Hydroconversion process of uncured Fisher-Tropsch process synthesized oil product

A technology of hydroconversion and torpedo synthesis, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems such as the complexity of hydrogenation process, achieve high olefin saturation rate, high hydrodeoxygenation rate, reduce The effect of reaction coking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

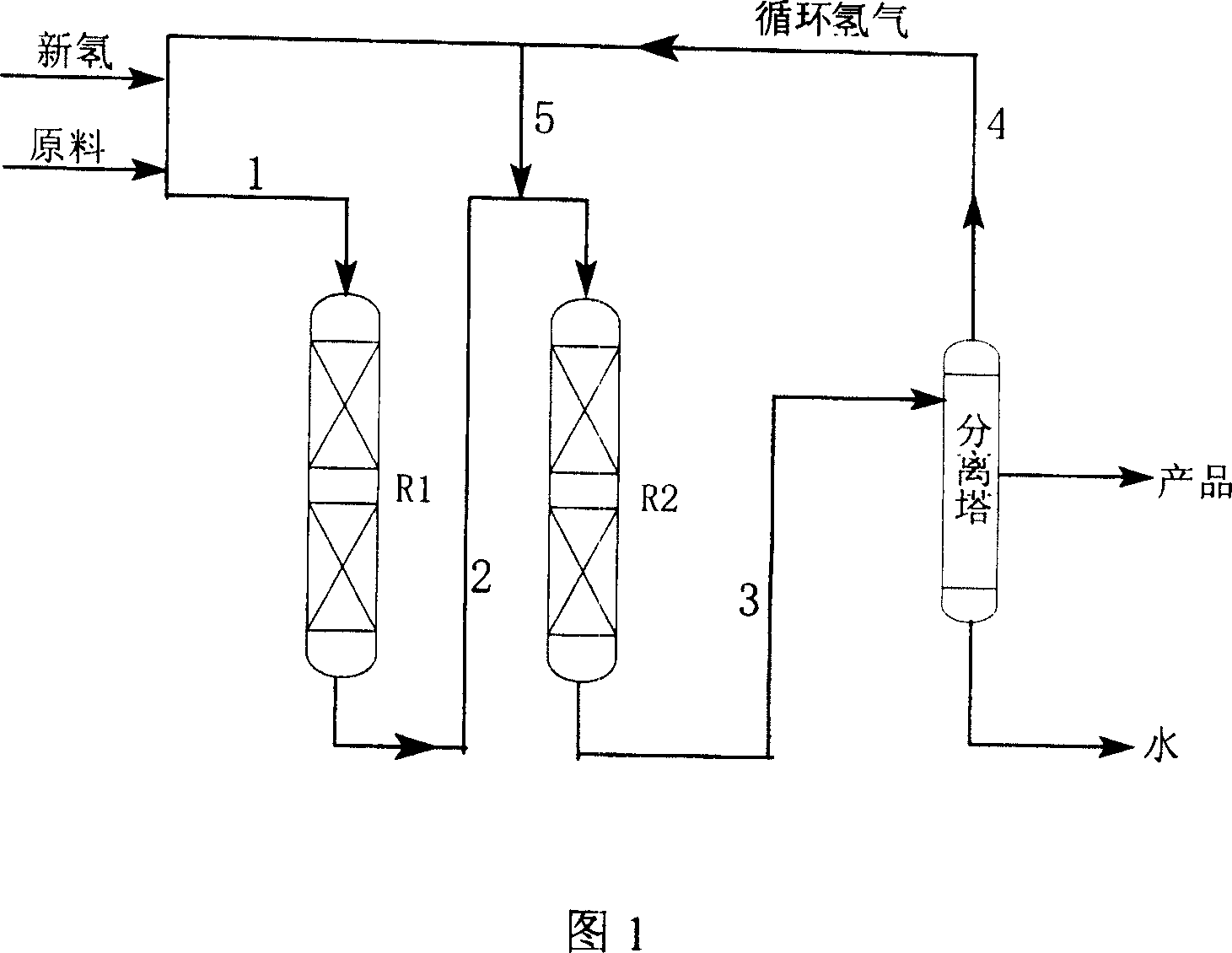

Embodiment 1

[0022] Using Fischer-Tropsch synthetic oil as raw material, the catalyst installed in the first reactor is Pt / Al 2 o 3 , the content of Pt is 0.5wt%; the catalyst added in the second reactor is Ni-Mo / Al 2 o 3 , the metal contents of Ni and Mo are 8.0wt% and 1.2wt%, respectively, and the amount of catalyst added is calculated as metal. The Fe-based slurry bed Fischer-Tropsch synthetic oil is metered by a metering pump, mixed with hydrogen, and then enters the first reverse reactor R1. By controlling appropriate reaction conditions, the unsaturated olefins are hydrogenated and saturated under relatively mild conditions; The hydrogenated product enters the second reactor R2 for hydrodeoxygenation; the refined material can be separated to obtain products of different fractions such as naphtha, diesel fraction, and wax oil. The conversion rate of olefins was 100.0%, and the conversion rate of oxygenates was 95.0%. The process conditions are shown in Table 1.

[0023] ...

Embodiment 2~6

[0025] Embodiments 2 to 6 are based on Fe-based slurry bed Fischer-Tropsch synthesis of oil as raw material, carried out on a continuous fixed-bed reaction device, the operation process is the same as in Example 1, but the catalyst and reaction conditions used are changed, the specific operation The conditions and experimental results are shown in Table 2.

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com