Technological method of removing hydrogen chloride through powder injection of blast furnace gas pipeline and device of removing hydrogen chloride through powder injection of blast furnace gas pipeline

A kind of blast furnace gas, technology of process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

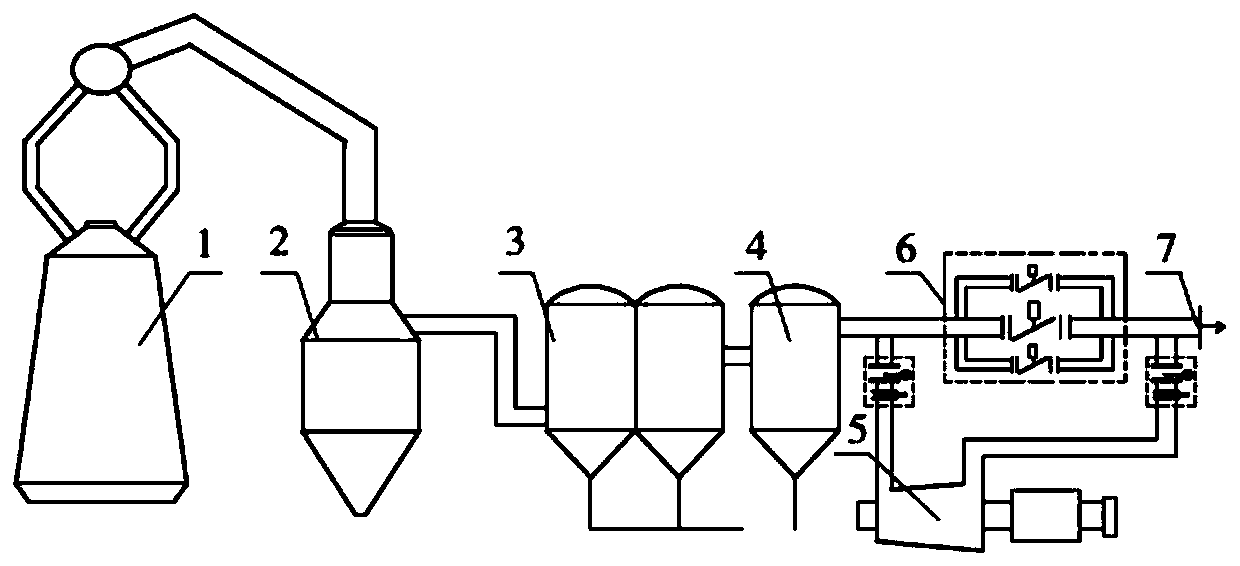

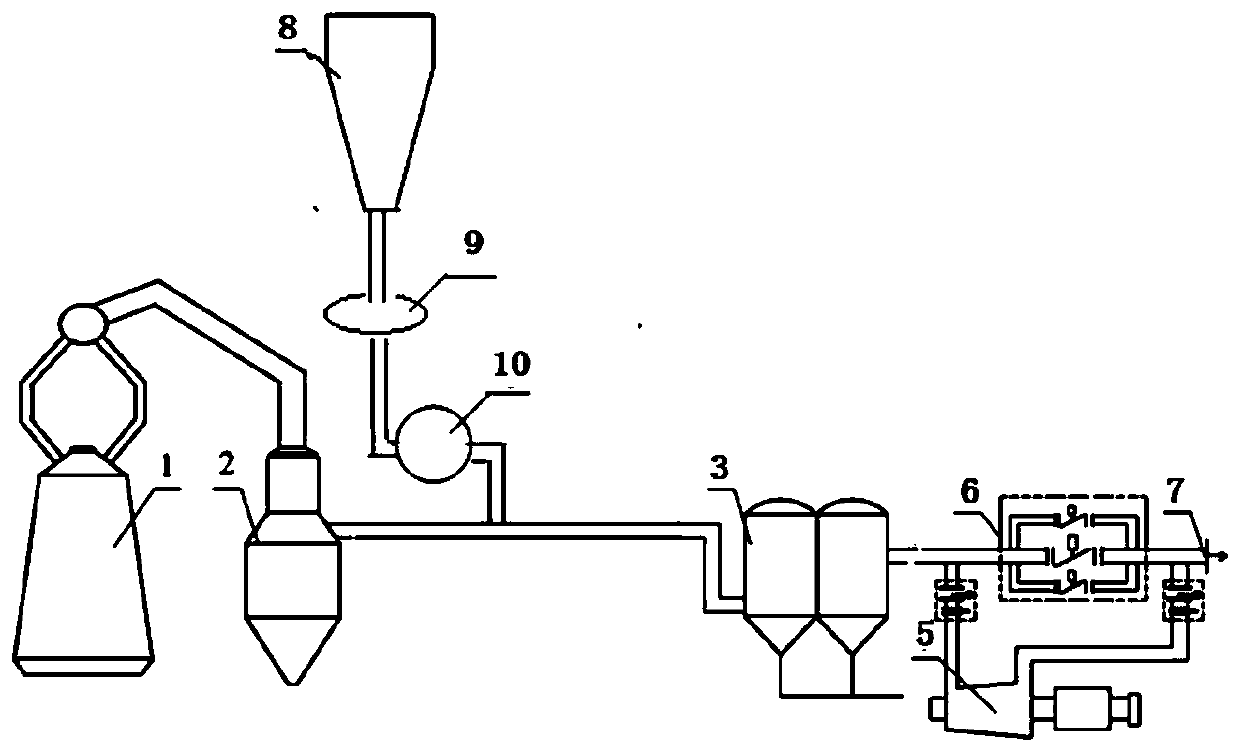

Image

Examples

Embodiment 1

[0039] The condition of the blast furnace gas in the outlet pipeline of the coarse dust collector 2 is: the flow rate is 200,000 / Nm 3 / h, the pressure is about 0.2MPa, the temperature is about 150℃, the line speed is about 20m / s, and the dust content is 10g / m 3 , water content 52g / Nm 3 About, containing HCl 98mg / m 3 .

[0040] The larger particle dechlorination agent loaded in the hopper 8 of the dechlorination agent bag filter is ground into a powder below 300 mesh (50um) by the mill 9, and then the fan 10 draws and transports the dechlorination agent and sprays it. into the pipeline. The sprayed powder dechlorination agent is 100kg / h, and the powder content in the gas is 0.5g / m 3 . The dechlorination agent is activated in the pipeline, and the specific surface area increases rapidly. The powder particles are suspended in the air flow, and fully and evenly contact with the blast furnace gas for 1 to 2 seconds. A chemical reaction occurs, and the HCl in the blast furnace ...

Embodiment 2

[0043] The condition of the blast furnace gas in the outlet pipeline of the coarse dust collector 2 is: the gas flow rate is 200,000 / Nm 3 / h, the pressure is about 0.2MPa, the temperature is about 150℃, the line speed is about 20m / s, and the dust content is 10g / m 3 , water content 52g / Nm 3 About, containing HCl 103mg / m 3 .

