Patents

Literature

58results about How to "Eliminate reaction force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Initiator assembly

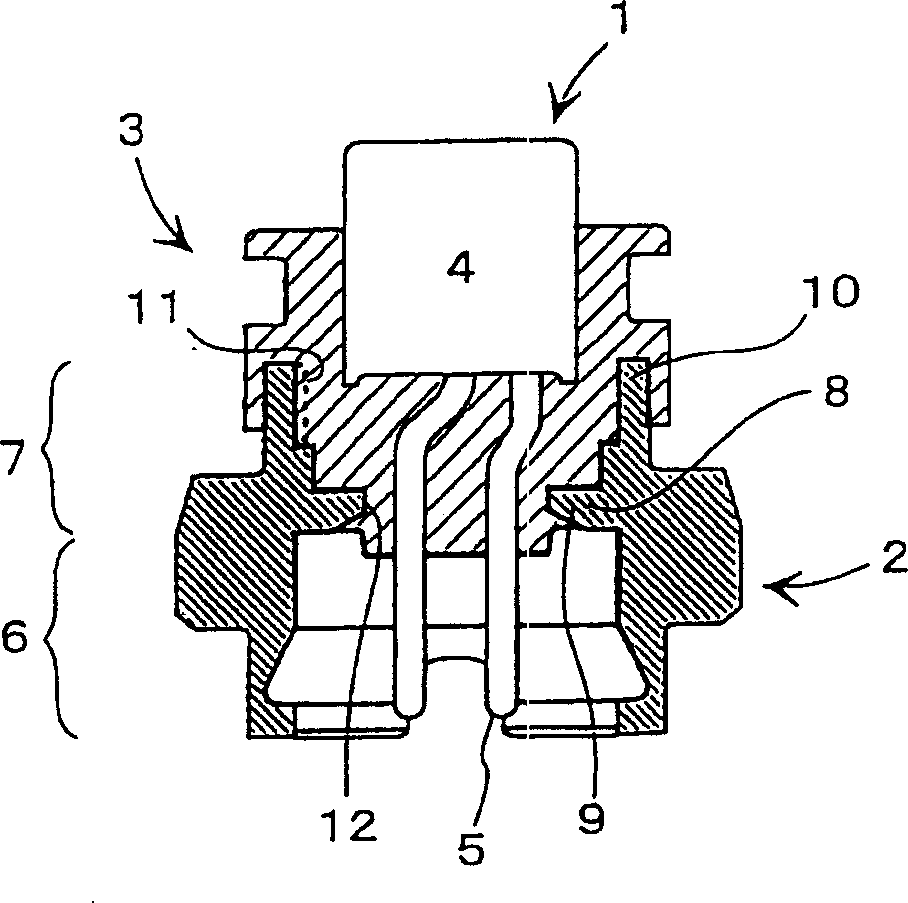

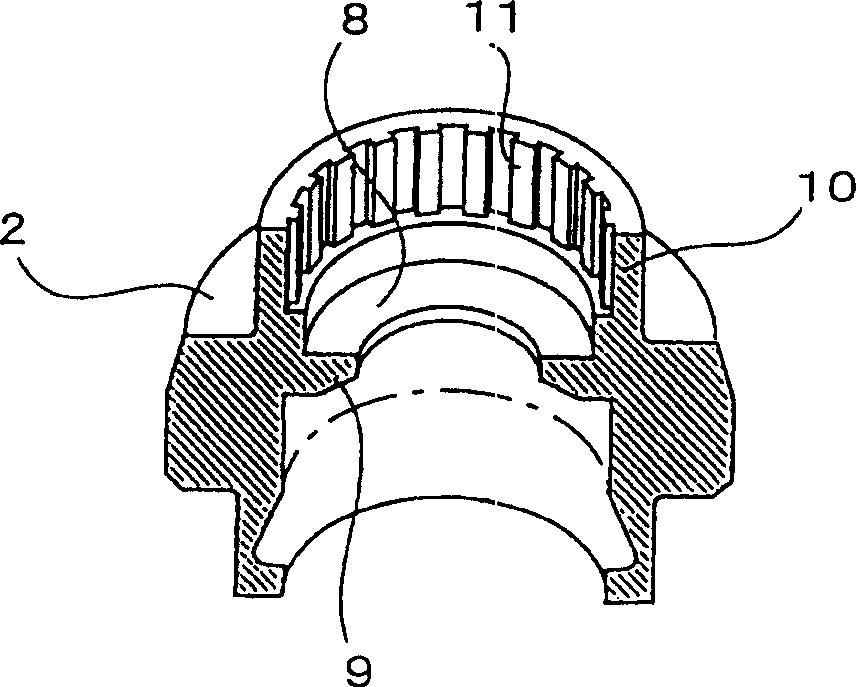

InactiveCN1589390AImprove bindingEliminate reaction forceBelt retractorsPedestrian/occupant safety arrangementEngineeringSignal generator

An initiator assembly capable of guaranteeing the assured operation of a gas generator by assuring the structure of connection between a metal collar and an electric initiator to prevent the entry of moisture into the gas generator, comprising the electric initiator and the metal collar surrounding at least a part of the electric initiator formed integrally with each other with resin, wherein at least either of an annular projected part and a tubular projected part provided in a direction that surrounds the electric initiator is formed on the metal collar, and the projected part is covered with the resin.

