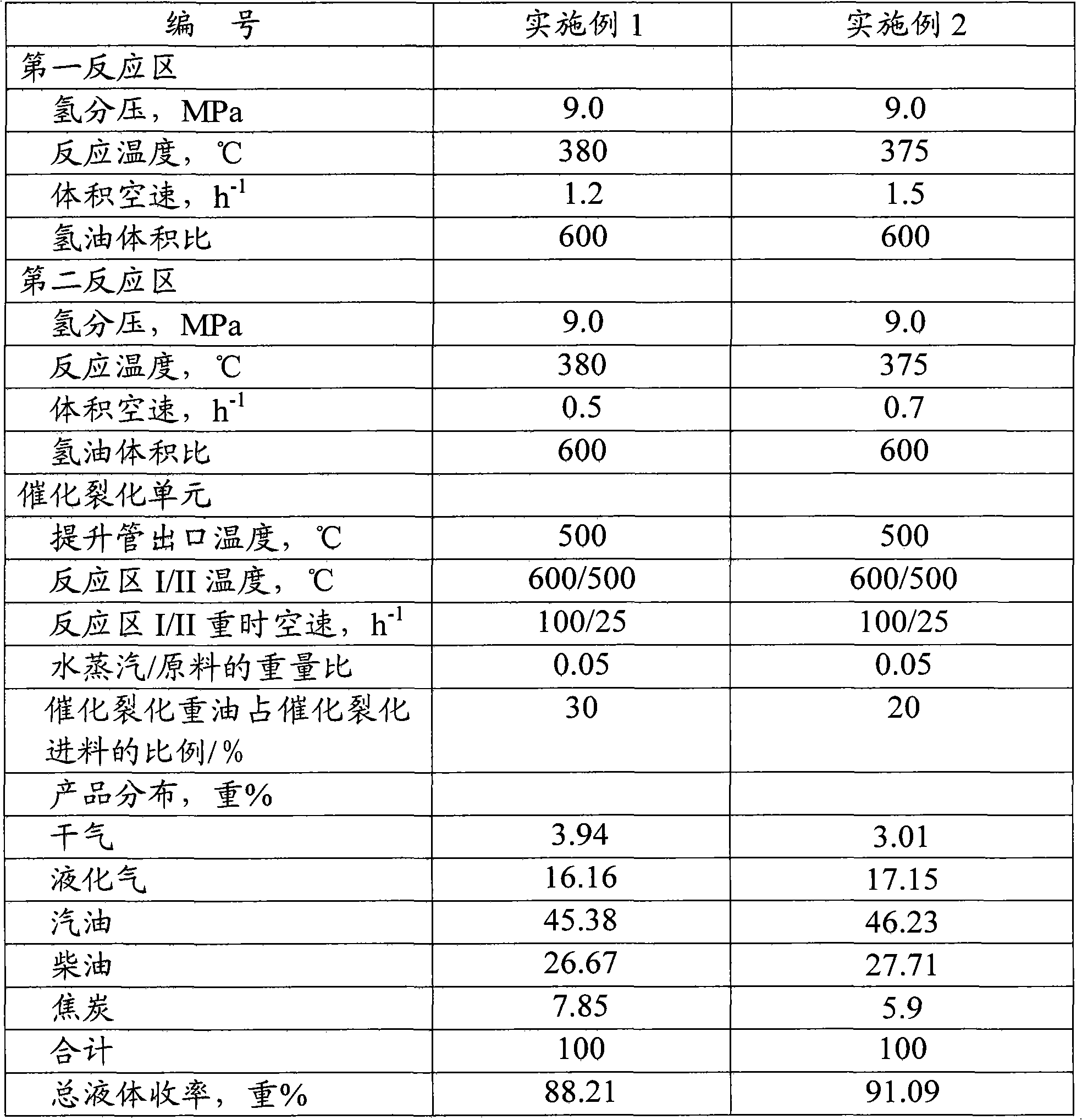

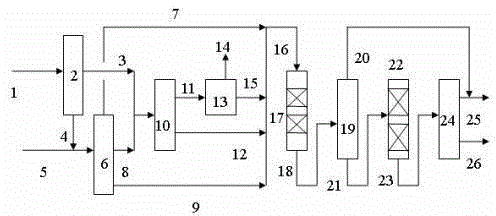

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for hydrogenating and refining oil from Fischer-Tropsch synthesis

InactiveCN1865405AExtend your lifeHigh Hydrodeoxygenation ActivityTreatment with hydrotreatment processesExhaust gasChemistry

The invention discloses a hydrogenation refined technology of feituo synthesized oil, which comprises the following steps: preheating the feituo synthesized oil and hydrogen in the blender; loading the mixture in the pre-hydrogenation reactor to proceed olefin saturation; proceeding hydrogenation and deoxidation in the hydrogenation refined reactor with hydrogenation refined catalyst; putting the hydrogenated refined product in the cool high pressure separator to separate gas phase (hydrogen-rich gas) and liquid phase; adding the liquid product in the low pressure oil water separator to separate water and tail gas to produce the product; circulating the hydrogen-rich gas in the reactor through purifying; cutting the product into petrol fraction and diesel fraction. The invention possesses higher olefin saturated rate and hydrogenation dioxide rate, which lengthens the lifetime of catalyst.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

