Patents

Literature

131 results about "Plug nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The plug nozzle is a type of nozzle which includes a centerbody or plug around which the working fluid flows. Plug nozzles have applications in aircraft, rockets, and numerous other fluid flow devices.

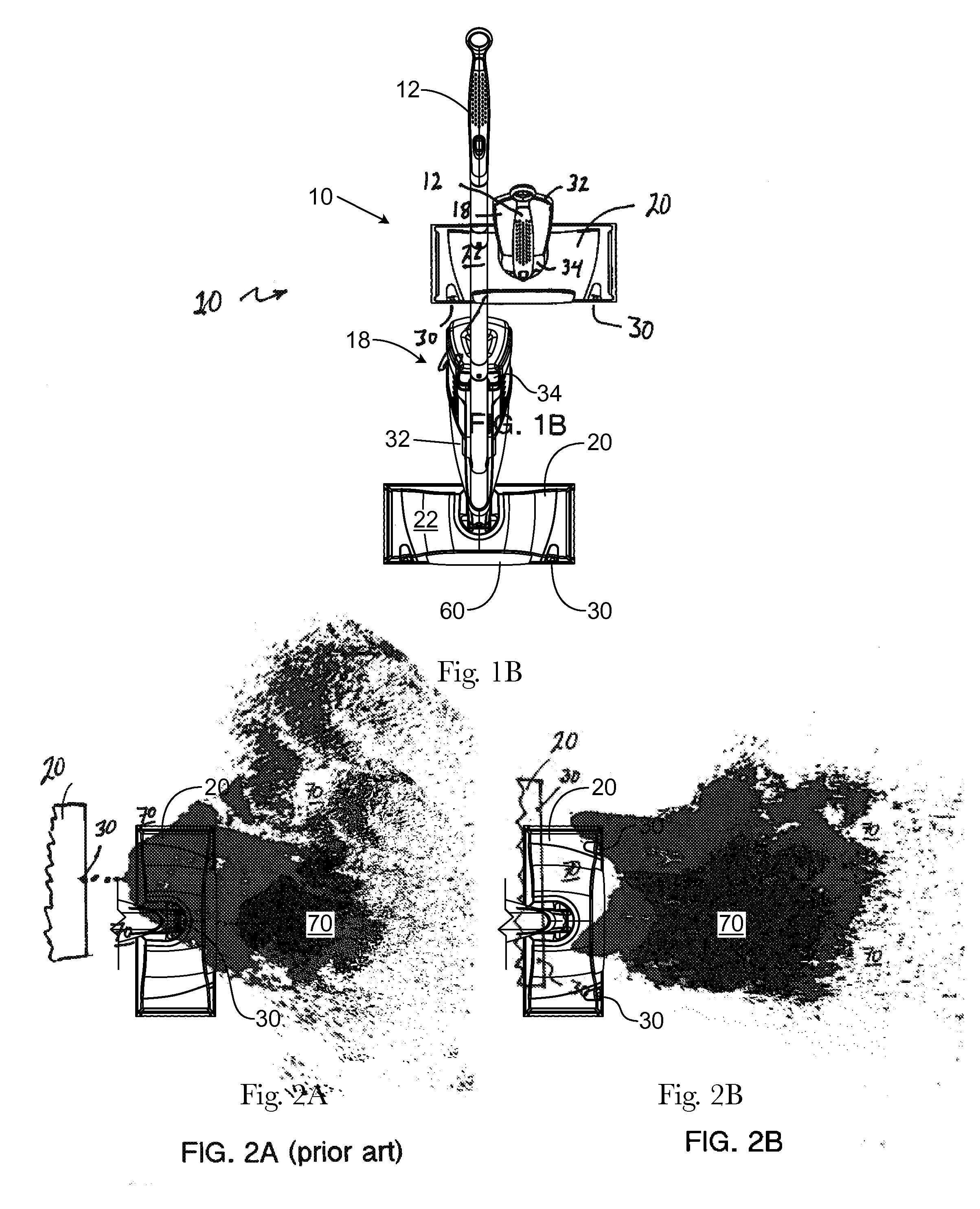

Preventing gas from occupying a spray nozzle used in a process of scoring a hot glass sheet

ActiveUS20100287991A1Improve spraying effectImprove performanceGlass drawing apparatusGlass forming apparatusSolubilityHigh energy