Owner:DAICEL CHEM IND LTD

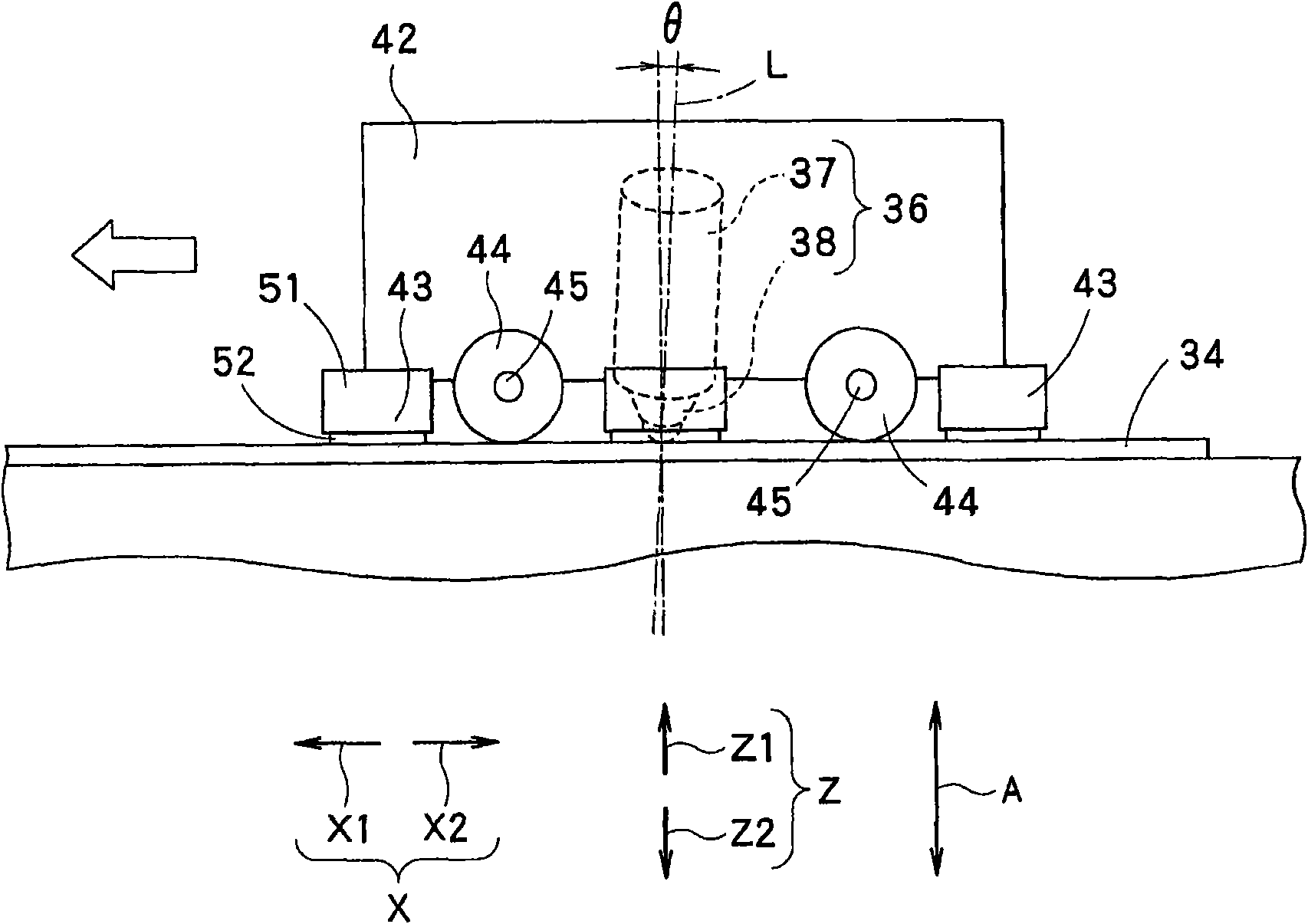

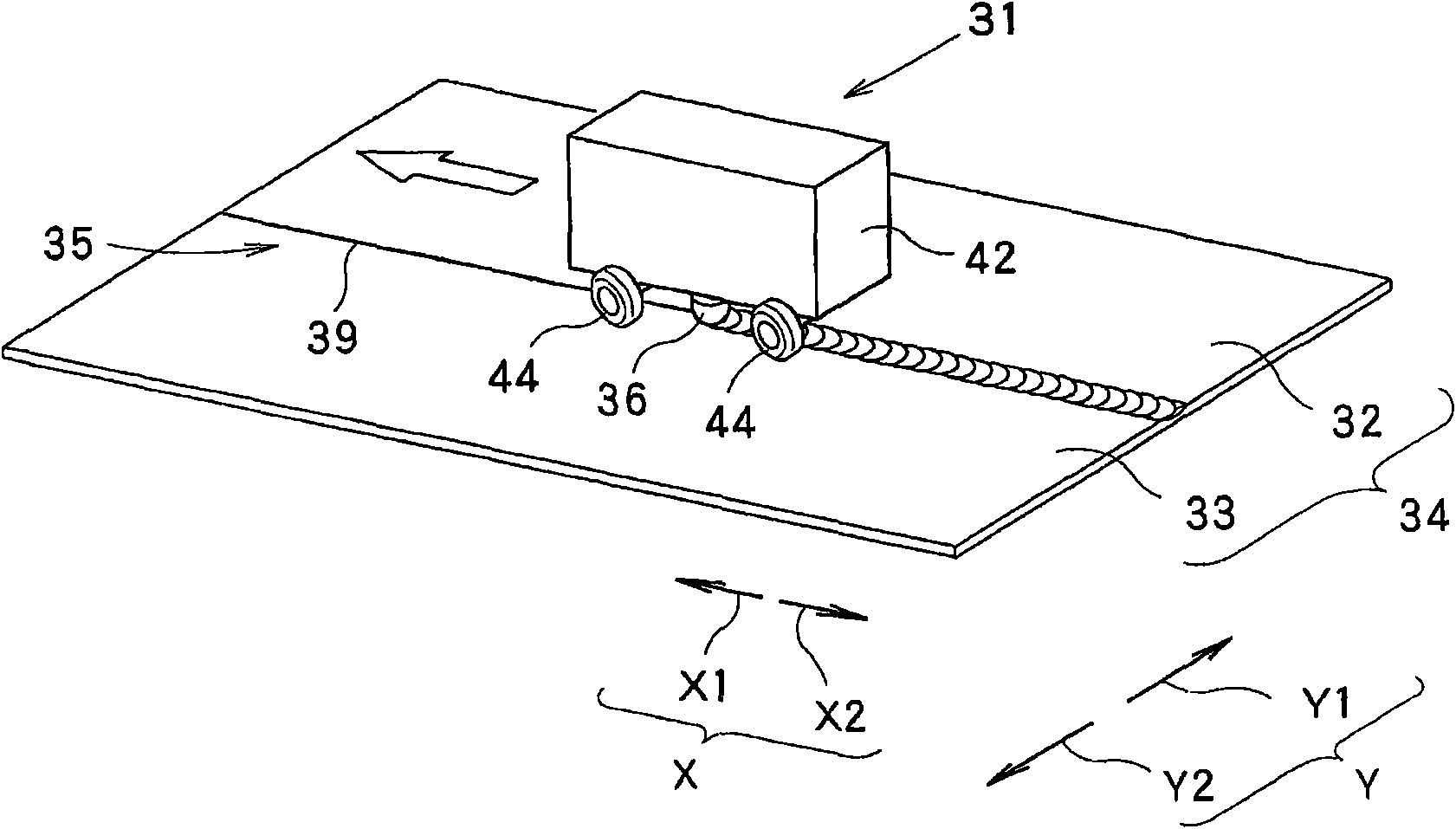

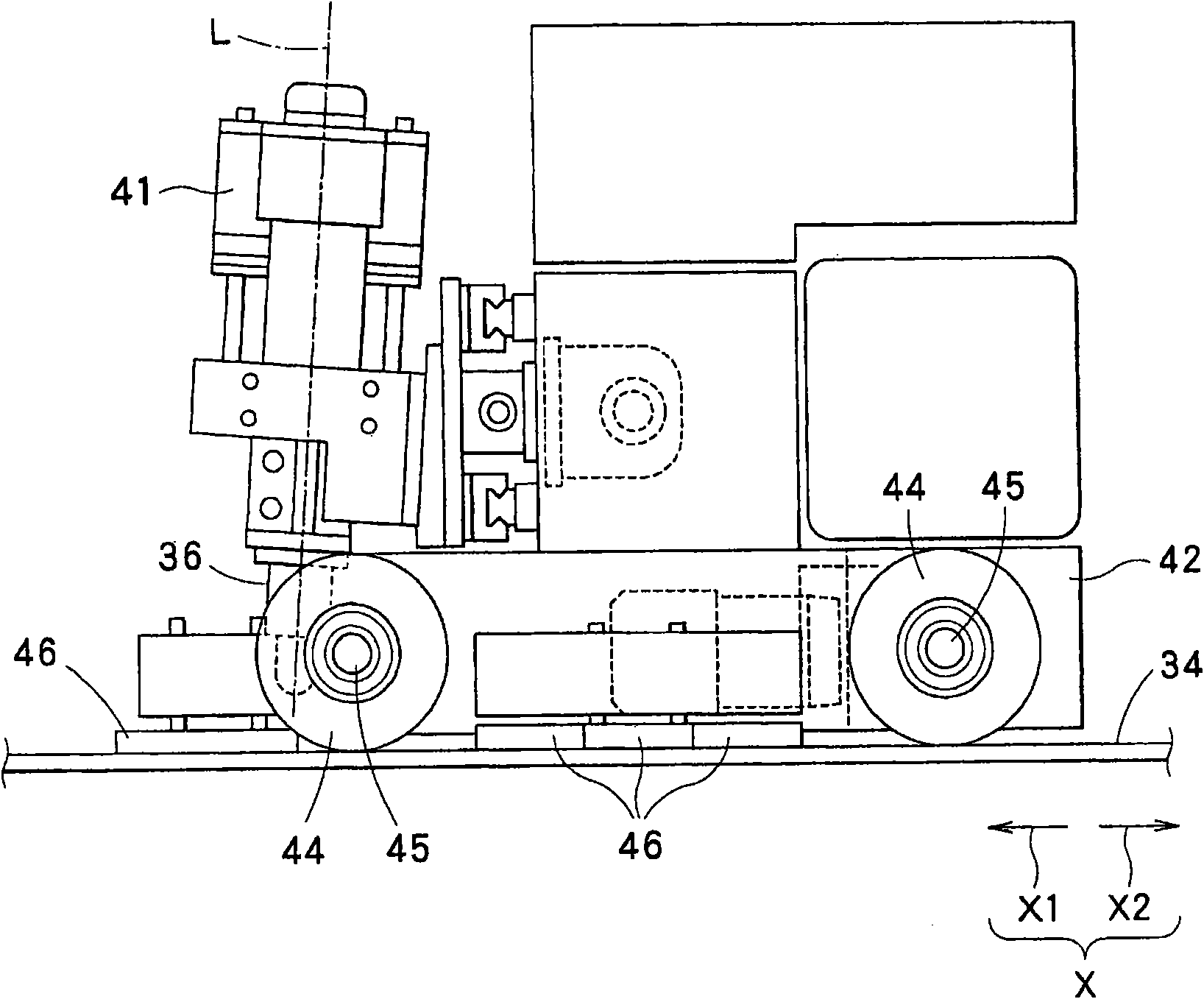

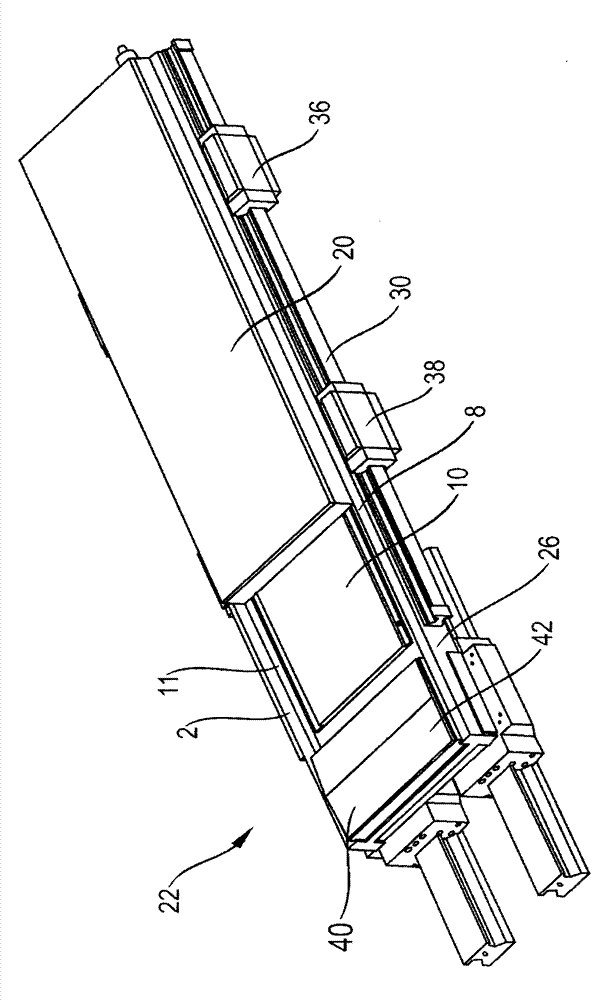

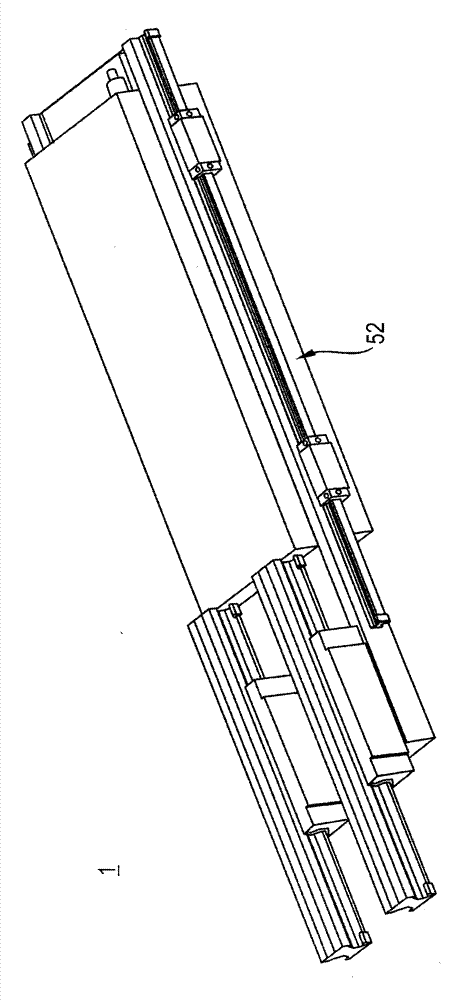

Suction pad, friction stir welding device, and friction stir welding system

ActiveCN101622093AEasy to slideIncrease splicing speedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Provided are a friction sir welding device that is light in weight and can travel by a small force, a suction pad used for the friction sir welding device, and a friction stir welding system. The suction pad (46) includes a plate-like facing section (51) facing an object to which the suction pad sticks; an annular pad section (52) projecting from one surface in the thickness direction of the facing section (51) at its end near the object and making a round on the surface of the facing section (51); a gliding body (53) provided on the surface of the pad section (52) at a portion near the object; and one or more deformation prevention projections (56) projecting from the one surface in the thickness direction of the facing section (51). The gliding body (53) is made of a material having a friction coefficient against the object which is smaller than the friction coefficient of the pad section (52) against the object.

