Patents

Literature

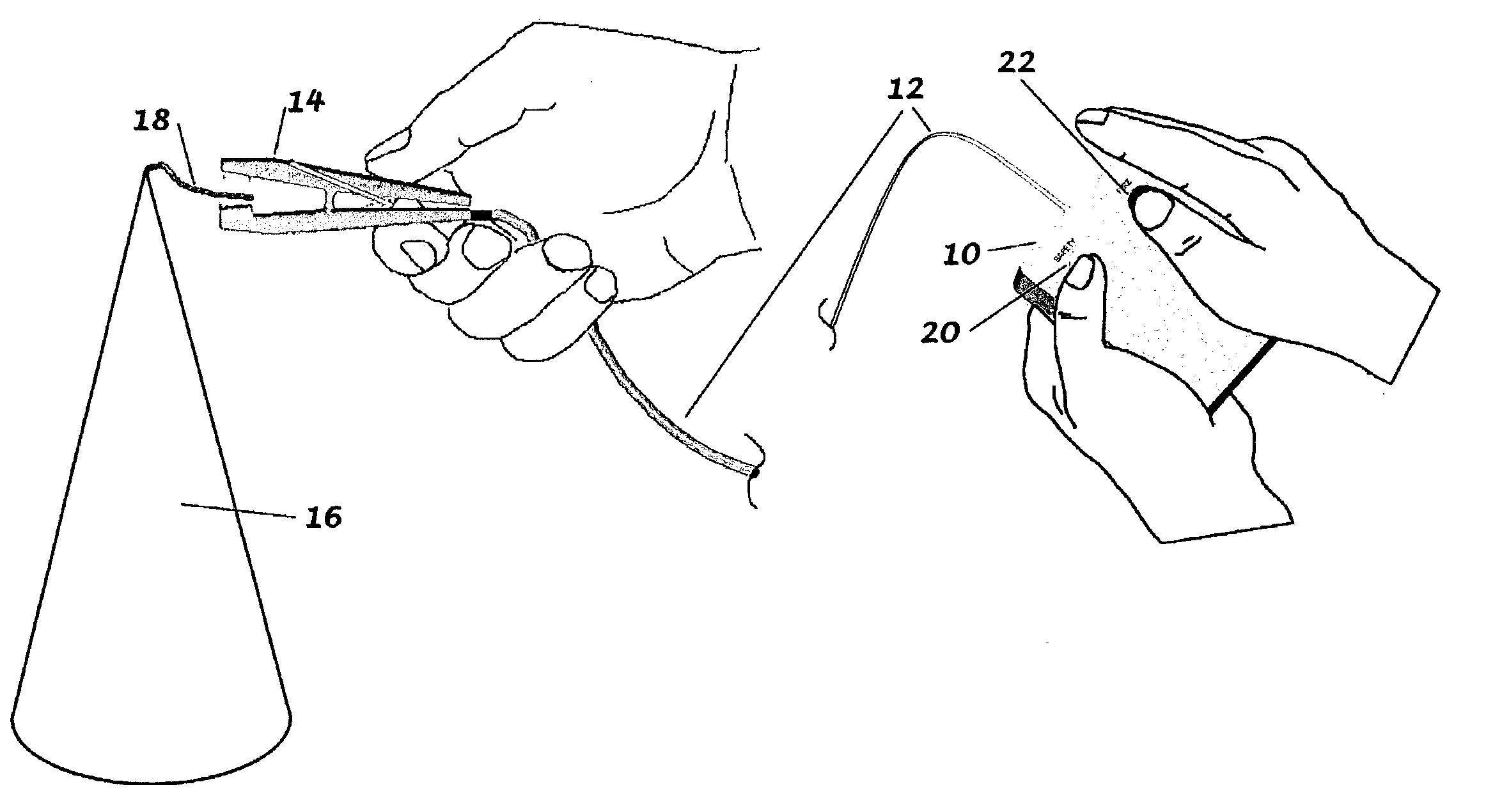

59 results about "Igniter Device Component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A device designed to light a fire.

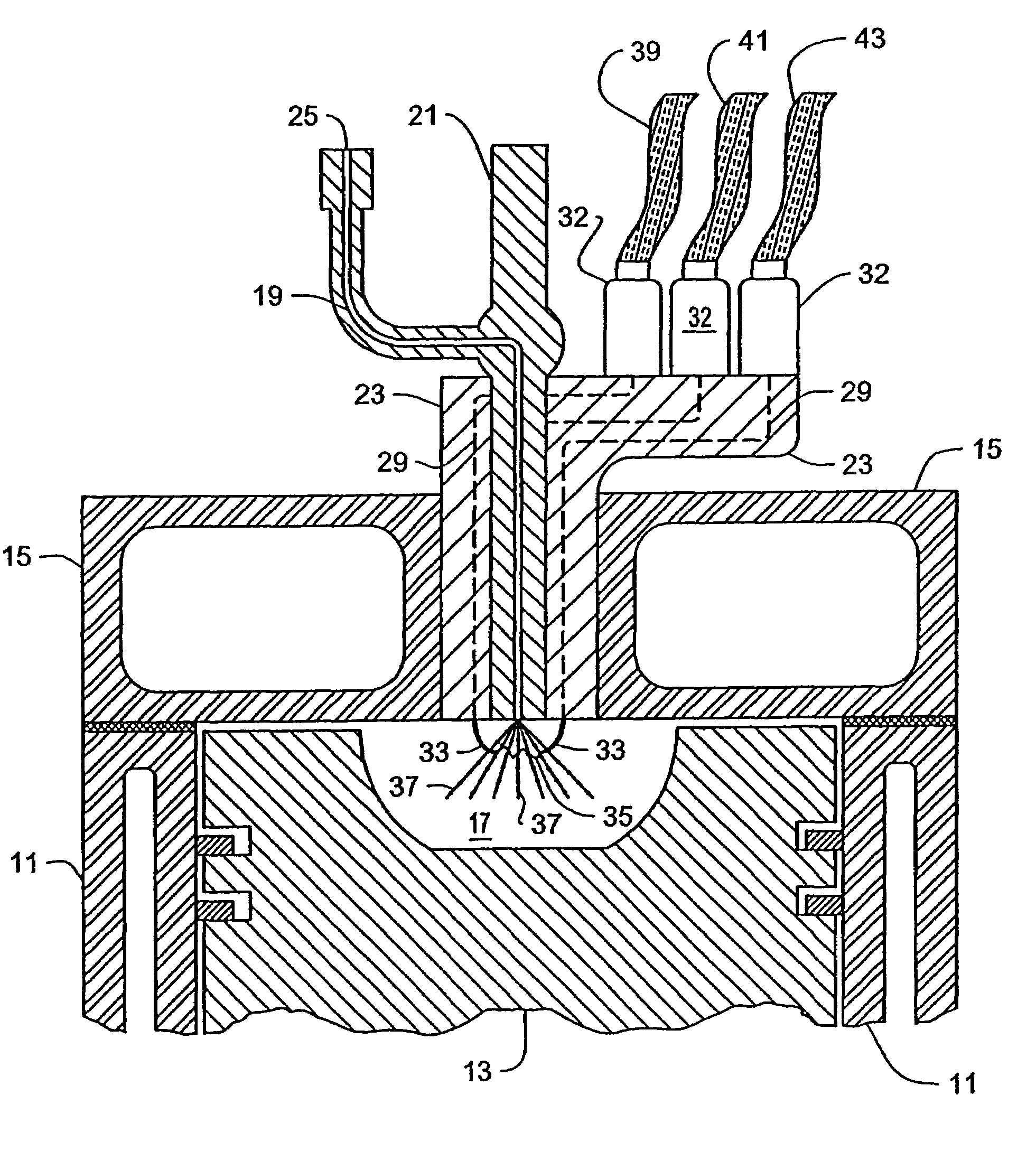

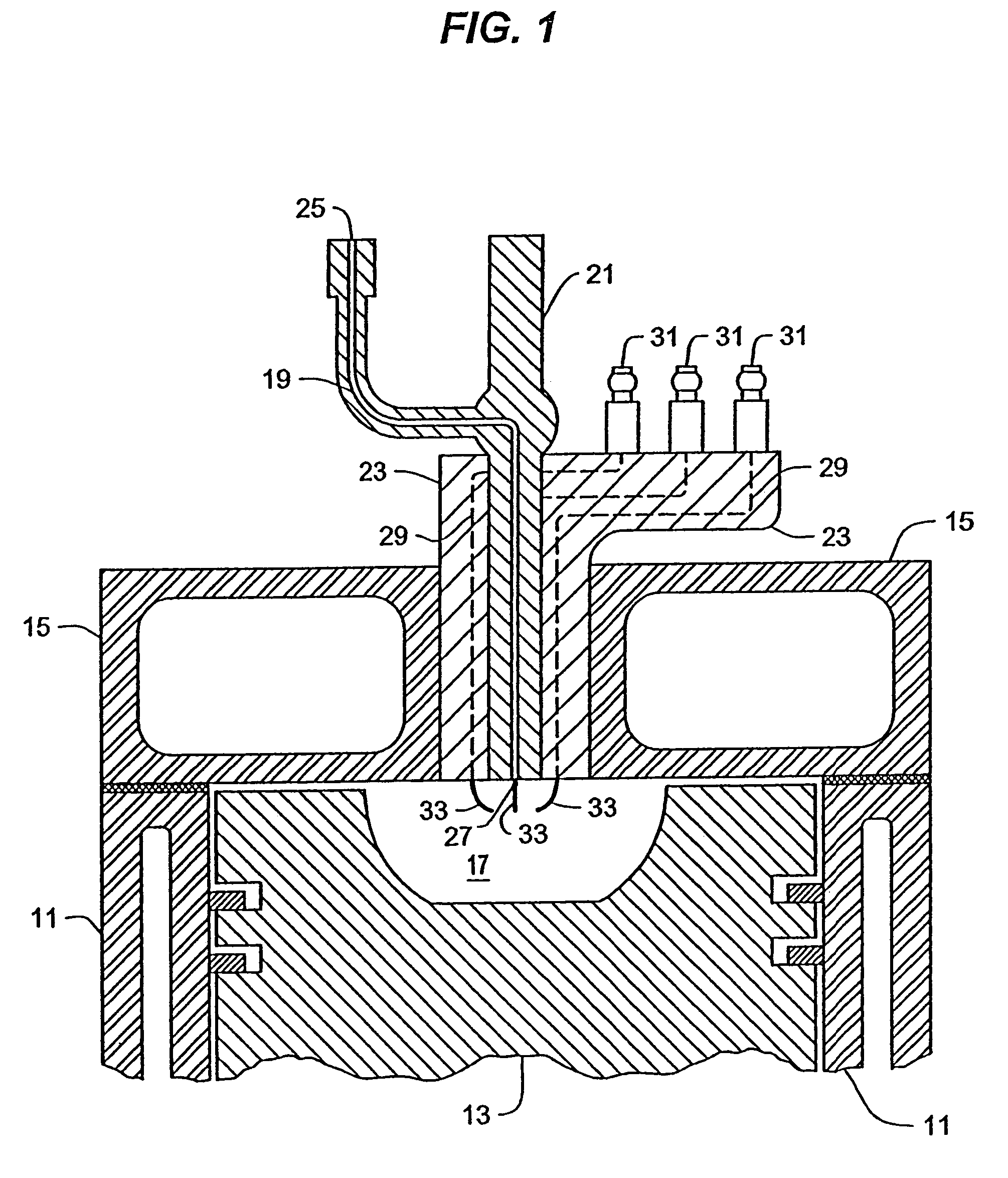

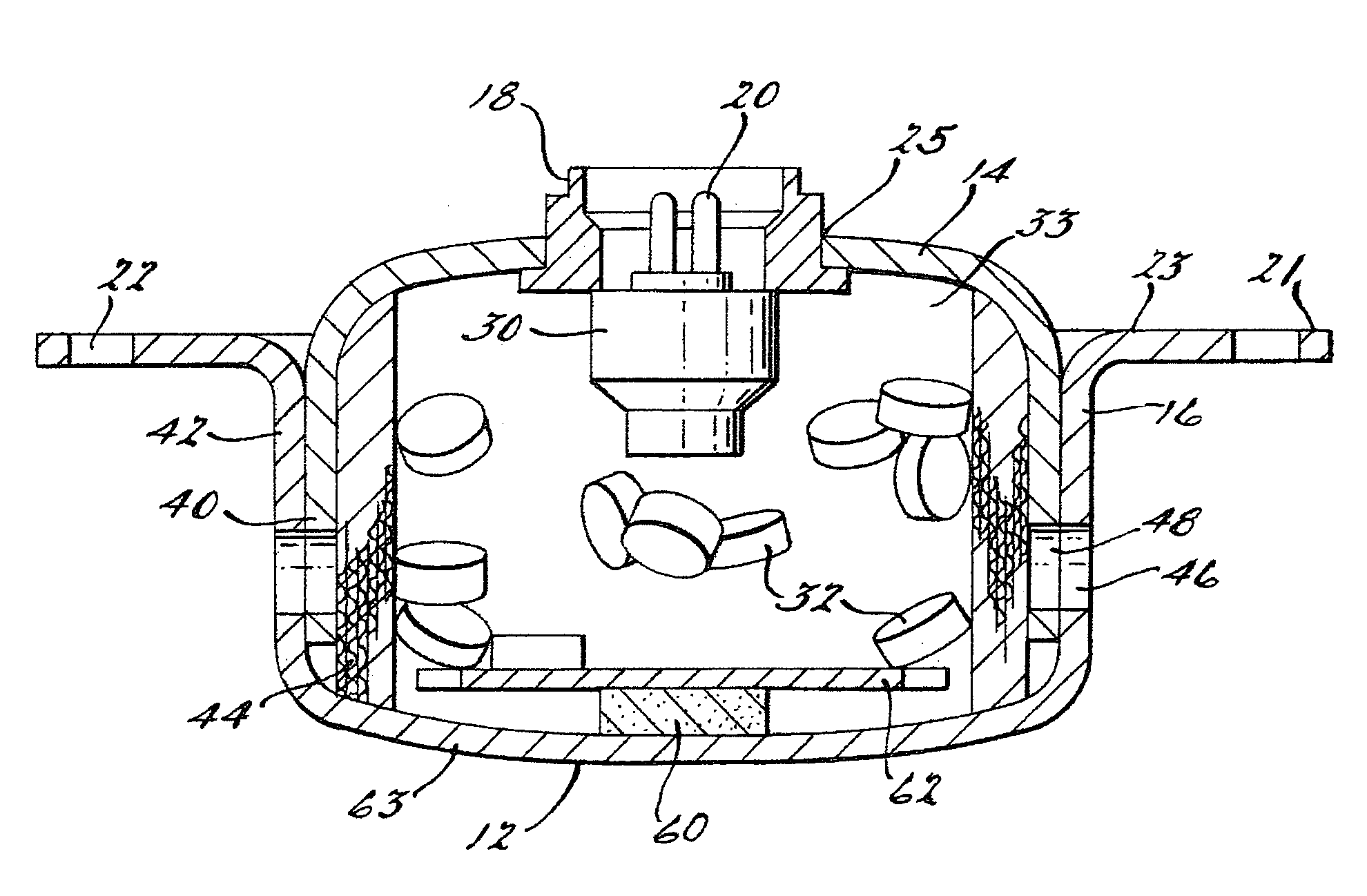

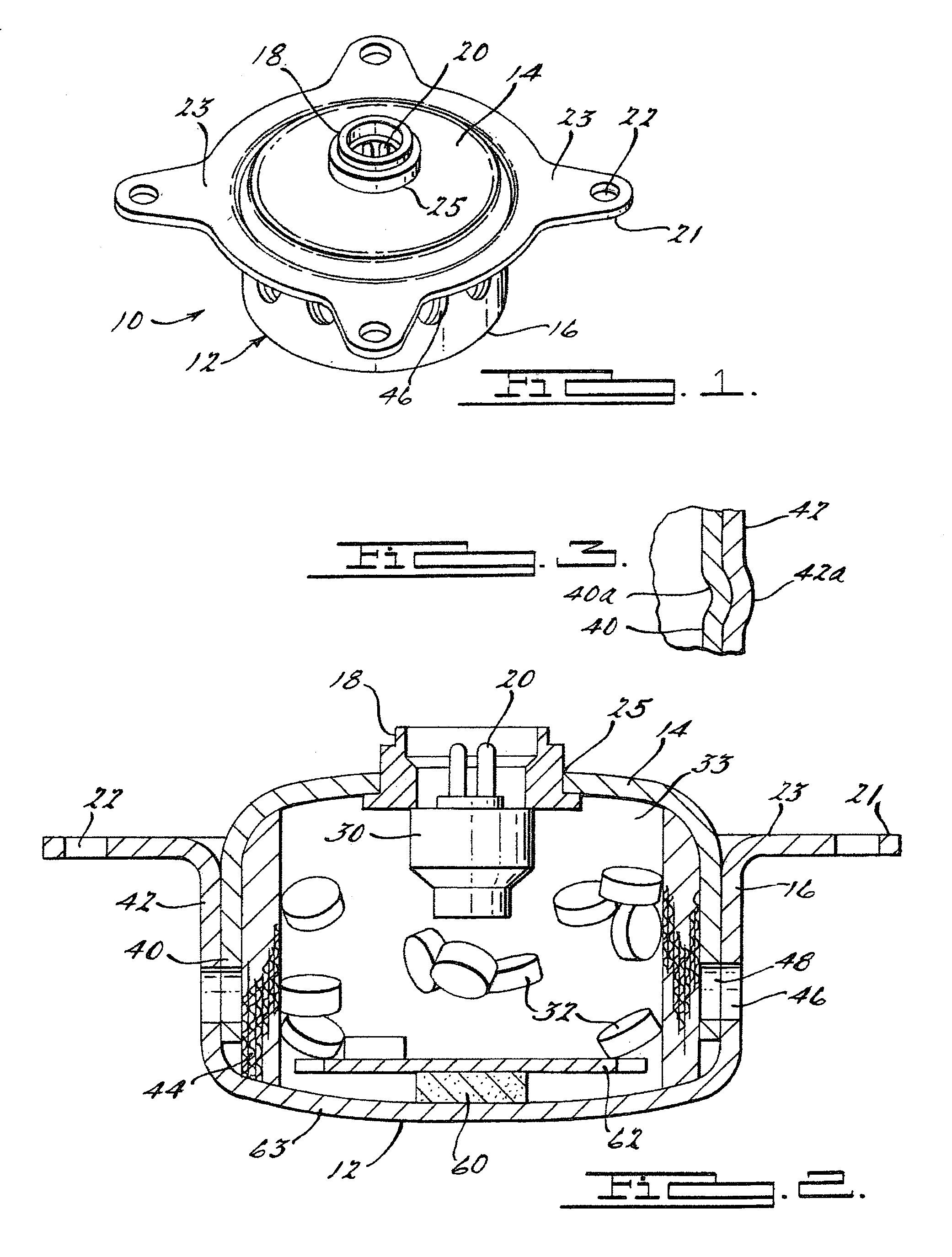

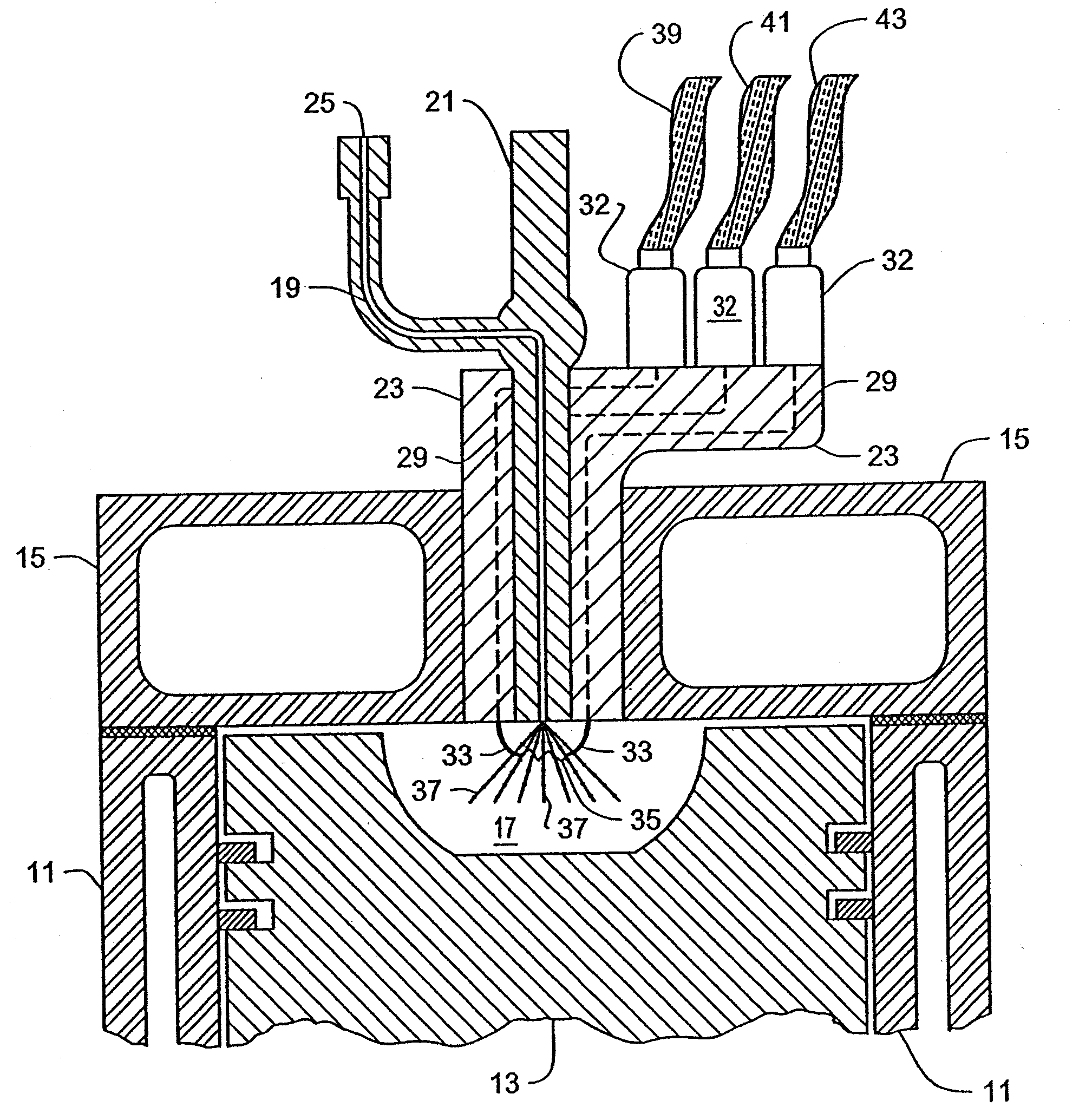

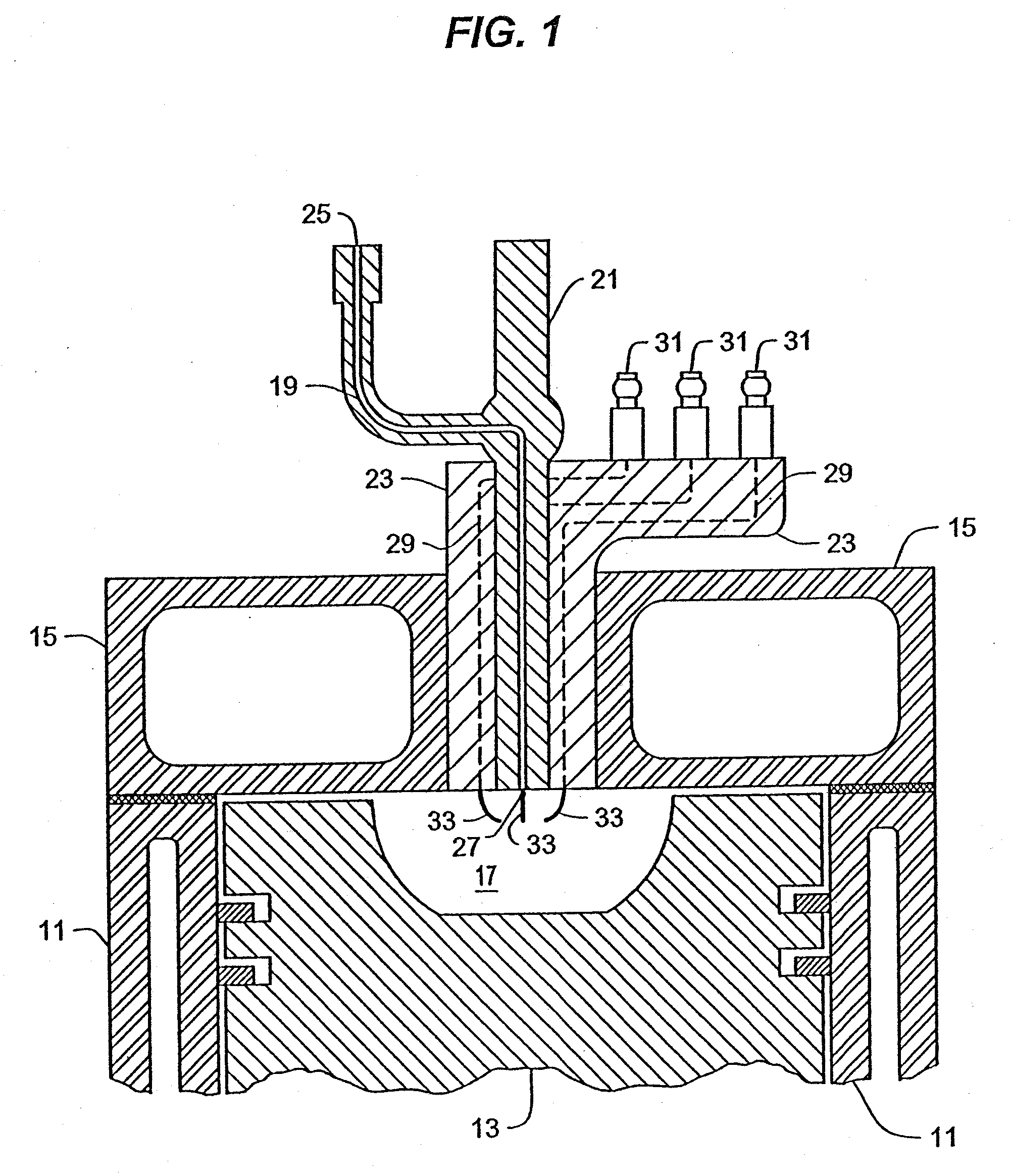

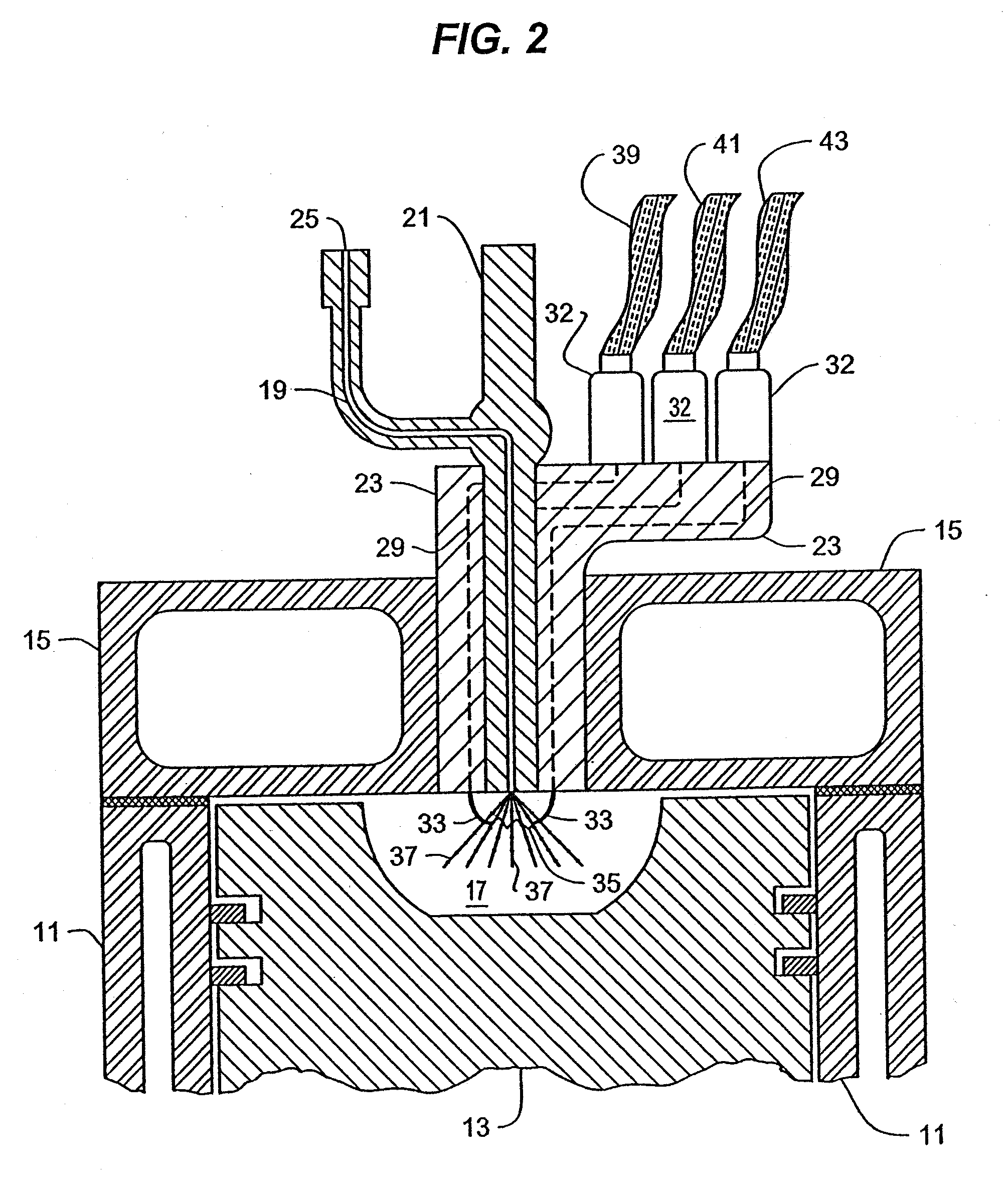

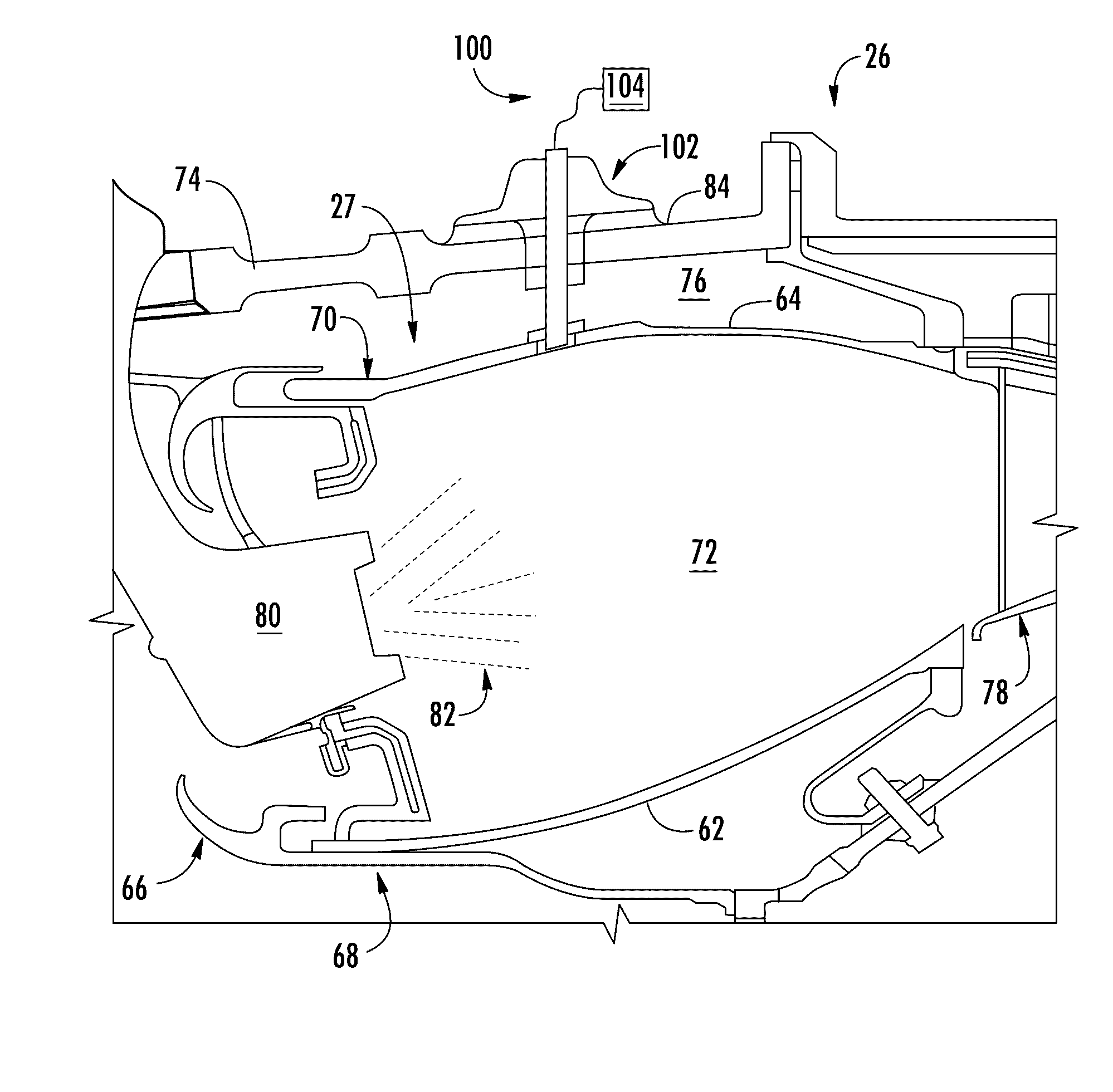

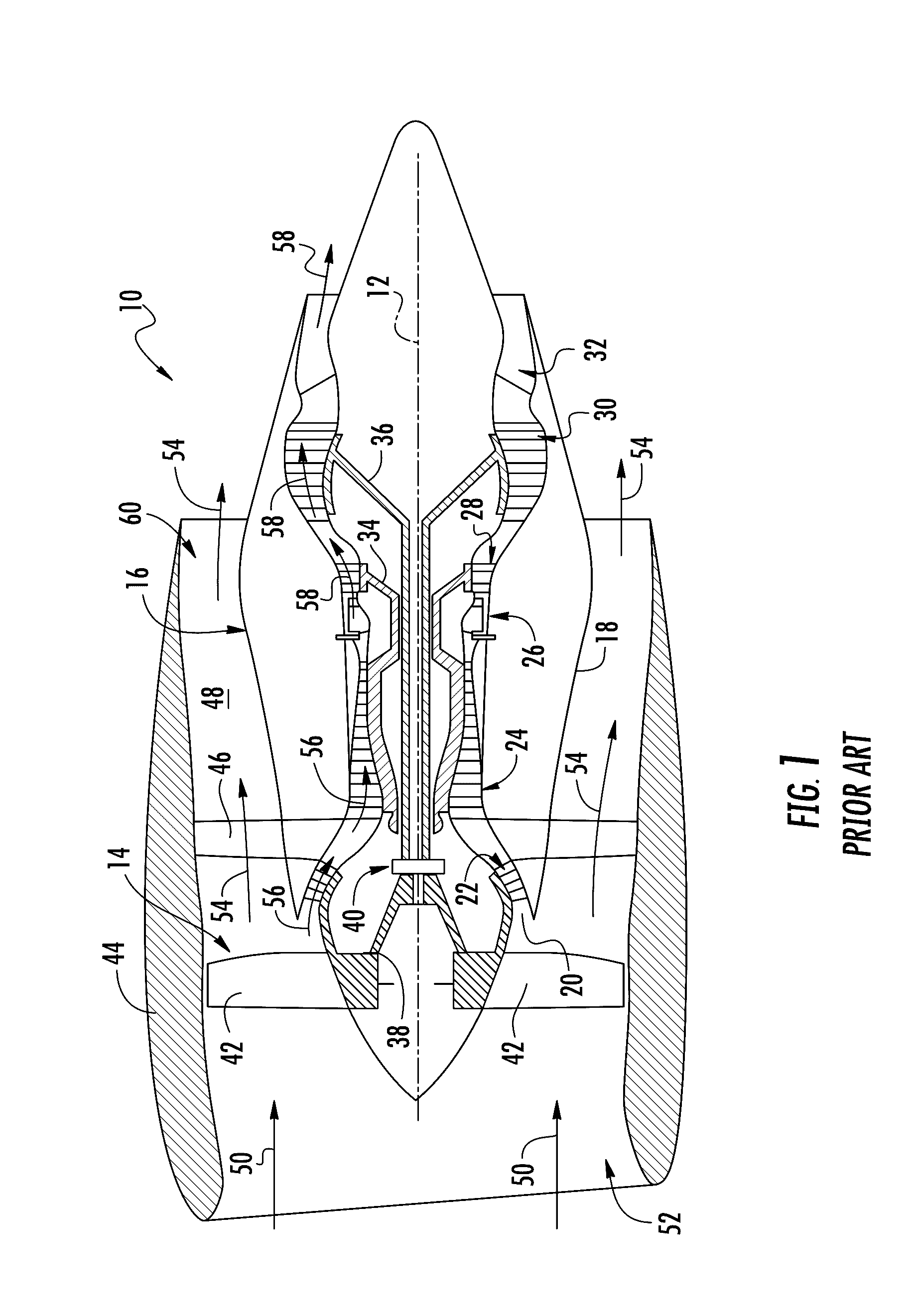

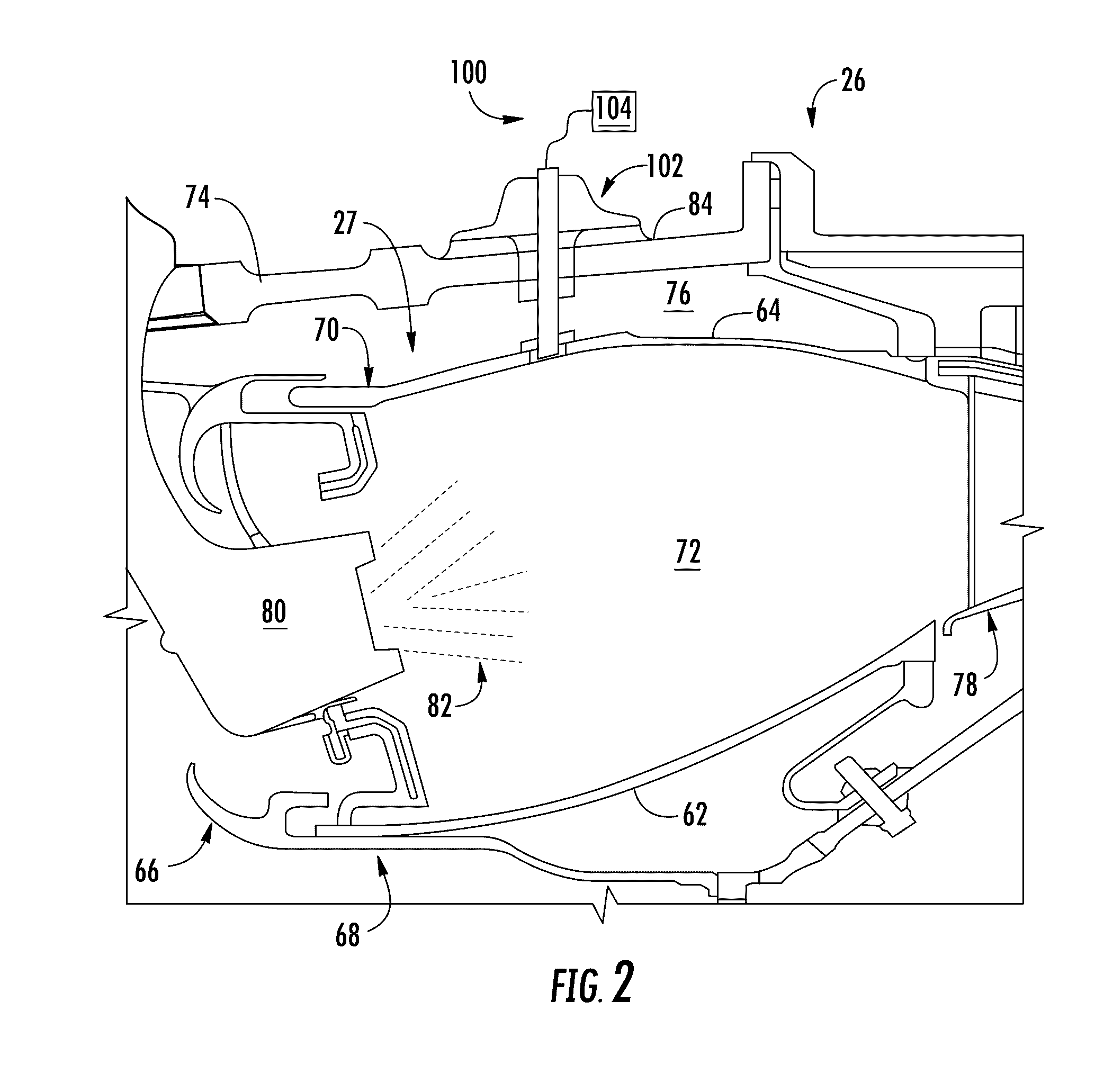

Adaptive heated stage inflator

InactiveUS6139055AImprove performanceImprove protectionPedestrian/occupant safety arrangementEngineeringMechanical engineering