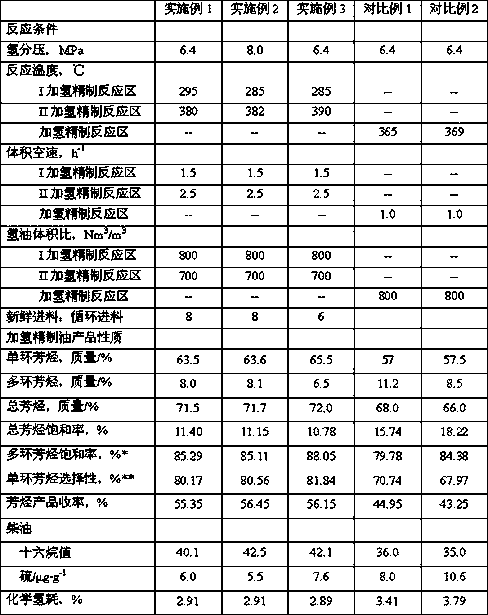

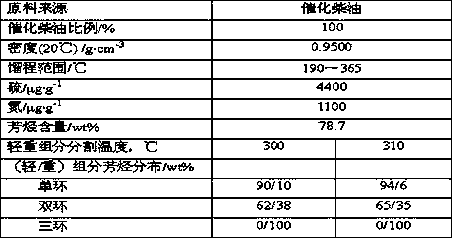

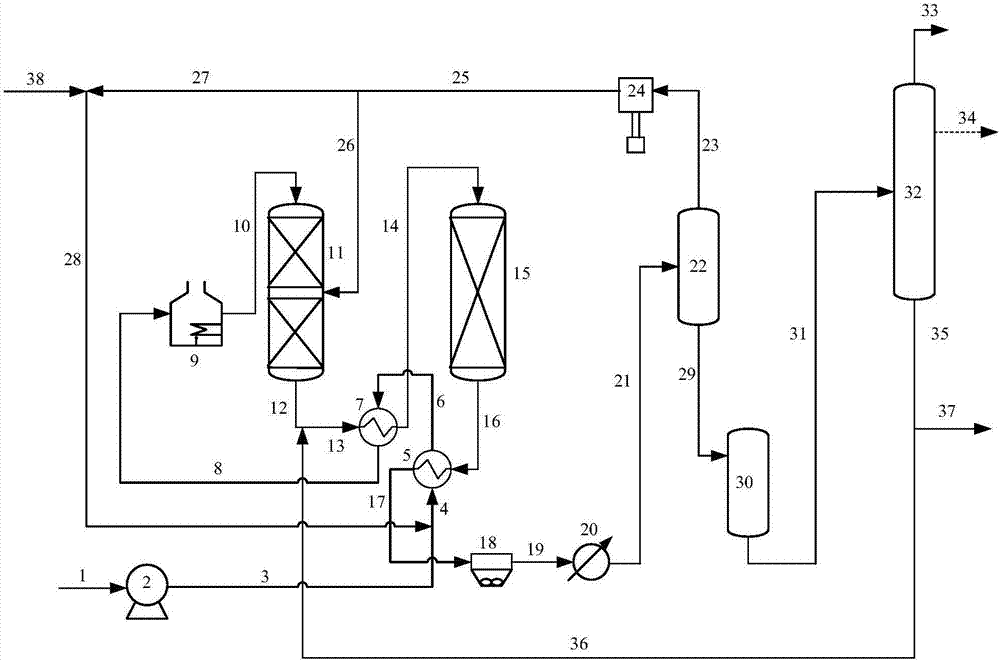

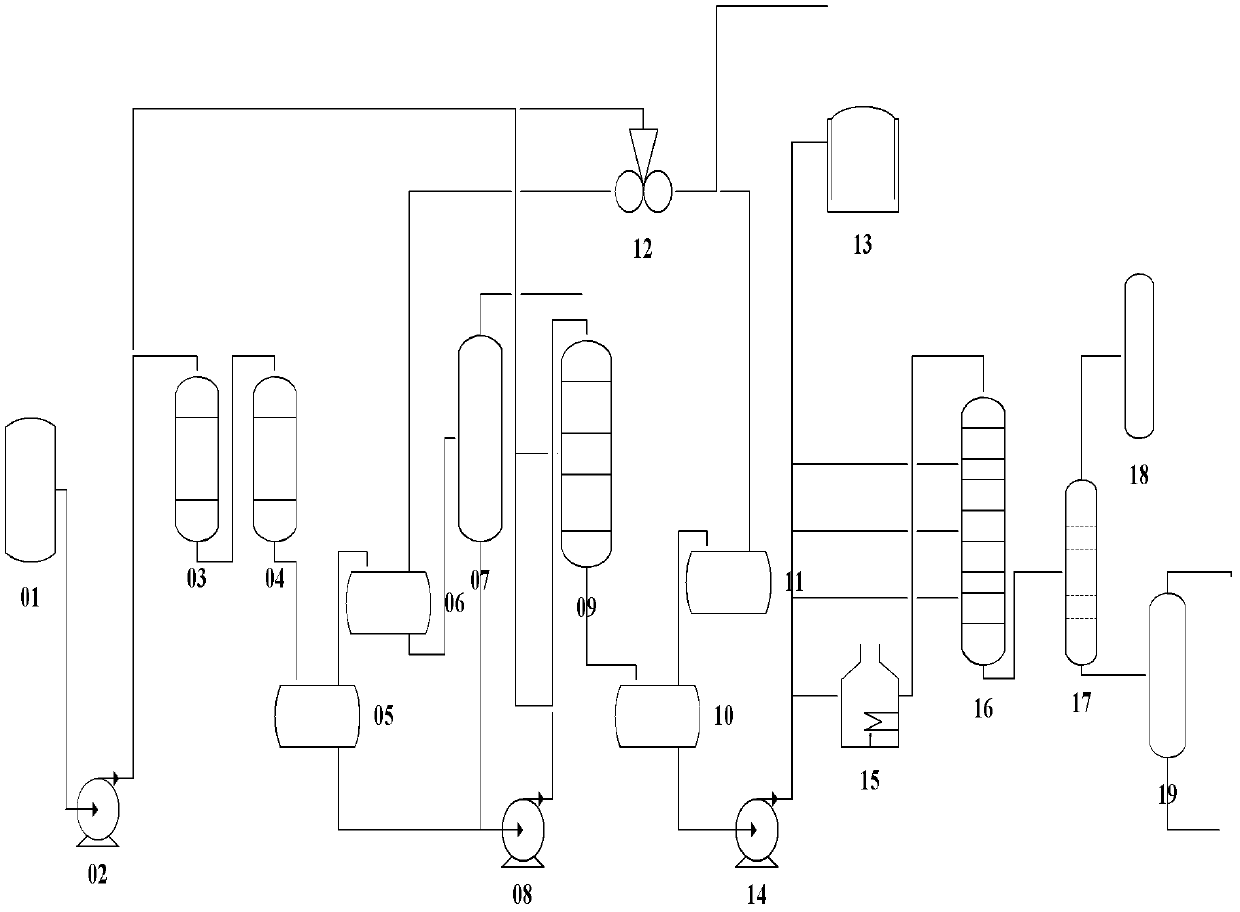

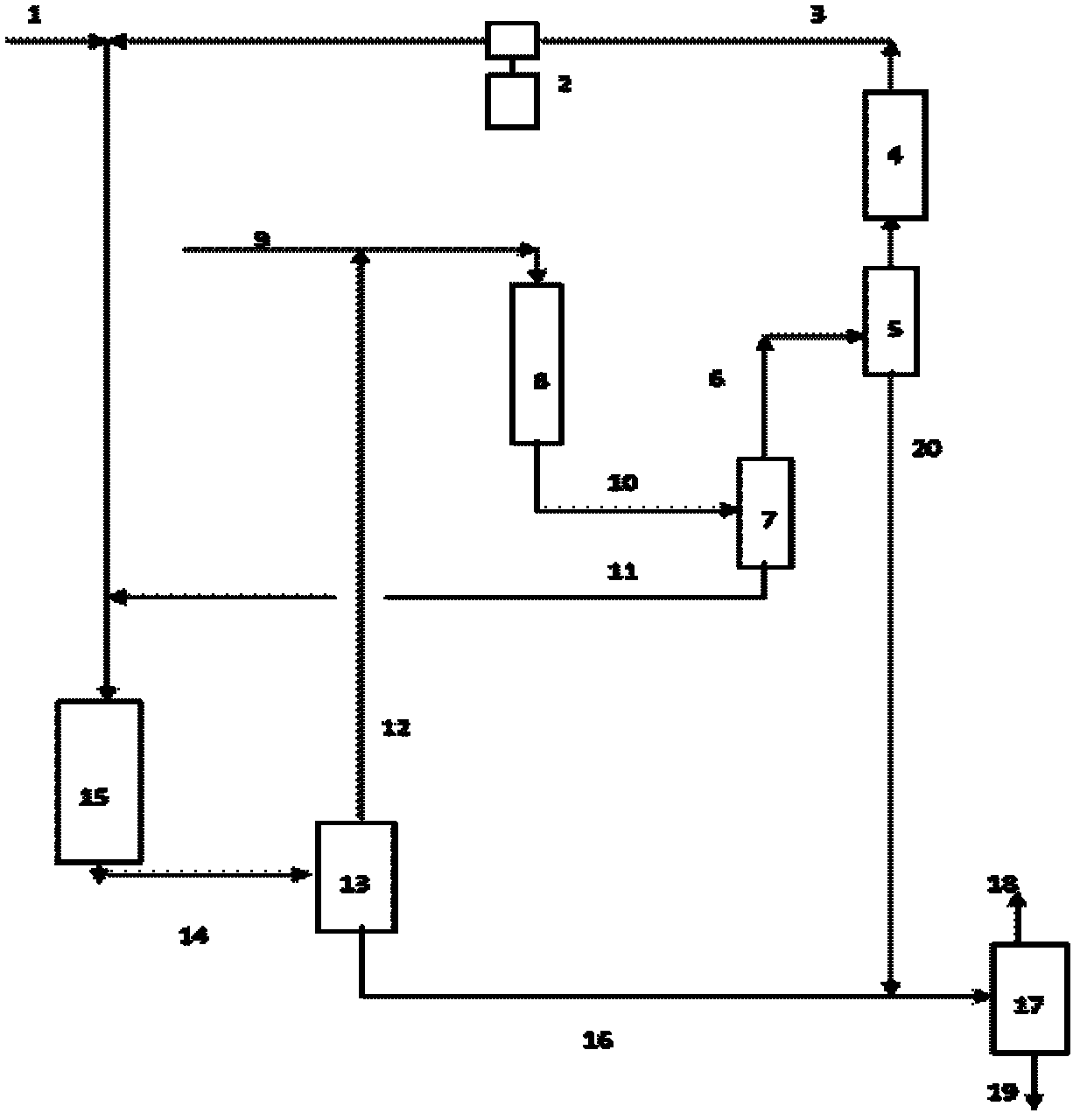

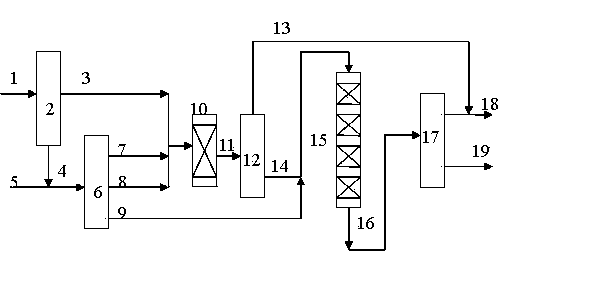

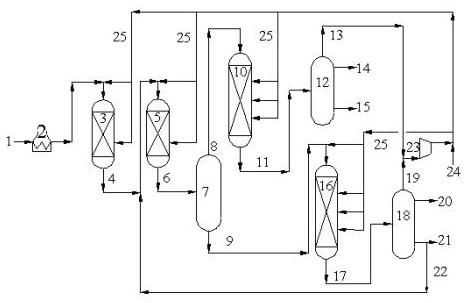

Method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion

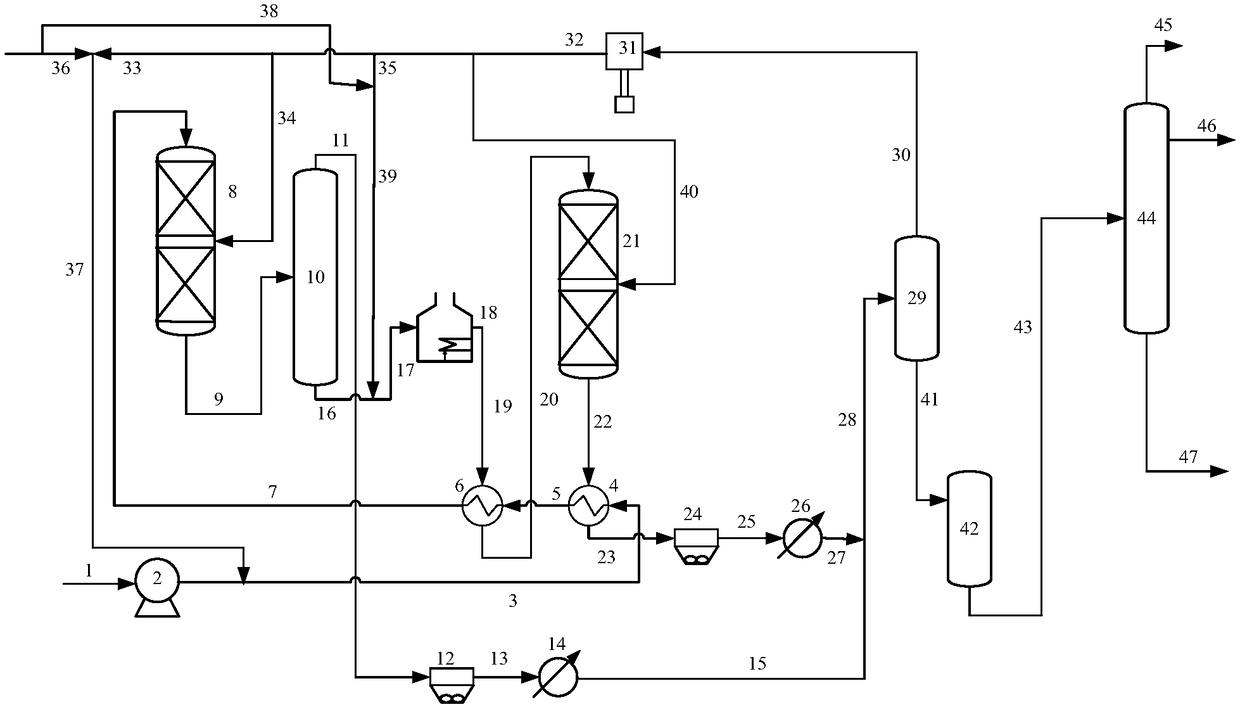

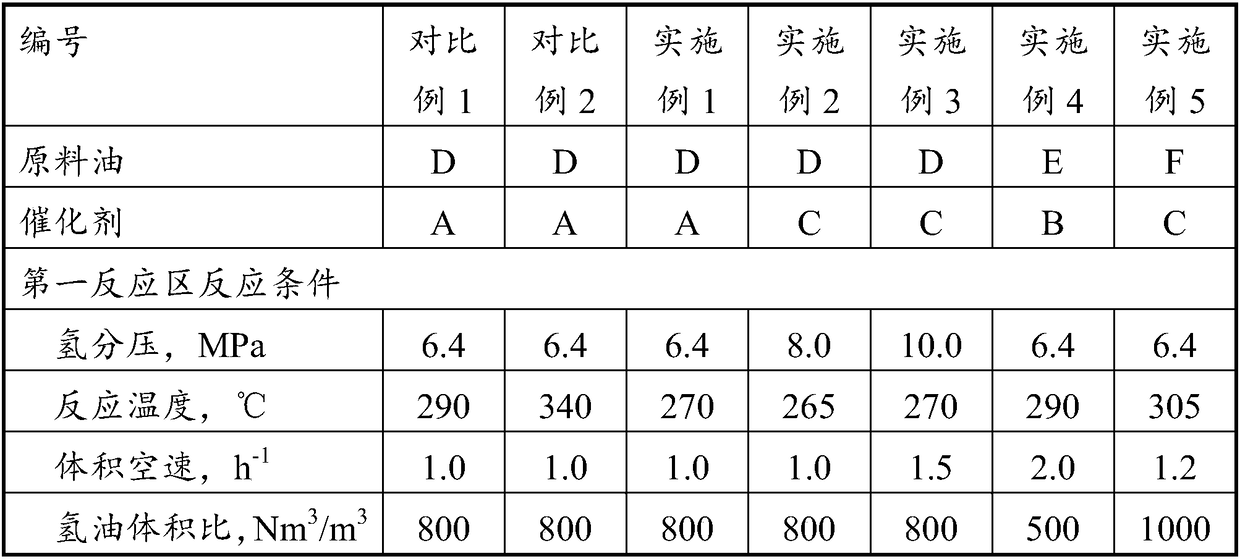

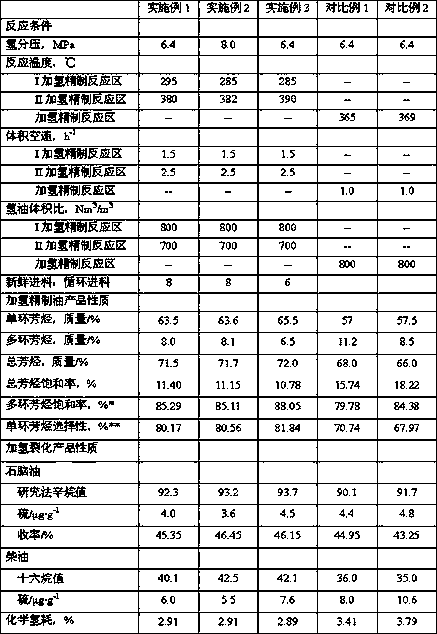

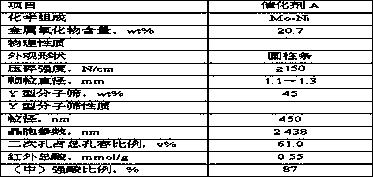

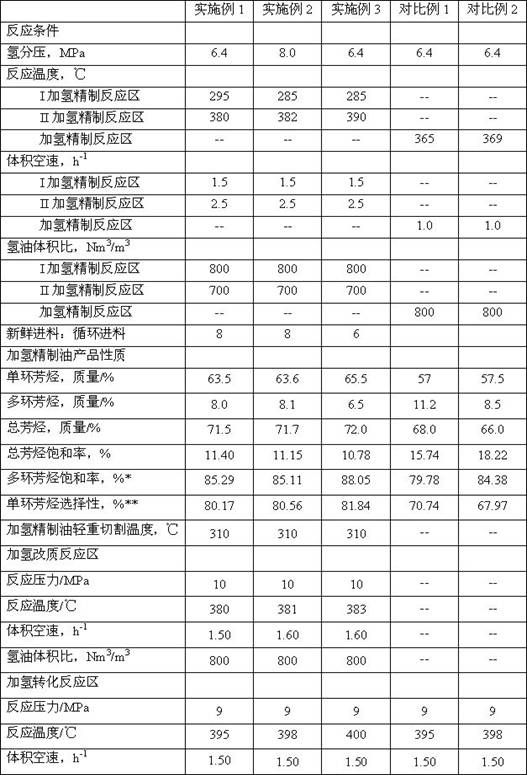

ActiveCN109777514AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

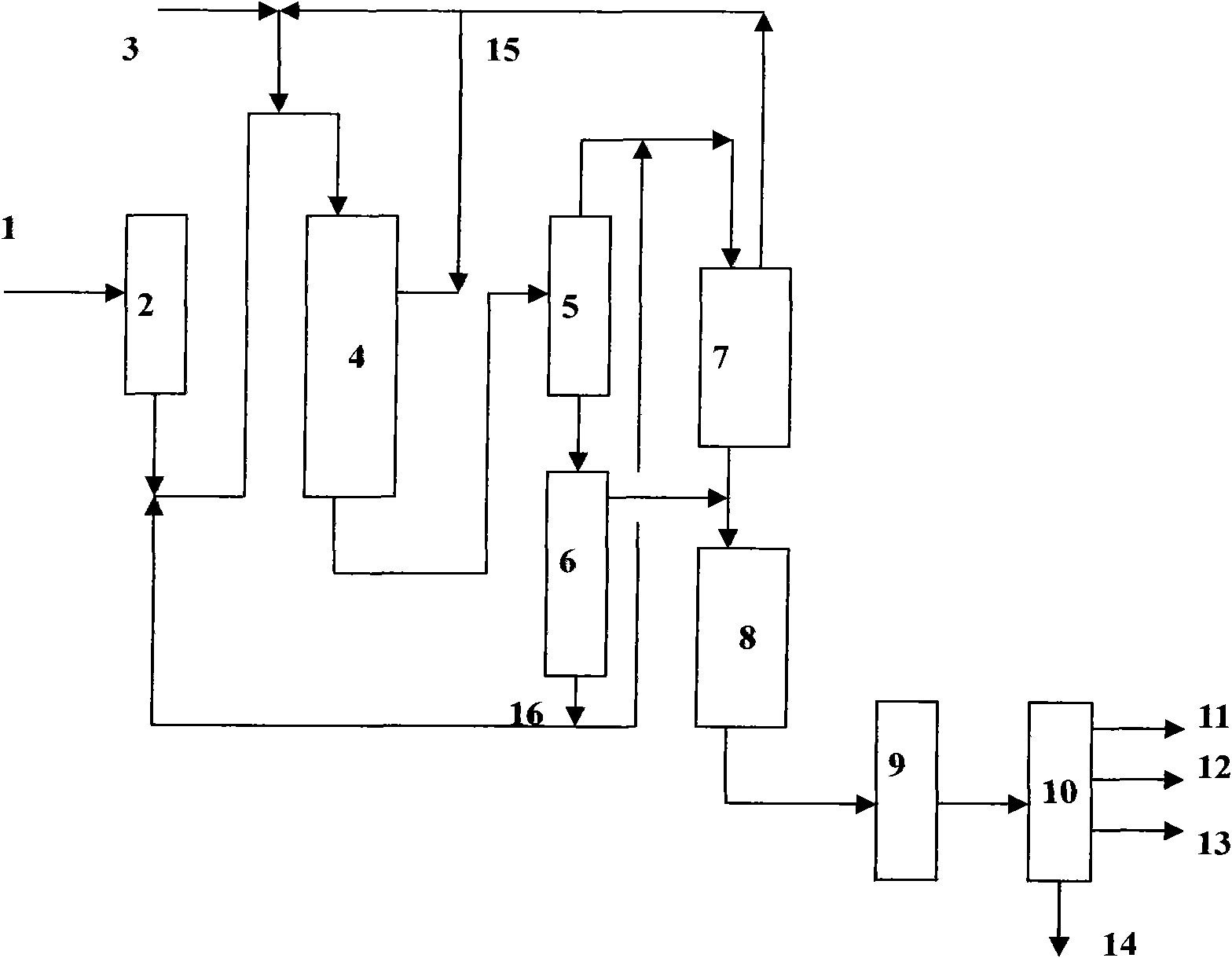

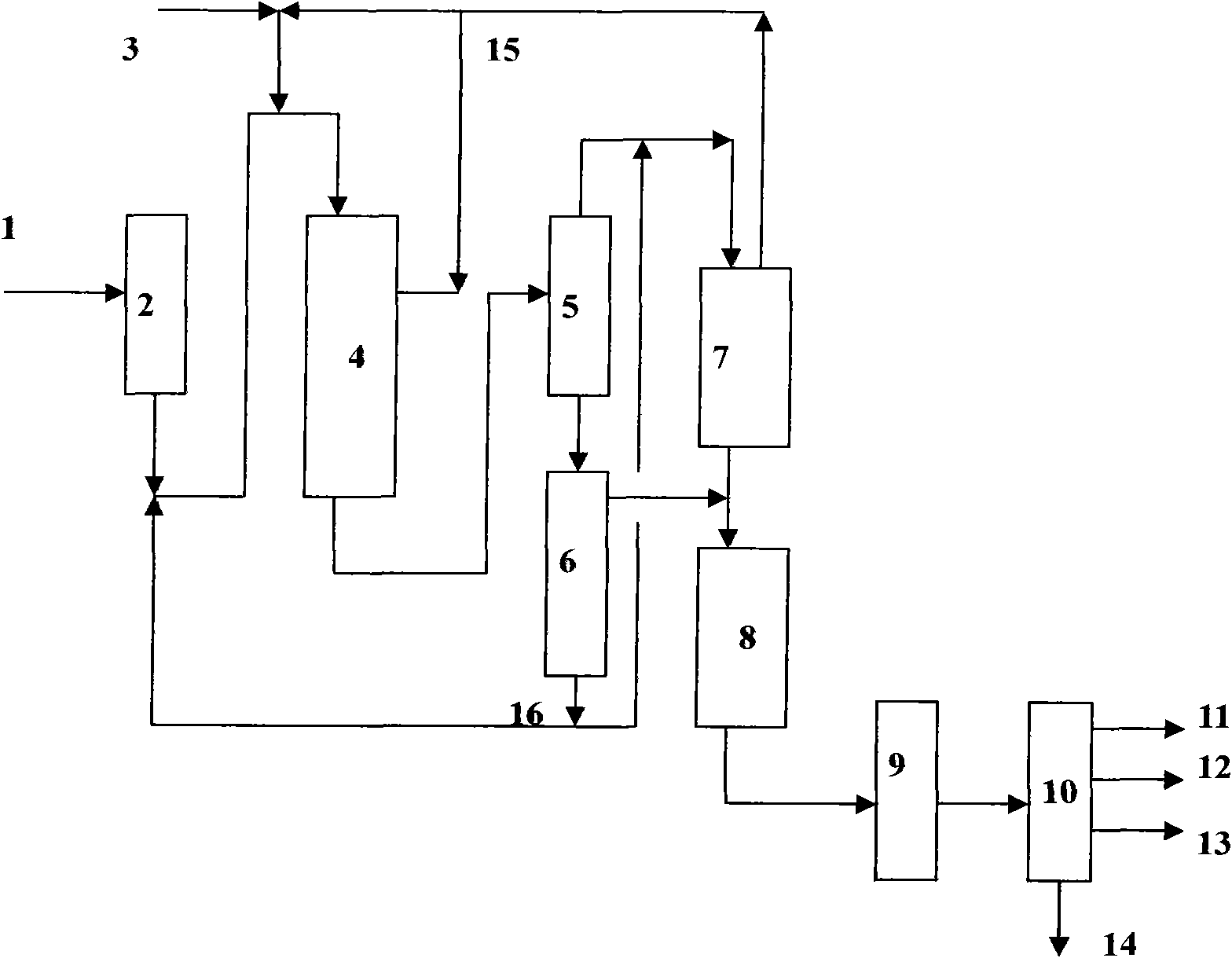

The invention discloses a method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion. The method comprises the following steps: (1) mixing high aromatic hydrocarboncatalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, andfeeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen and feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to a hydrofining reaction zone II, and discharging the other part of the diesel oil from a device; and (5) feeding theheavy naphtha fraction obtained in the step (4) into an aromatic hydrocarbon extraction system to obtain an aromatic hydrocarbon product. By the coupling hydrocracking-aromatic hydrocarbon extractionprocess method for processing catalytic diesel oil raw materials, the yield of the aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

