Initiator assembly

An igniter and electric igniter technology, which is applied in the direction of weapon accessories, vehicle parts, belt tighteners, etc., can solve the problems that do not involve consideration of the operational reliability of the igniter components, gas generators, etc. Effects of preventing moisture and deterioration, avoiding moisture absorption, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

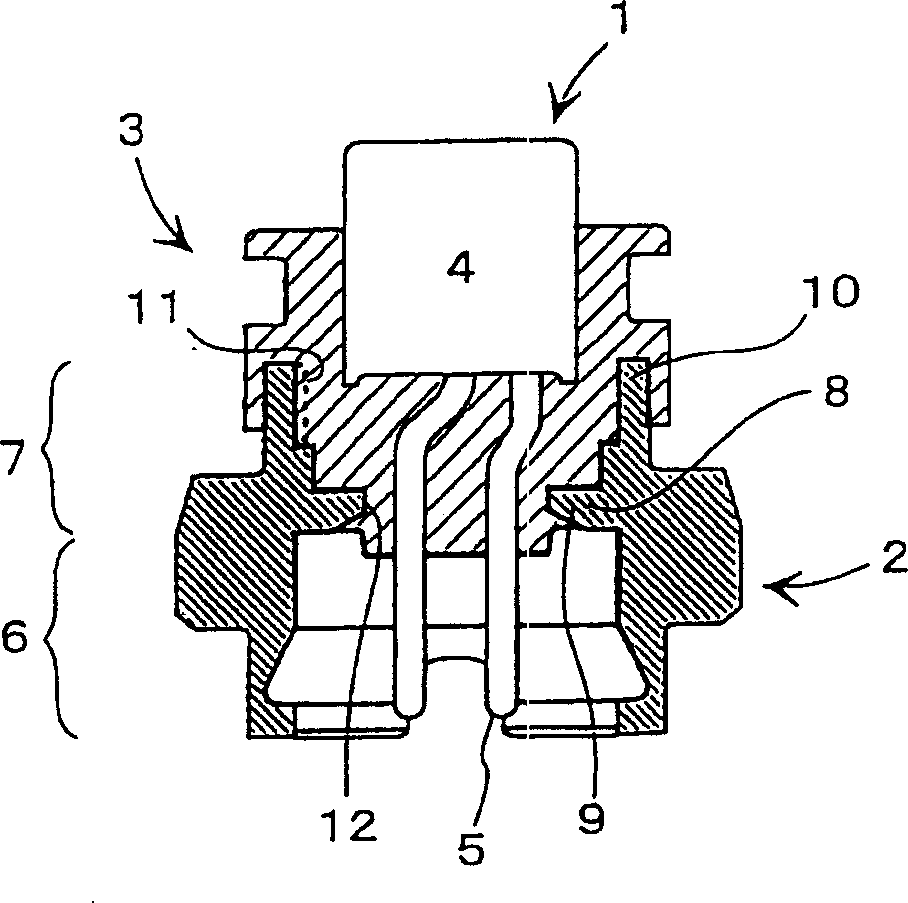

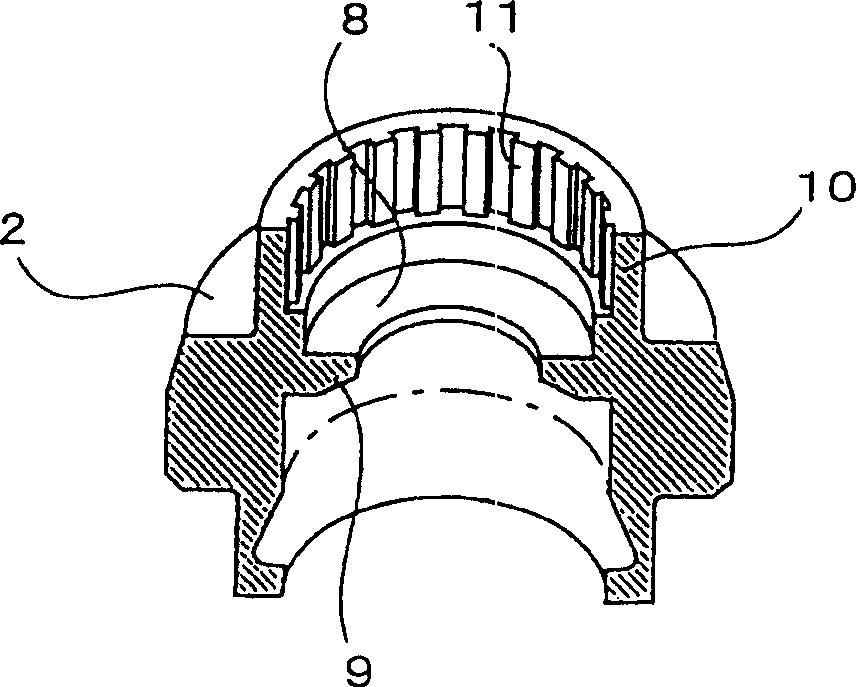

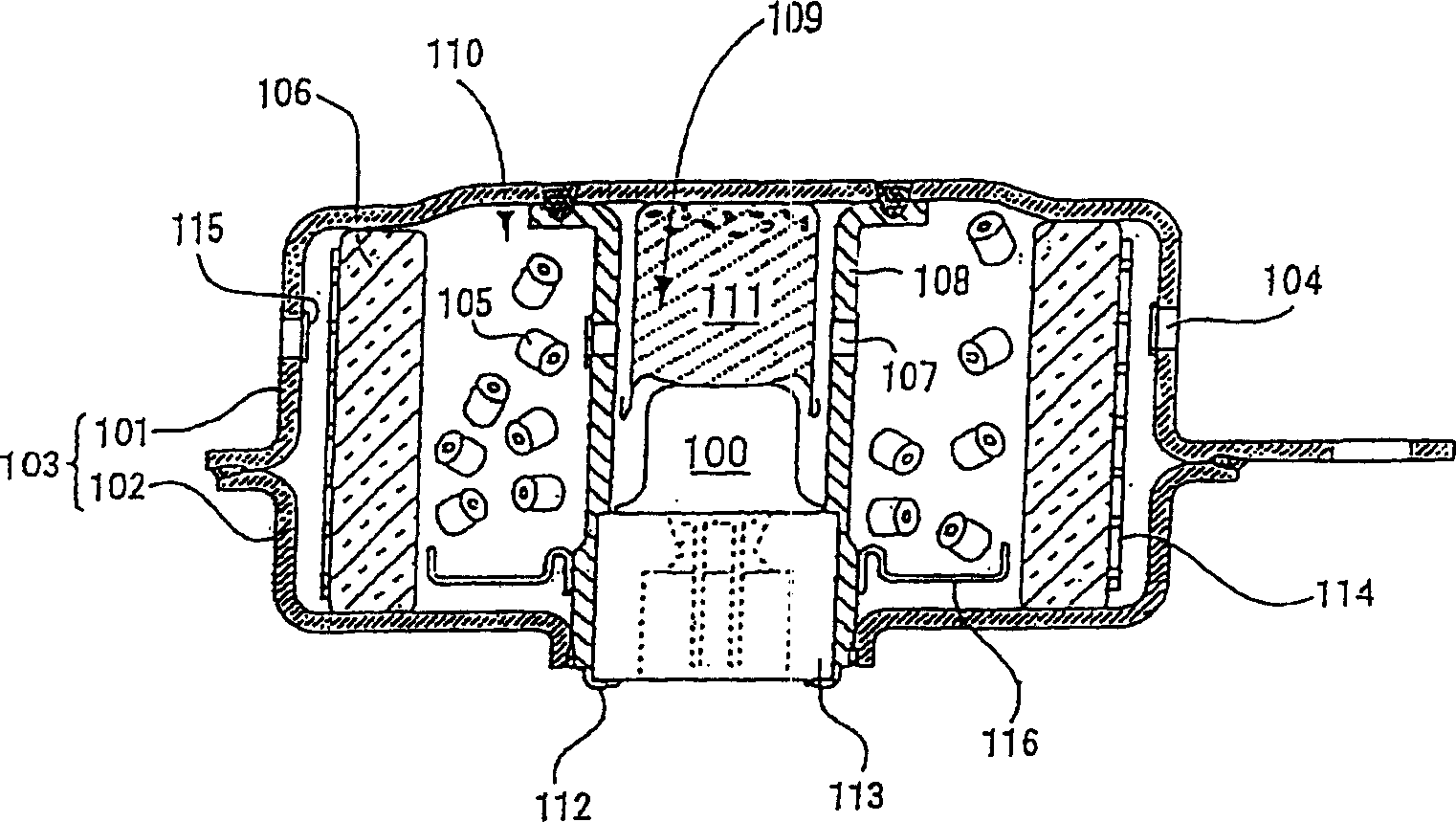

[0060] image 3 with 4 An example of a gas generator for an air bag using an igniter assembly 100 having the same features as the above-described igniter assembly is shown.

[0061] This gas generator has, inside a casing 103, an ignition device including the above-mentioned igniter assembly 100, a gas generating agent 105 which is ignited and burnt due to activation of the ignition device to generate operating gas for inflating an air bag (bag body), and The filter device 106 for purifying and / or cooling the operating gas produced by the combustion of the gas generating agent 105, the housing 103 is formed by connecting the diffuser housing 101 having an exhaust port and the closing shell closing the diffuser housing The bodies 102 are assembled together to form.

[0062] exist image 3 In the shown gas generator, an inner cylindrical member 108 provided with a plurality of flame transmission holes 107 on its outer peripheral surface is arranged at the center of the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com