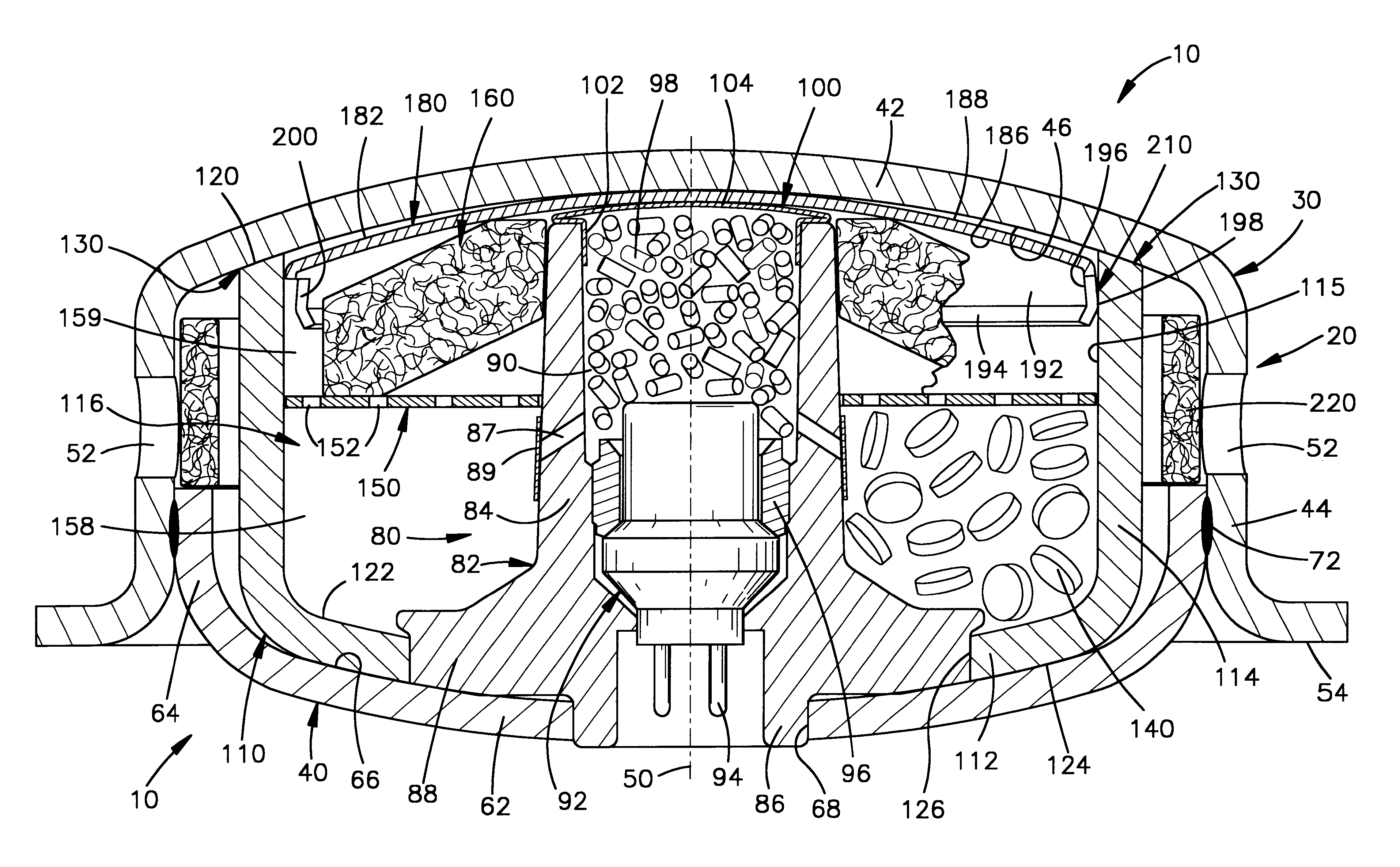

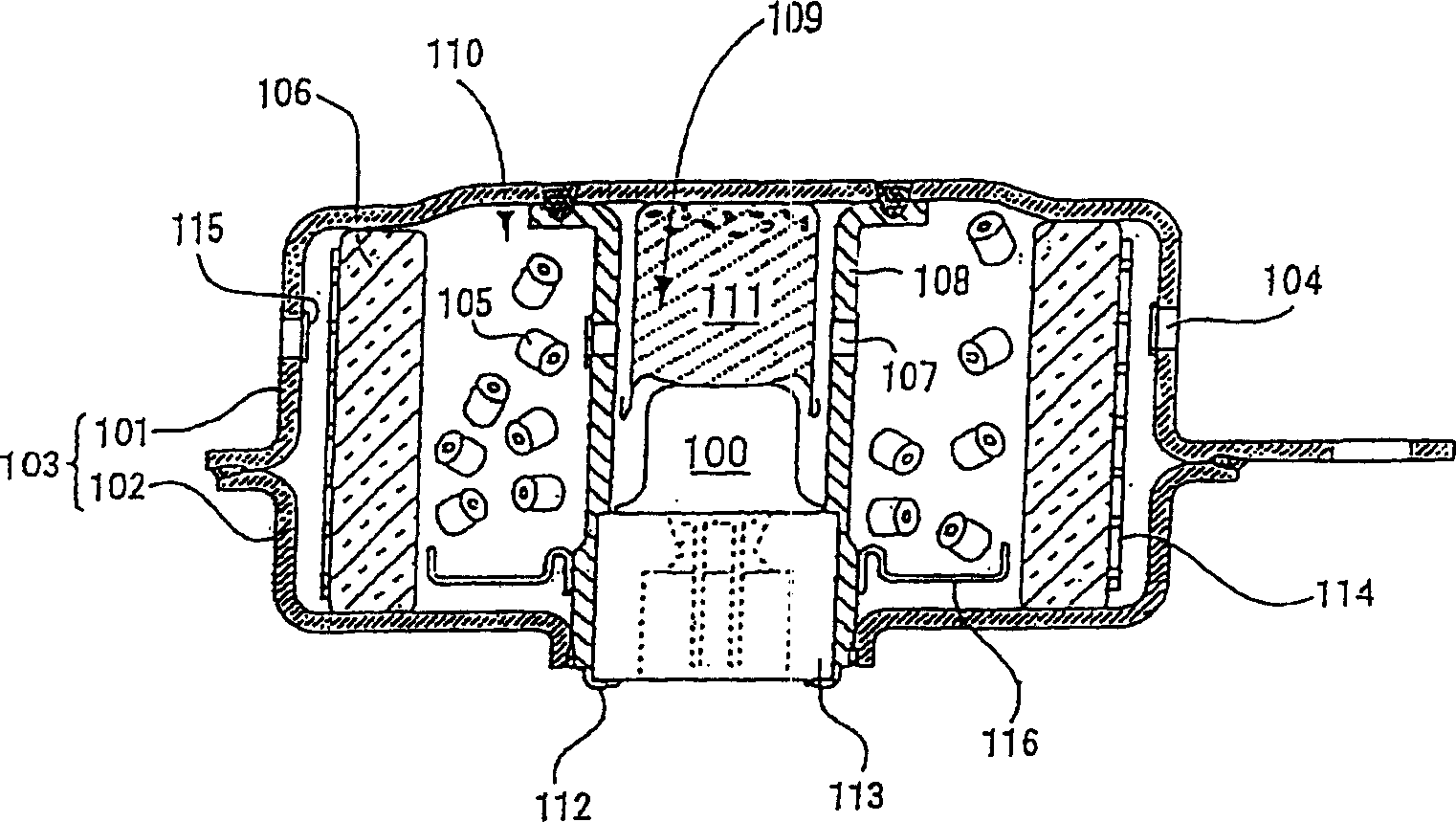

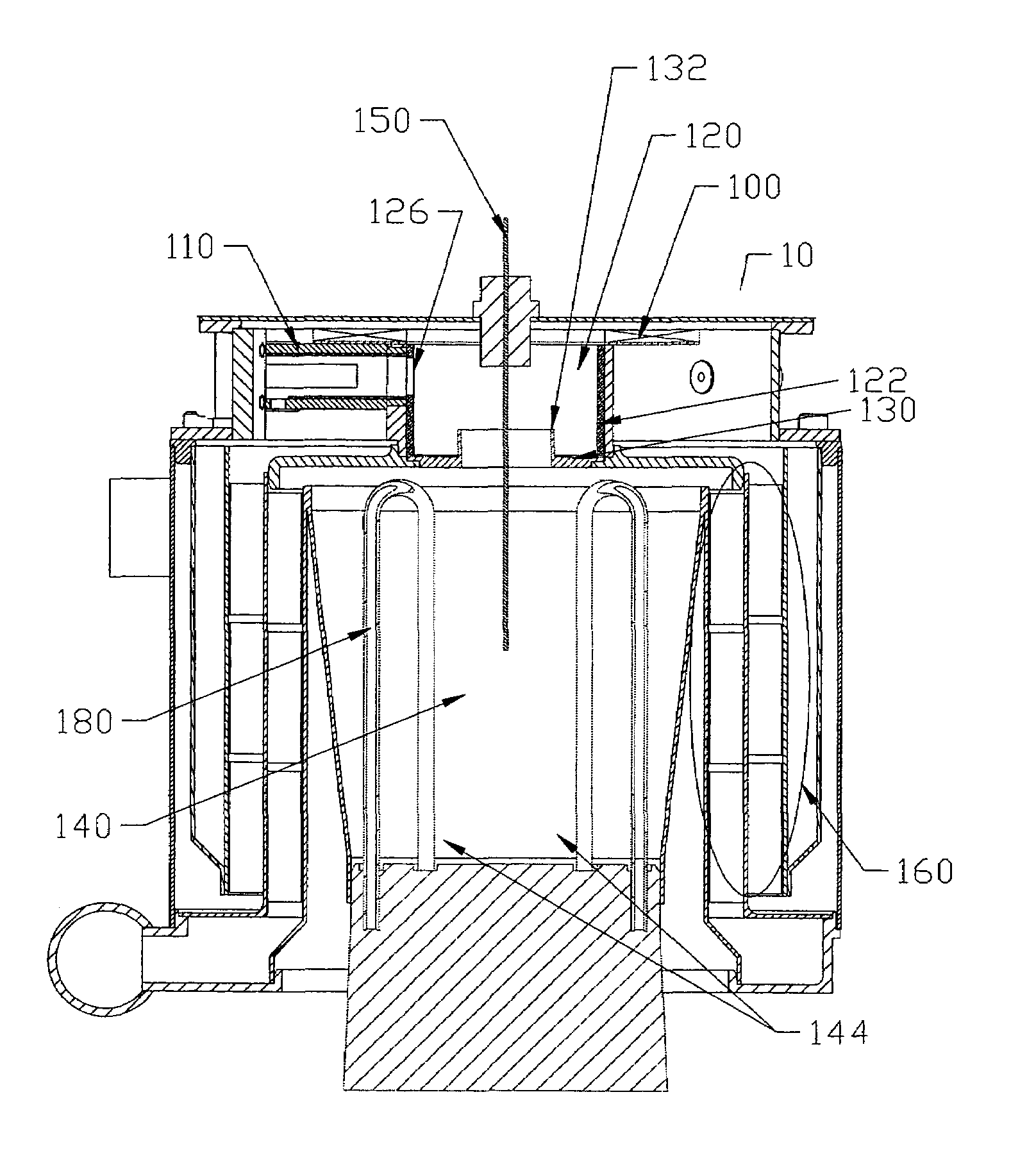

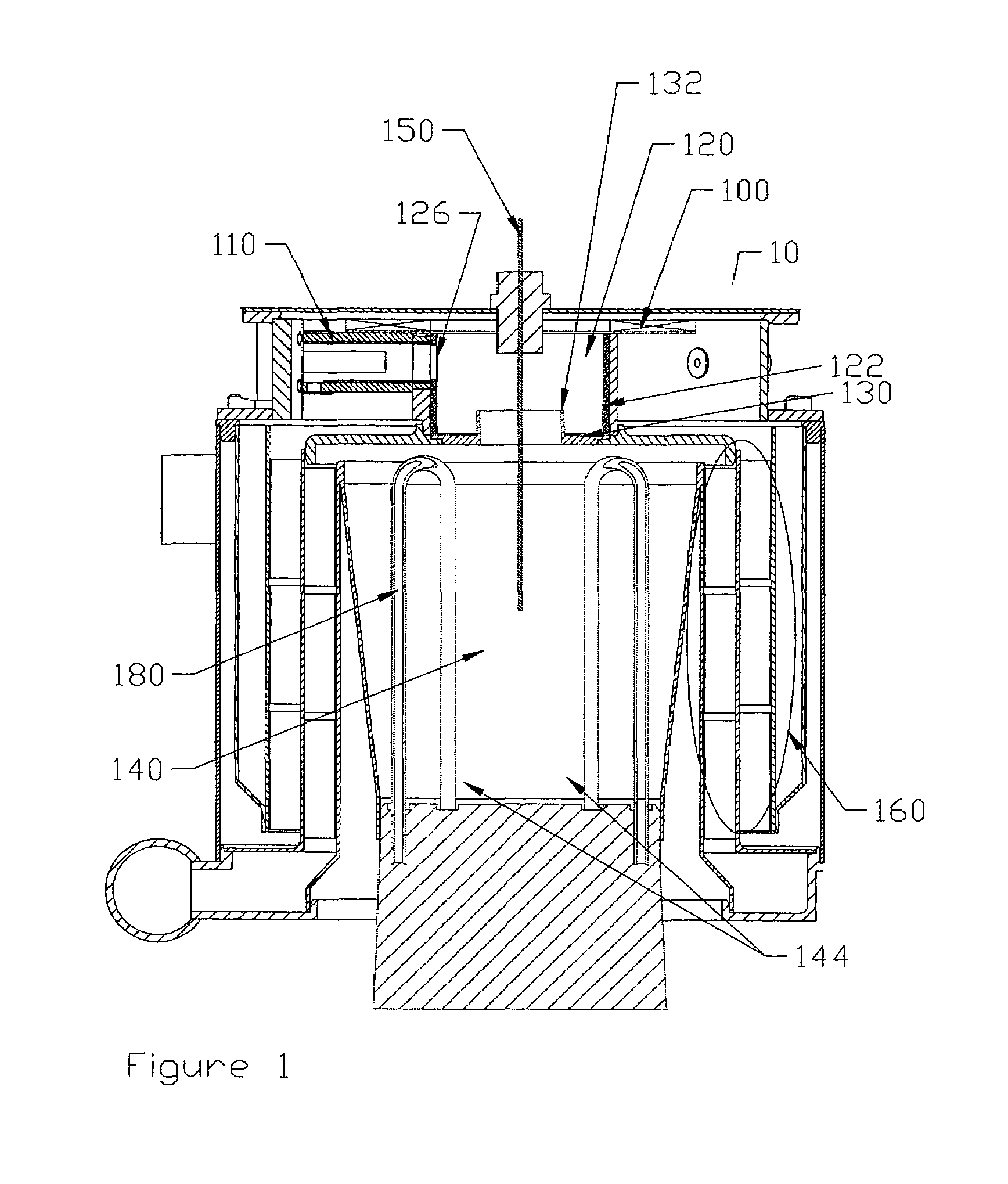

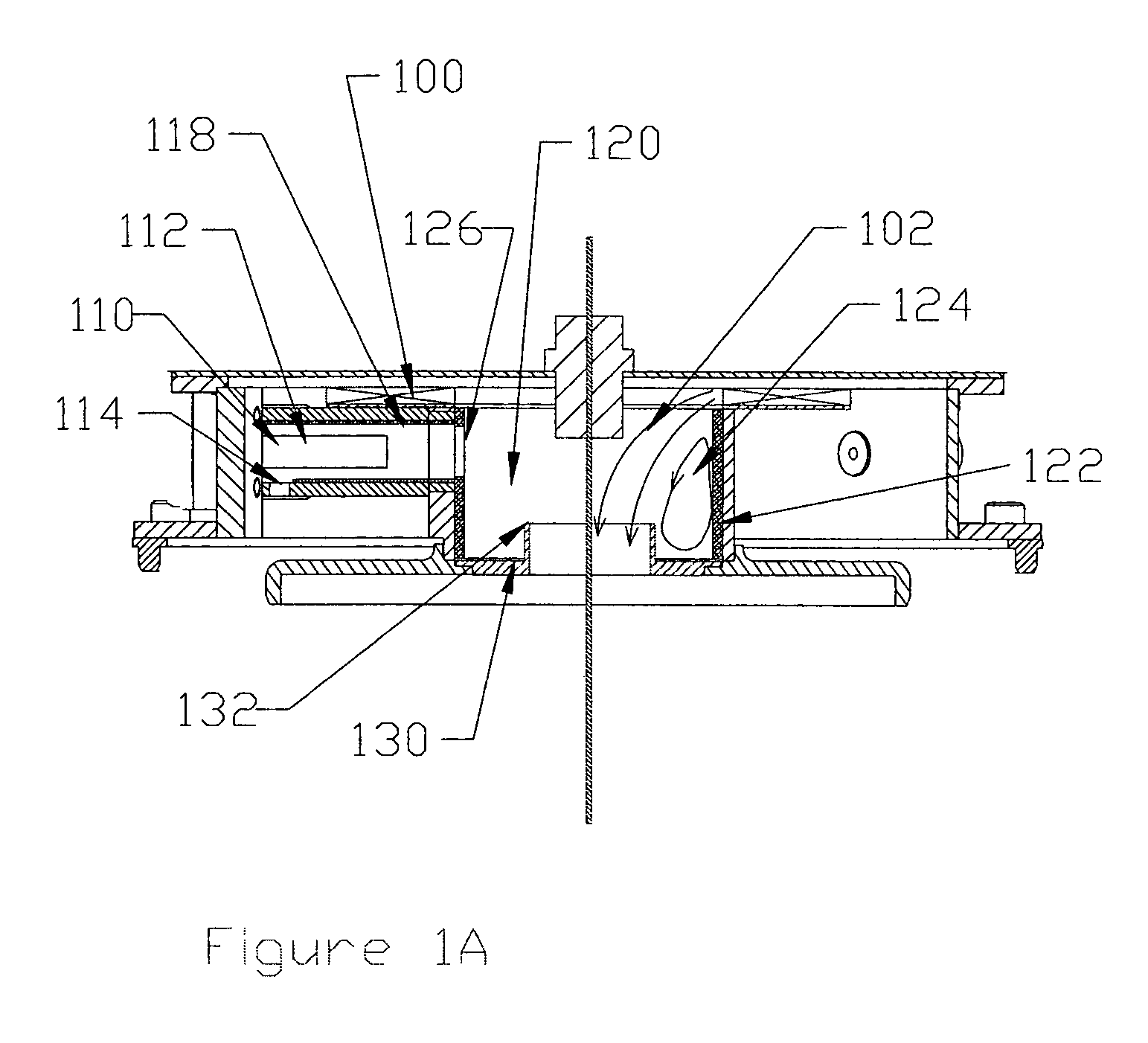

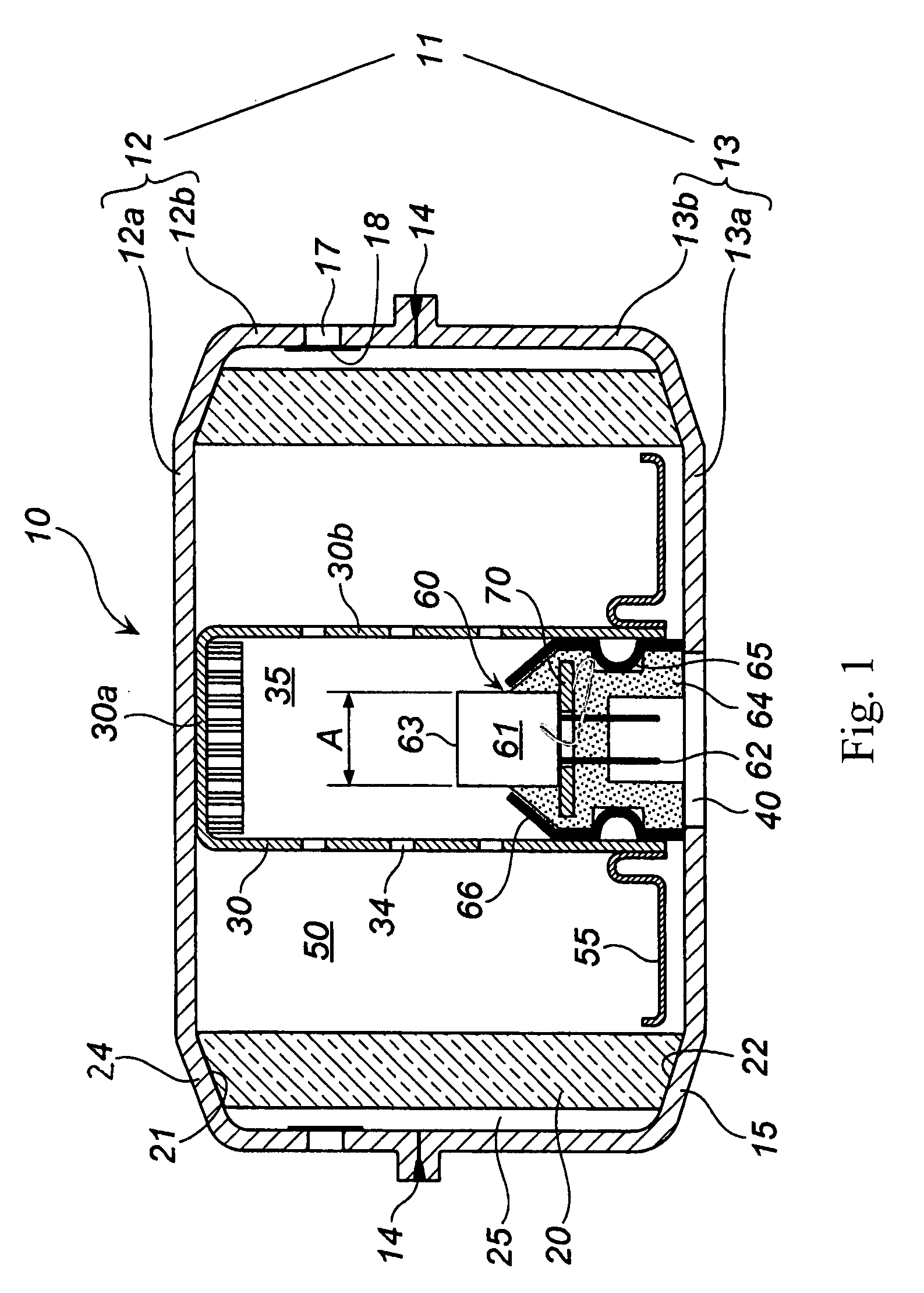

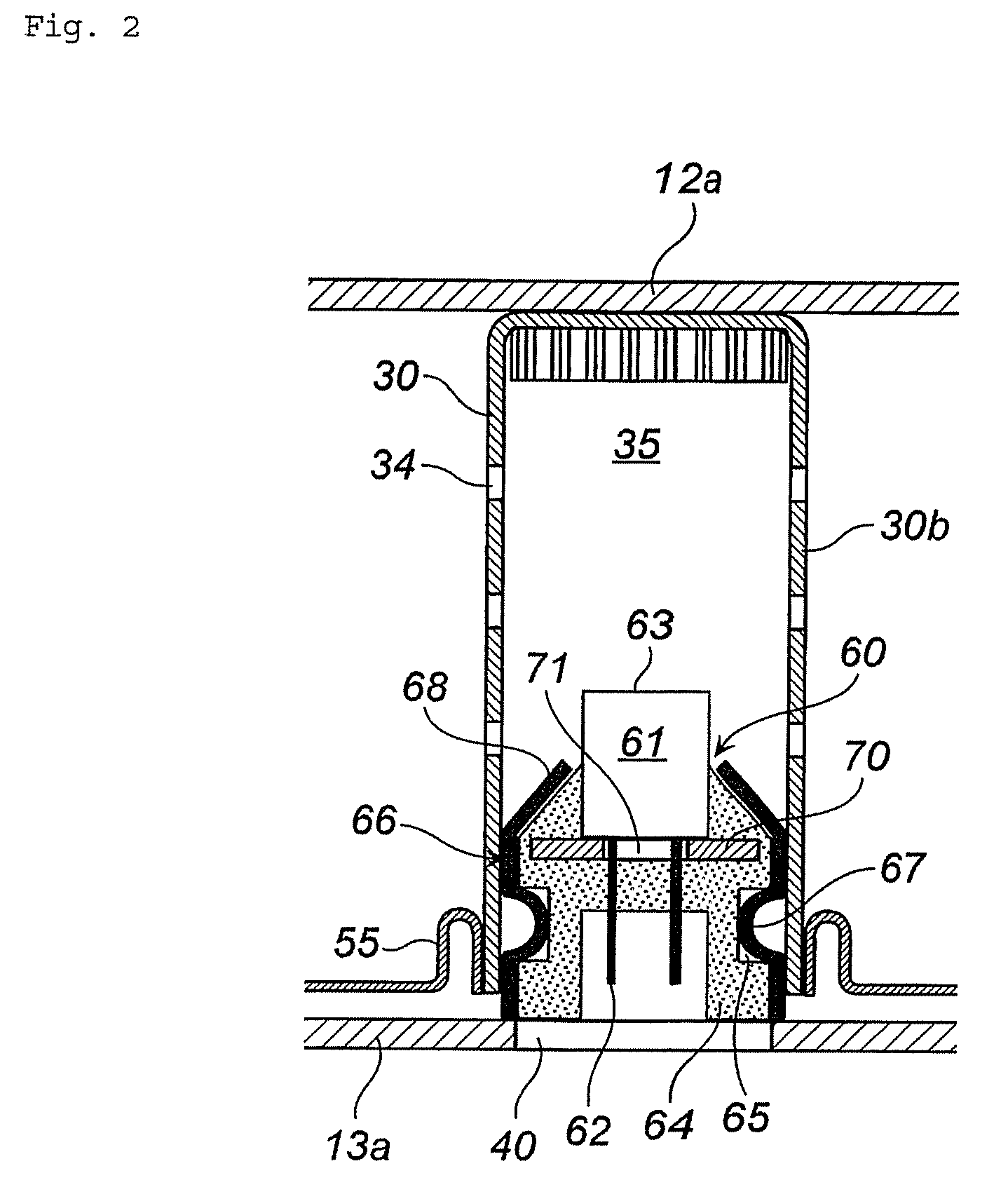

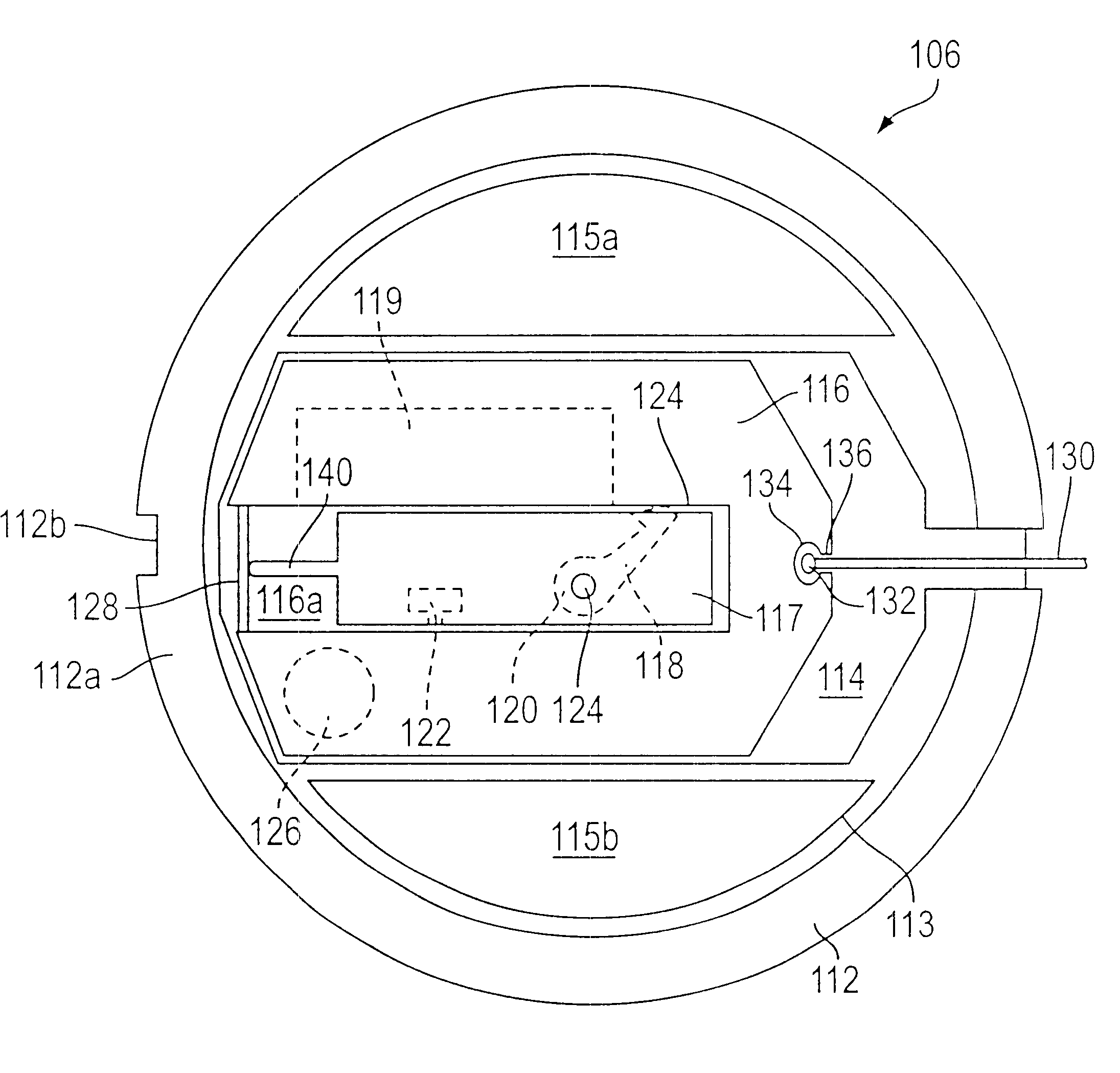

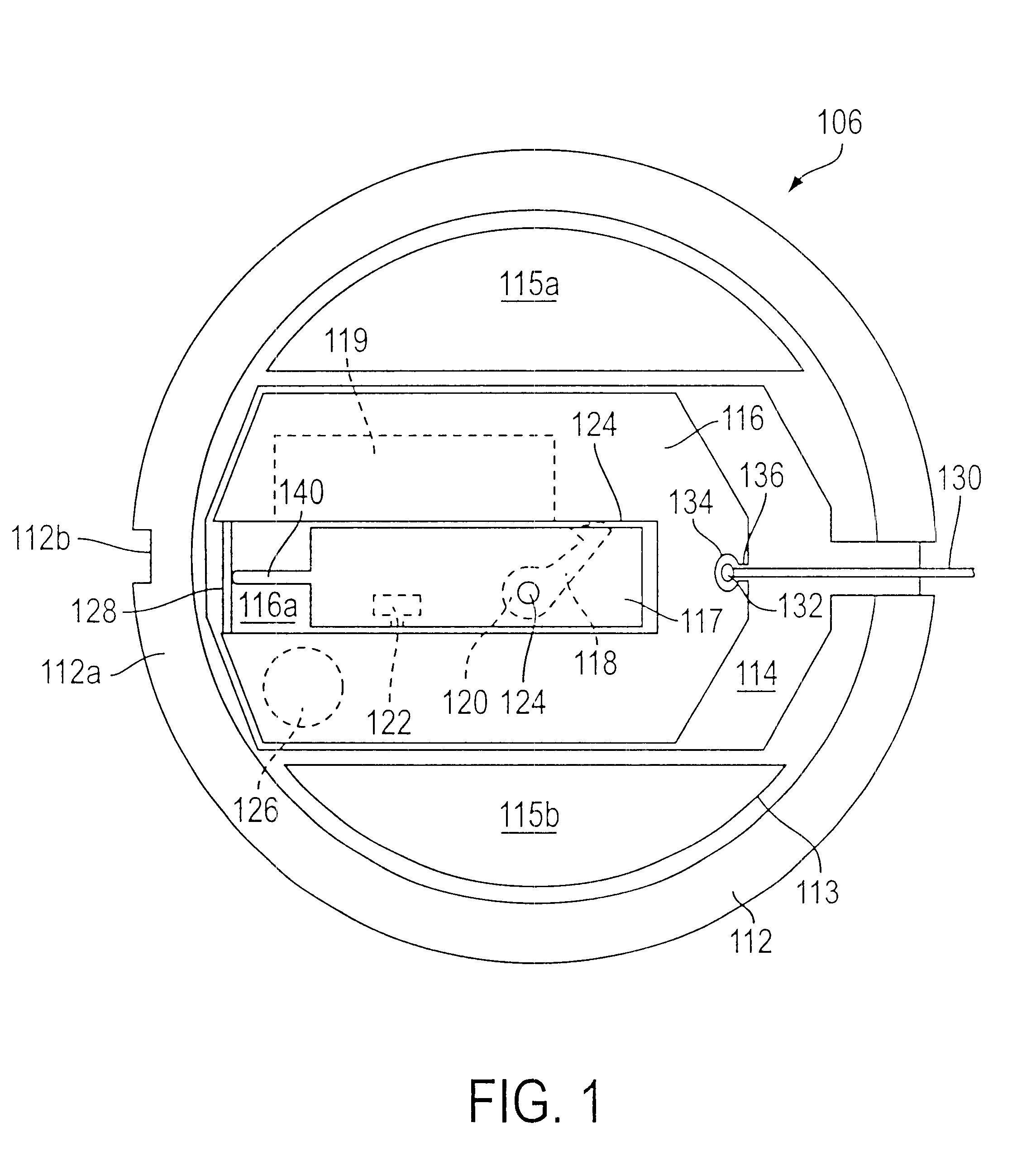

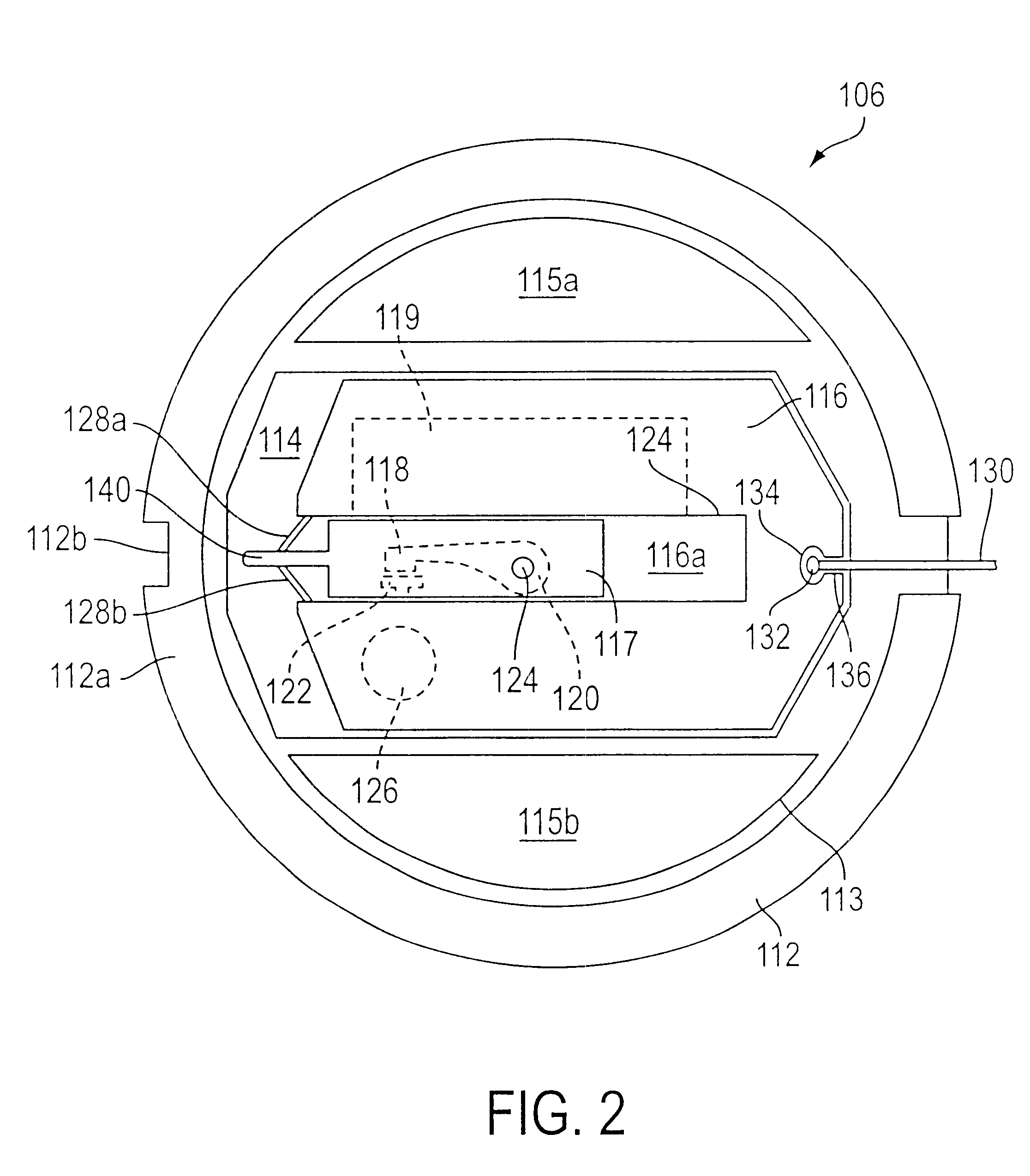

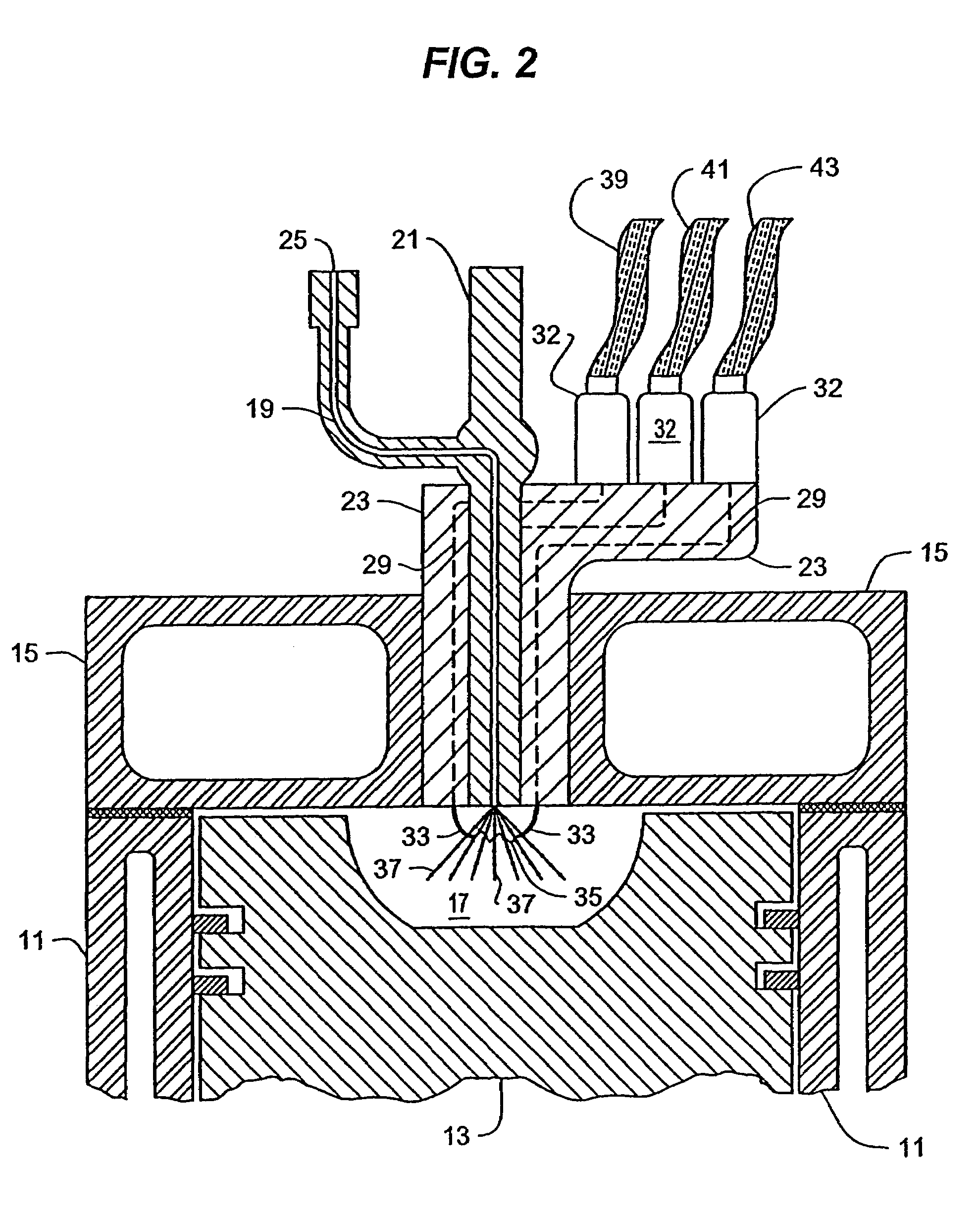

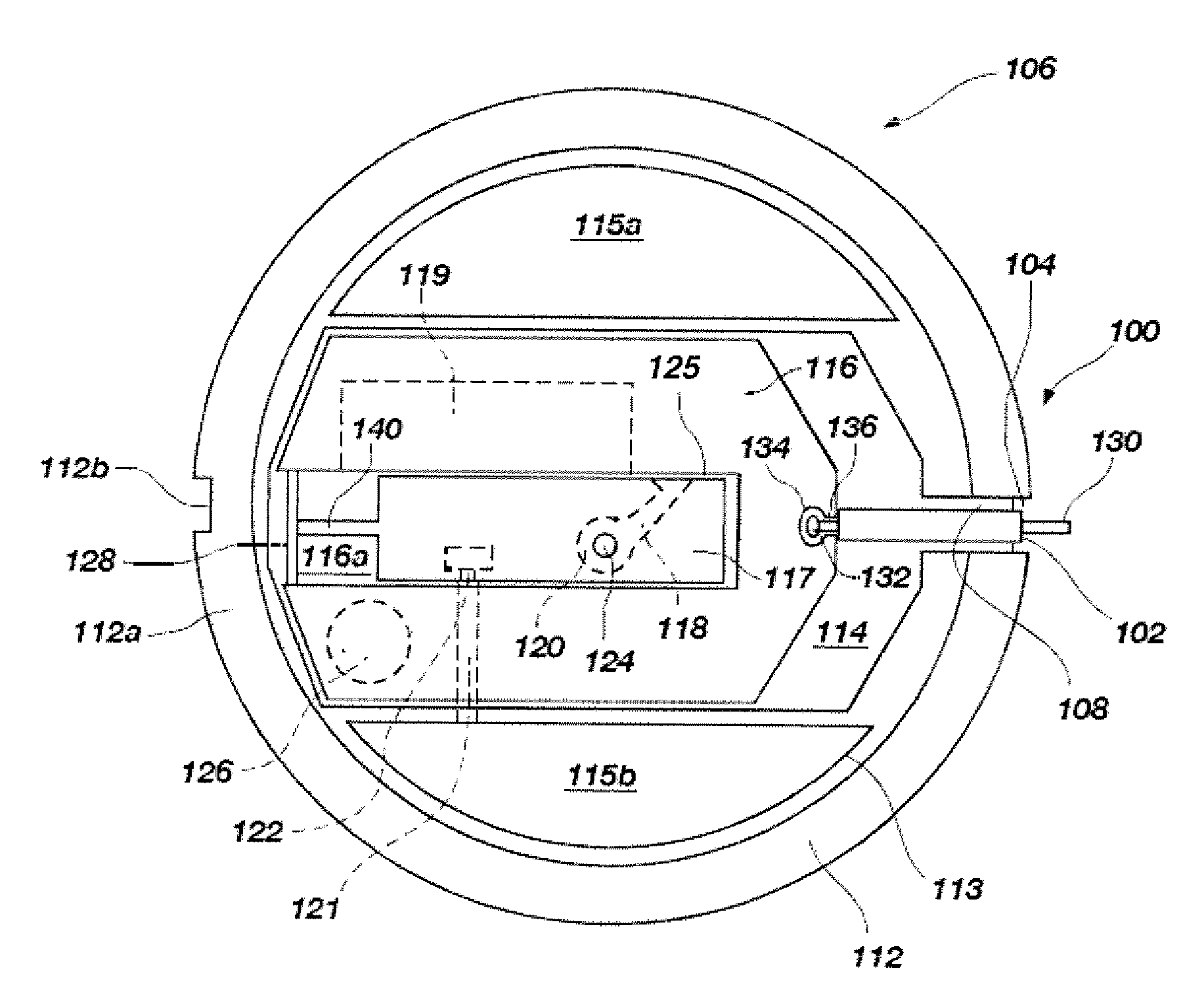

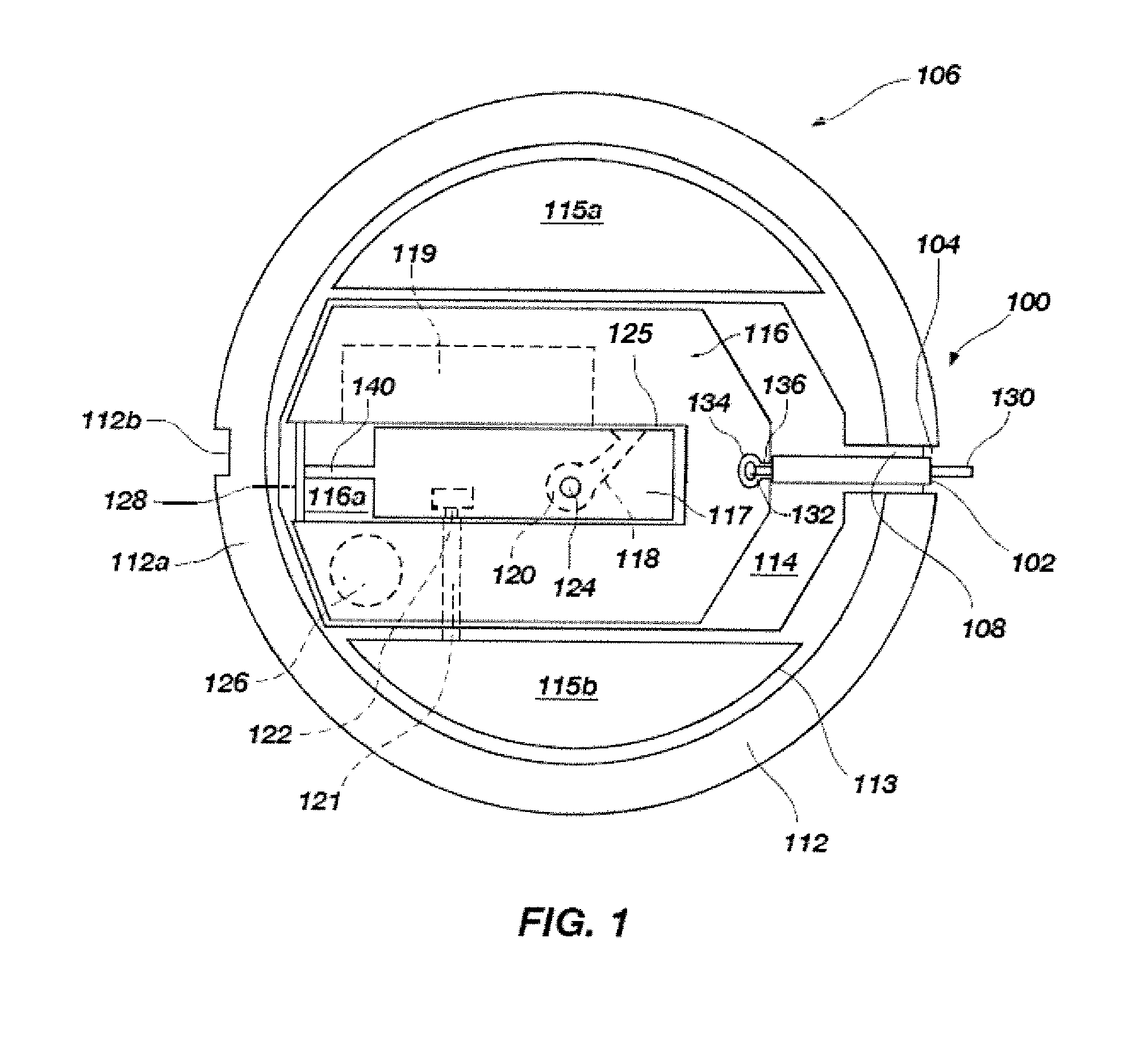

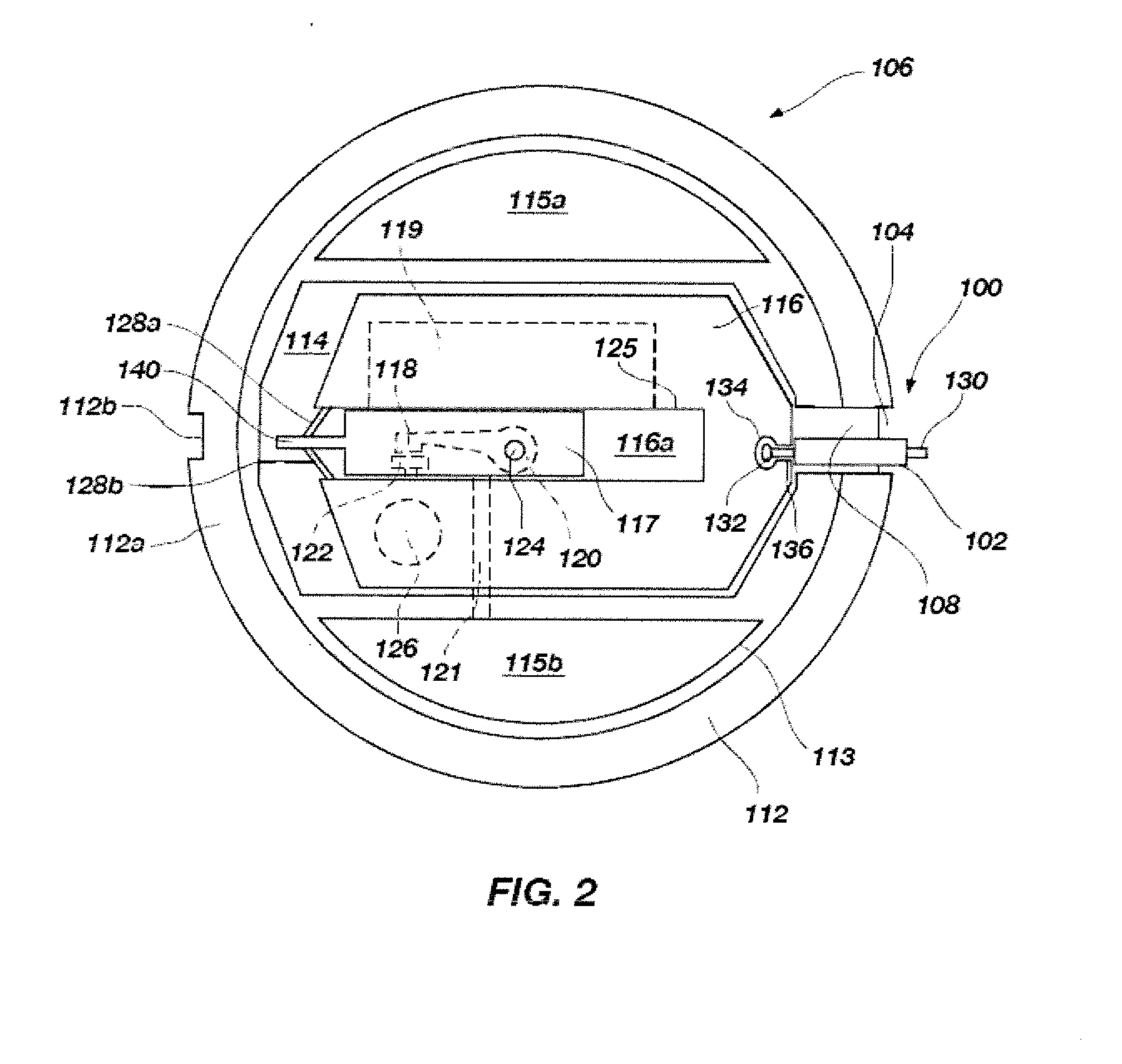

An adaptive multi-stage inflator for inflating an air bag in an air bag safety system. The adaptive multi-stage inflator comprises a housing, a primary igniter assembly and a secondary igniter assembly. The housing has a top wall, a bottom wall and a side wall, which together define an interior chamber therebetween. The primary igniter assembly is disposed in the interior chamber of the housing and is configured to initiate the generation of a primary inflation fluid to inflate an air bag. The secondary igniter assembly is also disposed in the interior chamber of said housing. The secondary igniter assembly is configured to augment the primary inflation fluid by producing a secondary inflation fluid to further inflate the air bag. The inflator also includes a bypass assembly that is configured to provide the secondary inflation fluid to the air bag at substantially the same temperature as it was produced by the secondary igniter assembly, thereby increasing the pressure of the primary inflation fluid. The bypass assembly comprises a bypass passage configured such that the secondary igniter assembly is in direct fluid communication with the air bag. The bypass assembly has a retainer disk which in combination with the interior surface of the housing defines the bypass passage. The inflator also includes a filter disposed in the housing proximate to the side wall thereof to prevent the passage of particulates. The bypass assembly is configured to direct the secondary inflation fluid to the air bag without the secondary inflation fluid passing through the filter. Both the primary igniter assembly and the secondary igniter assembly comprises a quantity of igniter material.

Owner:AUTOLIV ASP INC

Energetic material initiation device utilizing exploding foil initiated ignition system with secondary explosive material

An igniter assembly with a housing, an initiator, an input charge, a first barrier, a second barrier, and an output charge. The input charge is formed of a secondary explosive and disposed adjacent the initiator. The first barrier cooperates with the housing to form a chamber into which the input charge is received. The second barrier is disposed on a side of the first barrier opposite the input charge and combusts in response to energy released during detonation of the input charge. The output charge is formed of a pyrotechnic material and disposed on a side of the second barrier opposite the first barrier. The output charge can combust in response to energy released during combustion of the second barrier. The housing and the first barrier cooperate to isolate the output charge from heat and pressure generated by the input charge if the input charge is cooked-off.

