Method for producing raw material rich in monocyclic aromatic hydrocarbons

A technology for single-ring aromatics and raw materials, which is applied in the field of raw materials rich in single-ring aromatics, can solve the problems of poor selectivity of single-ring aromatics, achieve the effects of improving activity and stability, high activity, and preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

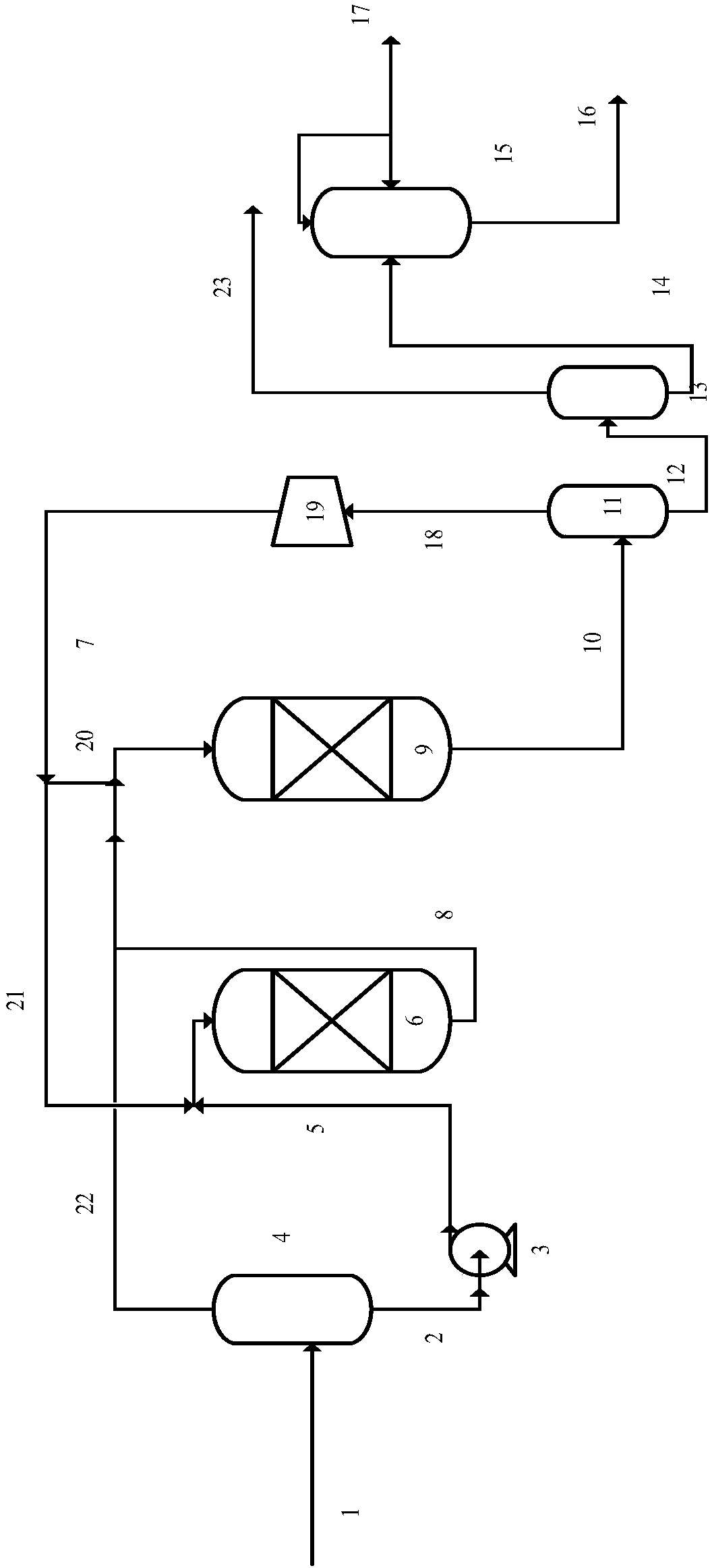

Method used

Image

Examples

Embodiment 1

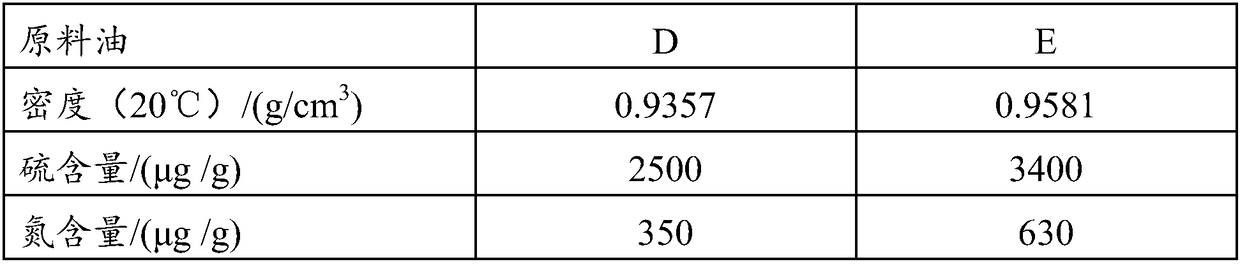

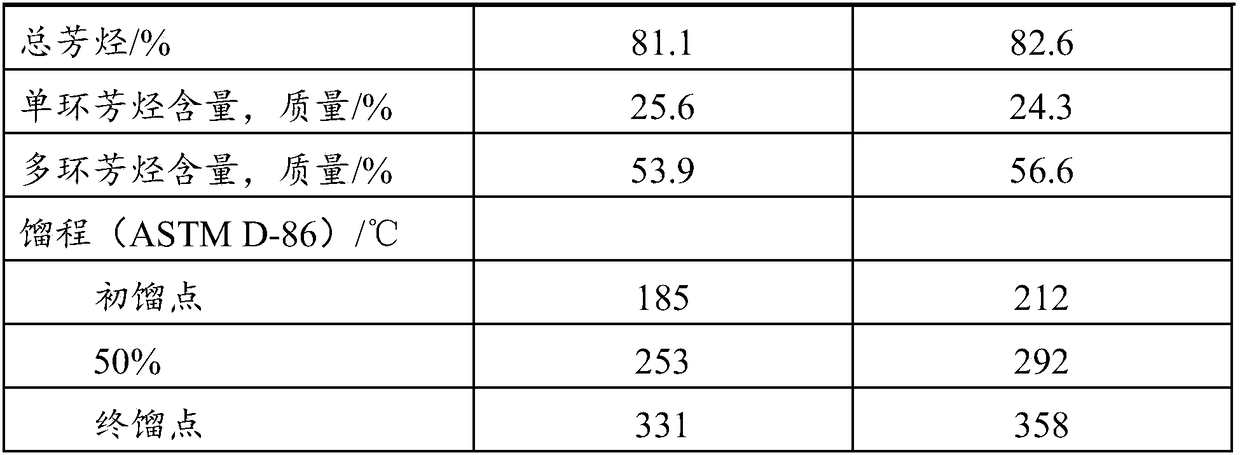

[0089] Diesel feed oil D is cut into light diesel oil fraction and heavy diesel oil fraction, the cutting point is 250°C, the heavy diesel oil fraction is mixed with hydrogen, in the first reaction zone it contacts with hydrotreating catalyst A, and under hydrogenation reaction conditions, hydrogenation is carried out Hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization reactions; the light diesel oil fraction is mixed with the effluent from the first reaction zone and then enters the second reaction zone to contact with hydrofining catalyst B, and further proceeds under hydrogenation reaction conditions Hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization reactions, the effluent of the second reaction zone is separated to obtain whole fraction products.

[0090] The hydrogenation reaction conditions and product properties of the two reaction zones are as shown in Table 2. As can be seen from Table 2, the saturation rate of poly...

Embodiment 2