Owner:KAWASAKI JUKOGYO KK

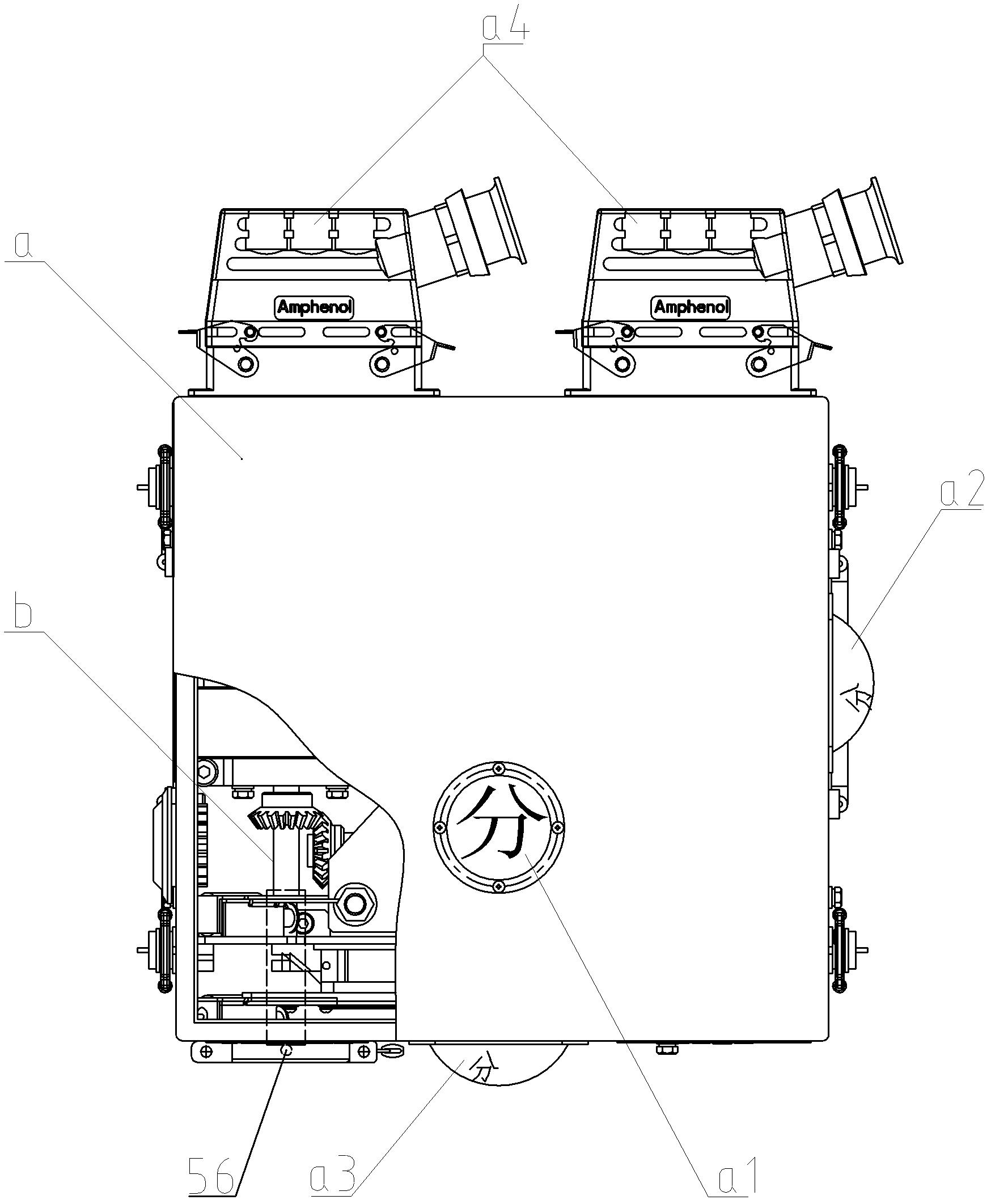

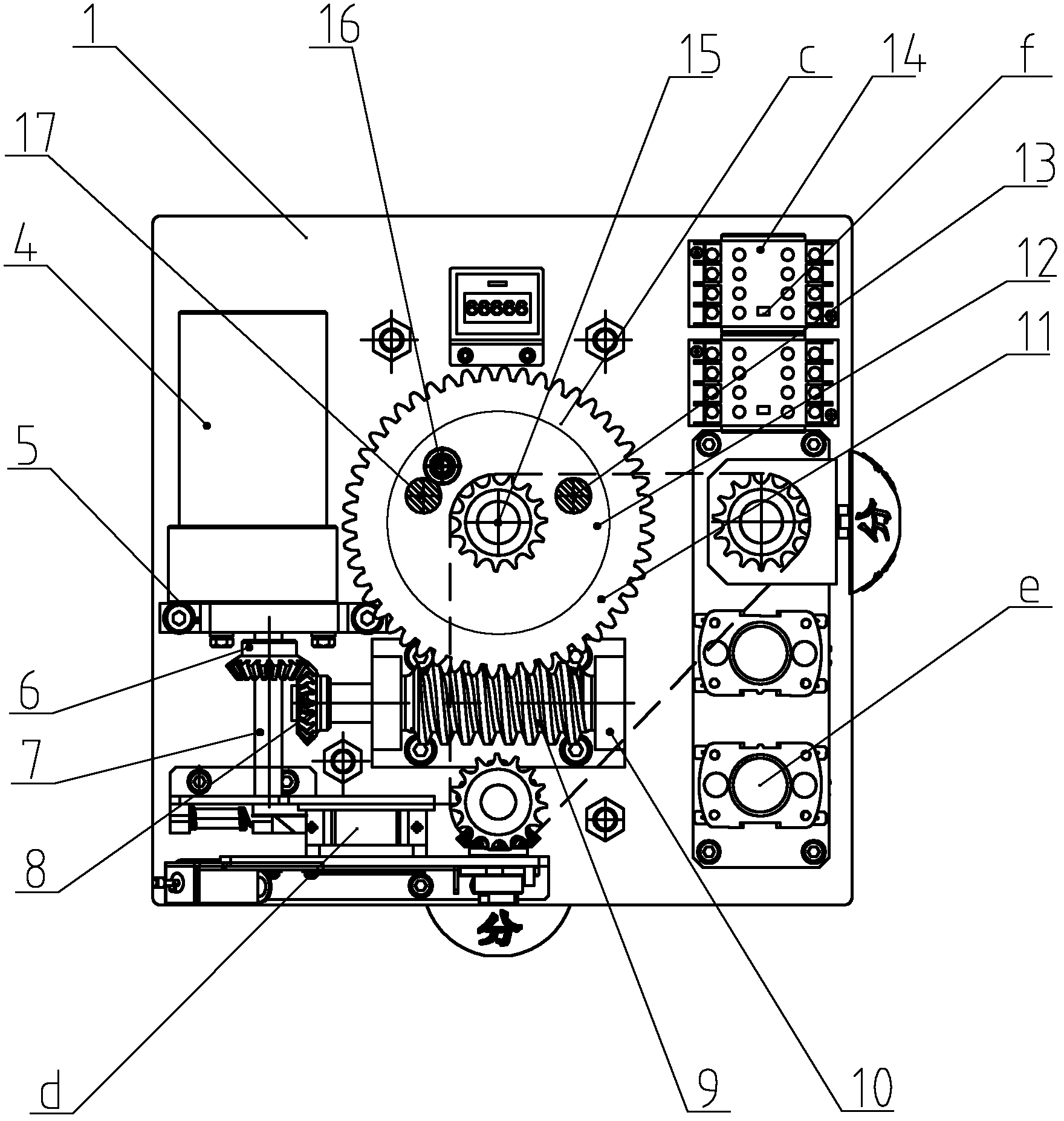

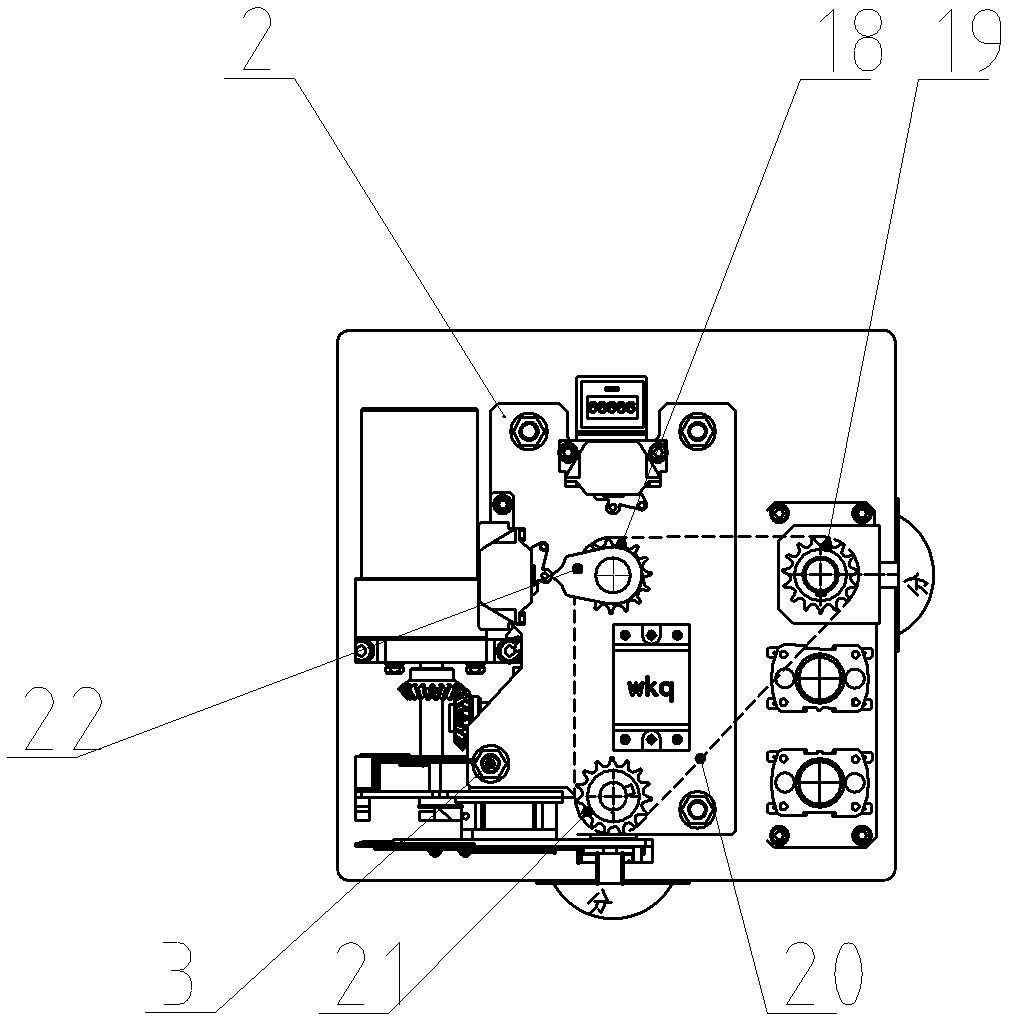

Electric operating mechanism for switchgear

InactiveCN102360964AWon't burnSo as not to damageSwitch power arrangementsGear wheelElectric machine

The invention discloses an electric operating mechanism for switchgear. A core mounted in a case a comprises a driving device, a manual interlocking device, an auxiliary switch component and an electrical element, and brake closing and separating are completed by a motor and an isolation / ground switch through a gear pair / worm gear pair / bidirectional overrunning clutch / output shaft. An output shaft sprocket is connected with a lateral and front face indication sprocket by means of a chain for transmission, the manual interlocking device enables electromagnetic interlocking, manual-electric interlocking and suspension locking, and an operating handle cannot be inserted or pulled until a brake is closed or separated. The electric operating mechanism for the switchgear is simple in structure, systematic inertia has no influences on the output angle and position, and damage of the motor, parts or a main switch of the mechanism caused by uncompleted switching of contacts or a failed position switch are avoided by means of mechanical in-place protection. Furthermore, the electric operating mechanism for the switchgear is complete in interlocking, simple, reliable, small in size, low in cost and small in manual operation moment of force and enables rapid brake closing and separating.

