Low-cost and simple unit round-to-square plug nozzle test device

A plug-type nozzle and test device technology, which is applied to jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of limited use of test pieces, long test preparation time, limited test tasks, etc., and achieves a simple structure. , The effect of low renewal cost and rich research content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

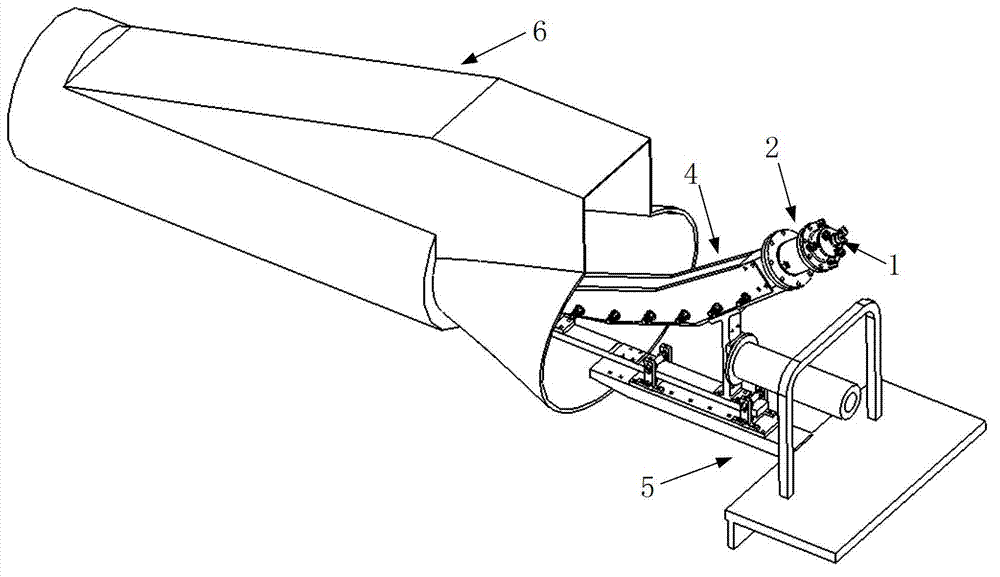

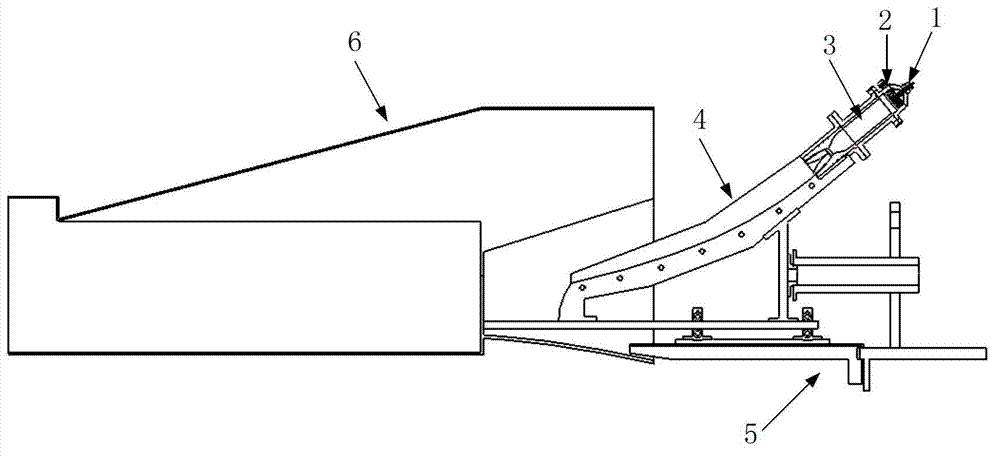

[0046] The present invention is a low-cost simple unit round-rotating square plug nozzle test device, the present invention is a low-cost simple unit round-rotating square plug nozzle test device, such as figure 1 with figure 2 As shown, the test device mainly includes an igniter assembly 1 , an injector assembly 2 , a thrust chamber assembly 3 , a plug cone assembly 4 , a thrust measurement support bench assembly 5 and an ejector exhaust cylinder 6 .

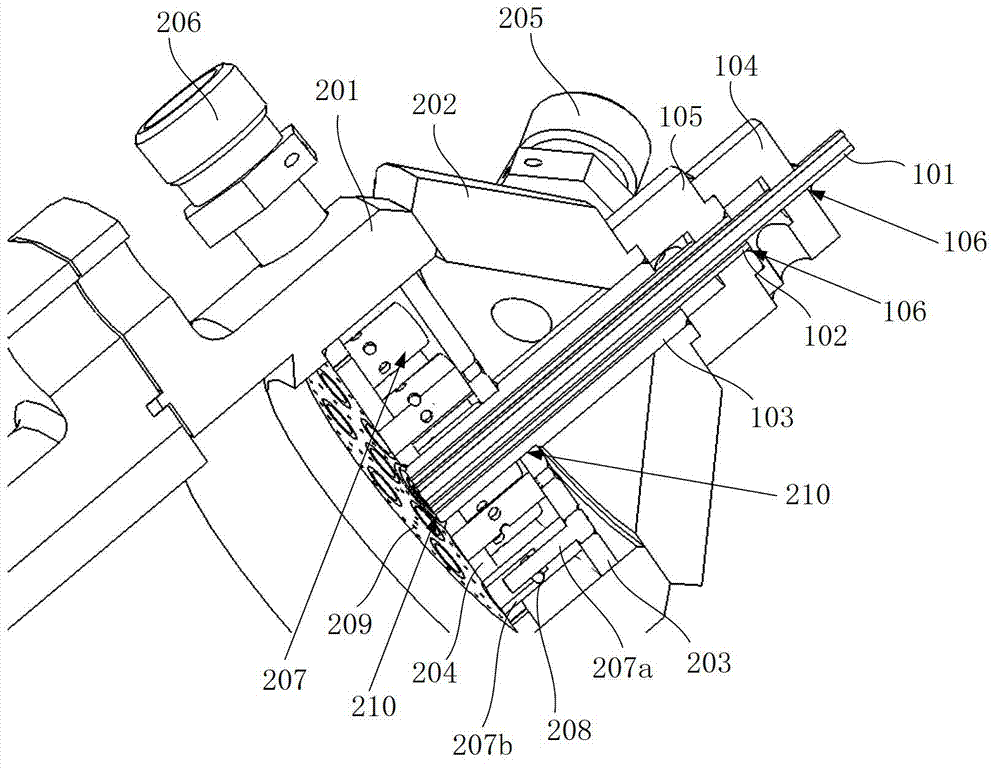

[0047] The injector assembly 2 includes an injector barrel 201, an injector cover 202, an injector upper bottom 203 and an injector lower bottom 204, a gas-oxygen pipeline connector 205 and a gas-hydrogen pipeline connector 206, such as image 3 shown. Among them, the upper end of the injection cylinder 201 is welded with a conical injector cover 202, and the inside of the injection cylinder 201 is coaxially welded with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com