Solid-liquid rocket engine annular slot plug nozzle

A technology of solid-liquid rockets and plug nozzles, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of not being applicable to solid-liquid rocket engines and not considering the application of solid-liquid rocket engines, and achieve compact structure, small size Small, good blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

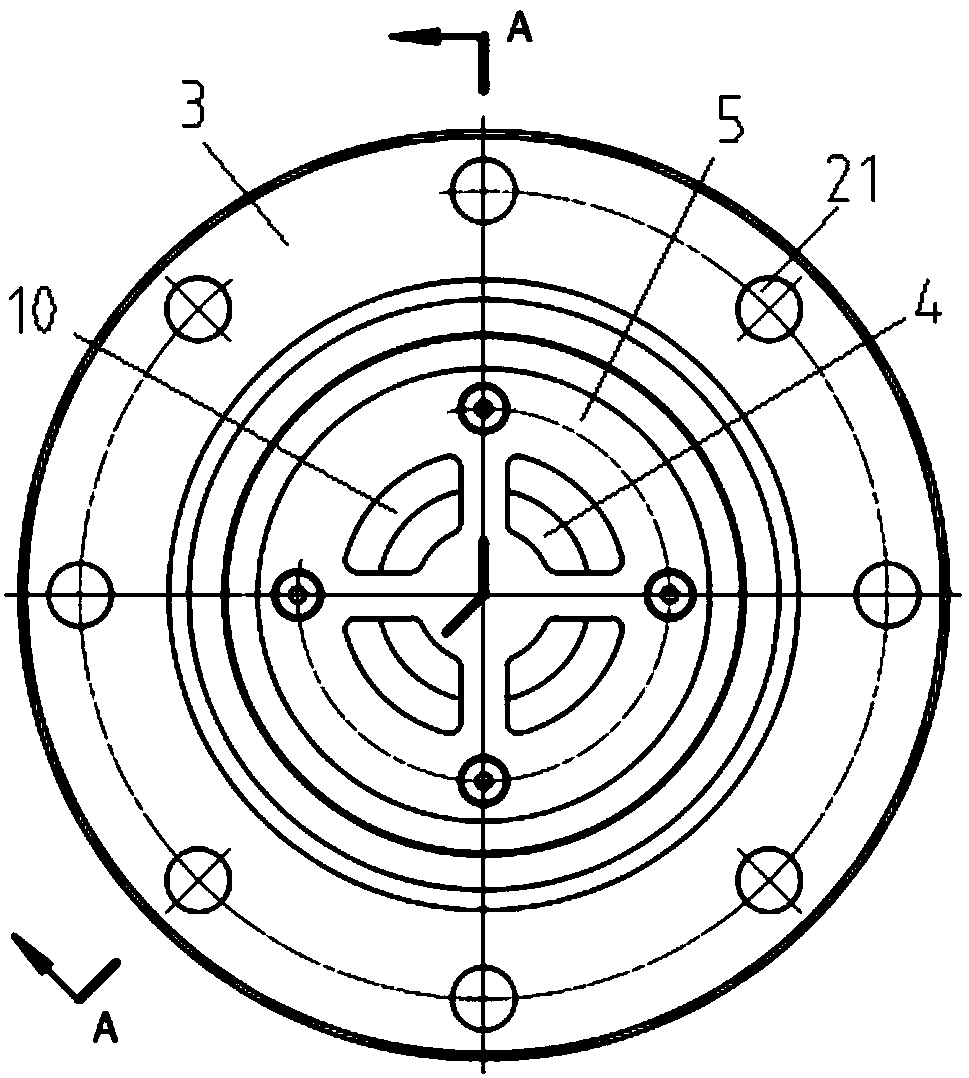

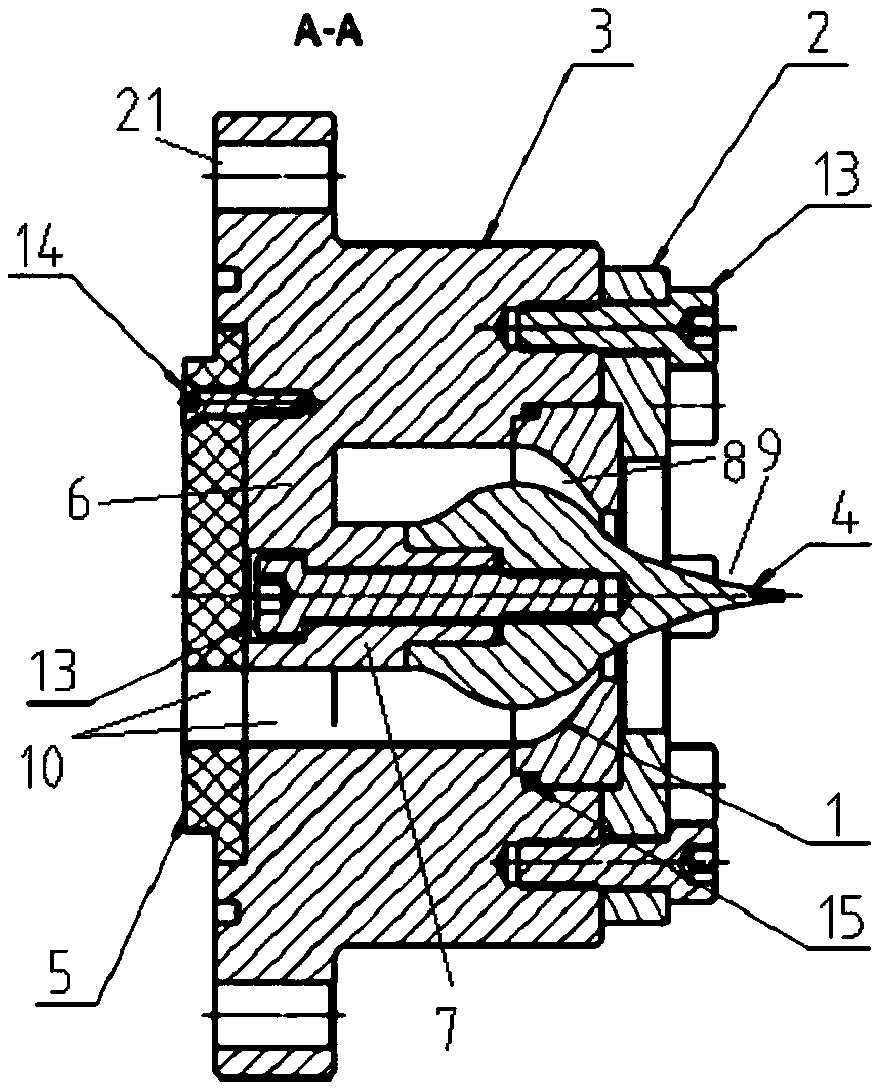

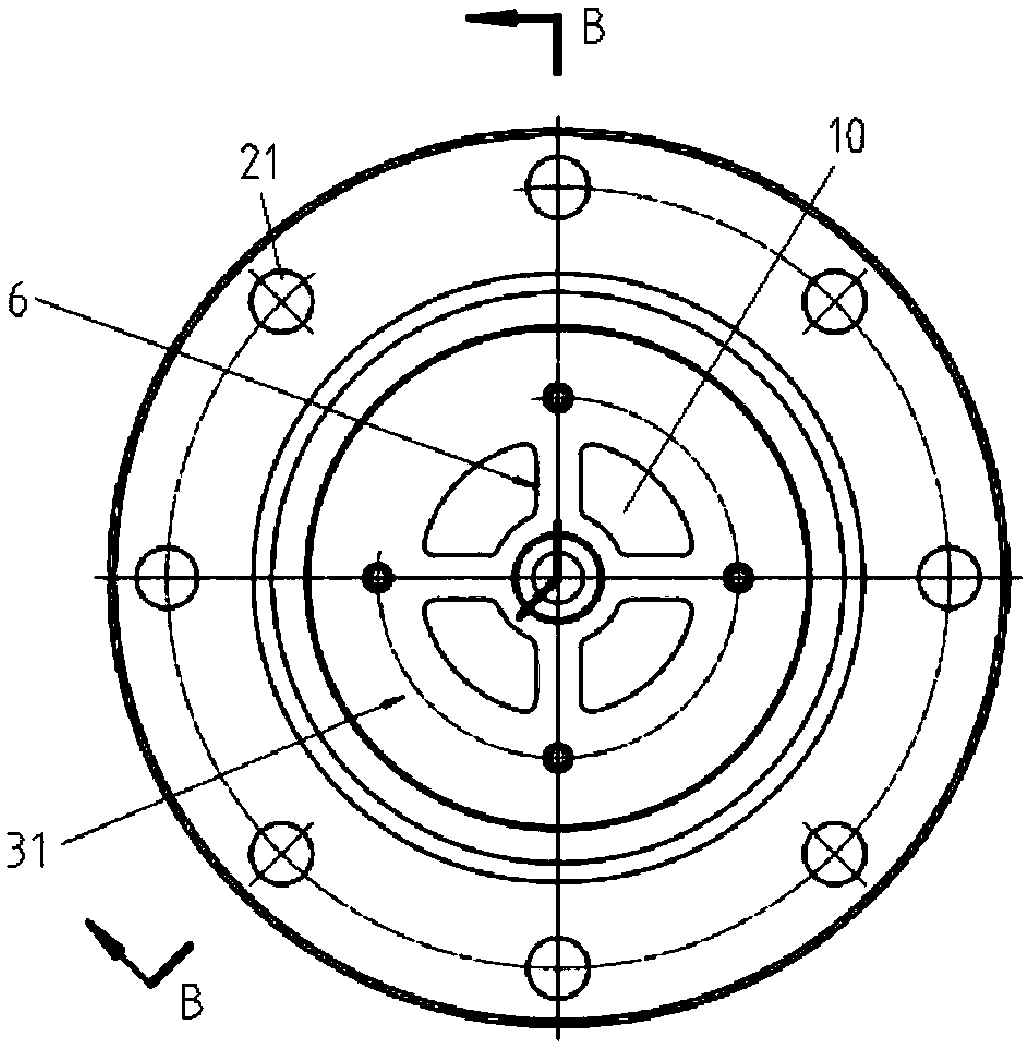

[0044] figure 1 Schematic diagram of the structure of the solid-liquid rocket engine annular plug nozzle provided by Embodiment 1 of the present invention; figure 2 for figure 1 A-A sectional view of ; image 3 Schematic diagram of the structure of the nozzle housing provided in Embodiment 1; Figure 4 for image 3 The B-B sectional view of; Figure 5 Schematic diagram of the structure of the laryngeal mask provided in Example 1; Image 6 Schematic diagram of the structure of the plug cone provided in Example 1; Figure 7 Schematic diagram of the structure of the nozzle platen provided in Example 1; Figure 8 for Figure 7 C-C sectional view of ; Figure 9 Schematic diagram of the structure of the thermal insulation board provided in the first embodiment; Figure 10 for Figure 9 The D-D sectional view; such as Figure 1-Figure 10 As shown, the solid-liquid rocket engine annular plug nozzle provided by the present invention includes a throat mask 1, a nozzle pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com