Owner:REYNOLDS SYST

Air bag inflator with pressure regulation

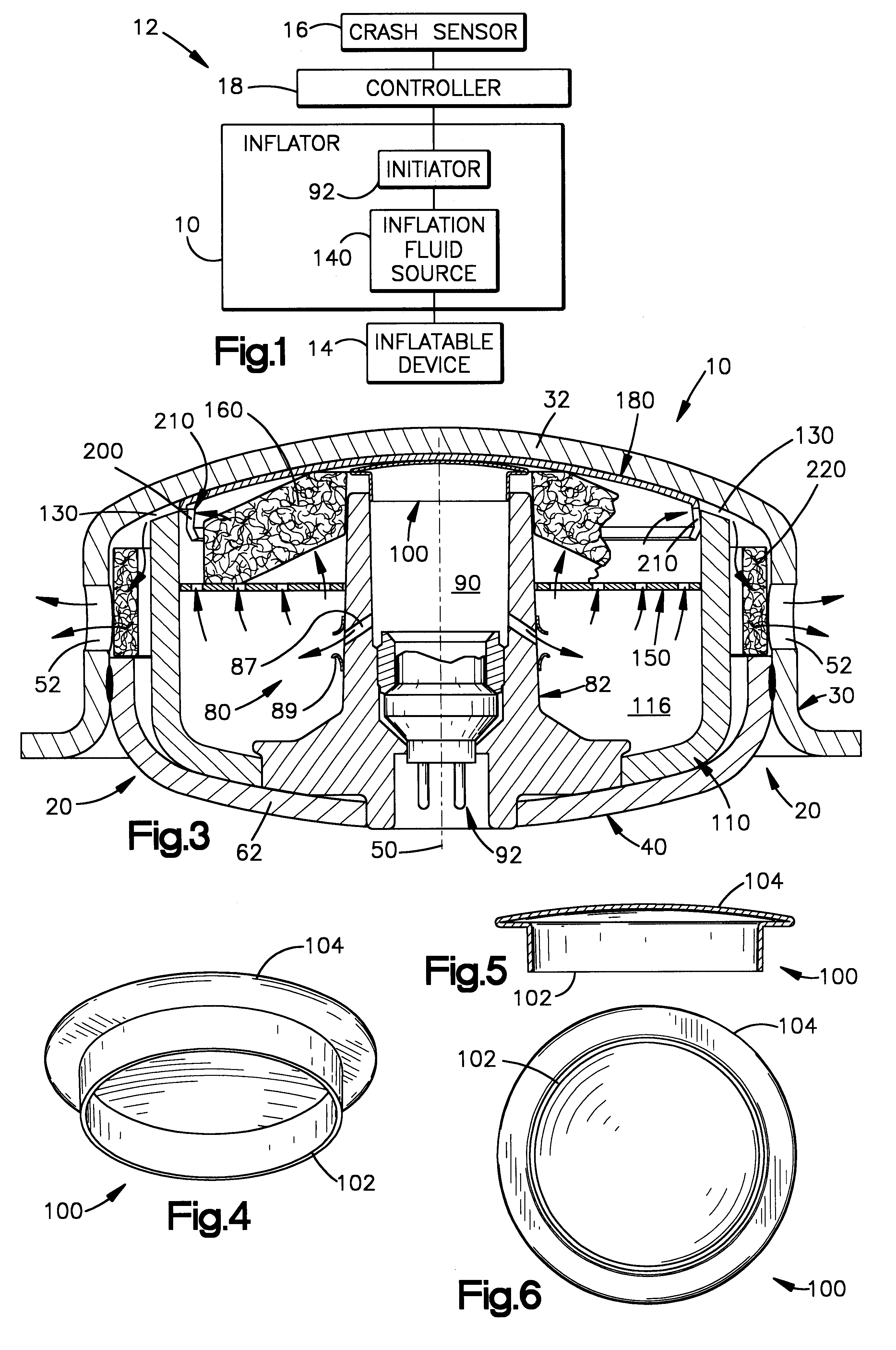

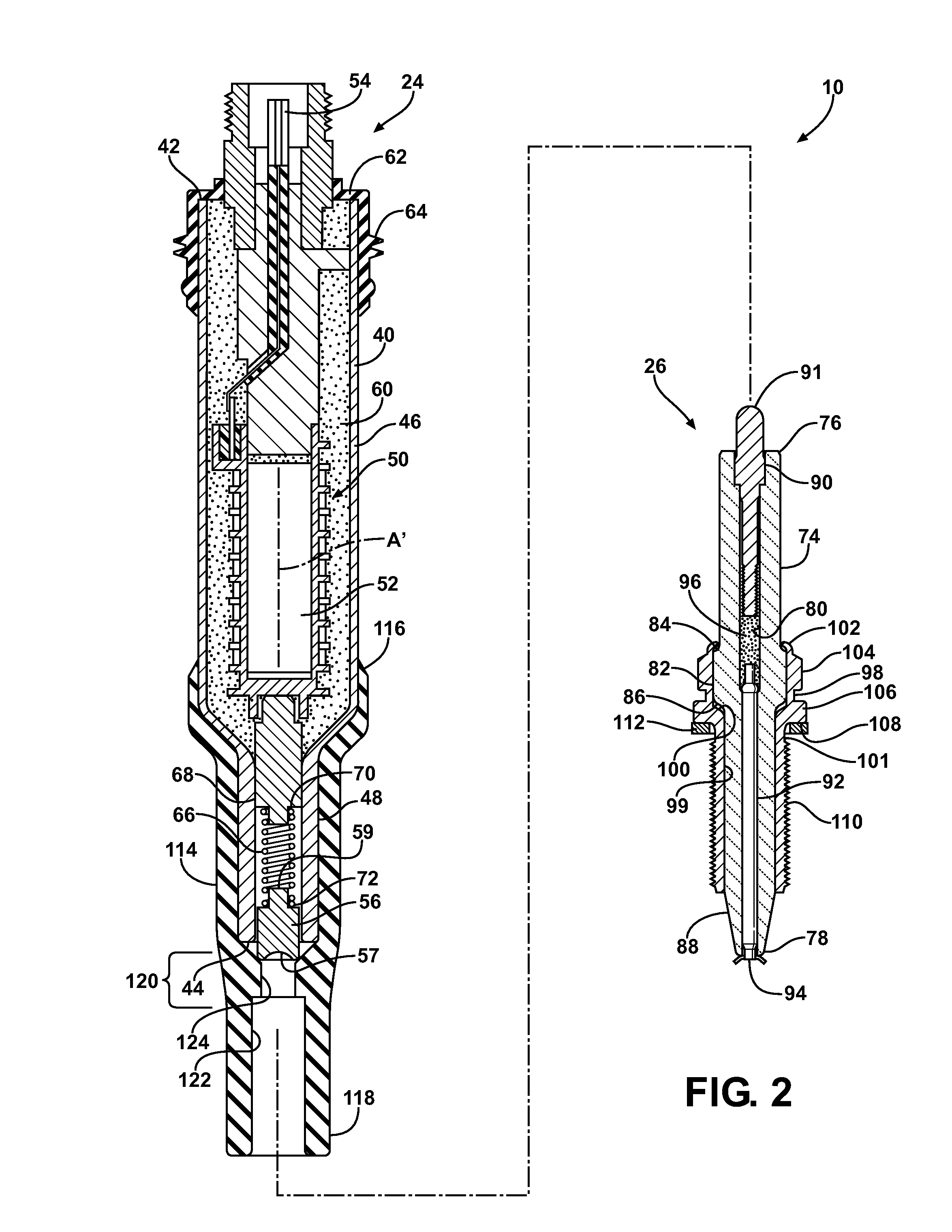

InactiveUS6290256B1Avoid shockPedestrian/occupant safety arrangementMechanical engineeringIgniter Device Component

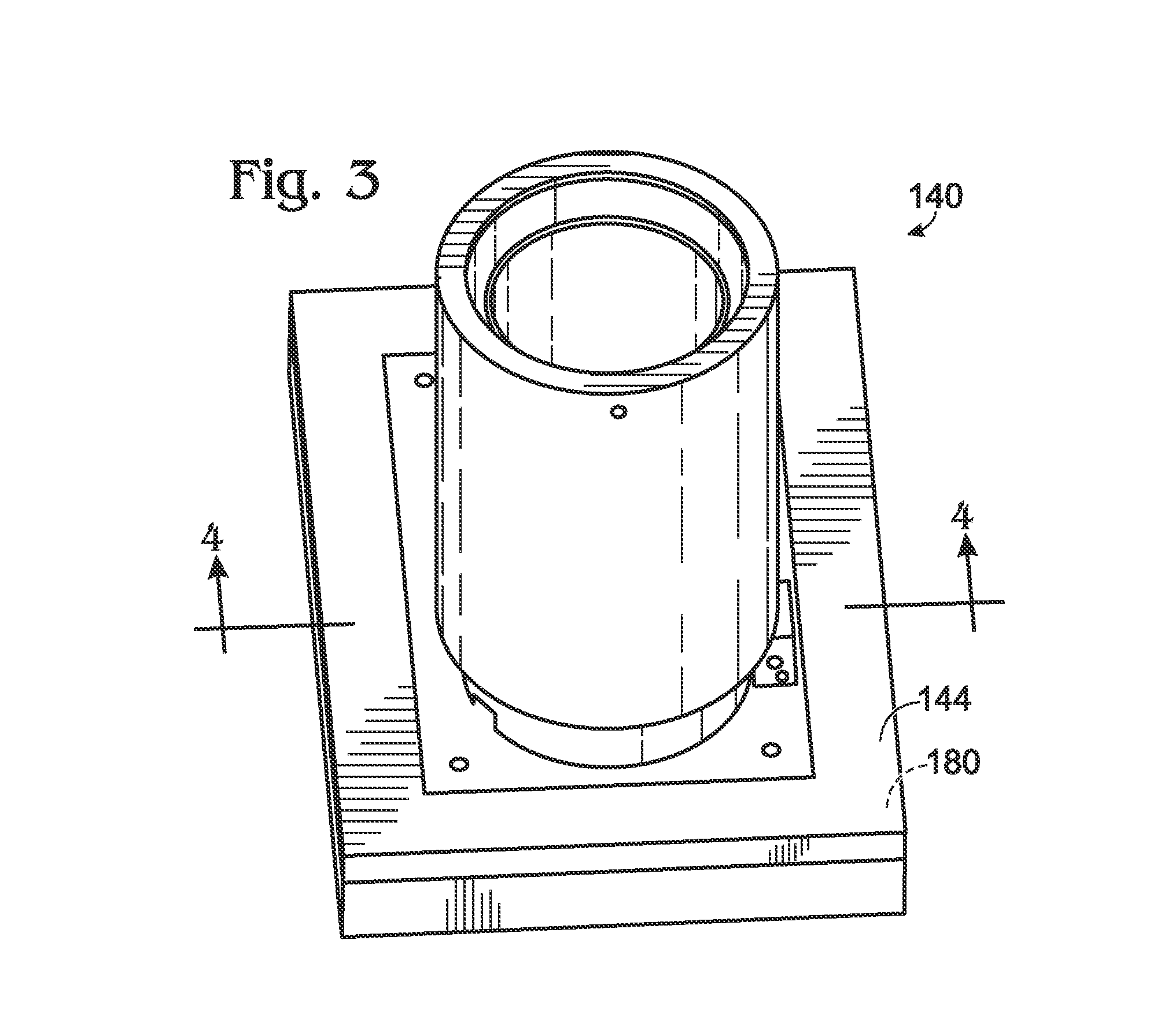

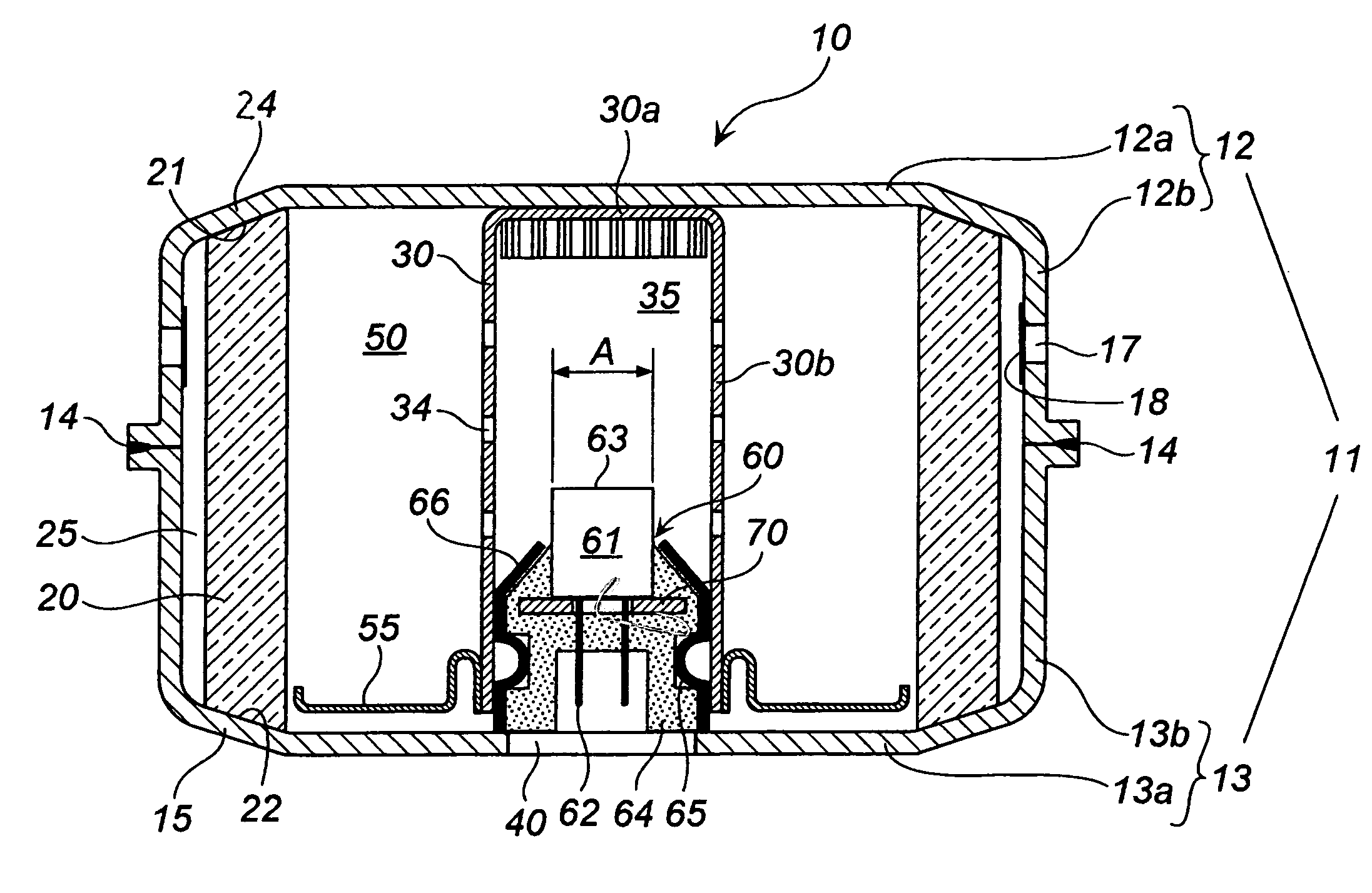

An apparatus (10) for inflating an inflatable vehicle occupant protection device (14) comprises an inflator housing (20) including first and second end walls (32, 62). An inflation fluid source (140) in the inflator housing (20) is actuatable to provide inflation fluid under pressure. An igniter assembly (80) in the inflator housing (20), for actuating the inflation fluid source (140), includes an igniter housing (82) located between the first and second end walls (62, 32) of the inflator housing and an igniter (92) located in the igniter housing. The first and second end walls (62, 32) of the inflator housing (20) move away from each other upon actuation of the inflation fluid source (140). The igniter housing (82) moves with the second end wall (62) away from the first end wall (32). The igniter assembly (80) further includes a cap (100) on the igniter housing (82) for closing an open end of the igniter housing. The cap (100) bodily moves with the first end wall (32) away from the second end wall (62) and relative to the igniter housing (82) upon actuation of the inflation fluid source (140).

Owner:TRW INC

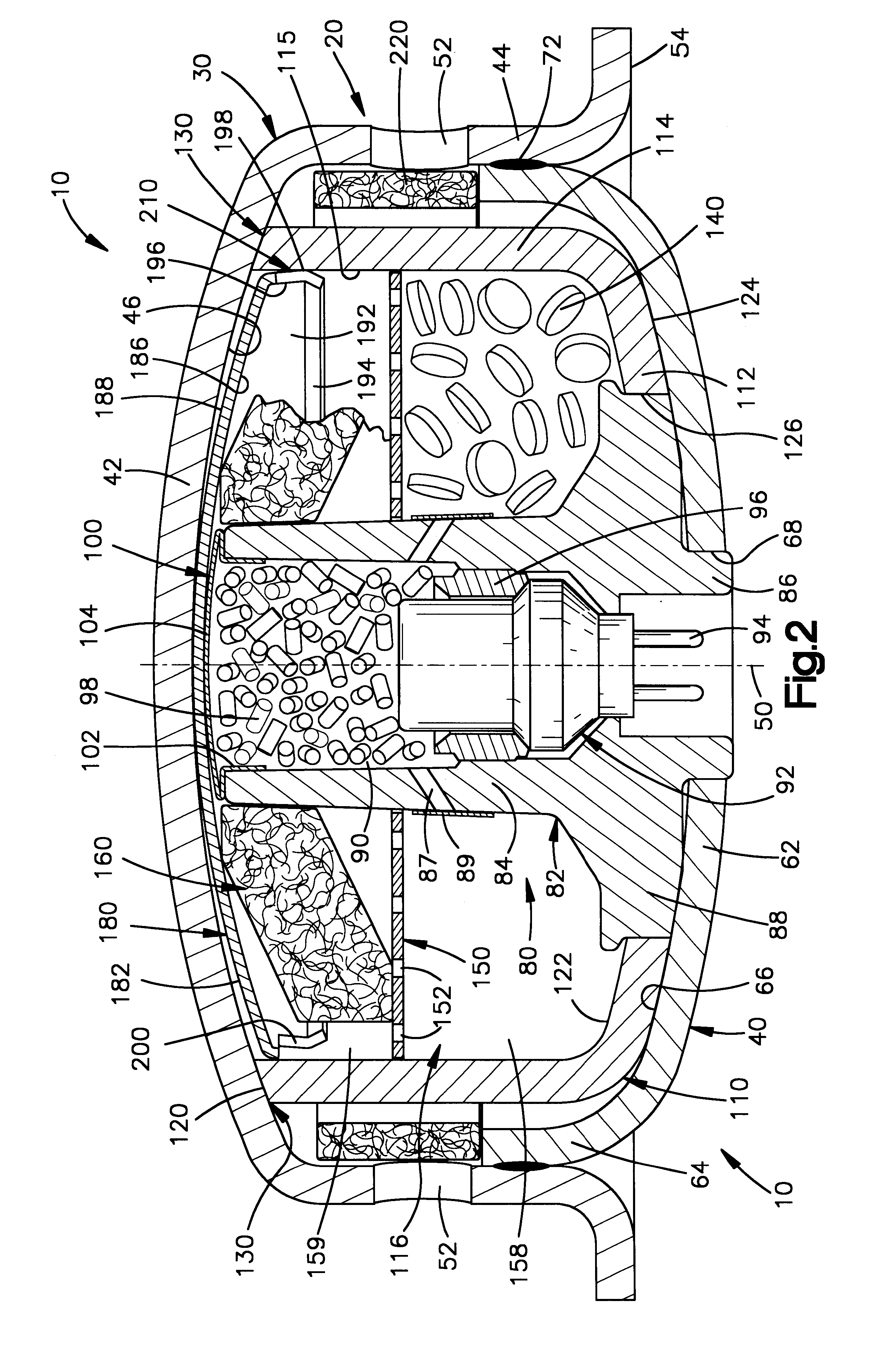

Hydrogen generation assemblies and hydrogen purification devices

Hydrogen generation assemblies, hydrogen purification devices, and their components, and methods of manufacturing those assemblies, devices, and components are disclosed. In some embodiments, the assemblies may include a vaporization region with packing material configured to transfer heat from a heated exhaust stream to a liquid-containing feed stream, and / or an insulation base adjacent a combustion region and configured to reduce external temperature of an enclosure. In some embodiments, the assemblies may include a cooling block configured to maintain an igniter assembly in thermal communication with a feed stream conduit, an igniter assembly including a catalytic coating, and / or a fuel stream distribution assembly. In some embodiments, the assemblies may include a heat conducting assembly configured to conduct heat from external heaters to an enclosure portion. In some embodiments, the devices may include frames with membrane support structures and / or may include a microscreen structure configured to prevent intermetallic diffusion.

