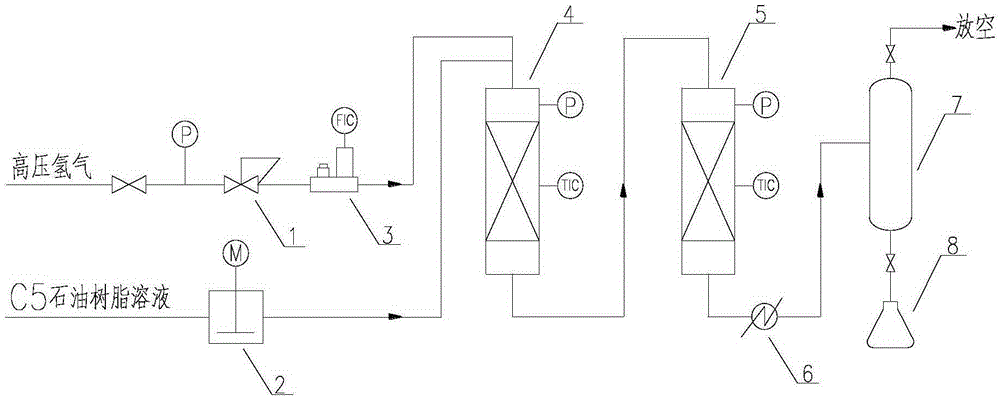

Dechlorination method and apparatus suitable for C5 petroleum resin hydrogenation process

A petroleum resin and hydrogenation process technology, which is applied in the field of C5 petroleum resin catalytic hydrogenation process, can solve the problems of large alkaline wastewater, high cost, and difficult operation, so as to reduce equipment investment, reduce investment and operation costs, simplify The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

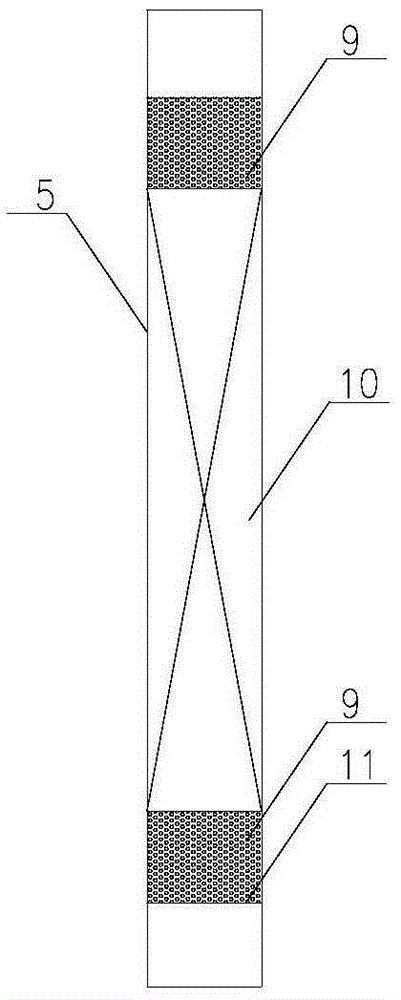

Method used

Image

Examples

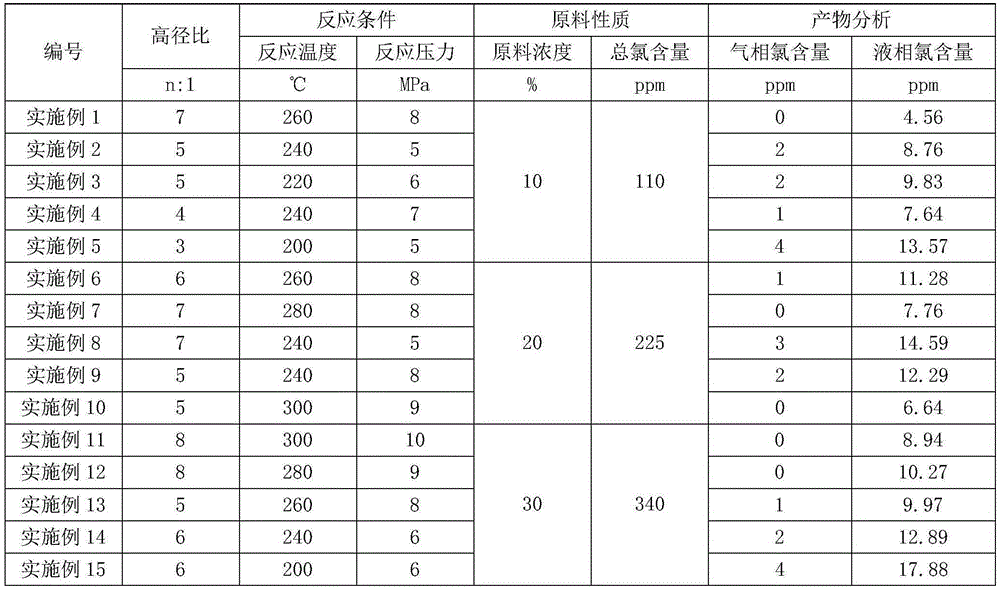

Embodiment 1~15

[0030] Carry out dechlorination agent filling, dechlorination reaction and sampling analysis according to the above-mentioned implementation method, carry out the dechlorination effect investigation under different conditions, wherein the liquid volume space velocity is 2h -1 , the gas volumetric space velocity is 400h -1 . The specific implementation conditions and analysis data are shown in Table 1:

[0031] Table 1 Dechlorination reaction conditions and analysis data table

[0032]

Embodiment 16~27

[0034]Carry out the filling, dechlorination reaction and sampling analysis of dechlorination agent according to the above-mentioned implementation method, investigate the processing capacity of dechlorination agent per unit volume and unit time, that is, the dechlorination effect under different feed volume space velocity situations, wherein The aspect ratio of the dechlorination agent is 8:1, the reaction temperature is 260°C, and the pressure is 8Mpa. The specific implementation conditions and analysis data are shown in Table 2:

[0035] Table 2 Different airspeed conditions and analysis data table

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com