Owner:NINGBO XINGBANG ELECTRIC

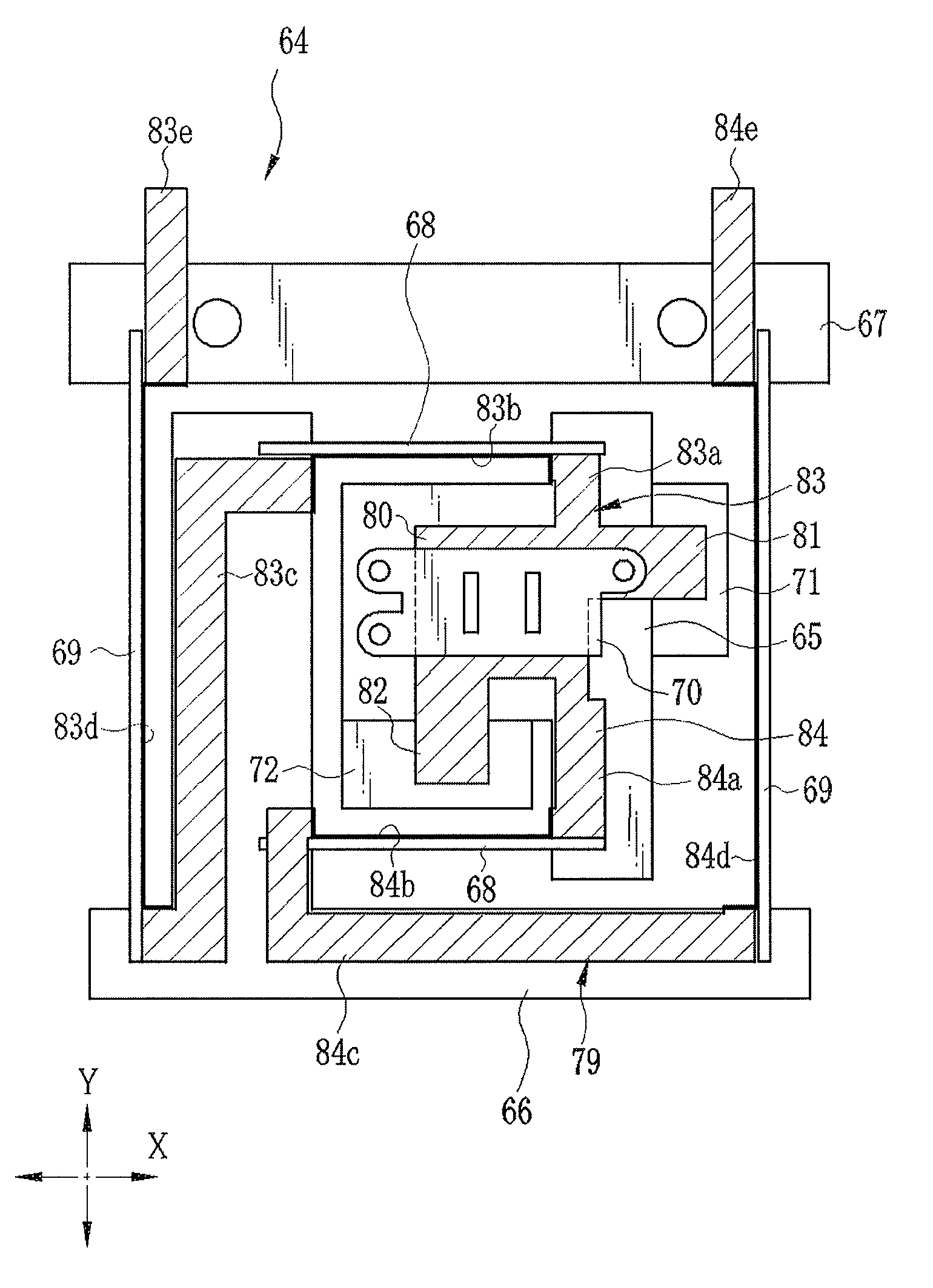

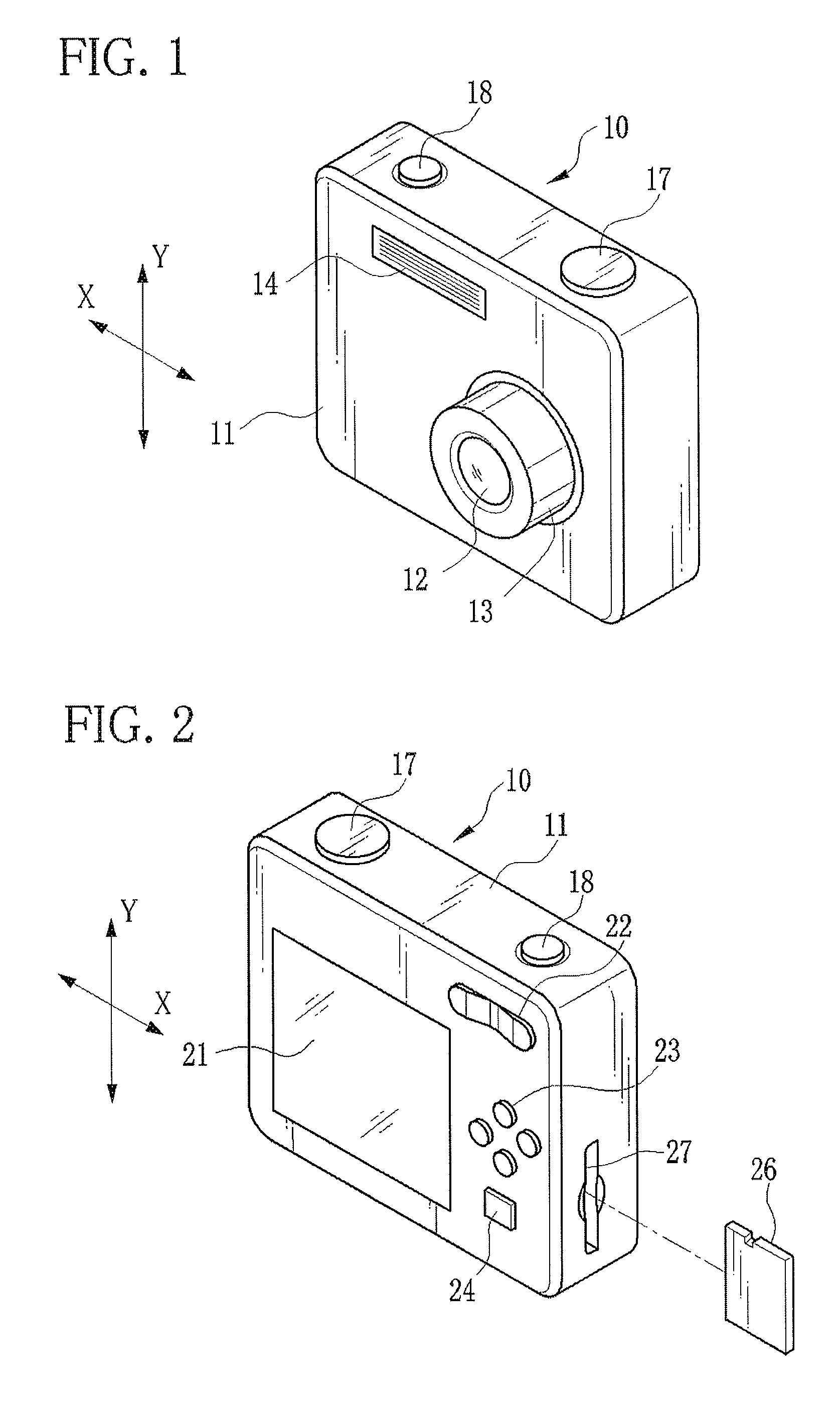

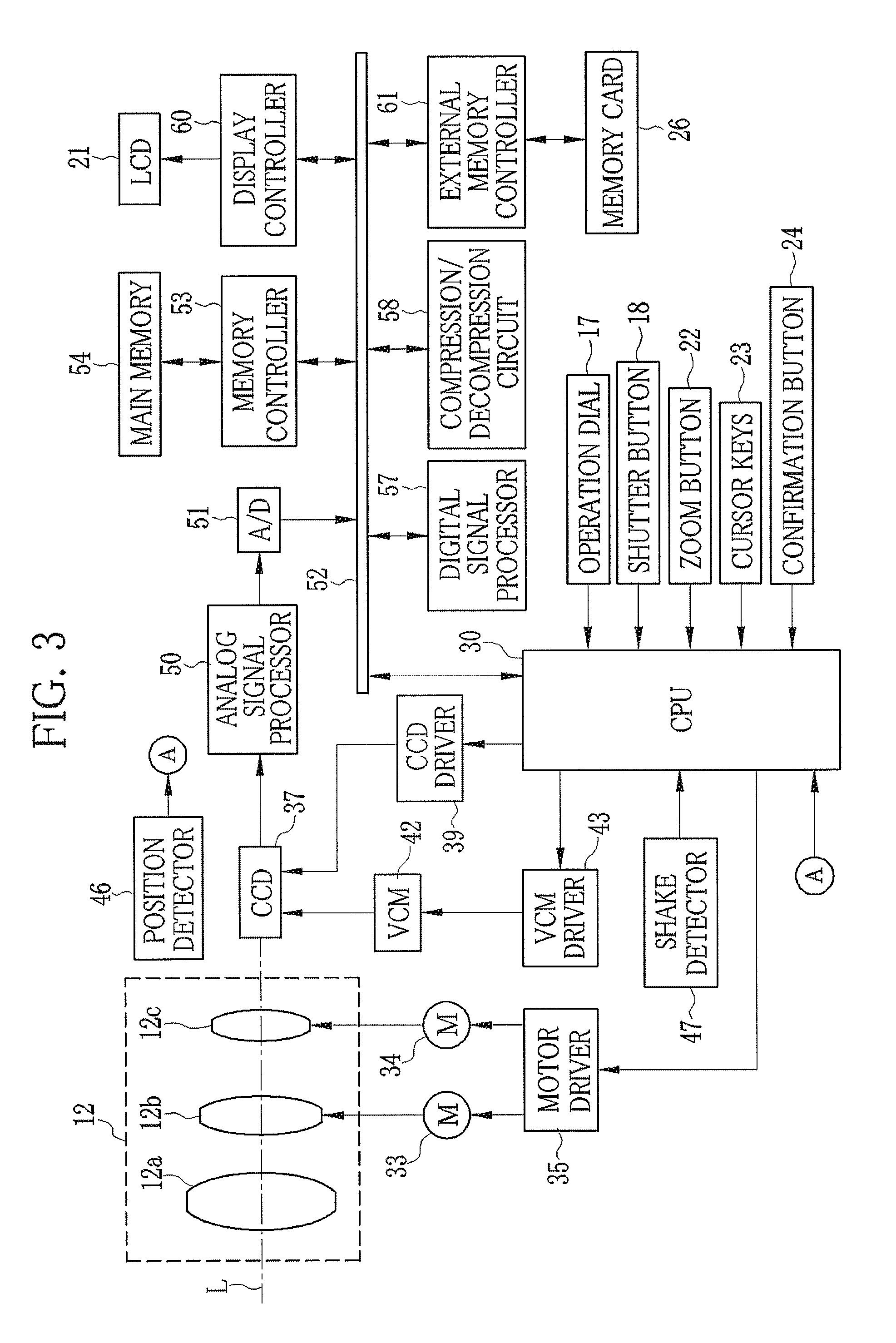

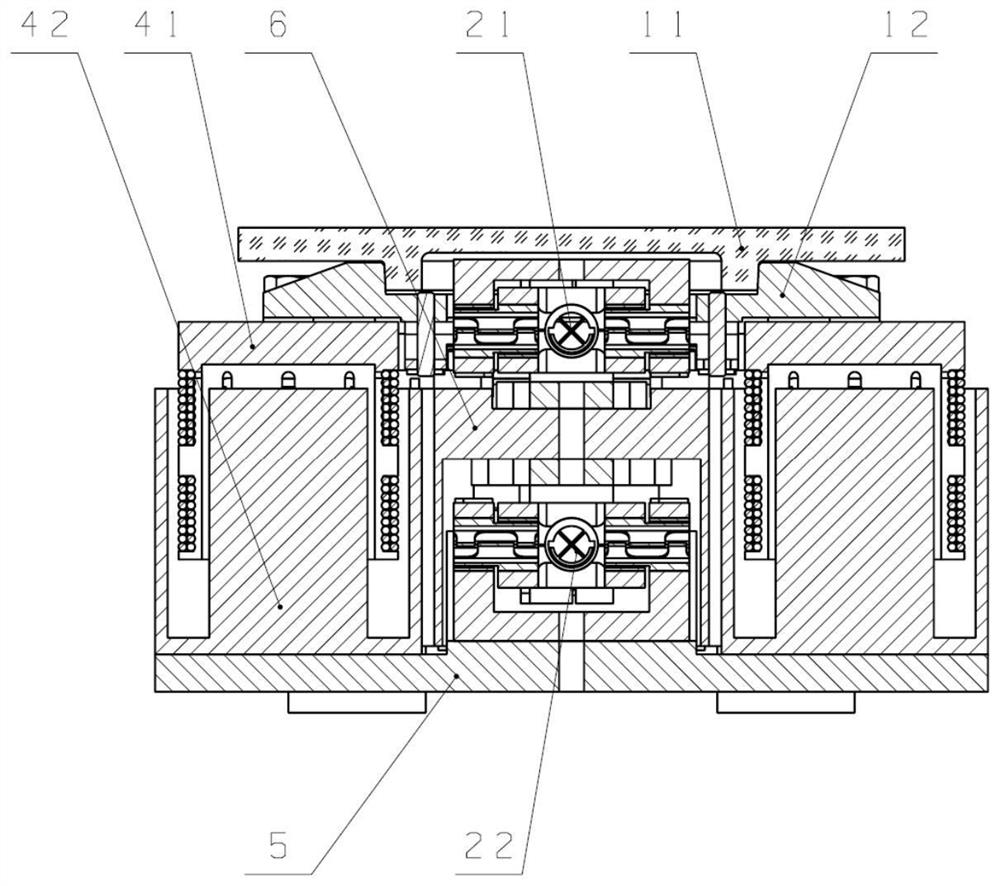

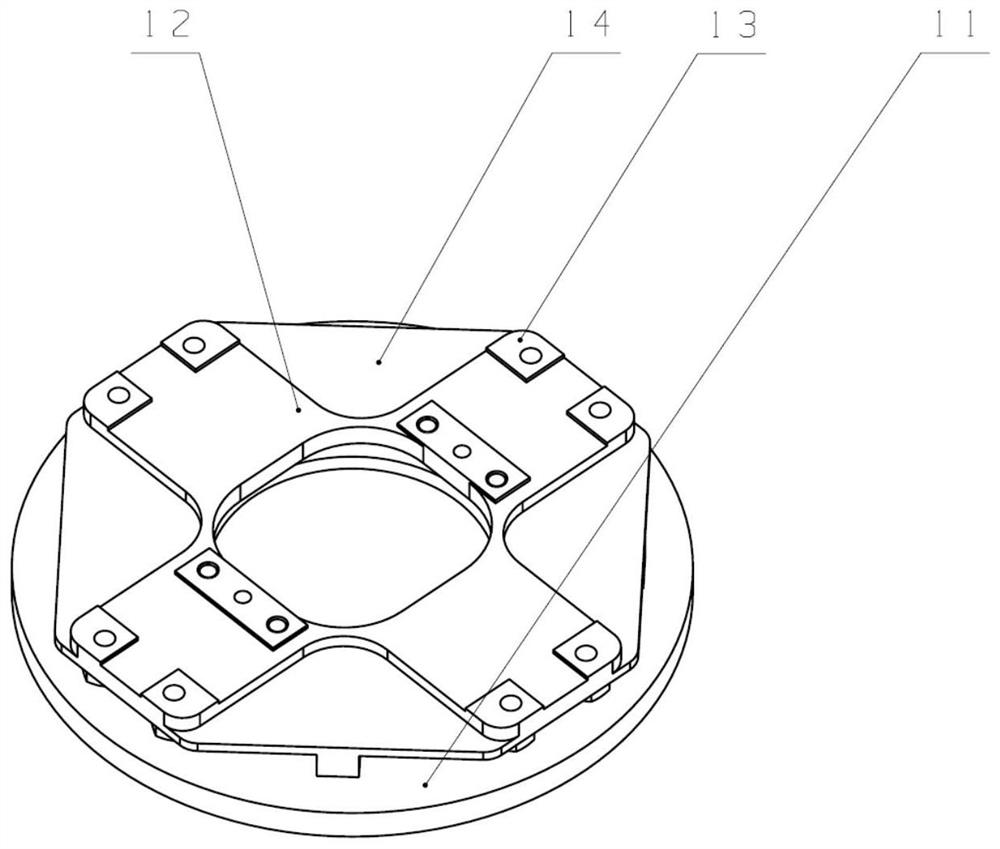

Image stabilizer and optical instrument therewith

ActiveUS8208031B2Eliminate saggingImage is often very smallTelevision system detailsPrintersEngineeringOptical instrument

An image stabilizer has a base block, an inner frame for holding a CCD, an outer frame, a pair of horizontal leaf springs, a pair of vertical leaf springs, voice coil motors (VCMs) and a flexible printed circuit (FPC). Upon a shake of a digital still camera due to hand-held shooting, the VCMs shift the inner or outer frame while bending the horizontal or vertical leaf springs so that the CCD is shifted to counteract the camera shake. The FPC connected to the CCD and the VCMs is routed from the inner frame, through the horizontal leaf spring, the outer frame and the vertical leaf spring, and pulled out above the base block. The FPC is glued to the horizontal and vertical leaf springs, and elastically bent together with the horizontal and vertical leaf springs.