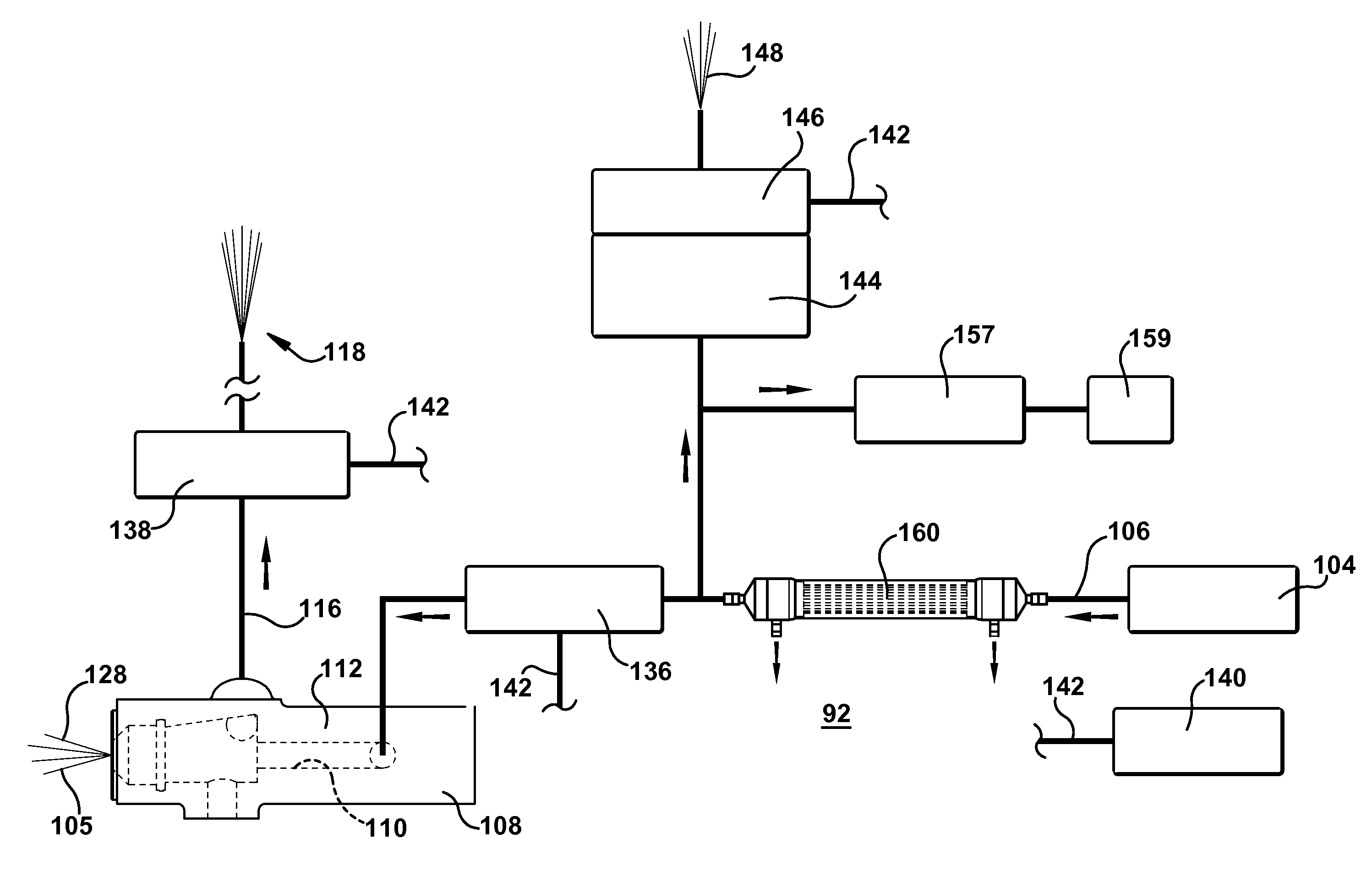

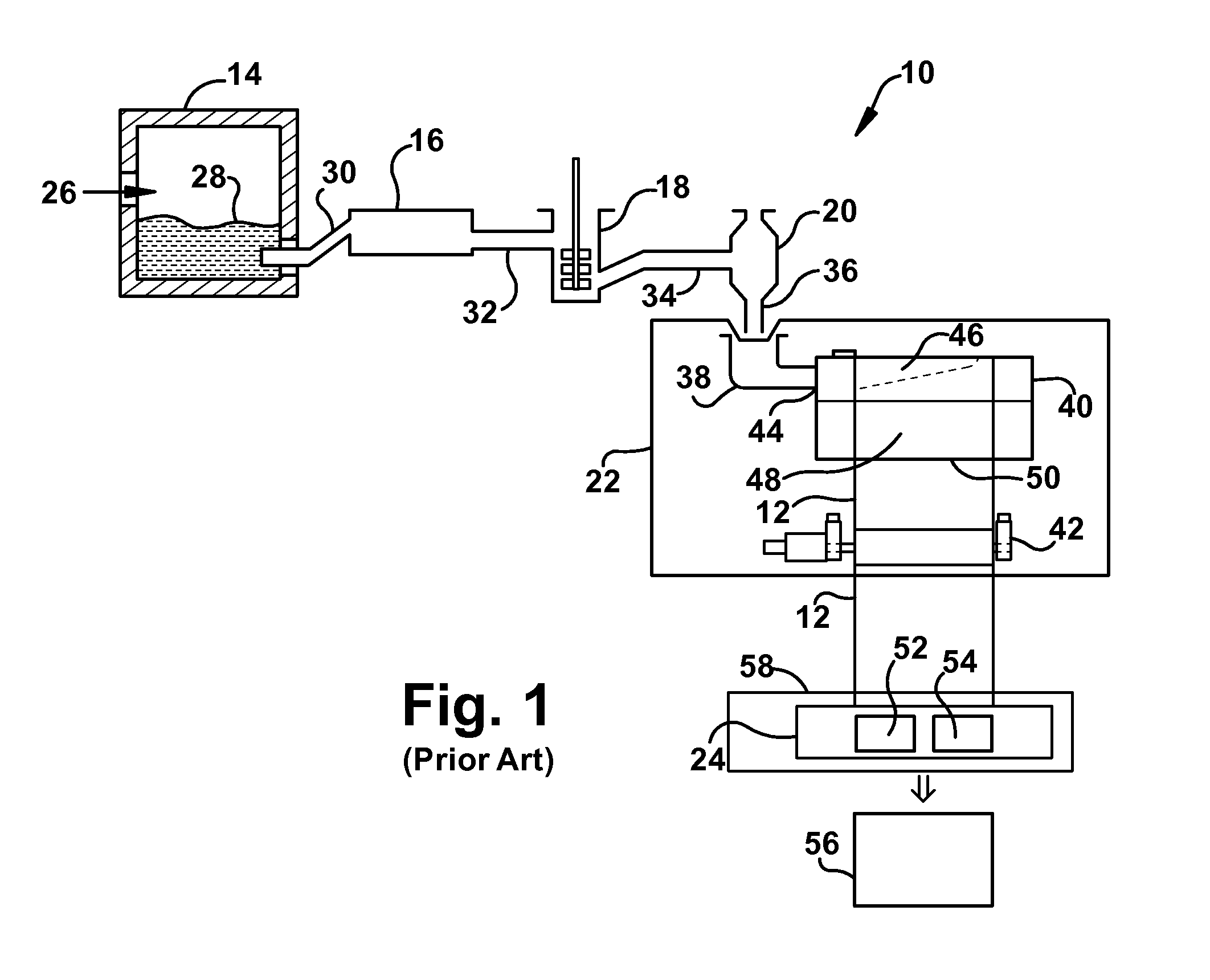

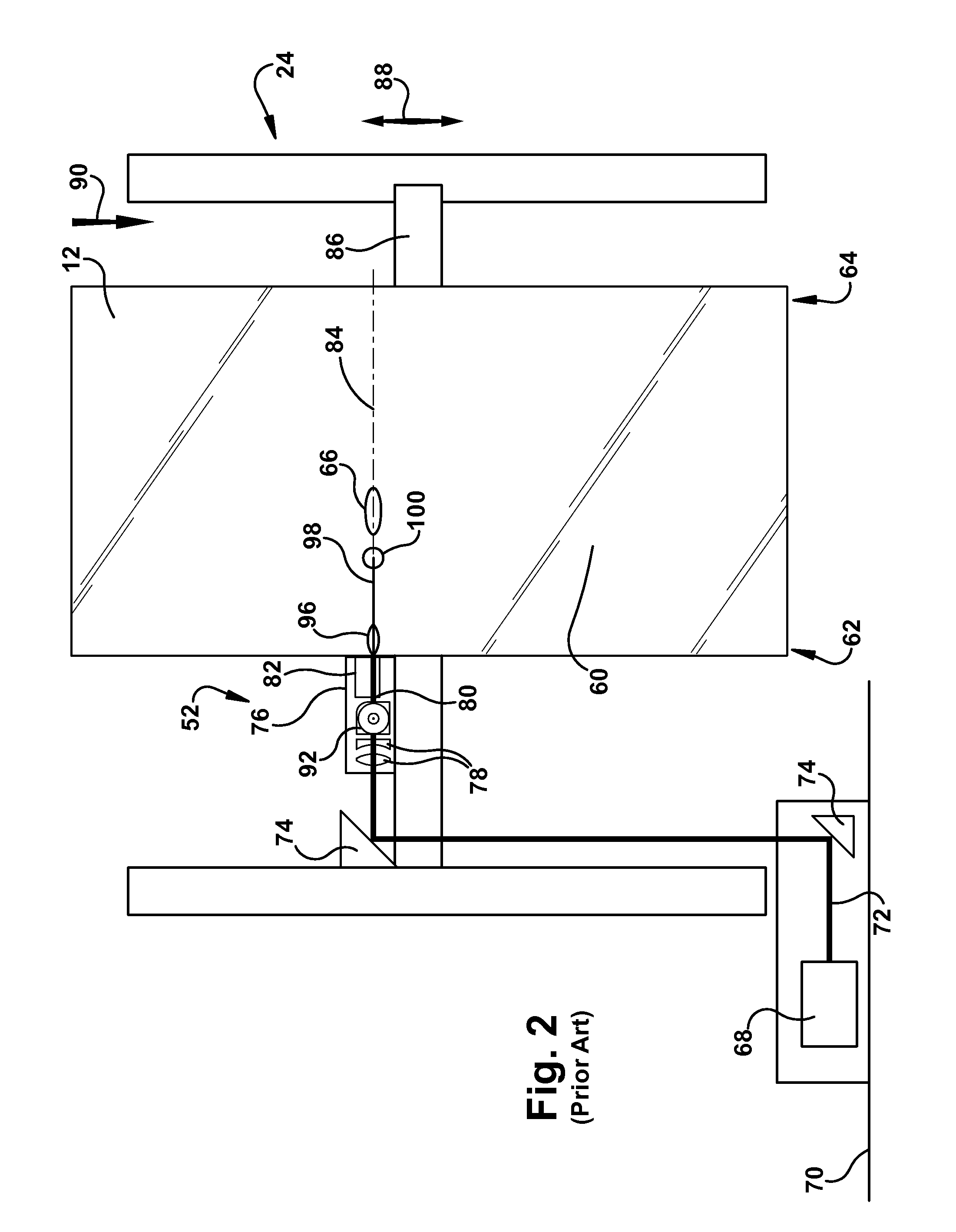

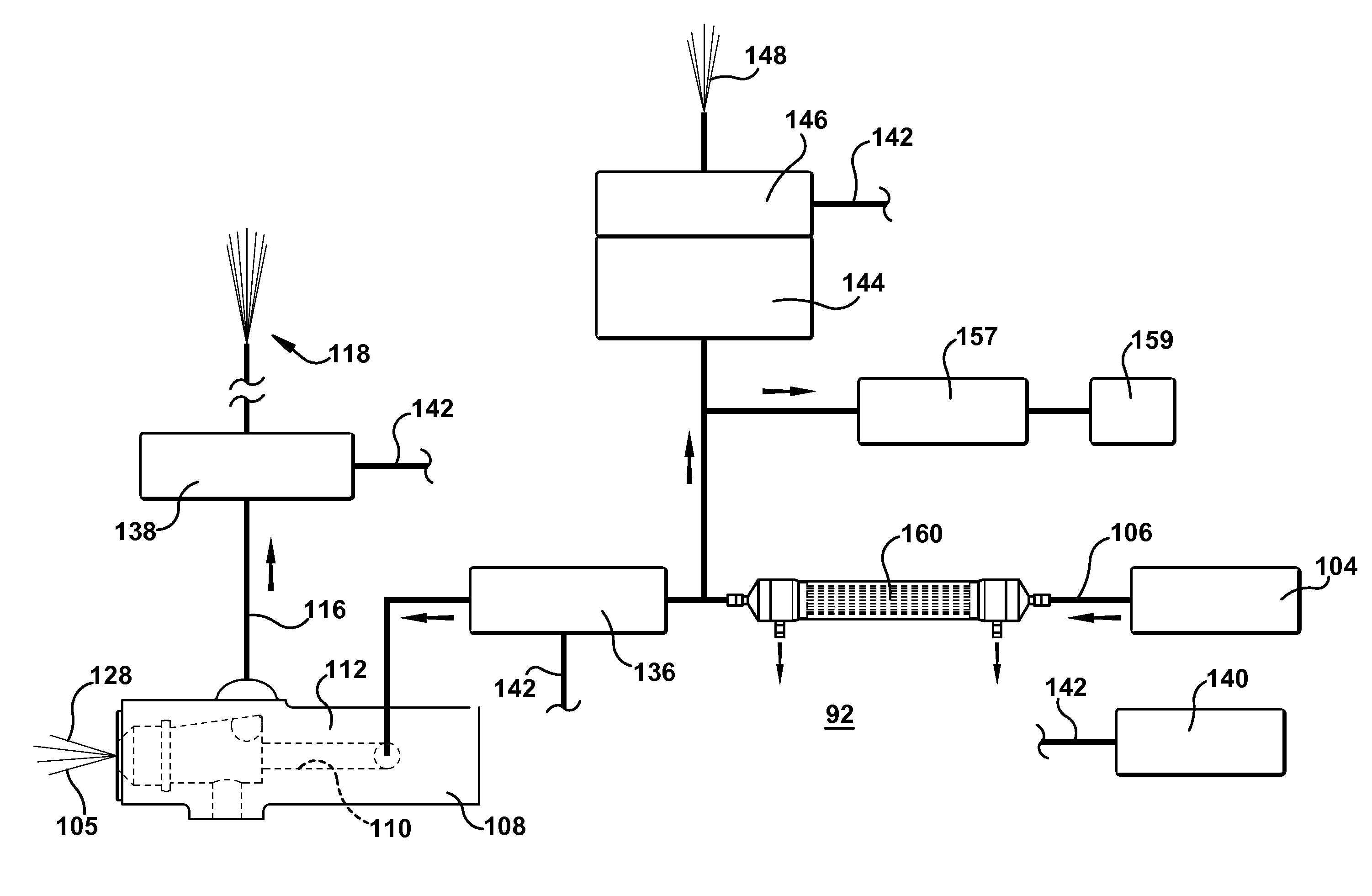

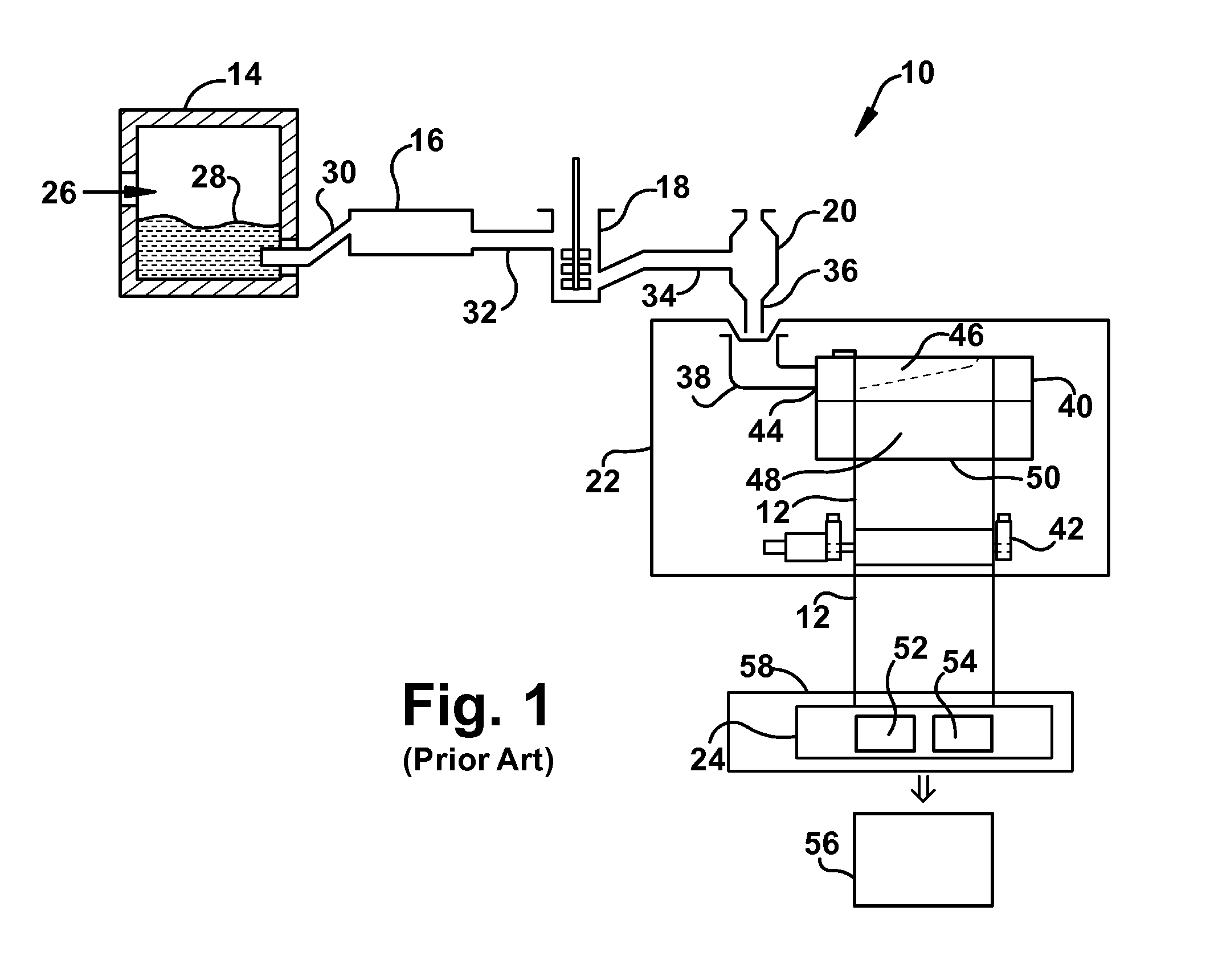

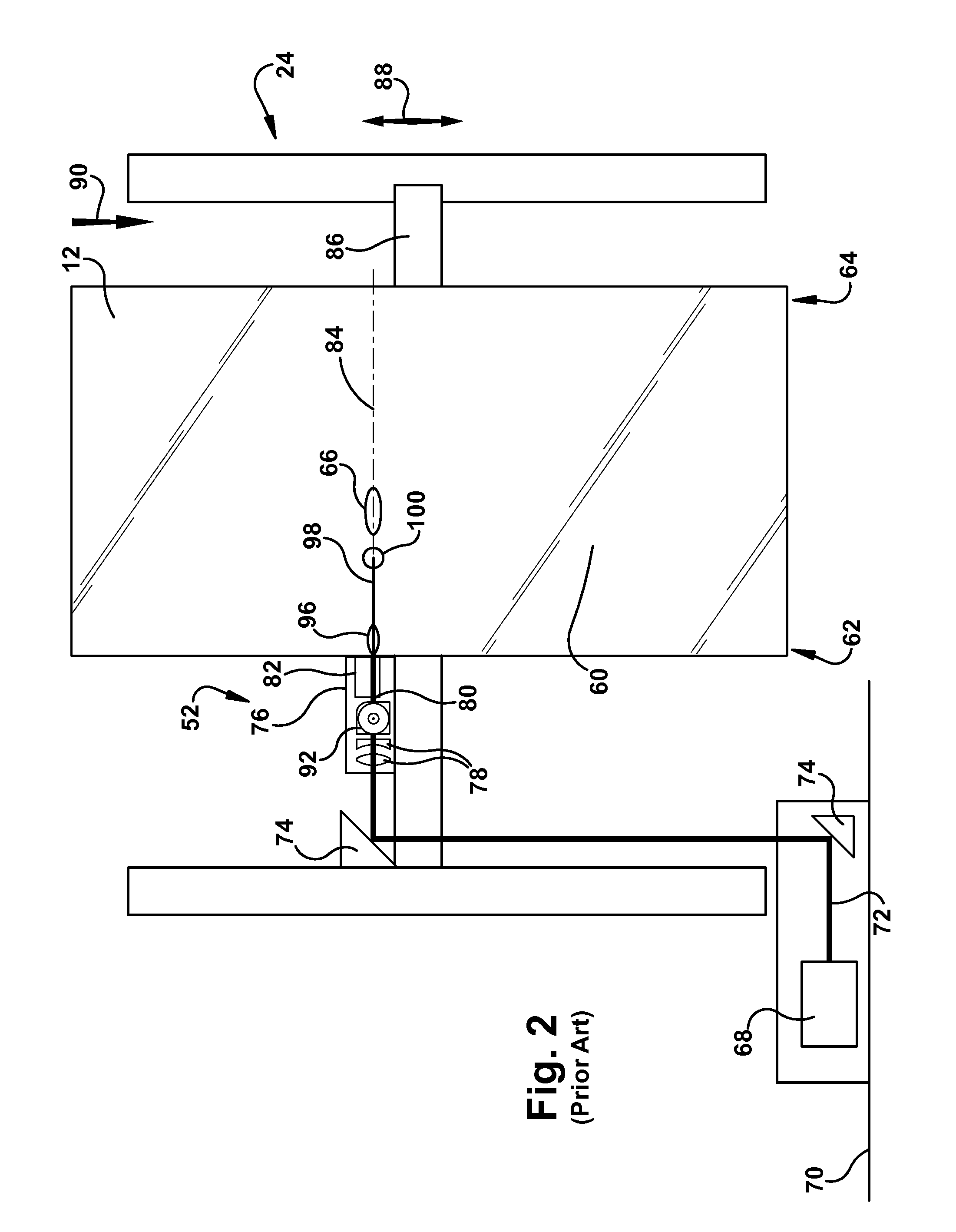

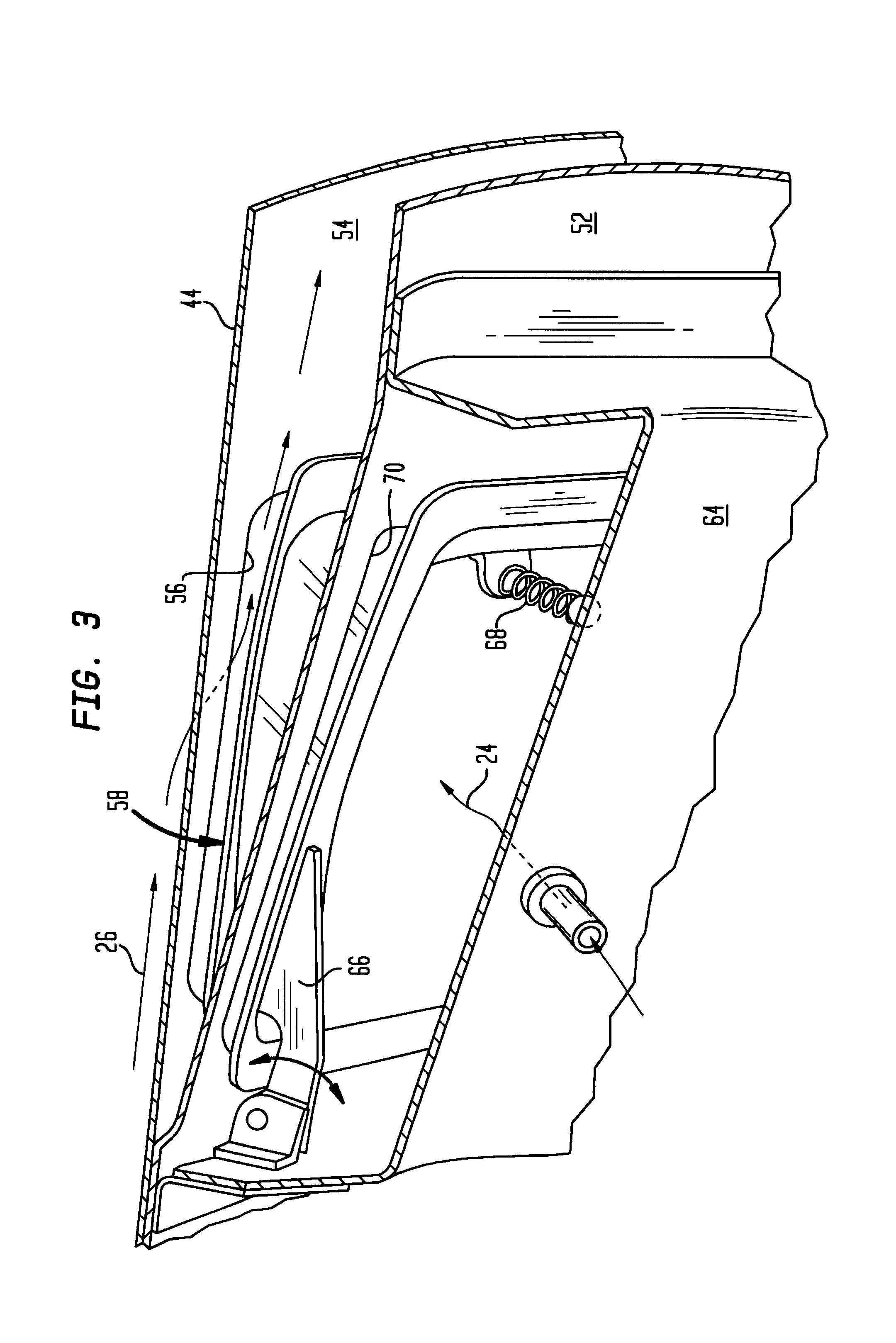

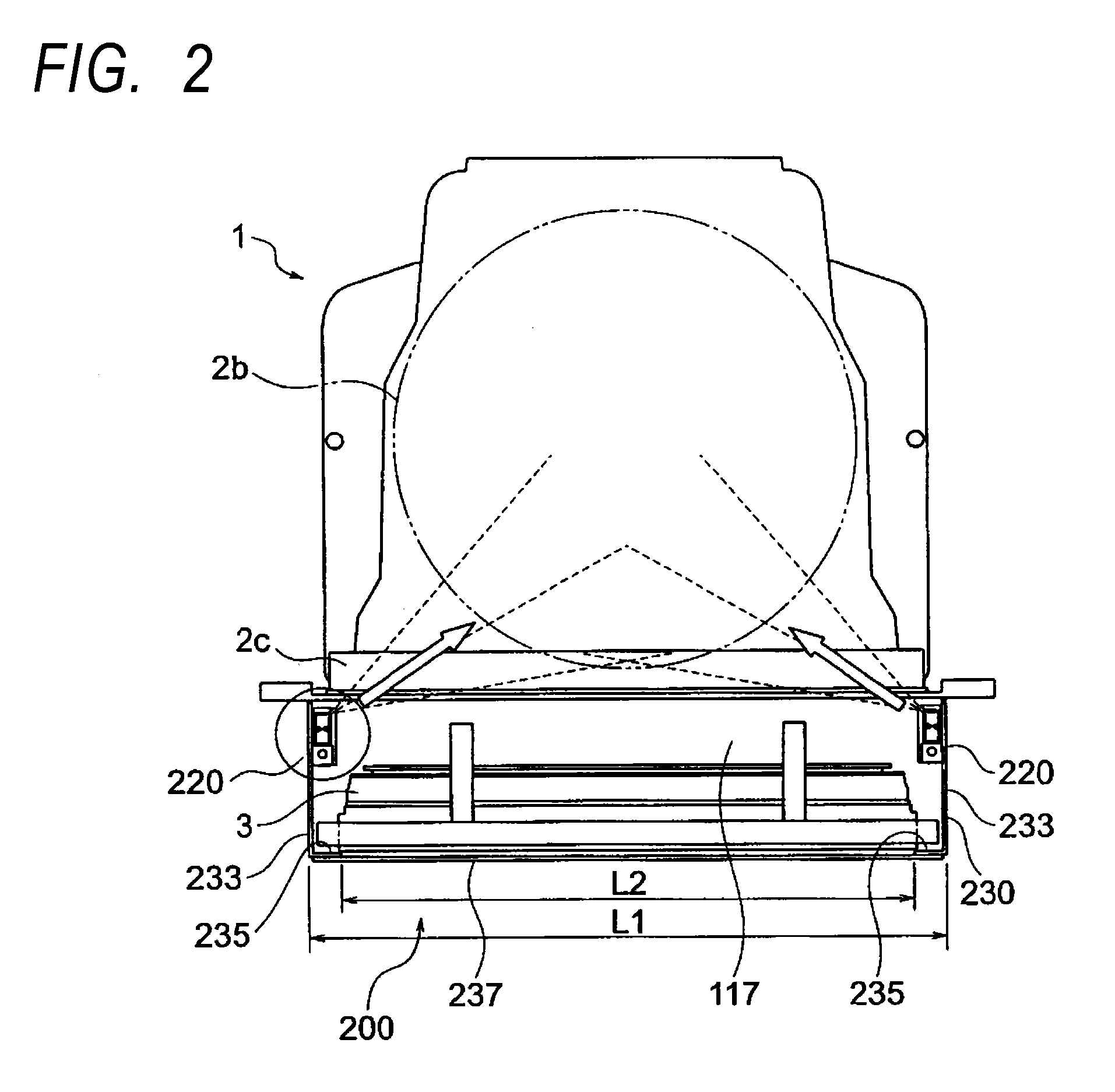

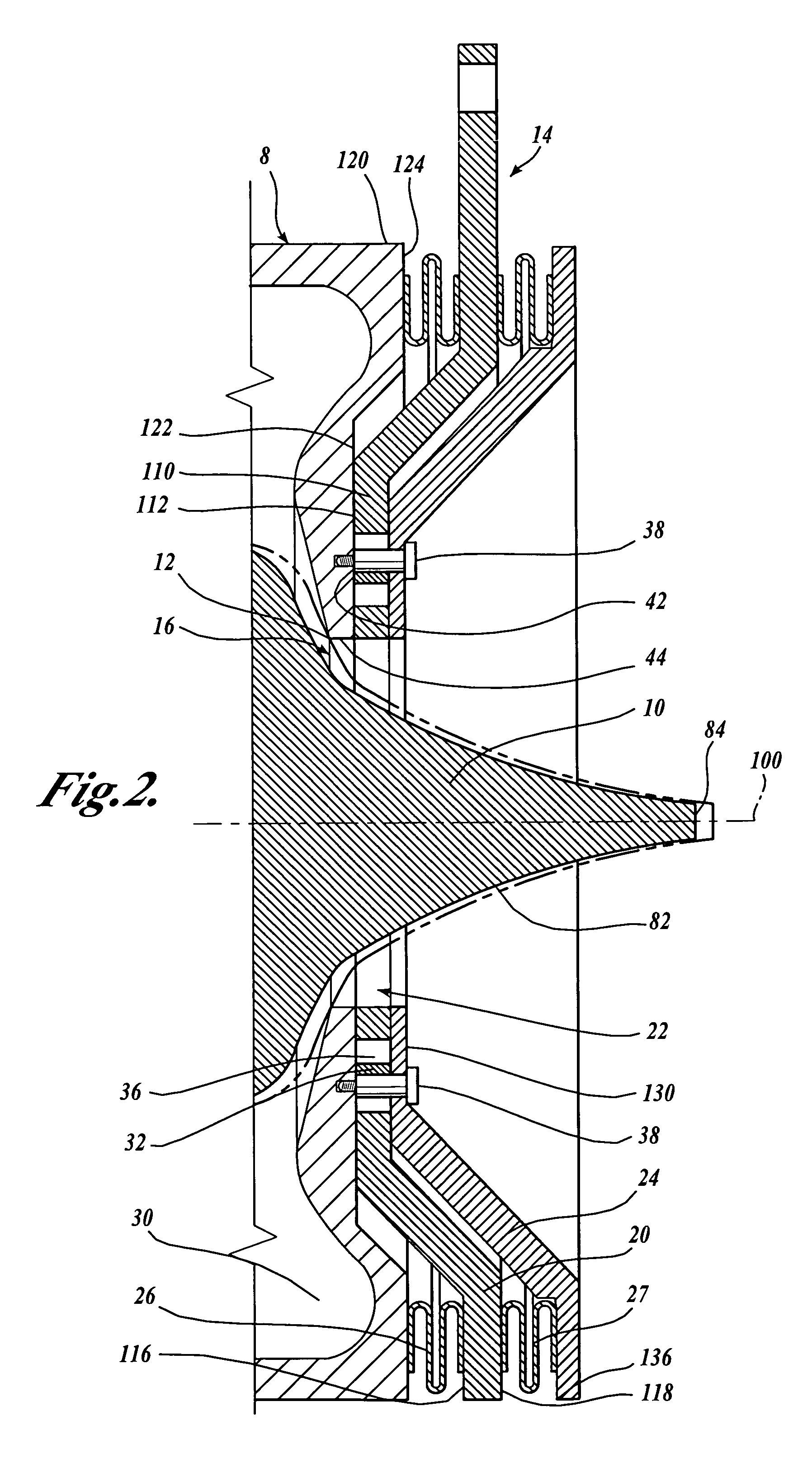

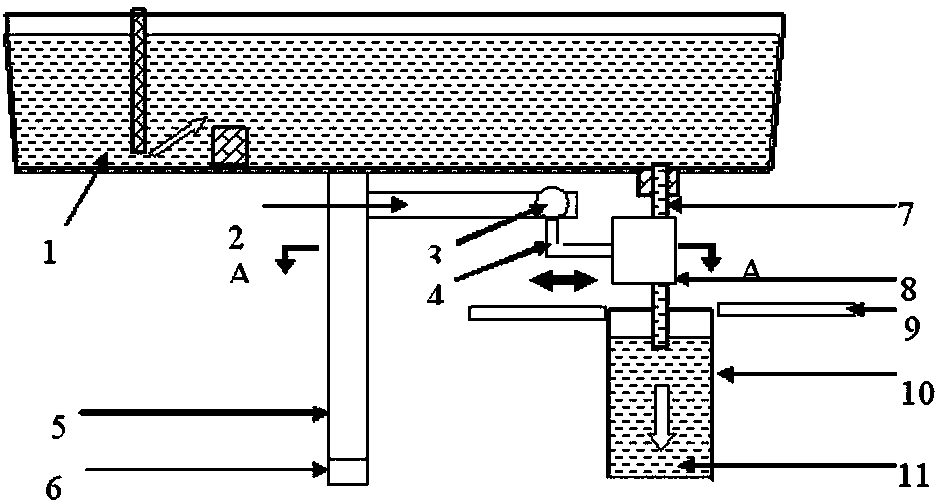

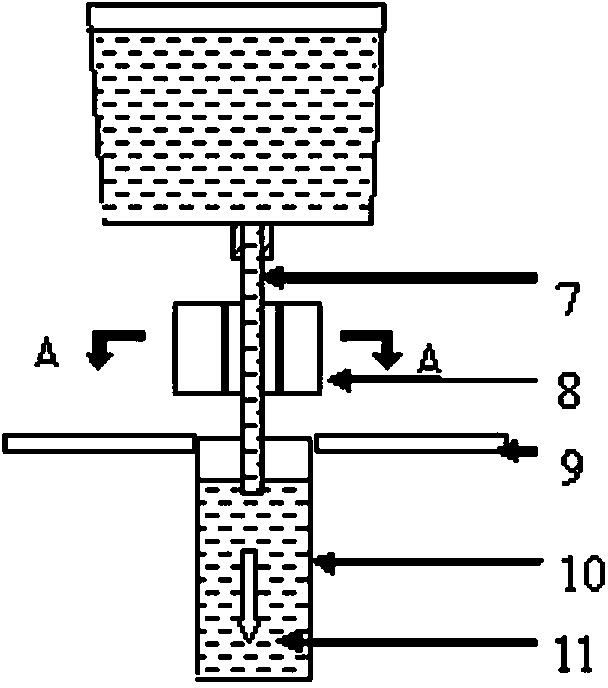

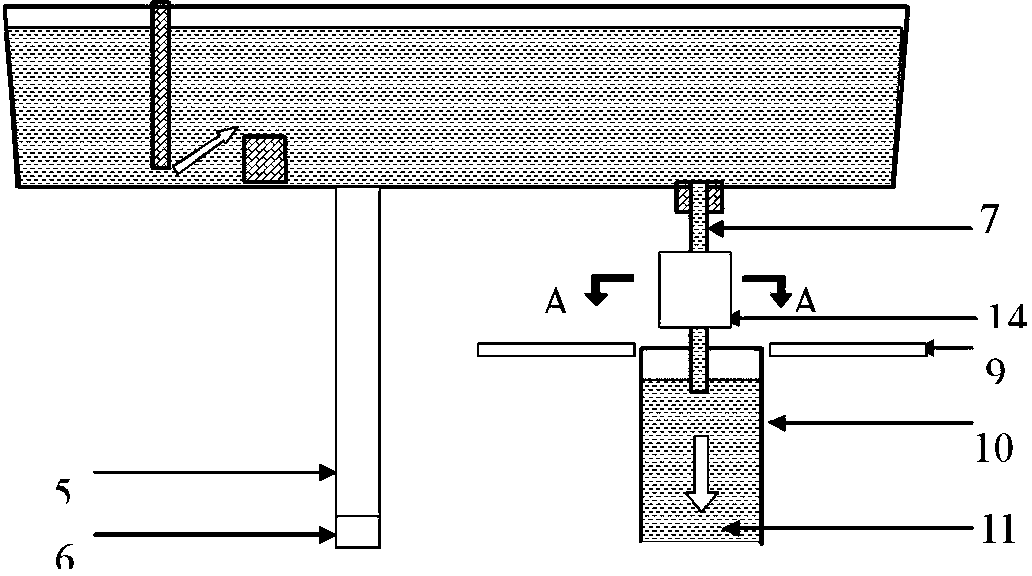

A spray nozzle is used in a process of quenching a hot glass sheet during a laser scoring process or other high energy glass heating process. The scoring is conducted by a high energy means such as a laser. The nozzle is located in proximity to the glass sheet, creating gas in liquid used to quench the glass located in the nozzle (e.g., water). The gas (e.g., air bubbles) is removed from the quenching liquid. Then, the spray nozzle is used to spray the quenching liquid onto the sheet at a location trailing laser scoring of the sheet, such as using a traveling anvil machine at the bottom of the draw. The spray nozzle (purge nozzle) has a purge opening and tubing leading to a discharge location. The purge nozzle can have a sloped passageway that pre-stages gas bubbles near the purge opening in the nozzle. The spray nozzle can include a cooling coil passing around the nozzle passageway that enables a coolant to travel along the coil. This cools the quenching liquid passing through the nozzle, and increases the solubility of bubbles in the quenching liquid in the nozzle. A gas filter can receive gas-rich quenching liquid from the pressurized quenching liquid source, remove gas from the liquid, and send gas-depleted quenching liquid to the spray nozzle.

Owner:CORNING INC

Preventing gas from occupying a spray nozzle used in a process of scoring a hot glass sheet

ActiveUS8132427B2Reduce solubilityAvoid occupyingGlass drawing apparatusGlass forming apparatusSolubilityHigh energy

A spray nozzle is used in a process of quenching a hot glass sheet during a laser scoring process or other high energy glass heating process. The scoring is conducted by a high energy means such as a laser. The nozzle is located in proximity to the glass sheet, creating gas in liquid used to quench the glass located in the nozzle (e.g., water). The gas (e.g., air bubbles) is removed from the quenching liquid. Then, the spray nozzle is used to spray the quenching liquid onto the sheet at a location trailing laser scoring of the sheet, such as using a traveling anvil machine at the bottom of the draw. The spray nozzle (purge nozzle) has a purge opening and tubing leading to a discharge location. The purge nozzle can have a sloped passageway that pre-stages gas bubbles near the purge opening in the nozzle. The spray nozzle can include a cooling coil passing around the nozzle passageway that enables a coolant to travel along the coil. This cools the quenching liquid passing through the nozzle, and increases the solubility of bubbles in the quenching liquid in the nozzle. A gas filter can receive gas-rich quenching liquid from the pressurized quenching liquid source, remove gas from the liquid, and send gas-depleted quenching liquid to the spray nozzle.

Owner:CORNING INC

Variable area plug nozzle

InactiveUS6845607B2Increase the circulation areaShorten speedCosmonautic vehiclesCosmonautic propulsion system apparatusAirplaneTakeoff

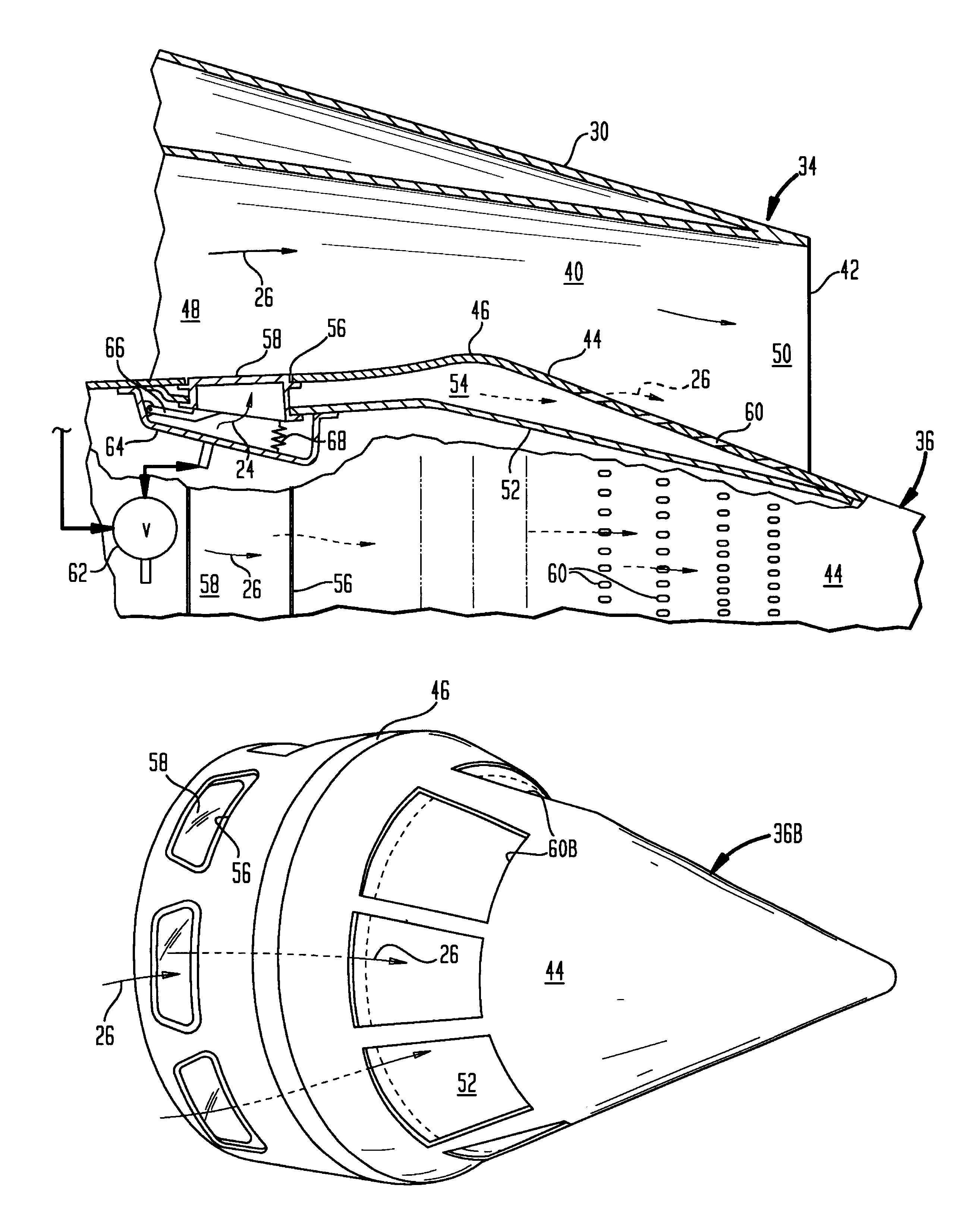

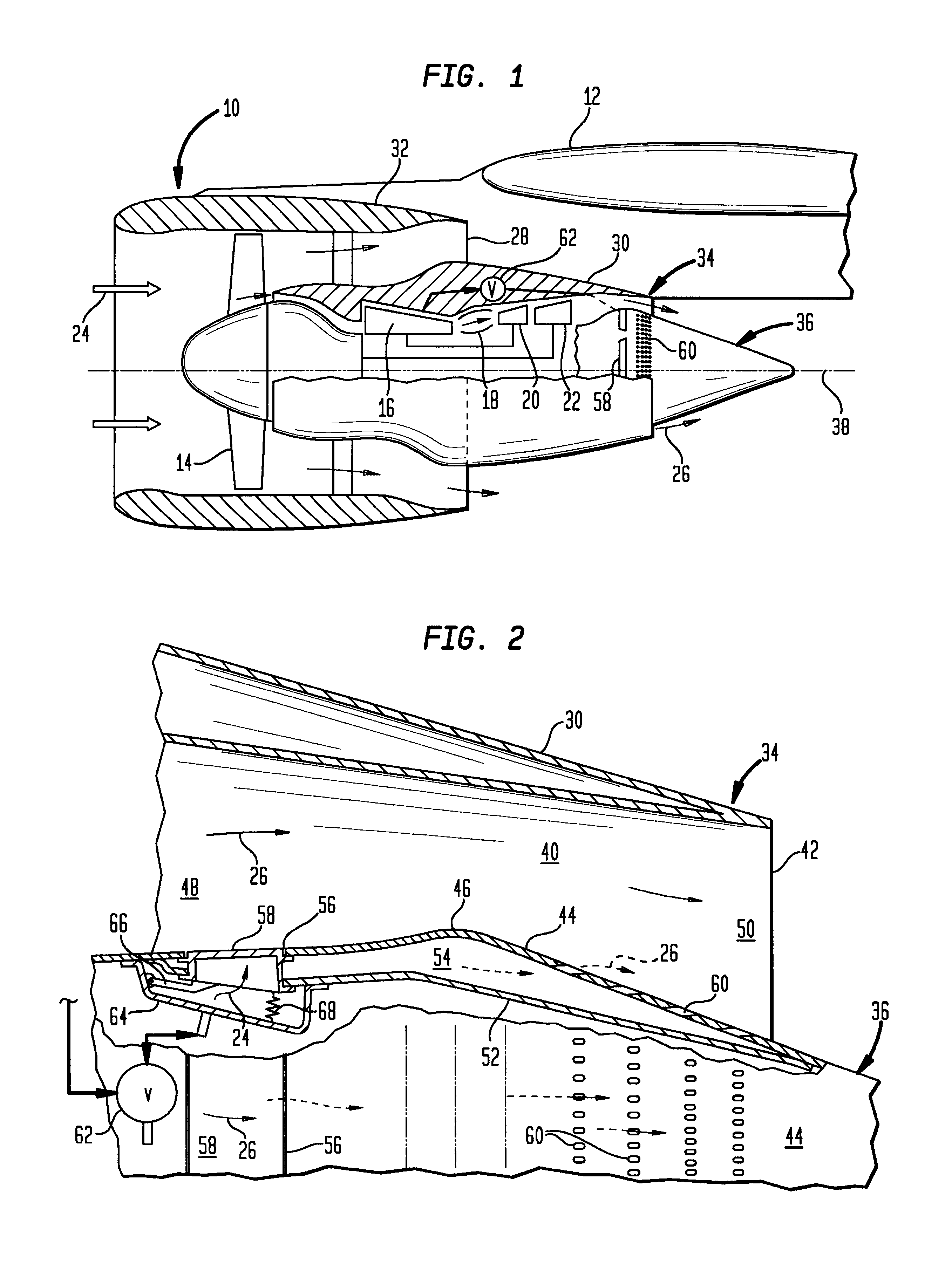

A center plug is configured for variable area use in an exhaust nozzle. A forward portion of the plug includes an inlet having a closing flap therein, and an aft portion of the plug includes an outlet. The flap is selectively open during aircraft takeoff operation and up to a preset climb altitude for bypassing a portion of core exhaust flow through the plug, with the flap being closed from preset altitude and cruise operation. Opening the flap correspondingly increases the available flow area for discharging the exhaust flow for reducing velocity thereof, and attenuating noise.

Owner:AERONAUTICAL CONCEPT OF EXHAUST +1

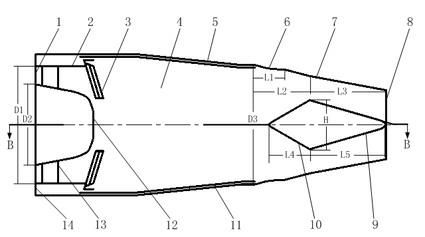

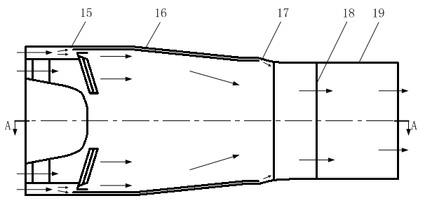

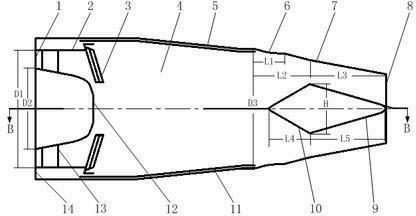

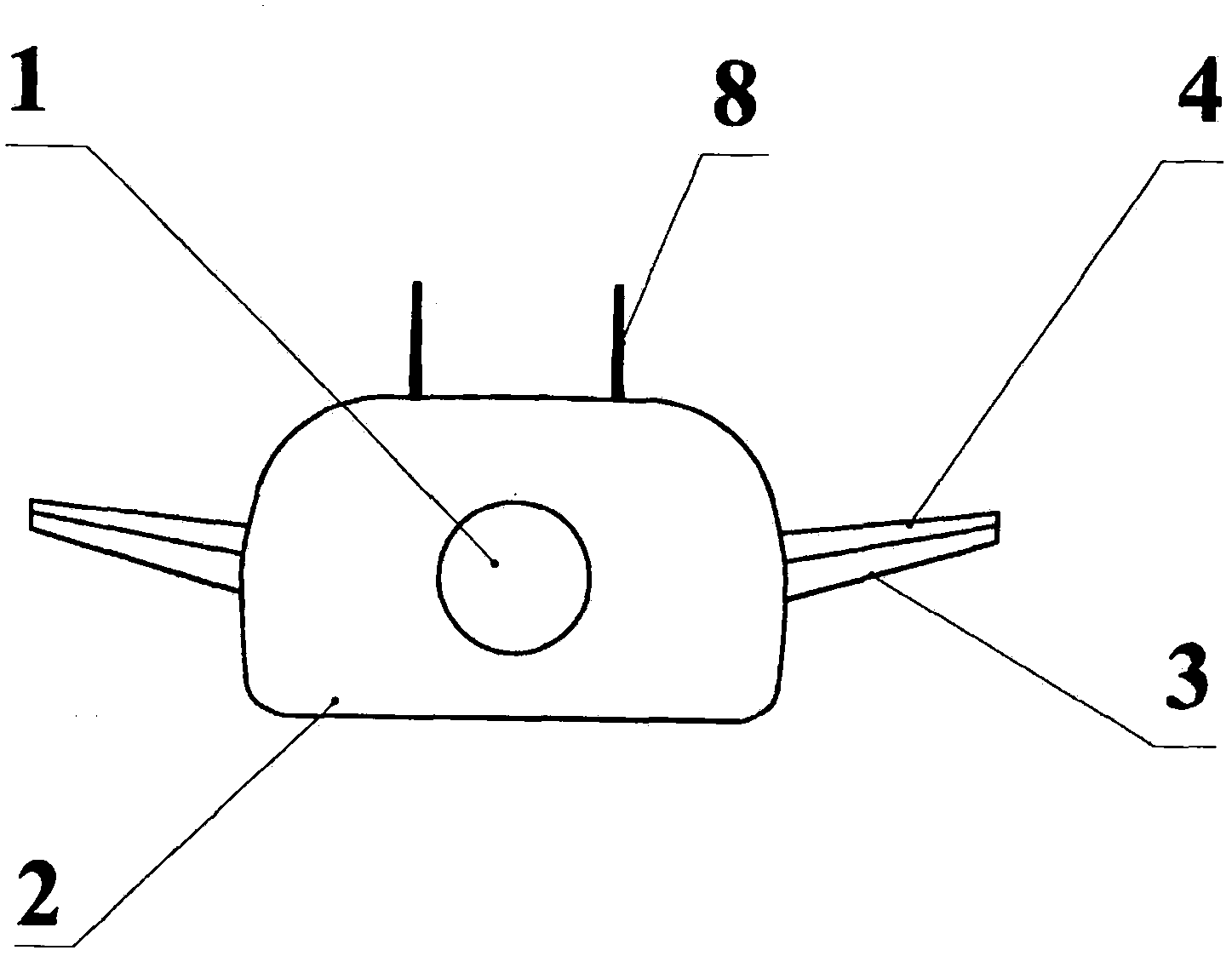

Binary plug nozzle of turbofan engine with afterburning

InactiveCN102536514AImprove thrust performanceEffectively block infrared radiationJet propulsion plantsCombustion chamberTurbofan

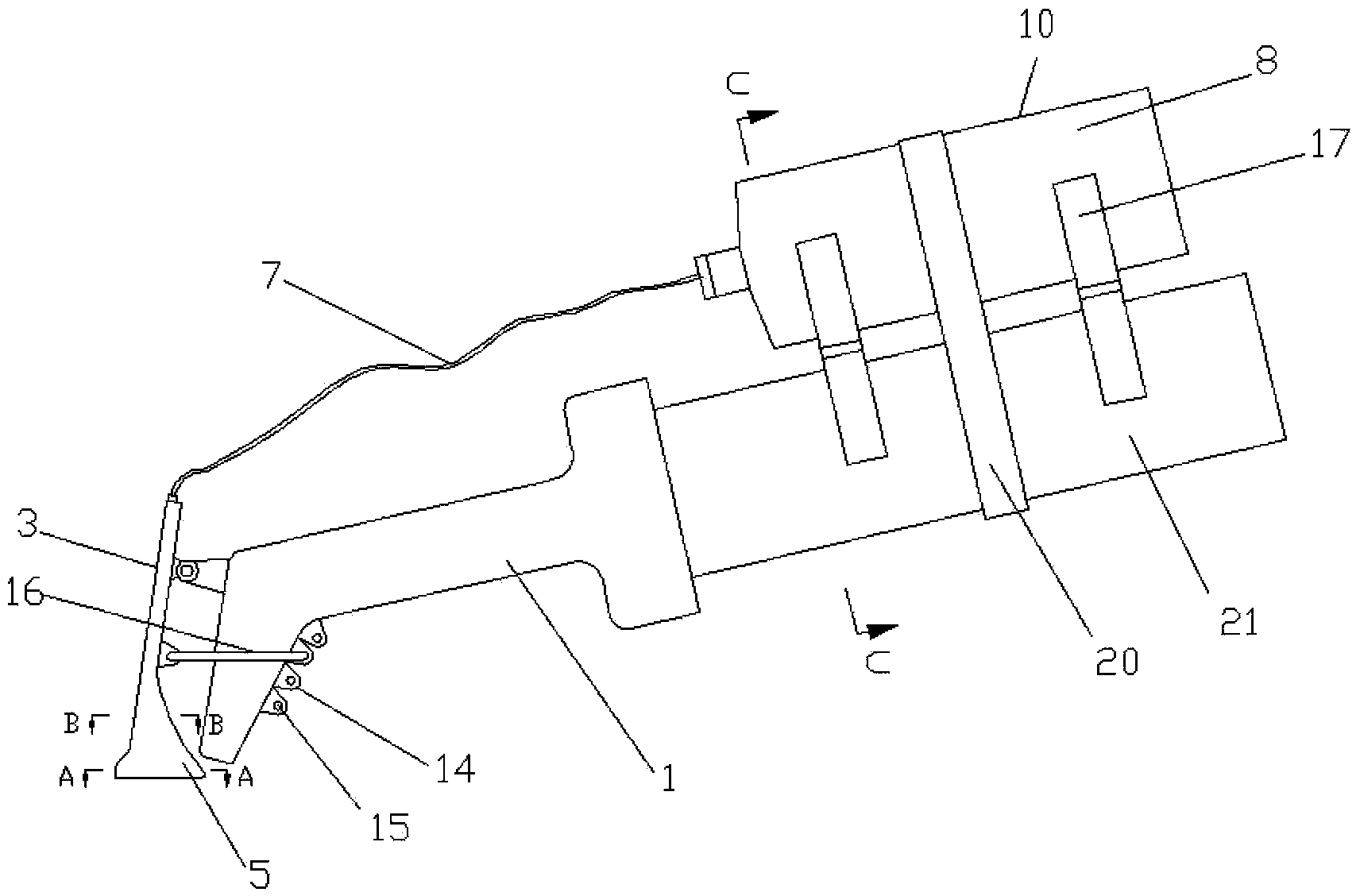

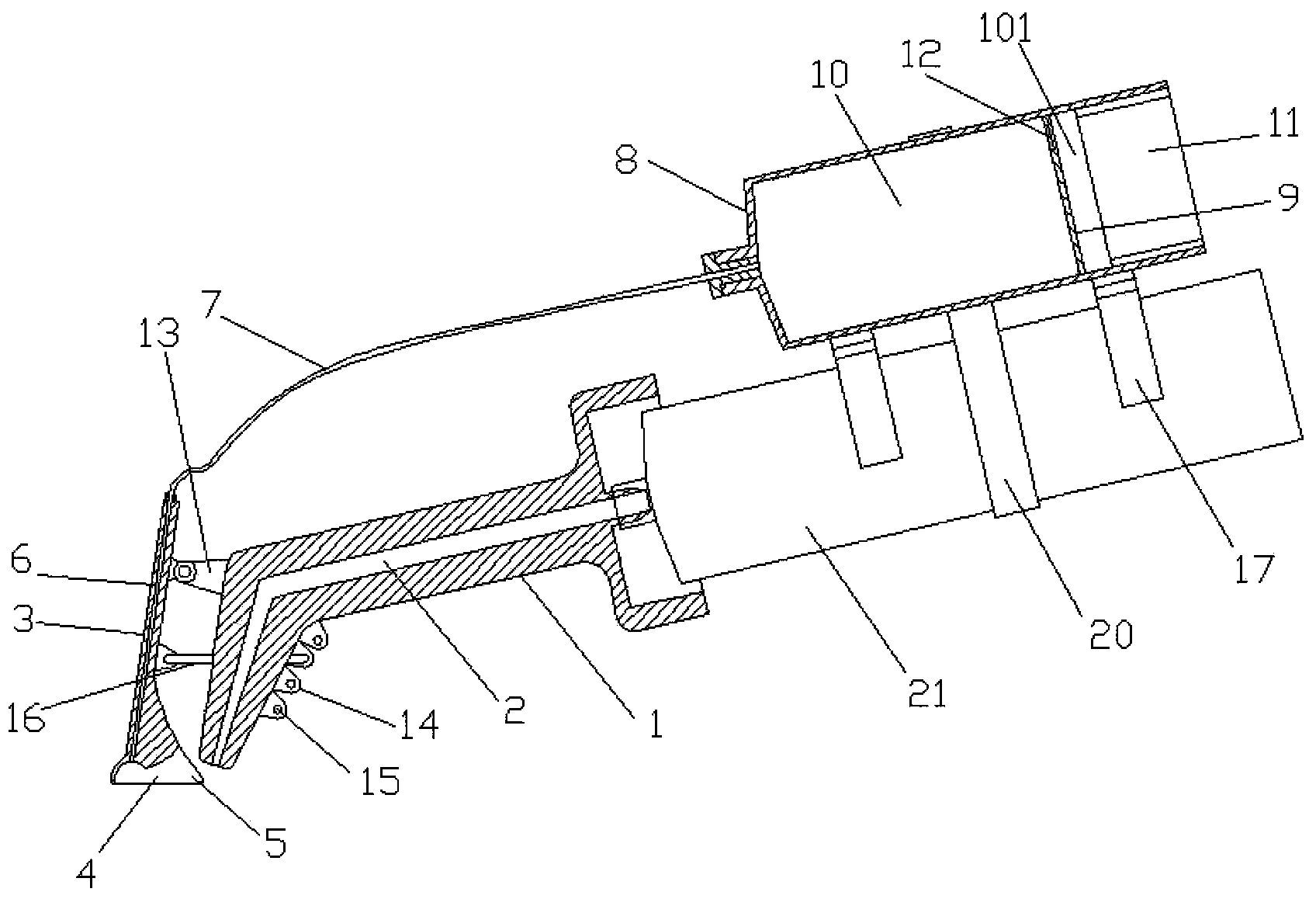

The invention relates to a binary plug nozzle of a turbofan engine with afterburning, and belongs to the field of suppressing an infrared radiation characteristic of an aircraft. The front part of the nozzle is provided with an external channel (14) and an internal channel (1), a central cone (12) is arranged in the internal channel (1) through a support plate (13), and a flame holder (3) is also arranged at the downstream of the central cone (12); the middle part of the nozzle is provided with an afterburning chamber, the rear part of the nozzle is sequentially provided with a transitional section (6) and a retracting and expanding section (7), and a tapered plug which is of a prism shape is arranged in the retracting and expanding section (7), and the tapered plug comprises a front part (10) of the tapered plug and a rear part (9) of the tapered plug. In the invention, while the pneumatic performance is maintained to be high, the infrared radiation characteristic of an engine exhaust emission system is remarkably reduced, and the tracking distance of an infrared detection system is shortened, so that the battlefield survival ability of the aircraft is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

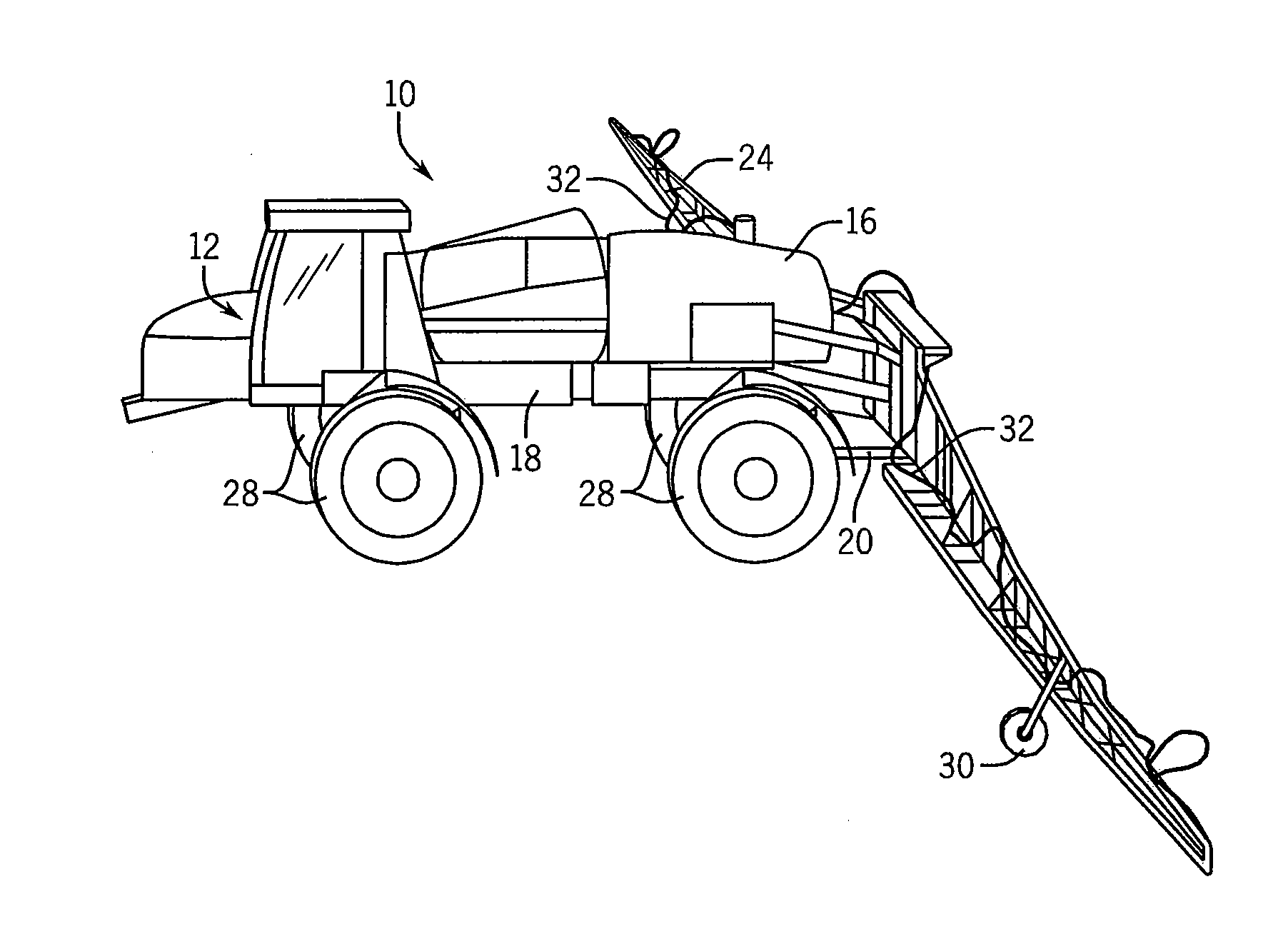

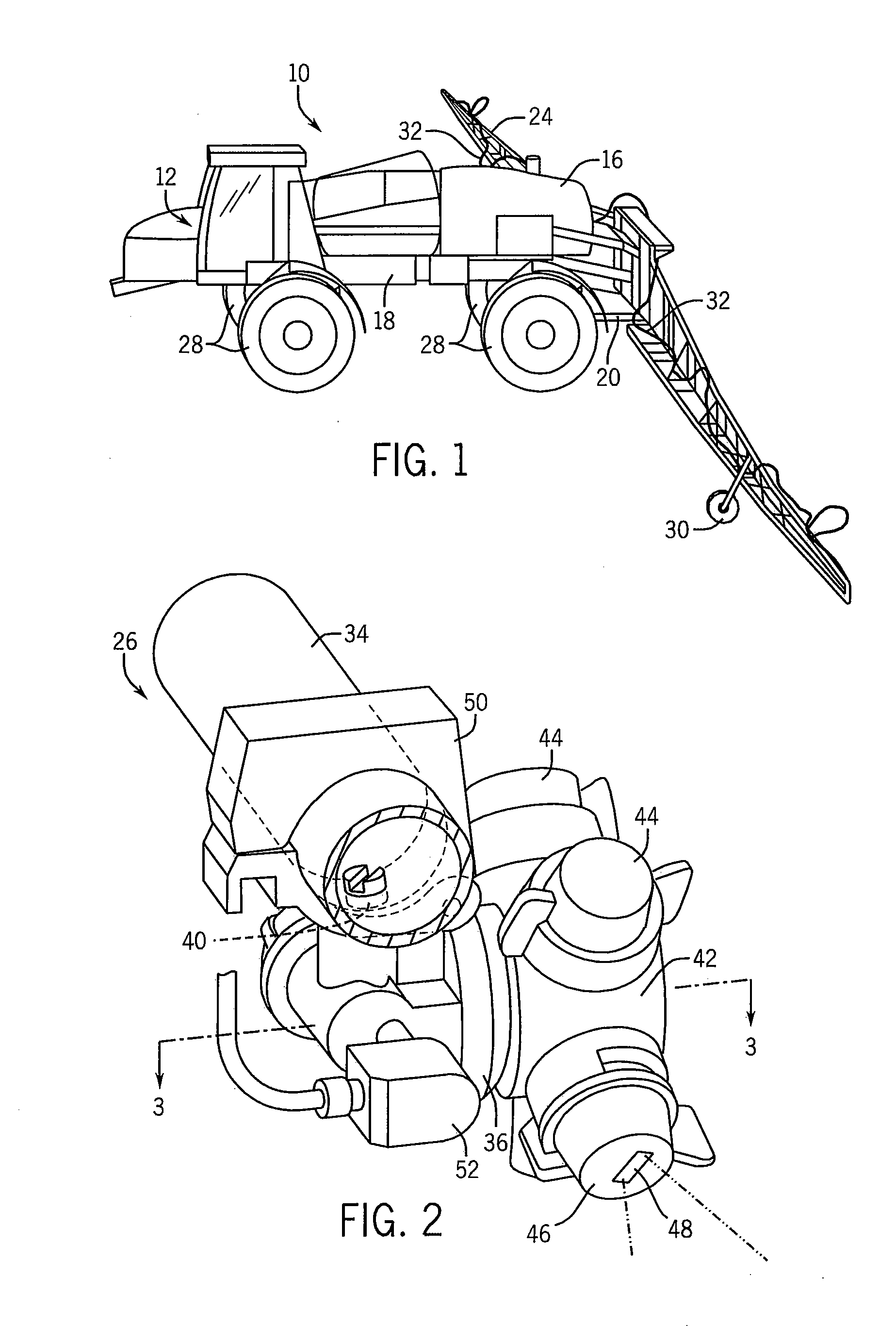

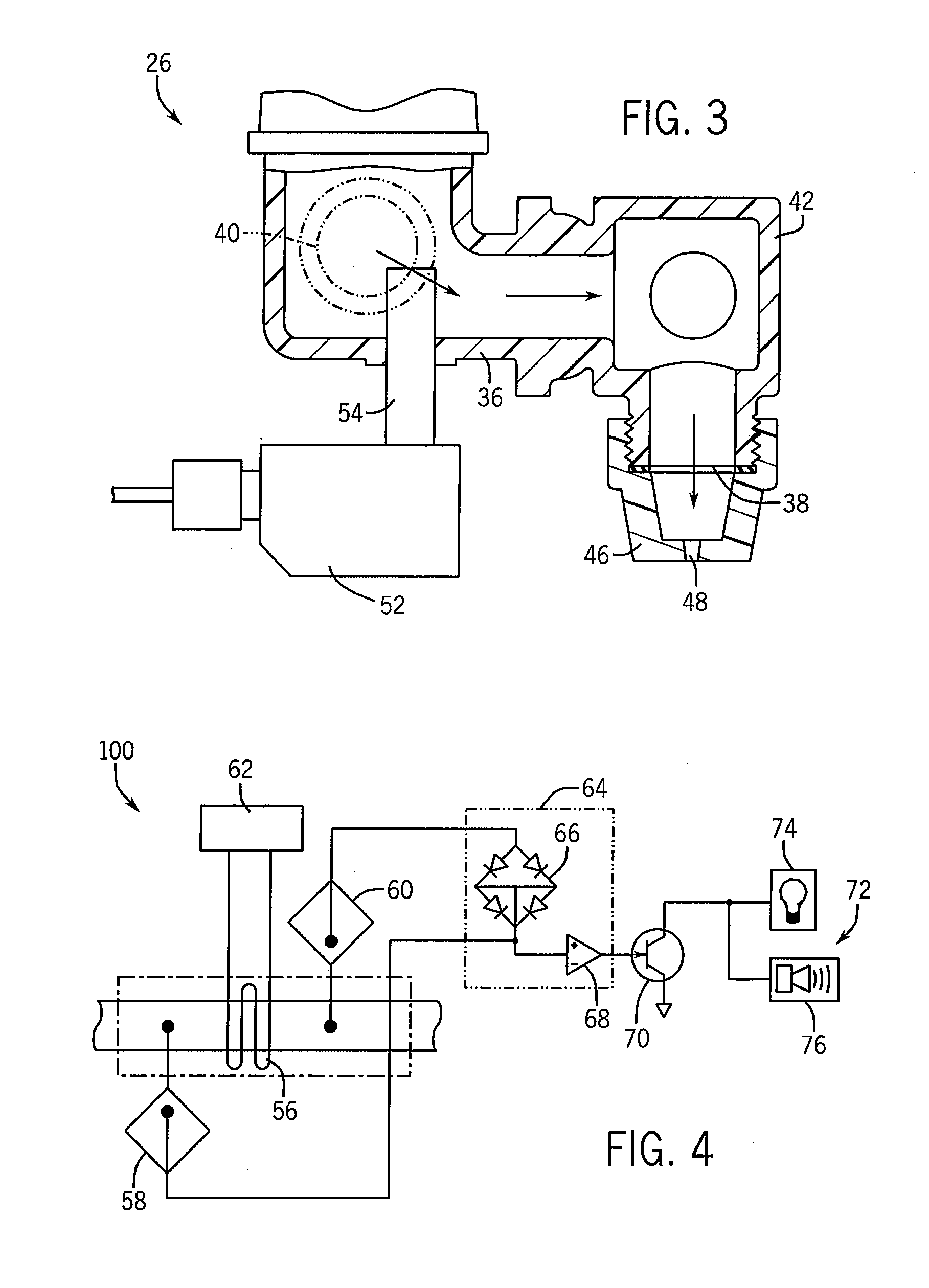

Method And Apparatus For Detecting A Plugged Nozzle Of A Sprayer

InactiveUS20120168530A1Liquid fertiliser regulation systemsSpray nozzlesMonitoring systemSpray nozzle

A plugged nozzle monitoring system uses a thermal flow sensor located within a spray nozzle of an agricultural sprayer. The thermal flow sensor is free of moving parts and is made of corrosion-resistant materials. The thermal flow sensor is placed within the fluid flow path through the nozzle and activates an alarm if flow through the nozzle falls below the baseline value.