[0093] Diesel feed oil D is cut into light diesel oil fraction and heavy diesel oil fraction, the cutting point is 250°C, the heavy diesel oil fraction is mixed with hydrogen, in the first reaction zone it contacts with hydrotreating catalyst A, and under hydrogenation reaction conditions, hydrogenation is carried out Hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization reactions; the light diesel oil fraction is mixed with the effluent of the first reaction zone and then enters the second reaction zone to contact with hydrofining catalyst C, and further proceeds under the conditions of hydrogenation reaction Hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization reactions, the effluent of the second reaction zone is separated to obtain whole fraction products.

[0094] The hydrogenation reaction conditions and product properties of the two reaction zones are as shown in Table 2. As can be seen from Table 2, the saturation rate of...

Embodiment 3

[0097] Diesel feedstock oil E is cut into light diesel oil fraction and heavy diesel oil fraction. The cutting point is 255°C. The heavy diesel oil fraction is mixed with hydrogen and contacted with hydrotreating catalyst A in the first reaction zone. Under hydrogenation reaction conditions, hydrogenation is carried out Hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization reactions; the light diesel oil fraction is mixed with the effluent of the first reaction zone and then enters the second reaction zone to contact with hydrofining catalyst C, and further proceeds under the conditions of hydrogenation reaction Hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization reactions, the effluent of the second reaction zone is separated to obtain whole fraction products.

[0098] The hydrogenation reaction conditions and product properties of the two reaction zones are as shown in Table 2. As can be seen from Table 2, the saturation rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com