Owner:ELEMENT 1

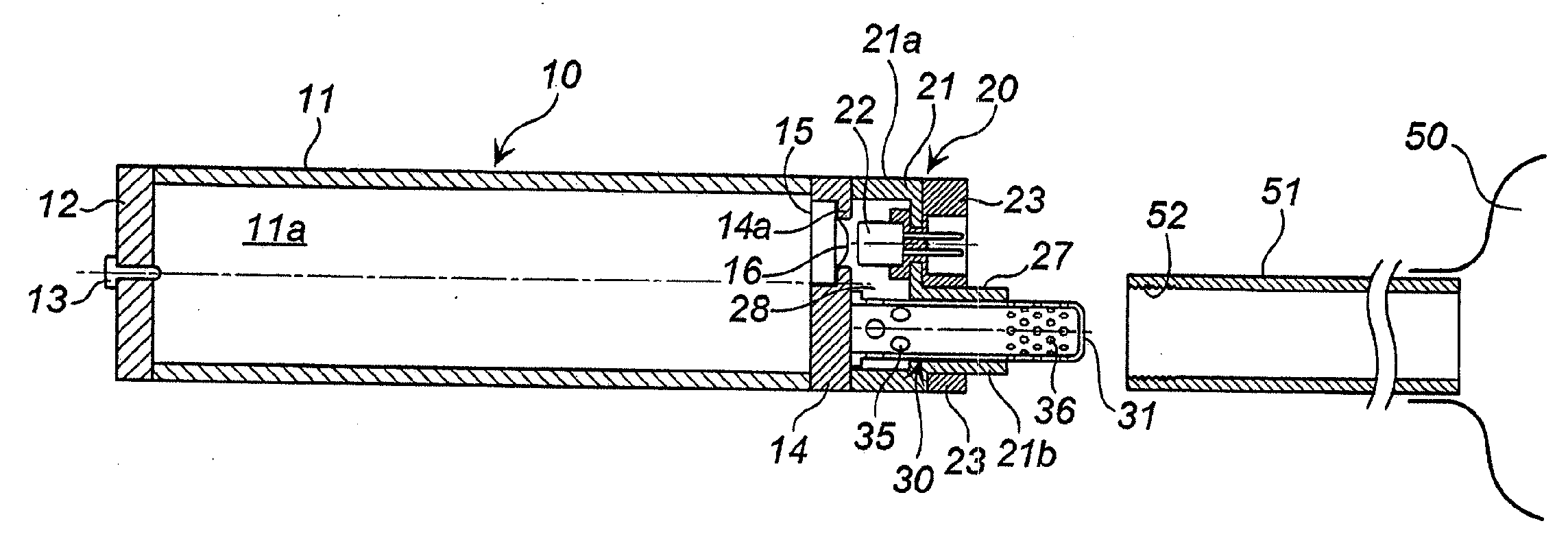

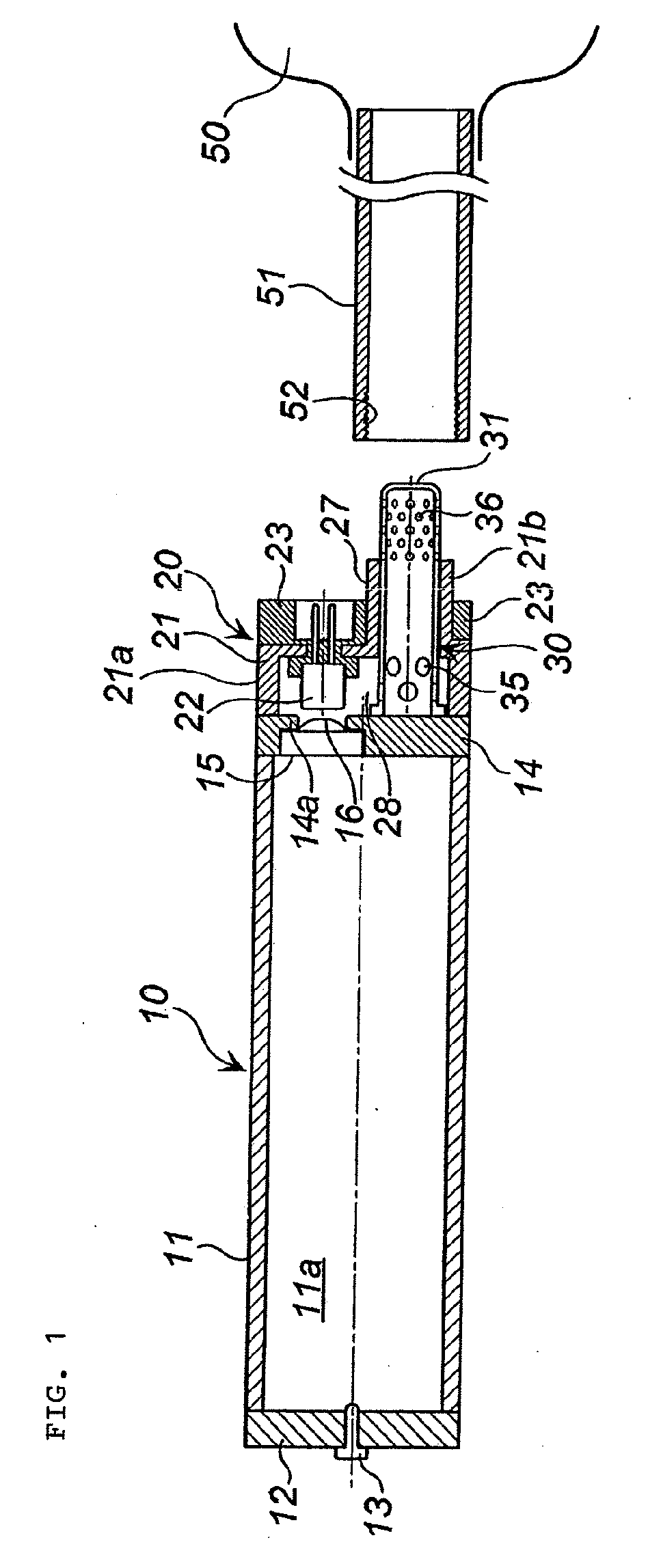

Initiator assembly

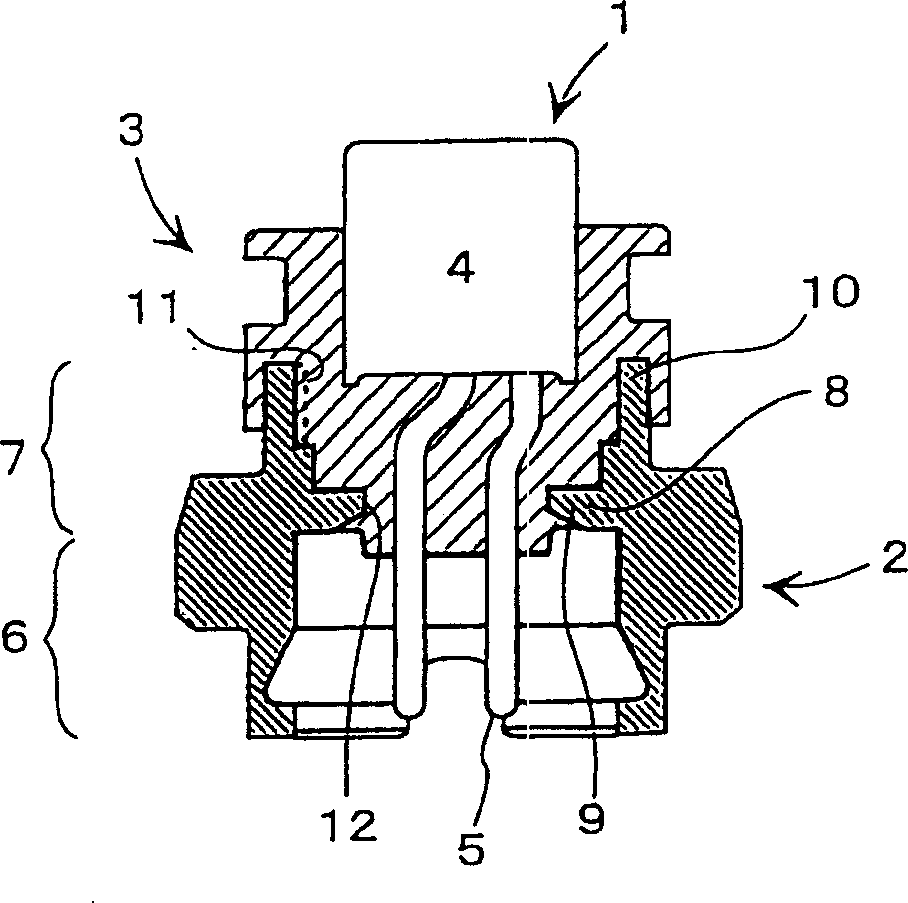

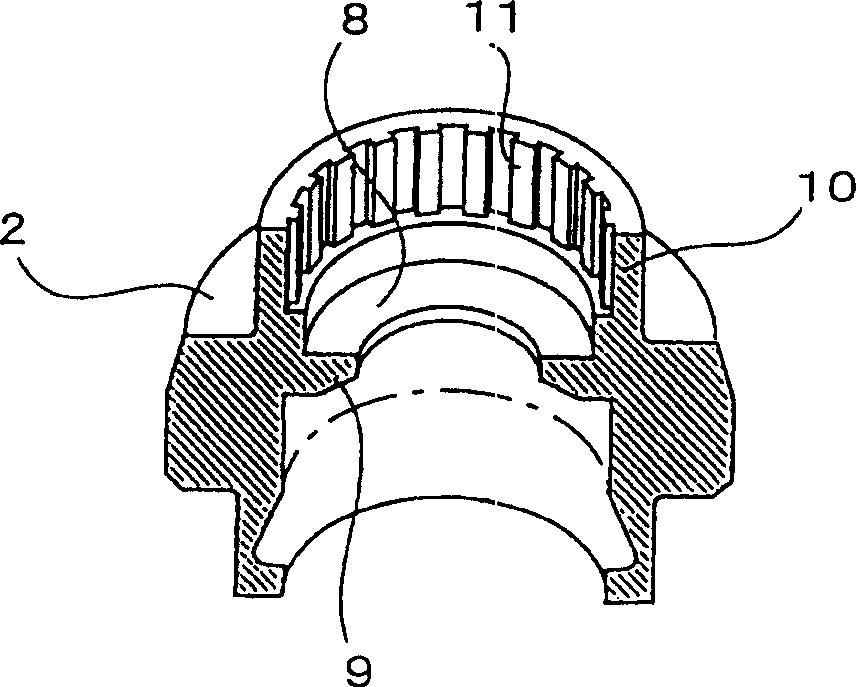

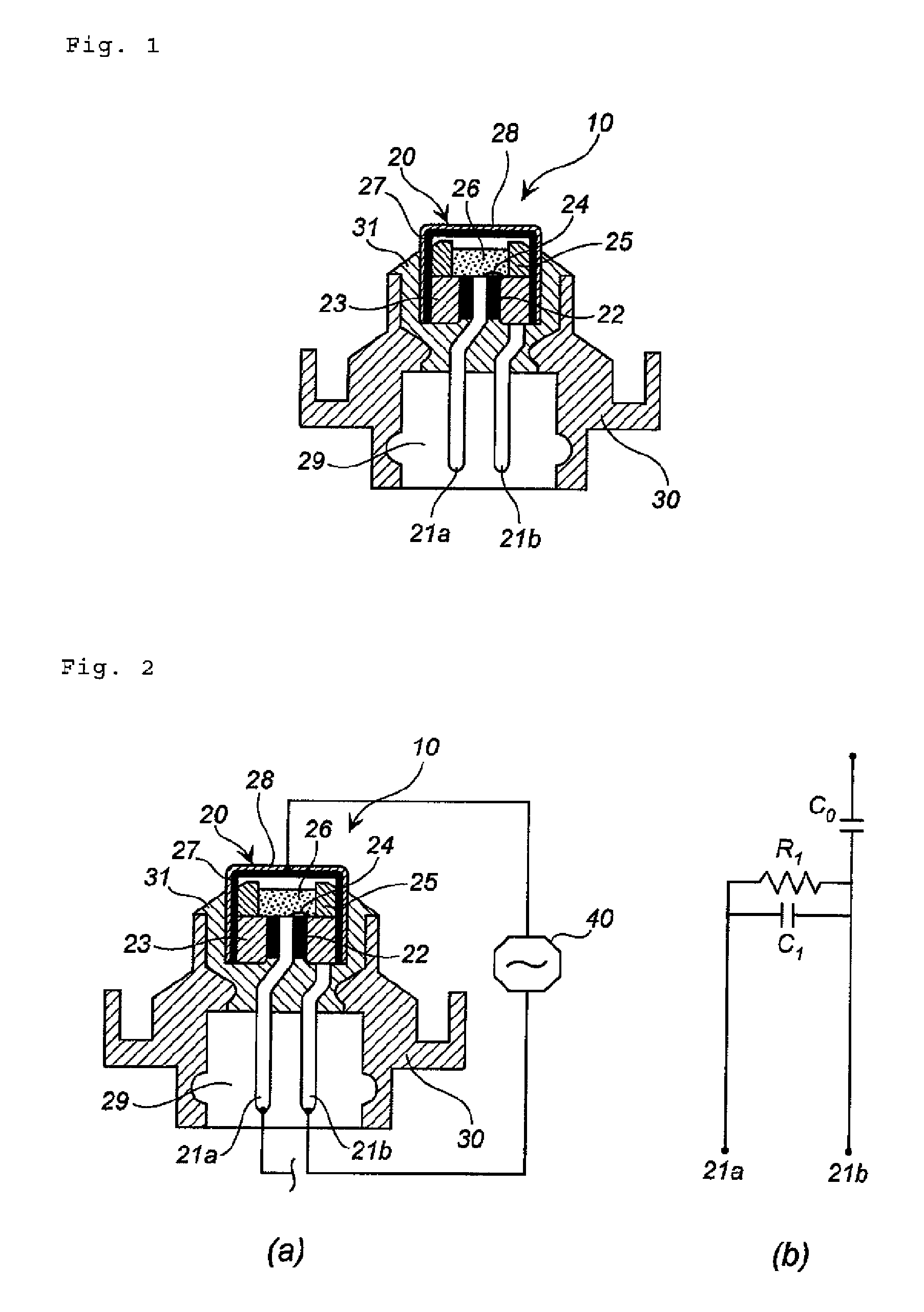

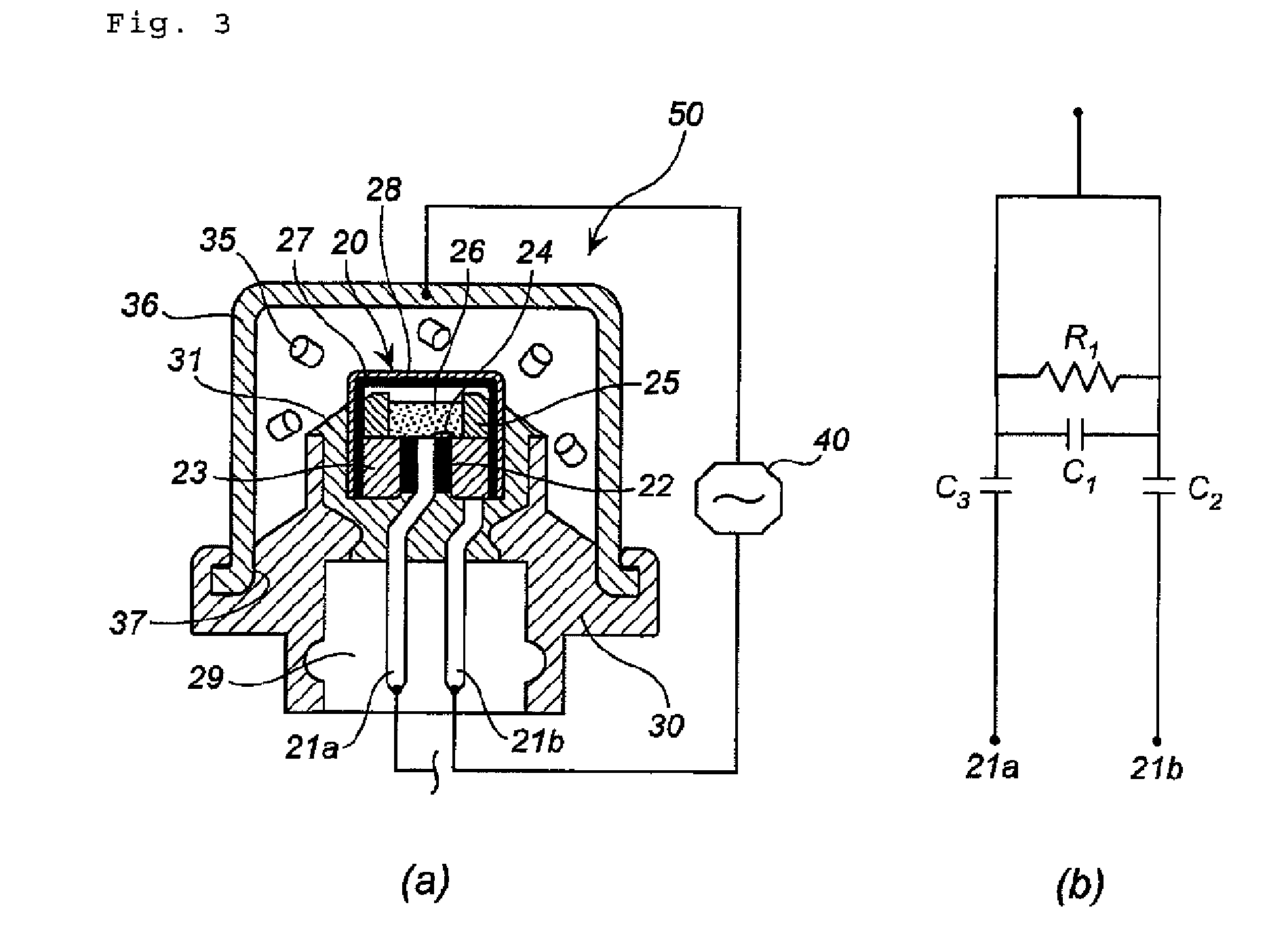

InactiveCN1589390AImprove bindingEliminate reaction forceBelt retractorsPedestrian/occupant safety arrangementEngineeringSignal generator

An initiator assembly capable of guaranteeing the assured operation of a gas generator by assuring the structure of connection between a metal collar and an electric initiator to prevent the entry of moisture into the gas generator, comprising the electric initiator and the metal collar surrounding at least a part of the electric initiator formed integrally with each other with resin, wherein at least either of an annular projected part and a tubular projected part provided in a direction that surrounds the electric initiator is formed on the metal collar, and the projected part is covered with the resin.

Owner:DAICEL CHEM IND LTD

Gas generator

ActiveUS7125041B2Easy to assembleLow production costIncandescent ignitionBelt retractorsEngineeringIgniter Device Component

An igniter includes: an igniter assembly including an igniter main body having an ignition portion adapted to be ignited by an ignition electric current; an igniter collar which accommodates the igniter main body; a cup body having an opening portion, the igniter assembly and the cup body being connected to each other, such that at least the ignition portion of the igniter main body is surrounded by the cup body; and a tubular crimp case that connects and fastens at least a part of an exterior surface of the igniter collar and at least a part of an exterior surface of the cup body from an outside.

Owner:DAICEL CHEM IND LTD

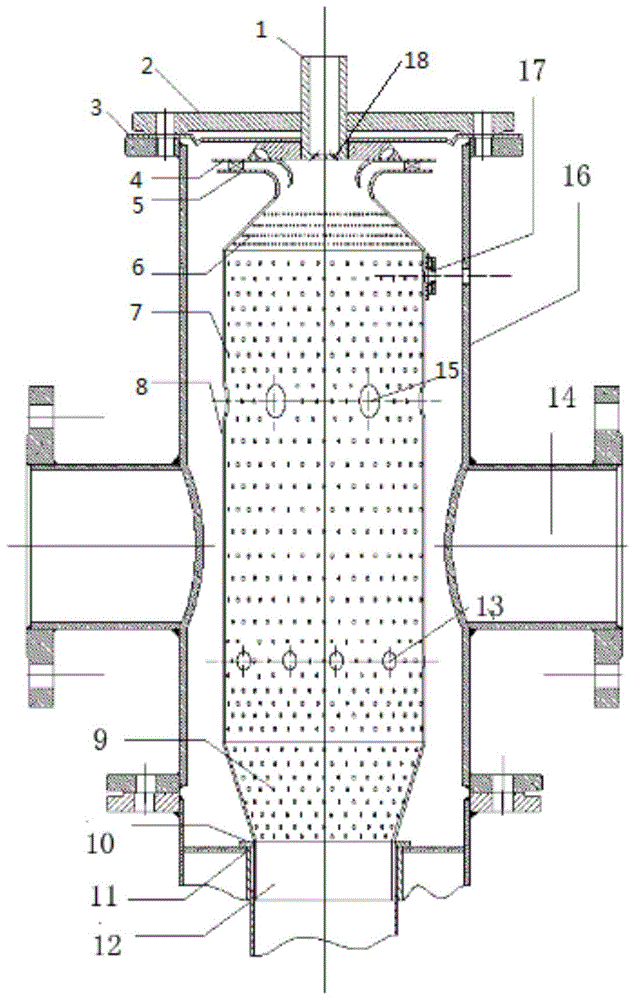

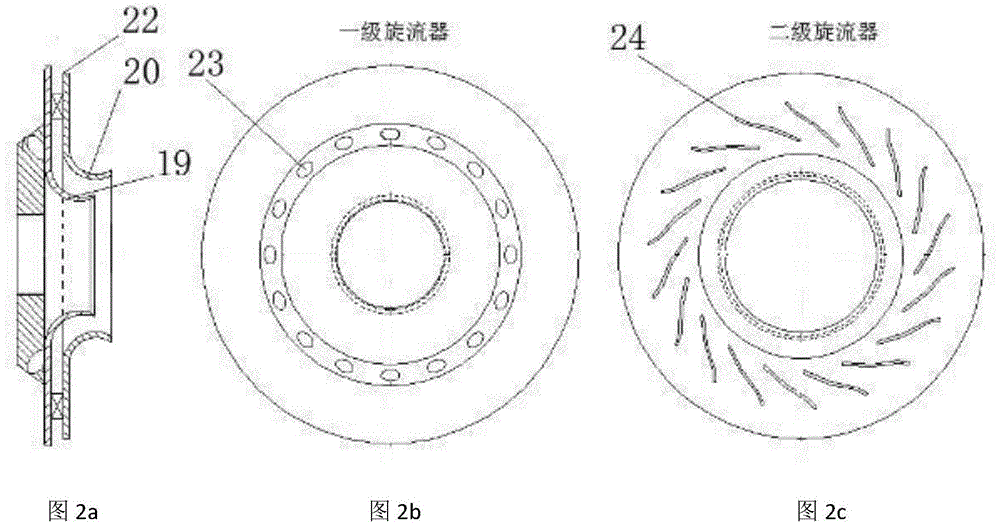

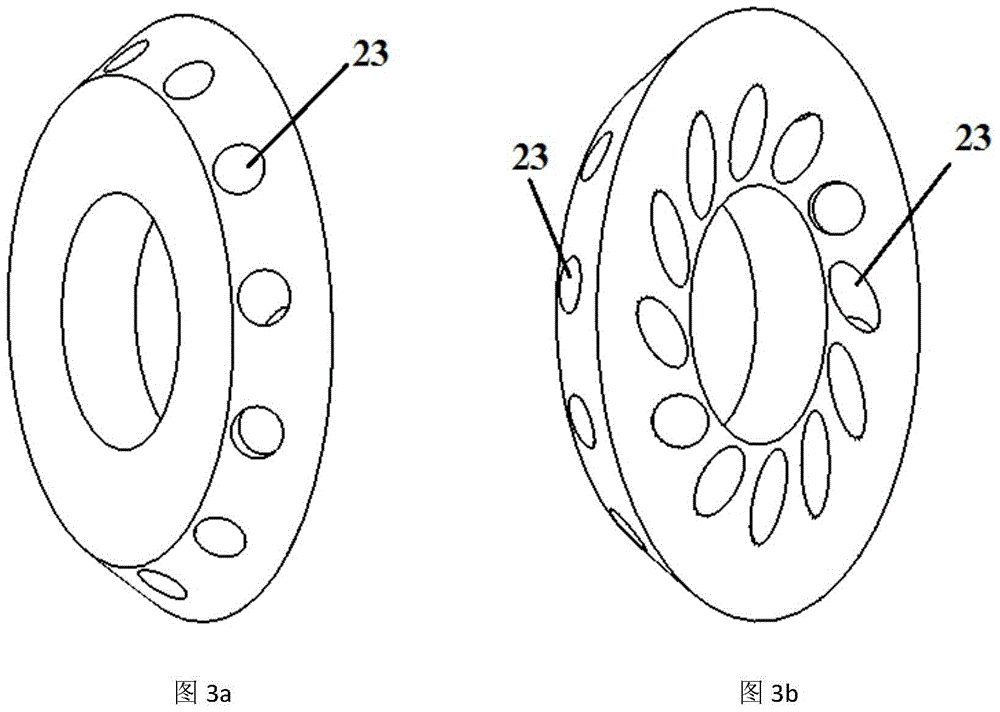

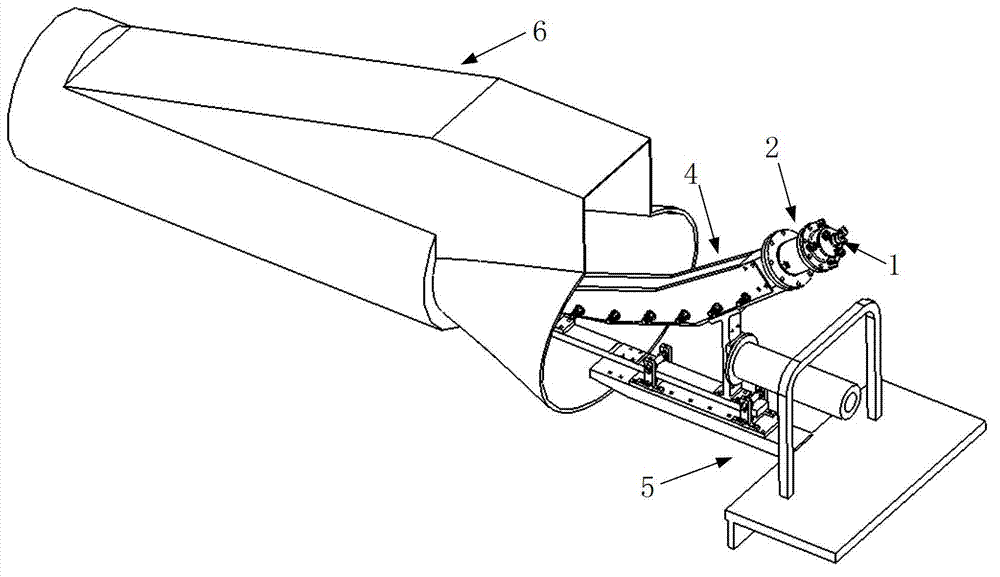

Single-tube combustor device of ground combustion gas turbine

The invention provides a single-tube combustor device of a ground combustion gas turbine. The single-tube combustor device of the ground combustion gas turbine comprises a casing and a flame tube arranged in the casing. A natural gas inlet pipeline is arranged on the top of the flame tube in an externally connected mode. A first-stage beveling hole whirlcone and a second-stage radial whirlcone which are opposite in rotation direction are arranged in the neck position of the flame tube sequentially from top to bottom. The first-stage beveling hole whirlcone is of a circular truncated cone structure and provided with a through hole enabling the side wall and the bottom face to communicate. The two stages of whirlcones are each provided with a Venturi tube. An igniter assembly, a main combustion hole and a mixing hole are formed in the side wall of the flame tube sequentially from top to bottom. A plurality of tiny full-coverage air film cooling holes are formed in the surface of the flame tube. A pair of symmetrical air inlets are formed in the side wall of the casing, and a convergence outlet is formed in the tail of the flame tube. By arranging the two stages of whirlcones on the neck of the flame tube and arranging the main combustion hole, the mixing hole and the tiny cooling holes in the flame tube, reasonable distribution of a combustion flow field, outlet temperature and wall temperature and reasonable temperature rise of a combustor can be achieved, and the service life of the flame tube is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

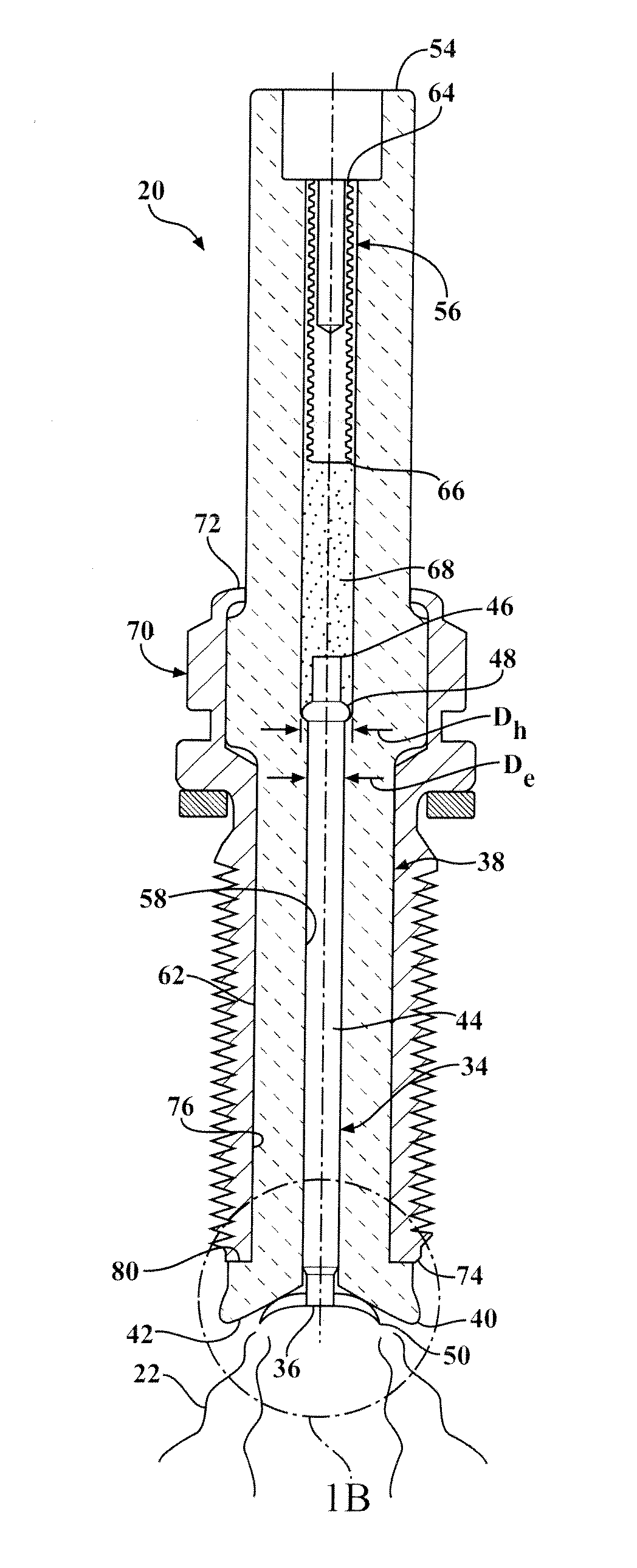

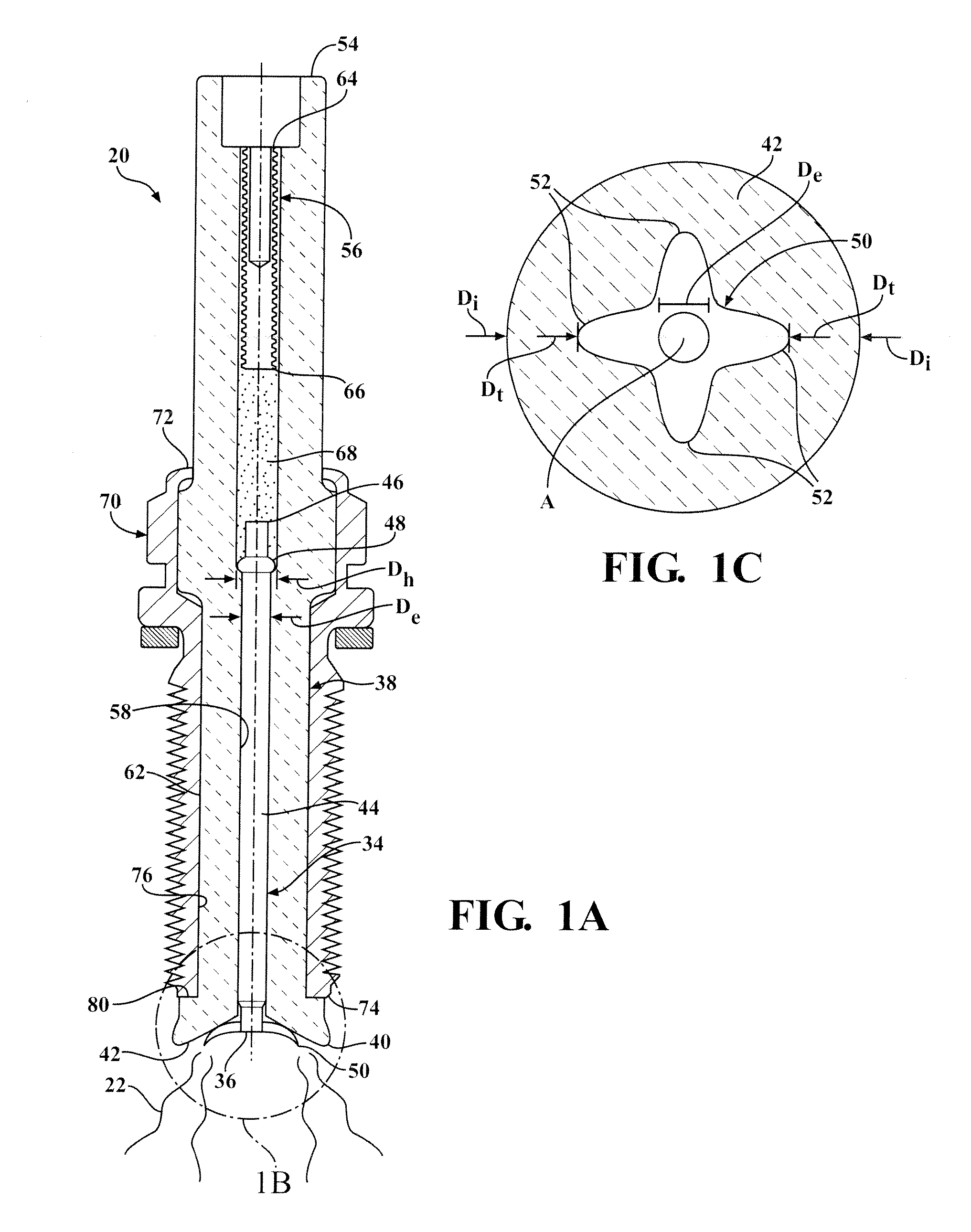

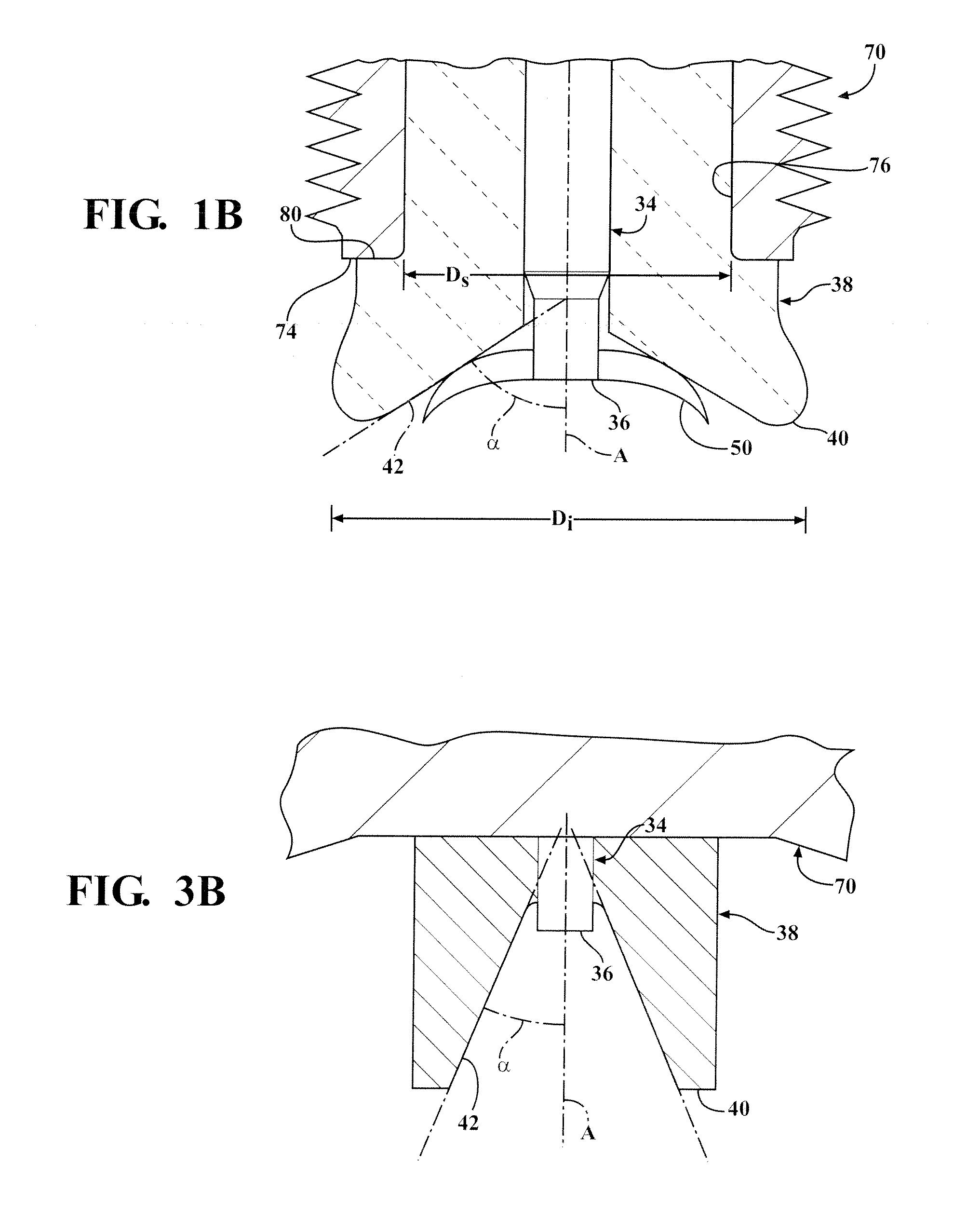

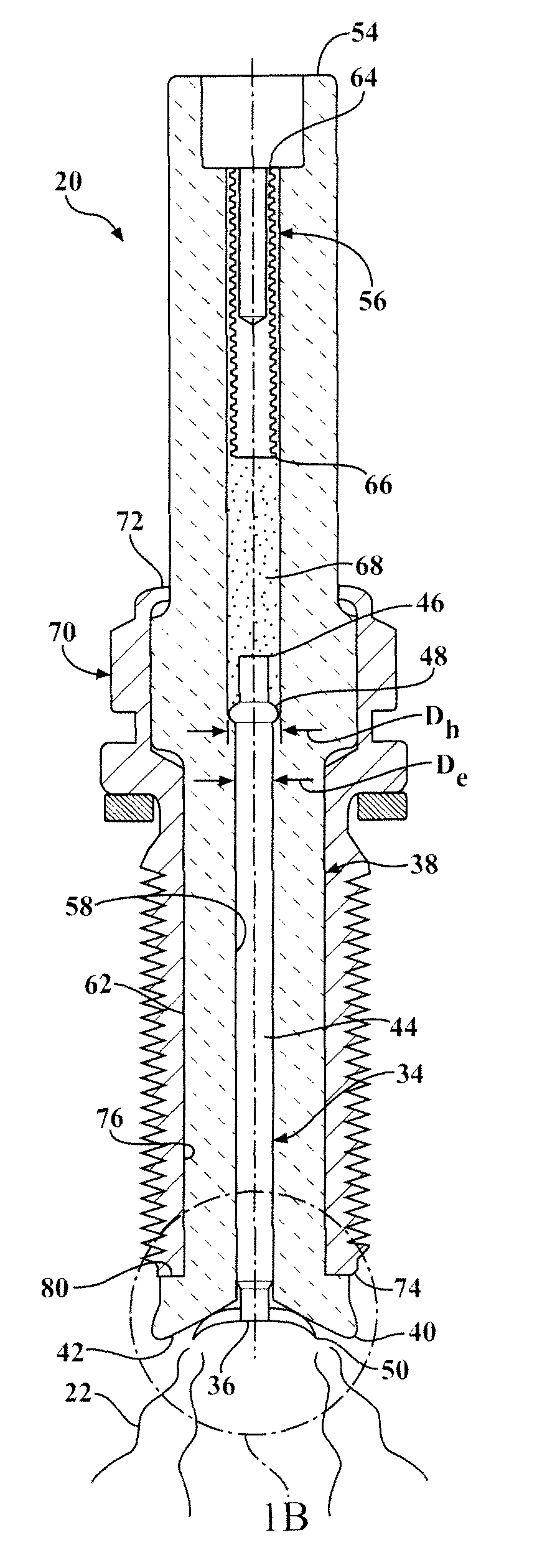

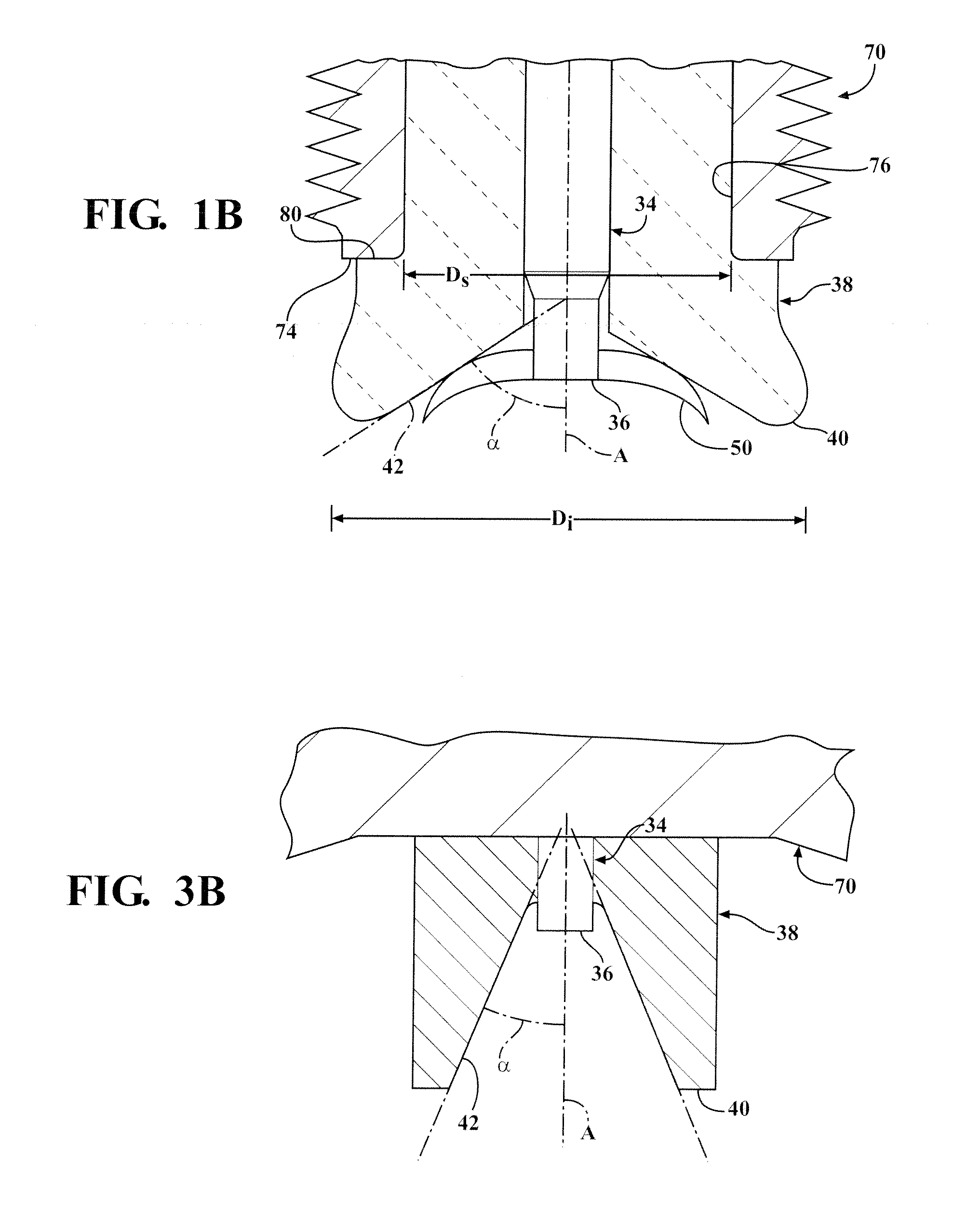

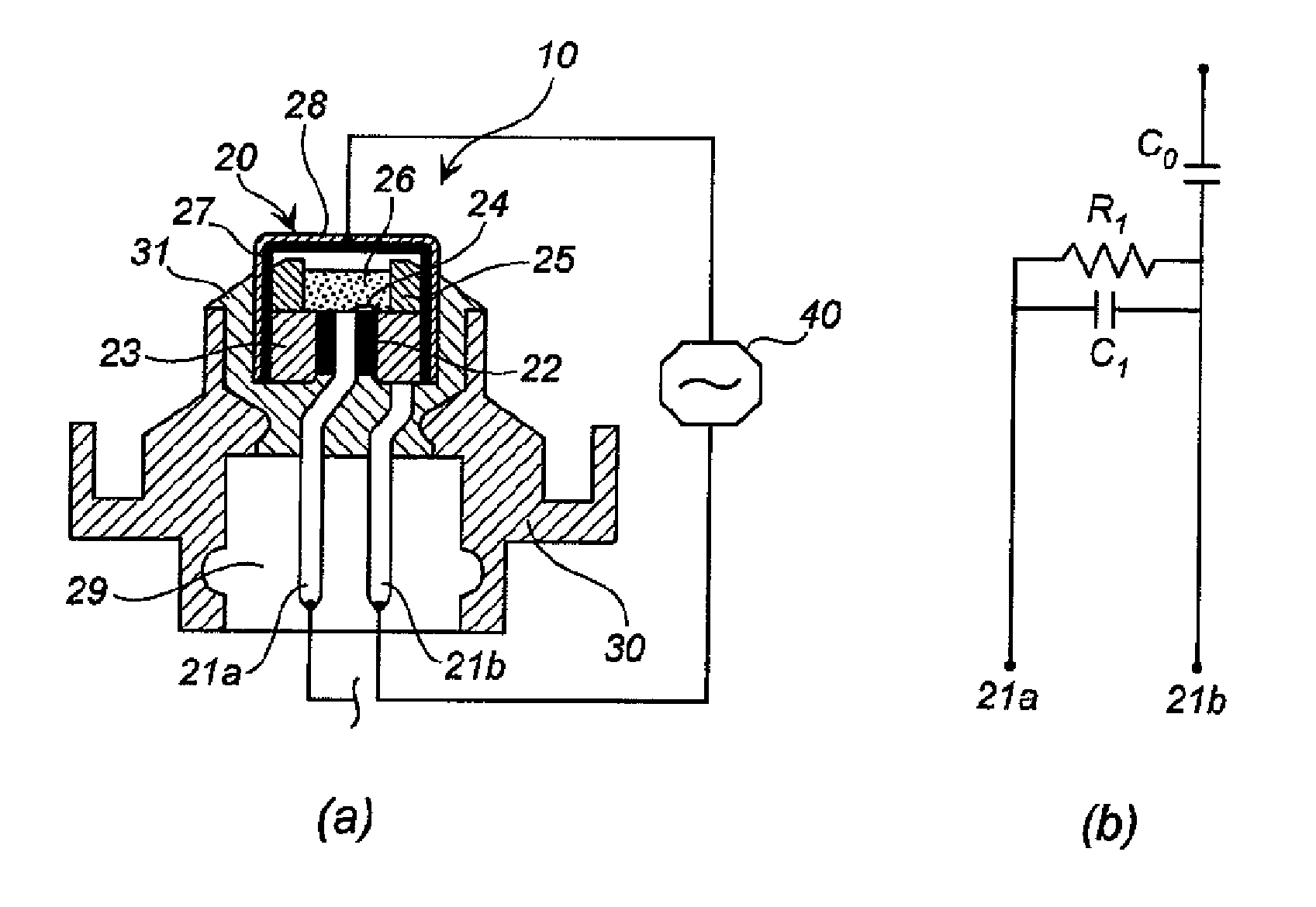

Corona igniter assembly including corona enhancing insulator geometry

ActiveUS20130003251A1Improve performanceQuality improvementSparking plugsElectric spark ignitersCorona dischargeRadio frequency

A corona igniter 20 includes a central electrode 34 for receiving a high radio frequency voltage from a power source and emitting a radio frequency electric field to ionize a fuel-air mixture and provide a corona discharge 22. The corona igniter 20 includes an insulator 38 extending along the central electrode 34 longitudinally past the central electrode 34 to an insulator firing end 40. The insulator tiring surface 42 and the center axis A present an angle α of not greater than 90 degrees therebetween, for example the insulator firing surface may be concave. The central electrode 34 may also include a firing tip 50, in which case the insulator firing surface 42 surrounds all sides of the firing tip 50. The geometry of the insulator firing surface 42 concentrates and directs the corona discharge 22.