Owner:BLUE LEAF I P INC

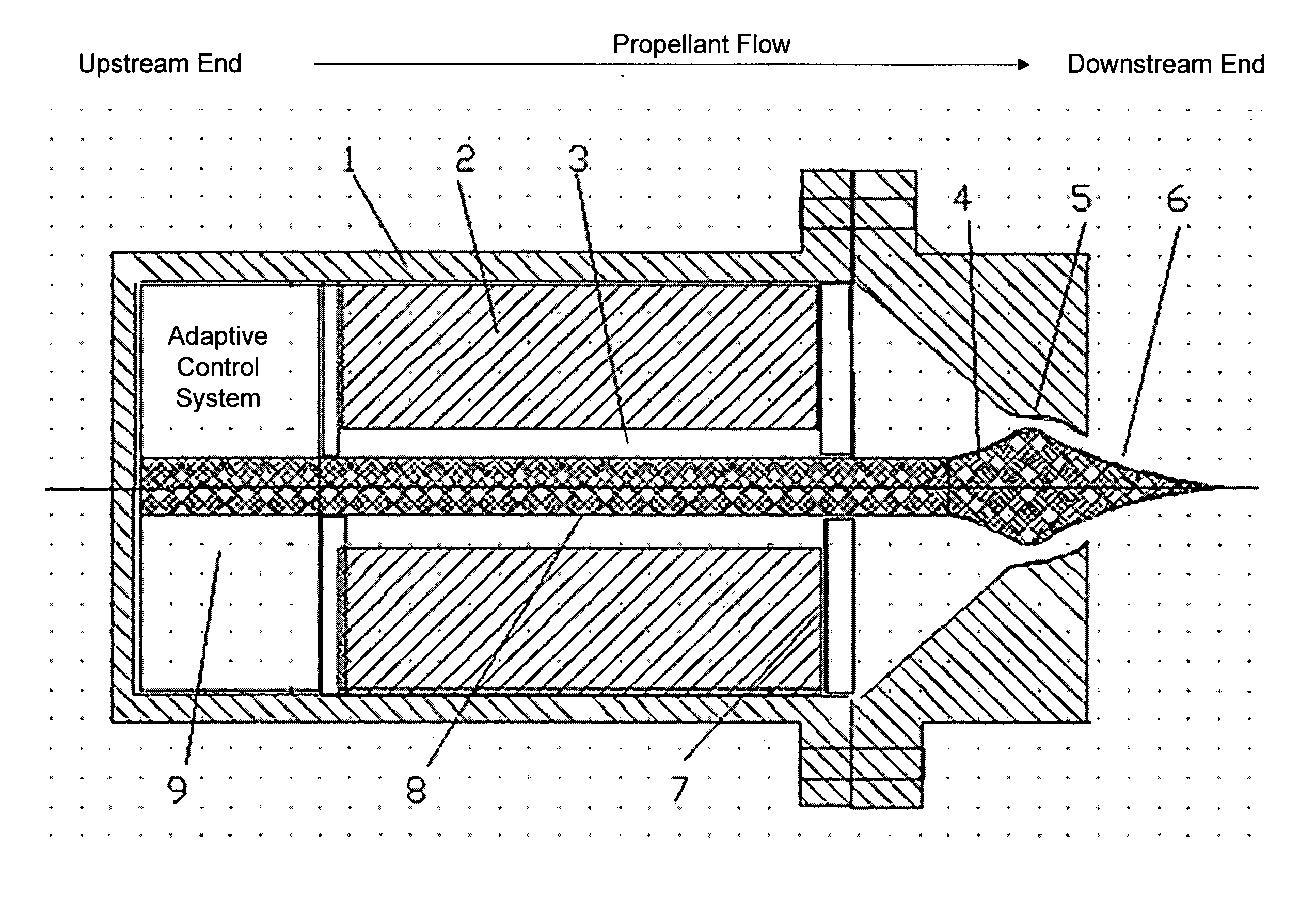

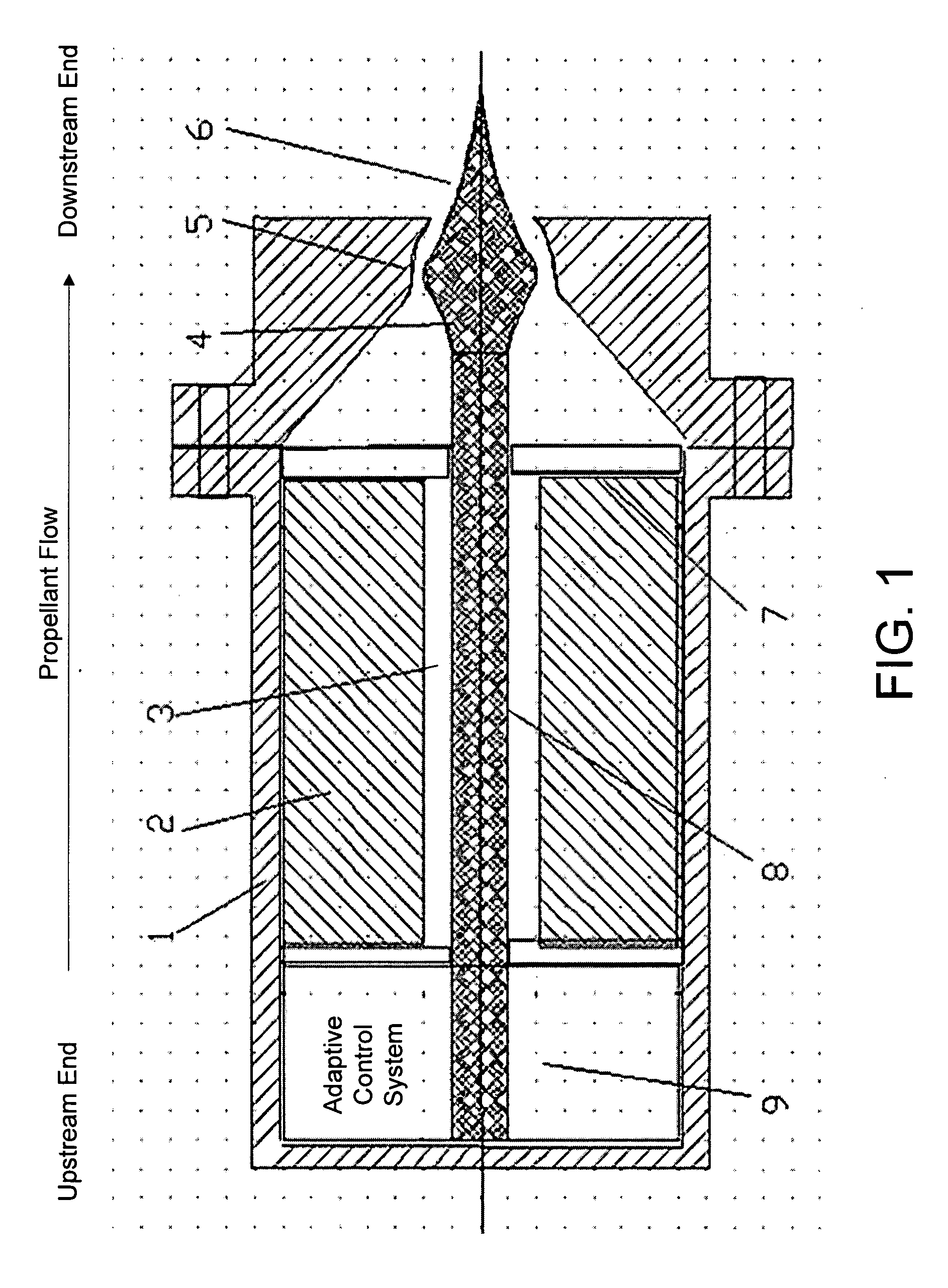

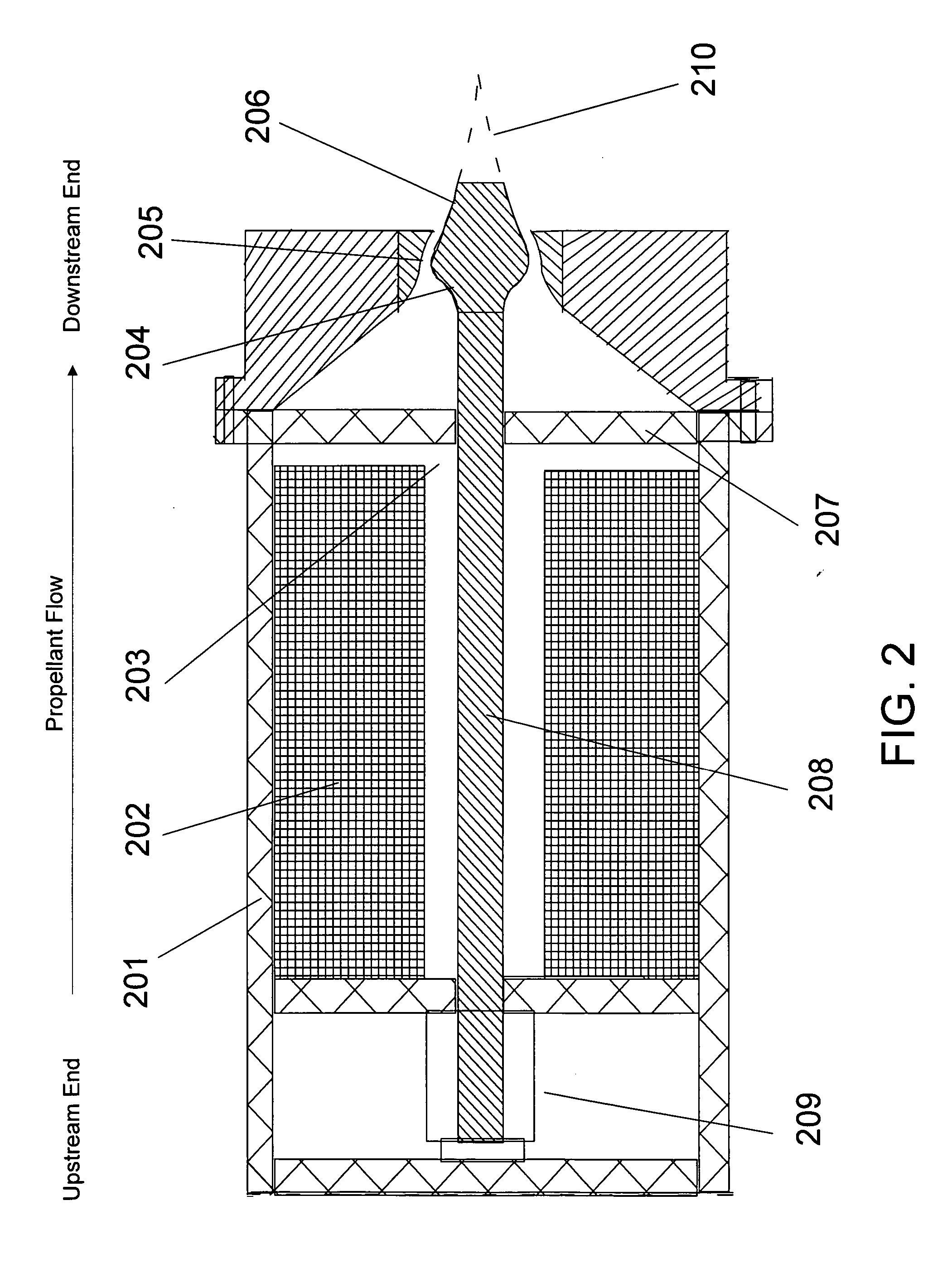

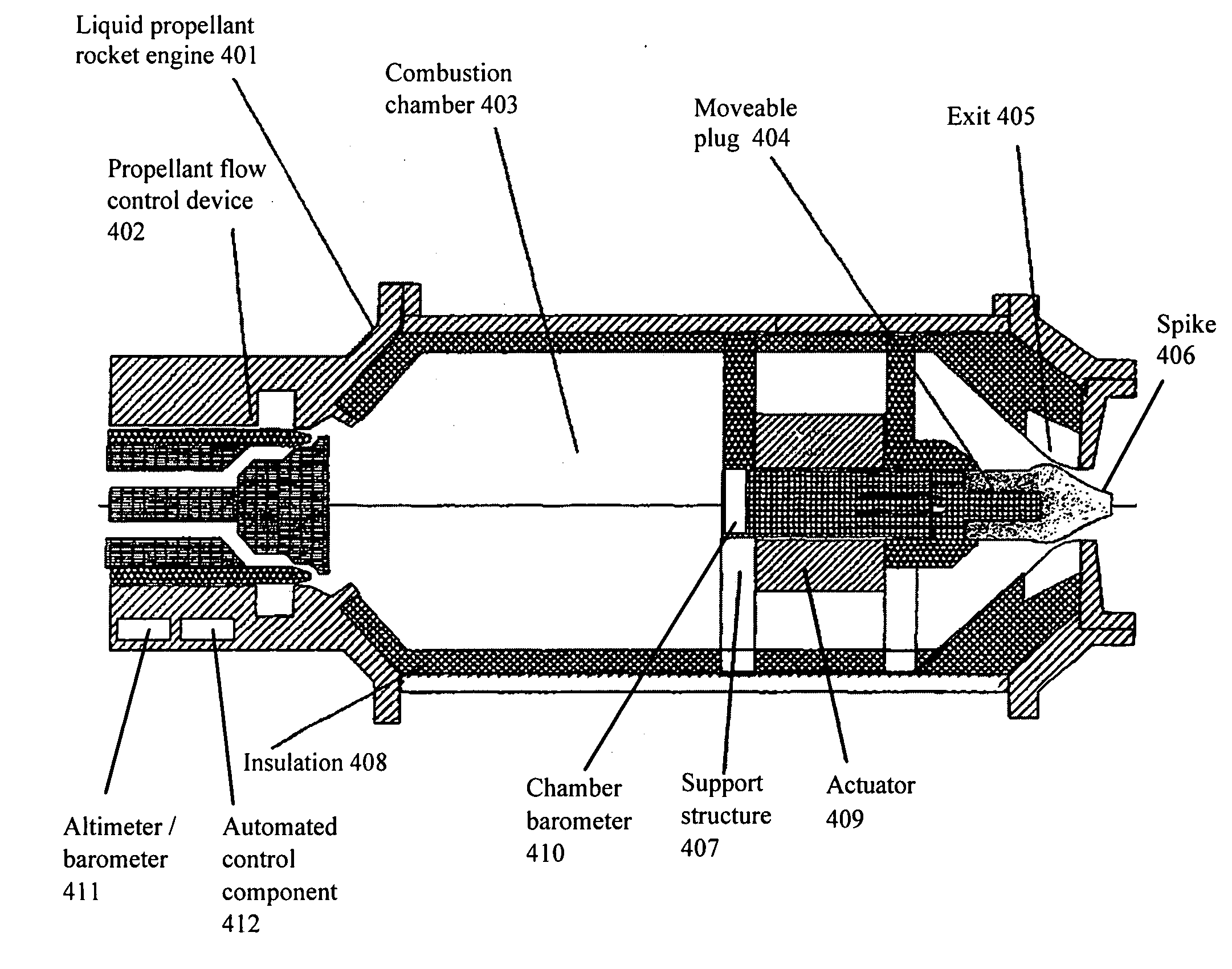

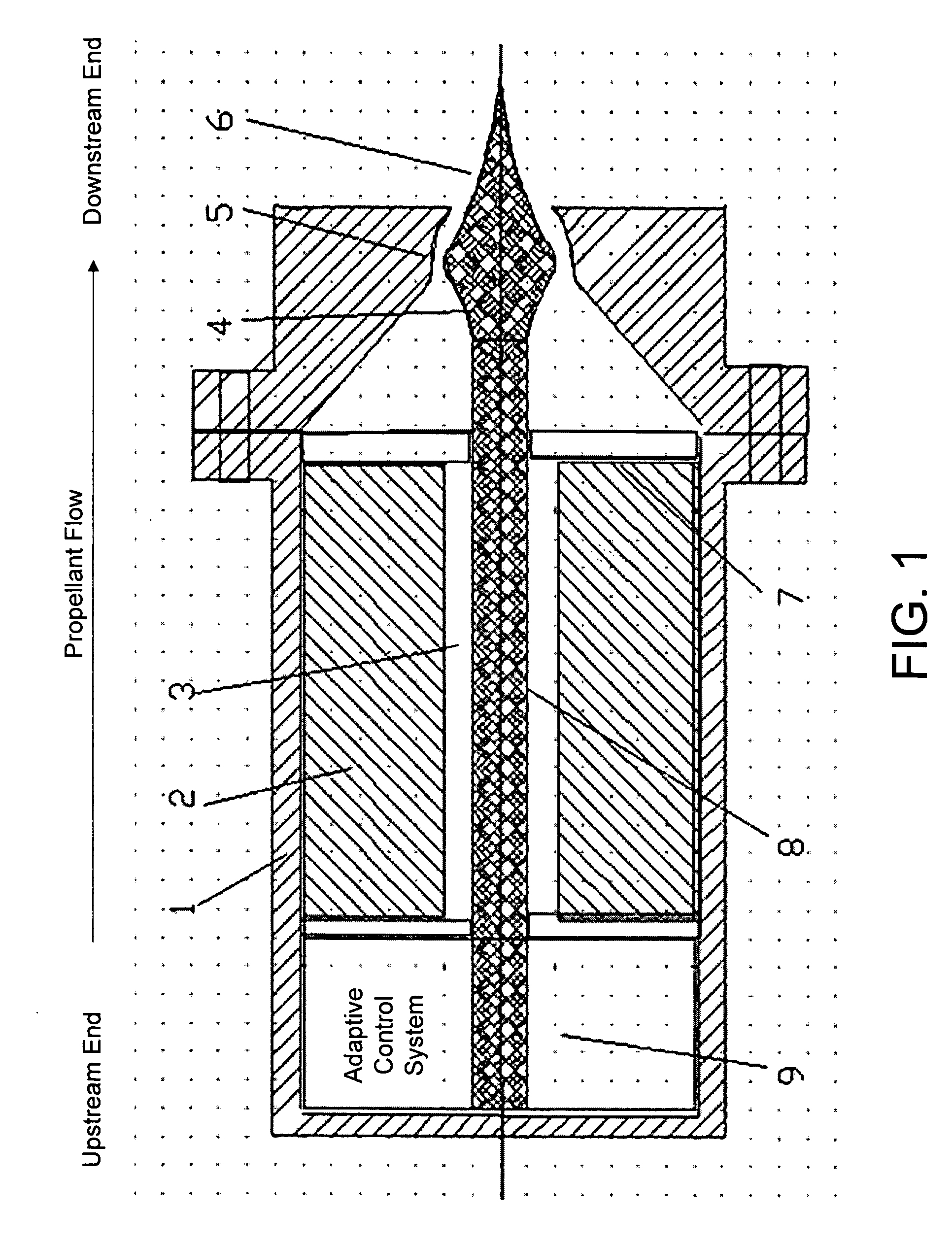

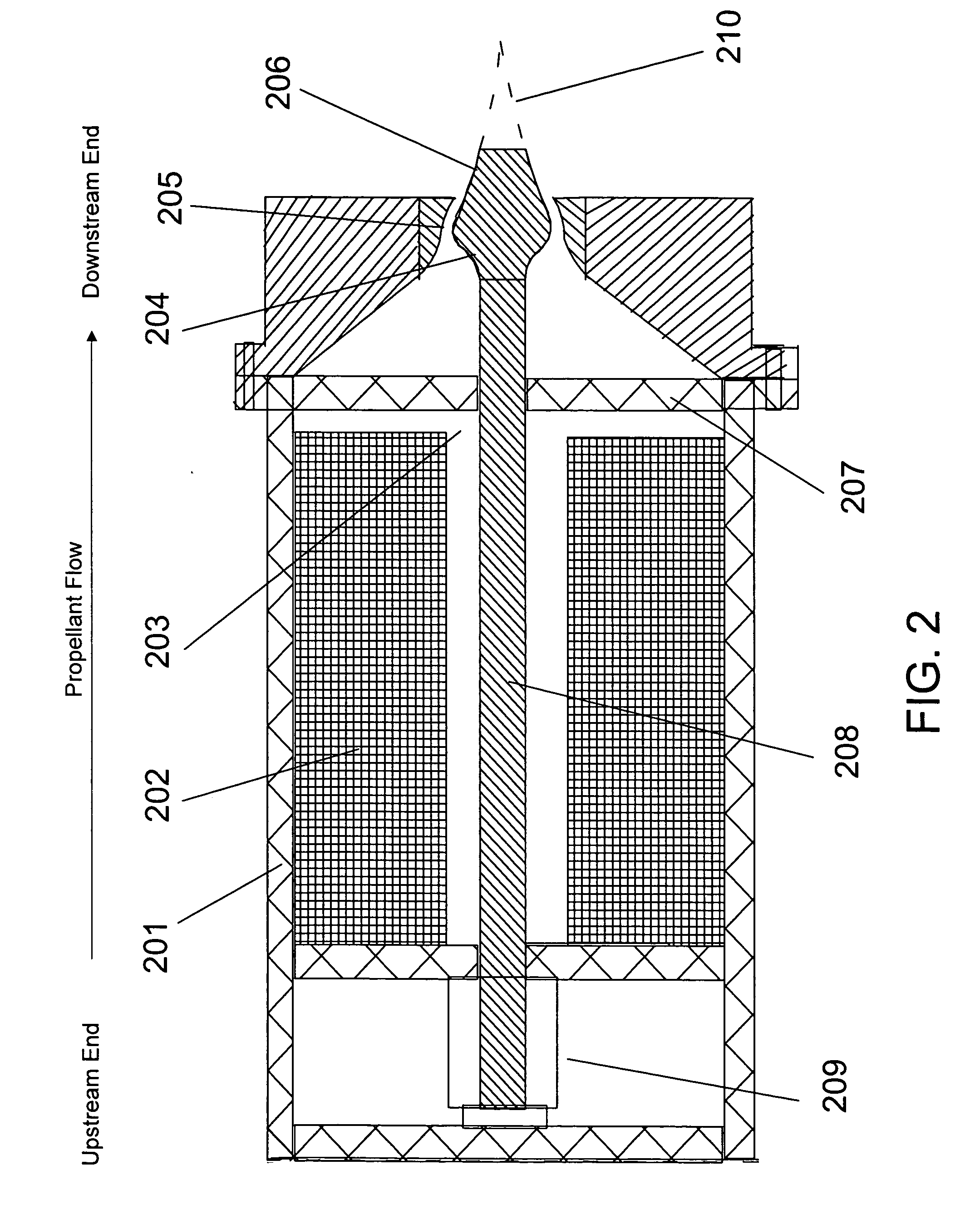

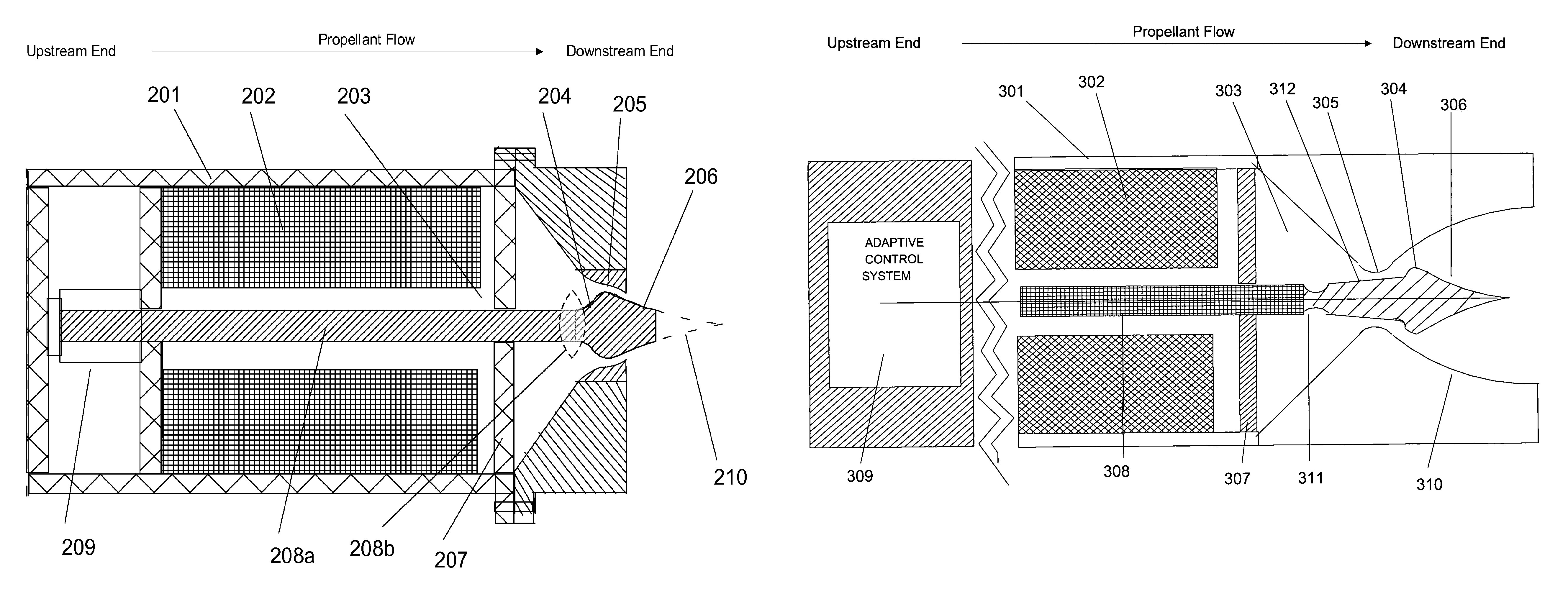

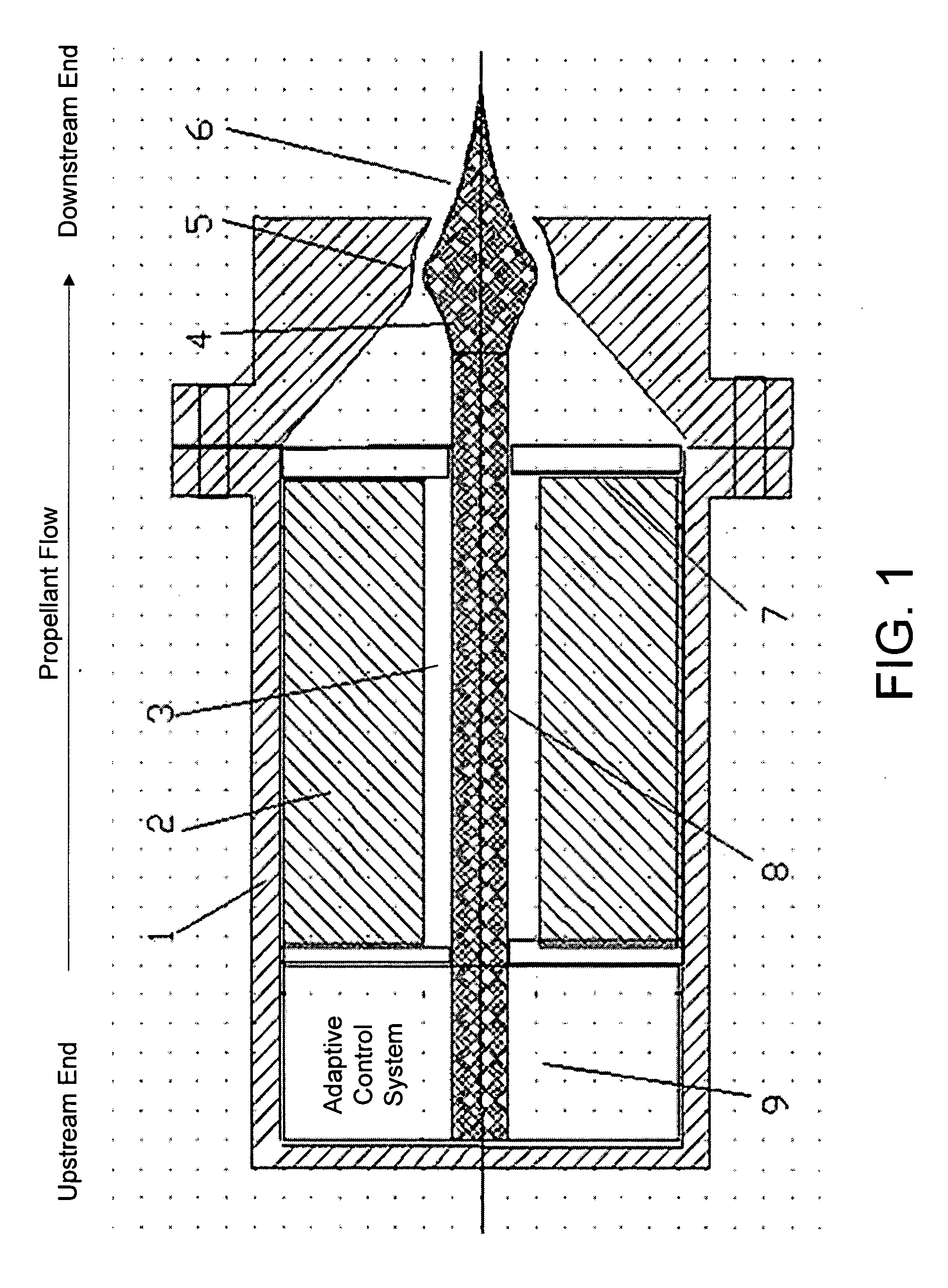

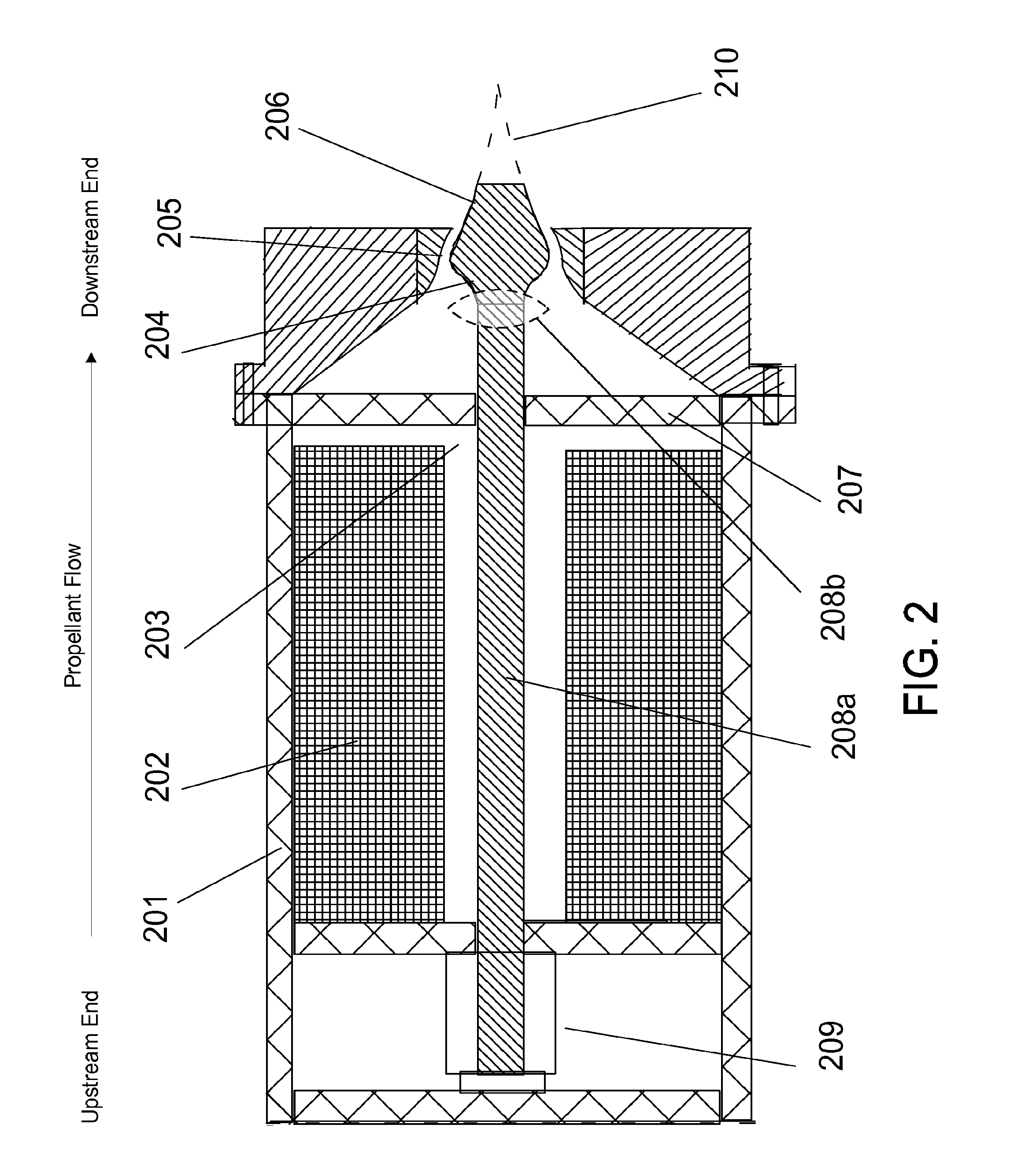

Systems and methods for varying the thrust of rocket motors and engines while maintaining higher efficiency using moveable plug nozzles

ActiveUS20050188677A1Improve efficiencyRocket engine plantsHot gas positive displacement engine plantsCombustion chamberControl system

The thrust of a rocket motor can be varied while maintaining efficiency over a range of pressure ratios using a design that allows for changing the relative position of a plug and a combustion chamber exit. The plug or the chamber exit may be attached to an adaptive control system for position modification. The plug may be positioned in a plug nozzle configuration or in an expansion-deflection (ED) configuration. In either configuration, the elongated downstream portion of the plug allows for efficiency over a wide range of pressure ratios, while ability to change plug position with respect to the chamber exit allows adjustment of rocket thrust.

Owner:GHKN ENG

Systems and methods for varying the thrust of rocket motors and engines while maintaining higher efficiency using moveable plug nozzles

The thrust of a rocket motor can be varied to optimize Nozzle Pressure Ratio (NPR) using a design that allows for adjusting the relative position of a plug and a combustion chamber exit. The plug or the exit may be attached to an adaptive control system for position modification. The relative position of the plug and exit may be adjusted to optimize NPR to account for changing propellant flow and / or changing ambient pressure.

Owner:GHKN ENG

Systems and methods for varying the thrust of rocket motors and engines while maintaining higher efficiency using moveable plug nozzles

ActiveUS7565797B2Rocket engine plantsHot gas positive displacement engine plantsCombustion chamberControl system

The thrust of a rocket motor can be varied while maintaining efficiency over a range of pressure ratios using a design that allows for changing the relative position of a plug and a combustion chamber exit. The plug or the chamber exit may be attached to an adaptive control system for position modification. The plug may be positioned in a plug nozzle configuration or in an expansion-deflection (ED) configuration. In either configuration, the elongated downstream portion of the plug allows for efficiency over a wide range of pressure ratios, while ability to change plug position with respect to the chamber exit allows adjustment of rocket thrust.

