Agricultural mechanical pesticide spraying machine pesticide liquid mixing device based on fluid mechanics

A technology of agricultural machinery and fluid mechanics, applied in spraying devices, devices for catching or killing insects, animal husbandry, etc., can solve problems such as failure to achieve the original intention of use, poor applicability of spraying machines, and reduced drug effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

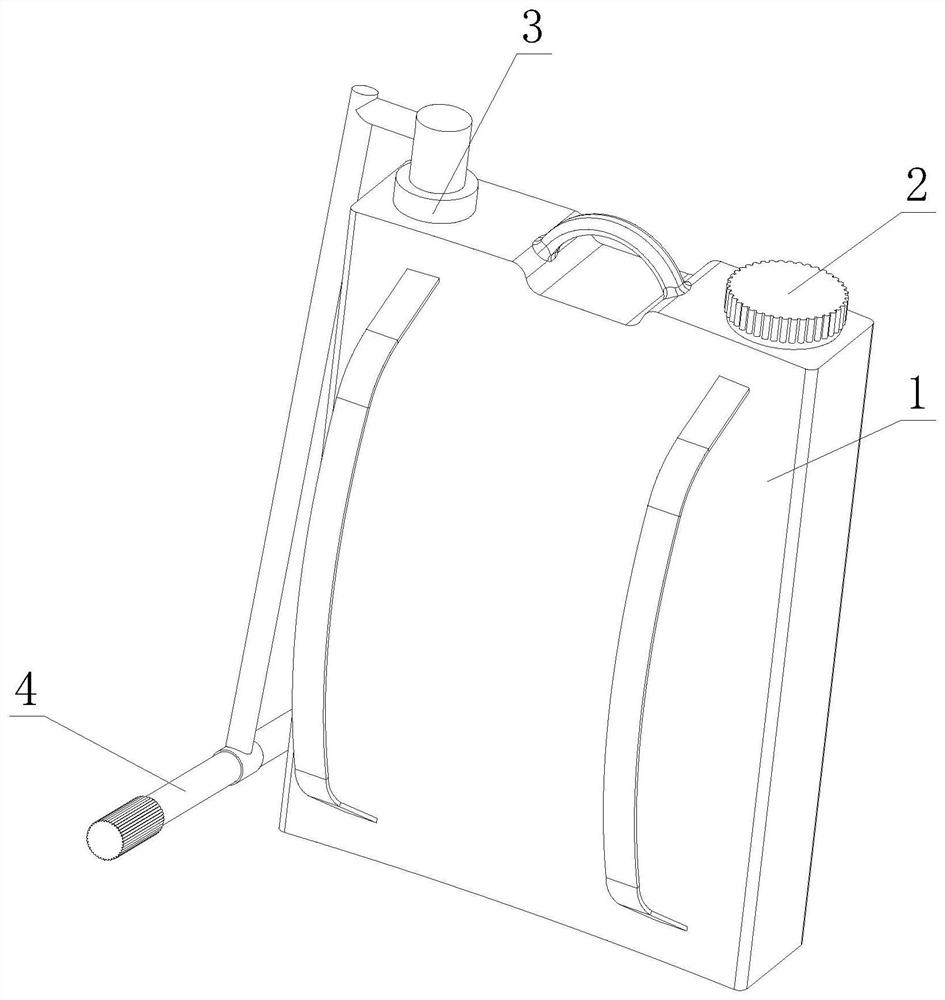

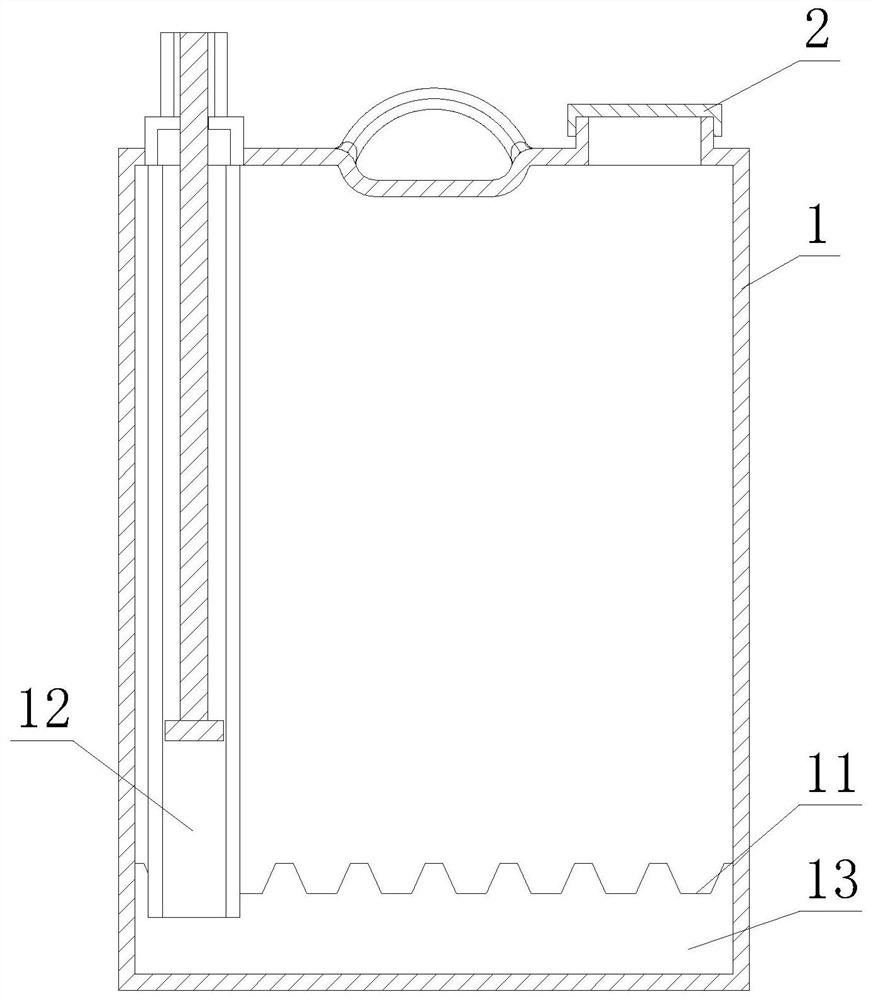

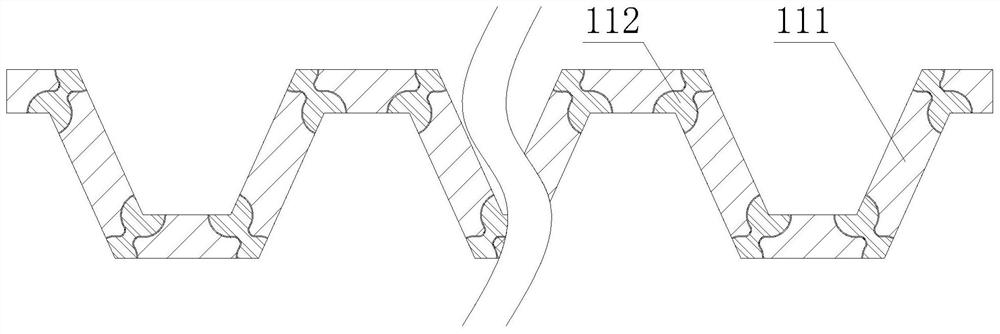

[0024] Such as figure 1 - image 3 As shown, the present invention provides a liquid medicine mixing device for an agricultural machinery spraying machine based on fluid mechanics, comprising a casing 1, the two sides of the upper end of the casing 1 are respectively provided with a liquid inlet 2 and a pressure chamber 3, and the casing 1 is close to the pressure chamber. The bottom of one side of the chamber 3 is movably connected with a pressure rod 4, and the inner middle part of the cabinet 1 is provided with a mixing plate 11, and the inside of the cabinet 1 is located at the bottom of the pressure chamber 3 and is provided with a discharge channel 12. A liquid retention chamber 13 is arranged below, and the discharge channel 12 is connected to the liquid retention chamber 13 . The inside of the mixing plate 11 is provided with a partition 111 , and the corners of the partition 111 are provided with a liquid mixing structure 112 .

[0025] In this embodiment, the partit...

Embodiment 2