Owner:FEDERAL MOGUL IGNITION

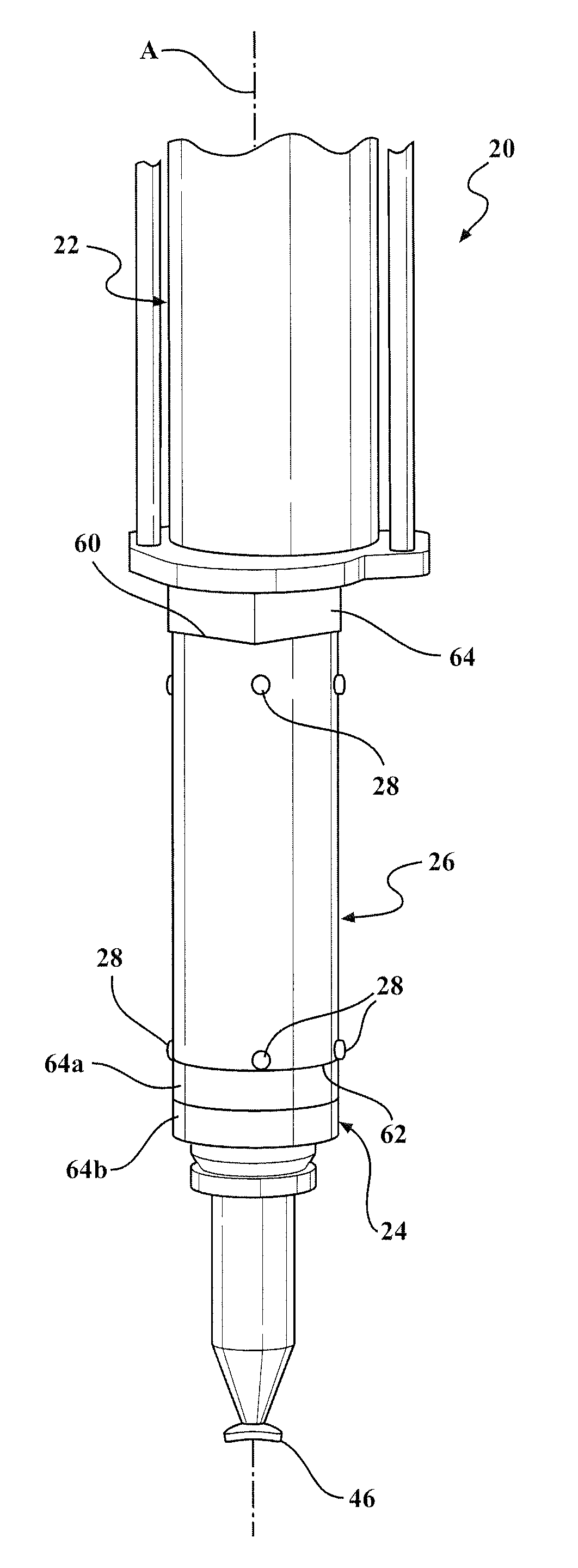

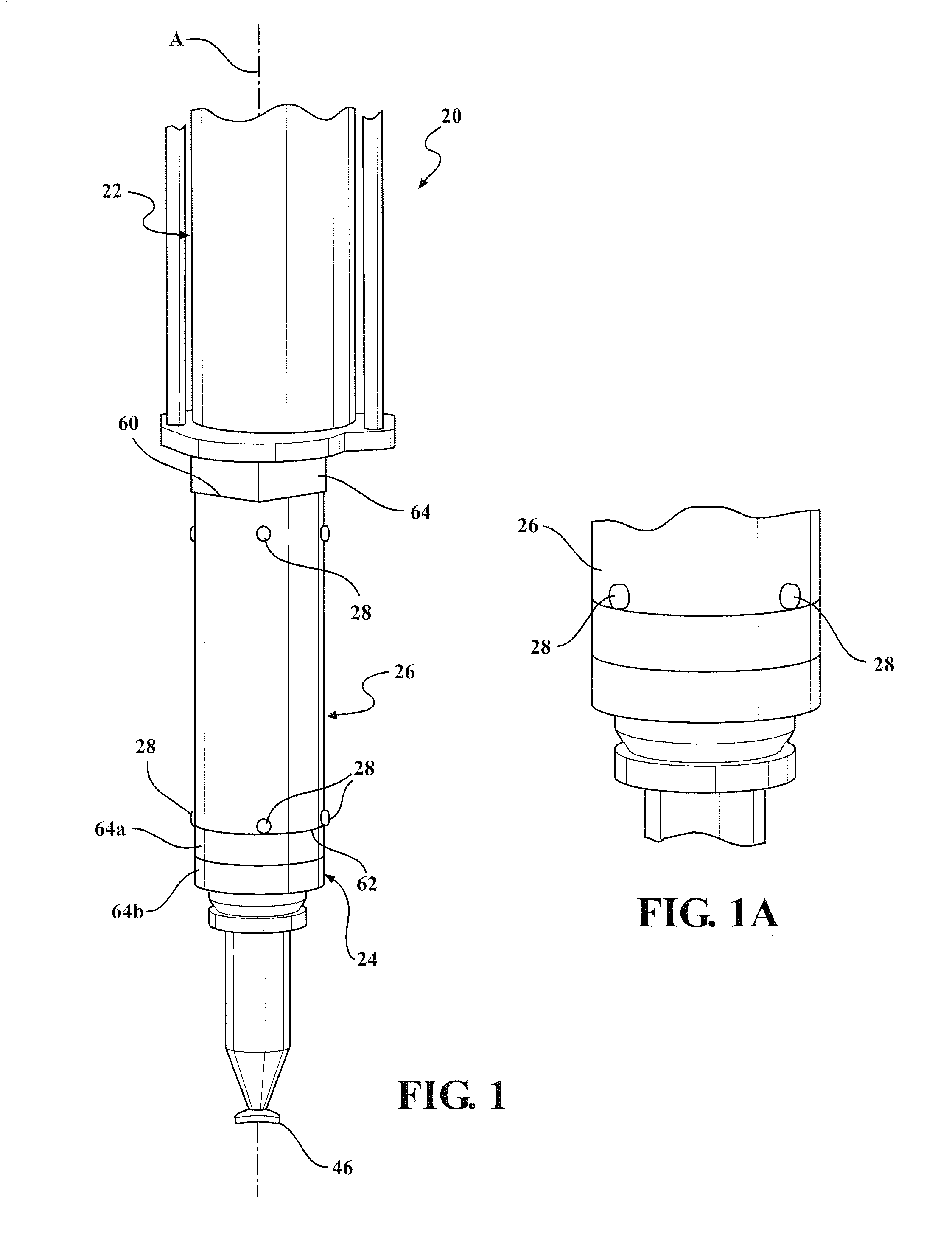

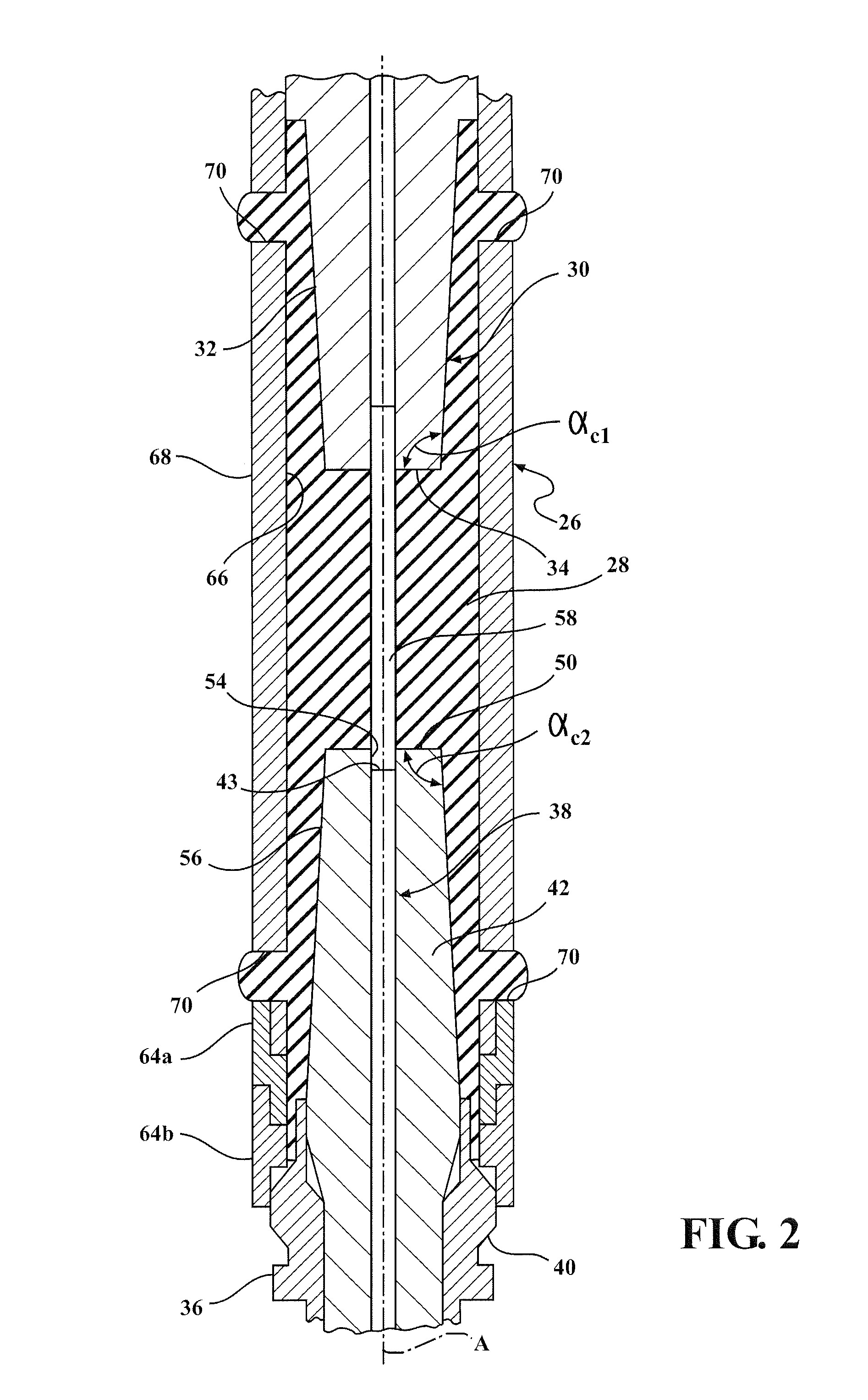

High voltage connection sealing method for corona ignition coil

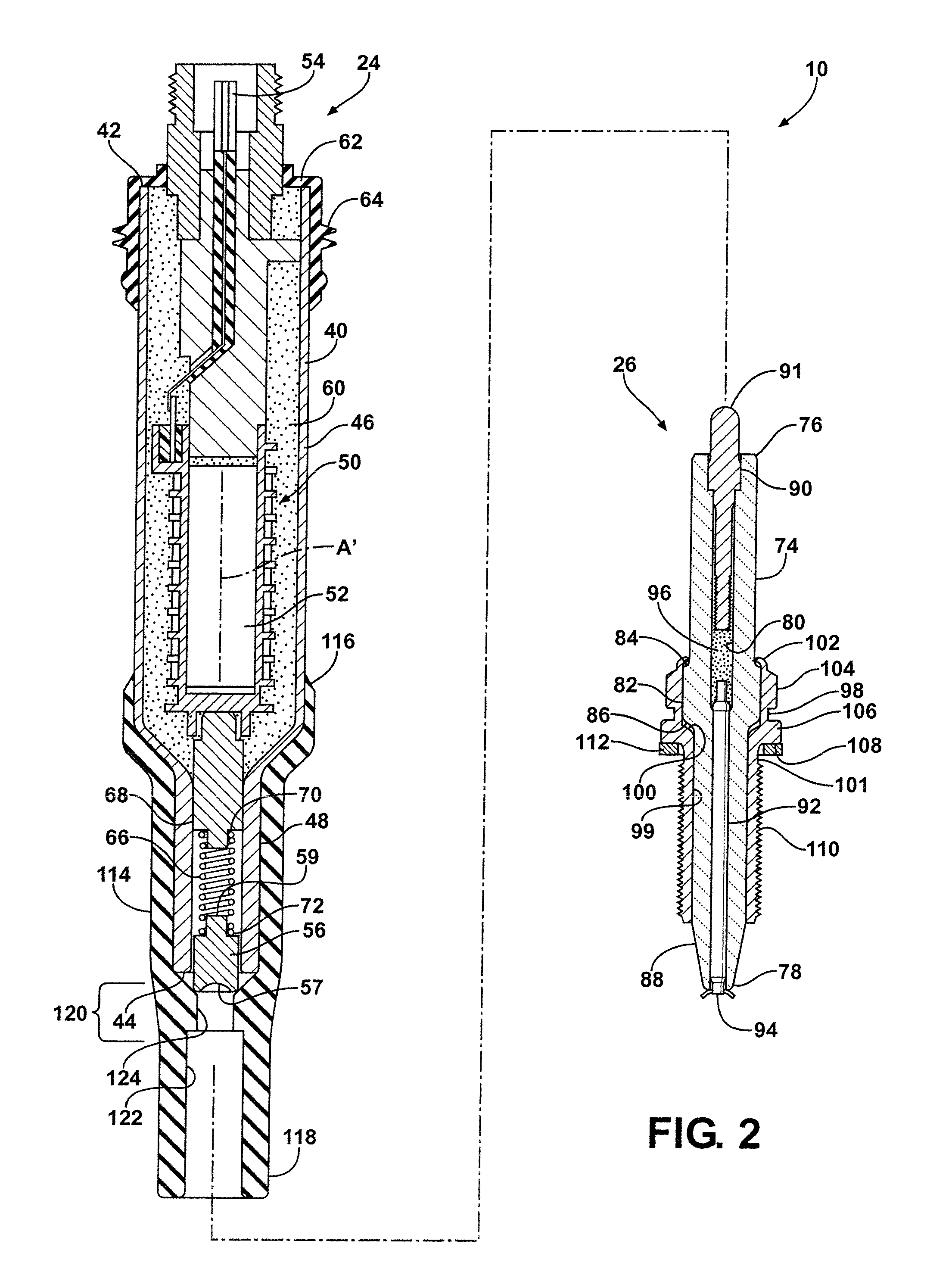

InactiveUS20140268480A1Improve performanceWave amplification devicesElectric spark ignitersIgnition coilHermetic seal

A corona igniter assembly 20 comprises an ignition coil assembly 22, a firing end assembly 24, and a metal tube 26 connecting the ignition coil assembly 22 to the firing end assembly 24. A rubber boot 28 is disposed in the metal tube 26 and compressed symmetrically between a coil output member 30 of the ignition coil assembly 22 and an insulator 42 of the firing end assembly 24. Thus, the rubber boot 28 fills any air gaps and provides a hermetic seal between the ignition coil assembly 22 and the firing end assembly 24 to prevent unwanted corona discharge from forming from those air gaps.

Owner:FEDERAL MOGUL IGNITION

Evaporative burner

InactiveUS6971235B2Improved evaporation burnerNo longer very powerfulBurnersFuel supply regulationCombustion chamberCombustor

An evaporative burner that includes an igniter assembly, a swirler, an evaporation chamber, and a reverse throat. The reverse throat has raised ends that protrude into the evaporation chamber. The reverse throat in combination with the evaporation chamber and the swirler, facilitate the recirculation of air in the evaporation chamber such that a flame is stabilized near the evaporation chamber walls. This flame gradually evaporates the fuel in the lining of the evaporation chamber. The fuel-air mixture results in a steady and uniformly distributed flame in the combustion chamber. This flame can heat uniformly the walls of the combustion chamber, and thus be applicable for high efficiency and low emissions applications. Furthermore, this burner can start and reach full burner power rapidly.

Owner:NEW POWER CONCEPTS

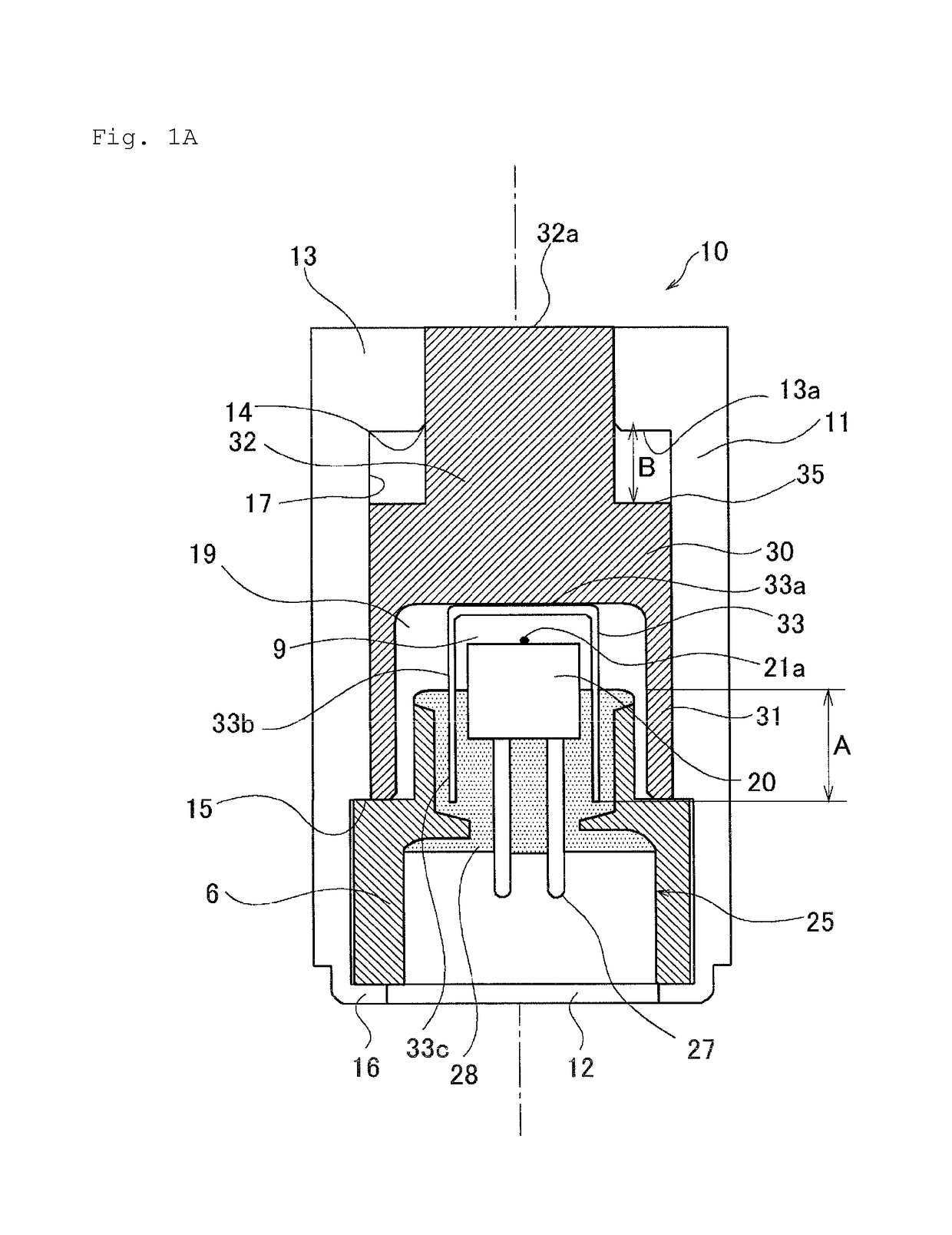

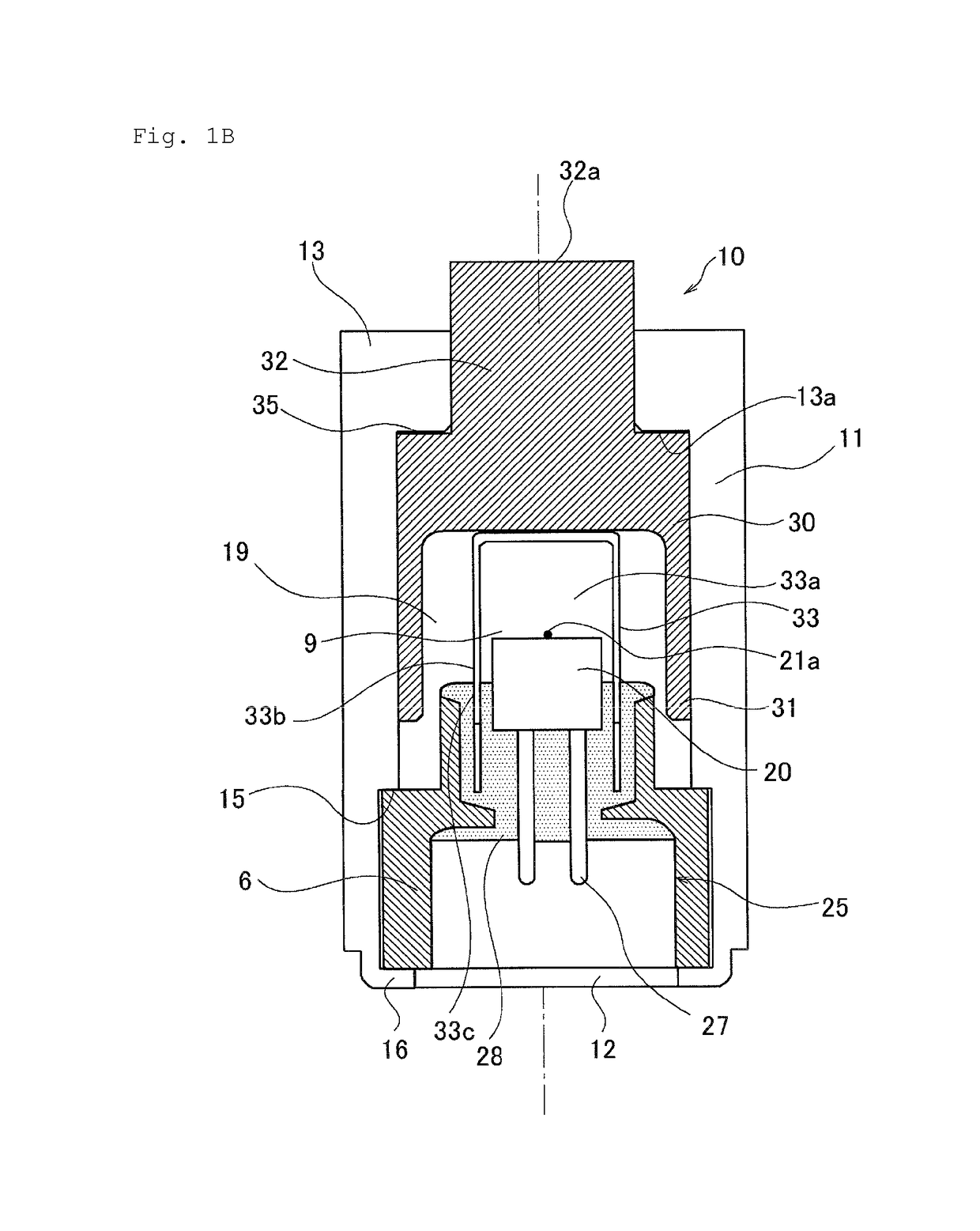

Apparatus including igniter assembly

ActiveUS7744124B2Pedestrian/occupant safety arrangementBlasting cartridgesEngineeringMechanical engineering

The present invention provides an apparatus provided with an igniter assembly including: an igniter main body having an ignition portion, provided with an ignition agent, and an electroconductive pin, a resin portion surrounding at least part of the igniter main body and a substantially cylindrical igniter collar fixed to an outer surface of the resin portion, the igniter assembly being disposed in an opening formed in a bottom portion of a housing, the igniter collar of the igniter assembly being fixed to the housing, the igniter collar fixing to the resin portion y deforming the igniter collar so as to engage the igniter collar with a concave portion in the resin portion.

Owner:DAICEL CHEM IND LTD

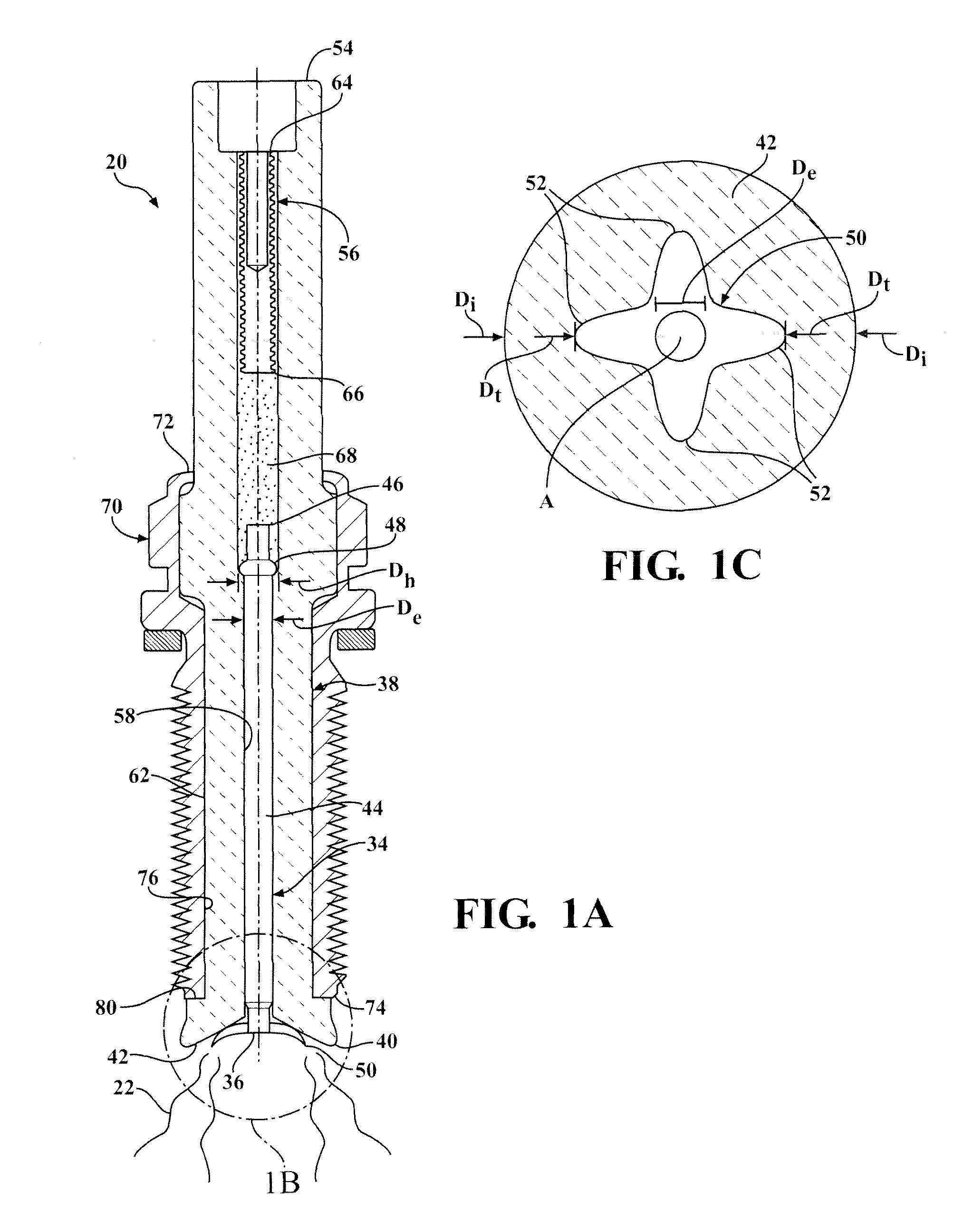

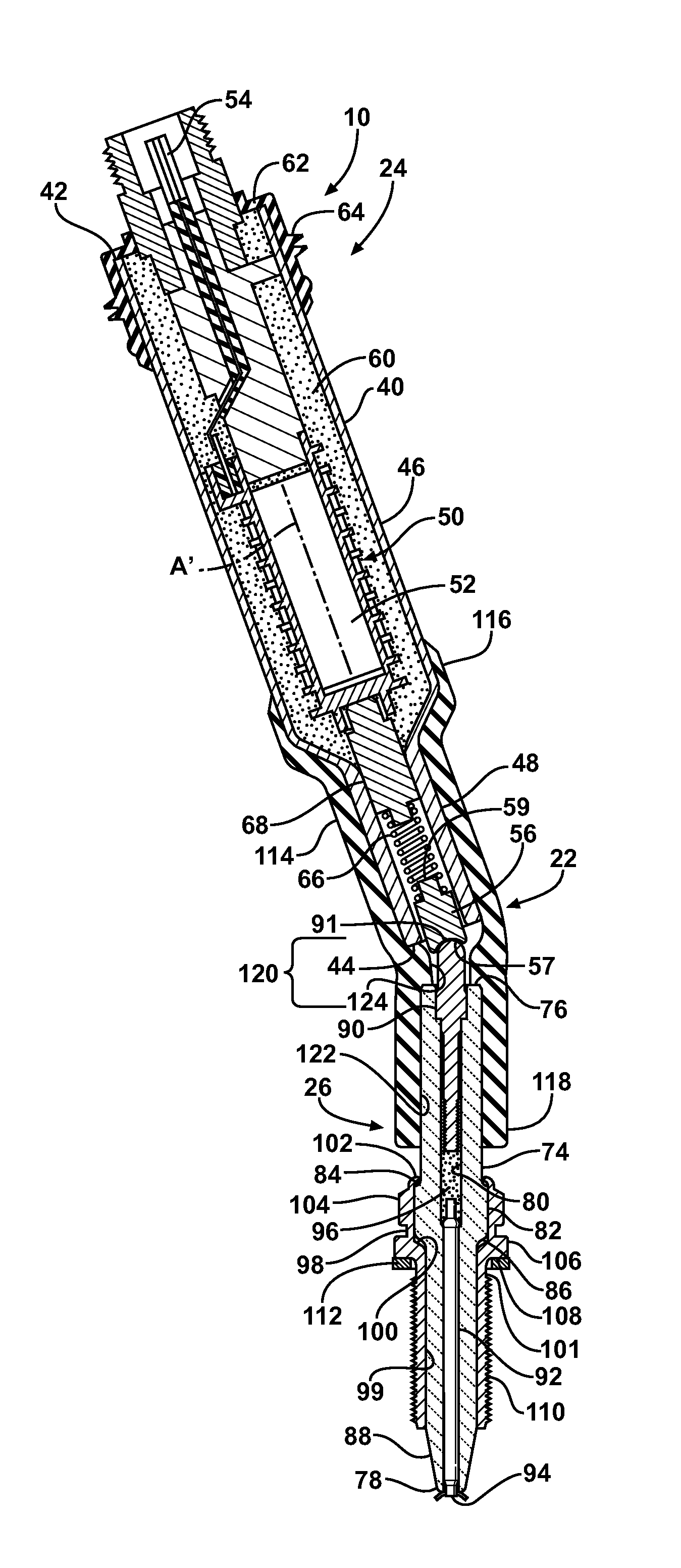

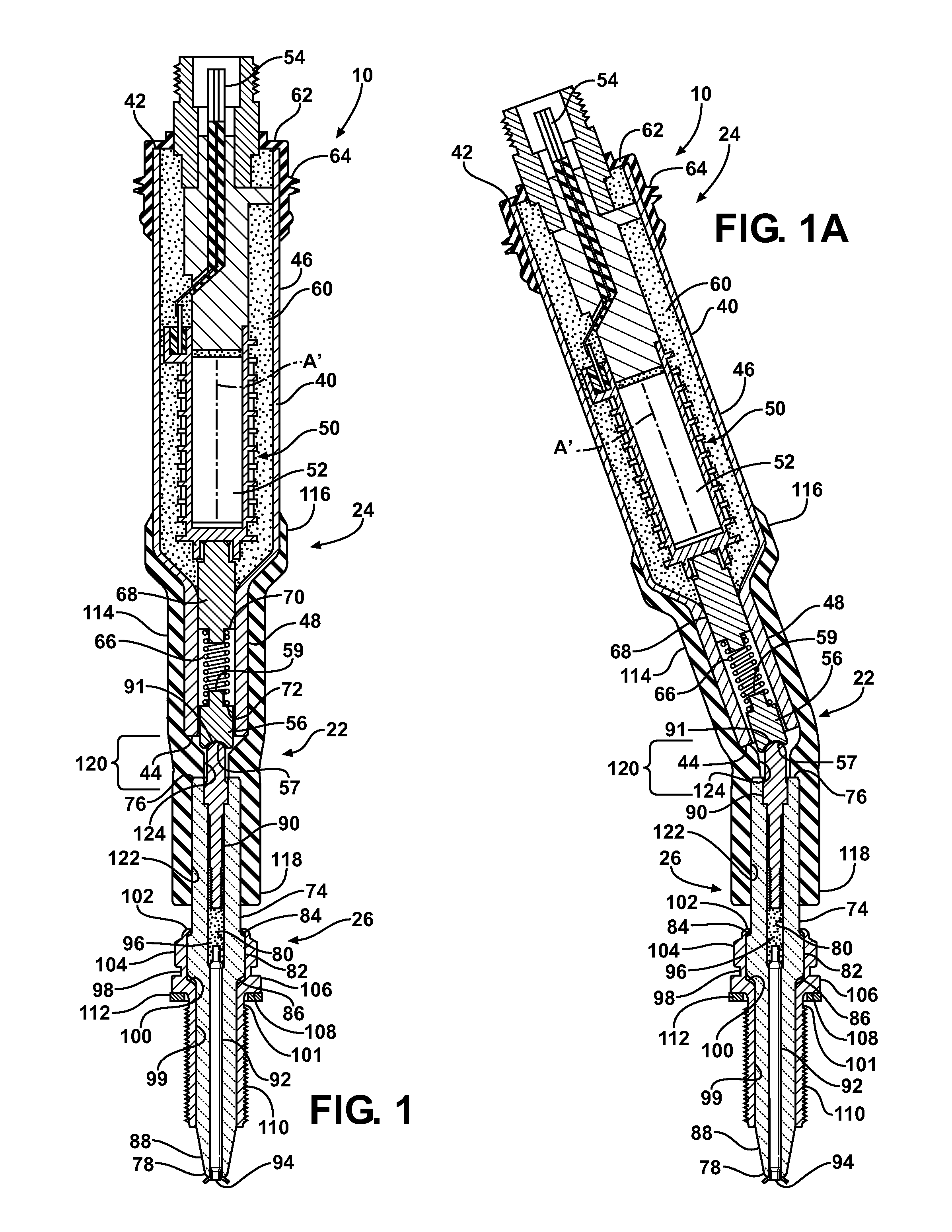

Flexible ignitor assembly for air/fuel mixture and method of construction thereof

ActiveUS20120161604A1Less spaceDecrease size and weight and costSparking plugsTransformersInductor windingsElectrical connector

An ignitor assembly constructed in accordance with one aspect of the invention has an upper inductor subassembly coupled to a lower firing end subassembly for relative pivot movement between the subassemblies. The upper inductor subassembly includes a tubular housing with inductor windings received therein with an upper electrical connector adjacent an upper end of the housing and a lower electrical connector adjacent a lower end of the housing. The lower firing end subassembly includes a ceramic insulator and a metal housing surrounding at least a portion of the ceramic insulator. The ceramic insulator has an electrical terminal extending from a terminal end and an electrode extending from a firing end. A flexible tube couples the upper inductor subassembly to the lower firing end subassembly and maintains the electrical terminal of the lower firing end subassembly in electrical contact with the lower electrical connector of the upper at a pivot joint.

