Double metal oxide catalyst and preparation method and application

A double metal oxide, catalyst technology, applied in metal/metal oxide/metal hydroxide catalyst, organic compound preparation, physical/chemical process catalyst, etc., can solve the problem of low selectivity of target products and easy metal catalysts Deactivation, low conversion rate of reactants, etc., to achieve the effect of single selectivity improvement, less time-consuming consumables, and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

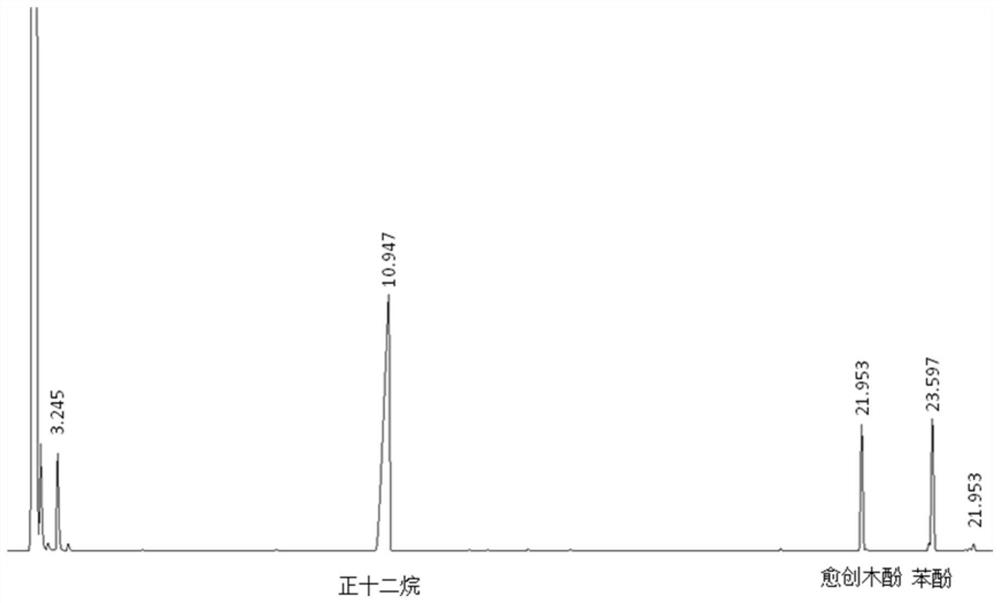

Embodiment 1

[0040] Methanol treatment of 6SnO 2 -1MoO 3 Preparation of catalyst:

[0041] a) SnCl with a mass of 7.012 g 4 .5H 2 O was completely dissolved in 100 mL of deionized water with a concentration of 0.2 mol / L, and 25-28% ammonia water was added to adjust pH=10;

[0042] b) Add (NH) with a mass of 0.589 g 4 ) 6 Mo 7 O 24 .4H 2 O is dissolved in the above solution of a), (NH 4 ) 6 Mo 7 O 24 .4H 2 O concentration is 0.033mol / L, fully stir and mix, add 0.047mol hydrochloric acid, and the molar amount of hydrochloric acid is 2 times the molar amount of metal (Sn+Mo) at this moment;

[0043] c) The white turbid solution obtained in b) was fully stirred, reacted in a 60°C oven for 1 hour, washed and filtered, vacuum dried at 40°C for 12 hours, and the obtained white product was calcined in a muffle furnace at 100°C for 10 hours Then calcined at 300 °C for 5 hours to obtain a dark green product, and after cooling to room temperature, ground into a powder state;

[0044] d...