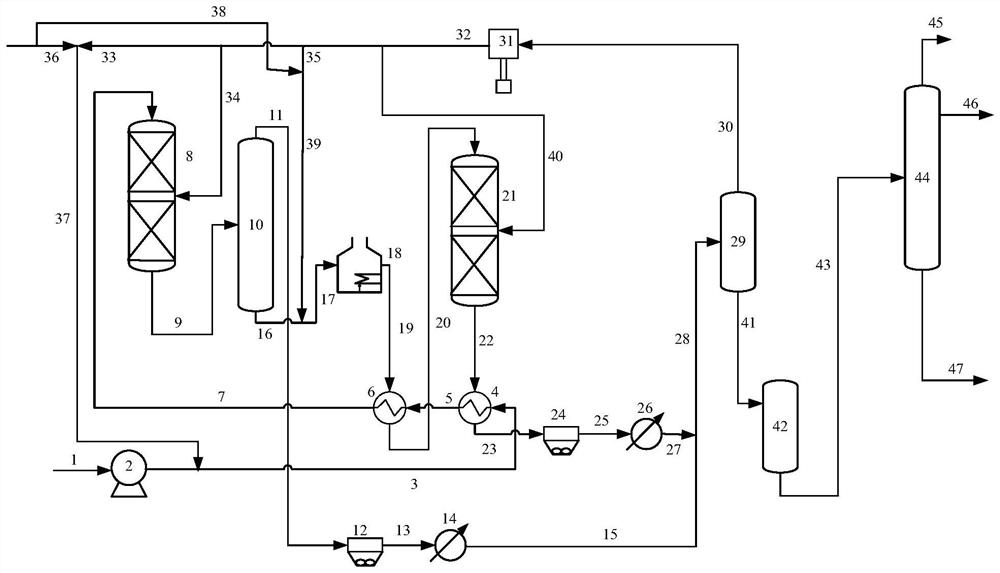

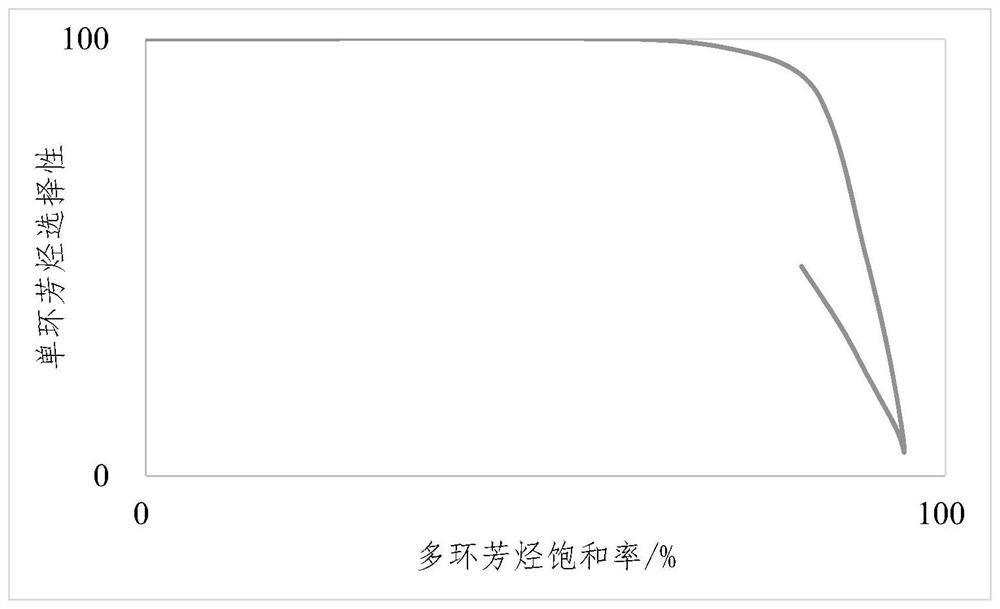

Method for producing raw material rich in monocyclic aromatic hydrocarbons

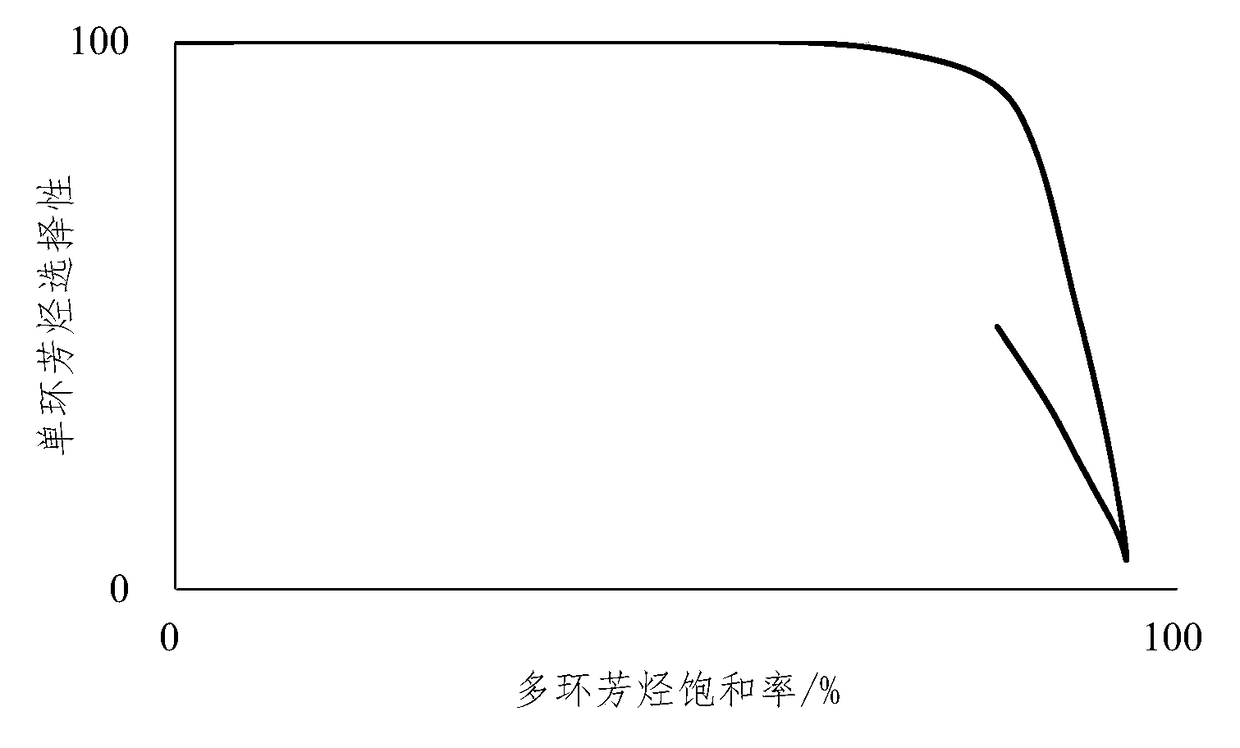

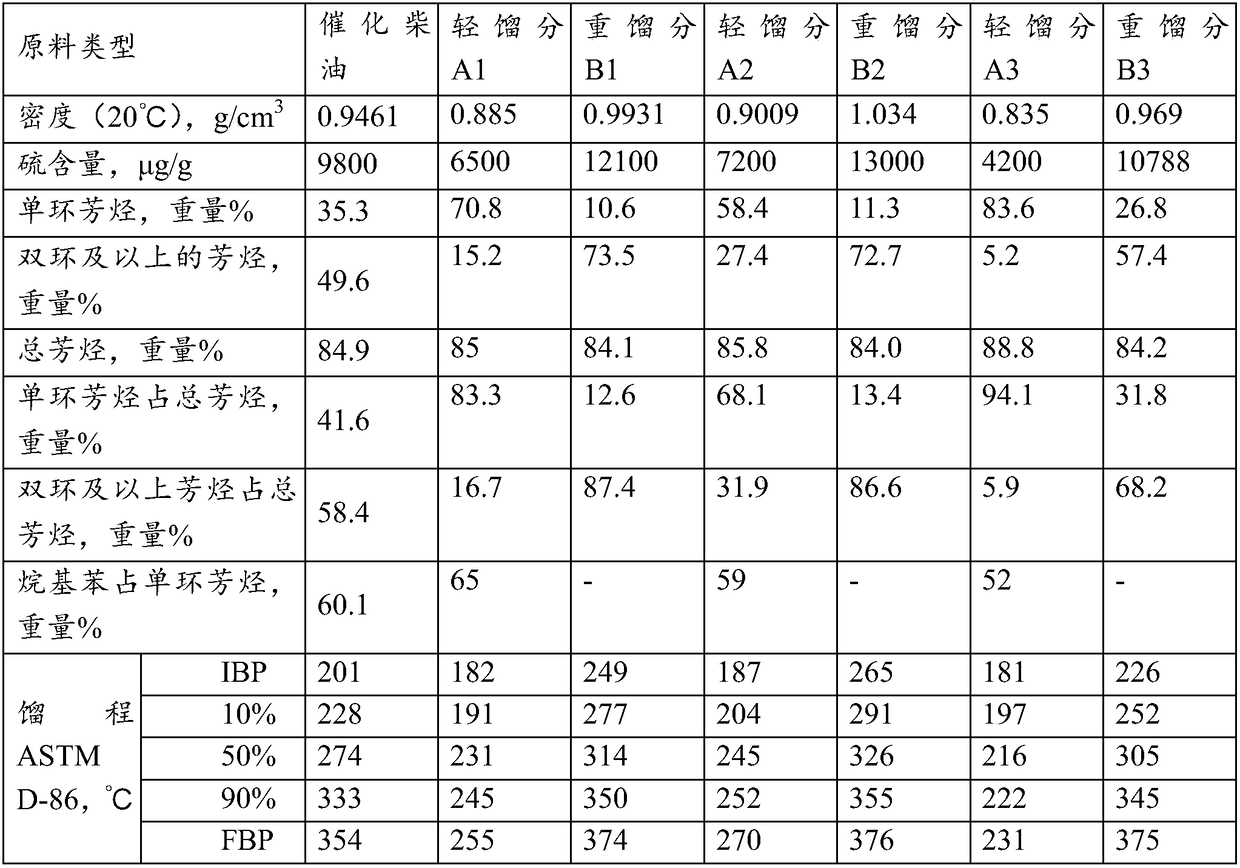

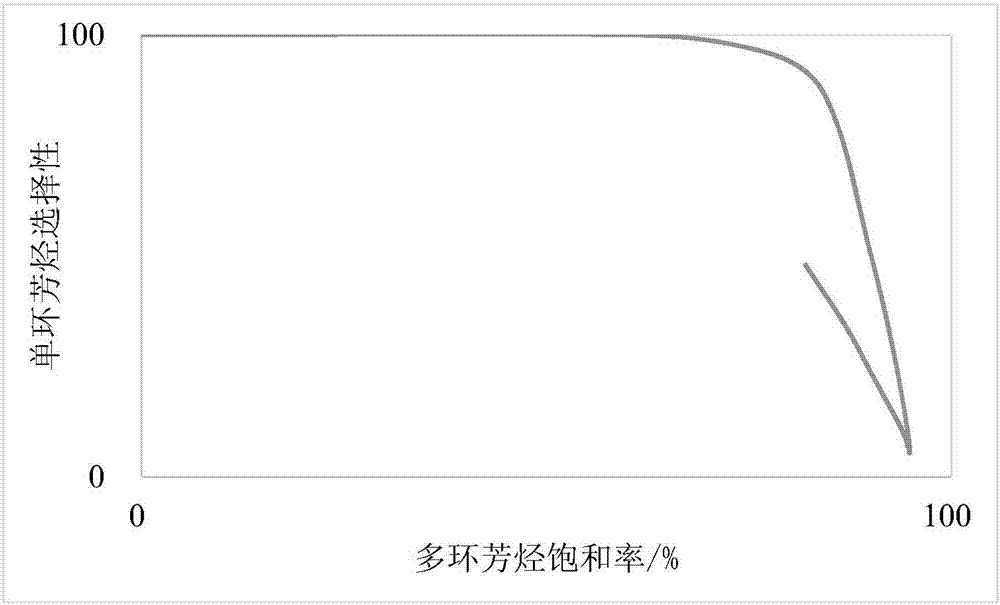

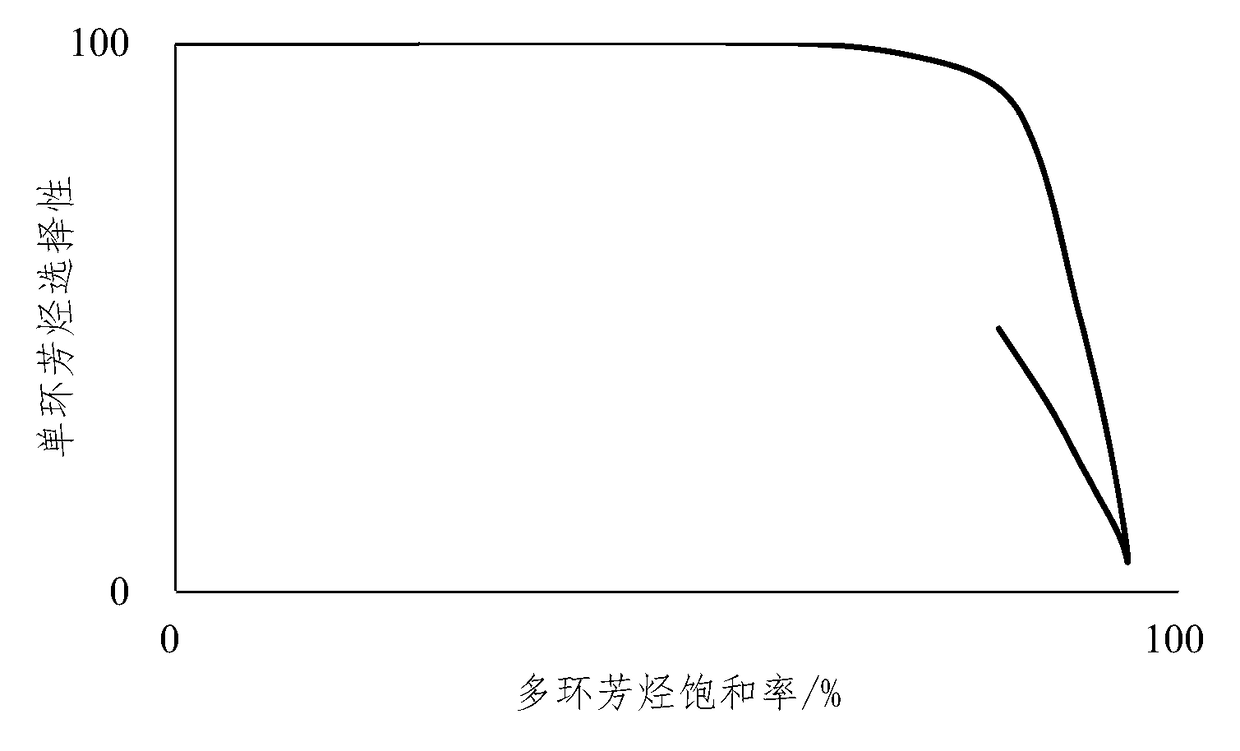

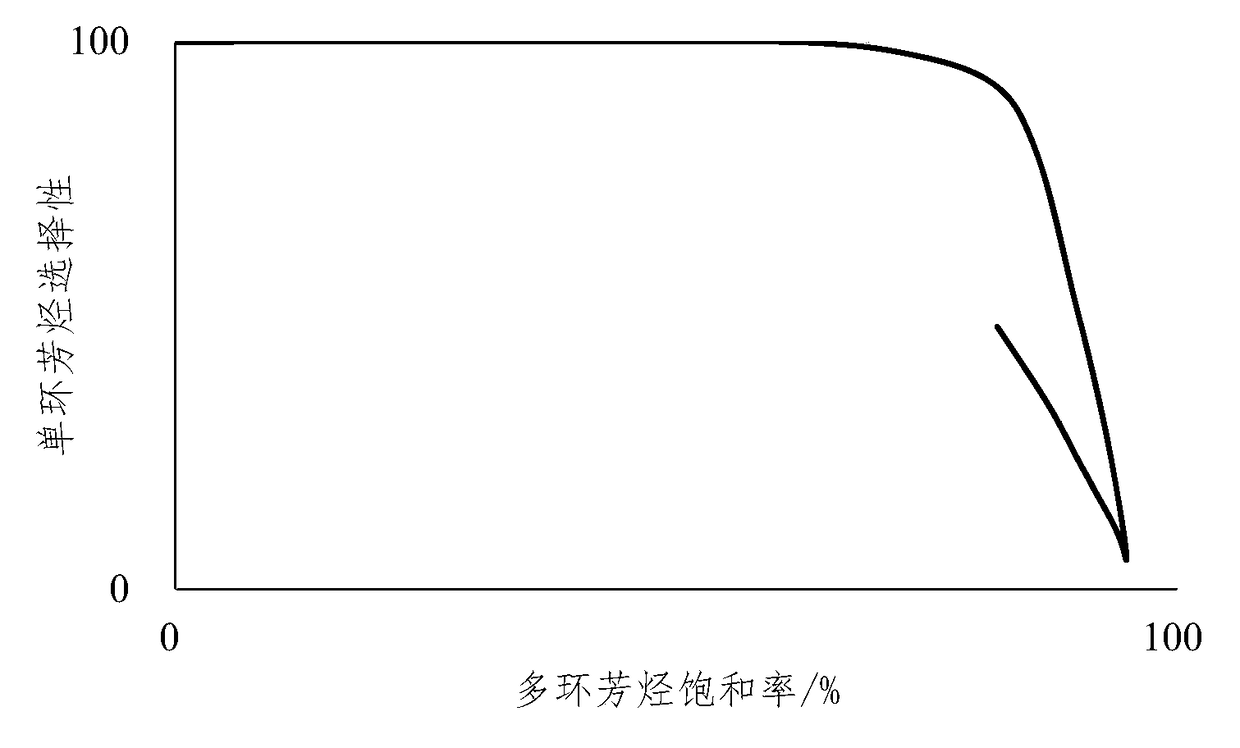

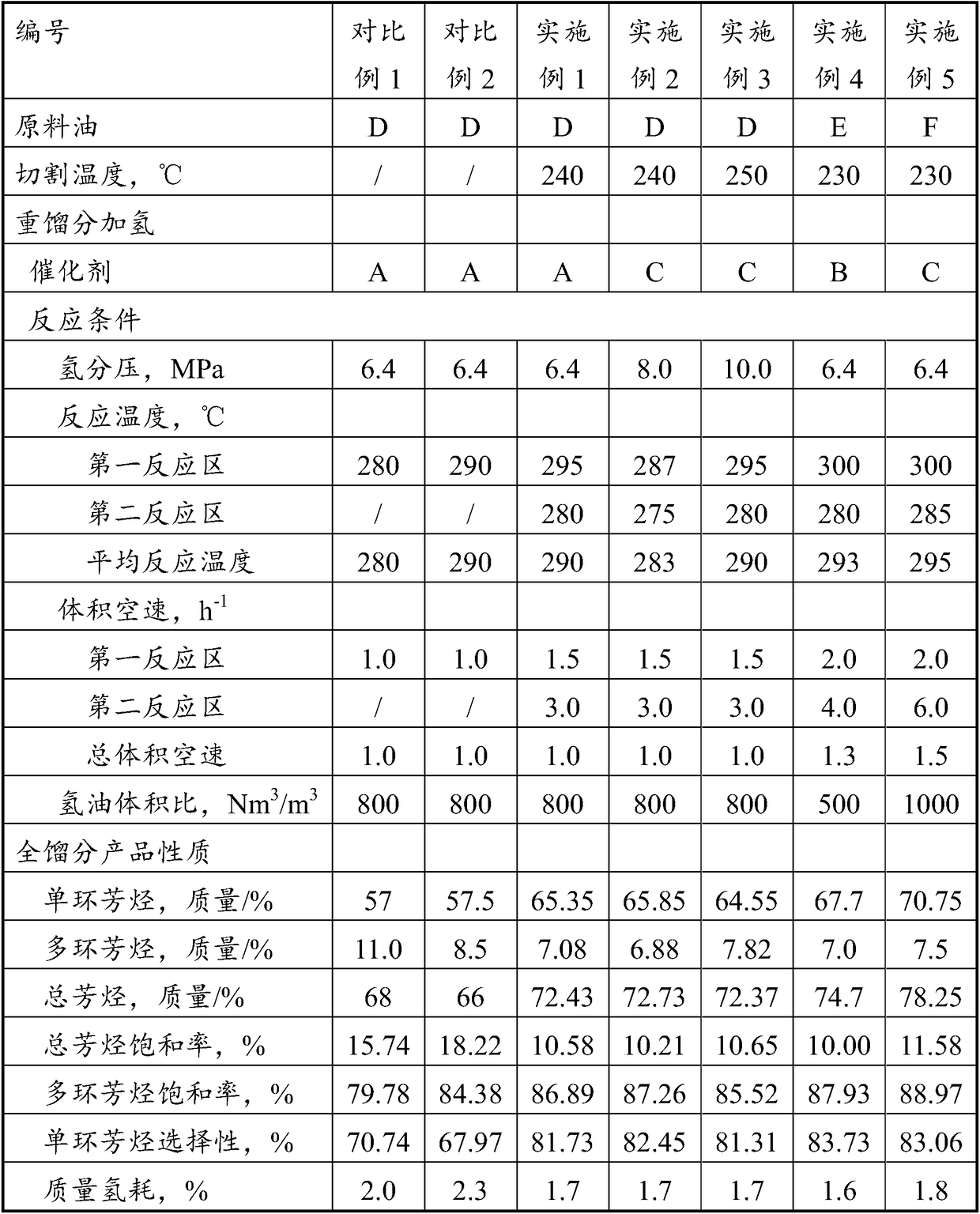

ActiveCN108728162AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesHydrocarbon oils treatment productsRaw materialPolycyclic aromatic hydrocarbon

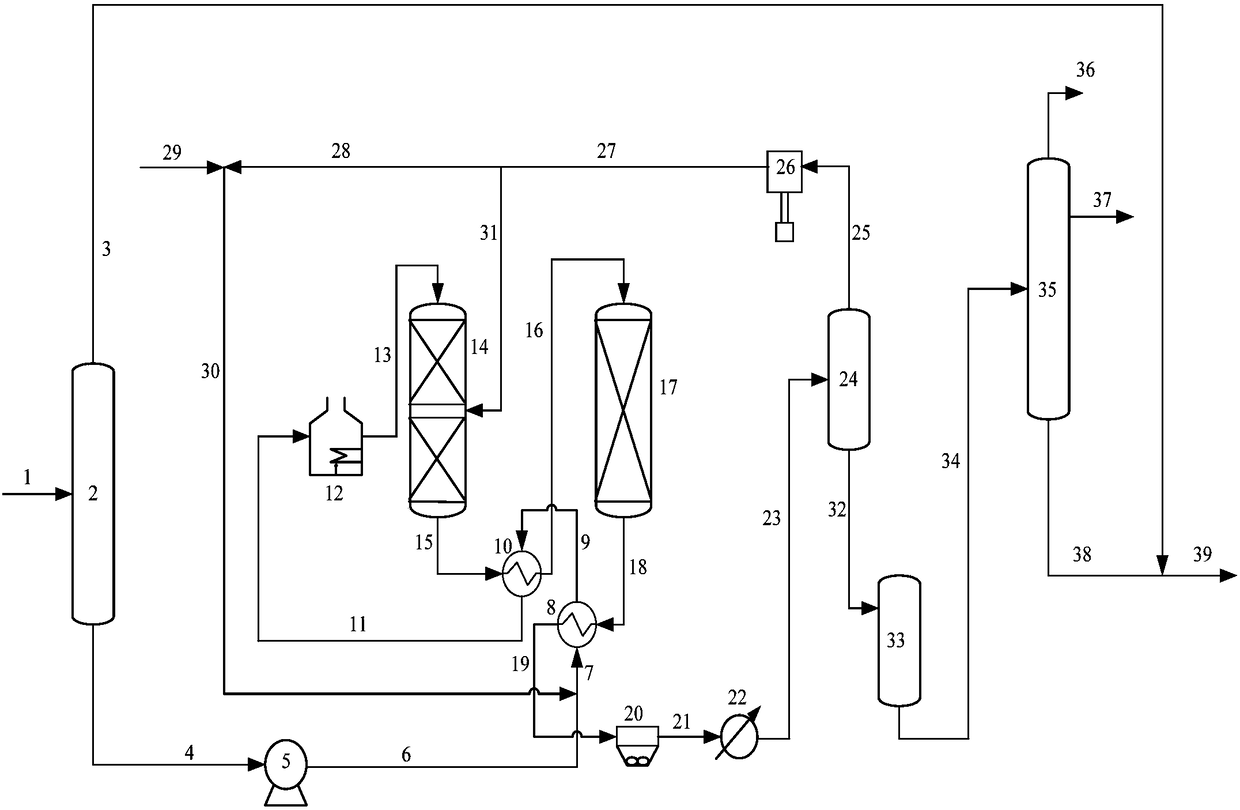

The invention discloses a method for producing a raw material rich in monocyclic aromatic hydrocarbons. The method comprises the following steps: diesel feedstock oil is cut into a light diesel oil fraction and a heavy diesel oil fraction, the heavy diesel oil fraction is mixed with hydrogen, the mixture is in contact with a hydrorefining catalyst I in a first reaction zone, and hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are carried out under hydrogenation reaction conditions; the light diesel oil fraction is mixed with an effluent from the first reaction zone, and then the mixture enters into a second reaction zone to be in contact with a hydrorefining catalyst II, hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are furthercarried out under the hydrogenation reaction conditions, and the effluent from the second reaction zone is separated to obtain a whole fraction product; based on the diesel feedstock oil, polycyclic aromatic hydrocarbons in the whole fraction product have a saturation ratio of 85% to 90%, and the monocyclic aromatic hydrocarbons have a selectivity of 80% to 85%. The method provided by the invention provides high-quality raw materials for catalytic cracking or hydrocracking to produce high-octane gasoline or BTX components, reduces the hydrogen consumption in a hydrogenation process, and improves the stability of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of ethylene tar

ActiveCN103102976AImprove economic efficiencyAvoid concentrated heatDistillation purification/separationTreatment with hydrotreatment processesCrystallization PurificationGasoline