Owner:GHKN ENG

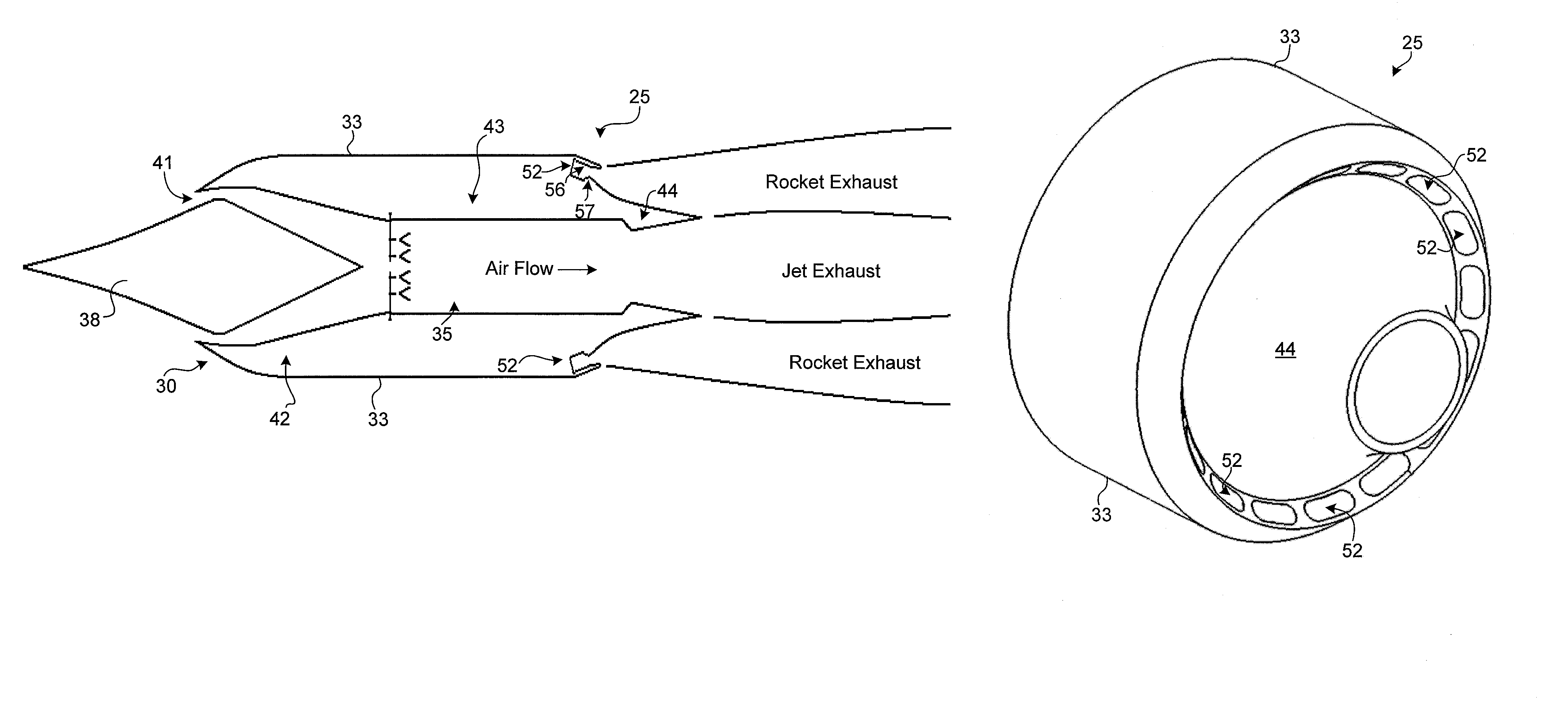

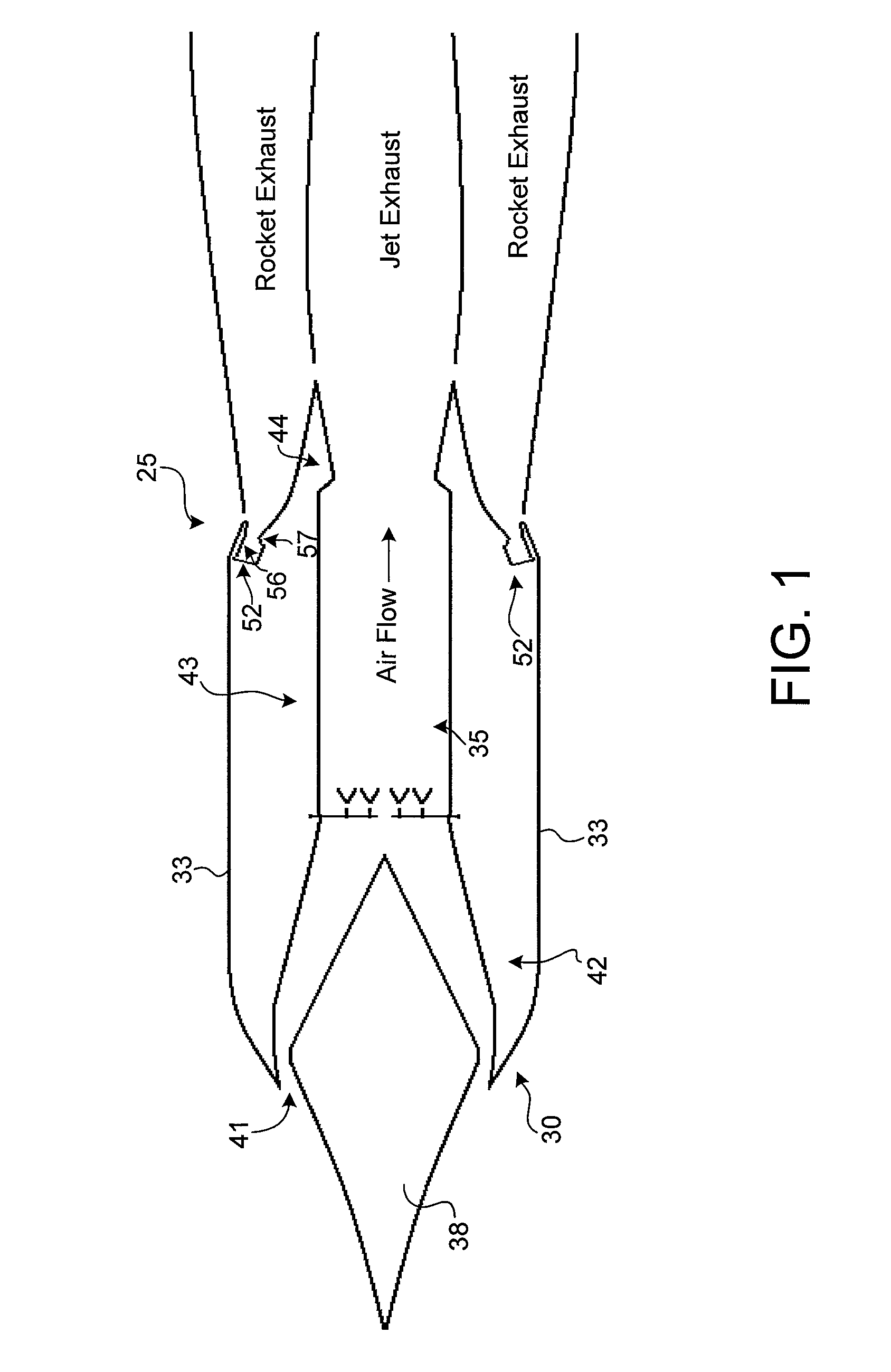

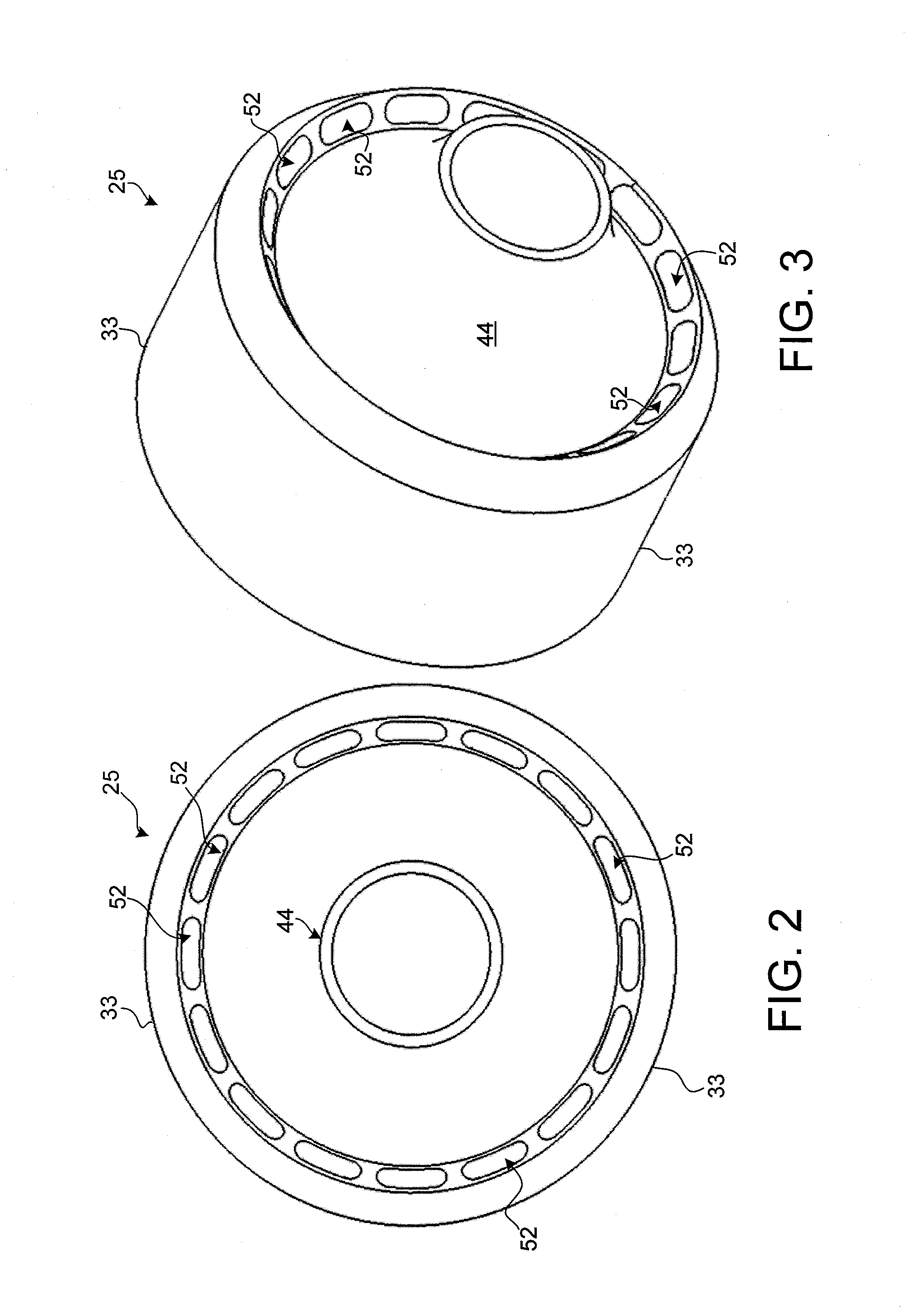

Rocket based combined cycle propulsion unit having external rocket thrusters

The present disclosure generally pertains to rocket based combined cycle (RBCC) propulsion units. In one exemplary embodiment, at least one rocket thruster is integrated with a jet engine but is external to the flow path of the jet engine, forming an altitude compensating plug nozzle. Since the rocket thruster is external to such flow path, the rocket flow from the rocket thruster interacts with the jet flow from the jet engine aft of the nozzle of the jet engine. Such interaction occurs without a significant performance penalty in the operation of the jet engine. In fact, it is possible that the interaction of the rocket flow with the jet flow may actually improve the efficiency of the jet engine under some conditions. Moreover, having the rocket thrusters positioned external to the flow path of the jet engine helps to avoid many of the problems plaguing conventional RBCC propulsion units.

Owner:UNIVERSITY OF ALABAMA

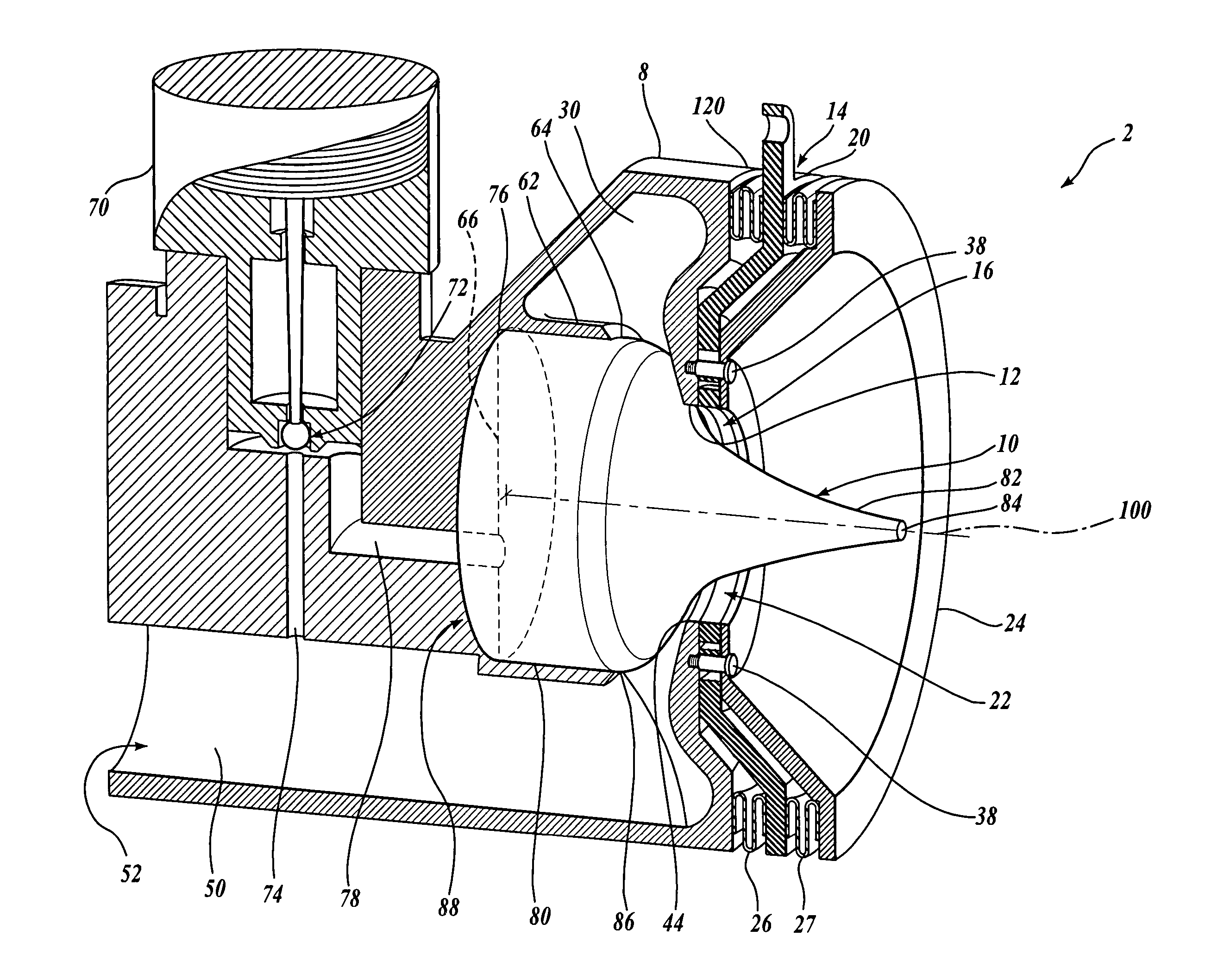

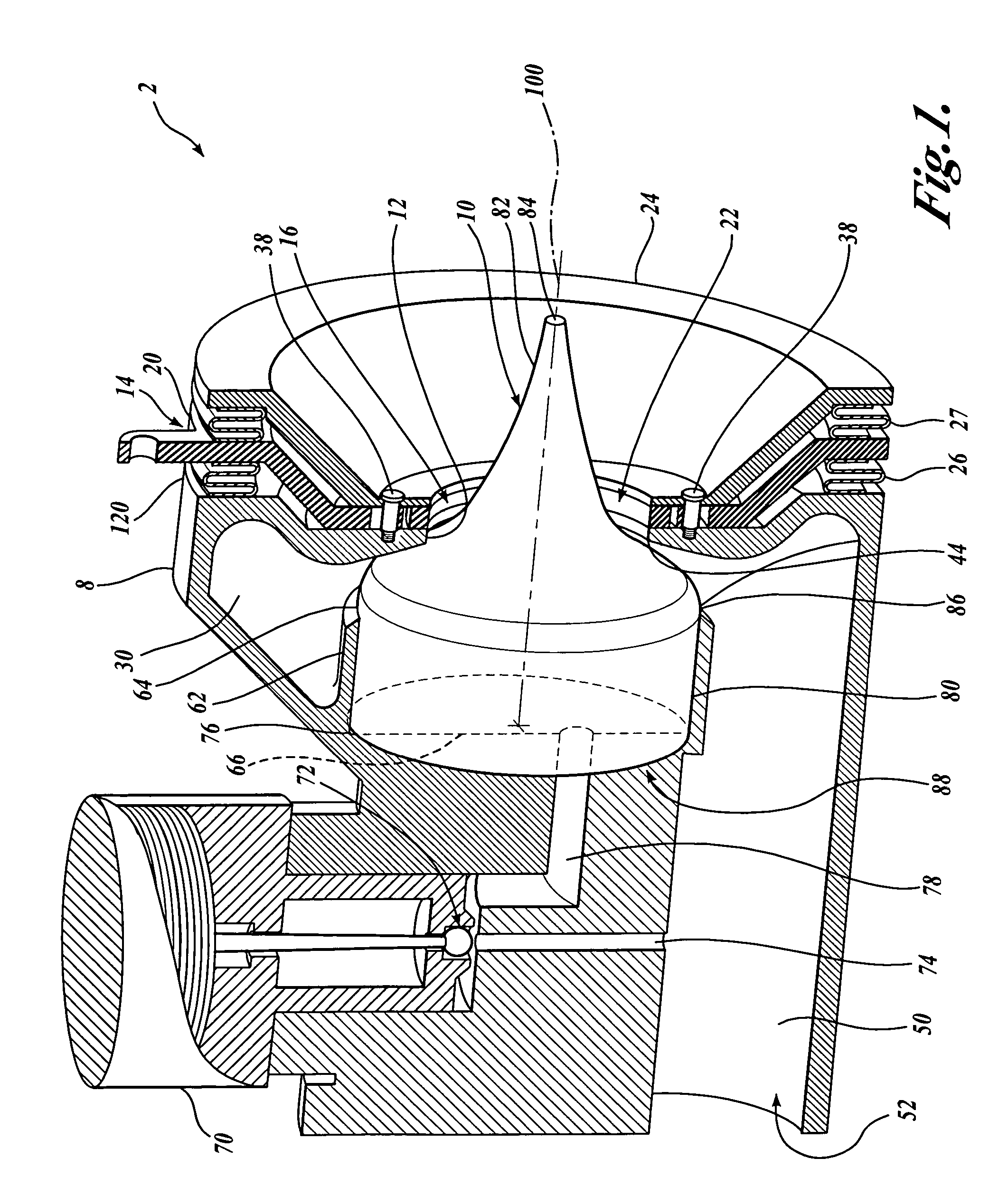

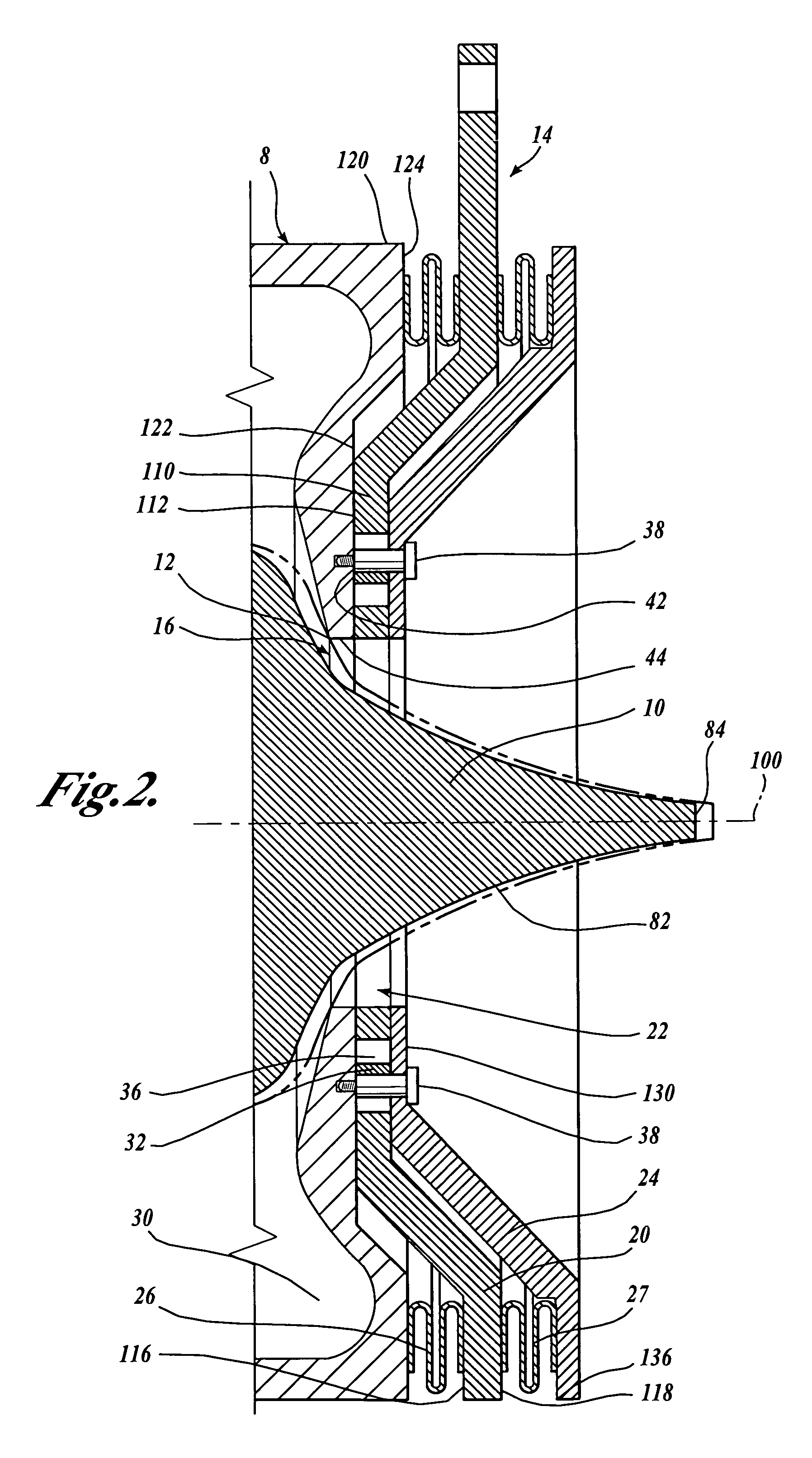

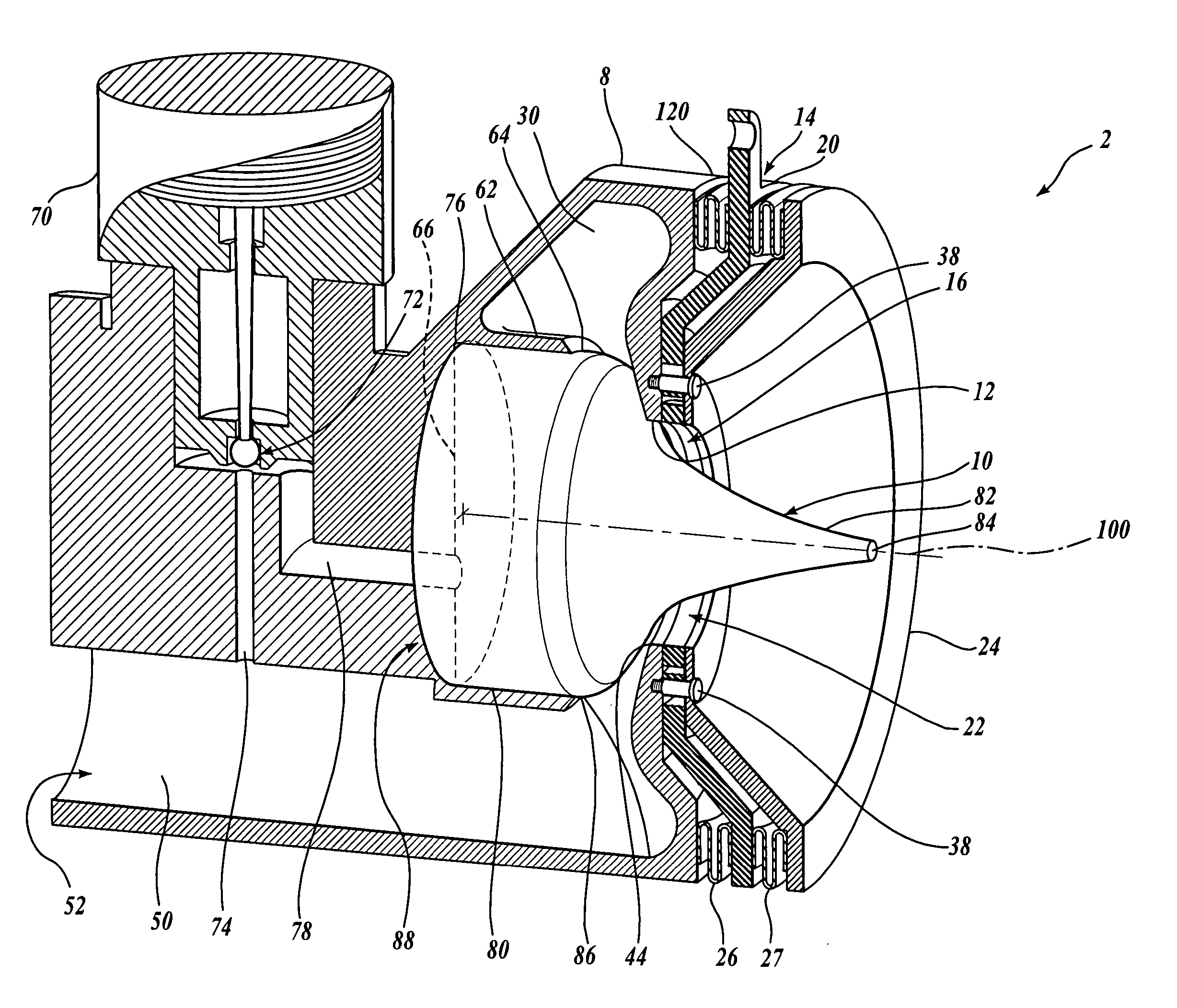

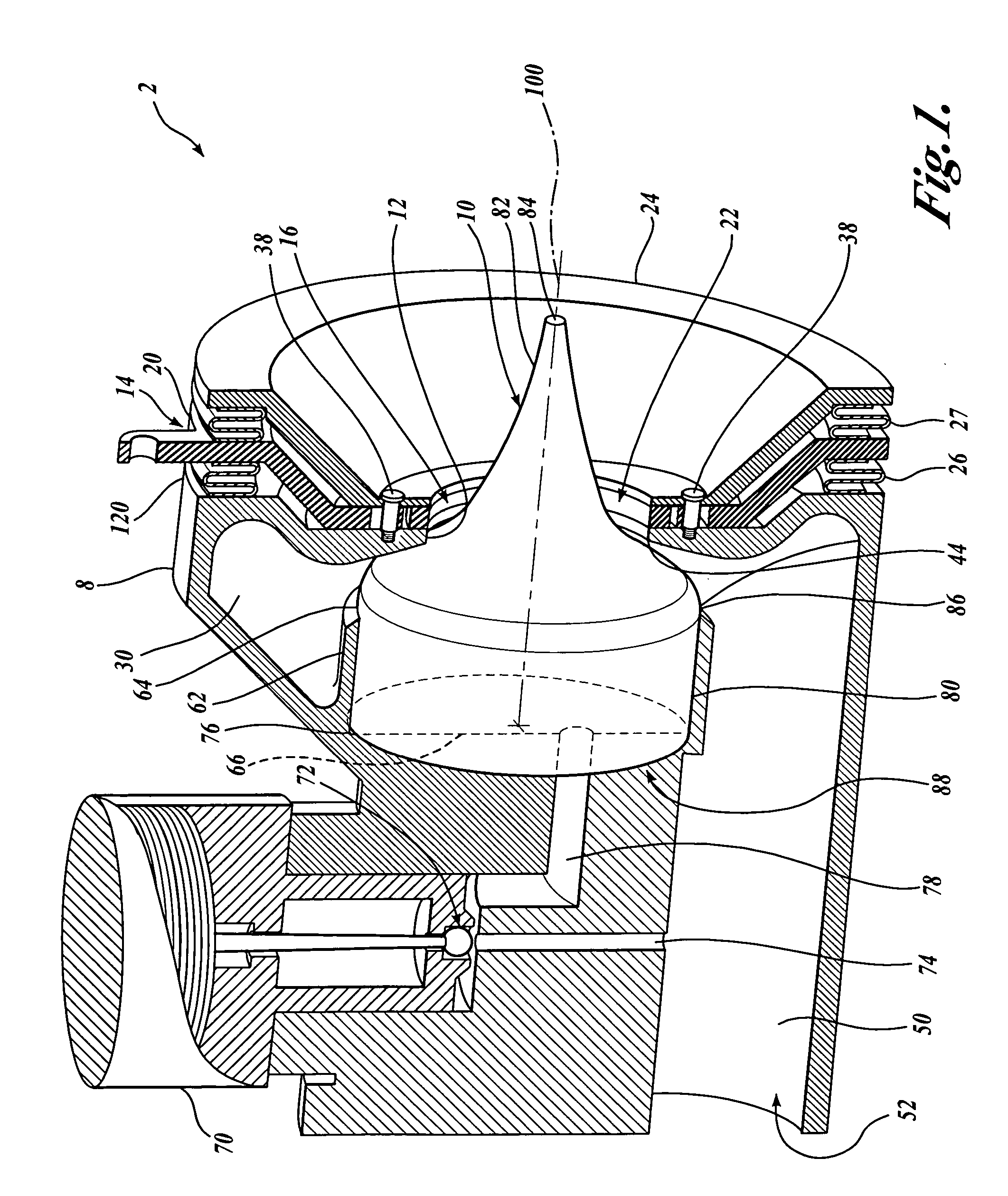

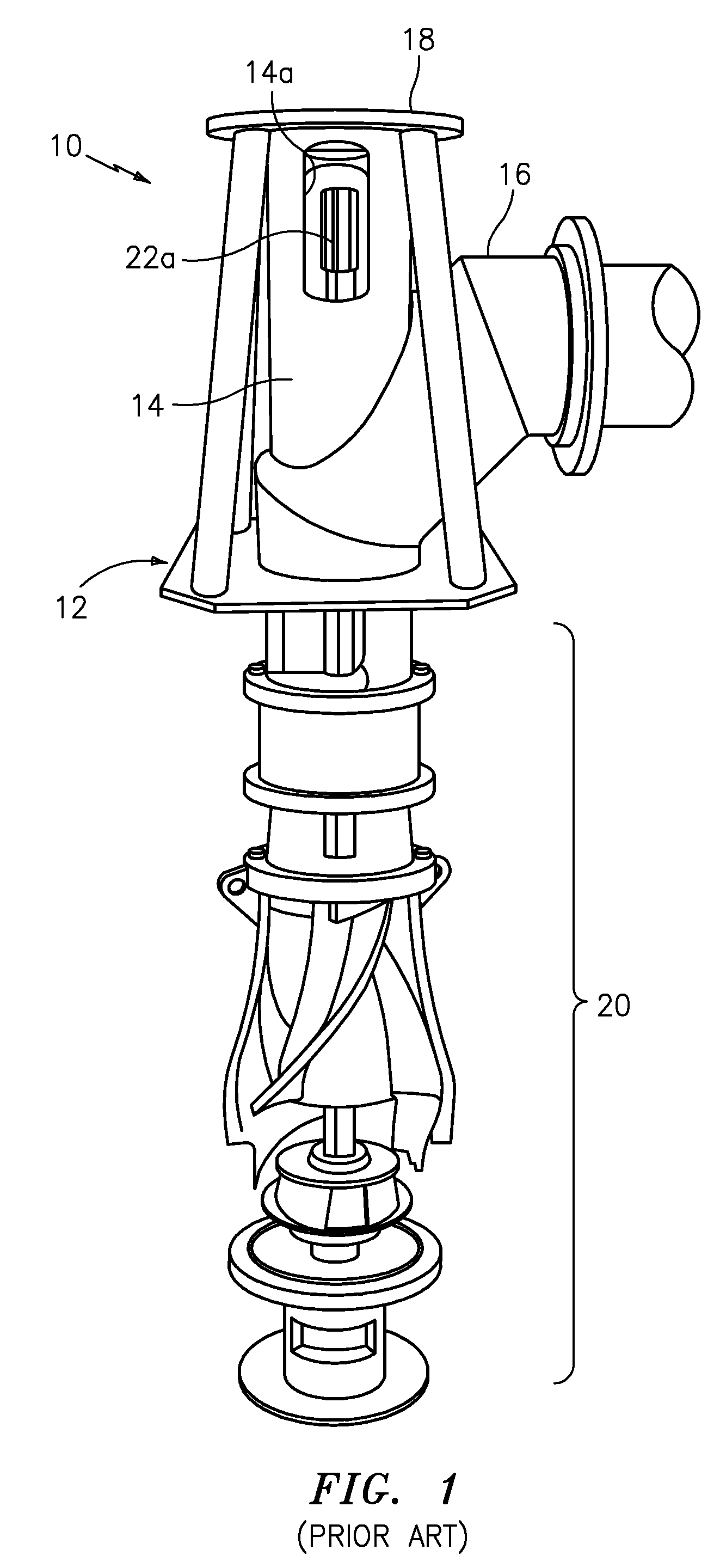

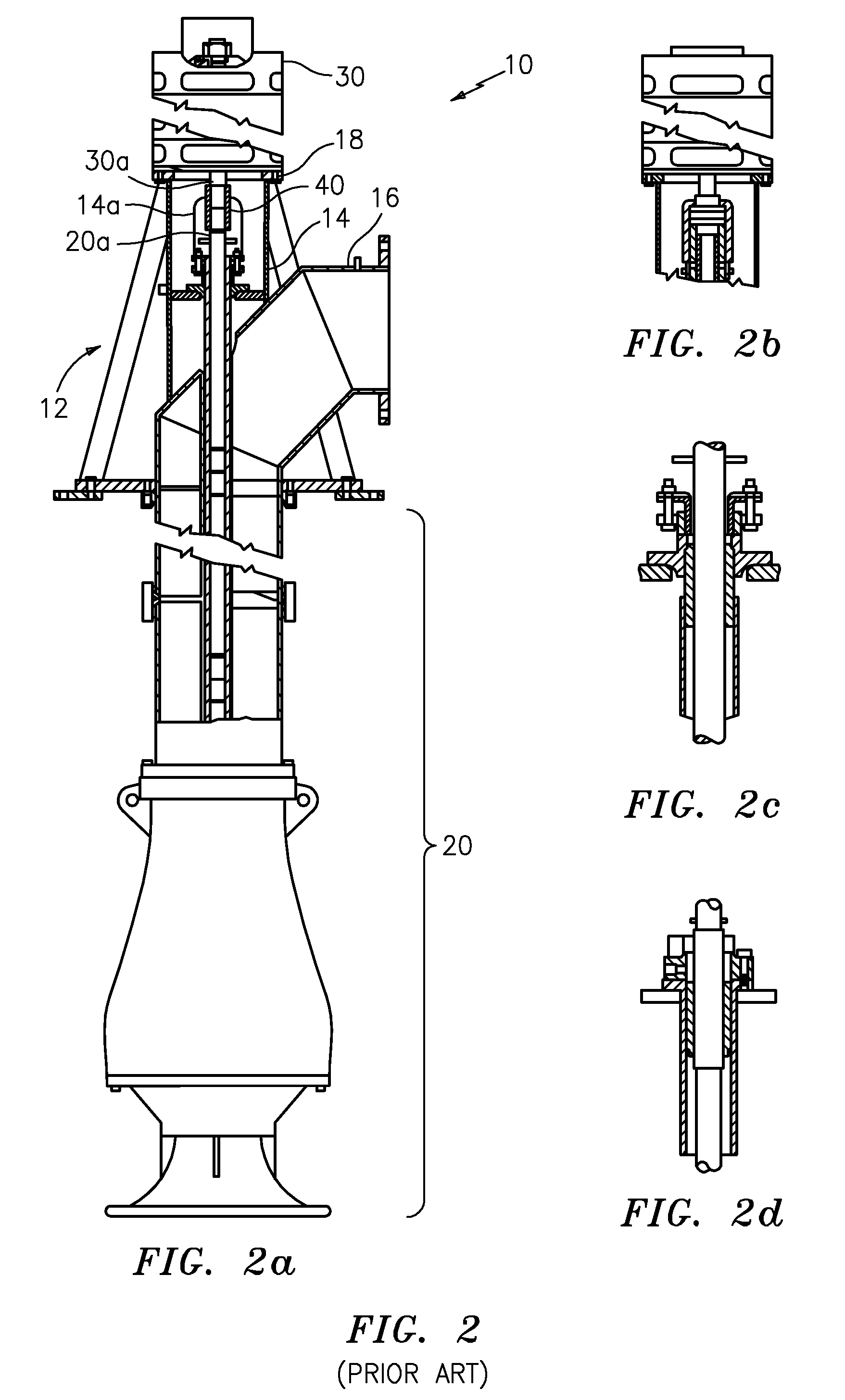

Thrust vector control system for a plug nozzle rocket engine

A thrust vector control system for a plug nozzle rocket engine for propelling and maneuvering a vehicle is disclosed. The plug nozzle rocket engine includes a housing having a nozzle throat, a plug disposed within the housing and positioned within the nozzle throat to define a space between the plug and the nozzle throat, and a thrust diverter moveably disposed relative to the housing to define an asymmetric pressure distribution along the plug for thrust-vectoring. In one embodiment, the thrust diverter is normally biased to a non-thrust-vectoring position, but is moveable in a plane substantially perpendicular to an axis extending longitudinally through the plug.