[0044] The larger particle dechlorination agent loaded in the hopper 8 of the dechlorination agent bag filter is ground into a powder below 300 mesh (50um) by the mill 9, and then the fan 10 draws and transports the dechlorination agent and sprays it. into the pipeline. The sprayed powder dechlorination agent is 60kg / h, and the powder content in the gas is 0.3g / m 3 . The dechlorination agent is activated in the pipeline, and the specific surface area increases rapidly. The powder particles are suspended in the air flow, and fully and evenly contact with the blast furnace gas for 1 to 2 seconds. A chemical reaction occurs, and the HCl in the blast furn...

Embodiment 3

[0047] The condition of the blast furnace gas in the outlet pipeline of the coarse dust collector 2 is: the gas flow rate is 200,000 / Nm 3 / h, the pressure is about 0.2MPa, the temperature is about 150℃, the line speed is about 20m / s, and the dust content is 10g / m 3 , water content 52g / Nm 3 About, containing HCl 110mg / m 3 .

[0048] The larger particle dechlorination agent loaded in the hopper 8 of the dechlorination agent bag filter is ground into a powder below 300 mesh (50um) by the mill 9, and then the fan 10 draws and transports the dechlorination agent and sprays it. into the pipeline. The sprayed powder dechlorination agent is 50kg / h, and the powder content in the gas is 0.25g / m 3 . The dechlorination agent is activated in the pipeline, and the specific surface area increases rapidly. The powder particles are suspended in the air flow, and fully and evenly contact with the blast furnace gas for 1 to 2 seconds. A chemical reaction occurs, and the HCl in the blast fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com