The invention discloses a treatment method of ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline, coker diesel oil and coker gas oil, mixing the coker diesel oil with the ethylene tar light fraction, performing rectification / crystallization purification to obtain naphthalene, mixing the naphthalene removed oil, naphthalene after-cut oil, with the coker gasoline and the coker gas oil, taking the obtained mixture as a hydrotreating raw material, leaving the material to undergo a hydrofining reaction, separating gasoline fraction I, subjecting the obtained fraction heavier than gasoline to hydrocracking so as to obtain gasoline fraction II and a diesel oil product, and mixing the gasoline fraction II with the gasoline fraction I so as to obtain a final gasoline product. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes, thus increasing the added value of ethylene tar. While generating the chemical raw material naphthalene, the method also improves the product quality of light fuel oil, and also enables the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diesel raw material treatment method

ActiveCN108795495AHigh activityExtended service lifeTreatment with hydrotreatment processesHydrocarbon oils treatment productsAlkaneGasoline

A diesel raw material treatment method includes: cutting raw diesel into light diesel fraction and heavy diesel fraction; allowing the light diesel fraction to react in a first traction area to obtaina component rich in cycloalkane; allowing the heavy diesel fraction to react in a second reaction area; enabling obtained hydrogenation diesel fraction to enter a catalytic cracking unit for catalytic cracking reaction at the presence of a catalytic cracking catalyst; separating reaction oil gas to obtain a gasoline product rich in aromatic hydrocarbon class compounds. By the method, the raw diesel with high aromatic hydrocarbon content can be treated to produce BTX, high-octane gasoline and jet fuel components, so that the objective of converting low-quality diesel into high-added-value products is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

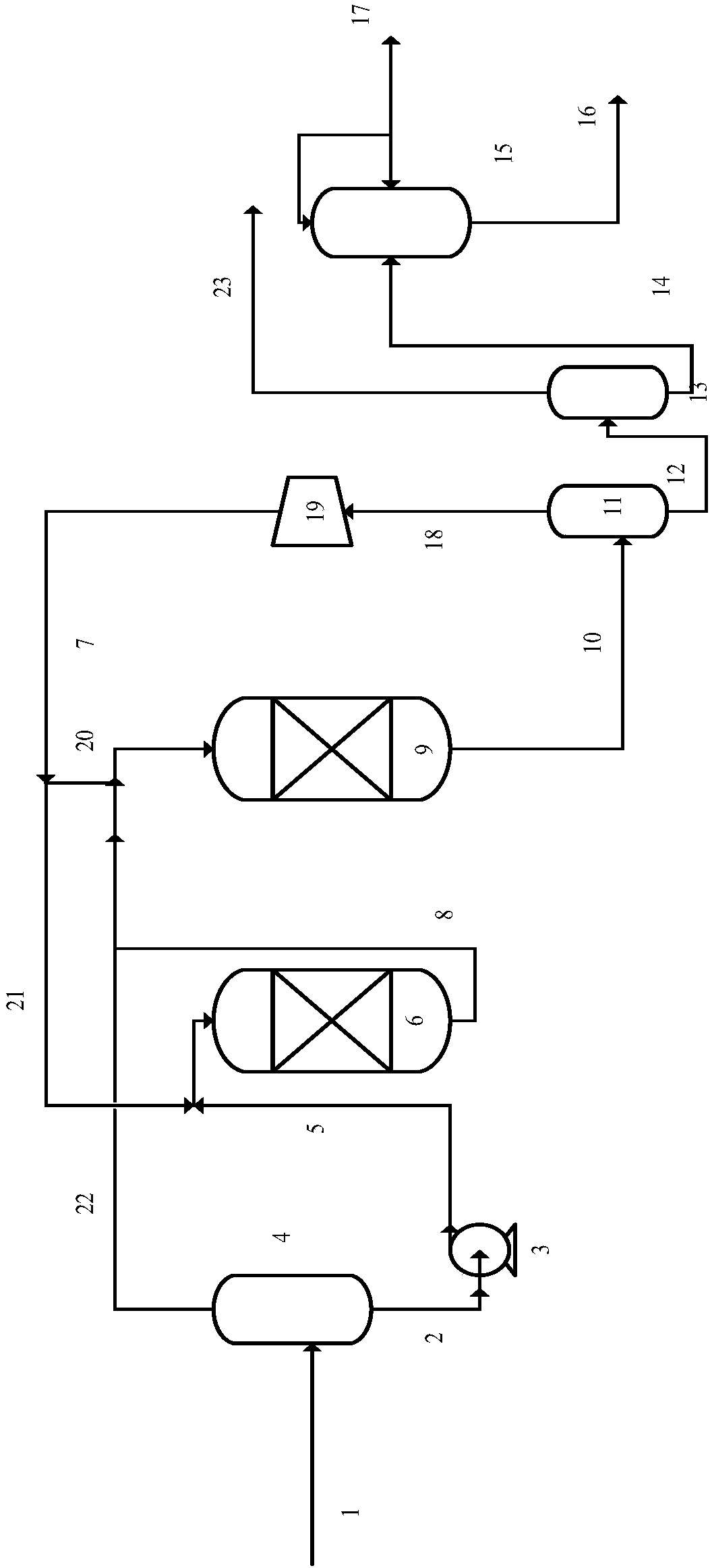

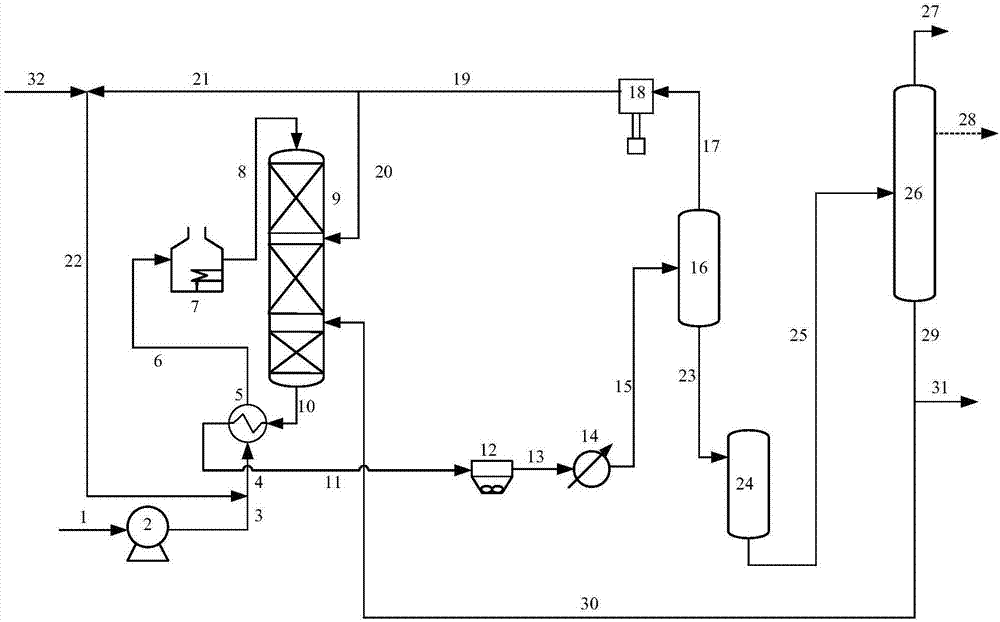

Method for producing hydrocarbon raw material rich in monocyclic aromatic hydrocarbons