Owner:AEROJET ROCKETDYNE INC

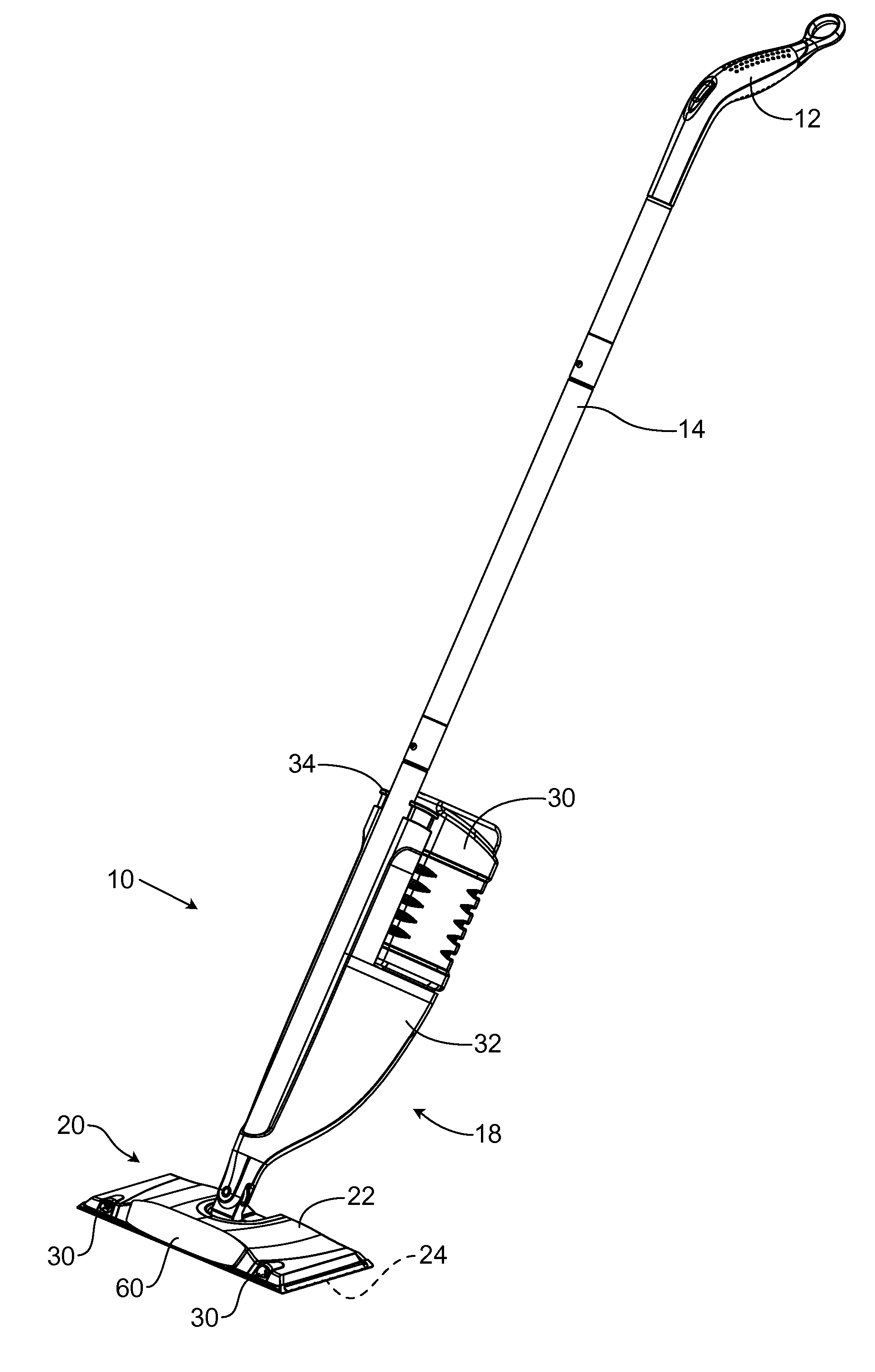

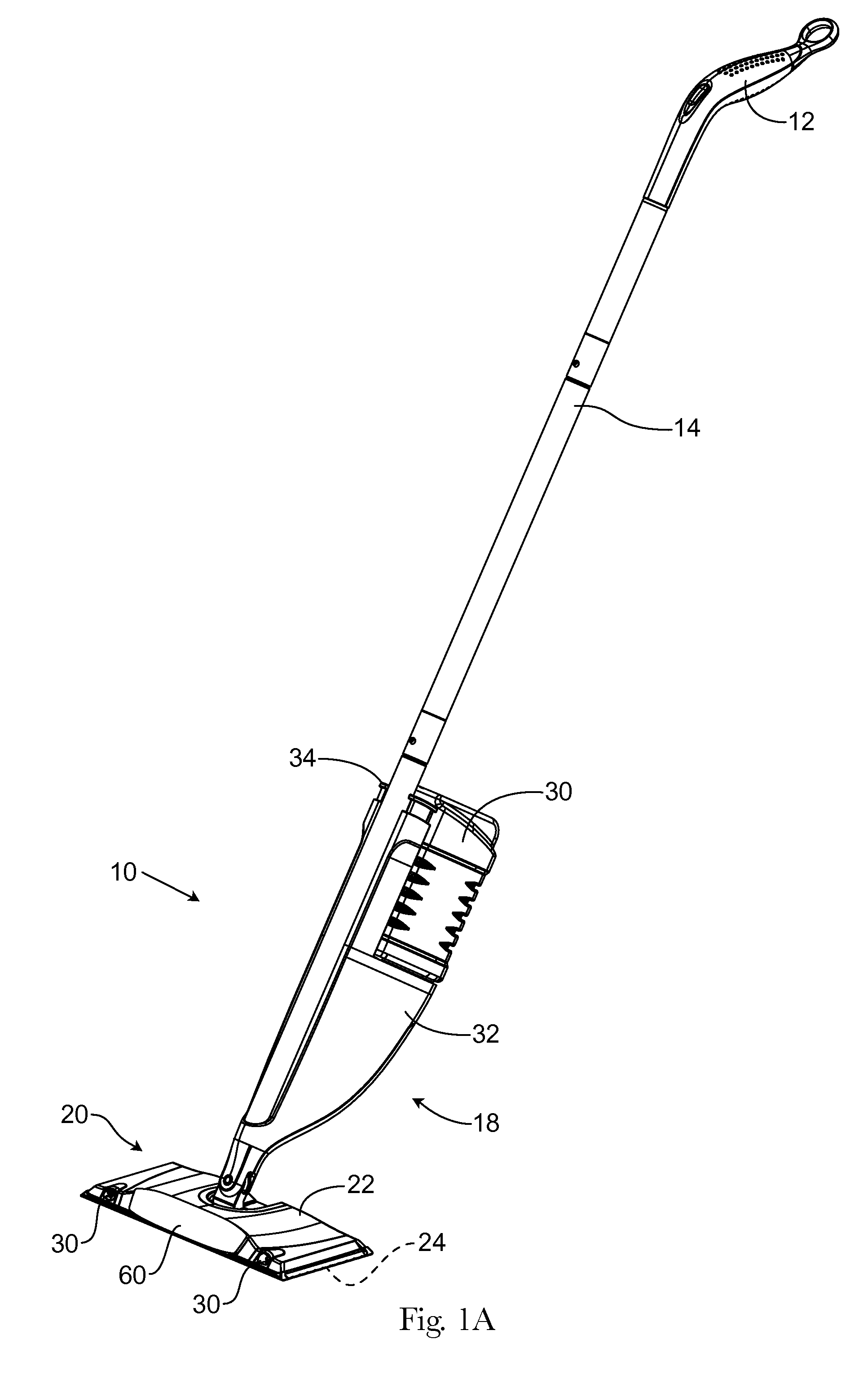

Plural nozzle cleaning implement

A plural nozzle cleaning implement. The nozzles are oriented inwardly, to provide a converging spray pattern. The converging spray pattern provides more coverage of the target surface, which increases residence time of fluid sprayed onto debris.

Owner:THE PROCTER & GAMBLE COMPANY

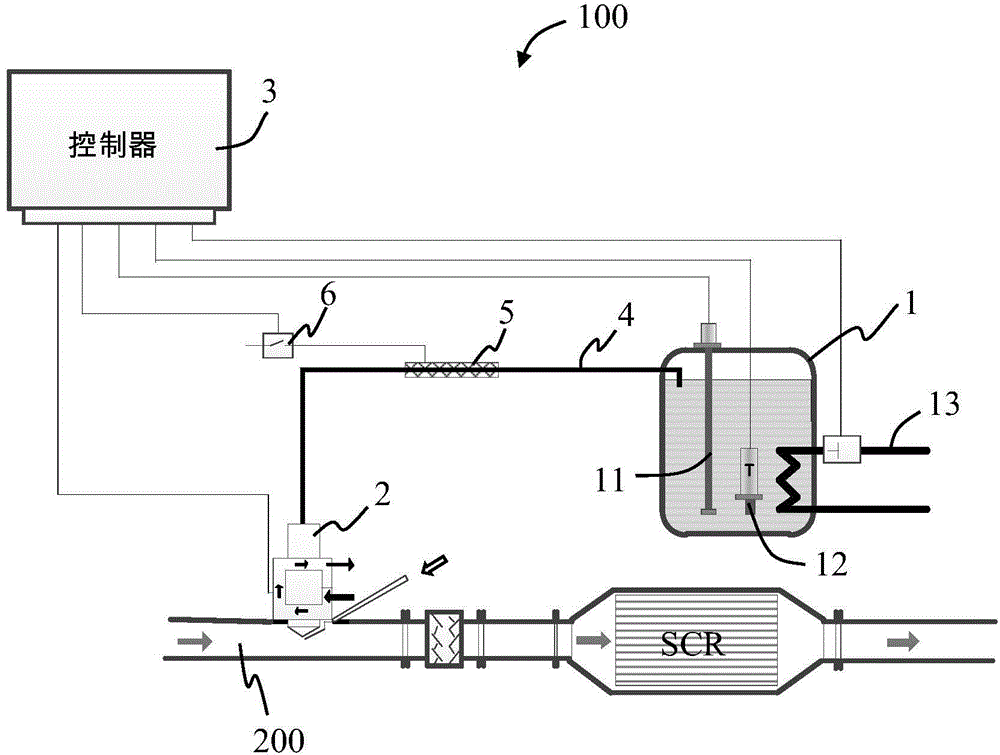

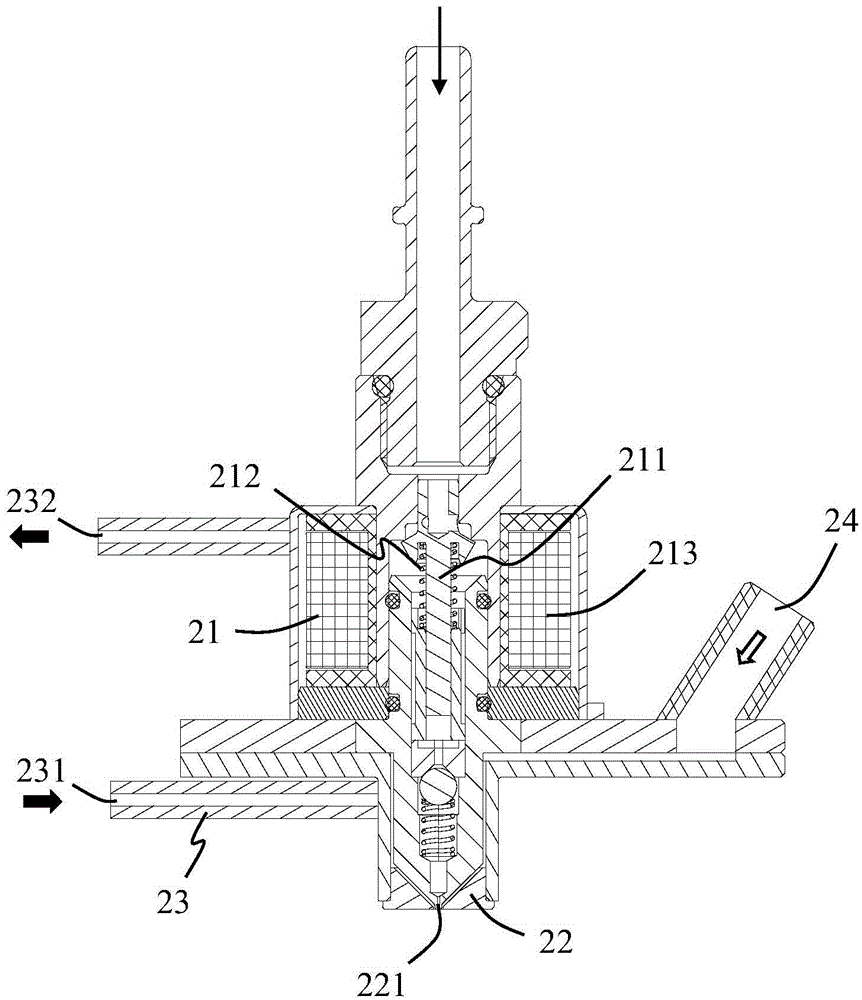

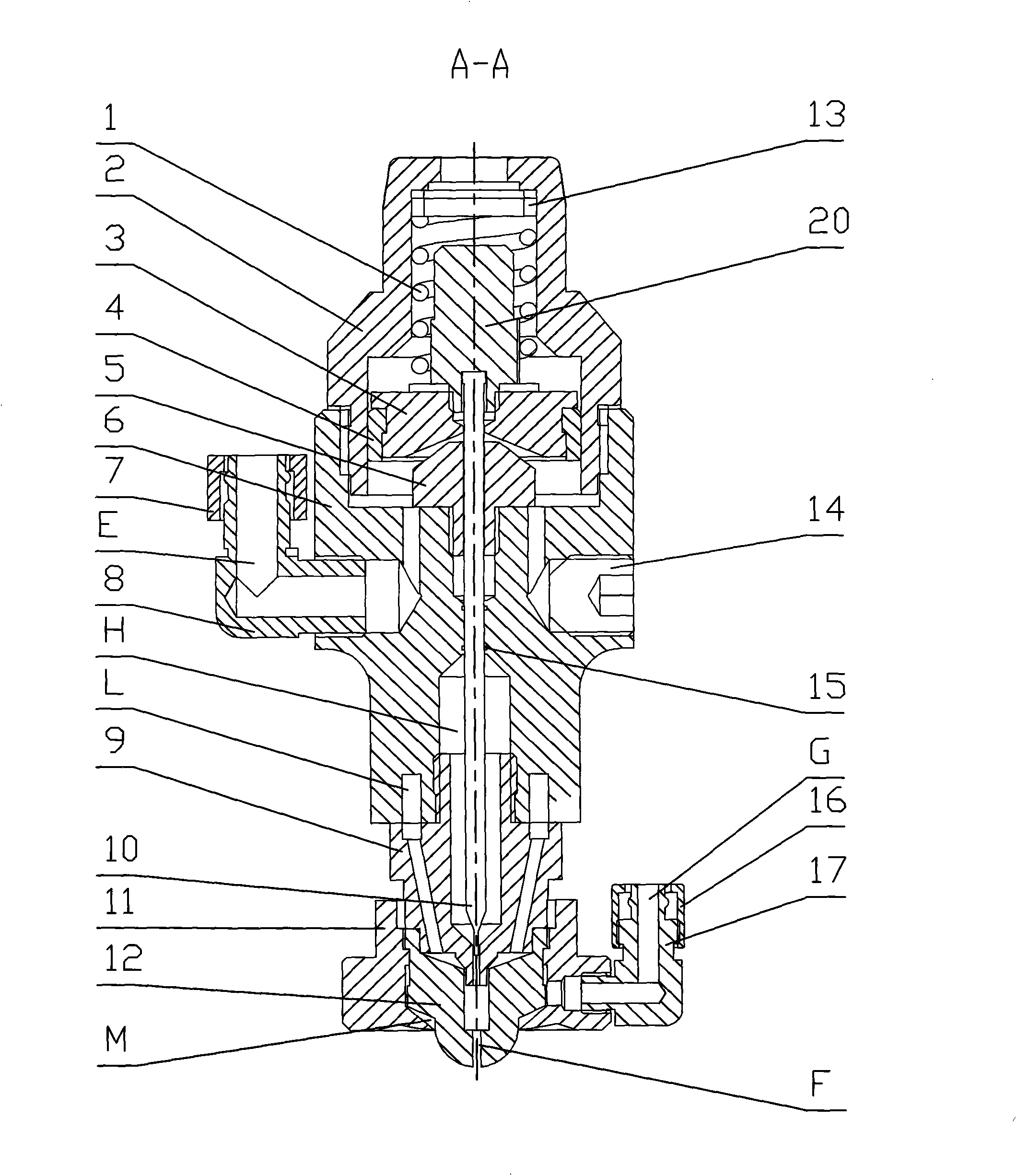

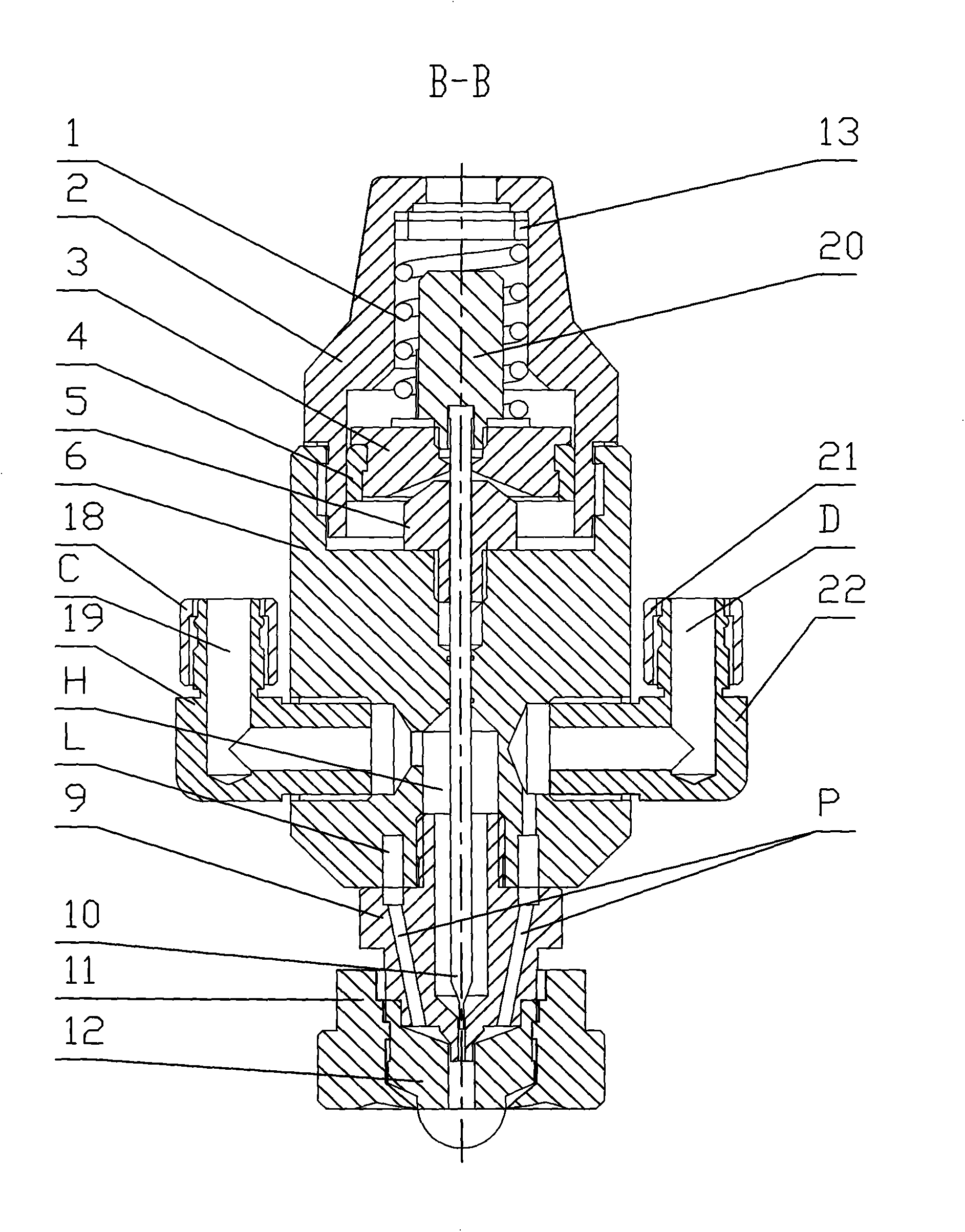

Metering pump nozzle and engine exhaust post-treatment system with same

ActiveCN105986860AAvoid risk of leakageReduced risk of burnoutExhaust apparatusSilencing apparatusEngineeringHigh pressure

A metering pump nozzle and an engine exhaust post-treatment system with the same are provided. The metering pump nozzle comprises a pump and a nozzle positioned below the pump, the pump and the nozzle are adjacent and integrated together, the pump is used for pumping urea solution, the nozzle is mounted to an exhaust pipe of an engine to spray the urea solution into the exhaust pipe, the metering pump nozzle also comprises a cooling device positioned around the nozzle and / or the pump and an air atomizer for mixing with the urea solution. A high-pressure pipe connecting the pump and the nozzle is omitted, avoiding the risk that the high-pressure pipe leaks; the cooling device is arranged to reduce temperature, lessening the risk that the nozzle and / or the pump are burned out by high-temperature exhaust; in addition, the air atomizer is arranged to provide improved atomization of the urea solution.

Owner:TENNECO SUZHOU EMISSION SYST

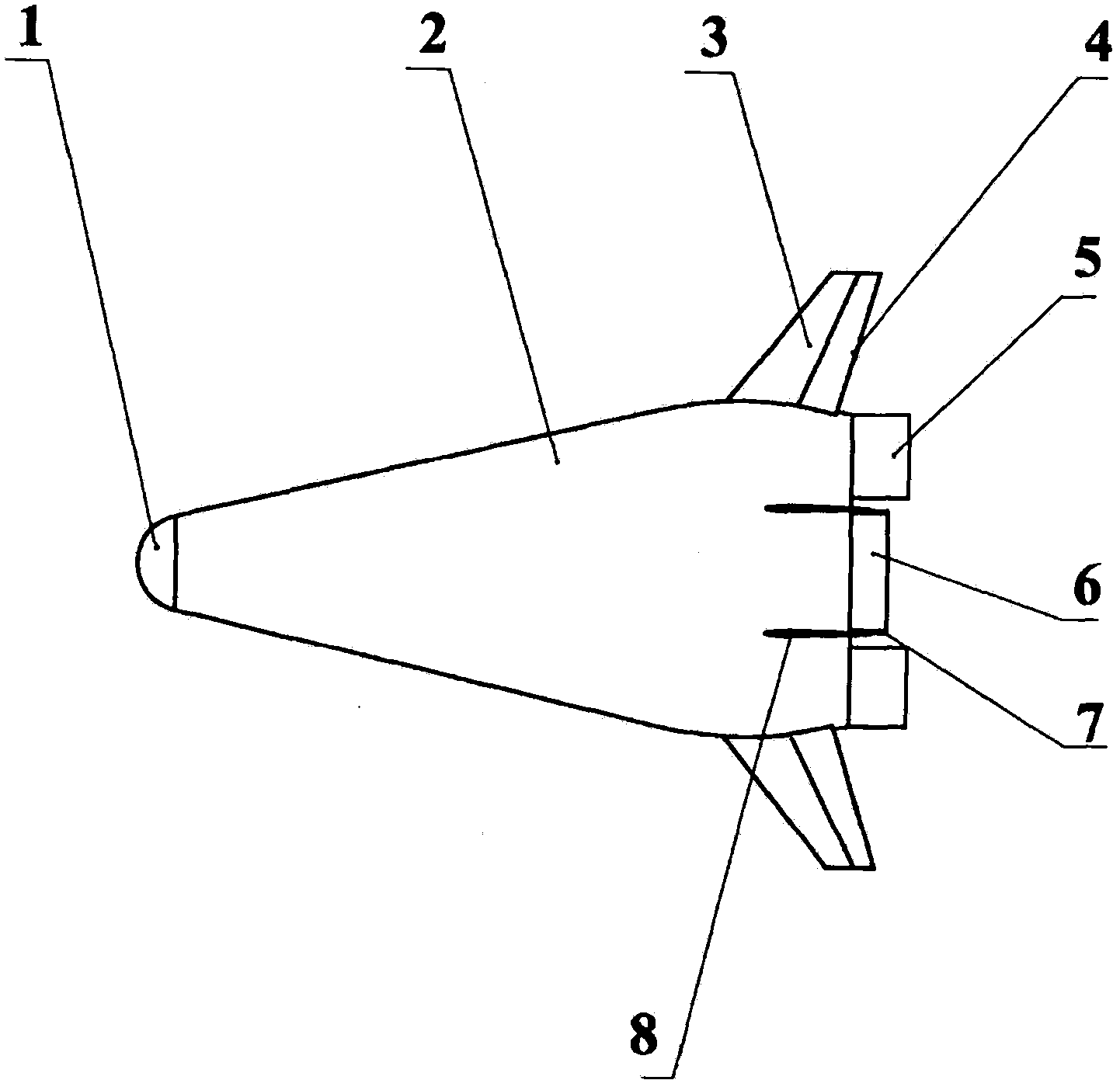

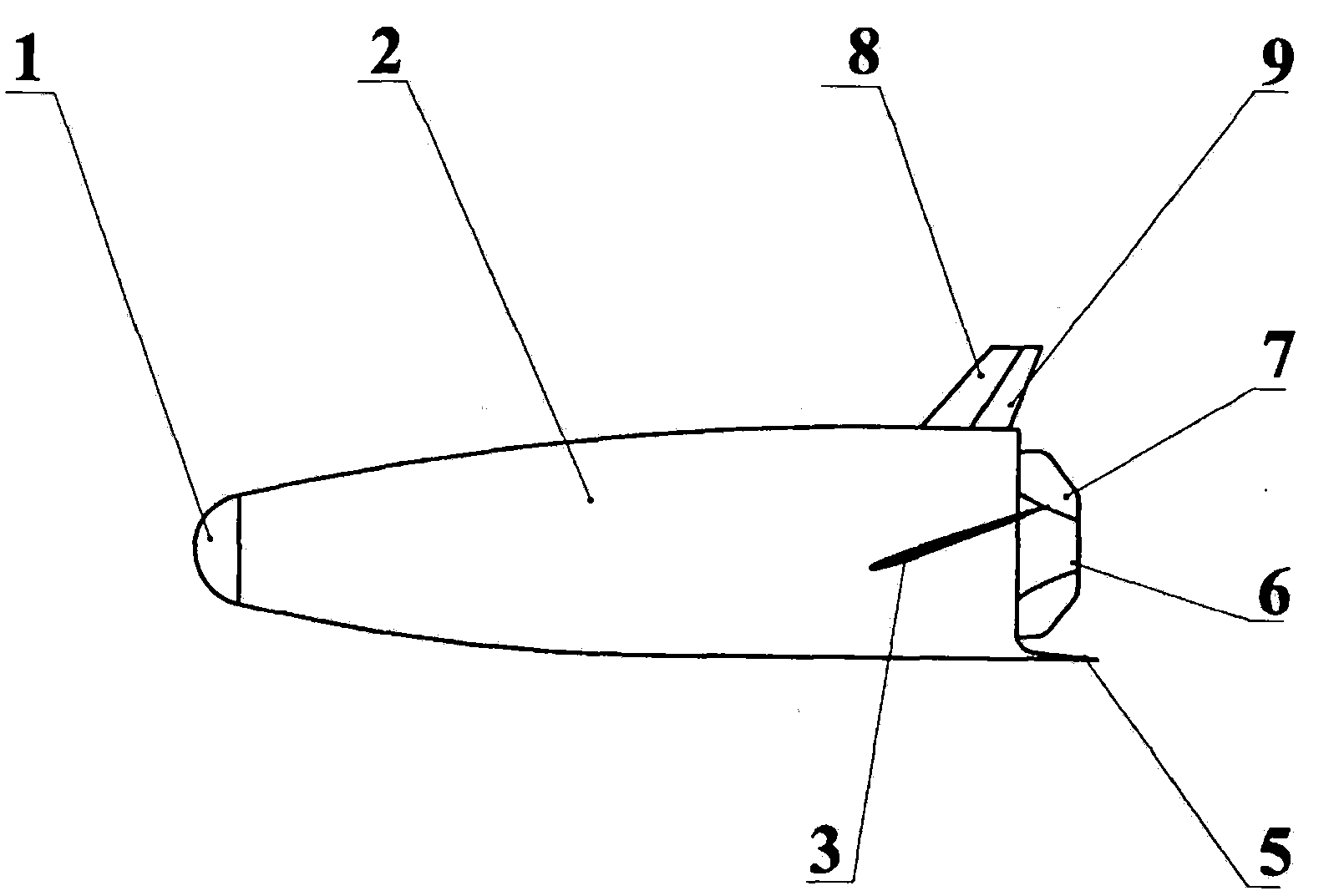

An Aerodynamic Layout of a Transatmospheric Reusable Vehicle

InactiveCN105659735BLow cost of launch usageShort launch lead timeSpace shuttlesLiquid hydrogenHigh lift

The invention discloses an aerodynamic layout of a transatmospheric reusable aircraft, which comprises a head, a fuselage, a horizontal wing, a vertical tail, a body flap and a liquid hydrogen / liquid oxygen linear plug-type nozzle rocket engine. The invention has no booster, and adopts a single stage to vertically launch into orbit from the ground; after completing the mission, it can return to the atmosphere and glide horizontally to land, and can be completely reused after recovery. Through reasonable aerodynamic configuration and optimized design, the aircraft has a high lift-to-drag ratio and good stability and maneuverability in a wide range of altitudes and speeds. At the same time, the fuselage has a large effective volume and needs to carry propulsion Dose less. The invention has low launching cost, short launching preparation period and high reliability. It can overcome the shortcomings of current space vehicles that cannot be completely reused, expensive to launch, and cumbersome to use and maintain. It can be used not only for military space missions, but also for commercial and civil space services.

Owner:BEIHANG UNIV

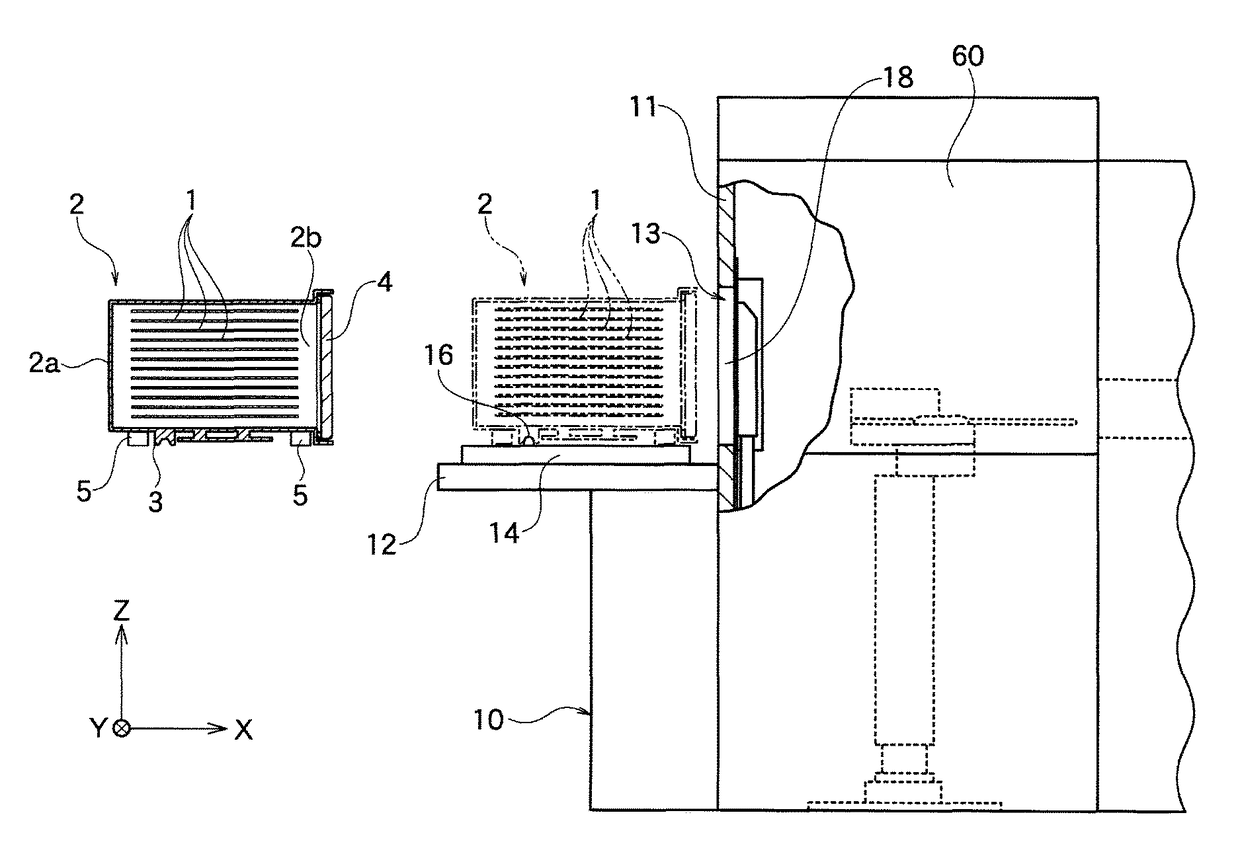

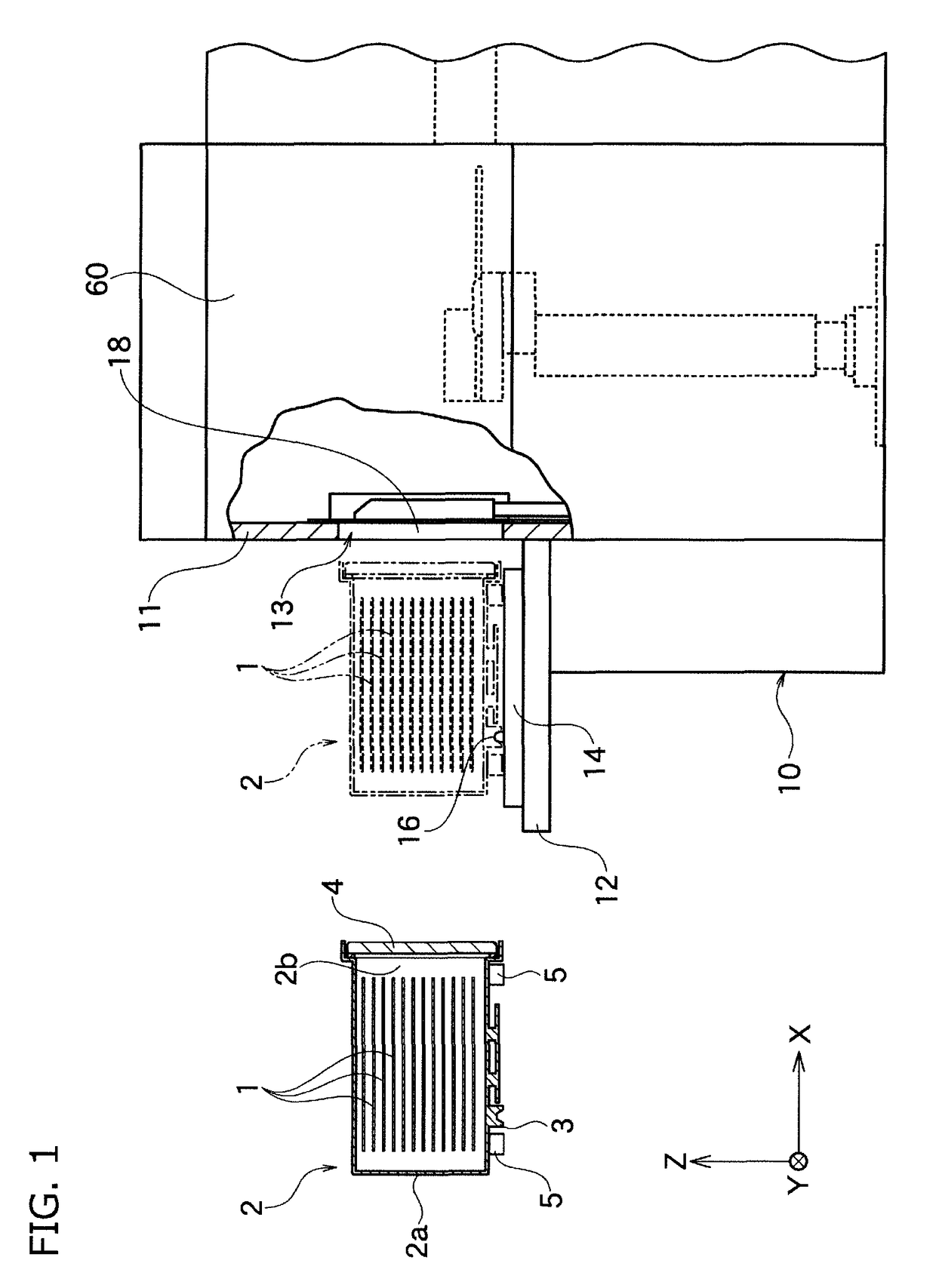

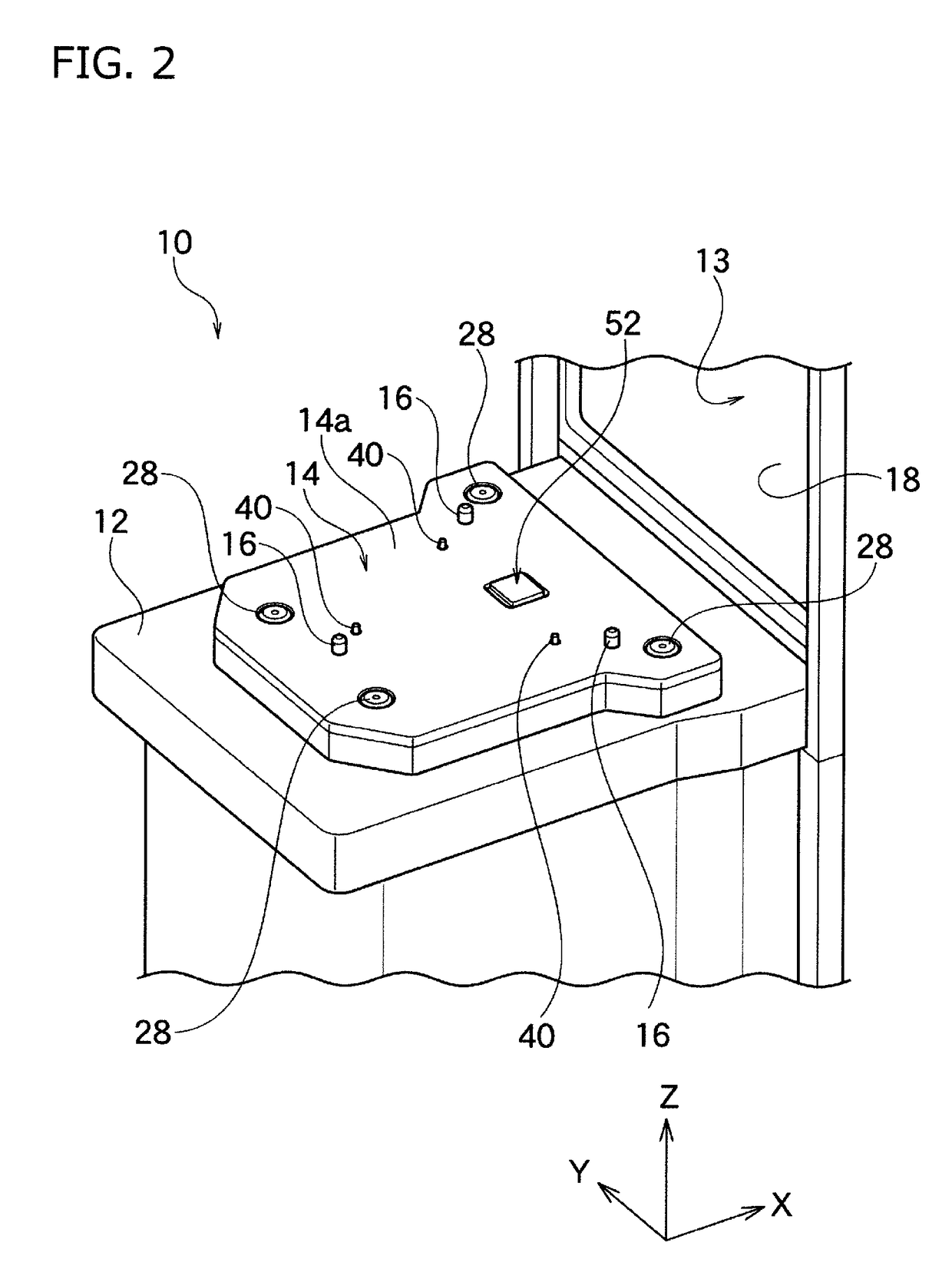

Purge device and load port apparatus including the same

To generate a gas-curtain for a load-port-apparatus and to supply a purge-gas into a pod by a single gas source, provided is a gas purge device including: purge nozzles extending along an outer side of side edges of the opening portion; a curtain nozzle arranged above an upper edge of the opening portion; a gas supply pipe arranged in parallel to each purge nozzle, for supplying an inert gas to the purge nozzle and the curtain nozzle, the gas being supplied from the gas supply pipe to the purge nozzle in a direction orthogonal to an extending direction of the gas supply pipe; and a conductance adjusting unit arranged at an end portion of the gas supply pipe, for generating a pressure loss in a gas flow in a configuration in which the gas is supplied to the curtain nozzle at the end portion of the gas supply pipe.

