Treatment method and system for washing and dechlorinating waste incineration fly ash and evaporating, grading and crystallizing washing liquid

A technology of waste incineration fly ash and treatment method, applied in the direction of alkali metal chloride, etc., can solve the problems of low salt quality, increased cost, waste of resources, etc., and achieve the effects of low water consumption, reduced consumption, and no dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

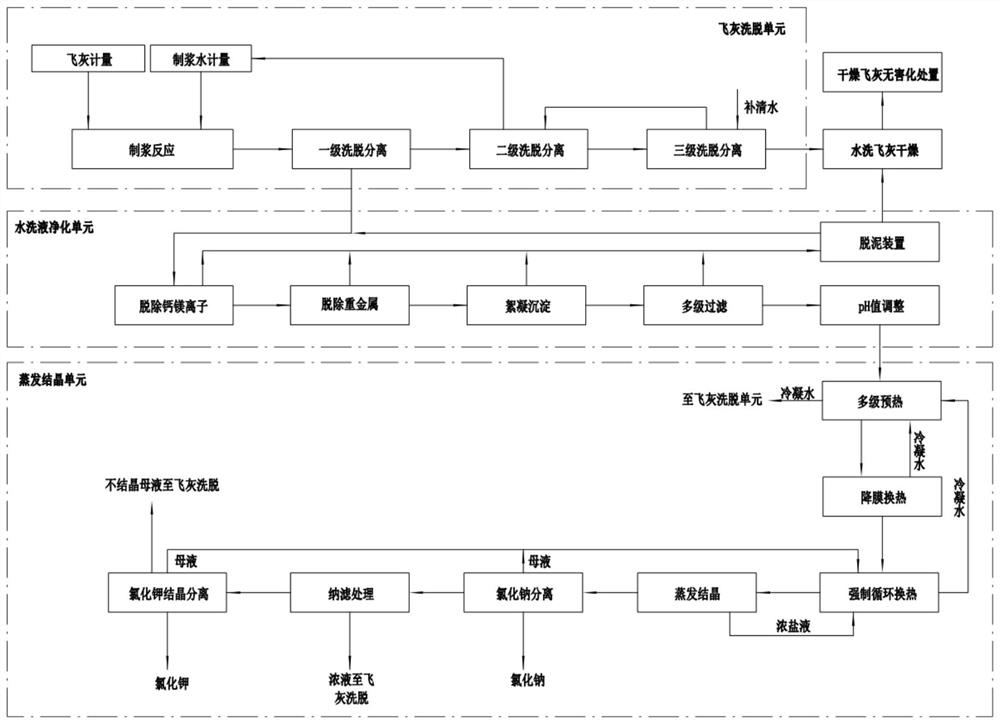

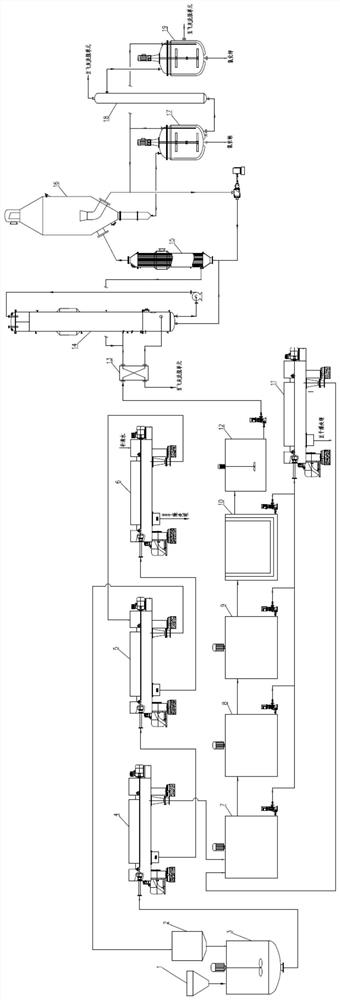

[0057] Step (1): After weighing the waste incineration fly ash and pulping water respectively, carry out stirring and mixing, hydration reaction, and pulping in the fly ash pulping device 3 according to the ratio of 1:3, and finally obtain the fly ash slurry .

[0058] Step (2): After the fly ash slurry is successively treated by primary elution, secondary elution and tertiary elution, a water wash solution with a solid content of less than 1% and a water washed fly ash with a water content of no more than 40% are obtained.

[0059] Step (3): Using steam or hot air as a drying medium (setting temperature of the drying medium is 230 degrees Celsius) to dry the washed fly ash in step (2), and finally obtain a finished fly ash with a moisture content of less than 5%.

[0060] Step (4): Purify the water washing solution obtained in step (1), followed by calcium and magnesium removal, heavy metal removal, flocculation precipitation, multi-stage filtration, solid-liquid separation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com