ActiveCN107974287AHigh activityExtended service lifeTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonGasoline

The invention relates to a method for producing a hydrocarbon raw material rich in monocyclic aromatic hydrocarbons. According to the method, hydrogen and raw oil of diesel oil are mixed and then successively enter a first reaction zone and a second reaction zone for a contact reaction with a hydrorefining catalyst; an effluent of the second reaction zone is separated so as to obtain a liquid material flow and a gas material flow; a part of the liquid material flow is used as a circulation product and returns to the inlet of the second reaction zone; and the rest part of the liquid material flow is used as a hydrocarbon raw material and enters a catalytic cracking unit and / or hydrocracking unit. The method provided by the invention provides a high-quality raw material for producing high-octane-number gasoline or BTX component through catalytic cracking or hydrocracking, reduces hydrogen consumption in hydrogenation and is beneficial for improving the economical efficiency of hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for selective hydrogenation of diesel oil

ActiveCN108690659AHigh activityExtended service lifeHeterogenous catalyst chemical elementsTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonGasoline

The invention relates to a method for selective hydrogenation of diesel oil. The method comprises that diesel oil raw material oil and hydrogen are mixed, the mixture contacts a hydrorefining catalystin a first reaction zone, and hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are performed under hydrogenation process conditions; the reaction effluent of the first reaction zone is separated by a separator to obtain a reaction effluent I and reaction effluent II, the reaction effluent II enters a second reaction zone and contacts a hydrorefining catalyst, and hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are further performed under hydrogenation process conditions to obtain a reaction effluent III; after the reaction effluent Iand the reaction effluent III are mixed, and separation is performed to obtain hydrogenation oil; and based on the diesel oil raw material oil, the saturation rate of the polycyclic aromatic hydrocarbon in the hydrogenation oil is more than 95%, and the selectivity of the monocyclic aromatic hydrocarbon is more than 85%. According to the present invention, with the method, the high-quality raw material is provided for the catalytic cracking or hydrocracking production of high-octane number gasoline or BTX components while the hydrogen consumption of the hydrogenation process is reduced, and the process economy is easily improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing polycyclic aromatic hydrocarbons from diesel oil distillate

ActiveCN108690655AIncrease saturation rateHigh selectivityHydrocarbon oils treatment productsRefining to eliminate hetero atomsRaw materialPolycyclic aromatic hydrocarbon

The invention relates to a method for removing polycyclic aromatic hydrocarbons from a diesel oil distillate. The method comprises that a diesel oil raw material oil is cut into a light diesel oil distillate and a heavy diesel oil distillate; the heavy diesel oil distillate is mixed with hydrogen, the mixture contacts a hydrorefining catalyst in a first reaction zone, and hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are performed under hydrogenation reaction conditions; the effluent of the first reaction zone enters a second reaction zone and contacts a hydrorefining catalyst, and hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are further performed under hydrogenation reaction conditions; the effluent of the second reaction zone is separated to obtain a hydrogenated heavy diesel oil distillate and a gas stream; and the hydrogenated heavy diesel oil distillate and the light diesel oil distillate are mixed to obtain the complete-distillate product, wherein the saturation rate of the polycyclic aromatic hydrocarbon in the complete-distillate product is 85-90% and the selectivity of the monocyclic aromatic hydrocarbon is 80-85% based on the diesel oil raw material oil. According to the present invention, with the method, the high-quality raw material is provided for the catalytic cracking or hydrocracking production ofhigh-octane number gasoline or BTX components while the hydrogen consumption of the hydrogenation process is reduced, and the process economy is easily improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for modification by coupling hydrodesulfurization of FCC (Fluid Catalytic Cracking) gasoline and aromatization of liquefied petroleum gas

InactiveCN103289739AHigh yieldSolving activityTreatment with hydrotreatment processesGaseous mixture working upHydrodesulfurizationFractionation

The invention provides a method for modification by coupling hydrodesulfurization of FCC (Fluid Catalytic Cracking) gasoline and aromatization of liquefied petroleum gas. All-fraction FCC gasoline is sequentially subjected to selective hydrogenation and preliminary desulfurization treatment to obtain HCN (Hydrogen Cyanide) heavy-component gasoline by fractionation, and the obtained HCN heavy-component gasoline is then subjected to hydrodesulfurization treatment; and the HCN heavy-component gasoline obtained from the hydrodesulfurization treatment and liquefied petroleum gas are co-fed into a fixed bed multi-stage aromatization reactor to recover / improve the octane number of a gasoline product through the processes of polymerization, pyrolysis, aromatization, hydrogen transfer and the like of olefin. The method is applied to the production process of ultra-low sulfur clean gasoline meeting national IV gasoline standard, and especially the ultra-low sulfur clean gasoline meeting national V gasoline standard. As a gradual desulfurization process is adopted, the operation conditions of all the units are mild, the desulfurization process is coupled with a liquefied petroleum gas aromatization process, and therefore the method has the characteristics that the gasoline desulfurization efficiency is high, the octane number loss of a product does not lose and is even increased, the gasoline yield is increased and the reaction process is flexible.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

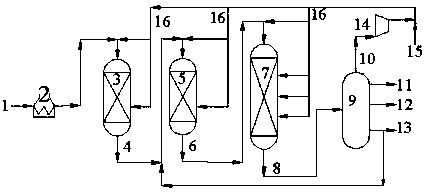

Method for producing light fuel oil from ethylene tar

ActiveCN103102979AImprove product qualityBroaden sources of raw materialsTreatment with hydrotreatment processesLighter fuelGasoline

The invention discloses a method for producing light fuel oil from ethylene tar. The method is as below: fractionating ethylene tar into a light fraction and a heavy fraction; mixing the heavy fraction with a conventional coking raw material, and subjecting the mixture to delayed coking to obtain coker gasoline, coker diesel and coker gas oil; mixing the coker gasoline and the coker diesel with the light fraction of the ethylene tar, and subjecting the mixture to a hydrofining reaction; distilling the product to obtain a gasoline fraction I and a fraction heavier than the gasoline; subjecting the fraction heavier than the gasoline to a hydrogenation treatment to obtain light fuel oil, and distilling to obtain a gasoline fraction II and a diesel product; and mixing the gasoline fraction I and the gasoline fraction II to obtain a final gasoline product. The method provided by the invention utilizes the characteristics of high contents of ethylene tar aromatic hydrocarbons, colloid, carbon residue and glial and asphaltene of ethylene tar to fractionate the ethylene tar into the light fraction and the heavy fraction; different processing methods are employed to improve the added value of ethylene tar, increase yield of gasoline and diesel, improve product quality of light fuel oil and realize long-period stable operation of devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method using gas oil and residual oil to process light fuel

ActiveCN102373086AImprove liquid yieldExpand sourceTreatment with hydrotreatment processesChemistryFuel oil

The invention discloses a method using gas oil and residual oil to process light fuel. The gas oil, catalytic cracking heavy oil and hydrogen are mixed to enter a first hydrogenation reaction area to react, the produced oil after the reaction and residual oil raw materials are mixed to react in a second hydrogenation reaction area, the obtained product after the reaction is separated to obtain a liquid phase product and a gas phase product, wherein the gas phase product is purified and pressurized to be fed back to the first hydrogenation reaction area for cycle use, the hydrogenation residual oil in the liquid phase product enters a catalytic cracking device to react, and the catalytic cracking heavy oil in a reaction product is circulated to the first hydrogenation reaction area. The method organically combines the heavy oil hydrotreatment and the catalytic cracking device, can translate inferior gas oil and residual oil into light fuel to the maximum extent, so the liquid yield is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

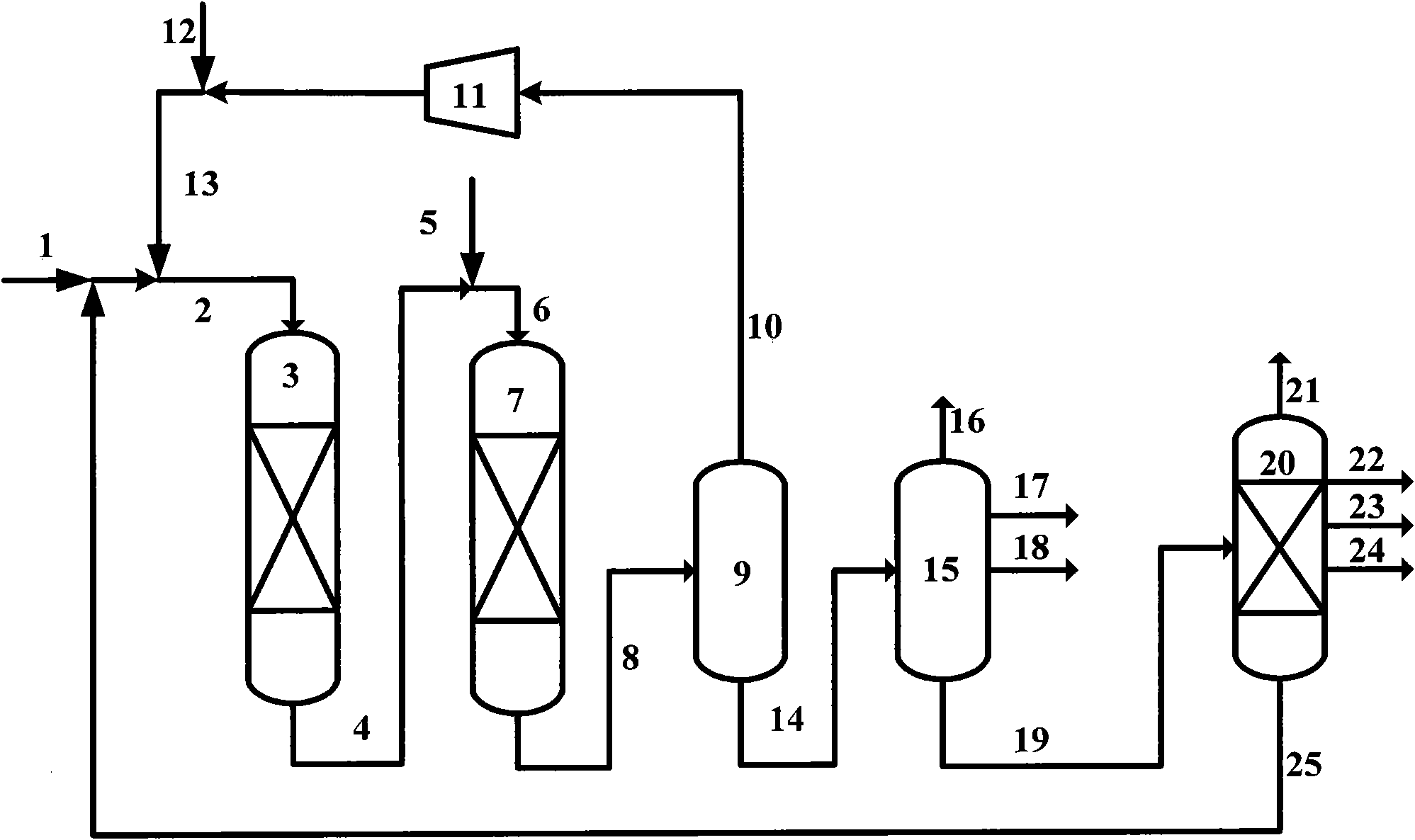

Aromatic hydrocarbon-rich wax oil hydrotreating method

InactiveCN103131466AImprove responseIncrease saturation rateTreatment with hydrotreatment processesGas phaseHigh pressure

The present invention relates to an aromatic hydrocarbon-rich wax oil hydrotreating method, which comprises that: an aromatic hydrocarbon-rich wax oil raw material oil and a gas phase material discharged from a second thermal high pressure separator are mixed, and then enter a first reactor; the first reactor reaction product enters a first thermal high pressure separator; the liquid phase material of the first thermal high pressure separator and circulation hydrogen are mixed, and enter a second reactor, and the gas phase material is cooled and then enters a cold high pressure separator; the gas phase material of the cold high pressure separator is subjected to desulfurization through a hydrogen sulfide removing tower, and the obtained gas is subjected to pressure increase through a compressor, and then is mixed with the circulation hydrogen; the second reactor reaction product enters the second thermal high pressure separator; the liquid phase material of the second thermal high pressure separator and the liquid phase product of the cold high pressure separator are subjected to mixing pressure reduction, and then enter a thermal low pressure separator; and the separated thermal low pressure separator gas phase material and the thermal low pressure separator liquid phase material are respectively processed into various products. The process reaction results show that an aromatic hydrocarbon saturation rate is substantially increased, and a cracking performance of the aromatic hydrocarbon-rich wax oil can be substantially improved.