Owner:TDK CORPARATION

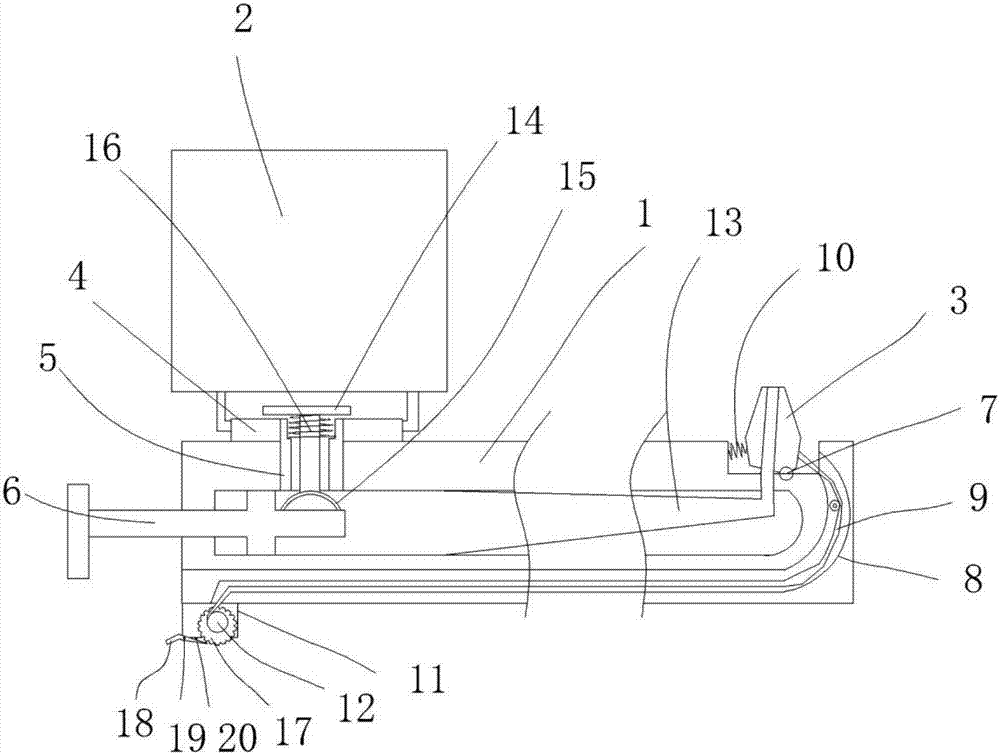

Glue gun

InactiveCN103406241AReduce wasteGlue evenlyLiquid surface applicatorsCoatingsPulp and paper industryFlange

The invention discloses a glue gun which comprises a glue nozzle, wherein a glue feeding hole is formed in the glue nozzle; a scraper blade is arranged at the head of the glue nozzle; a glue body accommodating cavity is formed in the lower end of the scraper blade; two sides of the glue body accommodating cavity extend towards the head of a nozzle body to form cambered flanges; a through hole is formed in the scraper blade; the lower end of the through hole is communicated with the glue body accommodating cavity; the upper end of the through hole is communicated with the end face of the upper end of the scraper blade; the through hole in the upper end of the scraper blade is connected with a hollow hose; the other end of the hollow hose is connected with a glue body collection device. When the glue gun is used for dispensing glue, redundant glue bodies in a slit can be scraped to another slit with a small amount of glue bodies under the action of the scraper blade, and the residual glue bodies are sucked into the glue body collection device. Therefore, the glue gun has the beneficial effects that the glue dispension is uniform, the redundant glue bodies can be recycled, the waste of glue bodies is effectively reduced, and the cost is reduced.

Owner:ZHEJIANG HAOQING AUTOMOBILE MFG CO LTD +1

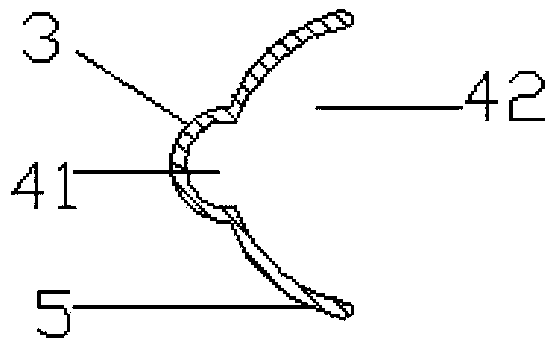

Drug feeding device for oral laryngeal part

The invention discloses a drug feeding device for an oral laryngeal part, which comprises a drug feeding catheter and a drug storage bottle connected with the drug feeding catheter; the front end of the drug feeding catheter is provided with a drug nozzle, and the outside end of the drug feeding catheter is provided with a piston push rod; the drug nozzle is connected to the inside end of the drug feeding catheter through a rotating shaft and a control hole is arranged in the side wall of the drug feeding catheter; a pull cable is arranged in the control hole, one end of the pull cable is fixed in the middle of the side face of the drug nozzle; a reset spring is arranged between the side face of the drug nozzle and the drug feeding catheter, and the reset spring and the pull cable are arranged on a symmetrical side face of the drug nozzle; the outside end of the drug feeding catheter is provided with a rotary supporting base, and a winding shaft is arranged on the rotary supporting base. The drug feeding device is reasonable in structure setting and convenient to operate; the drug nozzle position is adjusted as required; meanwhile, the drug spraying amount can also be controlled; therefore, the application range is greatly improved, the using stability is good and the practicability is strong.

Owner:THE SECOND AFFILIATED HOSPITAL OF SHANDONG FIRST MEDICAL UNIV

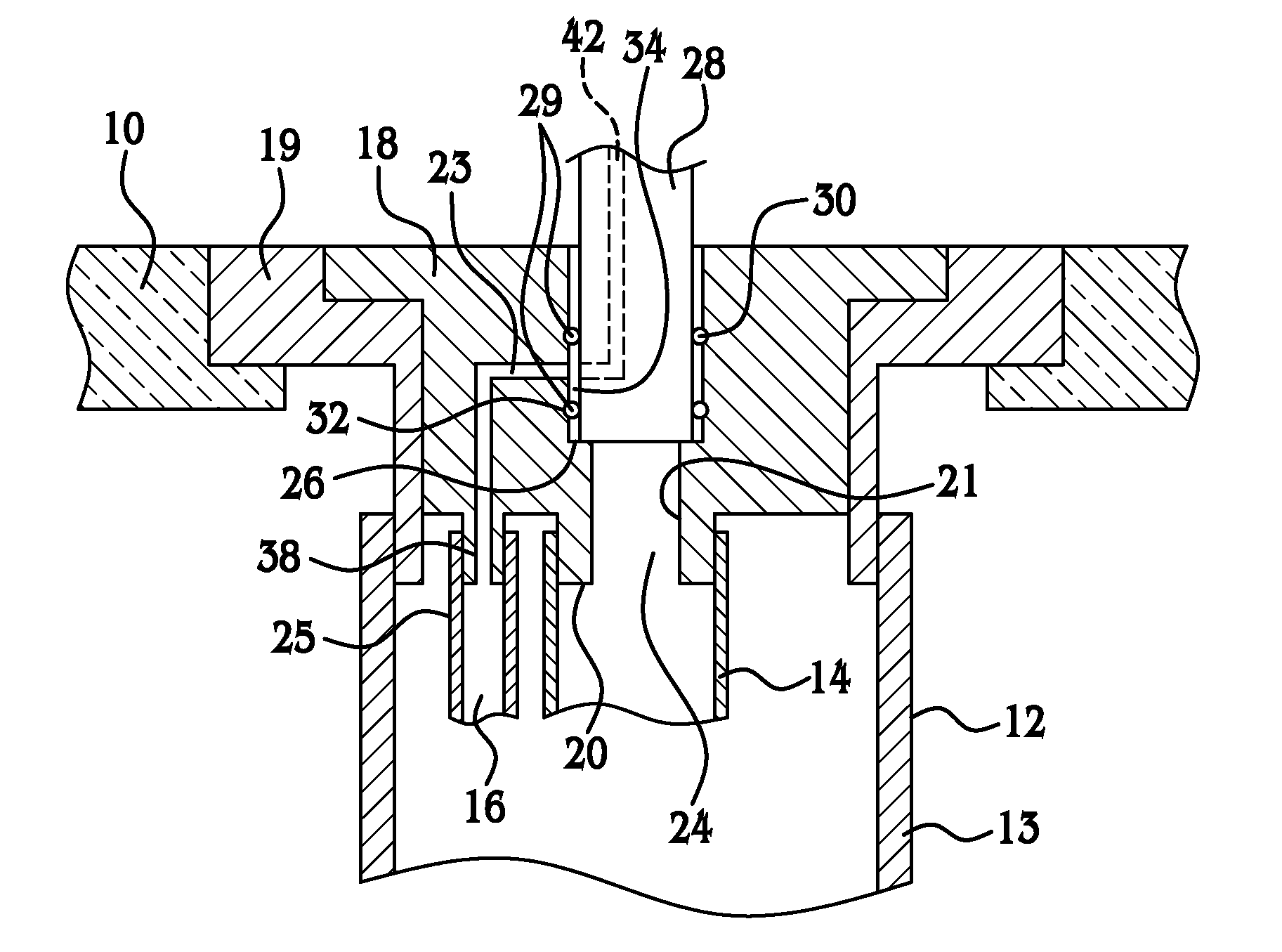

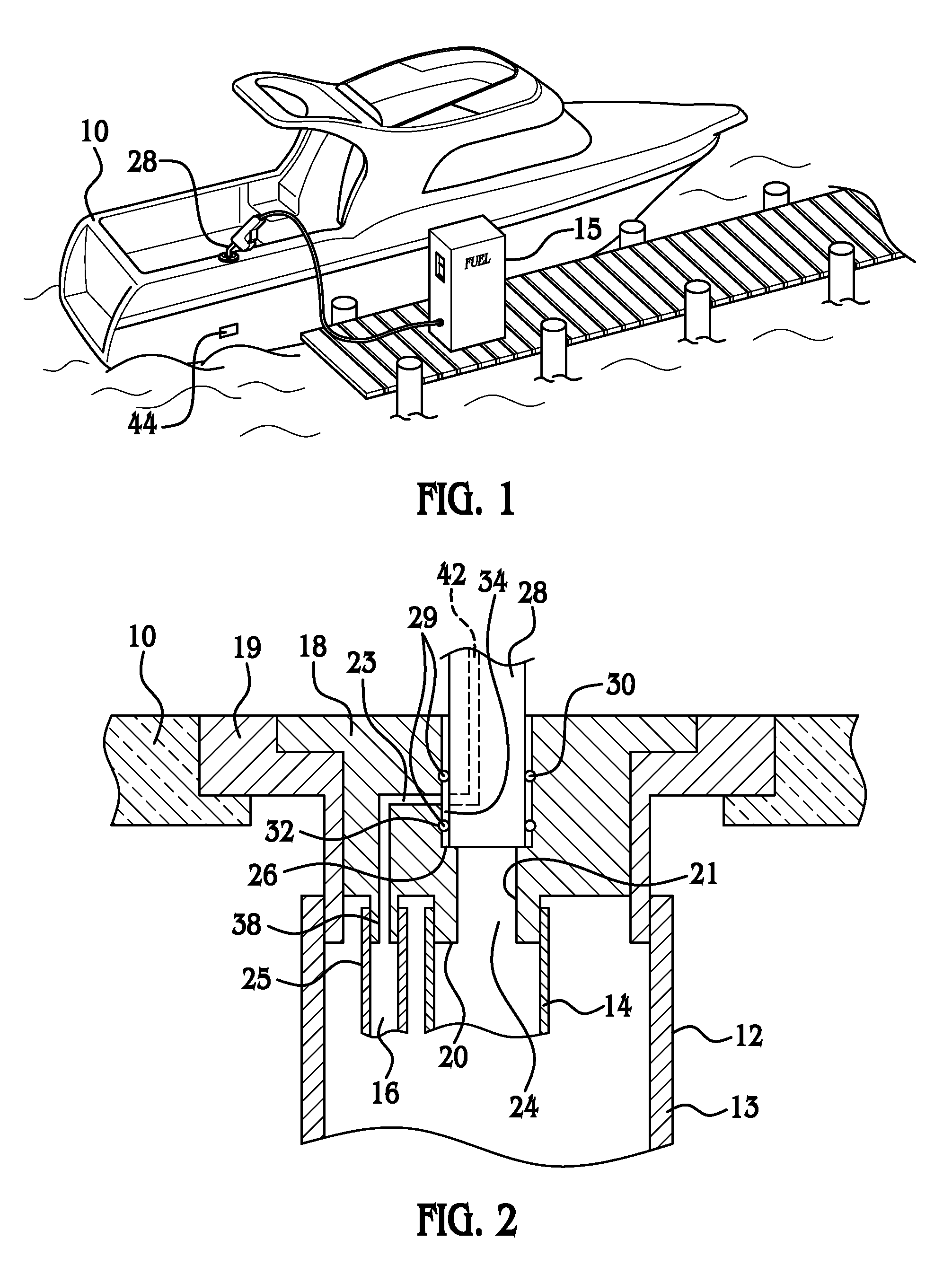

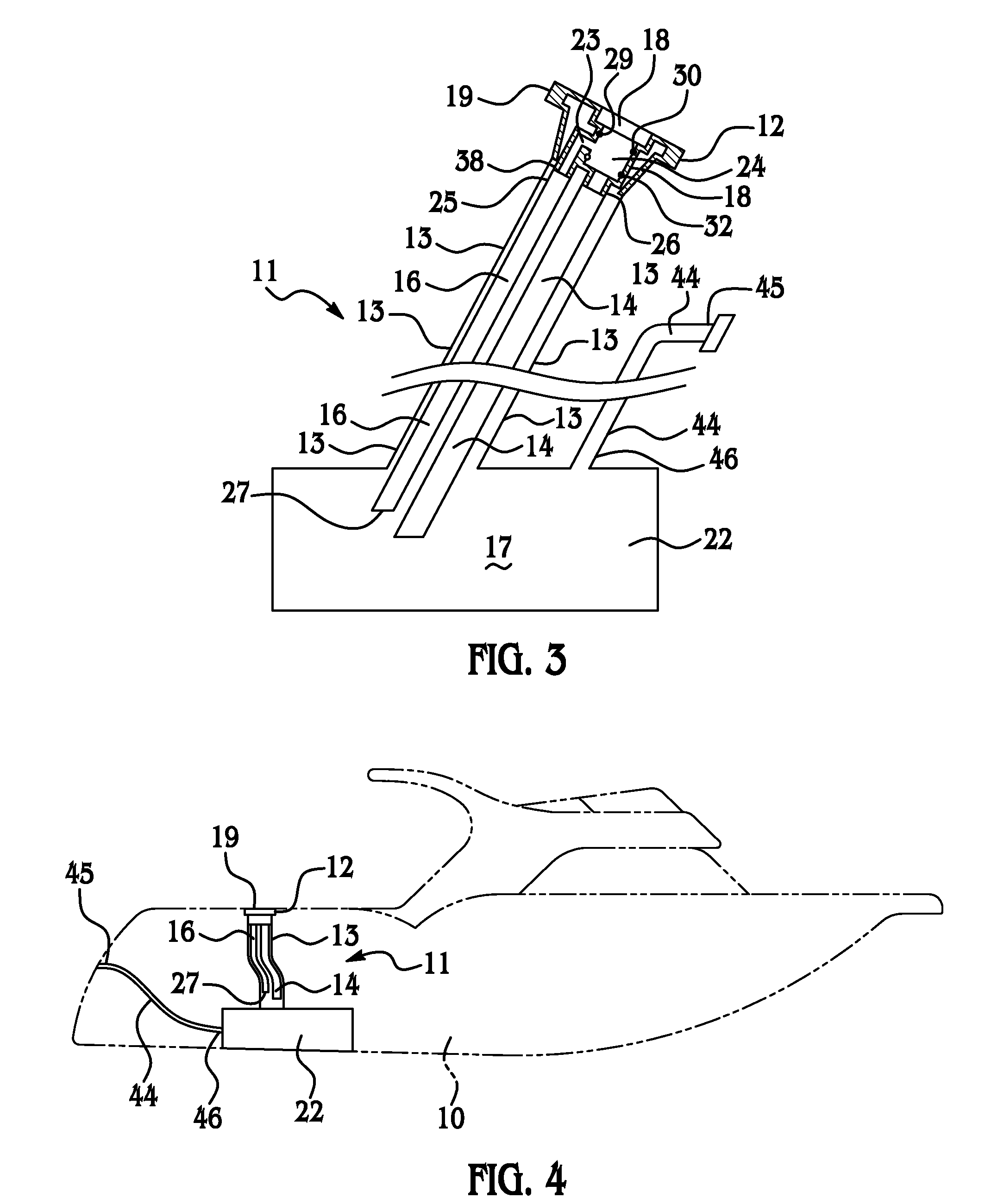

Filler tube assembly

ActiveUS7757729B2Prevent leakageLoad accommodationPackaging automatic controlFuel tankPressure sense

A filler tube assembly is used with a fuel pump nozzle having a pressure sensing port. The filler tube assembly includes a receiver having an inner wall defining an aperture, which receives the pump nozzle. The inner wall defines an orifice and a seal is coupled to the inner wall about the orifice for defining a chamber between the inner wall, the seal, and the fuel pump nozzle when the fuel pump nozzle is disposed in the aperture. A vacuum tube has a coupled end in fluid communication with the orifice and an open end in fluid communication with the fuel tank. The receiver defines a rim for seating the fuel pump nozzle in the aperture to align the pressure sensing port with the orifice. When fuel covers the open end of the vacuum tube, a pressure change is transmitted through the filler tube assembly to the pressure sensing port.

Owner:SMITH DAVID G

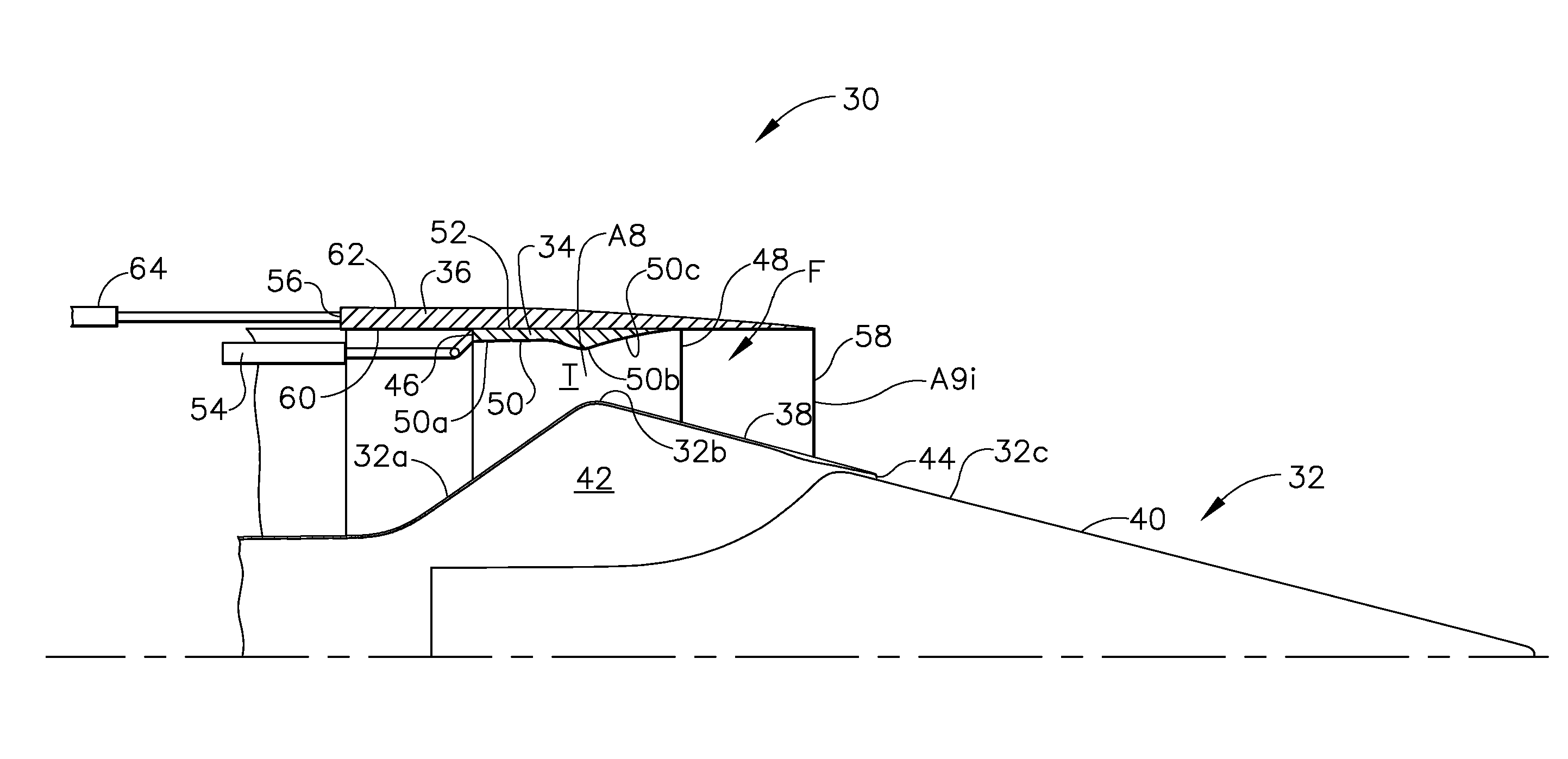

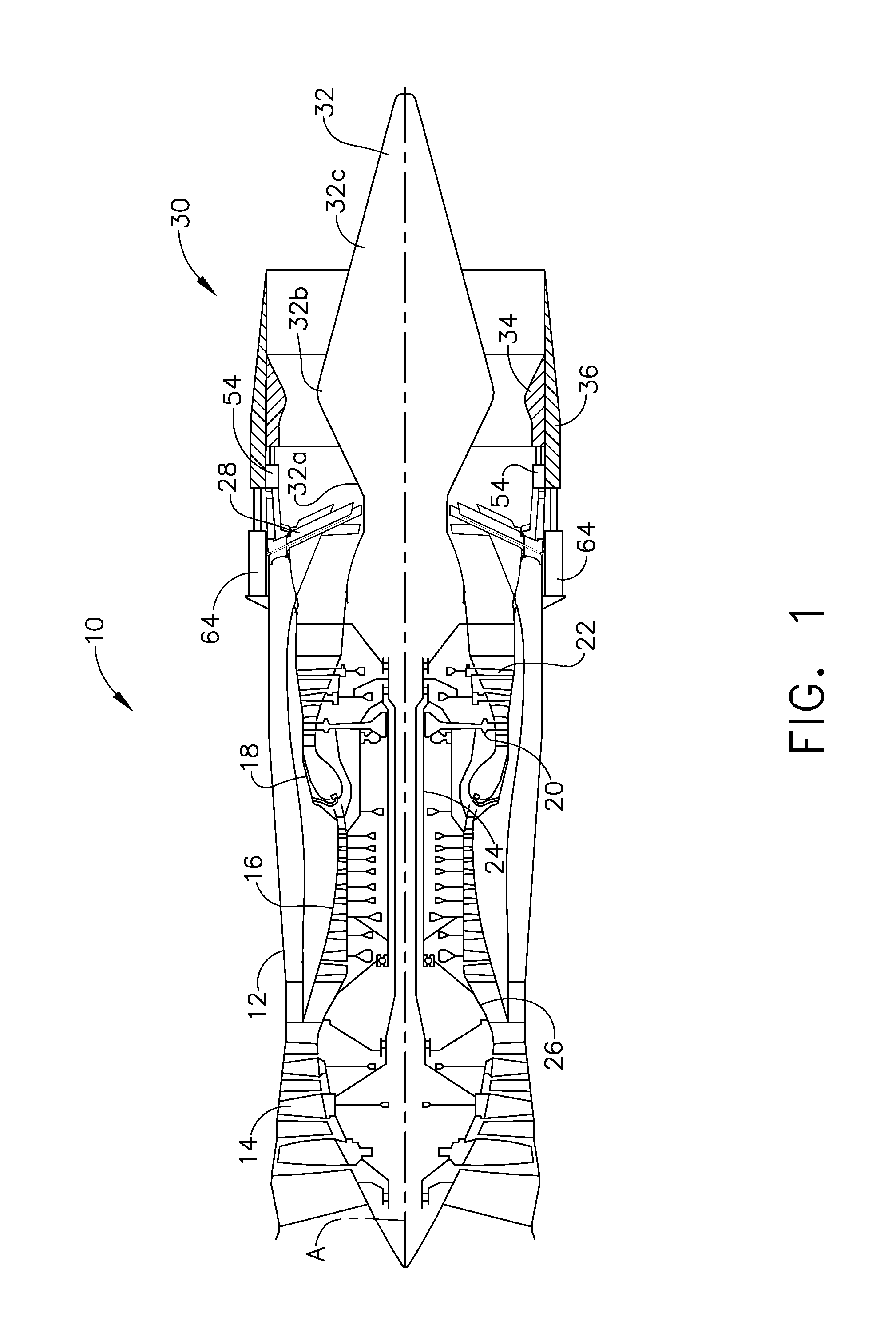

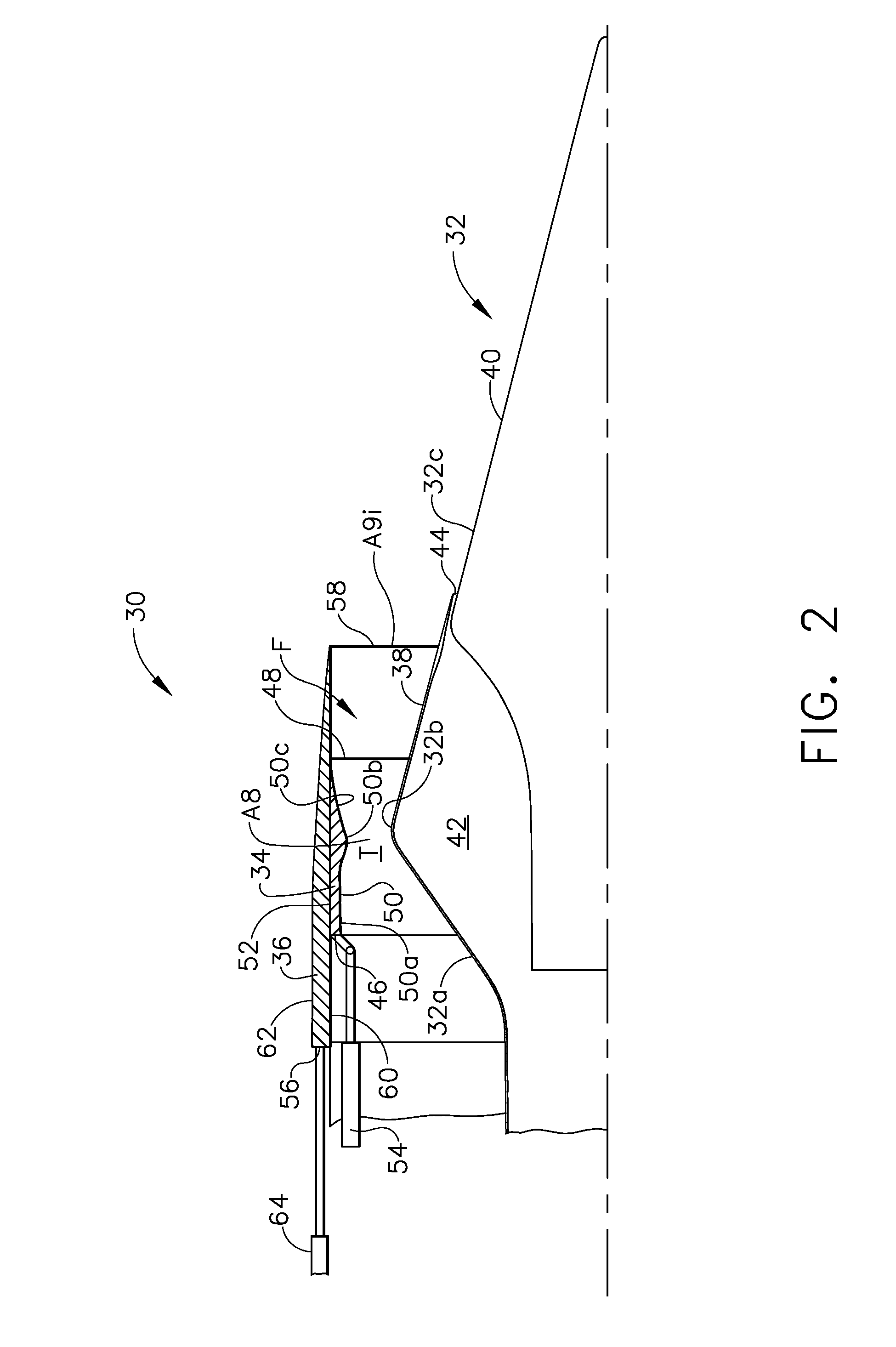

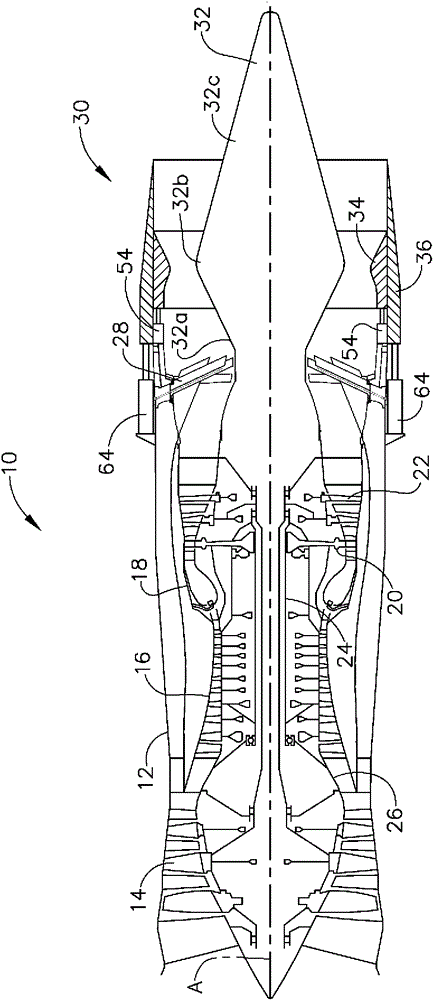

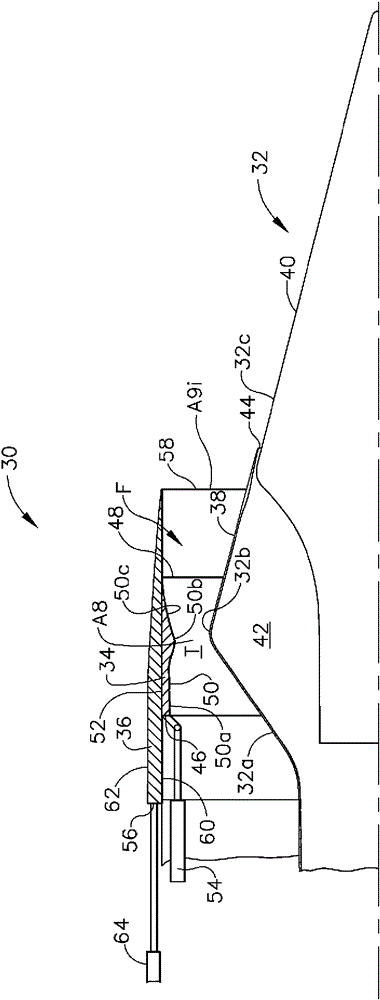

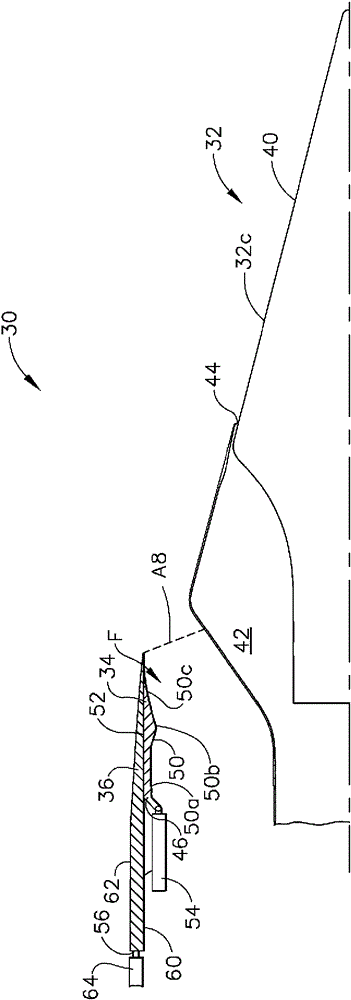

Dual-mode plug nozzle

InactiveUS20160123178A1Increase the diameterReduce the overall diameterEngine manufactureEfficient propulsion technologiesDual modeMaximum diameter

A variable geometry convergent-divergent nozzle for a gas turbine engine includes a centerbody extending rearward along a longitudinal axis of the engine which has a maximum diameter section. An inner shroud surrounds the centerbody and cooperates with the centerbody to define the throat of the nozzle. An outer shroud surrounds the inner shroud and cooperates with the centerbody to define the exit area of the nozzle. Both shrouds are independently translatable to provide independent control of the nozzle throat area and the nozzle expansion ratio. Additional actuation of the inner shroud results in the throat being disposed upon a fully forward portion of the centerbody, said fully forward shroud disposition being more forward than over the maximum diameter section. The nozzle may further comprise independent translation of the centerbody with respect to the shrouds.