[0027] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: both sides of the side wall of the partition 111 are fixedly connected with a spoiler a4, and a liquid flow channel a1 is arranged inside the liquid mixing structure 112, and the liquid Both ends of the flow channel a1 are movably connected with a mixing wheel a3, and the middle part of the liquid flow channel a1 is fixedly connected with a spoiler grid a2, and the mixing wheel a3 inside the corner of the partition 111 is a part far away from the spoiler a4. Installed on the side, the mixing wheel a3 outside the corner of the partition 111 is installed on the side close to the spoiler a4, and the inclined setting of the mixing wheel a3 makes the flow of water and air flow gather at the side of the mixing wheel a3 One side, so that the mixing wheel a3 is easier to rotate, so as to guide the flow direction of the water flow.

[0028] In this embodiment, through ...

Embodiment 3

[0030] Such as Figure 5 As shown, on the basis of Embodiment 2, the present invention provides a technical solution: preferably, the inside of the mixing wheel a3 is provided with a central axis s1, and both ends of the central axis s1 are fixedly connected with side plates s4, and the central axis The outer surface of s1 is fixedly connected with a support rod s2, and the end of each adjacent two support rods s2 away from the central axis s1 is fixedly connected with a meniscus s3, and there is a gap between the central axis s1, support rod s2, and meniscus s3. The cavity s5 is provided with an eccentric ball s6 inside the cavity s5, and the central axis s1, the support rod s2, and the meniscus s3 are designed in an integrated manner.

[0031] In this embodiment, the setting of the meniscus s3 is used to increase the impact force on the surface of the meniscus s3 when the fluid passes through, thereby promoting the rotation of the mixing wheel a3. When a3 rotates, the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com