Owner:PETROCHINA CO LTD +1

Catalytic diesel oil hydro-conversion method

ActiveCN109777511AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

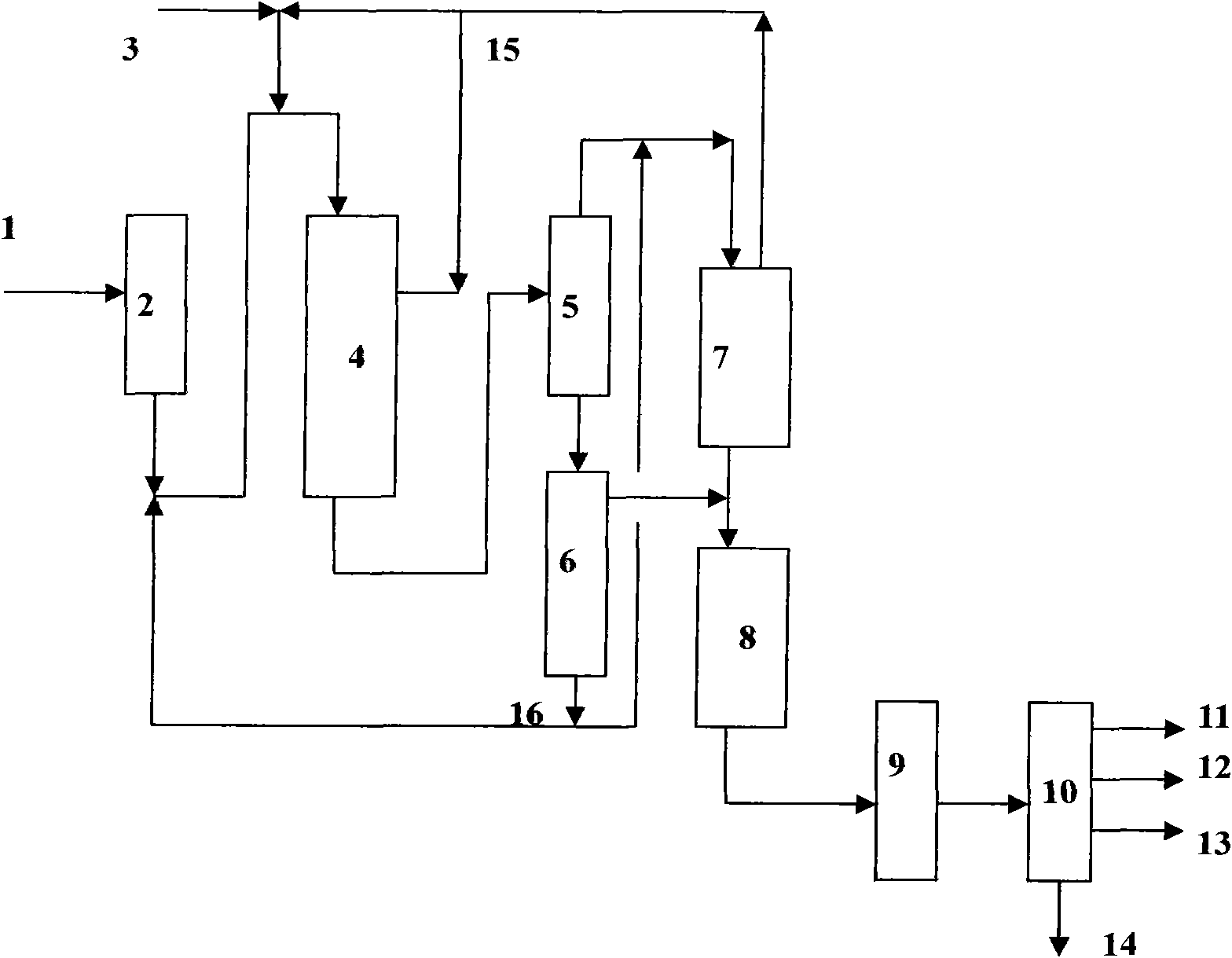

The invention discloses a catalytic diesel oil hydro-conversion method. The catalytic diesel oil hydro-conversion method comprises the following steps: (1) mixing high aromatic hydrocarbon catalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, and feeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen, feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to the hydrofining reaction zone II, and discharging the other part of the diesel oil from the device. By the catalytic diesel oil hydro-conversion method, the yield of aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

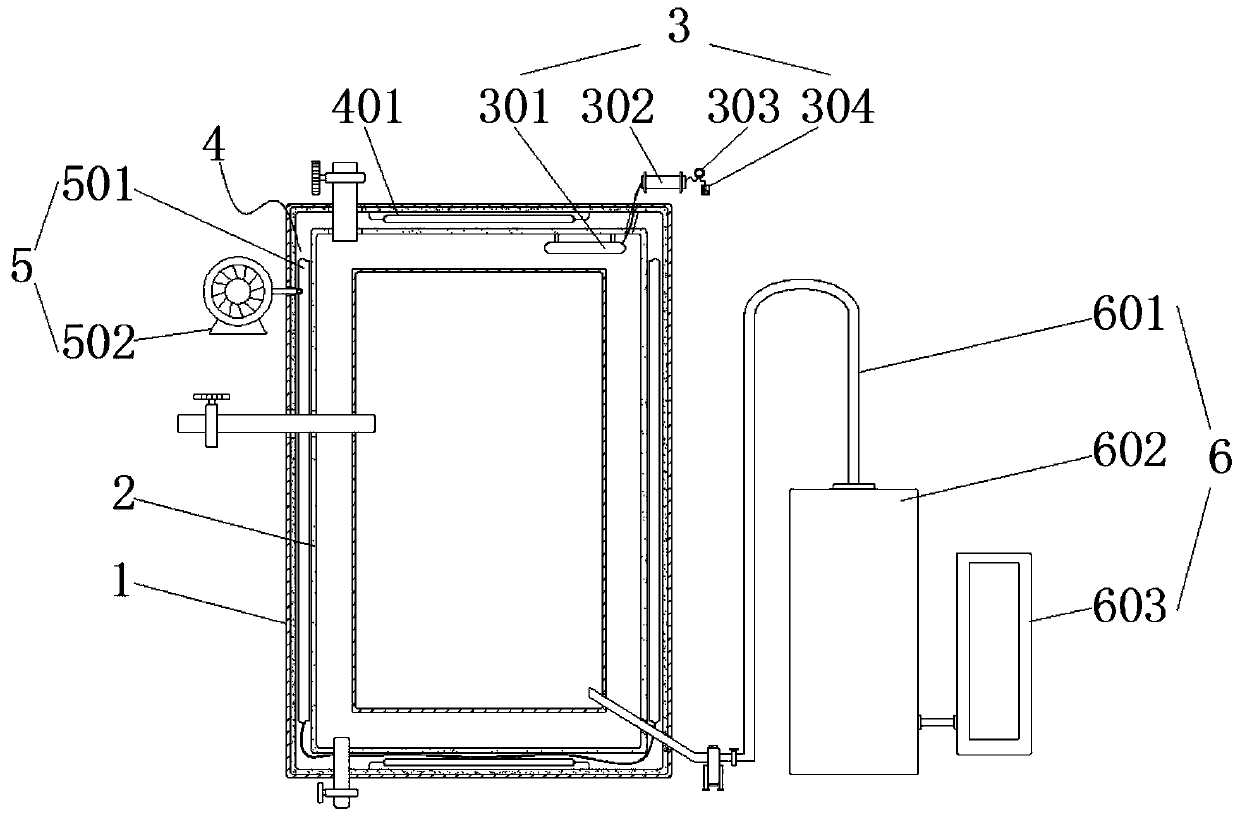

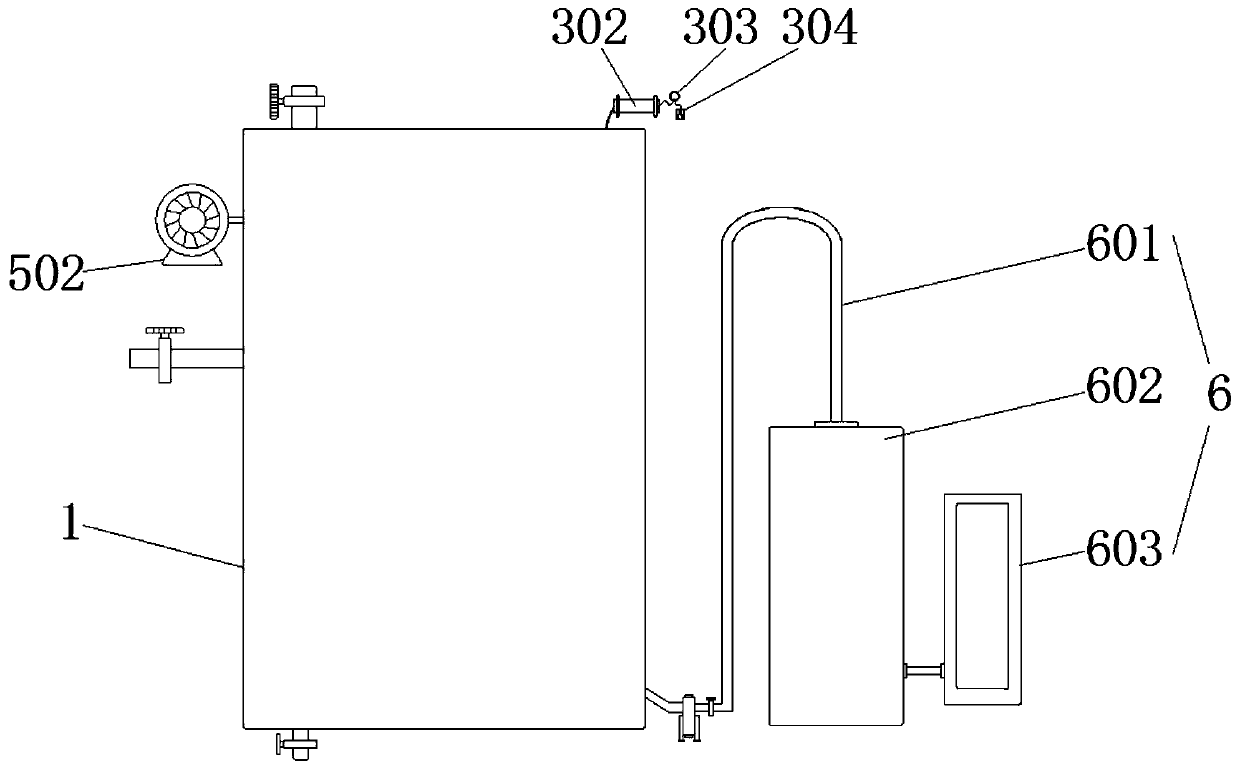

Environment-friendly water-thermal-storage power supply energy storage system

PendingCN111366022ATo achieve the purpose of constant heatingPrecise temperature water storageHeat storage plantsAir heatersAir pumpEngineering

The invention relates to an environment-friendly water-thermal-storage power supply energy storage system. The system comprises a hollow structure box for storing water, a heating assembly for heatingthe stored water, a heat preservation assembly for preventing the temperature of the stored water from decreasing quickly and a power generation assembly for instantaneous power generation. A sealingshell and a blocking plate wrapping the exterior of the sealing shell are arranged in the box, and a gap between the sealing shell and the blocking plate forms a water-thermal-storage cavity for storing hot water. Through cooperation of an electric heating wire, an airbag and an air pump, when the environment-friendly water-thermal-storage power supply energy storage system is used, the electricheating wire can heat a heat preservation cavity, through heat insulation of the heat preservation cavity, the heat of the heated stored water is prevented from losing quickly, the air pump is used for injecting air into the airbag, the expanded airbag can compress the gas in the heat preservation cavity, so as to increase the saturation factor of the heat in the heat preservation cavity, and theheat preservation and heat insulation efficiency of water thermal storage can be improved.

Owner:上海中如智慧能源集团有限公司

Cyclic heat supply and energy storage system for water thermal storage

PendingCN111365754ASolve the problem of supplying cryogenic liquid waterHigh thermal insulation efficiencyGeneral water supply conservationDomestic cooling apparatusLiquid waterThermal insulation

The invention relates to a cyclic heat supply and energy storage system for water thermal storage. The system comprises a hollow-structured tank used for storing water and further comprises a reactionassembly used for heating and cooling the stored water, a thermal insulation assembly used for preventing temperature of the stored water from losing too rapidly and a power generation assembly applied to instantaneous power generation; and a sealing shell and a partition surrounding the exterior of the sealing shell are arranged in the tank. According to the cyclic heat supply and energy storagesystem for water thermal storage, by cooperative use of a semiconductor chilling plate, a heat dissipating plate, a protective shell, a cold conducting block and a wrapping layer, while heating one kind of stored water, the system can cool another kind of stored water, so that hot water can be supplied to the needed environment, and cold water can also be supplied; and compared with a traditionalheat supply system for water thermal storage, the technical scheme effectively solves the problem that low-temperature liquid water can be supplied to the required environment without external equipment while the hot water is supplied.