Owner:FEDERAL MOGUL IGNITION

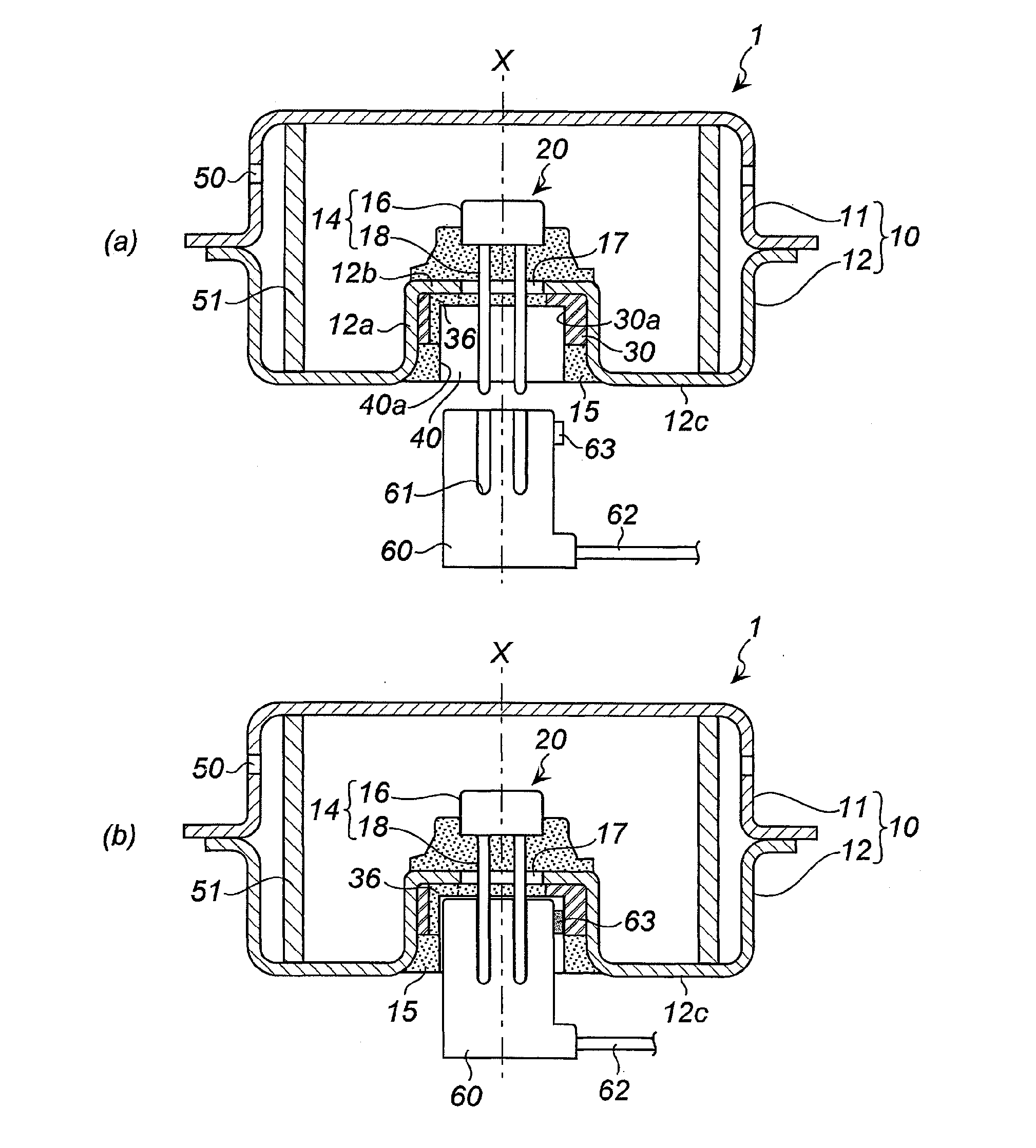

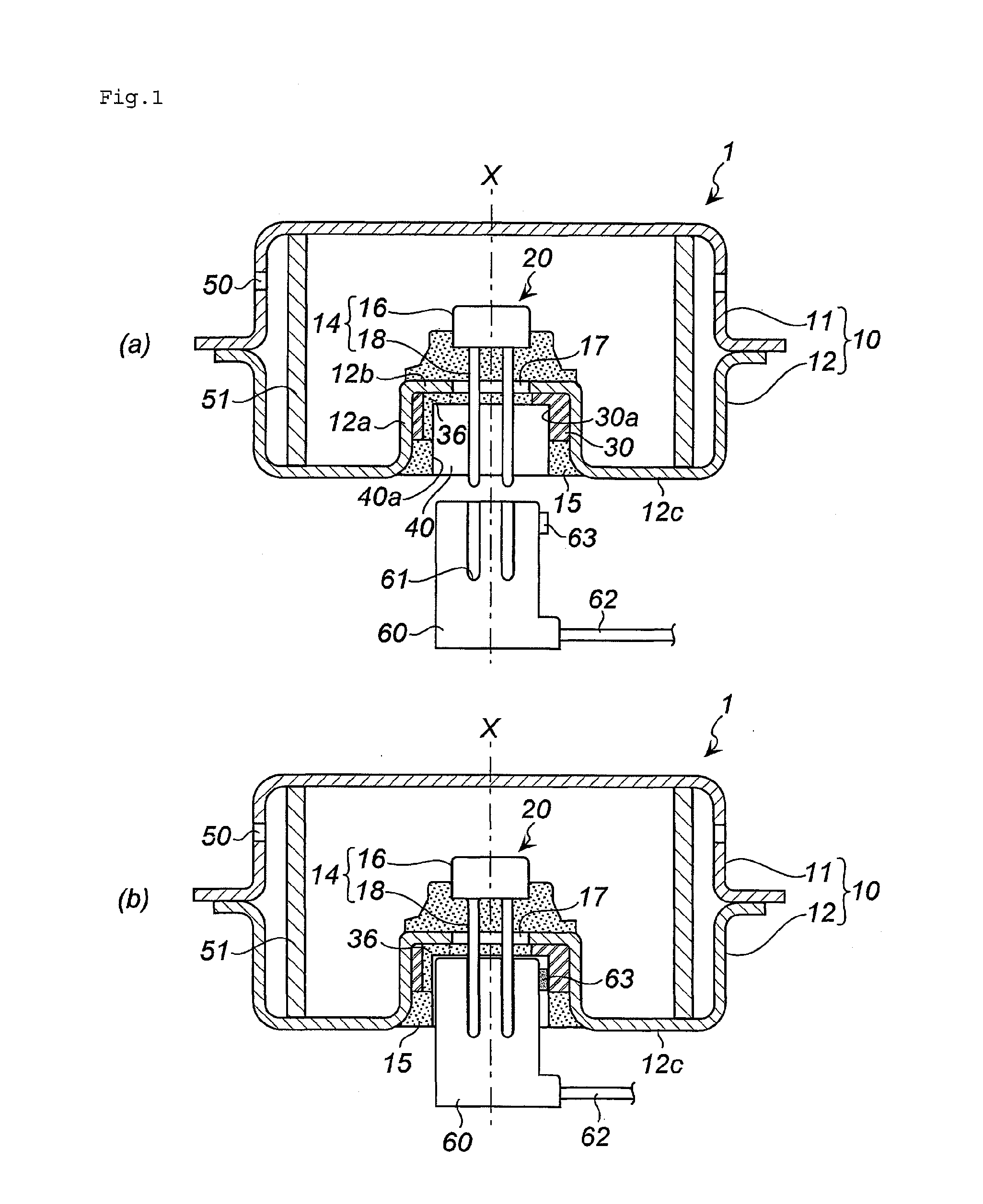

Inflator

The invention relates to an inflator including:a tubular inflator housing in which an opening portion at one end is closed, an opening portion at the other end is closed by a closure and the interior is charged with a gas, an igniter assembly, attached to the closure side, and a tubular gas discharge port,the closure having an opening portion that serves as a gas passage in a part thereof, the opening portion being closed by a rupturable plate,the igniter assembly formed by integrating a part of a metallic igniter collar and an electric igniter with a resin,the igniter collar being fixed to the closure such that a space serving as a gas passage is formed between the igniter collar and the closure and an ignition portion of the electric igniter directly opposes the rupturable plate, andthe tubular gas discharge port including a plurality of gas discharge holes in a peripheral surface thereof, one end side of the tubular gas discharge port being welded and fixed to a part of the closure excluding the opening portion, a part of the peripheral surface of the tubular gas discharge port being supported by another part of the igniter collar, the other end side of the tubular gas discharge port projecting to the outside of the igniter collar.

Owner:DAICEL CHEM IND LTD

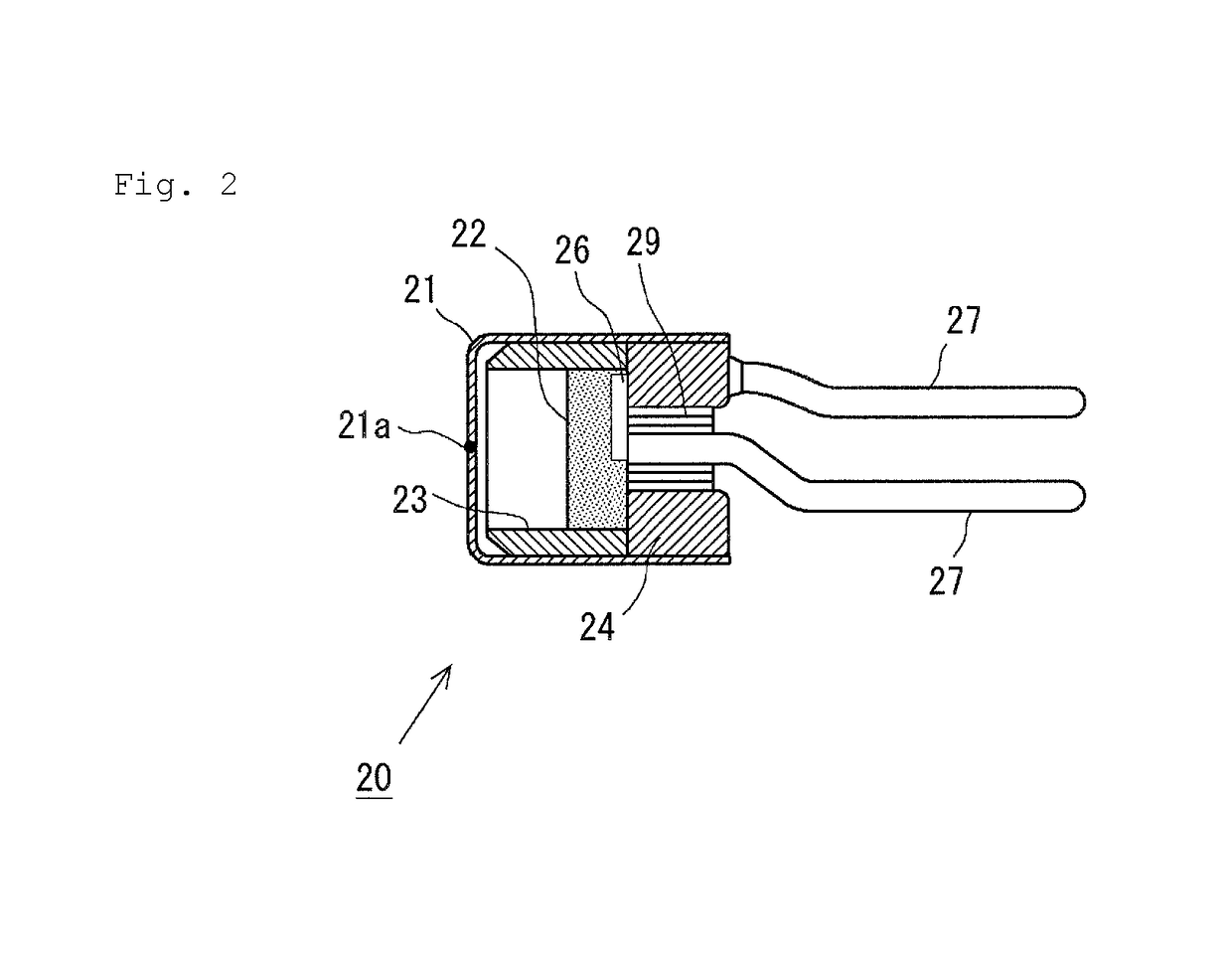

Igniter assembly actuated by parachute deployment, and flare containing the same

InactiveUS6412417B1Reduce the possibilitySufficient forceAerial display rocketsAmmunition fuzesFlareStationary state

This parachute flare igniter assembly has a novel slider for attaining high reliability in firing efficiency. The slider moves along a raceway of an igniter assembly housing. Also disposed in the housing is a cartridge retained in a stationary state relative to the housing. The cartridge includes a stationary primer and a spring. A striker arm connected to the cartridge is movable into a cocked state in which the spring urges the striker arm towards the primer. The slider has an igniter composition chamber and a cocking wall portion, and is movable in tandem with the igniter composition chamber along at least a portion of the length of said raceway from a loaded position to a firing position. In the loaded position, the striker arm is maintained in the cocked state by the cocking wall portion. In the firing position, the igniter composition chamber is aligned and in communication with the primer and the striker arm is free of the cocking wall portion to permit the spring to drive the striker arm from the cocked state into the primer with the force sufficient to detonate the primer.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

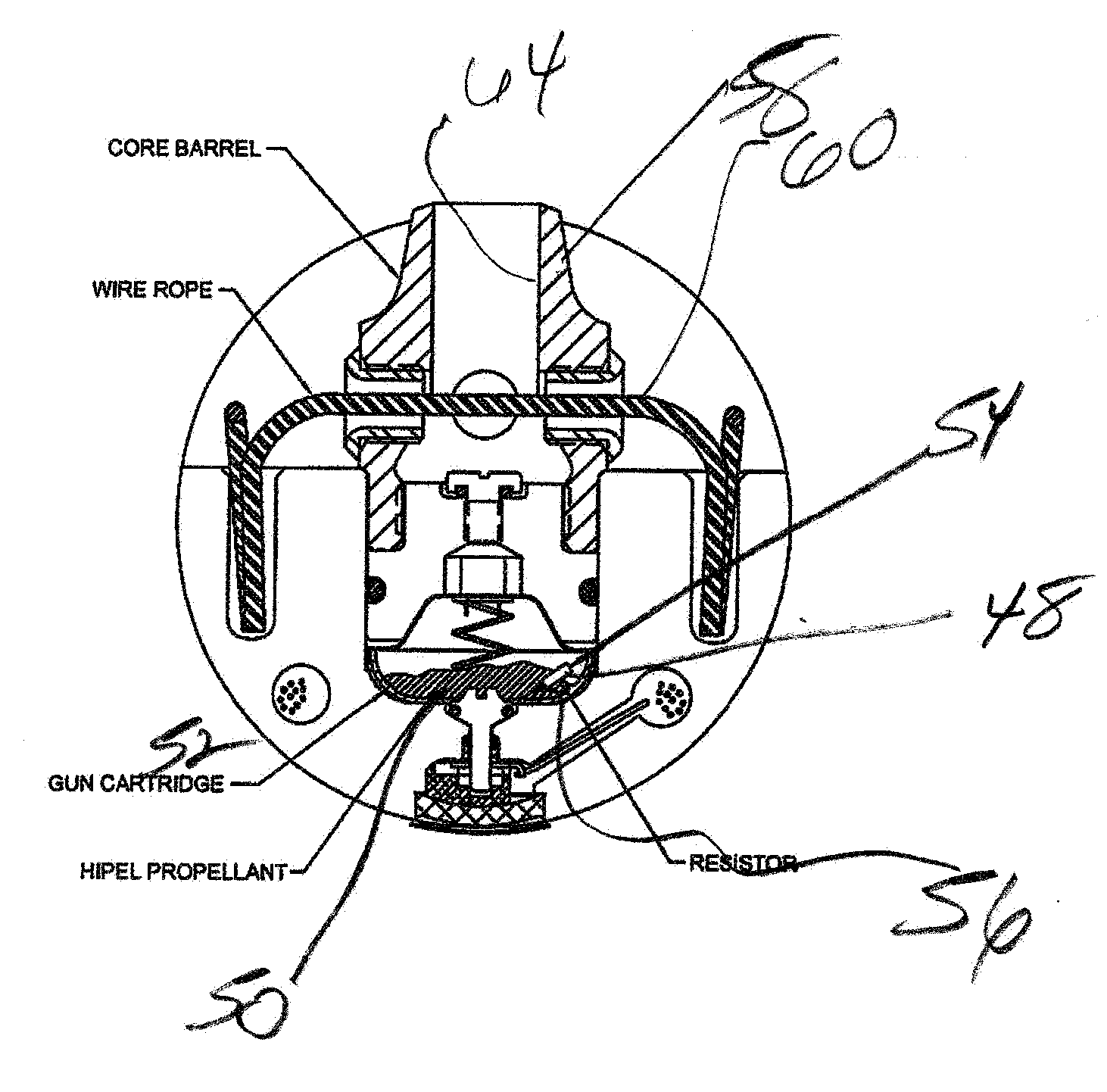

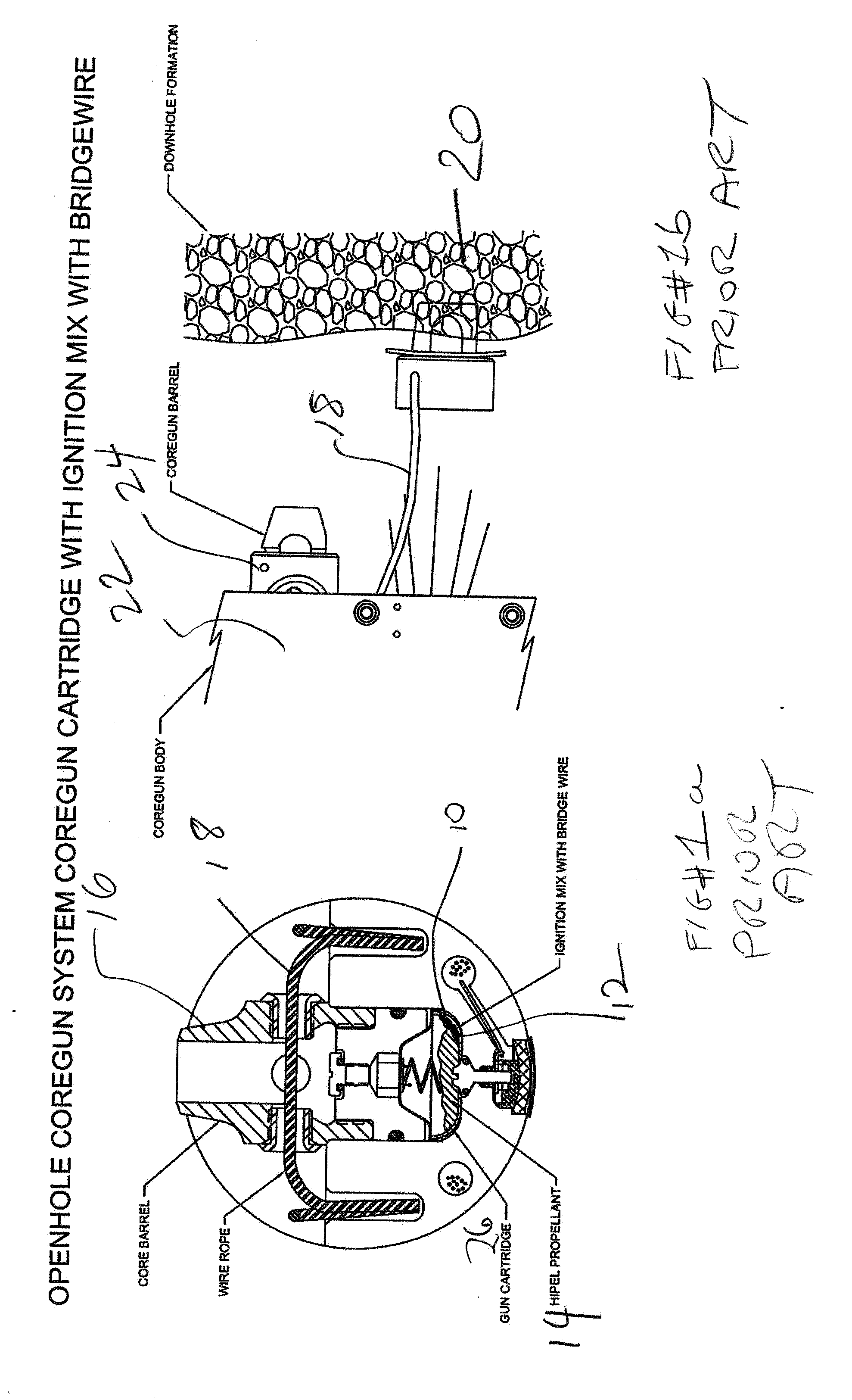

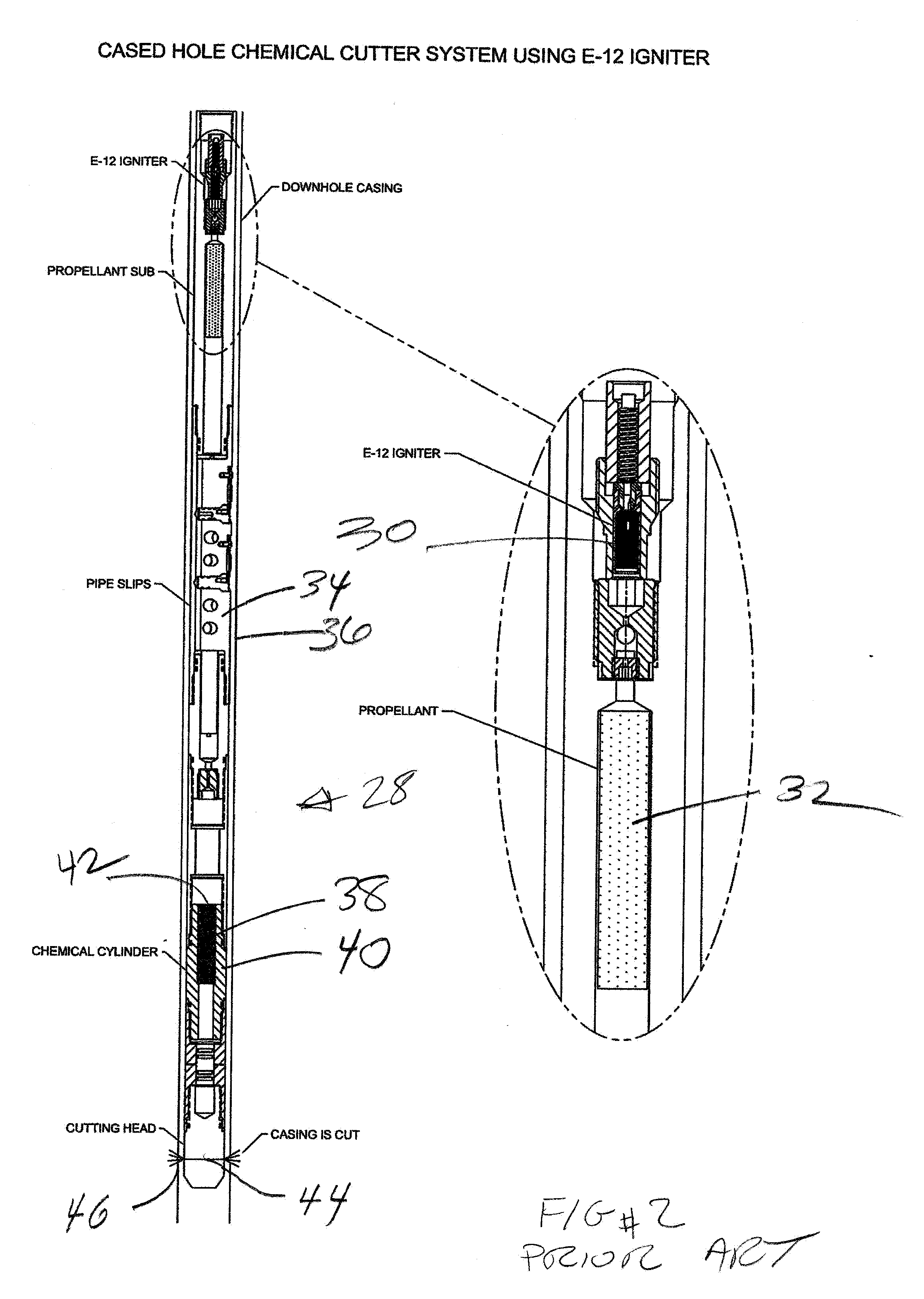

Resistor-based Ignition System for a Core Gun

InactiveUS20130228066A1Eliminate potential safety hazardsEliminate useFluid removalElectrical resistance and conductanceEngineering

A core gun igniter assembly features a resistor under 50 ohms that is welded rather than soldered to a circuit. Upon energizing the circuit, the resistor creates the heat needed to directly set off the propellant to directly drive the core barrel into the surrounding formation to obtain the desired core sample. The use of a titanium powder ignition mix on a nichrome wire with its attendant safety risks is eliminated.

Owner:BAKER HUGHES INC

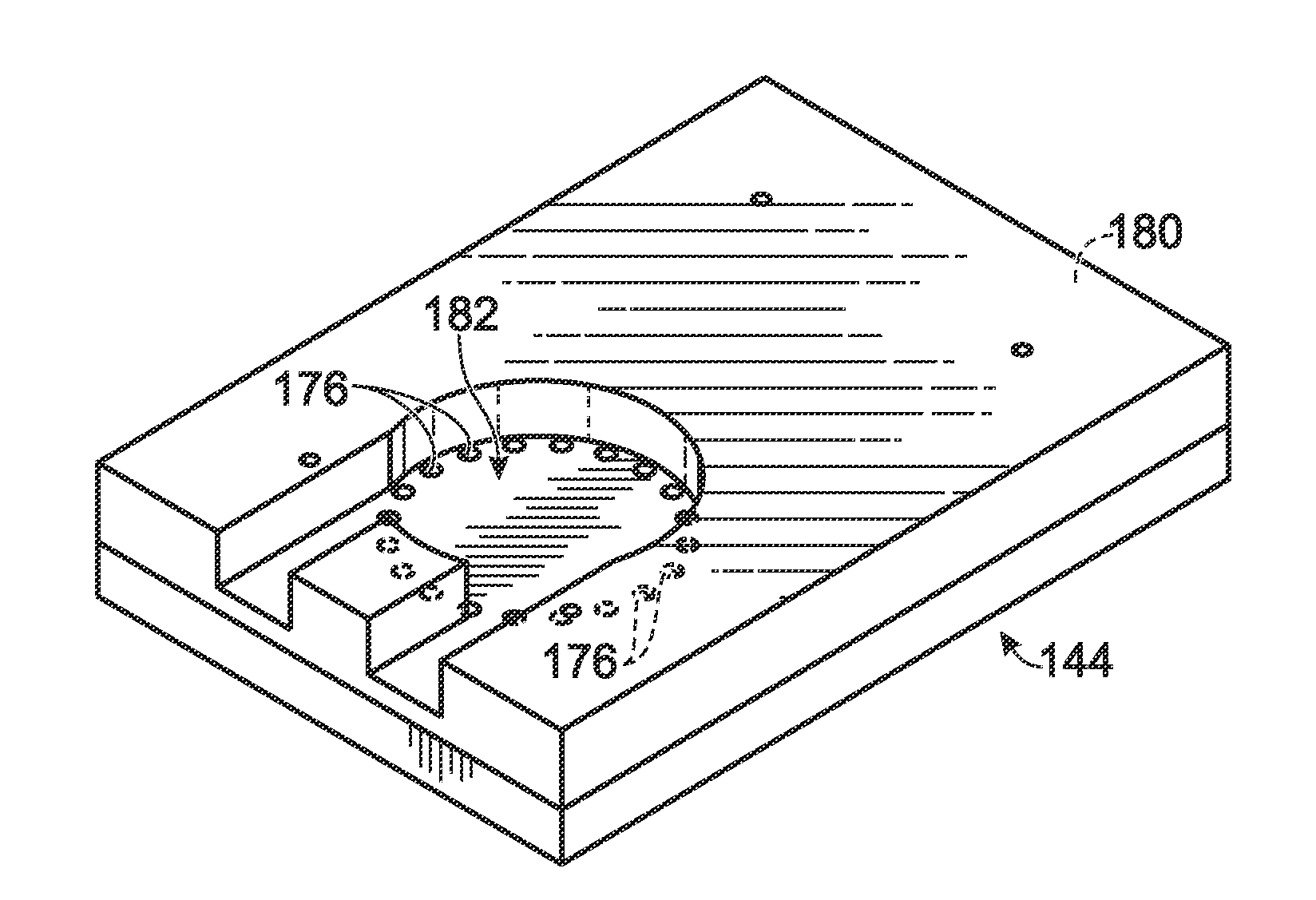

Furnace using plasma ignition system for hydrocarbon combustion

InactiveUS7435082B2Promote combustionImprove efficiencyBurnersInternal combustion piston enginesCombustorFuel efficiency

An apparatus and method for the creation, placement and control of an area of electrical ionization within an internal combustion engine combustion chamber or a fuel burner for a furnace is disclosed. A furnace includes a fuel source, a fuel burner, a plasma nozzle and igniter assembly, and the associated housing and flue structures. The plasma nozzle and igniter assembly is arranged so that the fuel sprayed out from the nozzle into the combustion area passes through or in close proximity to the area of plasma ionization. A fuel burner equipped with this electrical ionization device has its fuel efficiency enhanced by the complete and immediate combustion of substantially all of the fuel that passes through the area of plasma ionization. Exhaust gas recirculation using this system is also disclosed.

Owner:JAYNE MICHAEL E

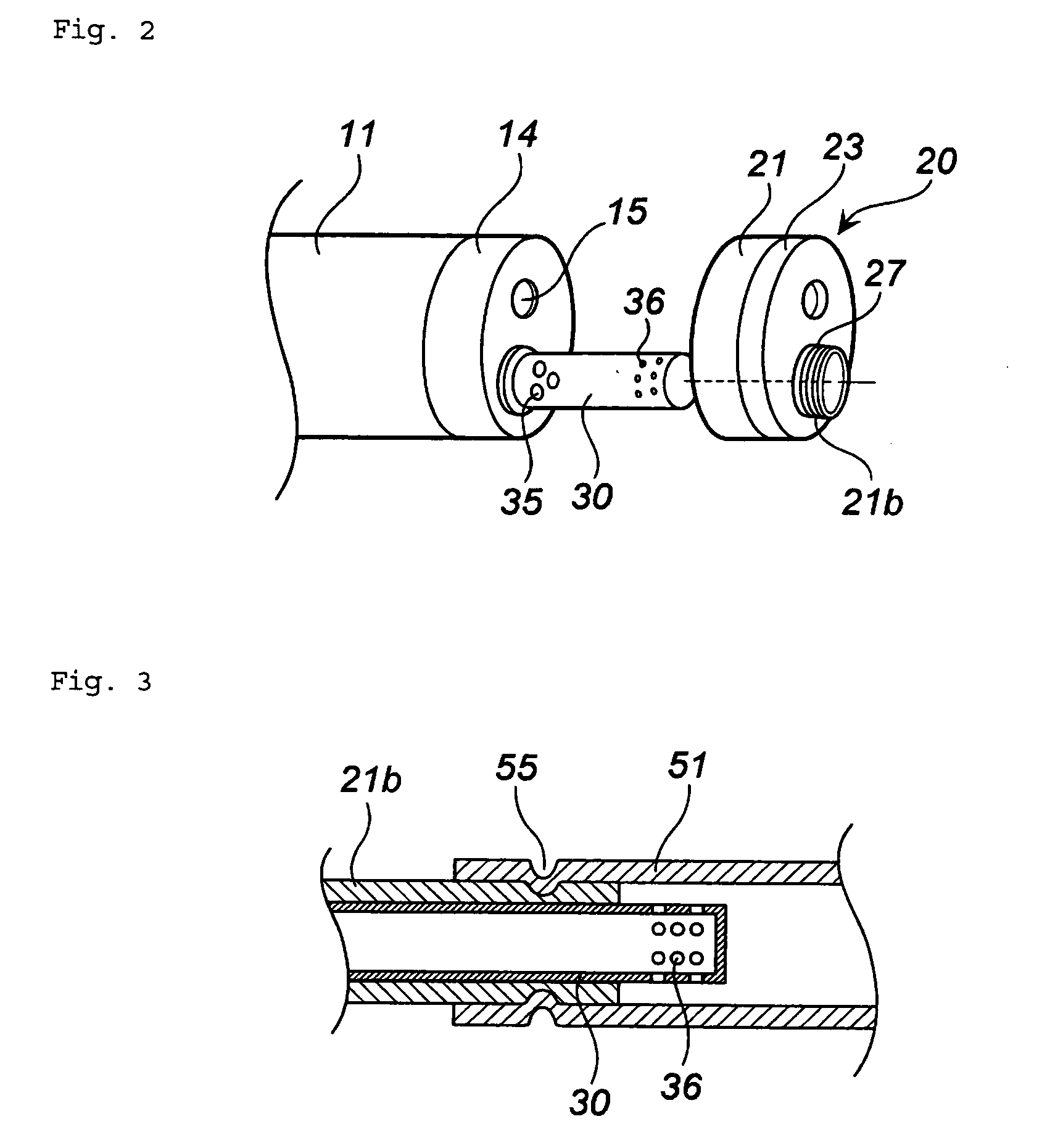

Igniter assembly

ActiveUS7854201B2Pedestrian/occupant safety arrangementBlasting cartridgesElectric lightMechanical engineering

An igniter assembly includes, an electric igniter and igniter collar, and a resin fixing the electric igniter into the igniter collar. The electric igniter has an igniter main body and a conductive pin which extends from the igniter main body. The igniter collar has a first through hole formed in the axial direction and at least one second through hole formed separately from the first through hole and being provided to the igniter collar. The electric igniter is fixed inside the first through hole by the resin, and the resin is also charged into the second through hole.

Owner:DAICEL CHEM IND LTD

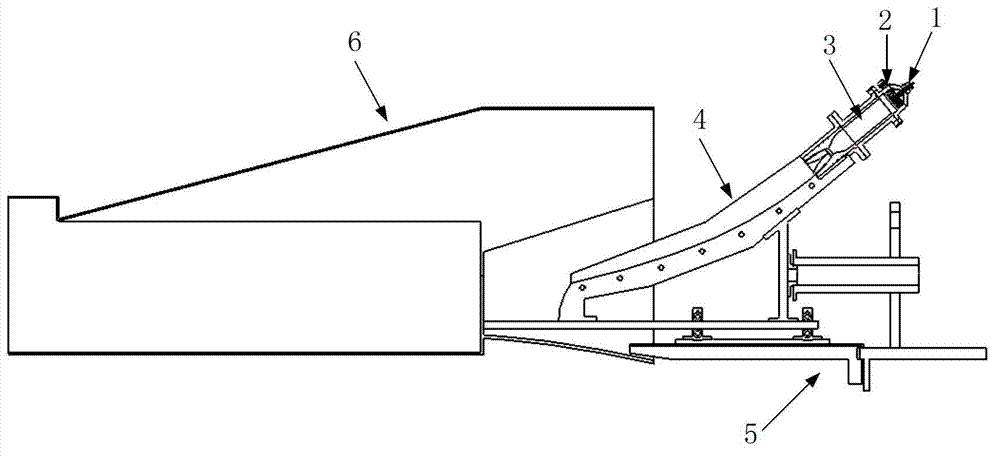

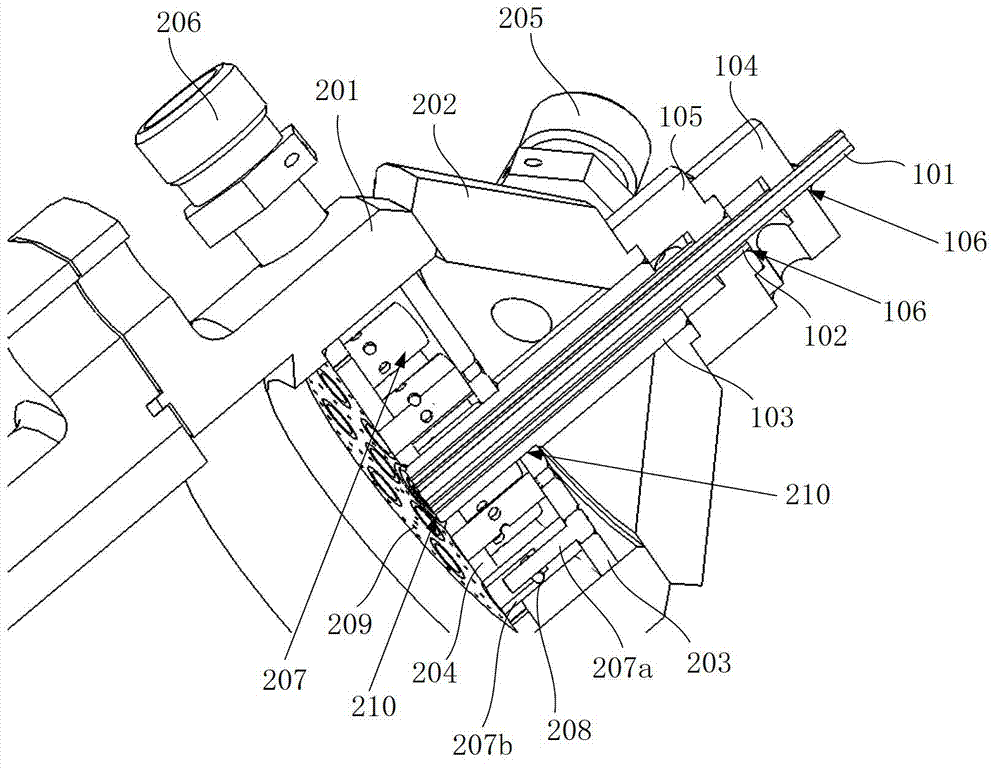

Low-cost and simple unit round-to-square plug nozzle test device

The invention discloses a low-cost and simple unit round-to-square plug nozzle test device, which comprises an igniter assembly, an injector assembly, a thrust chamber assembly, a plug cone assembly, a thrust measuring support table frame assembly and an ejection exhaust tube, wherein the injector assembly is provided with a hydrogen cavity and an oxygen cavity, a hydrogen and oxygen gas direct flow spray nozzle with the single hydrogen and oxygen injection function is arranged in the hydrogen cavity, the igniter assembly formed by three layers of sleeves is arranged inside the injector assembly, the injector assembly is connected with the thrust chamber assembly with a round-to-square inner nozzle, the plug cone assembly and the thrust chamber assembly are connected, are supported by the thrust measuring support table frame assembly and can forwards and backwards slide on the support table frame assembly, a platform with an installing thrust frame is also arranged on the support table frame assembly, and the back part of the plug cone is positioned in the ejection exhaust tube. The low-cost and simple unit round-to-square plug nozzle test device has the advantages that the structure is simple, the measurement precision is high, the cost is low, in addition, the application range is wide, the study content is rich, and the repeated use for many times can be realized.