Owner:FUJIFILM CORP

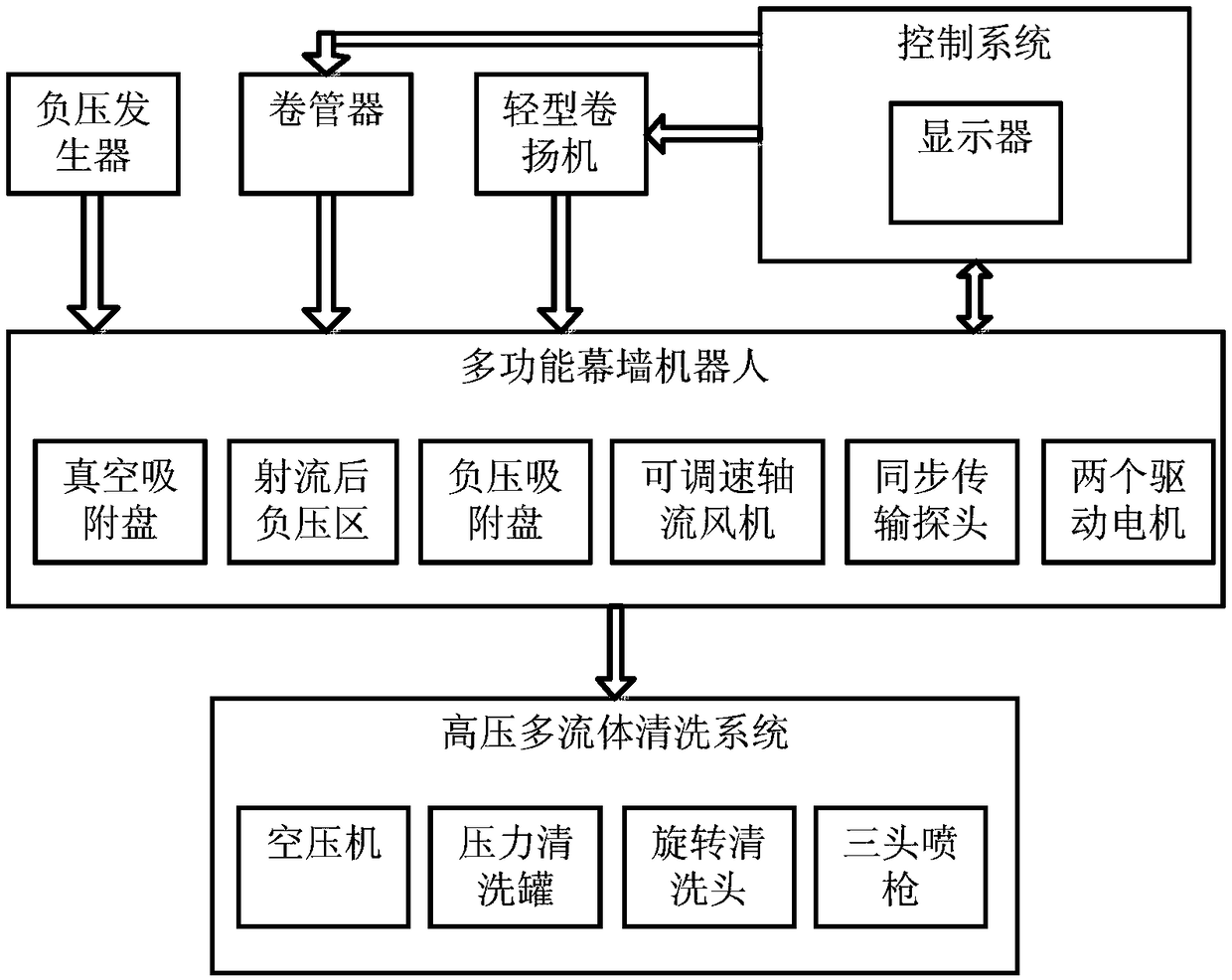

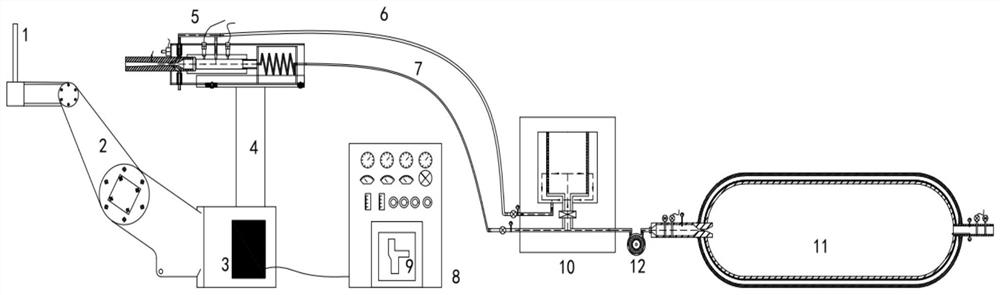

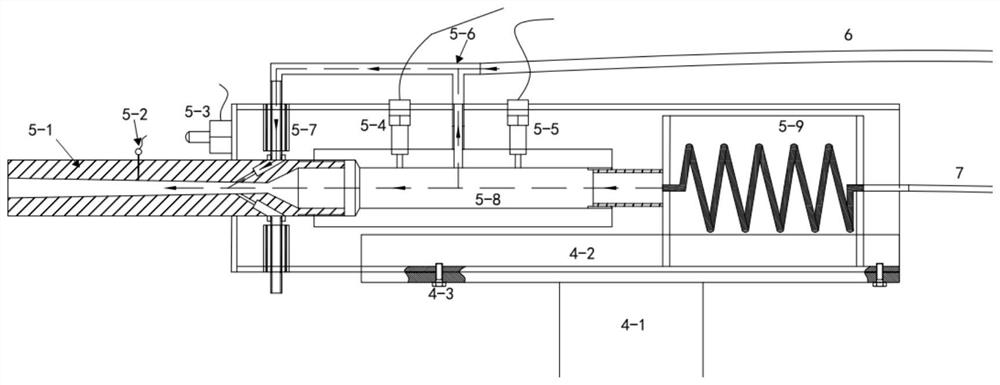

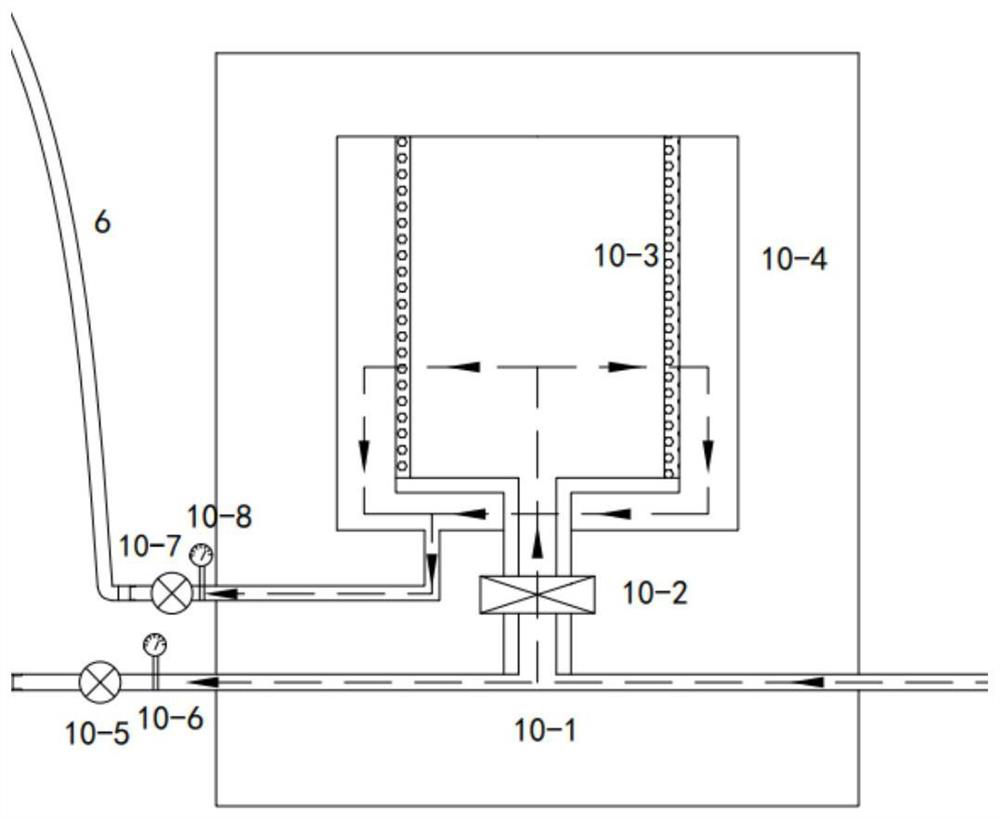

High-pressure multi-fluid curtain wall cleaning robot system

InactiveCN109008765AIncrease costLow efficiencyAutomatic obstacle detectionTravelling automatic controlRobotic systemsControl system

The invention discloses a high-pressure multi-fluid curtain wall cleaning robot system, belonging to the technical field of curtain wall cleaning. The high-pressure multi-fluid curtain wall cleaning robot system includes a multifunctional curtain wall robot which is sucked to a curtain wall and moves on the curtain wall, a high-pressure multi-fluid cleaning system, and a control system, wherein the high-pressure multi-fluid cleaning system comprises an air compressor, a pressure cleaning tank, a rotary cleaning head and a three-head spray gun; the air compressor and the pressure cleaning tankare arranged above the curtain wall; the rotary cleaning head and the three-head spray gun are all arranged on the multifunctional curtain wall robot; the three-head spray gun sprays high-pressure cleaning jet flows, and the cleaning head is placed to clean the curtain wall; and the control system controls movement of the robot on the curtain wall, and the control system controls the high-pressuremulti-fluid cleaning system to spray and clean the curtain wall. The high-pressure multi-fluid curtain wall cleaning robot system solves the problems that people hanging on the glass curtain wall performs cleaning operation, thus being low in efficiency, being high in cost and being high in the safety risk. Besides, the high-pressure multi-fluid curtain wall cleaning robot system solves a buckethanging cleaning operation mode, and solves the problems that the curtain wall surface cannot be effectively cleaned because of unevenness of the curtain wall surface and the direction rotates becauseof hanging. Moreover, the high-pressure multi-fluid curtain wall cleaning robot system solves the problem that a current negative pressure suck robot is hard to pass a wall surface with unevenness.

Owner:深圳聚纵科技有限公司

Solid 3D printing system for space component in-orbit manufacturing and repairing by using cold spraying and method

ActiveCN111962059AOvercoming difficulties that are difficult to combine effectivelyReduce burning lossAdditive manufacturing apparatusHeat inorganic powder coatingData controlData information

The invention relates to a solid 3D printing system for space component in-orbit manufacturing and repairing by using cold spraying and a method. The data information of a temperature sensor, a pressure sensor, a distance sensor and a flowmeter are all transmitted to a computer terminal, the computer terminal gives a control instruction according to the three-dimensional data, a three-dimensionalmobile platform is controlled by a three-dimensional mobile platform control chip, a matrix or a substrate moves according to the design path, and meanwhile, a valve and a heater are controlled according to the data of the temperature sensor, the pressure sensor and the flowmeter, so as to adjust the process parameters. The system and the method have the advantages that in the space environment, the problem that a melting state 3D printing technology is difficult to effectively combine under the weight loss condition is solved. In the system and method, powder has extremely high speed and accurate direction, and the kinetic energy generated by means of acceleration of gas through a Laval nozzle makes metallics completely overcome the weight loss environment in the space.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