Owner:上海中如智慧能源集团有限公司

Hydroconversion process of uncured Fisher-Tropsch process synthesized oil product

ActiveCN100345944CSimplify the hydrogenation processImprove the effect of hydrodeoxygenationTreatment with hydrotreatment processesOxygenOrganic compound

The hydroconversion process of uncured Fischer-Tropsch process synthesized oil product adopts two-section hydrogenating reactor for pre-hydrogenating and deep hydrogenating separately. The reactant material is first pre-hydrogenated inside the first reactor at low temperature to convert the unsaturated olefin into corresponding saturated olefin; and then deeply hydrogenated and deoxygenated inside the second reactor. During the two reaction sections, uncuring hydrogenating catalyst is used. The said process can complete deep hydrorefining of Fischer-Tropsch process synthesized oil product in relatively mild technological conditions, and is especially suitable for the hydroconversion of Fischer-Tropsch process synthesized oil product with high olefin content and certain amount of oxygen bearing organic compounds.

Owner:SYNFUELS CHINA TECH CO LTD

Processing method of ethylene tar

ActiveCN103102978BBroaden sources of raw materialsImprove product qualityTreatment with hydrotreatment processesLighter fuelGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-cracking method for blending ethylene bottom oil

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for selective hydrogenation of diesel

ActiveCN108690659BIncrease saturation rateHigh selectivityHeterogenous catalyst chemical elementsTreatment with hydrotreatment processesPtru catalystChemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing ethylene tar

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of ethylene tar

ActiveCN103102976BBroaden sources of raw materialsImprove product qualityDistillation purification/separationTreatment with hydrotreatment processesGasolineHydrogen treatment

Owner:CHINA PETROLEUM & CHEM CORP +1

Agricultural mechanical pesticide spraying machine pesticide liquid mixing device based on fluid mechanics

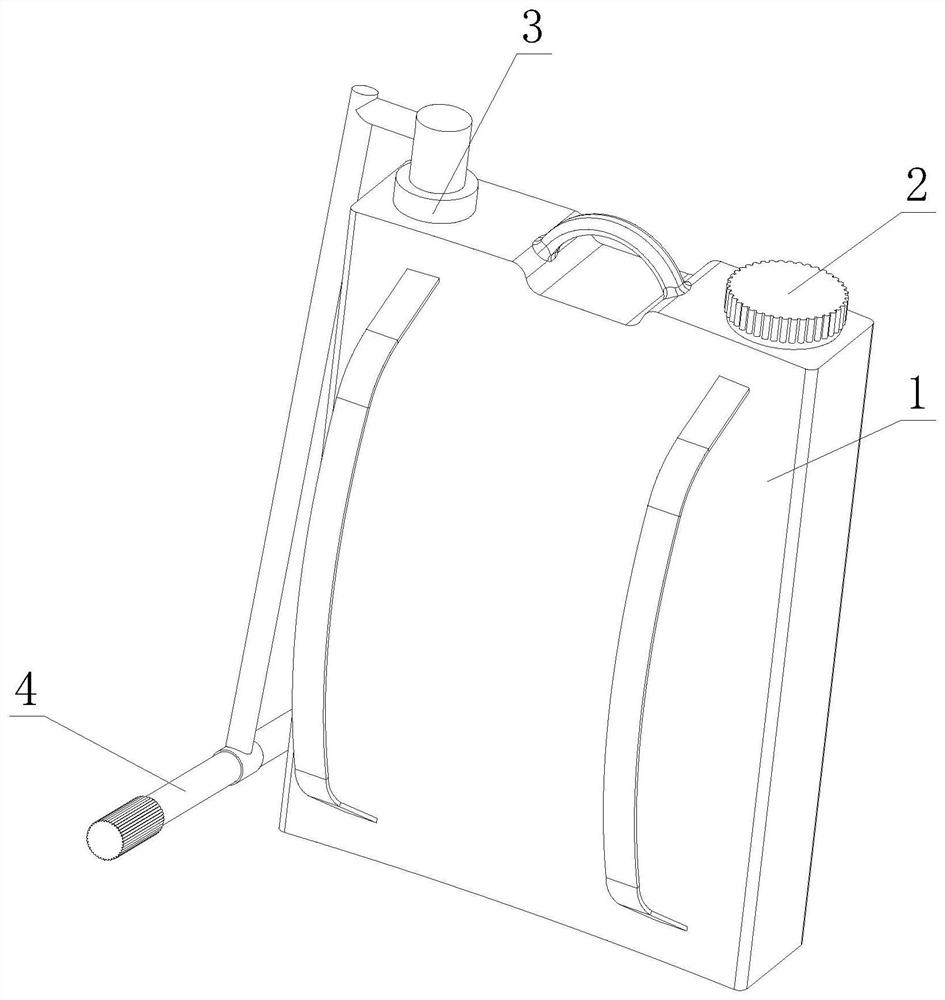

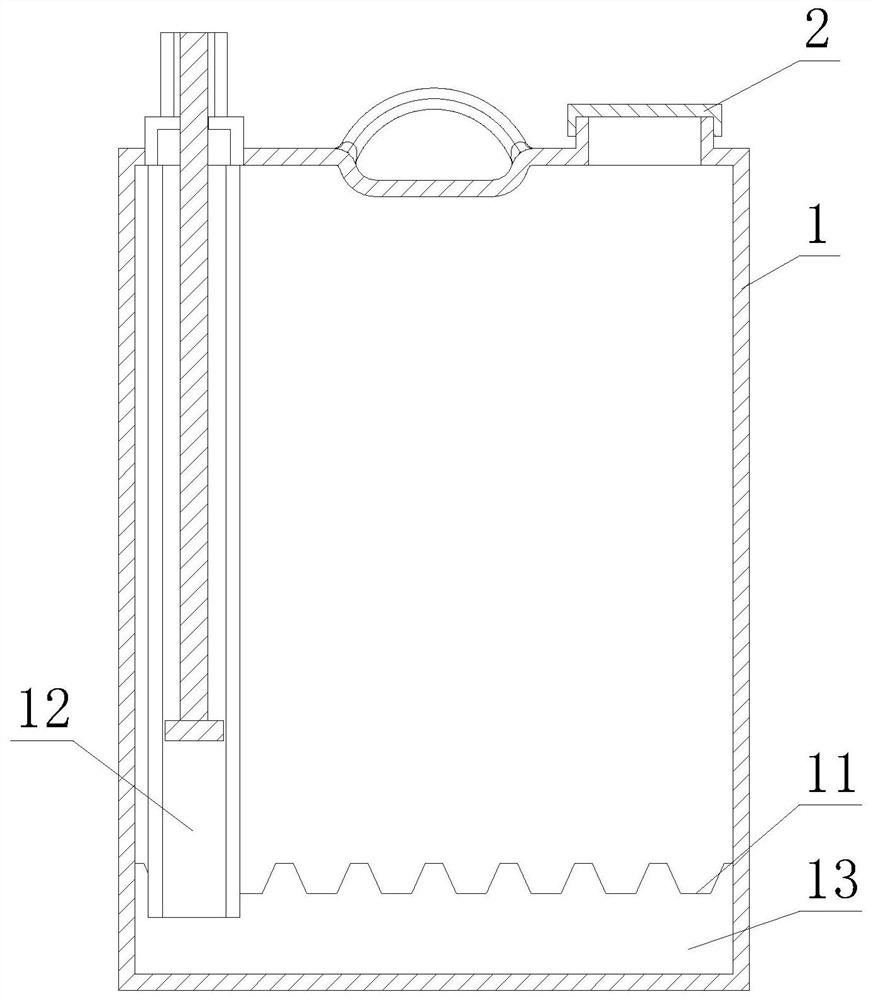

PendingCN112841158AAct as a distractionAvoid less effectiveSpraying apparatusPlant protectionEnvironmental engineeringBiology

The invention discloses an agricultural mechanical pesticide spraying machine pesticide liquid mixing device based on fluid mechanics, and relates to the technical field of agricultural machinery. The agricultural mechanical pesticide spraying machine pesticide liquid mixing device comprises a case, a liquid inlet and a pressure cavity are correspondingly formed in two sides of the upper end of the case, a pressing rod is movably connected to the lower part of one side, close to the pressure cavity, of the case, and a material mixing plate is arranged below the middle part in the case. Through combination of a liquid flow channel, a turbulent flow grid and a material mixing wheel, the material mixing wheel is conveniently rotated through flowing of fluid when the pesticide spraying machine pressurizes and sprays; a turbulent flow effect is achieved when a solution passes through the cambered surface of the material mixing wheel; and by arranging an eccentric ball, when the material mixing wheel rotates, the material mixing wheel impacts a meniscus to generate vibration, so that undissolved and coagulated blocky pesticide in the solution is vibrated and scattered, the pesticide is mixed with water, when the solution passes through the turbulent flow grid, turbulent flow is generated, the pesticide is further mixed with water, and the situation that the pesticide cannot be completely sprayed into a farmland due to pesticide precipitation when the pesticide is sprayed is avoided.

Owner:龙利和

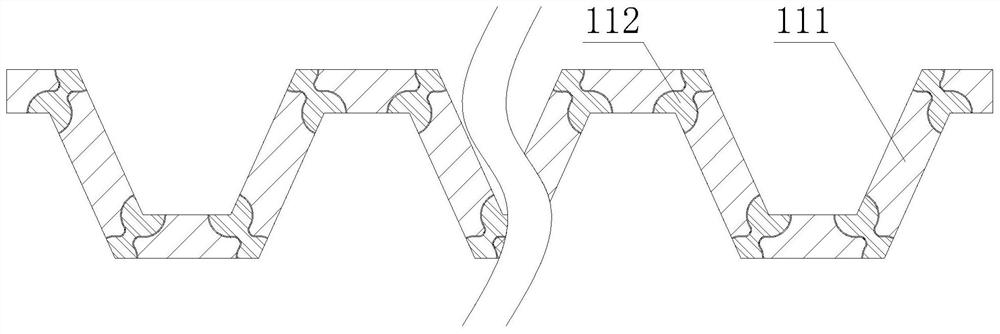

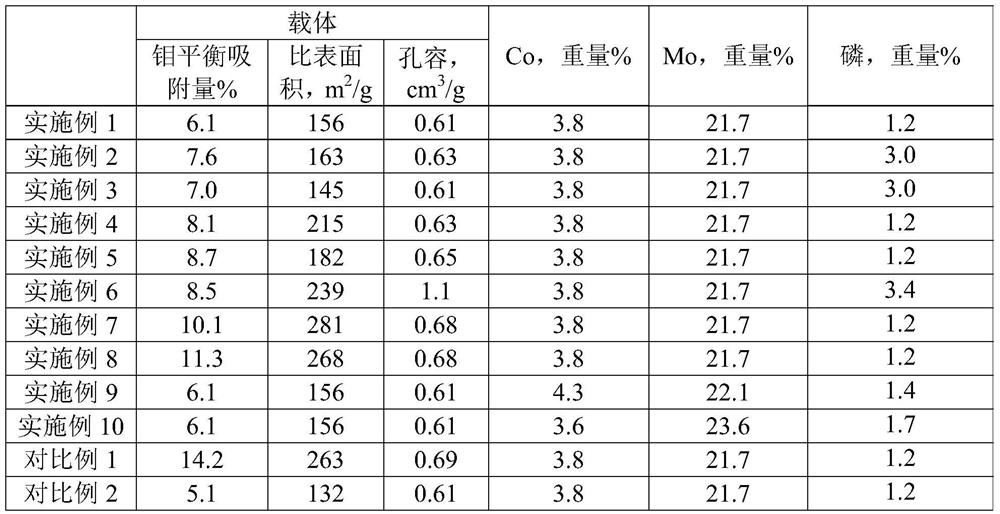

Gasoline selective hydrodesulfurization catalyst, preparation method and application thereof, and gasoline selective hydrodesulfurization method

ActiveCN112742431AHigh activityHigh selectivityPhysical/chemical process catalystsRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The invention relates to the field of catalysts, and particularly discloses a gasoline selective hydrodesulfurization catalyst, a preparation method and application thereof, and a gasoline selective hydrodesulfurization method. The catalyst comprises a carrier as well as an active component A, an active component B and a phosphorus element which are loaded on the carrier, the active component A is selected from at least one of VIII group metal elements, and the active component B is selected from at least one of VIB group metal elements; and the molybdenum equilibrium adsorption capacity of the carrier is 6-12% in terms of MoO3, the specific surface area is 100-400 m < 2 > / g, and the pore volume is 0.5-1.5 cm < 3 > / g. When the hydrodesulfurization catalyst provided by the invention is used for a gasoline selective hydrodesulfurization reaction, the sulfur content in gasoline can be remarkably reduced, and the hydrodesulfurization catalyst has a relatively high hydrodesulfurization rate and a relatively low olefin hydrogenation saturation rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing ethylene tar

ActiveCN102234539BIncrease added valueTake advantage ofTreatment with hydrotreatment processesFiberCarbon fibers

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-quality gasoline and diesel oil by catalyzing diesel oil

ActiveCN109777494BIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesReaction temperatureEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for blending ethylene tar

ActiveCN102234542BIncrease saturation rateHigh yieldTreatment with hydrotreatment processesJet fuelLight crude oil

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com