Owner:BEIHANG UNIV

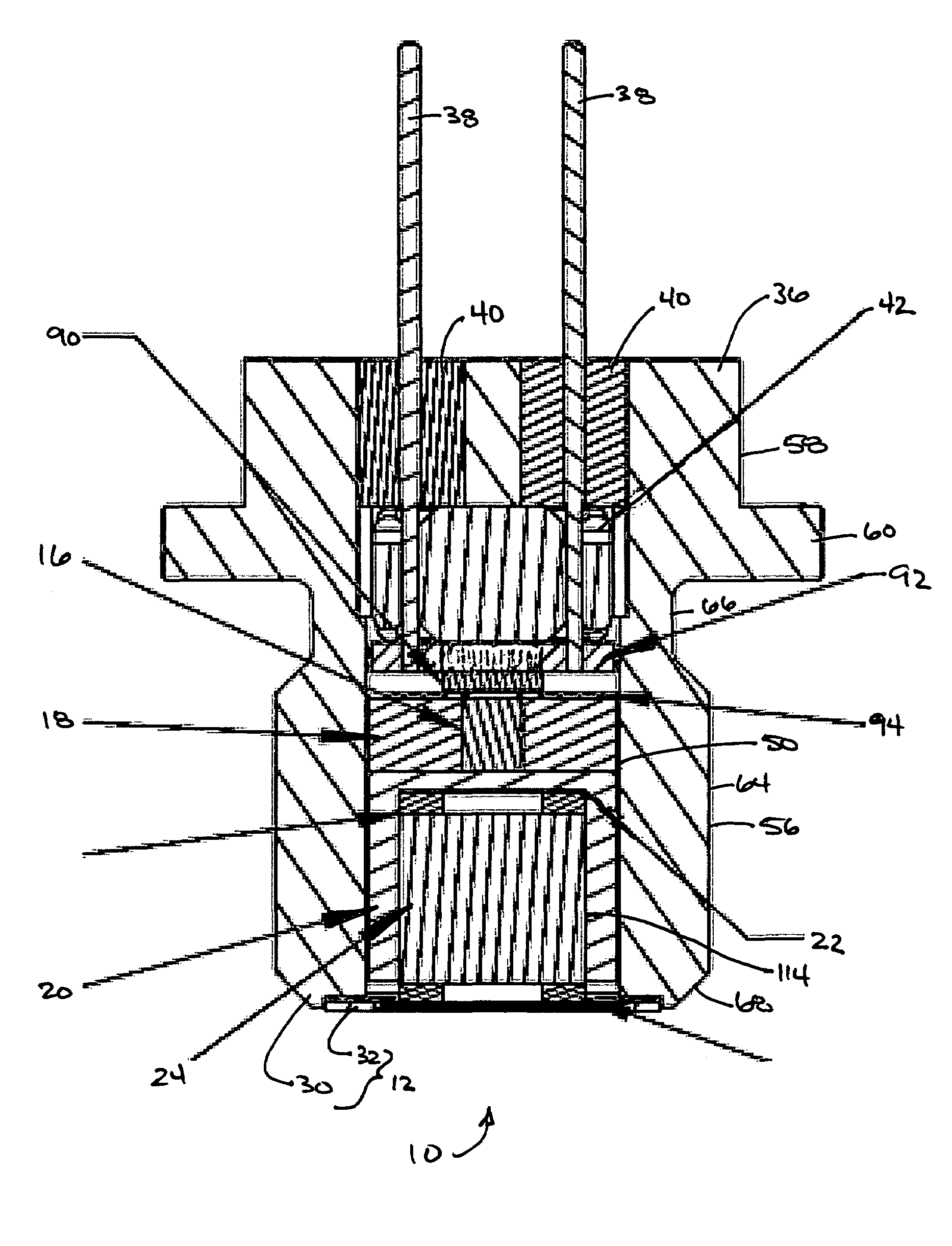

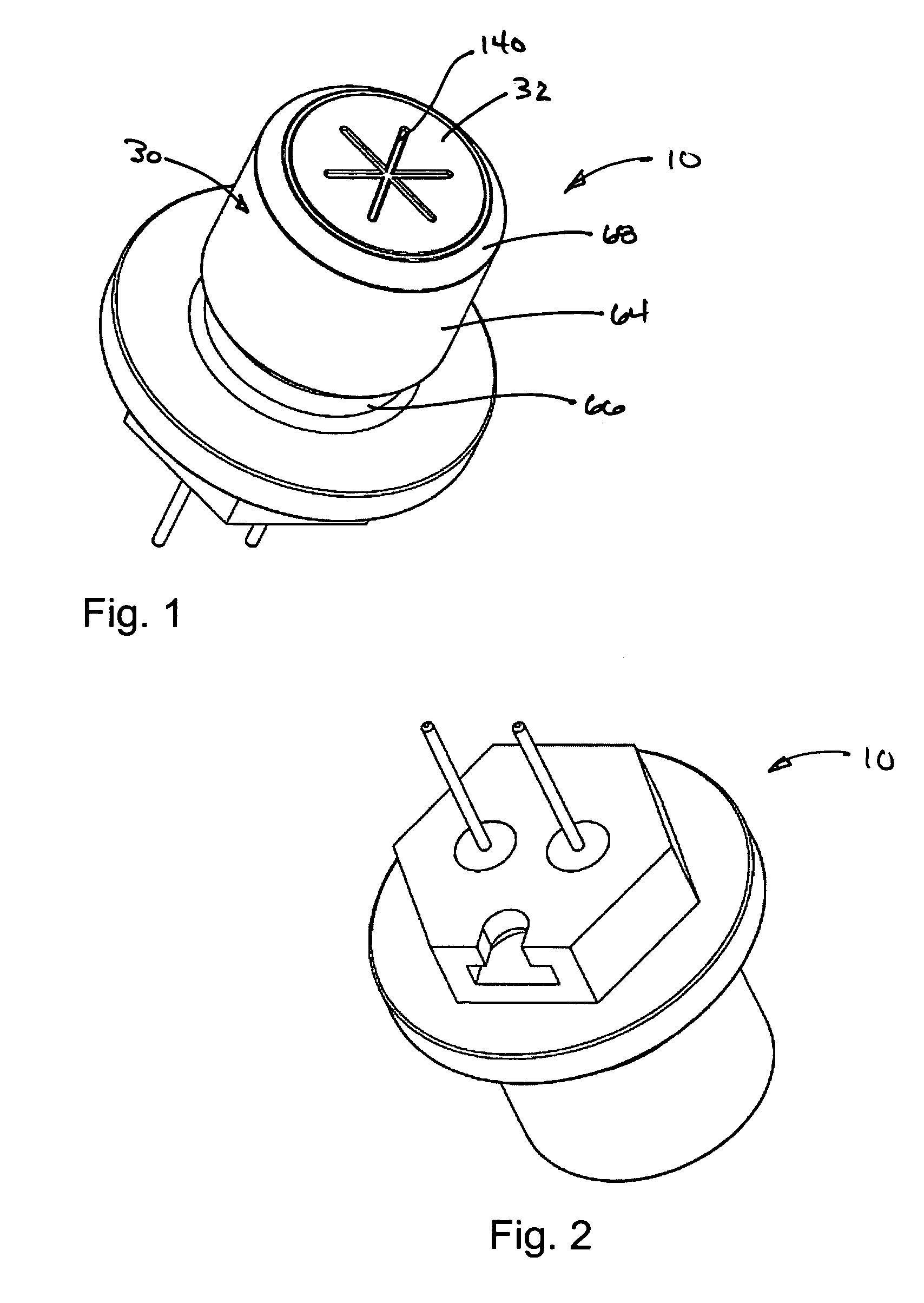

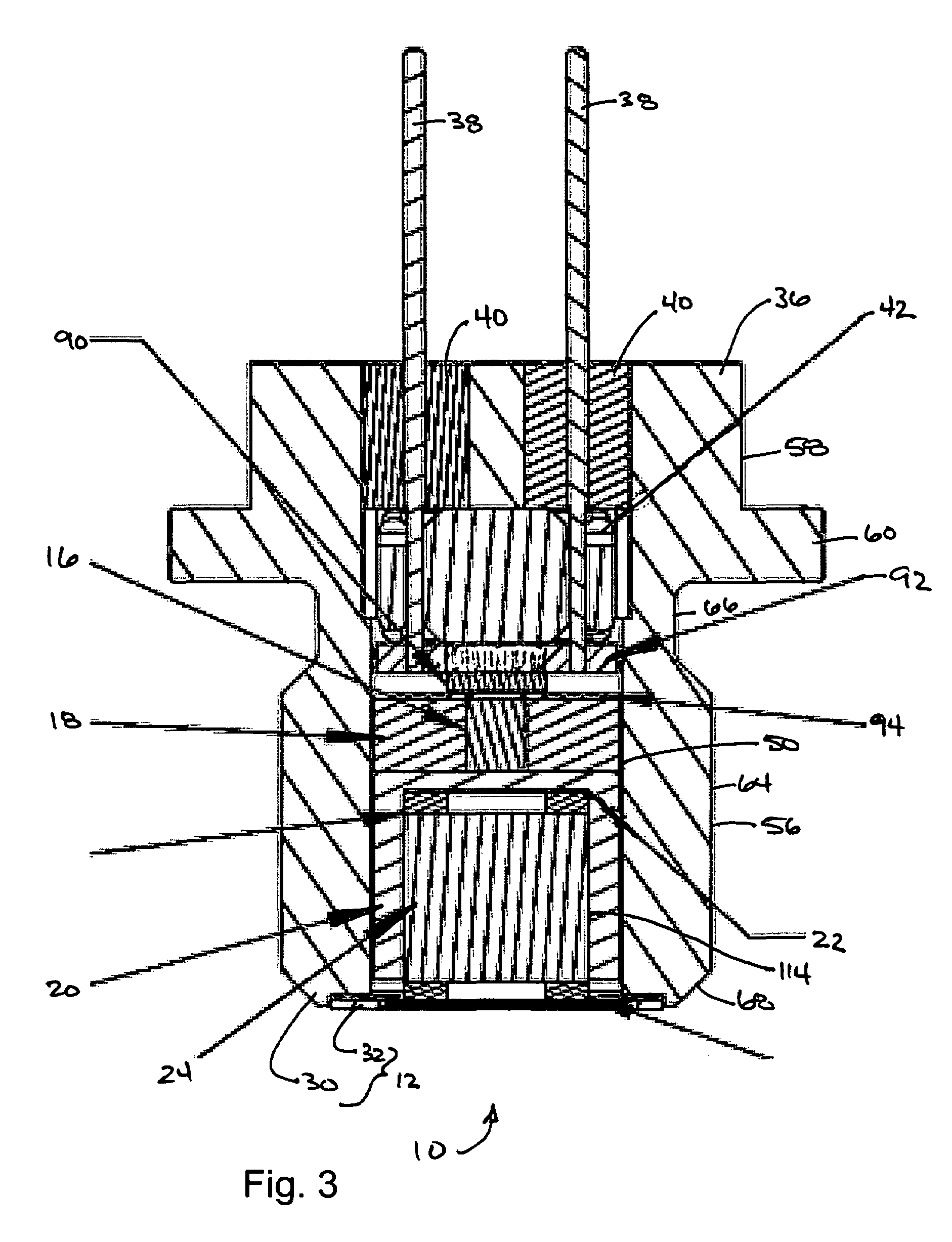

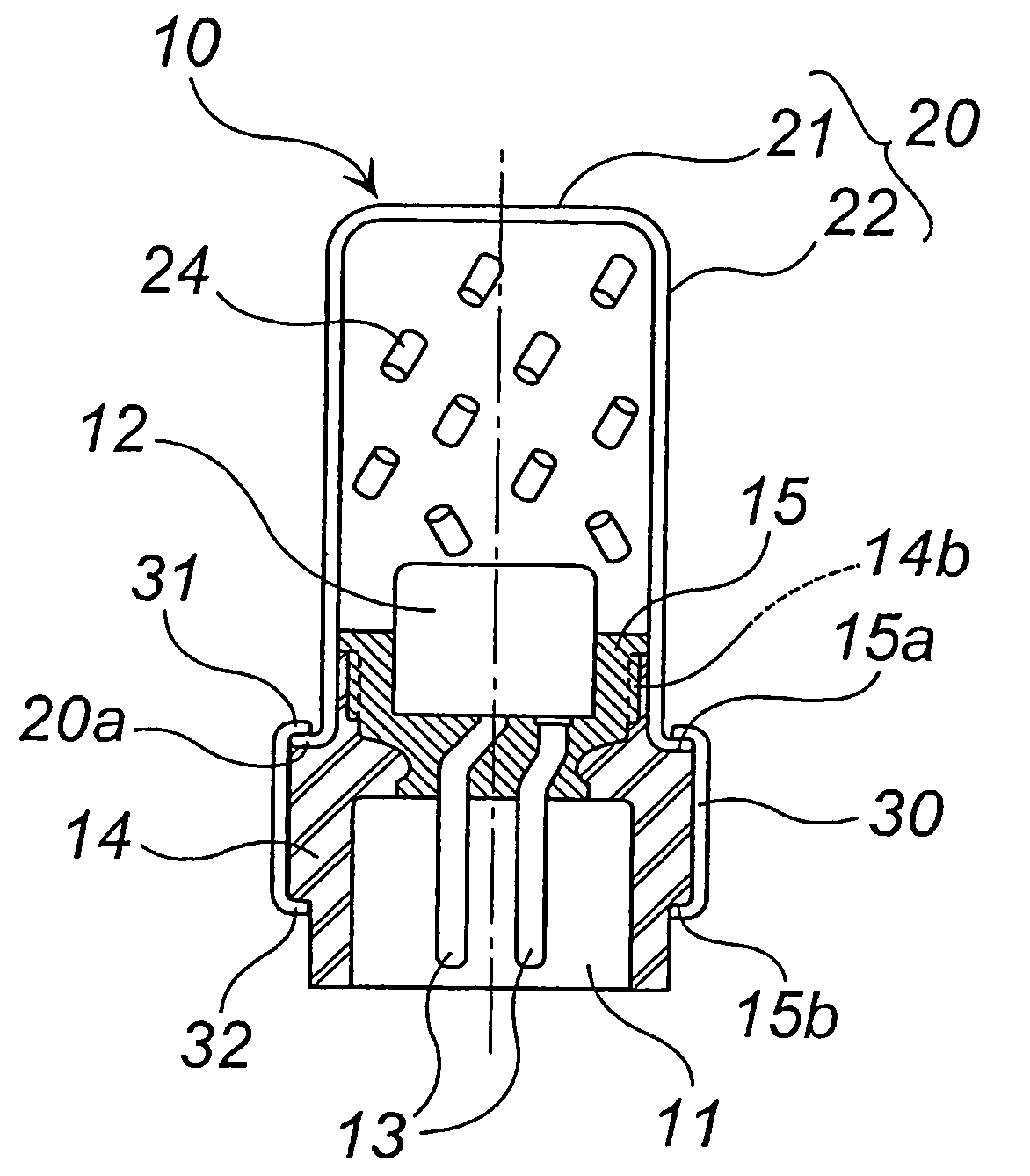

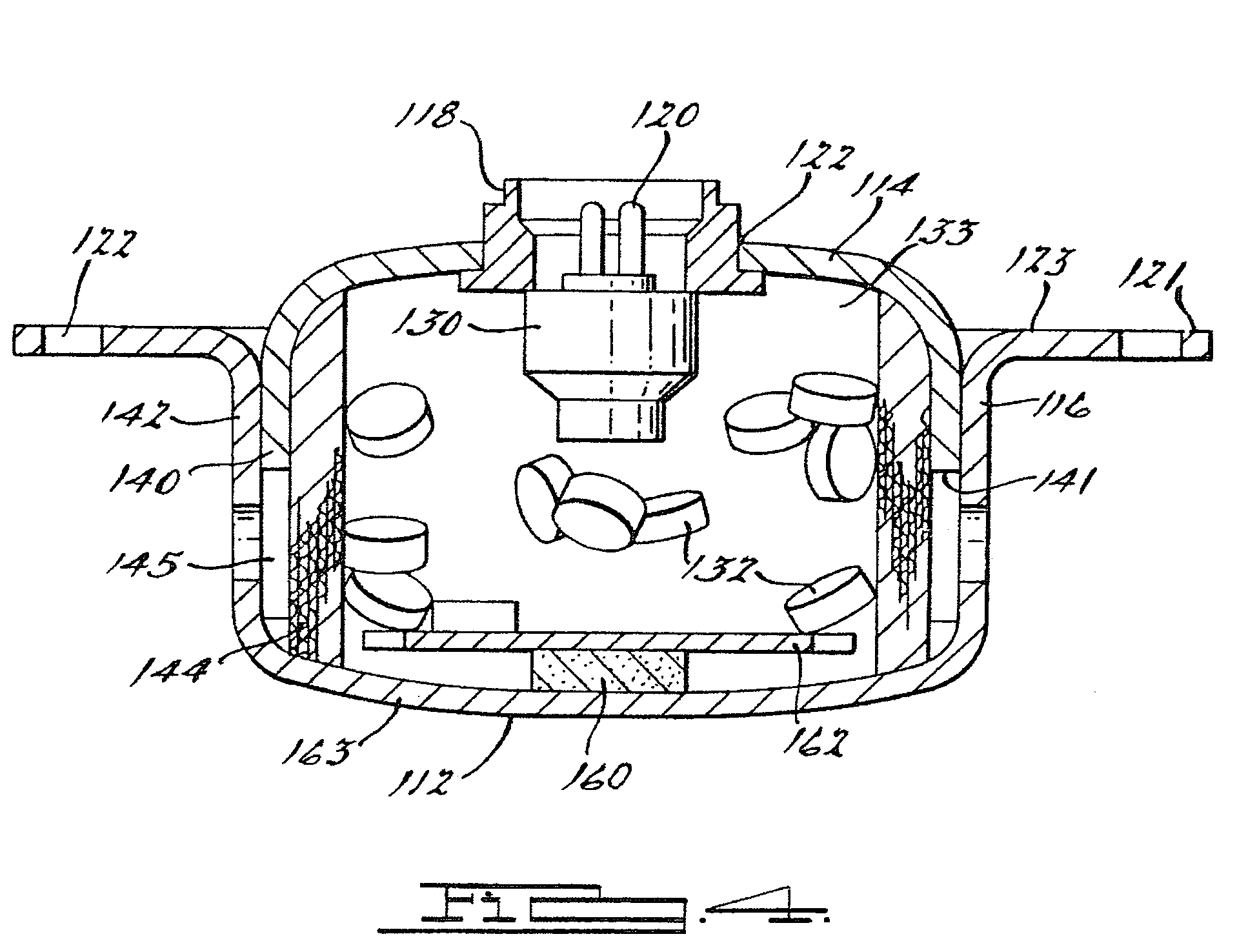

Weld-less driver-side inflator

InactiveUS6964430B2Light weightLess componentsPedestrian/occupant safety arrangementGas generation devicesCombustionEngineering

An inflator (10) is provided for supplying gas to a vehicle airbag from the combustion of pyrotechnic materials. The inflator (10) has a two-piece inflator body (12) held together by crimping the body components, rather than welding. An igniter assembly (18) is positioned in a bore (22) in an upper piece (14) of the inflator body and is held in place with a press-fit interface and an adhesive seal. The upper piece (14) of the inflator body is rounded, increasing its strength, and fits partially into the lower piece (16). A booster tube is unnecessary, making the inflator lighter in weight and increasing available volume for propellant.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY +1

Corona igniter assembly including corona enhancing insulator geometry

ActiveUS8749126B2High quality ignitionStable and good performanceSparking plugsMachines/enginesCorona dischargeEngineering

A corona igniter 20 includes a central electrode 34 for receiving a high radio frequency voltage from a power source and emitting a radio frequency electric field to ionize a fuel-air mixture and provide a corona discharge 22. The corona igniter 20 includes an insulator 38 extending along the central electrode 34 longitudinally past the central electrode 34 to an insulator firing end 40. The insulator firing surface 42 and the center axis A present an angle α of not greater than 90 degrees therebetween, for example the insulator firing surface may be concave. The central electrode 34 may also include a firing tip 50, in which case the insulator firing surface 42 surrounds all sides of the firing tip 50. The geometry of the insulator firing surface 42 concentrates and directs the corona discharge 22.

Owner:FEDERAL MOGUL IGNITION

Furnace using plasma ignition system for hydrocarbon combustion

InactiveUS20090104576A1Promote combustionImprove efficiencyBurnersPower operated startersCombustorFuel efficiency

An apparatus and method for the creation, placement and control of an area of electrical ionization within an internal combustion engine combustion chamber or a fuel burner for a furnace is disclosed. A furnace includes a fuel source, a fuel burner, a plasma nozzle and igniter assembly, and the associated housing and flue structures. The plasma nozzle and igniter assembly is arranged so that the fuel sprayed out from the nozzle into the combustion area passes through or in close proximity to the area of plasma ionization. A fuel burner equipped with this electrical ionization device has its fuel efficiency enhanced by the complete and immediate combustion of substantially all of the fuel that passes through the area of plasma ionization. Exhaust gas recirculation using this system is also disclosed.

Owner:JAYNE MICHAEL E

Pyrotechnic actuator mechanism, syringe and igniter assembly

ActiveUS10060452B2Suppress dischargeSuppress emissionJet injection syringesPyrotechnical actuatorsCombustionEngineering

Owner:DAICEL CHEM IND LTD

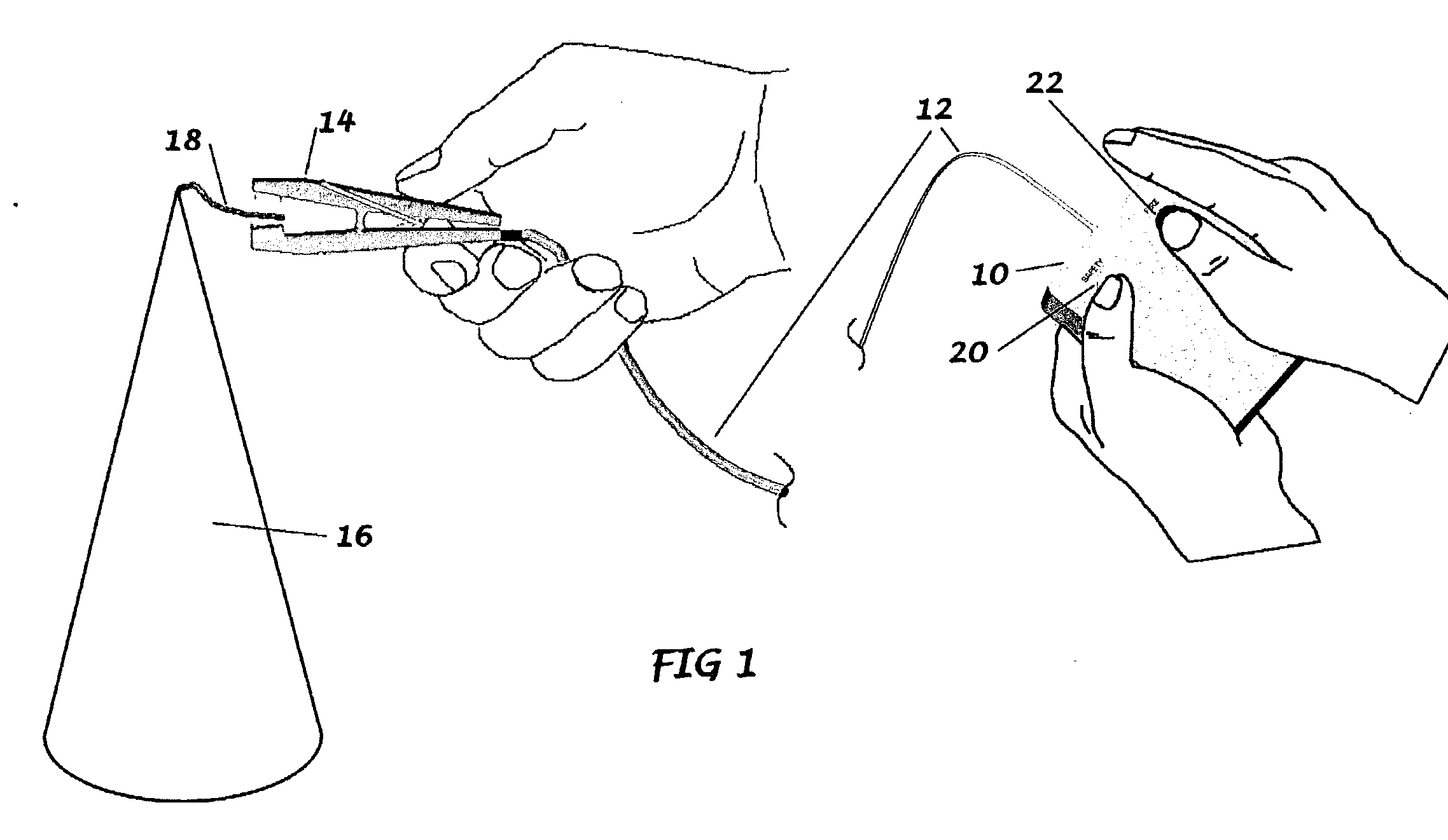

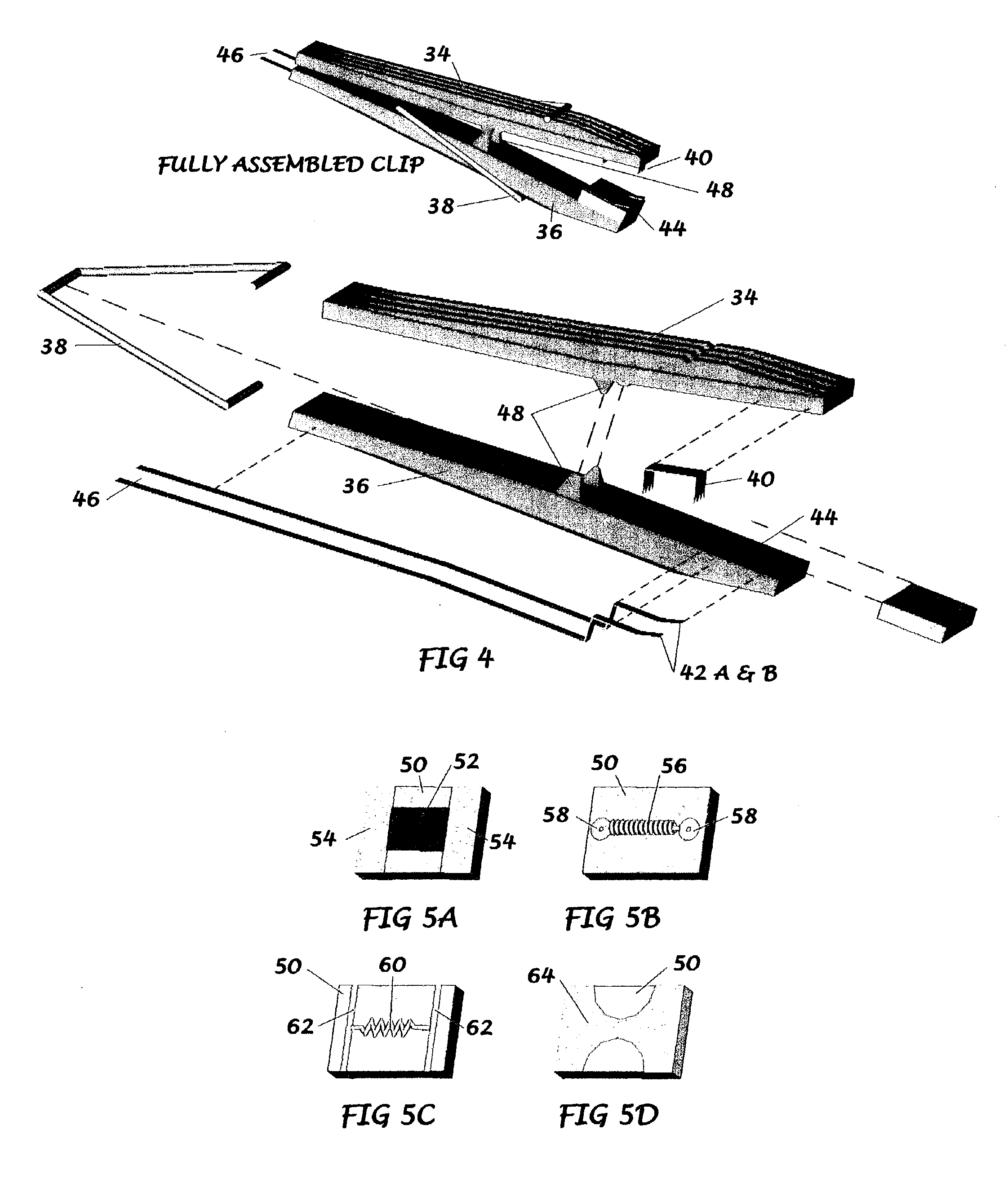

Low voltage pyrotechnic igniter assembly

The electric pyrotechnic igniter of the present invention comprises a controlled power source providing low-voltage electricity to one or more remotely located, replaceable ignition elements which are housed in compression clips capable of holding the ignition elements into direct contact with firework fuses.

Owner:BAILEY SAMUEL WALTERS +1

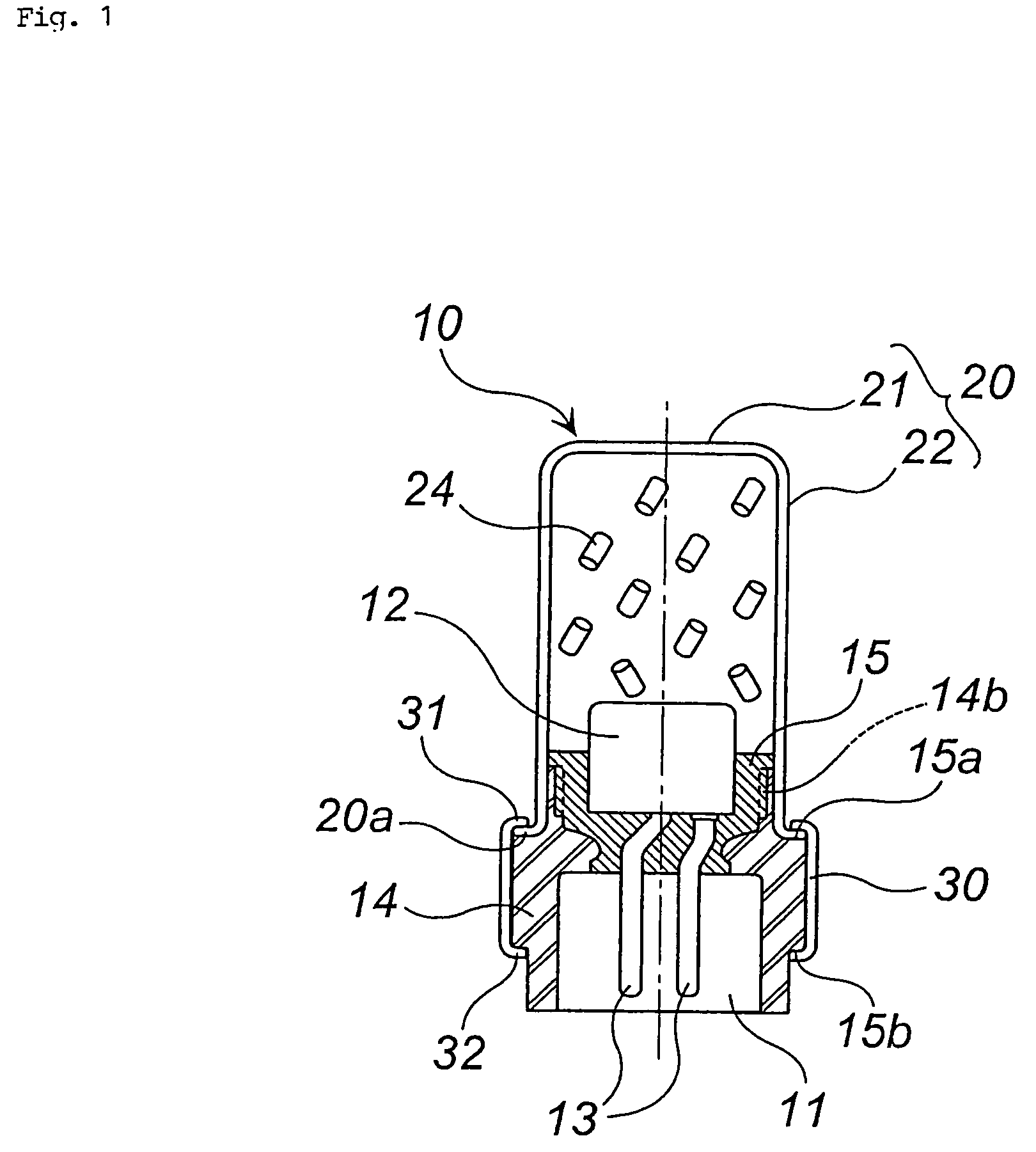

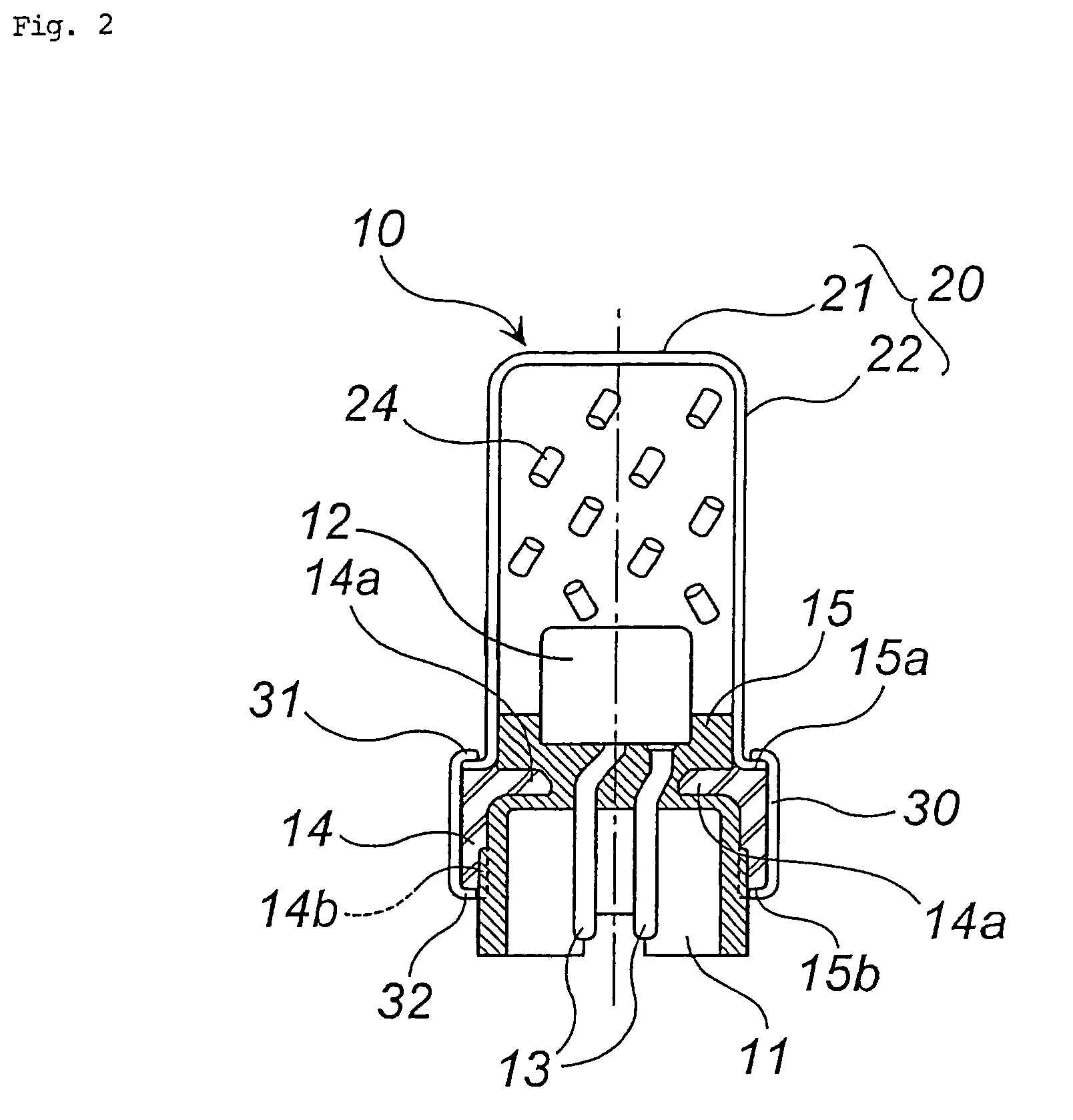

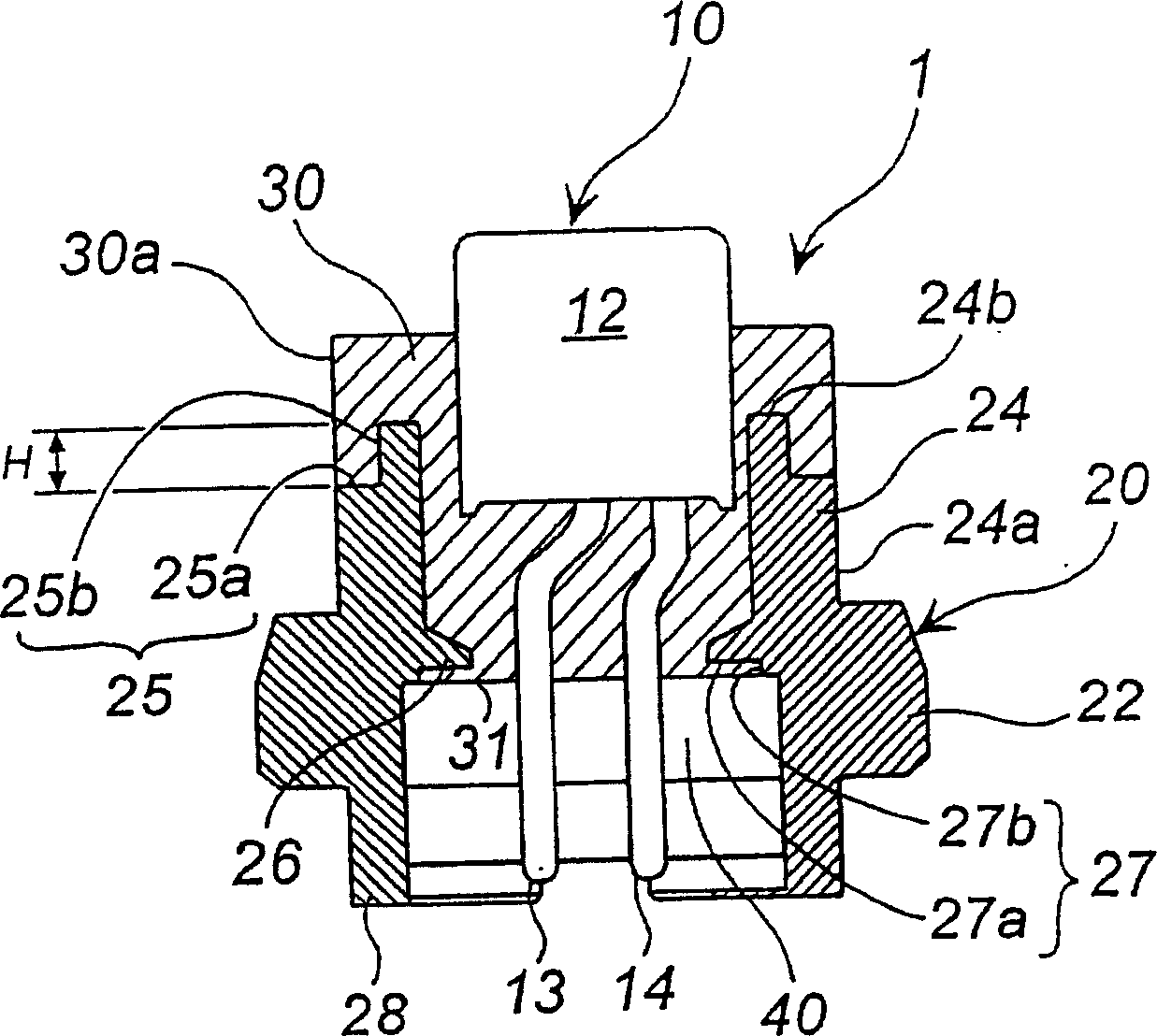

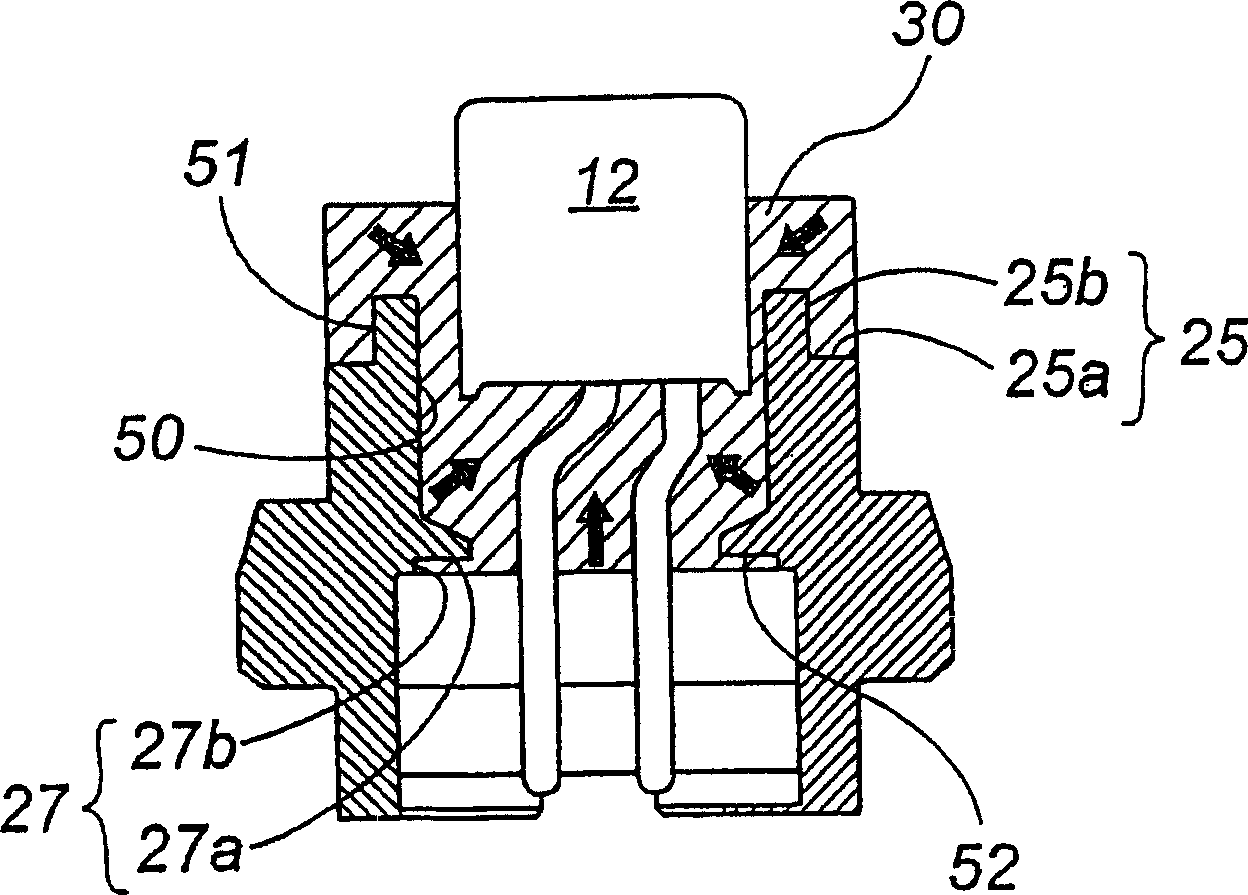

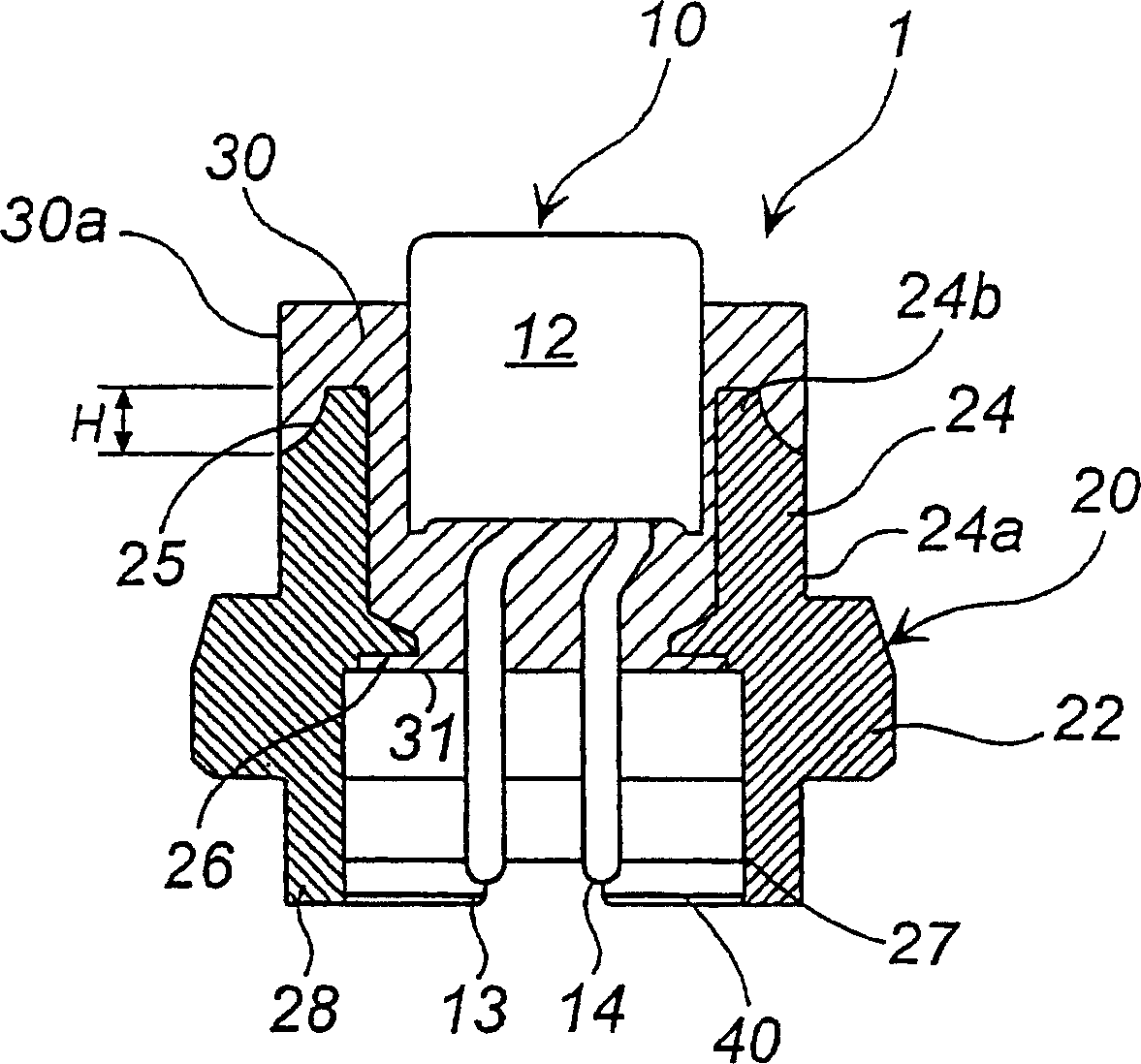

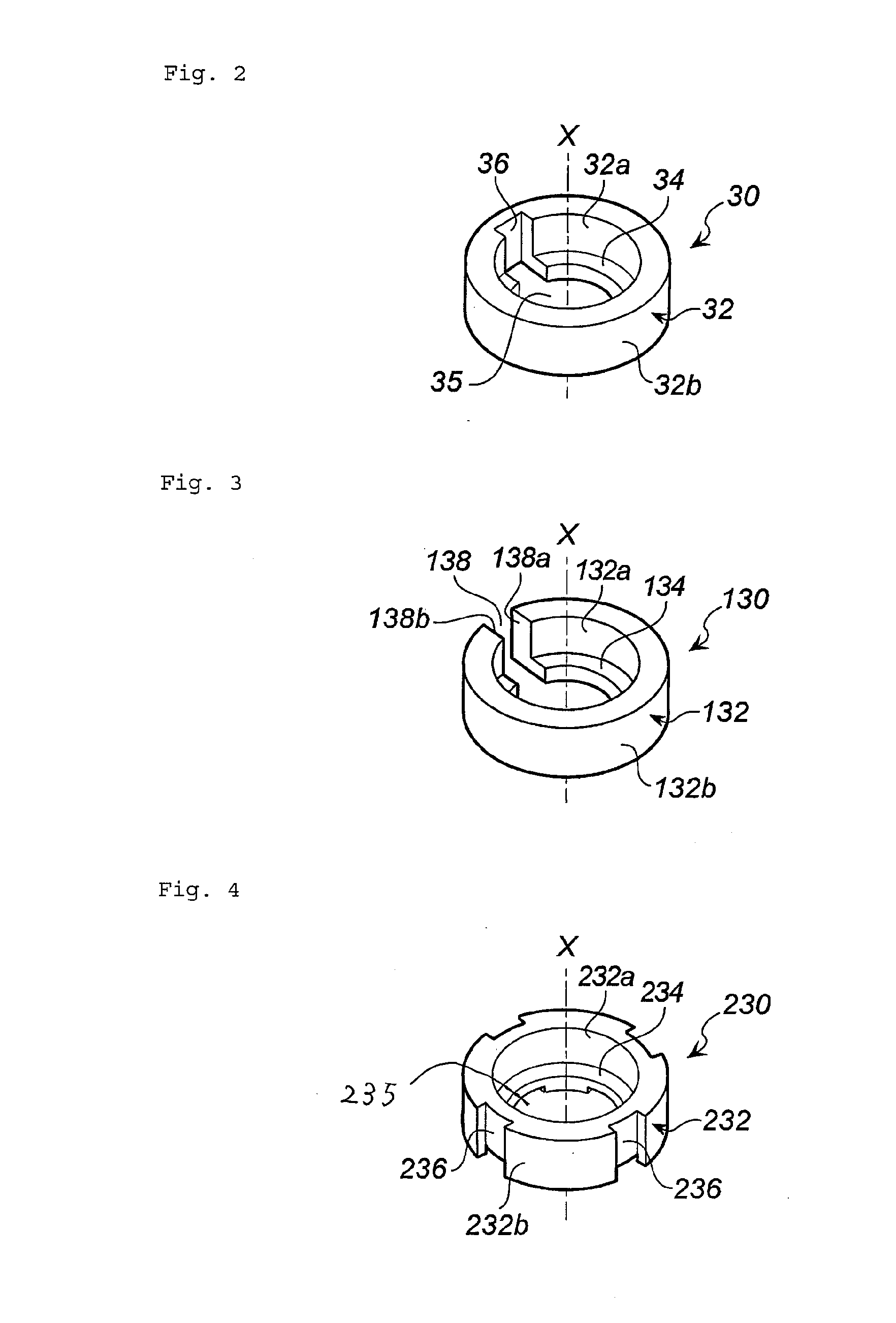

Ignitor assembly

ActiveCN1764817ADoes not increase production costsAvoid absorptionBlasting cartridgesPedestrian/occupant safety arrangementEngineeringMechanical engineering