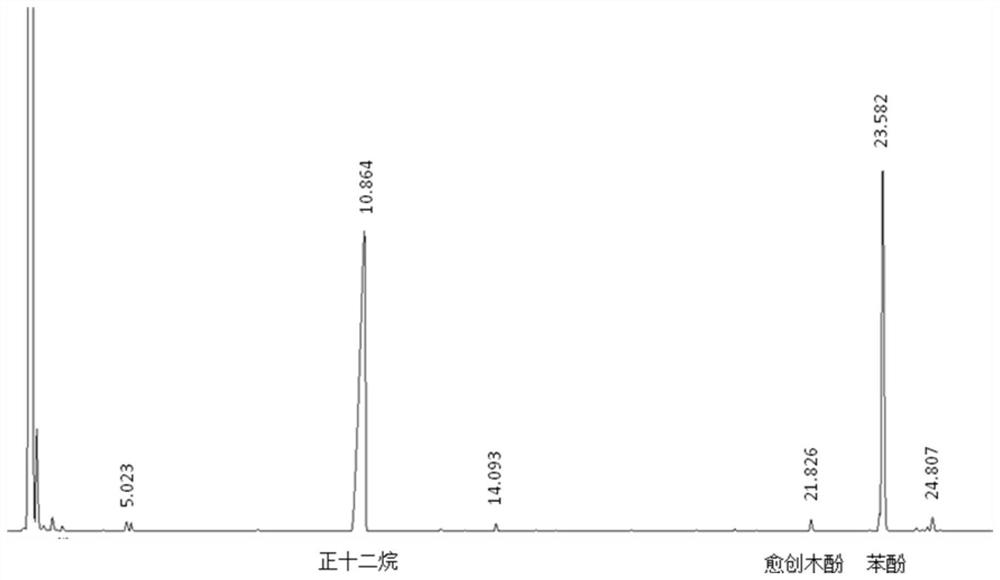

Embodiment 2

[0046] Isopropanol treatment of 5SnO 2 -1MoO 3 Preparation of catalyst:

[0047] a) SnCl with a mass of 7.012 g 4 .5H 2 O was completely dissolved in 100 mL of deionized water with a concentration of 0.2 mol / L, and 25-28% ammonia water was added to adjust pH=8;

[0048] b) Then add (NH) with a mass of 0.706 g 4 ) 6 Mo 7 O 24 .4H 2 O is dissolved in the above solution of a), (NH 4 ) 6 Mo 7 O 24 .4H 2 O concentration is 0.04mol / L, fully stir and mix, add 0.036mol concentrated hydrochloric acid, and the molar amount of hydrochloric acid is 1.5 times the molar amount of metal (Sn+Mo) at this time;

[0049] c) The white turbid solution obtained in b) was fully stirred, reacted in a 60°C oven for 1 hour, washed and filtered, vacuum dried at 60°C for 10 hours, and the obtained white product was calcined in a muffle furnace at 200°C for 8 hours Then calcined at 400 °C for 5 hours to obtain a dark green product, which was ground into powder after cooling to room temperatu...

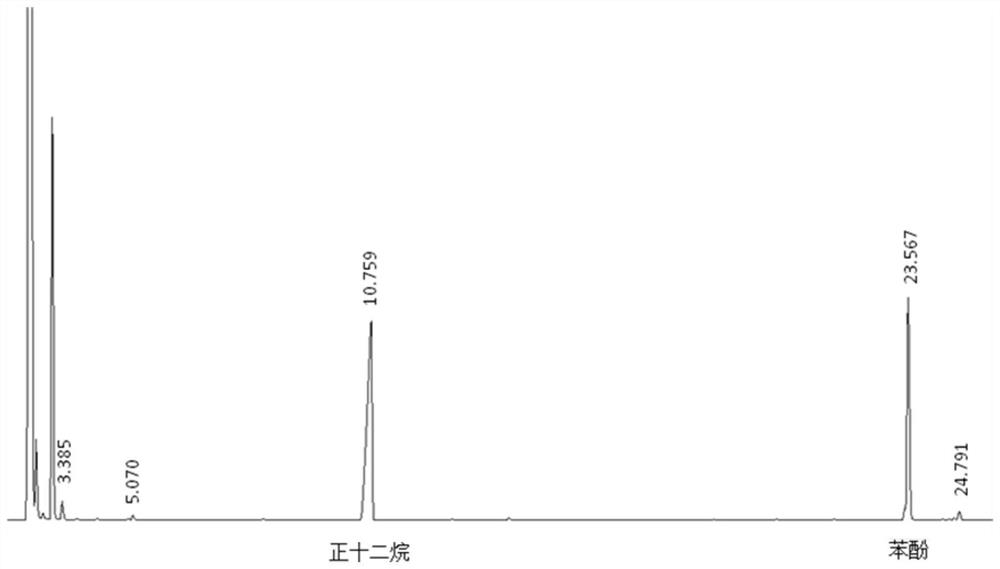

Embodiment 3

[0052] n-Butanol treatment of 4SnO 2 -1MoO 3 Preparation of catalyst:

[0053] a) SnCl with a mass of 7.012 g 4 .5H 2 O was completely dissolved in 100 mL of deionized water with a concentration of 0.2 mol / L, and 25-28% ammonia water was added to adjust pH=9;

[0054] b) Add (NH) with a mass of 0.883 g 4 ) 6 Mo 7 O 24 .4H 2 O is dissolved in the above solution of a), (NH 4 ) 6 Mo 7 O 24 .4H 2 O concentration is 0.05mol / L, fully stirring and mixing, adding 0.05mol hydrochloric acid, the molar amount of hydrochloric acid is 2 times the molar amount of metal (Sn+Mo) at this moment;

[0055] c) The white turbid solution obtained in b) was fully stirred, reacted in a 30°C oven for 2h, washed and filtered, vacuum dried at 60°C for 8h, and the obtained white product was calcined in a muffle furnace at 250°C for 8h Then calcined at 400 °C for 5 hours to obtain a dark green product, which was ground into powder after cooling to room temperature;

[0056] d) Take the dark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com