Owner:GENERAL ELECTRIC CO

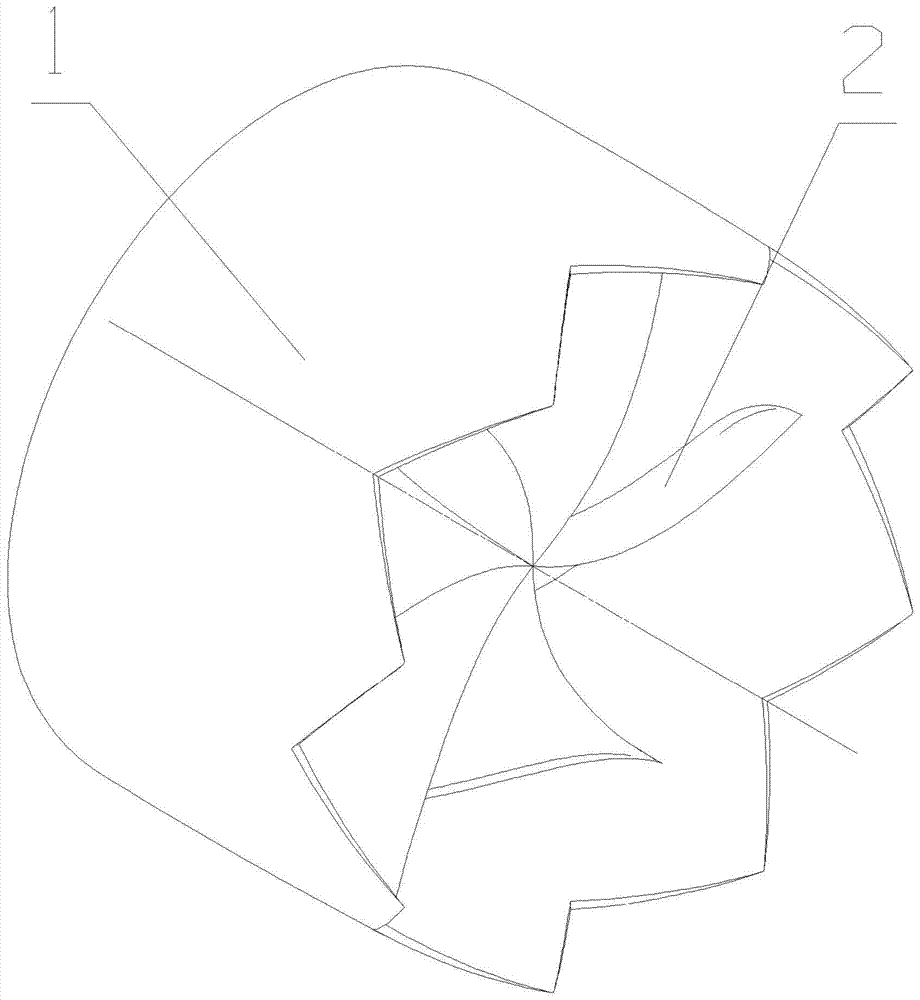

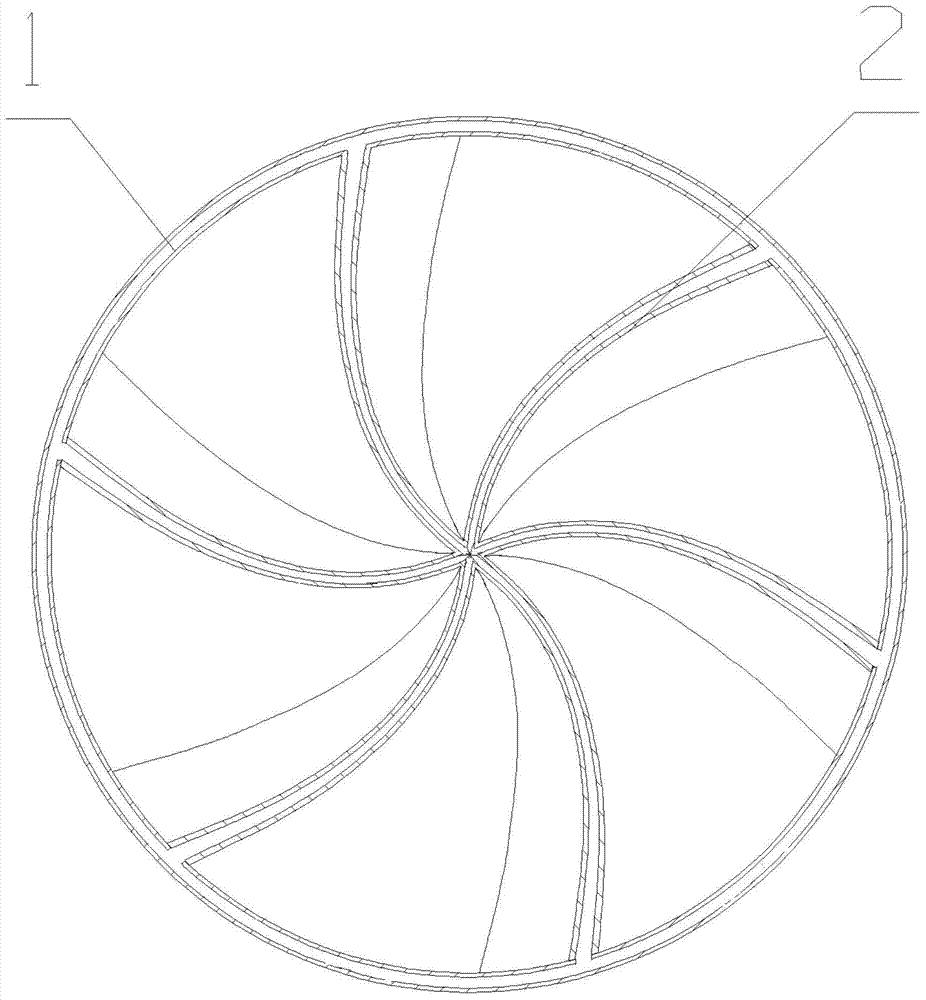

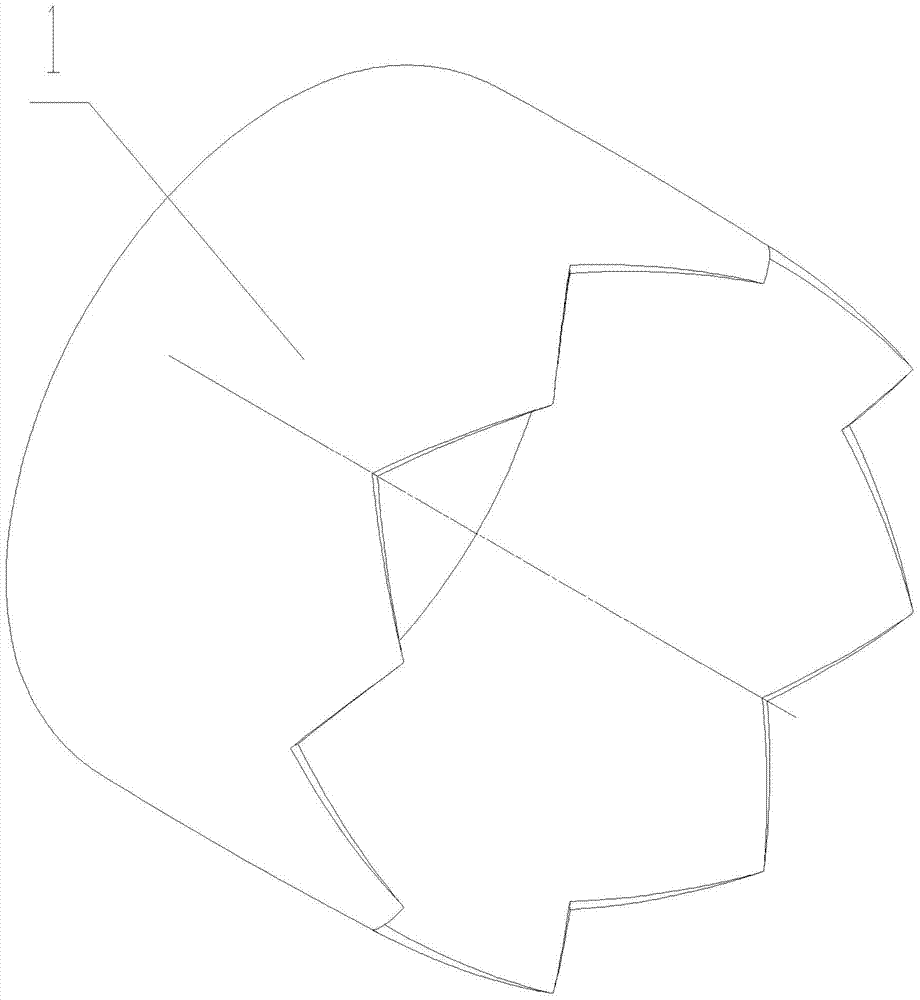

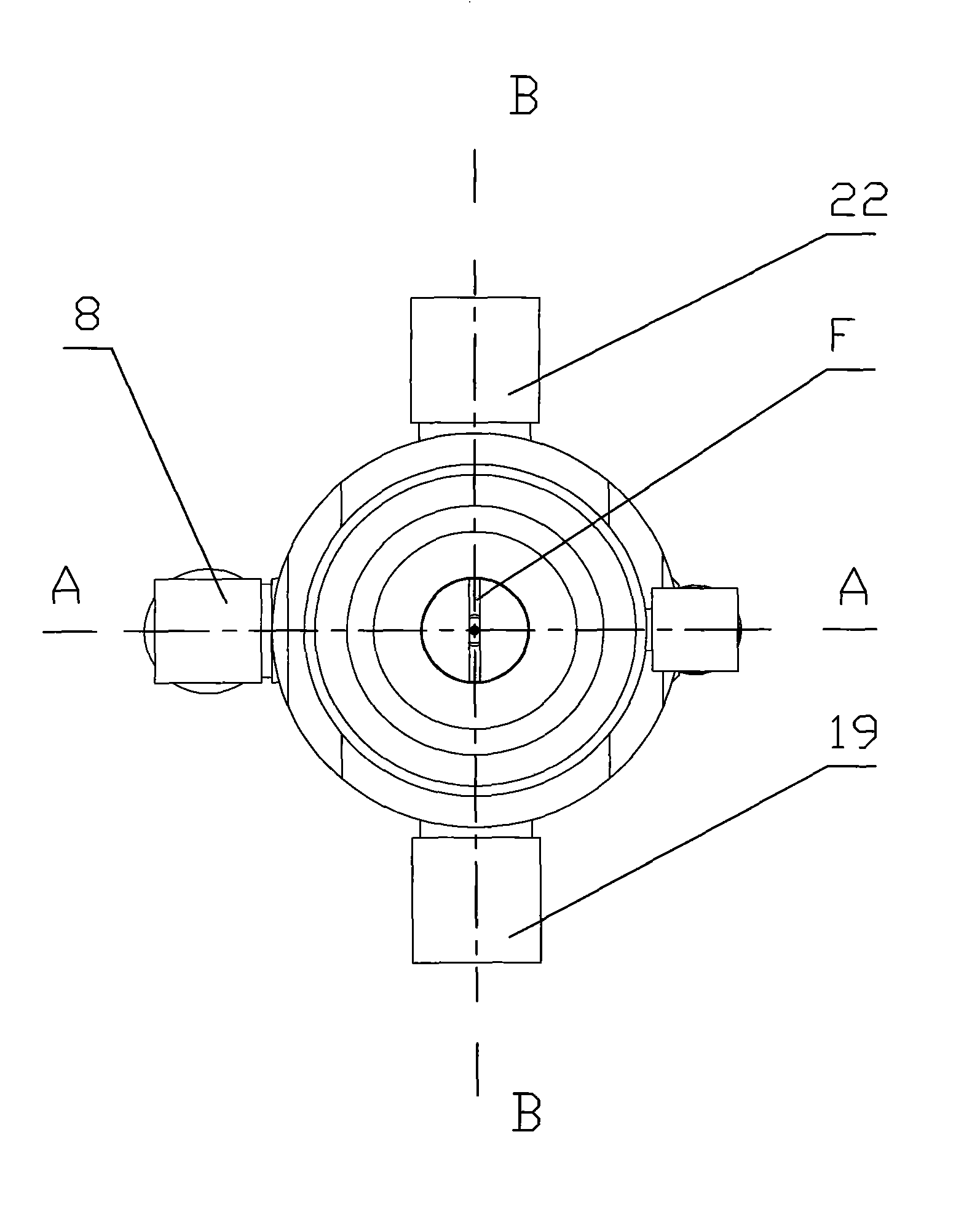

Thin-wall whirl central body structure

ActiveCN103696880ADoes not affect the throat area adjustment rangeGood stealthJet propulsion plantsEngineeringThin walled

The invention provides a thin-wall whirl central body structure which consists of a thin-wall annular structure and a thin-wall whirl blade-shaped structure and is characterized in that the thin-wall annular structure is positioned at the outside, connected with a cylinder of an axially symmetrical nozzle by virtue of a support member and used for fixing the thin-wall whirl blade-shaped structure and meanwhile changing the flow direction of airflow flowing through the thin-wall whirl blade-shaped structure into a direction along the axial direction of the nozzle; the thin-wall whirl blade-shaped structure is positioned at a front middle section inside the thin-wall annular structure, arranged along the circumferential direction of the thin-wall annular structure and fixedly connected with the thin-wall annular structure; the sections of the front and rear ends of the thin-wall whirl blade-shaped structure form a certain angle in the circumferential direction, so that the thin-wall whirl blade-shaped structure can shield a hot end member at the front end of the engine, and a hiding function is achieved. The thin-wall whirl central body structure has the following advantages that the regulation range of the throat area of a traditional axially-symmetrical plug nozzle is not influenced; the thin-wall whirl central body structure can be applied to other types of traditional axially-symmetrical nozzles, so that a favorable hiding function is achieved, the structure is simple, and hidden sawtooth shaping can be performed conveniently.

Owner:AECC SHENYANG ENGINE RES INST

Thrust vector control system for a plug nozzle rocket engine

A thrust vector control system for a plug nozzle rocket engine for propelling and maneuvering a vehicle is disclosed. The plug nozzle rocket engine includes a housing having a nozzle throat, a plug disposed within the housing and positioned within the nozzle throat to define a space between the plug and the nozzle throat, and a thrust diverter moveably disposed relative to the housing to define an asymmetric pressure distribution along the plug for thrust-vectoring. In one embodiment, the thrust diverter is normally biased to a non-thrust-vectoring position, but is moveable in a plane substantially perpendicular to an axis extending longitudinally through the plug.

Owner:AEROJET ROCKETDYNE INC

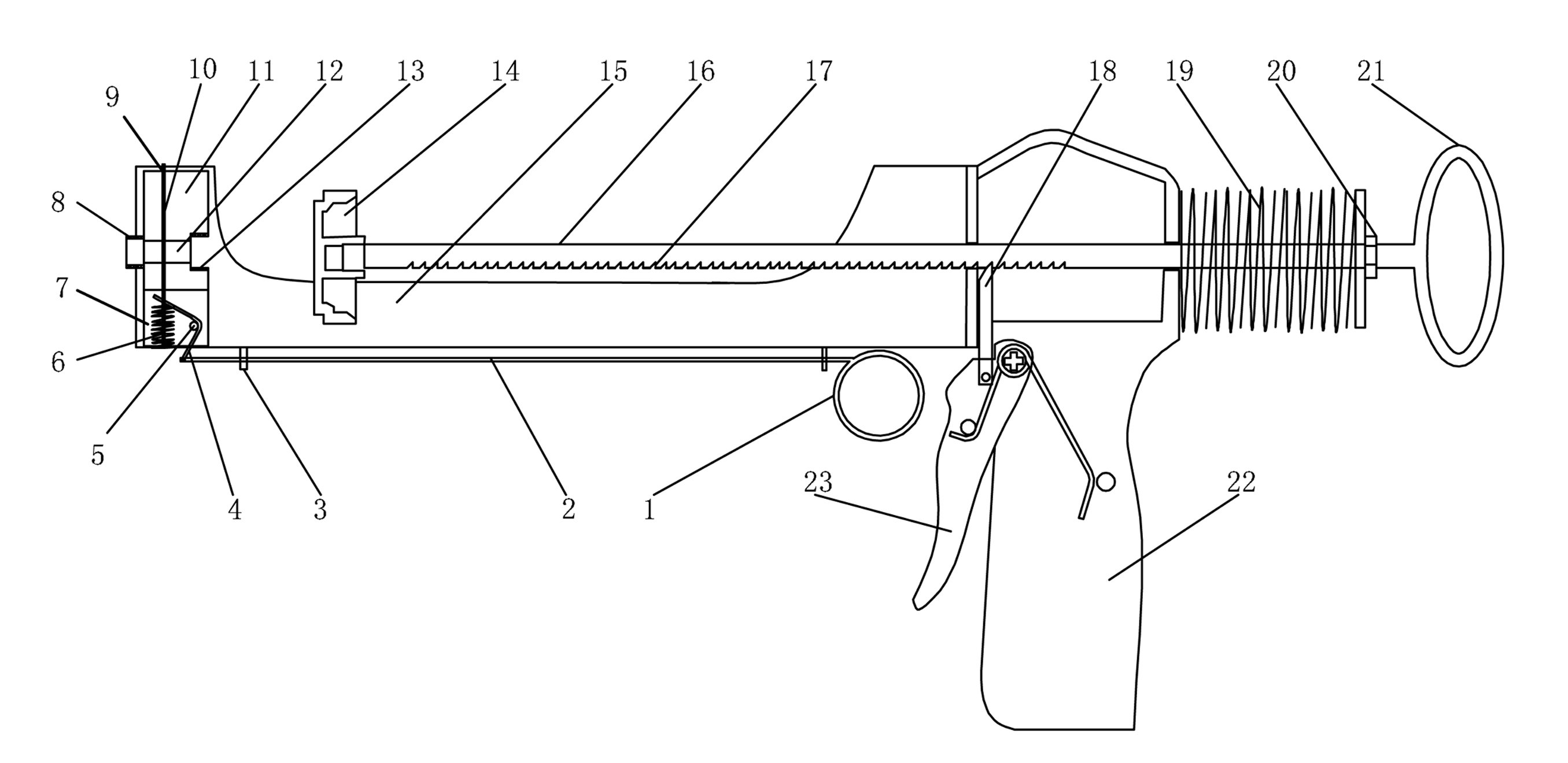

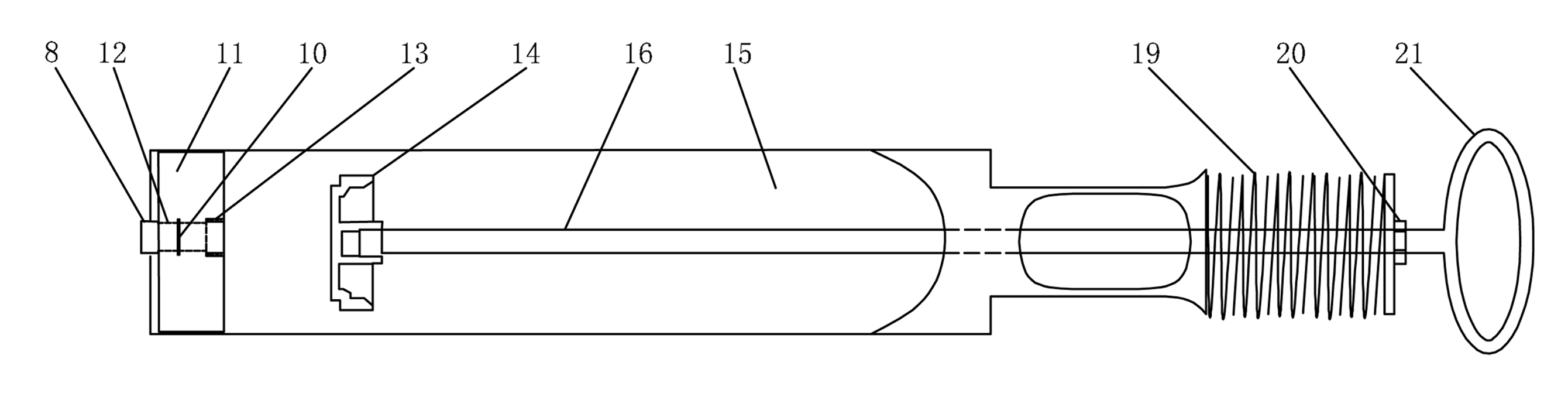

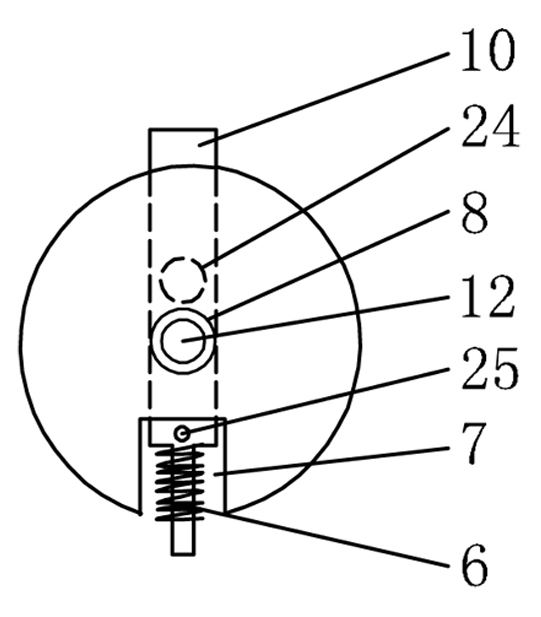

Novel glue smearing gun

ActiveCN102049369AReduce labor intensityFreely control the glue outputLiquid surface applicatorsCoatingsStart stopControl system

The invention relates to a novel glue smearing gun, in particular to a tool for spraying or smearing glue. The front end of the glue smearing gun provided by the invention is additionally provided with a glue charging-breaking start-stop device, and the rear end of the glue smearing gun is provided with an automatic propulsion device, thereby forming a secondary control system; a start-stop block of the glue charging-breaking start-stop device is a cylinder with the same diameter as a gun groove; a glue discharging channel is arranged in the center of the start-stop block; the inner side of the glue discharging channel is provided with an inner silk spinning opening connected with a glue pot silk opening, and the outer side of the glue discharging channel is provided with an outer silk spinning opening connected with a glue nozzle; a glue charging-breaking steel sheet jack is arranged on the start-stop block perpendicular to the glue discharging channel; the lower part of the start-stop block is provided with a groove; a return spring and a shift rod are arranged in the groove; a steel sheet glue discharging hole and a shift hole are formed on a glue charging-breaking steel sheet; the lower part of the glue charging-breaking steel sheet is provided with the return spring; the rear side of the return spring is provided with the shift rod; and the rear end of the shift rod is connected with a pull rod. The upper part of a braking trigger of a propulsion part is connected with a braking pin through a rivet; the lower side of the push rod is provided with a clamping groove matched with a braking pin slope-shaped plug; and a thrust spring and an adjustable fixed plate are arranged between a tension handle and a gun handle at the rear part of the pull rod, thereby forming the propulsion device.

Owner:山东高速德建集团有限公司

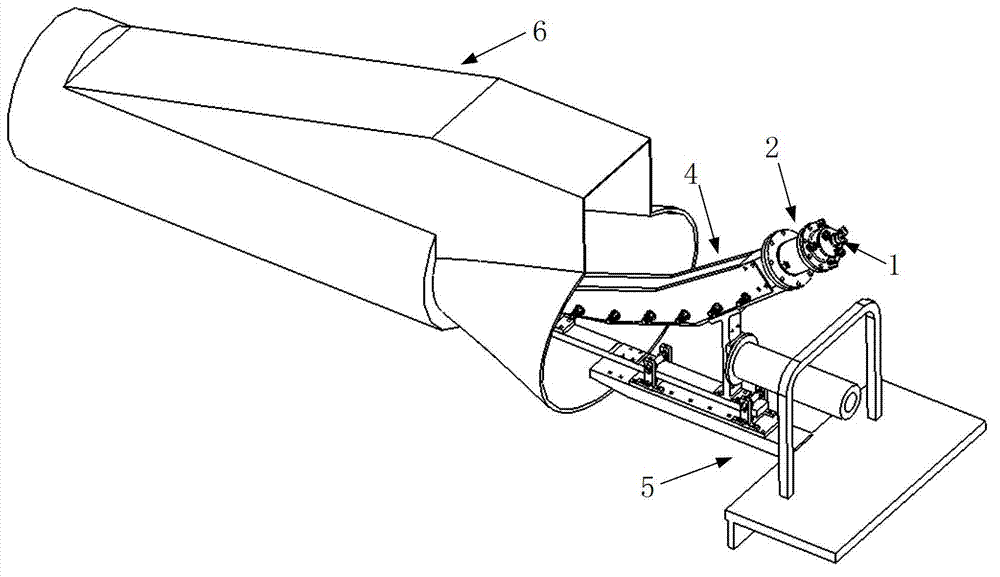

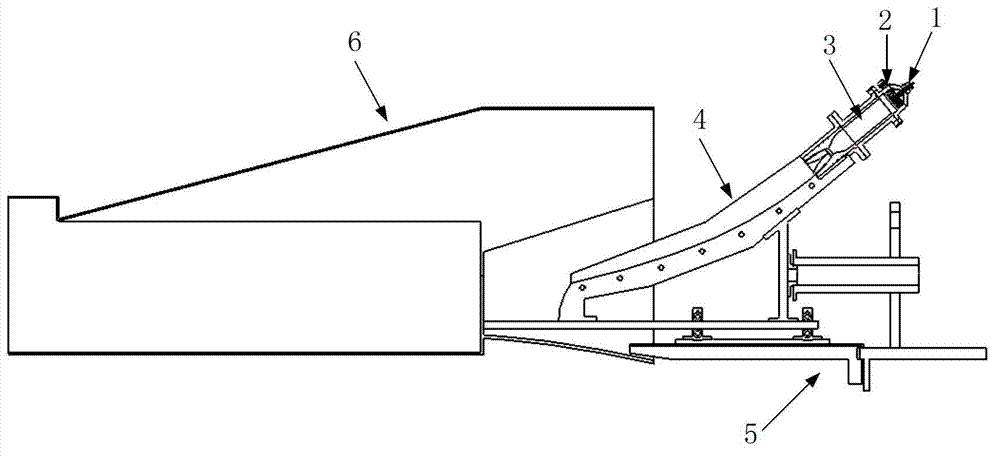

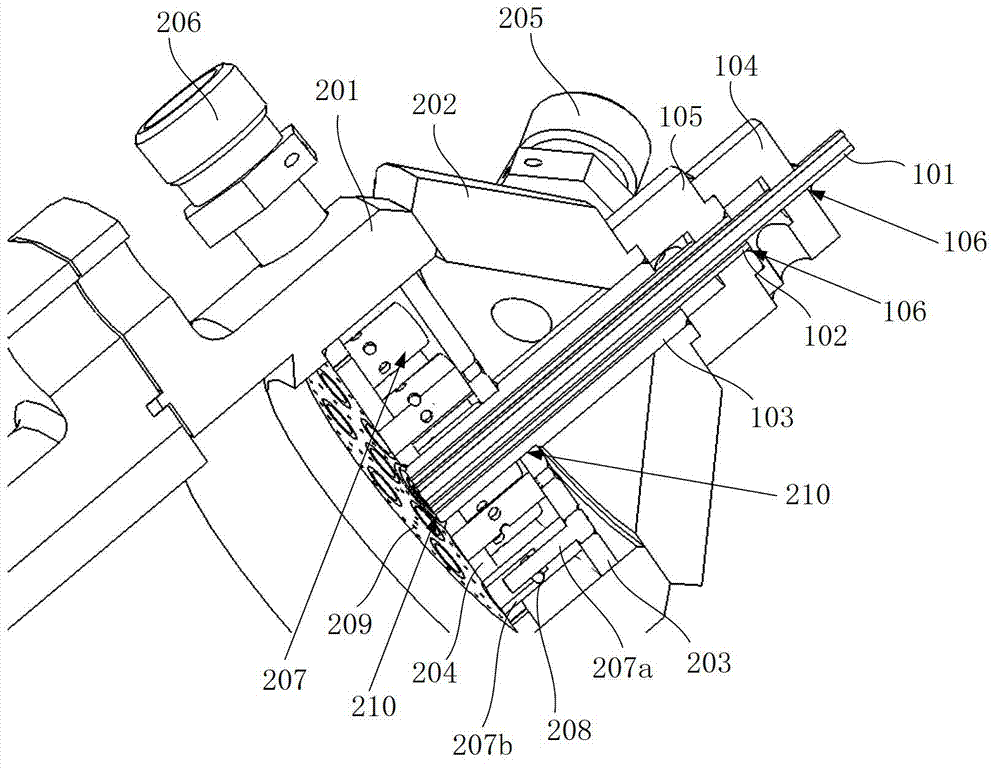

Low-cost and simple unit round-to-square plug nozzle test device

The invention discloses a low-cost and simple unit round-to-square plug nozzle test device, which comprises an igniter assembly, an injector assembly, a thrust chamber assembly, a plug cone assembly, a thrust measuring support table frame assembly and an ejection exhaust tube, wherein the injector assembly is provided with a hydrogen cavity and an oxygen cavity, a hydrogen and oxygen gas direct flow spray nozzle with the single hydrogen and oxygen injection function is arranged in the hydrogen cavity, the igniter assembly formed by three layers of sleeves is arranged inside the injector assembly, the injector assembly is connected with the thrust chamber assembly with a round-to-square inner nozzle, the plug cone assembly and the thrust chamber assembly are connected, are supported by the thrust measuring support table frame assembly and can forwards and backwards slide on the support table frame assembly, a platform with an installing thrust frame is also arranged on the support table frame assembly, and the back part of the plug cone is positioned in the ejection exhaust tube. The low-cost and simple unit round-to-square plug nozzle test device has the advantages that the structure is simple, the measurement precision is high, the cost is low, in addition, the application range is wide, the study content is rich, and the repeated use for many times can be realized.

Owner:BEIHANG UNIV

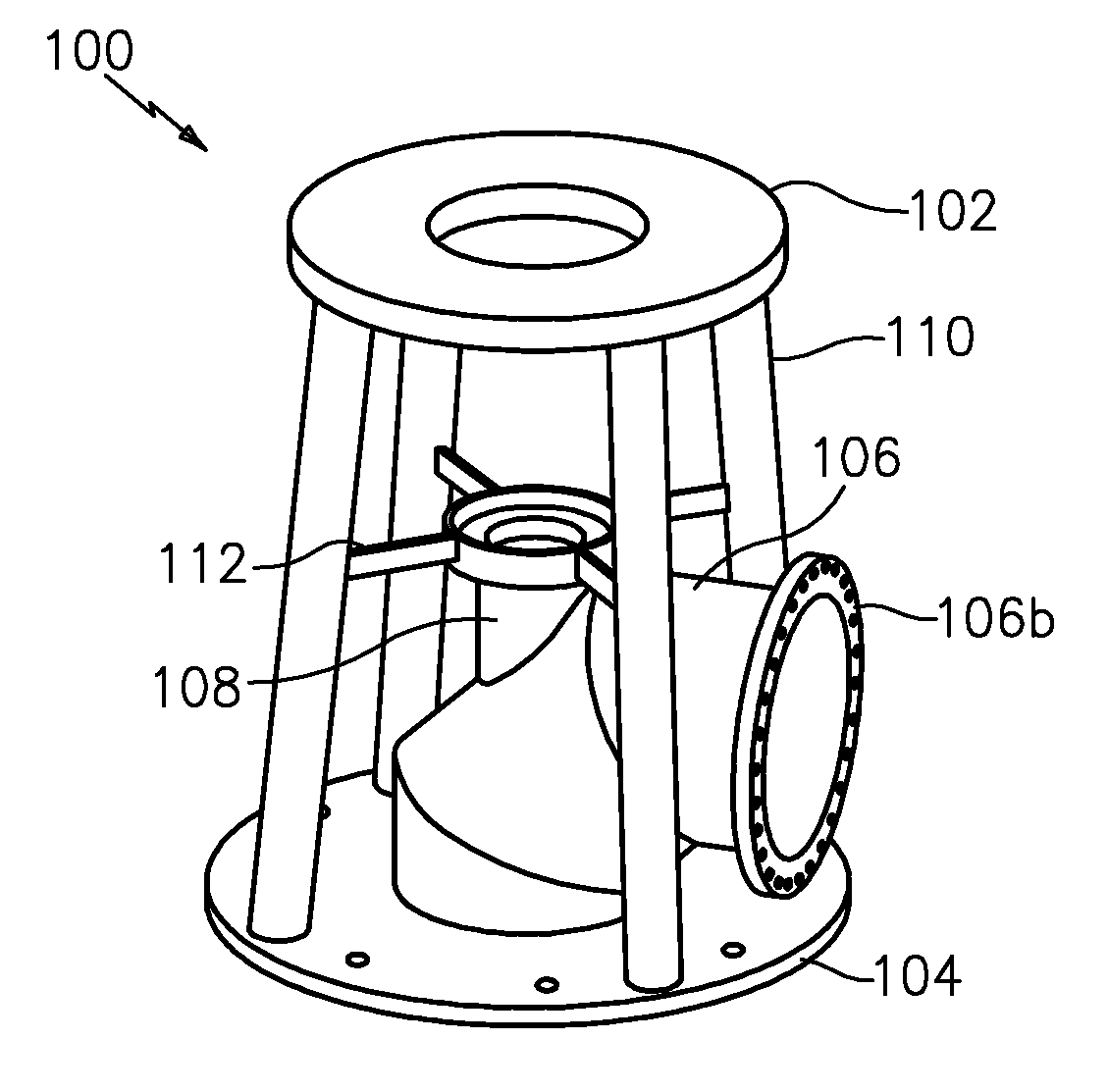

“O” head design

ActiveUS8226352B2Quicker and easy to couple togetherShorten the lengthEngine sealsPump componentsEngineeringBackplane

A discharge head features a motor mounting plate configured for mounting on a motor; a base plate configured for mounting on a pump assembly; an elbow transition mounted on the base plate configured for providing discharge from the pump assembly; a seal housing pipe coupled to the elbow transition configured for receiving a mechanical seal or packing arrangement; supporting pipes arranged between the motor mounting plate and the base plate; and ribs arranged between the supporting pipes and the seal housing pipe configured to prevent substantially lateral and torsional movement, including movement due to reacting hydraulic forces at a pump nozzle and inertia from a driver. The discharge head according to the present invention makes it quicker and easier to couple together the shaft of a pump and the shaft of a motor in such VTSH pumps when compared to the techniques known in the art.