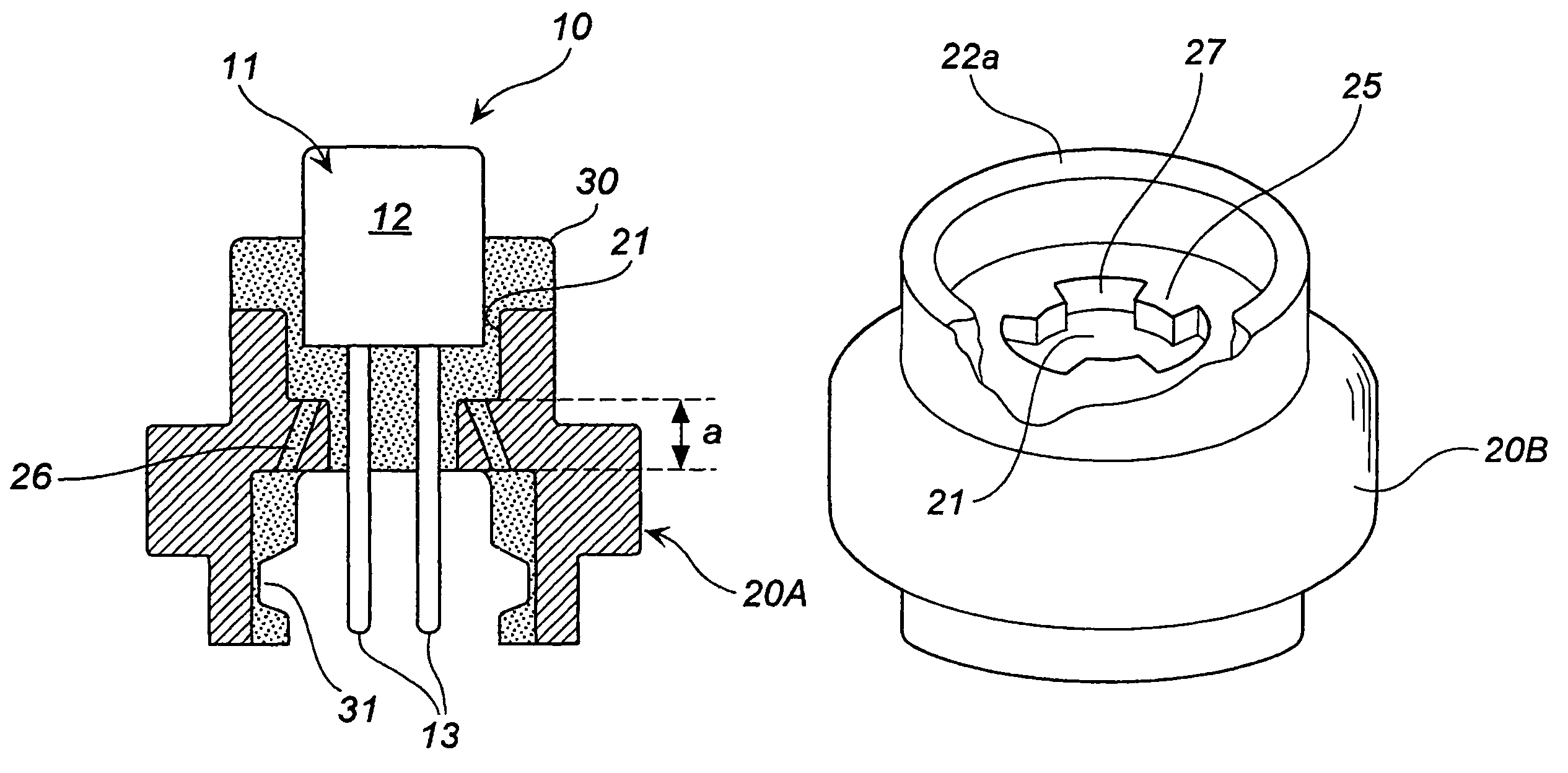

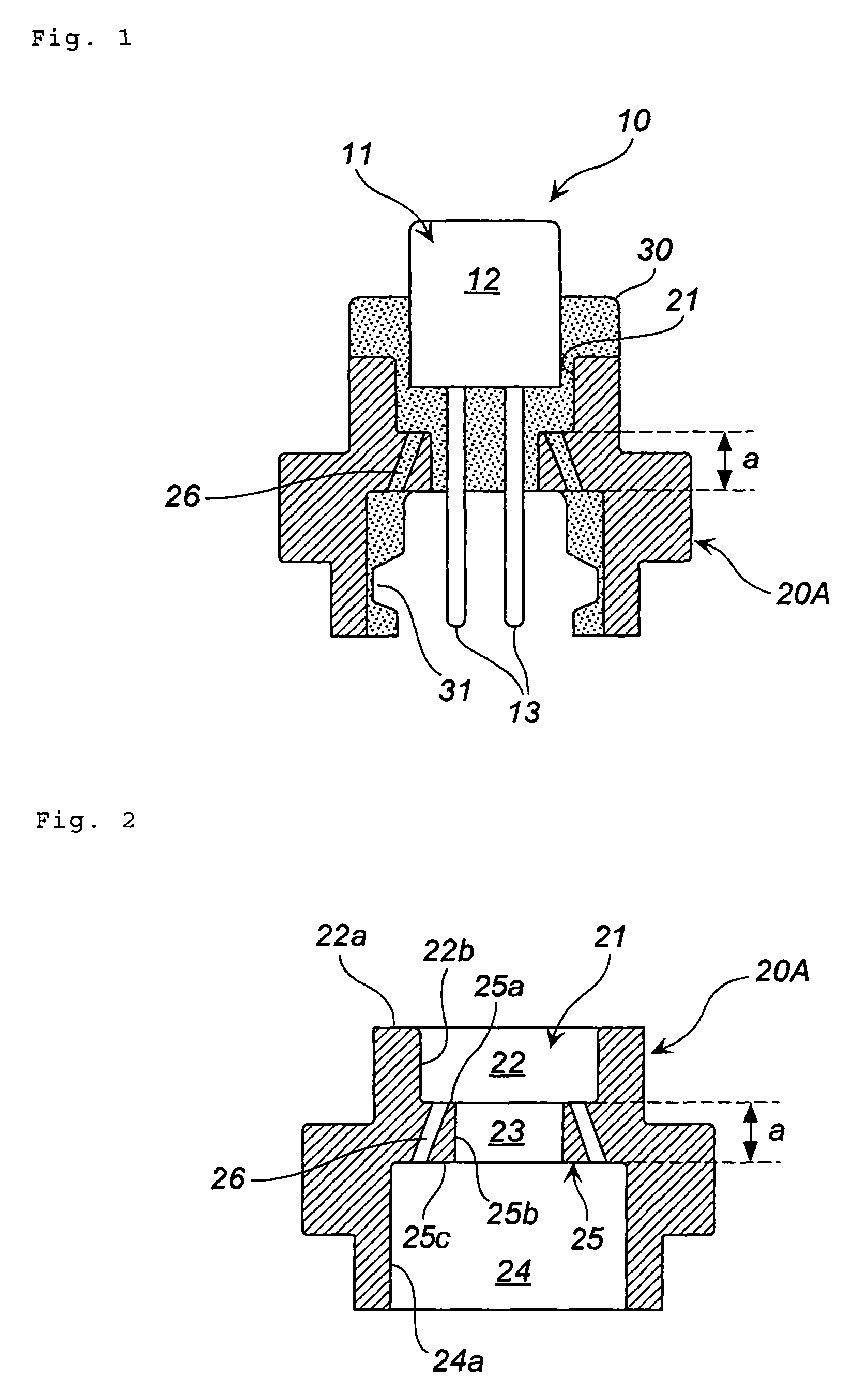

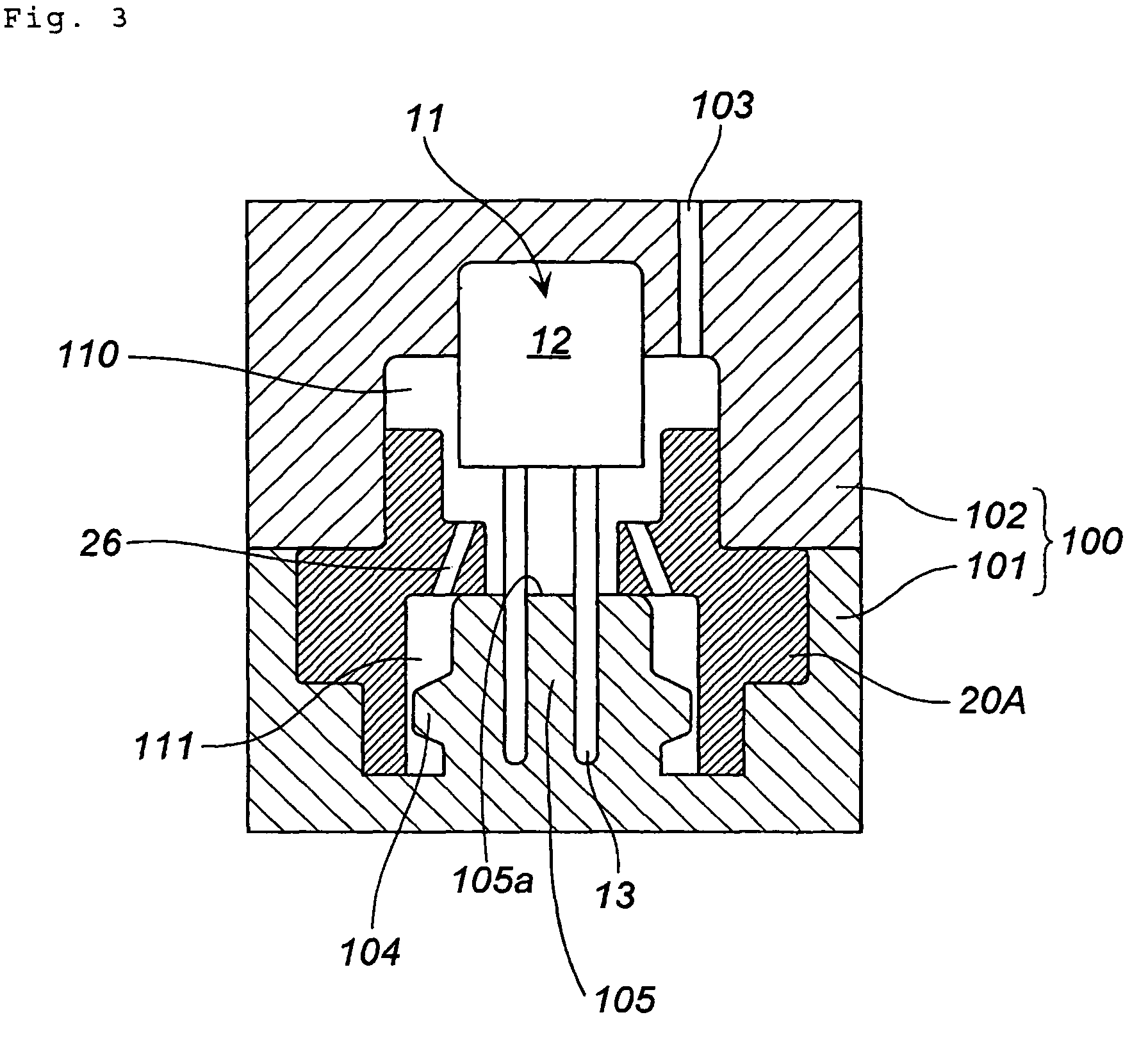

The invention discloses an igniter assembly with excellent moisture-proof performance, in which a cylindrical protruding portion (24) and a cylindrical step portion (25) are provided on a metal collar (20). The shrinkage of the resin (30) after injection molding forms a gap at the interface (50), but instead presses the above-mentioned cylindrical step portion (25) without forming a gap at the interface (51). Therefore, since continuous gaps can be prevented from being generated, moisture can be prevented from entering.

Owner:DAICEL CHEM IND LTD

Igniter assembly for a gas turbine engine

In one aspect the present subject matter is directed to an igniter assembly for a gas turbine engine. The igniter assembly includes an outer housing and an igniter tube that extends radially through the outer housing. The igniter tube includes an ignition tip, a nut coupled to the igniter tube and disposed at least partially within the outer housing and a biasing member that extends between an inner surface of a top portion of the outer housing and the nut. A flexible seal extends radially inwardly from a bottom side of the nut and a retention collar is coupled to the igniter tube proximate to the ignition tip. The retention collar is configured to couple to a mounting ring connected to an outer liner of a combustor for the gas turbine engine.

Owner:GENERAL ELECTRIC CO

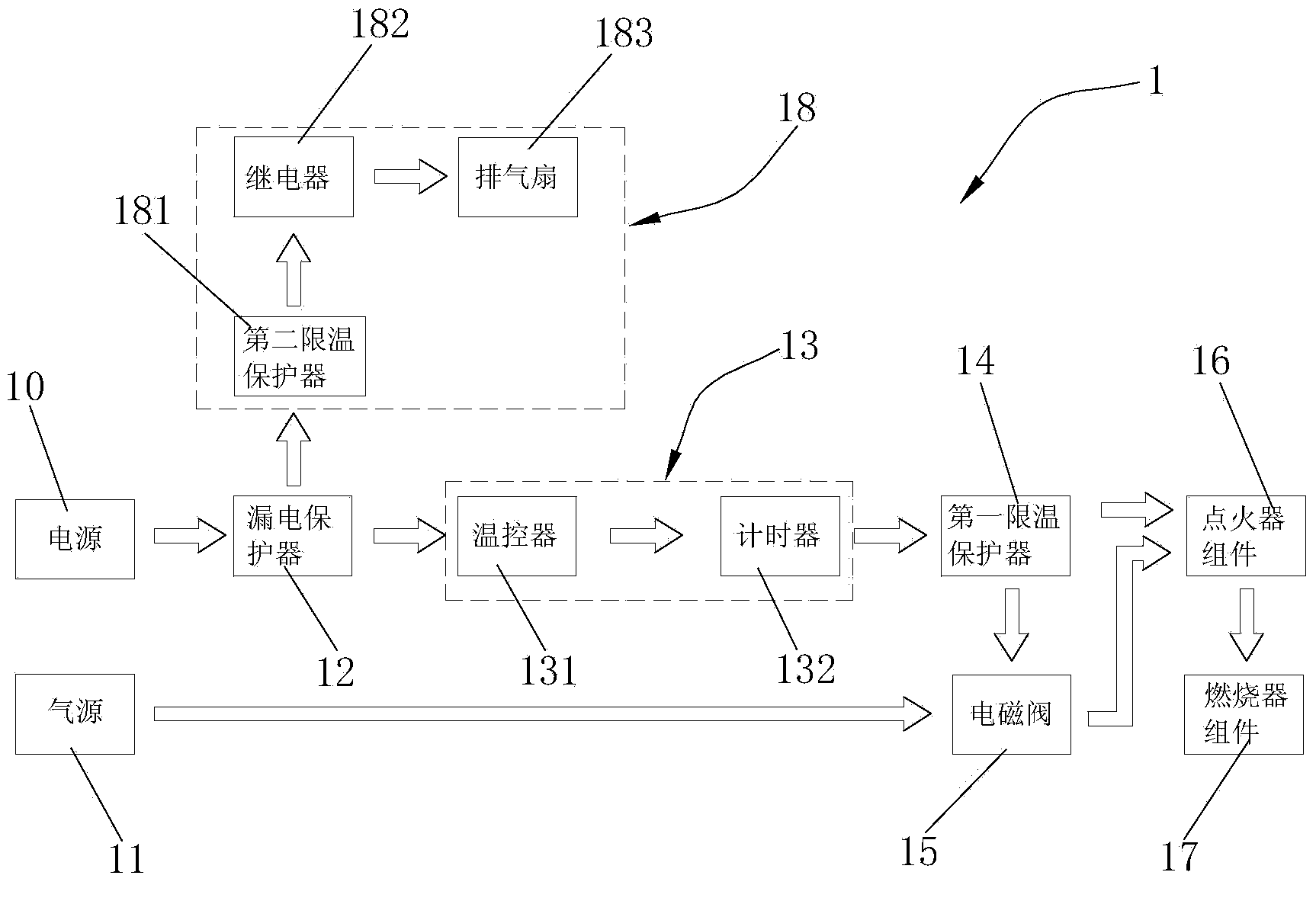

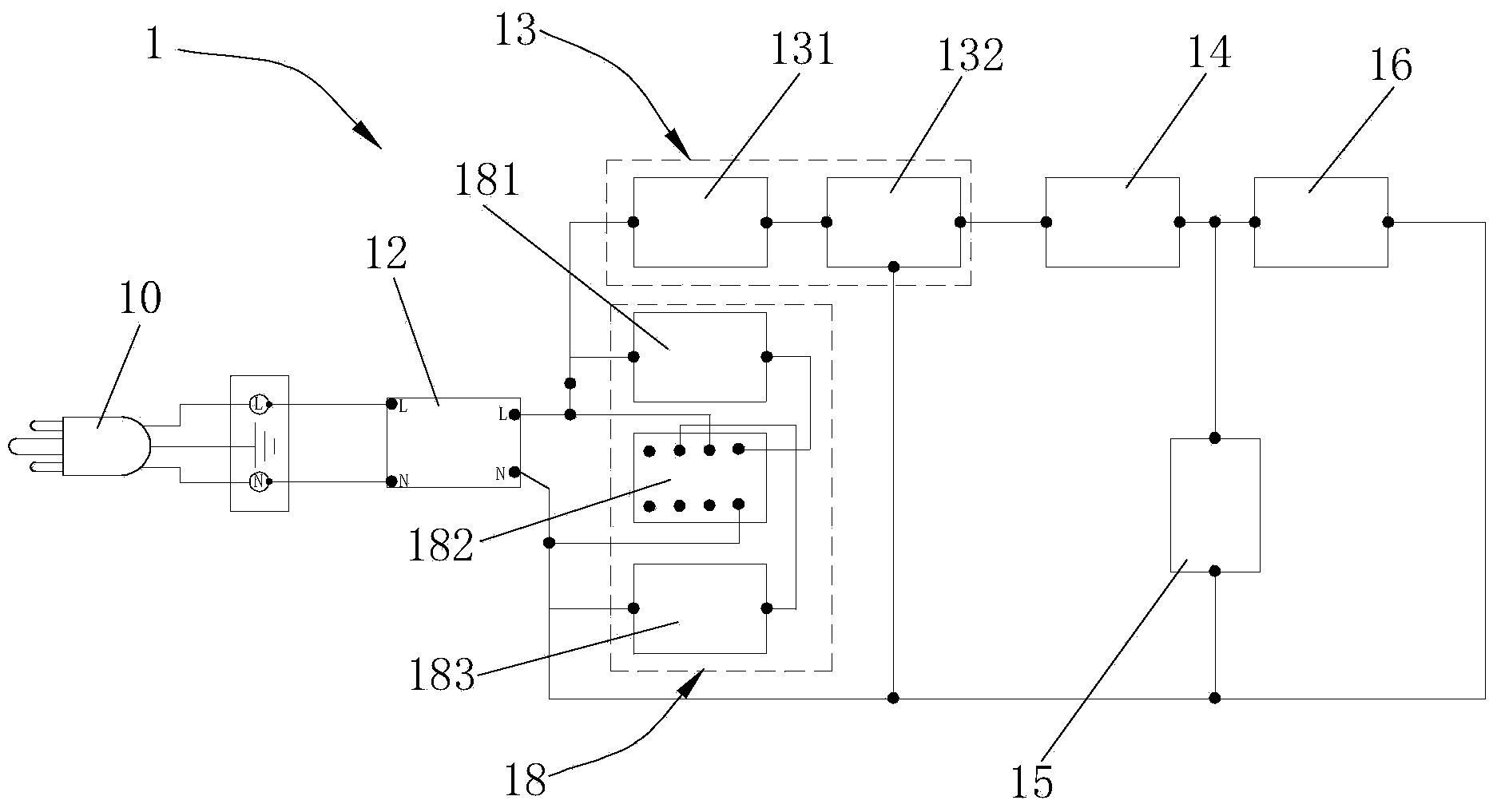

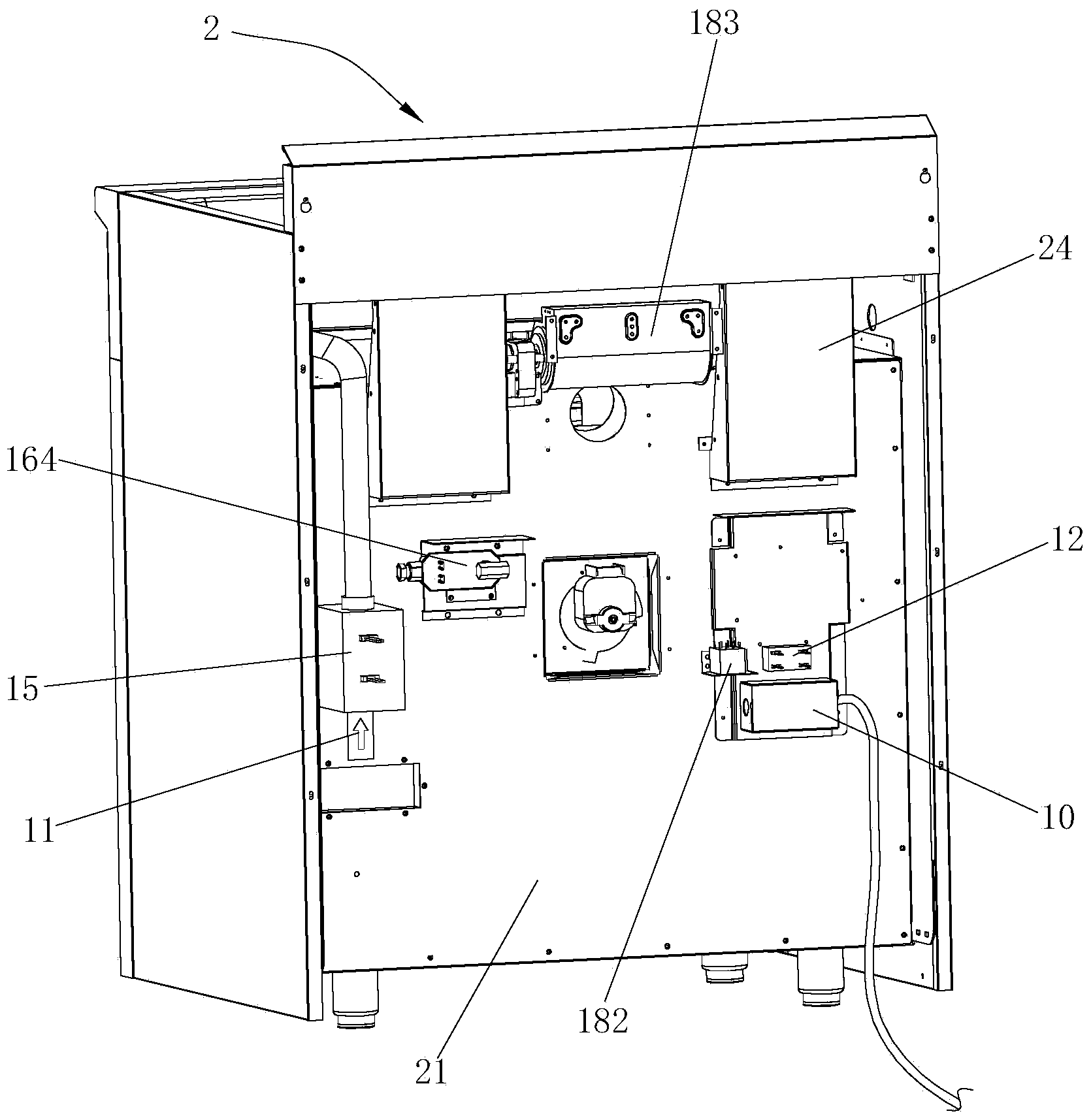

Oven safety control protection system and oven with same

The invention discloses an oven safety control protection system and an oven with the same. The oven safety control protection system comprises a power source, an air source, a leakage protector which is electrically connected with the power source, a safety control unit which is electrically connected with the leakage protector, a first temperature limiting protector which is electrically connected with the safety control unit and is used for monitoring the temperature of the oven, an electromagnetic valve which is electrically connected with the first temperature limiting protector and is used for controlling the on-off of the air source, an igniter assembly connected with the first temperature limiting protector and the air source, and a burner assembly connected with the igniter assembly. The purposes that an electric circuit and a gas circuit of the oven are safely controlled at the same time, and the power source and the air source can be cut off automatically at the same time are achieved, multiple intelligent protections such as leakage protection, intelligent time control, temperature limiting protection and temperature dropping protection to the oven are achieved, the oven is safer and more reliable to use, excessive manual control is of no need, using is simple and convenient, and the practicability is high.

Owner:DONGGUAN HYXION METAL TECH CO LTD

Assembly method for device employing electric ignition

The present invention is a method of assembling a device employing electric ignition by comprising assembling an igniter assembly in the device, the igniter assembly having an electric igniter provided with a first electroconductive pin and a second electroconductive pin, connected to a power source, the method comprising steps of:forming two measurement circuits by using the first electroconductive pin and the second electroconductive pin as a measurement terminal on one end side, respectively, and using another member provided in the igniter assembly as a terminal on the other end side with a pass through a dielectric provided in the igniter assembly,measuring pure resistances and / or impedances of the two measurement circuits, respectively, by applying a high frequency thereto separately,distinguishing the first electroconductive pin from the second electroconductive pin from a magnitude relationship (difference) between the measured pure resistance and / or impedance values, andthen, disposing the igniter assembly to the device such that the first electroconductive pin and the second electroconductive pin correspond to predetermined power source electrodes, respectively.

Owner:DAICEL CHEM IND LTD

Flexible ignitor assembly for air/fuel mixture and method of construction thereof

ActiveUS8151781B2Less spaceDecrease size and weight and costSparking plugsTransformersInductor windingsEngineering

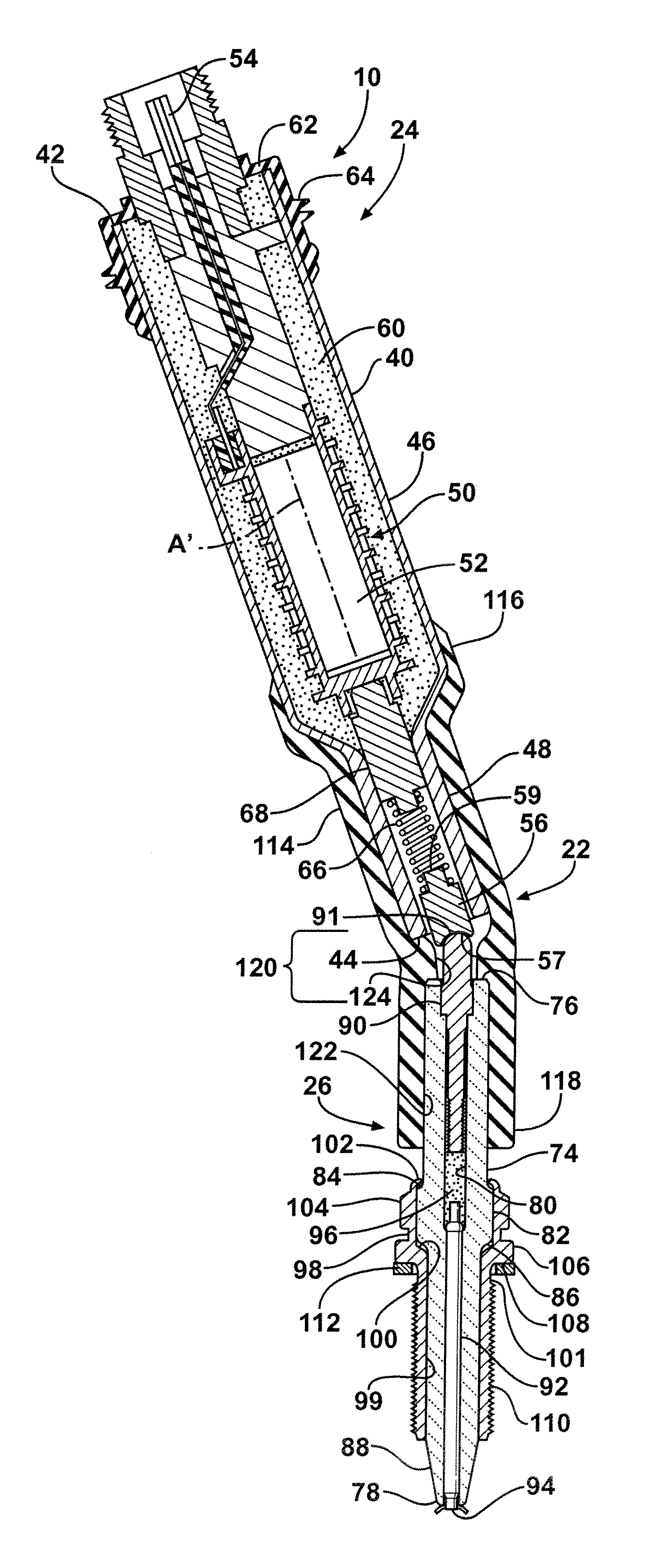

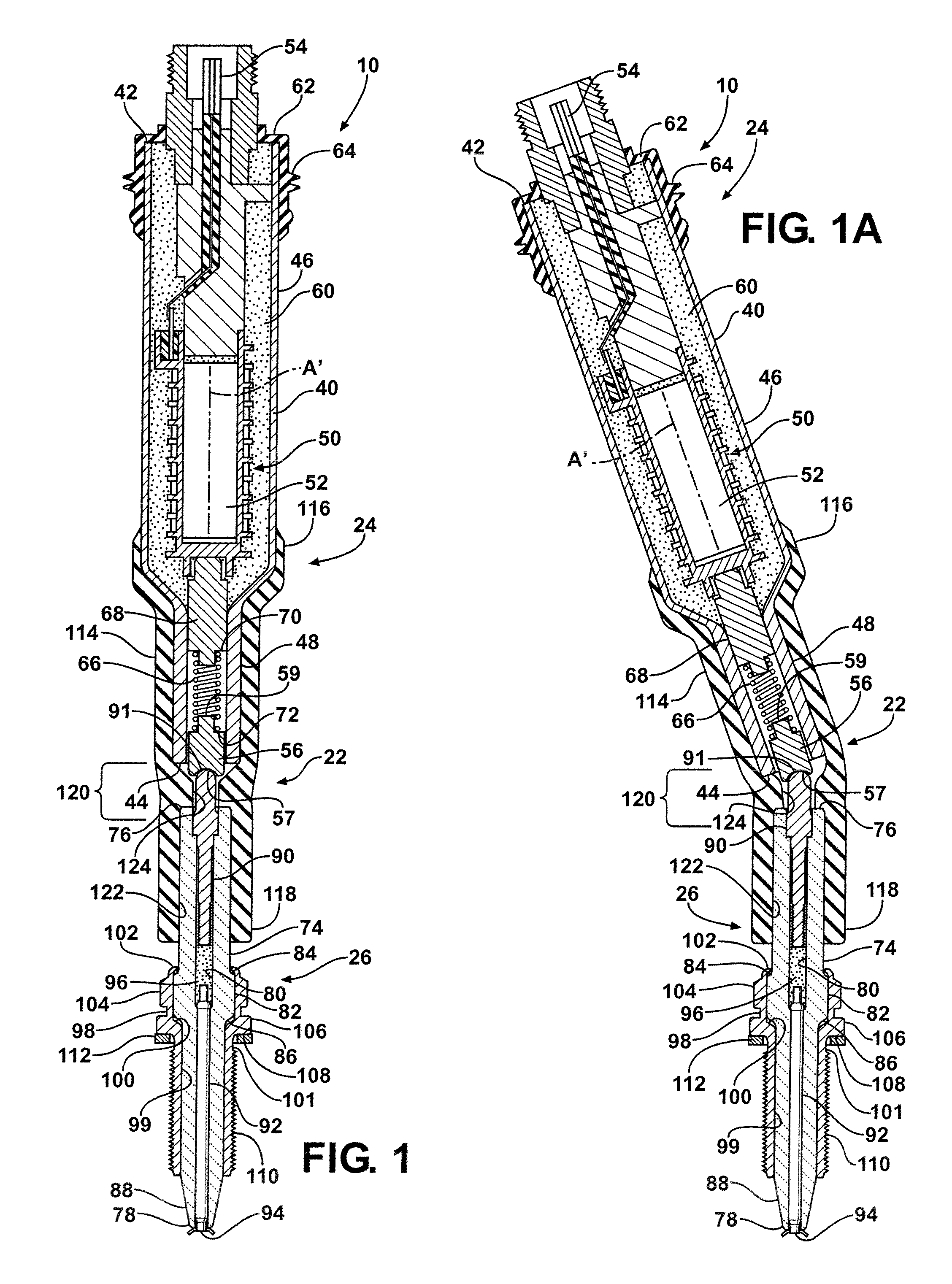

An ignitor assembly constructed in accordance with one aspect of the invention has an upper inductor subassembly coupled to a lower firing end subassembly for relative pivot movement between the subassemblies. The upper inductor subassembly includes a tubular housing with inductor windings received therein with an upper electrical connector adjacent an upper end of the housing and a lower electrical connector adjacent a lower end of the housing. The lower firing end subassembly includes a ceramic insulator and a metal housing surrounding at least a portion of the ceramic insulator. The ceramic insulator has an electrical terminal extending from a terminal end and an electrode extending from a firing end. A flexible tube couples the upper inductor subassembly to the lower firing end subassembly and maintains the electrical terminal of the lower firing end subassembly in electrical contact with the lower electrical connector of the upper at a pivot joint.

Owner:FEDERAL MOGUL IGNITION

Gas generator

ActiveUS20130255528A1Blasting cartridgesPedestrian/occupant safety arrangementEngineeringIgniter Device Component

The present invention provides a gas generator including a metallic housing, an ignition device including an igniter assembly, and gas generating agent, the igniter assembly including an igniter main body fixed to a metallic cylindrical fixing member with a resin and a connector-connecting portion for fitting a connector, at least part of the metallic cylindrical fixing member being electro-conductive to the housing, and including an exposed portion exposed to an inner surface of the connector-connecting portion, the exposed portion of the metallic cylindrical fixing member serving as a ground terminal, when the connector is connected to the connector-connecting portion, the ground terminal being in contact with an earth terminal of the connector, a grounding lead wire of the connector being grounded to a ground circuit located outside the gas generator.

Owner:DAICEL CHEM IND LTD

Igniter safe and arm, igniter assembly and flare so equipped and method of providing a safety for an igniter assembly

A parachute flare igniter assembly includes a novel safety for arresting the motion of a slider when subjected to external forces, but allows slider motion when subjected to intended cable actuation forces. The igniter safety includes a housing, a slider, a cable and a sleeve. The slider, connected to the cable, is slidably received within the housing. The cable moves the slider by applying a cable force conventionally obtained by actuation of a parachute associated with the flare and connected to an end of the cable opposite an end connected to the slider. The sleeve is connected to the cable and is disposed between the housing and the slider, so that the sleeve will arrest the slider with respect to the housing when the cable force is not present. A flare and a method of providing a safety in an igniter assembly is also provided.

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com