Owner:ITT MFG ENTERPRISES LLC

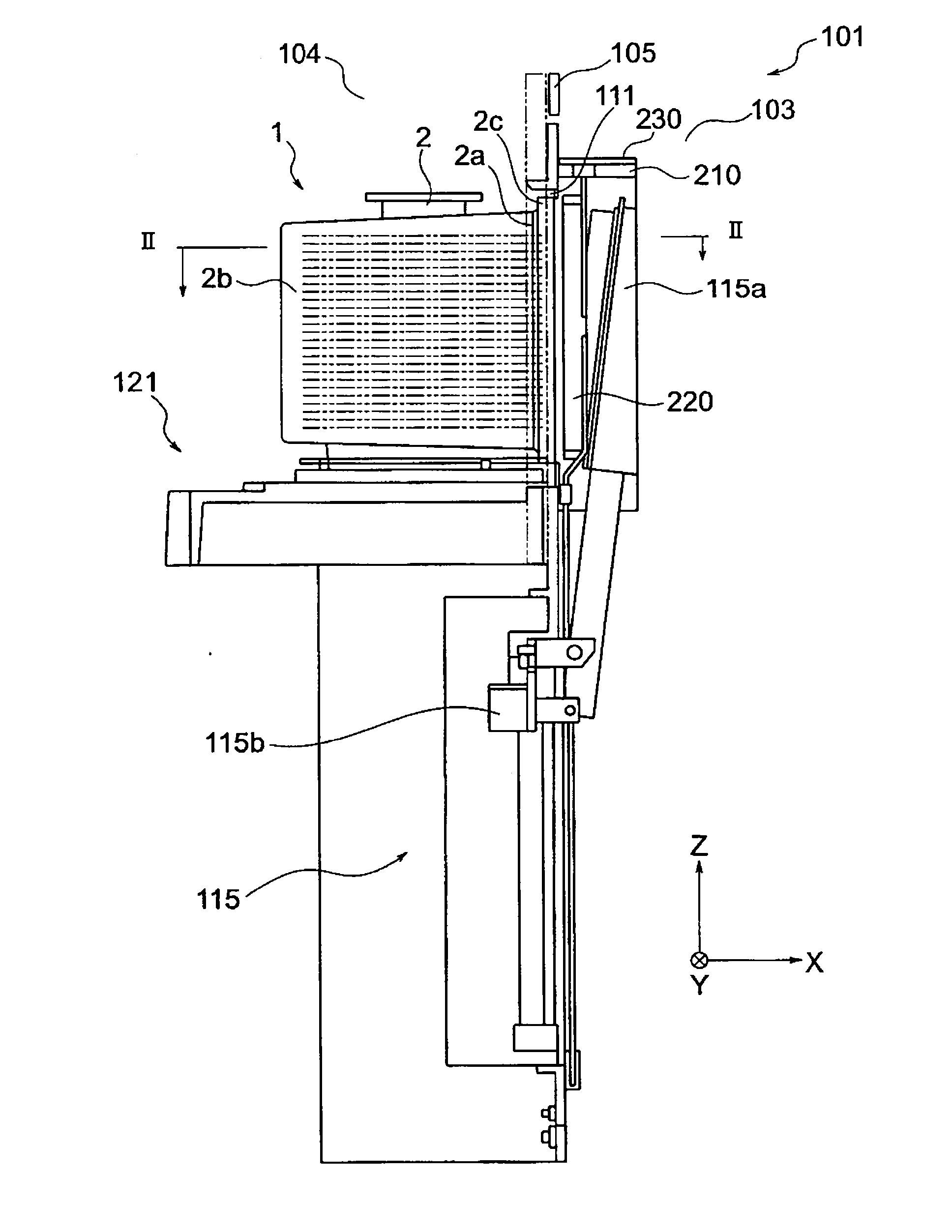

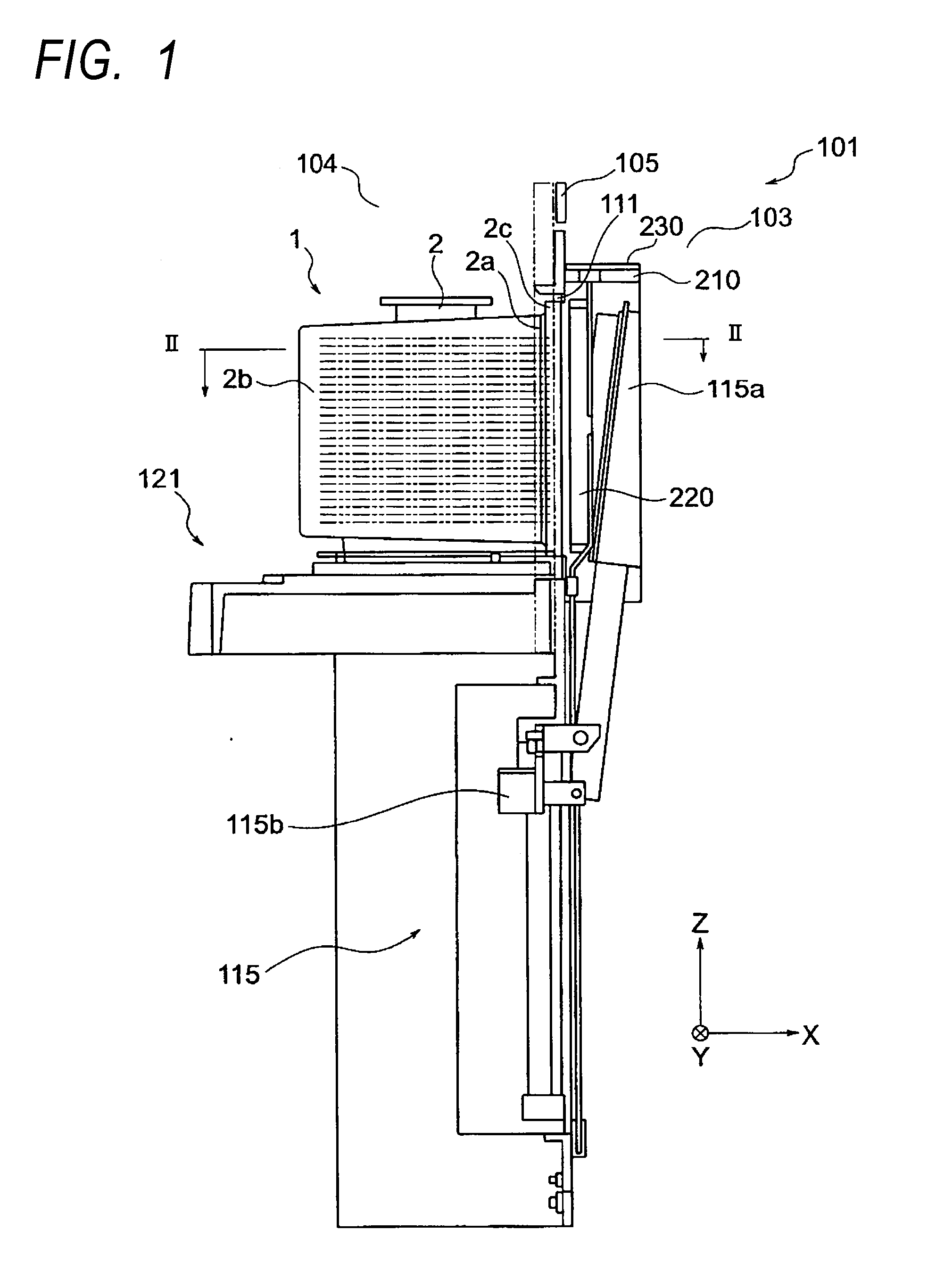

Gas purge apparatus, load port apparatus, installation stand for purging container, and gas purge method

ActiveUS9895723B2Avoid it happening againHollow article cleaningSemiconductor/solid-state device manufacturingEngineeringPlug nozzle

In a gas purge apparatus, a load port apparatus, an installation stand for a purging container, and a gas purge method, the inside of the purging container is filled with a cleaning gas until just before transportation, and a placement failure does not happen to the next purging container to be placed. A purge nozzle is moved to a direction separating from a purge port after detecting a movement of a table on which the purging container is installed to an undock position and a stop of a feeding of the cleaning gas.

Owner:TDK CORPARATION

Electromagnetic swirling continuous casting method

The invention discloses an electromagnetic swirling continuous casting method, and belongs to the technical field of smelting continuous casting. The electromagnetic swirling continuous casting method comprises the following steps: (1) a used electromagnetic swirling device is 180-degree semicircular ring-shaped, split 360-degree ring-shaped, horseshoe-shaped or improved horseshoe-shaped; (2) the electromagnetic swirling device is fixed onto a moving device; a nozzle is an immersive nozzle between a tundish and a crystallizer, or a long nozzle between a steel ladle and the tundish; (3) during continuous casting, the electromagnetic swirling device is moved close to the nozzle by the moving device so as to exert a swirling electrical field to molten steel. The electromagnetic swirling continuous casting method is universally applicable to various technical conditions such as a circular blank, a square blank and a slab blank, can be accurately and optimally designed, and is simple and easy to operate; original continuous casting equipment is not required to be restructured.

Owner:NORTHEASTERN UNIV

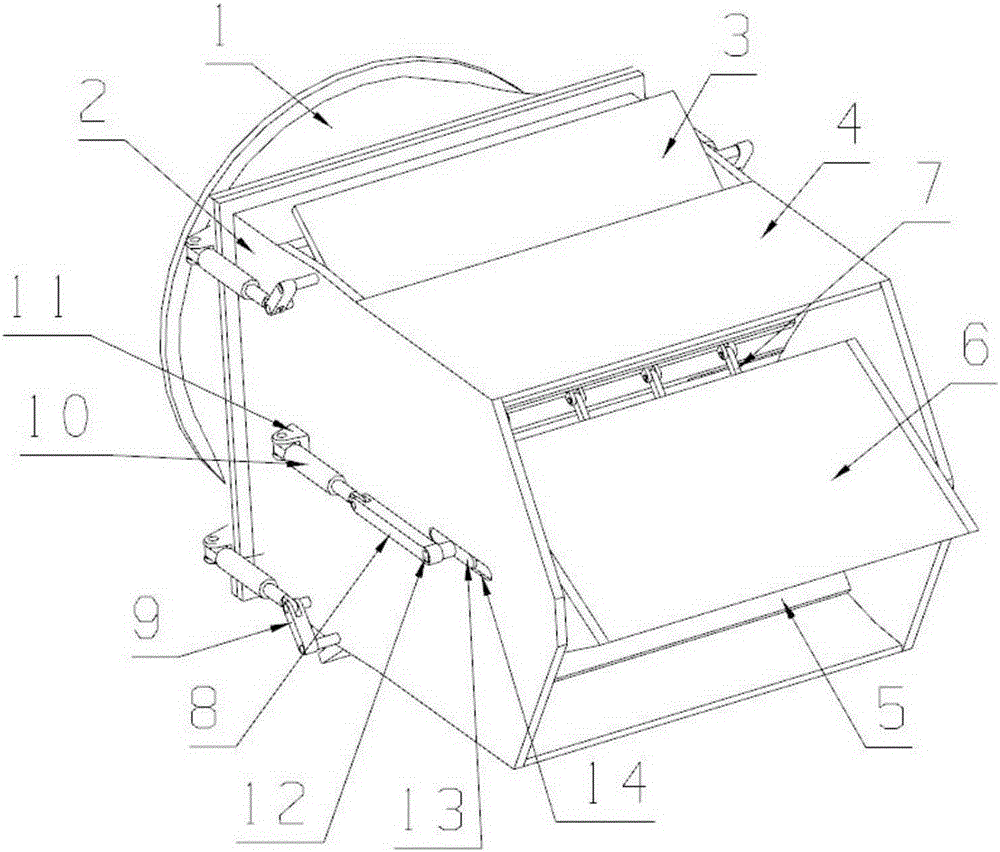

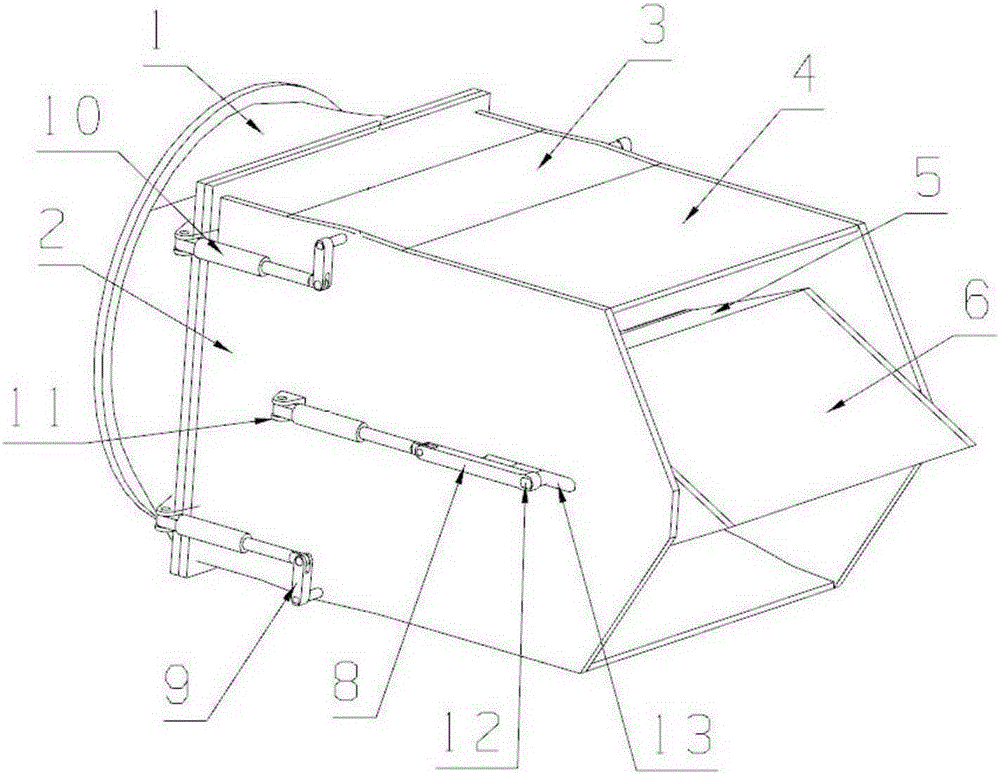

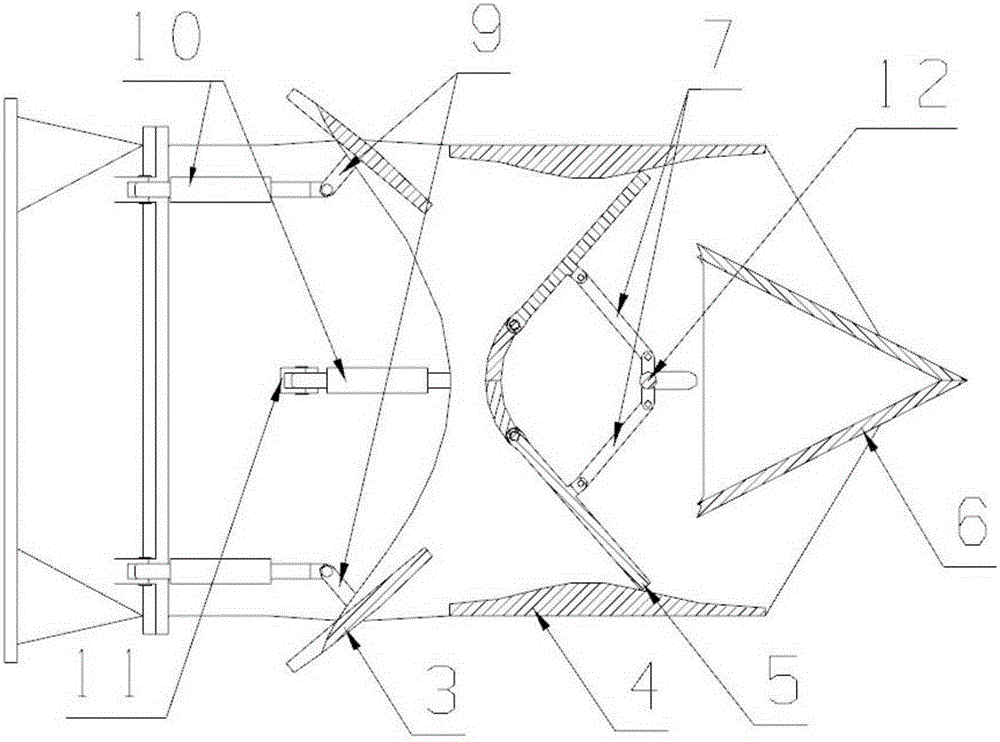

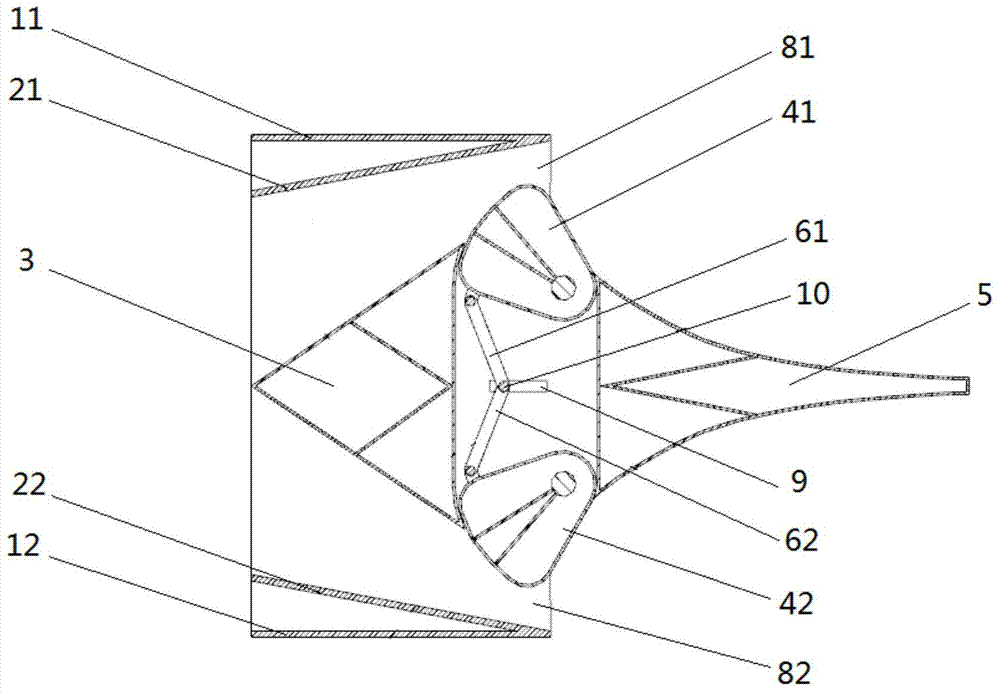

Two-dimensional plug nozzle with thrust reversing function

ActiveCN105240158AConducive to integrated designSimple structureJet propulsion plantsStructure typeFuselage

The invention relates to the technical field of structure design of aircraft engines, in particular to a two-dimensional plug nozzle with a thrust reversing function. The front end of a circular-rotating square-barrel body is connected with an engine, and the rear end of the circular-rotating square-barrel body is fixedly connected with two side wall boards distributed in left-right symmetry and two horizontal wall boards distributed in vertical symmetry. An adjustable wall board is a part of each horizontal wall board, and an adjustable baffle is a part of a plug cone. When the adjustable baffle rotates by a preset angle, the adjustable wall boards rotate synchronously, and a thrust reversing exhaust channel is formed by the adjustable wall boards, the left side wall board and the right side wall board. According to the two-dimensional plug nozzle with the thrust reversing function, on the premise that the thrust reversing function is achieved, the structure type and the function of a conventional two-dimensional plug nozzle are guaranteed; the overall dimension is small, the weight is low, the structure is simple, and the reliability is high; integral design of a rear fuselage is facilitated, and the defects of a conventional nozzle thrust reverser are overcome.

Owner:AECC SHENYANG ENGINE RES INST

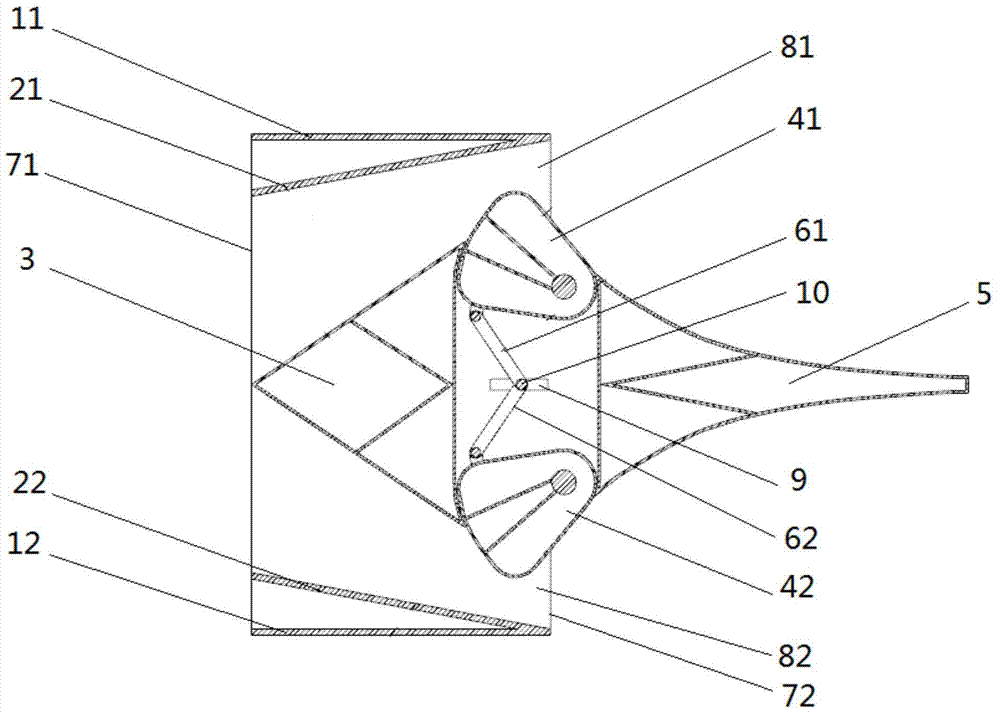

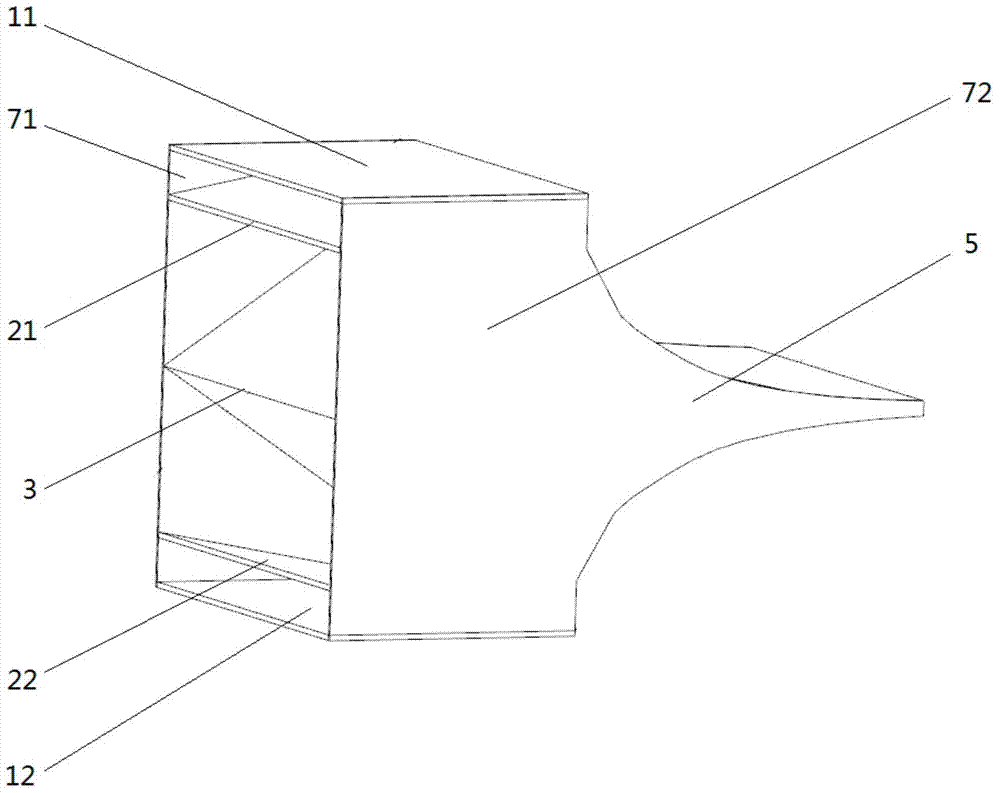

Binary plug nozzle and aircraft with binary plug nozzle

The invention discloses a binary plug nozzle and an aircraft with the binary plug nozzle. The binary plug nozzle comprises a first side wall panel, a second side wall panel, a first cone body, a second cone body, a first cam and a second cam, wherein the first side wall panel and the second side wall panel are in a hollow structure and used for arranging a cooling pipeline; the first cone body and the second cone body are in the hollow structure; the first cam and the second cam is in the hollow structure; the cooling pipeline is respectively arranged in the first side wall panel and the second side wall panel, one end of each pipeline is connected with a cooling air source, and the other end respectively extends into the hollow parts of the first cone body, the second cone body, the first cam and the second cam and used for accessing cooling gas into the first cone body, the second cone body, the first cam and the second cam. According to the binary plug nozzle, the cooling pipeline is respectively arranged in the first side wall panel and the second side wall panel and used for accessing the cooling gas to reduce temperature of all parts. The binary plug nozzle is simple in structure, low in cost and good in cooling effect.

Owner:AECC SHENYANG ENGINE RES INST

Automatic cleaning device of spray nozzle

ActiveCN103611648ASolve easy blockageTroubleshoot blocked nozzles or internal flow passagesSpraying apparatusSpray nozzleMechanical engineering

The invention discloses an automatic cleaning device of a spray nozzle. The automatic cleaning device is characterized in that a cleaning ring and solvent supply devices are additionally arranged on the outside of the spray nozzle of a spray gun, electromagnetic valves are arranged among the solvent supply devices and the cleaning ring, the solvent supply devices are connected with the cleaning ring by pipelines, and the electromagnetic valves are used for stopping solvent supply; solvent inlets are formed in the cleaning ring, an inner conical ring is arranged at the lower end of the inner wall of the cleaning ring, internal threads are arranged at the upper end of the inner wall of the cleaning ring, an outer cone is arranged at the lower end of the spray nozzle, a boss is arranged at the upper end of the spray nozzle, the cleaning ring compresses the boss of the spray nozzle to fix the boss of the spray nozzle, and the spray nozzle is fixed onto a glue nozzle by the aid of the cleaning ring; an outlet channel is communicated with a glue cavity, threads are arranged on an outer circle of the glue nozzle, the cleaning ring is connected with the glue nozzle in a threaded manner, and the glue nozzle is fixed to a shell by the aid of the threads. The automatic cleaning device has the advantages that when flowing into the annular channel from the solvent inlets, solvents are sprayed out of the annular channel under the effect of pressure, and sprayed solvents are aligned with the outer surface of a sphere at the lower end of the spray nozzle and clean the outer surface of the sphere, so that the purpose of automatically cleaning the spray nozzle can be achieved; the automatic cleaning device is applicable to automatically cleaning spray nozzles in spray guns in the paint spraying, glue spraying and glue coating industries and the like.

Owner:DALIAN HUAGONG INNOVATION TECH

Dual-mode plug nozzle

A variable geometry convergent-divergent nozzle for a gas turbine engine includes a centerbody extending rearward along a longitudinal axis of the engine which has a maximum diameter section. An inner shroud surrounds the centerbody and cooperates with the centerbody to define the throat of the nozzle. An outer shroud surrounds the inner shroud and cooperates with the centerbody to define the exit area of the nozzle. Both shrouds are independently translatable to provide independent control of the nozzle throat area and the nozzle expansion ratio. Additional actuation of the inner shroud results in the throat A8 being disposed upon a fully forward portion of the centerbody, said fully forward shroud disposition being more forward than over the maximum diameter section. The nozzle may further comprise independent translation of the centerbody 32 with respect to the shrouds.

Owner:GENERAL ELECTRIC CO

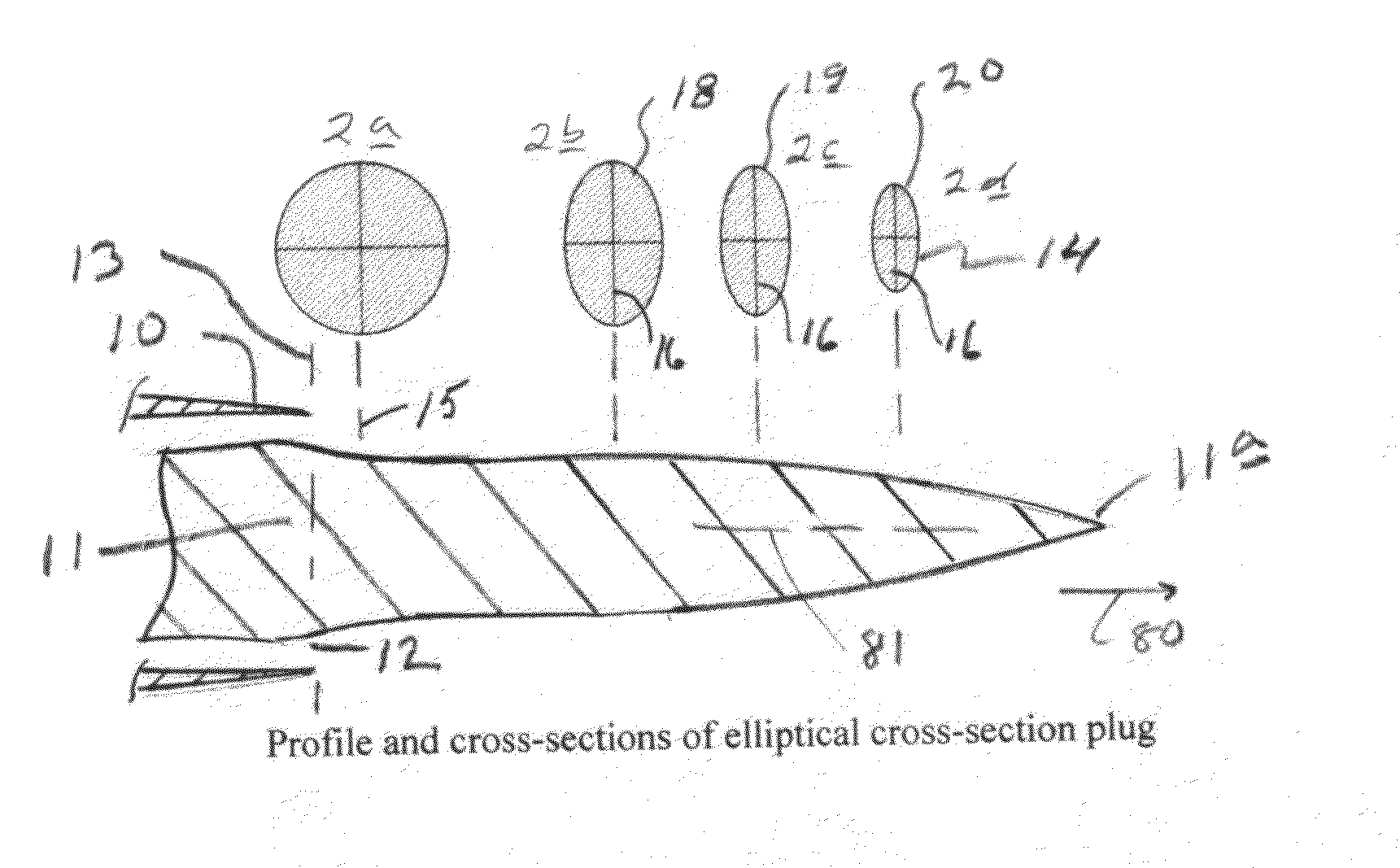

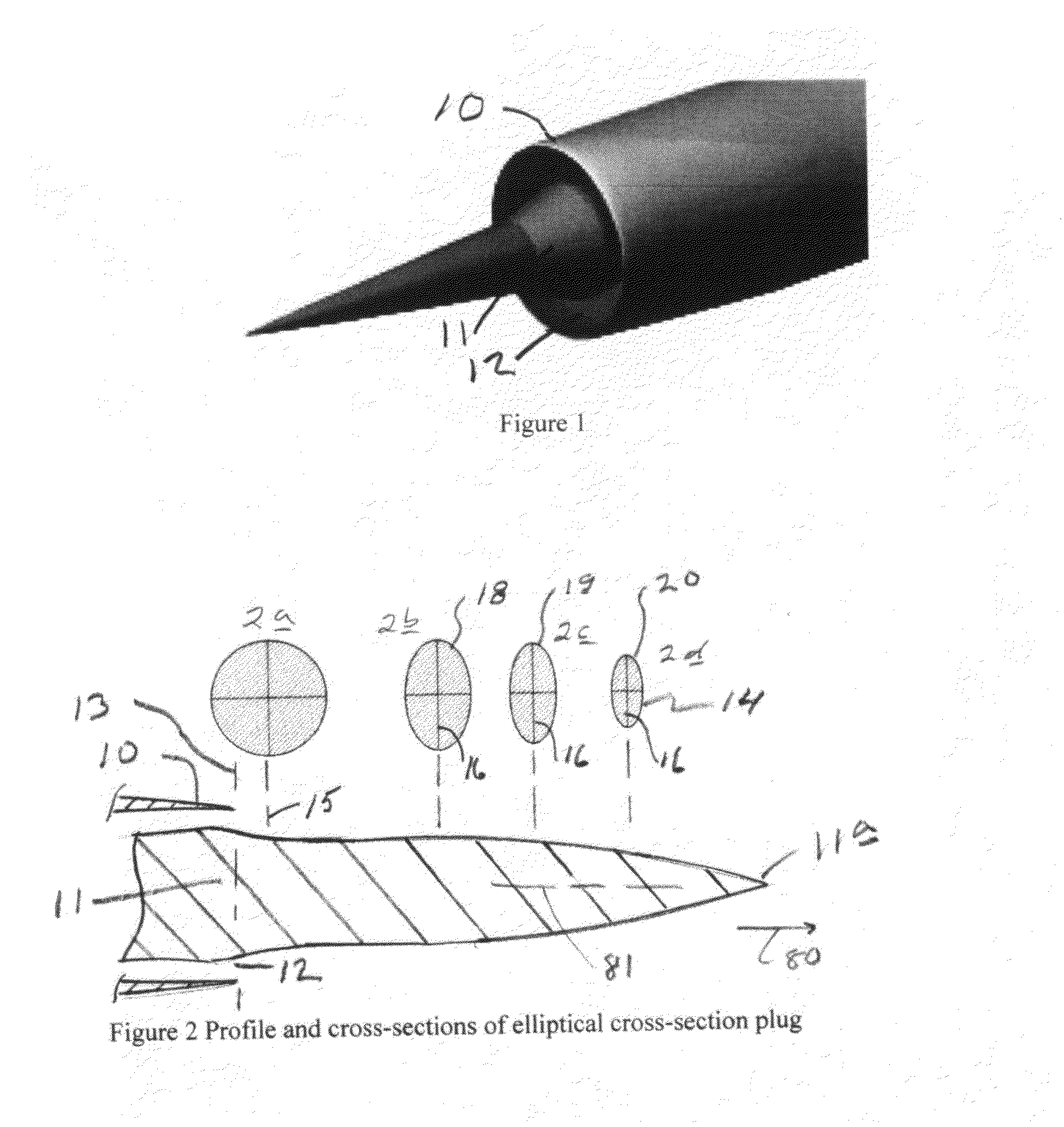

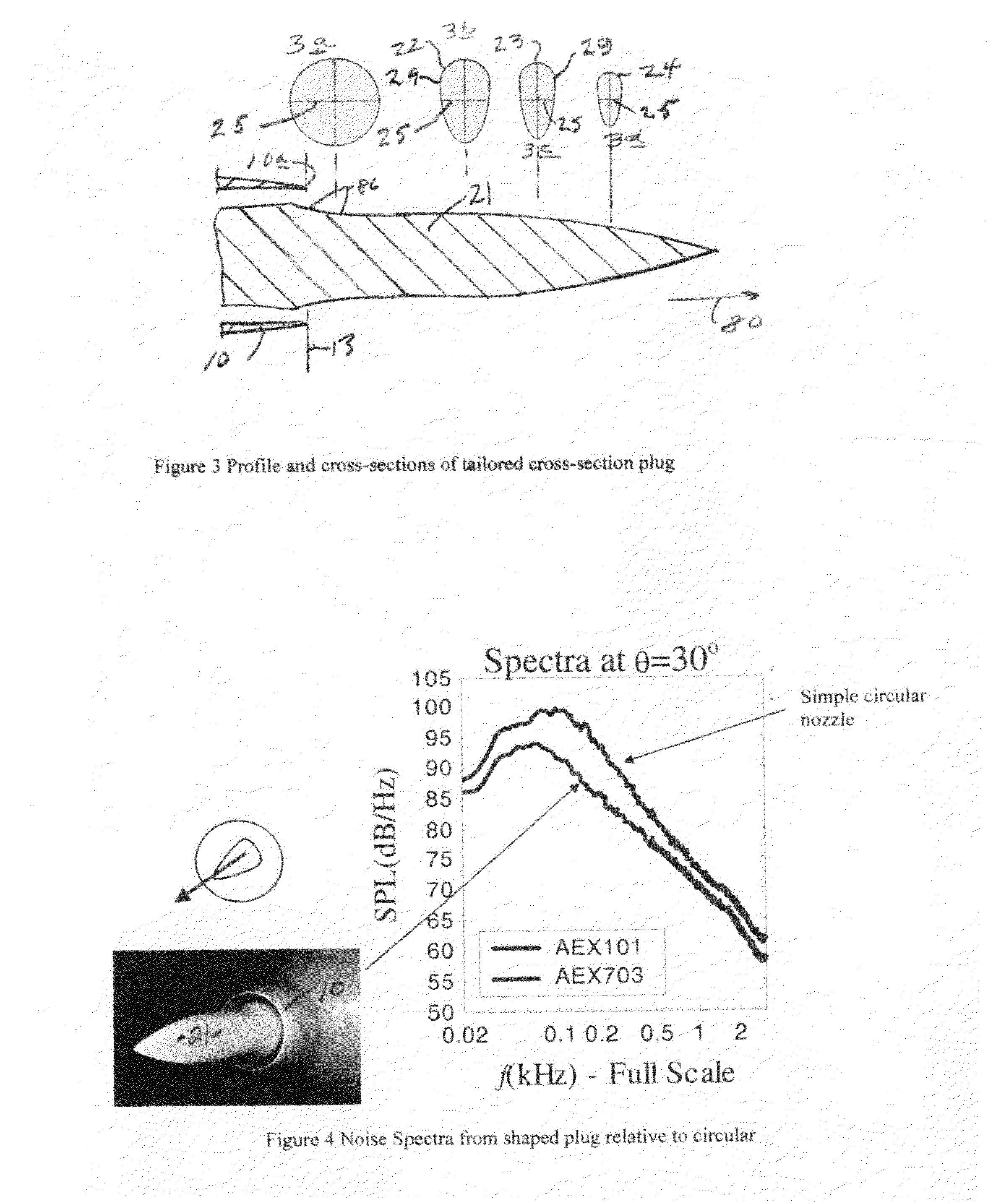

Jet nozzle plug with varying, non-circular cross sections

ActiveUS20100139284A1Acoustic emission reductionAircraft navigation controlPower plant exhaust arrangementsPlug nozzleExit plane

In a jet engine having a plug nozzle and a plug extending rearwardly from the nozzle exit, the improvement comprising a plug having successive cross sections spaced apart rearwardly of the nozzle exit, the cross sections transitioning from circular or near circular at the exit plane defined at the nozzle exit, to progressively non-circular, rearwardly.

Owner:AERION INTPROP MANAGEMENT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com