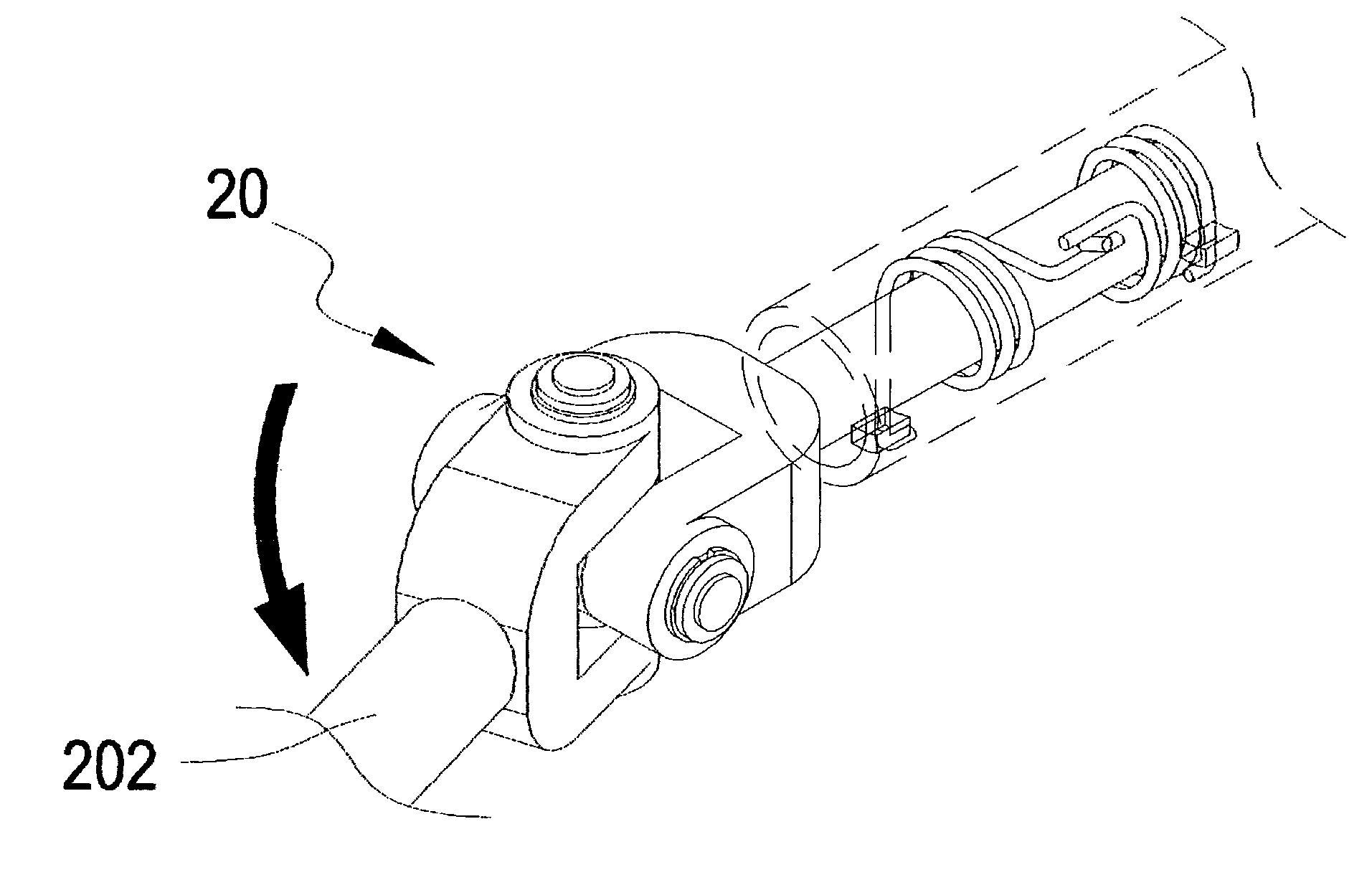

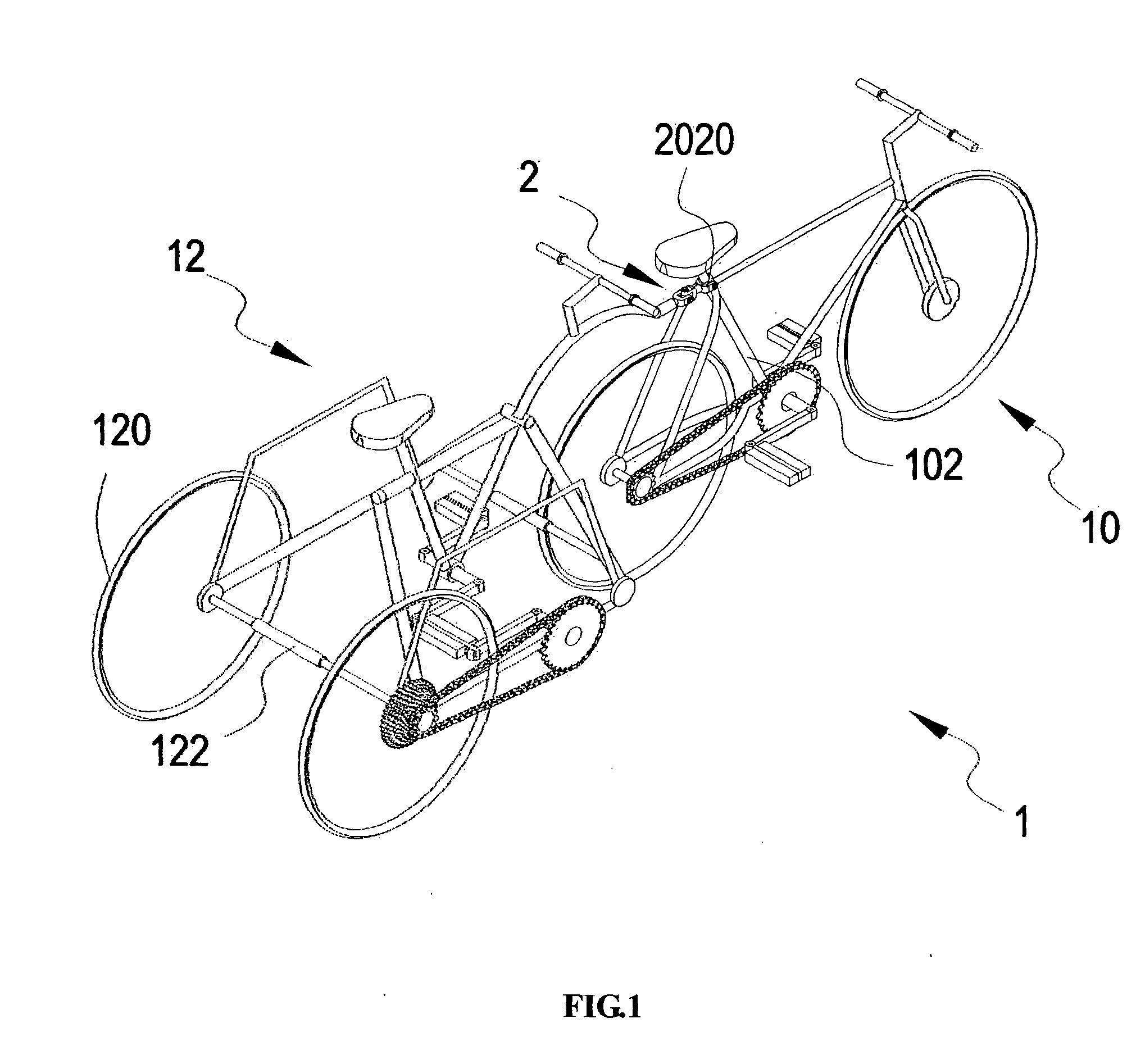

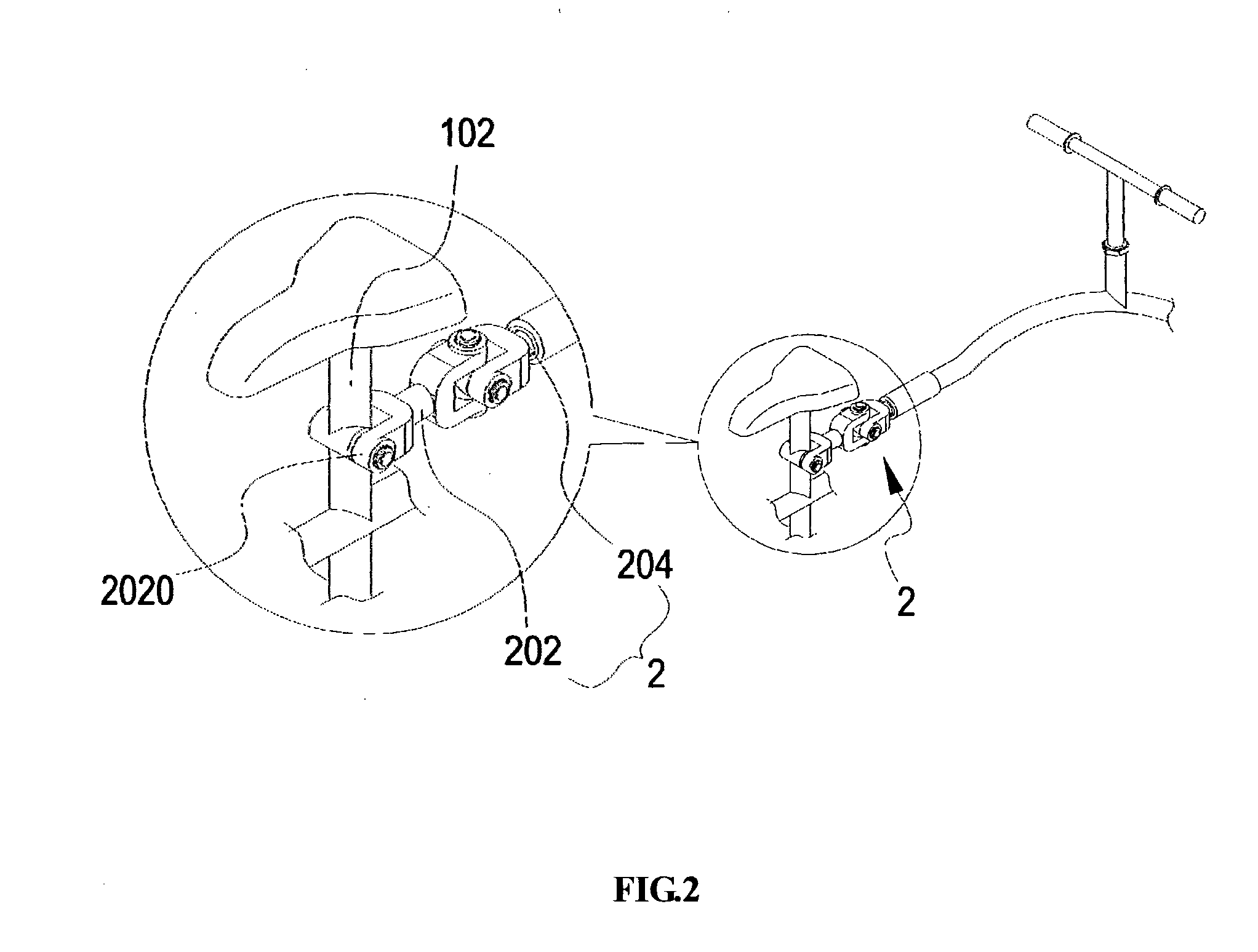

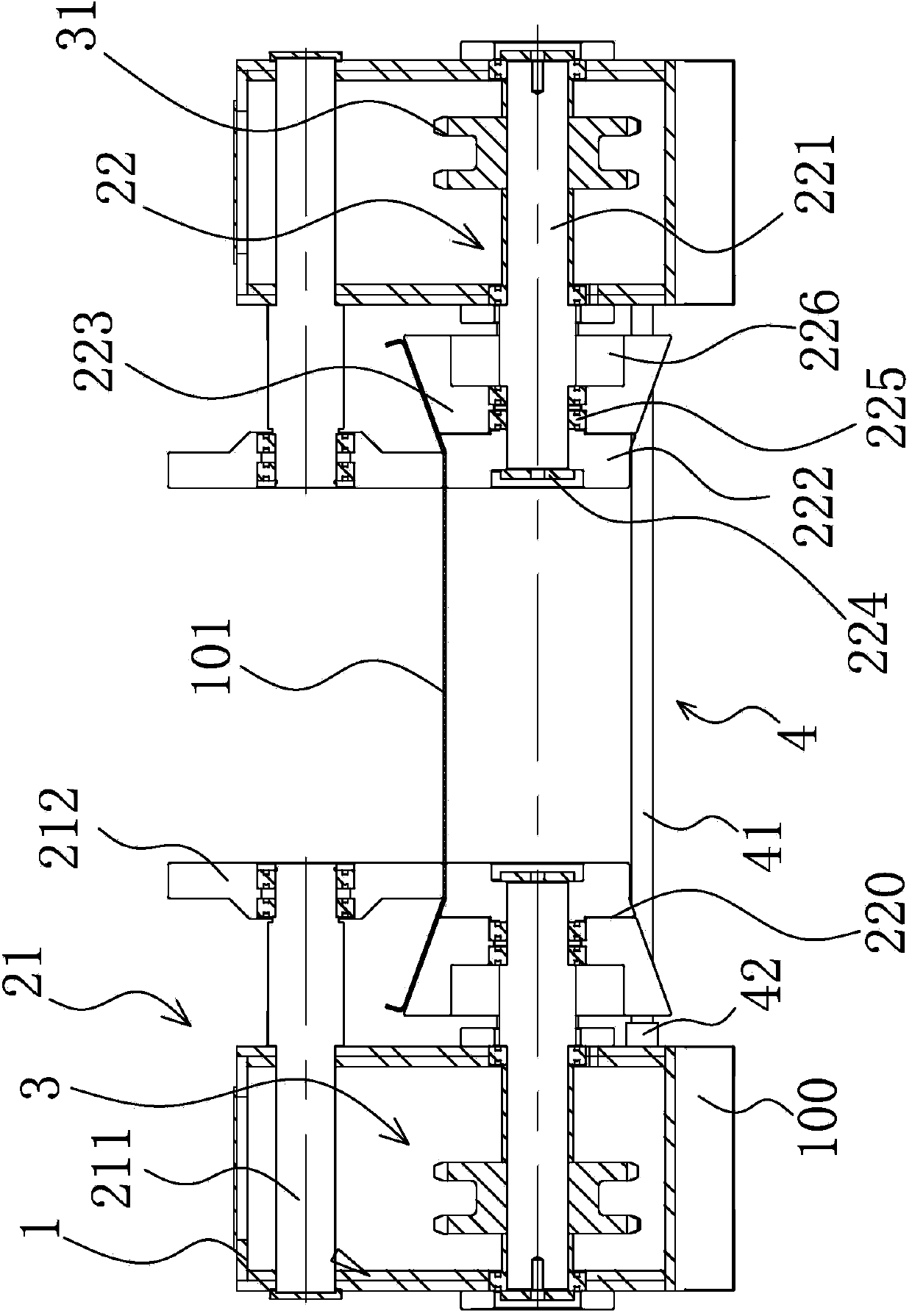

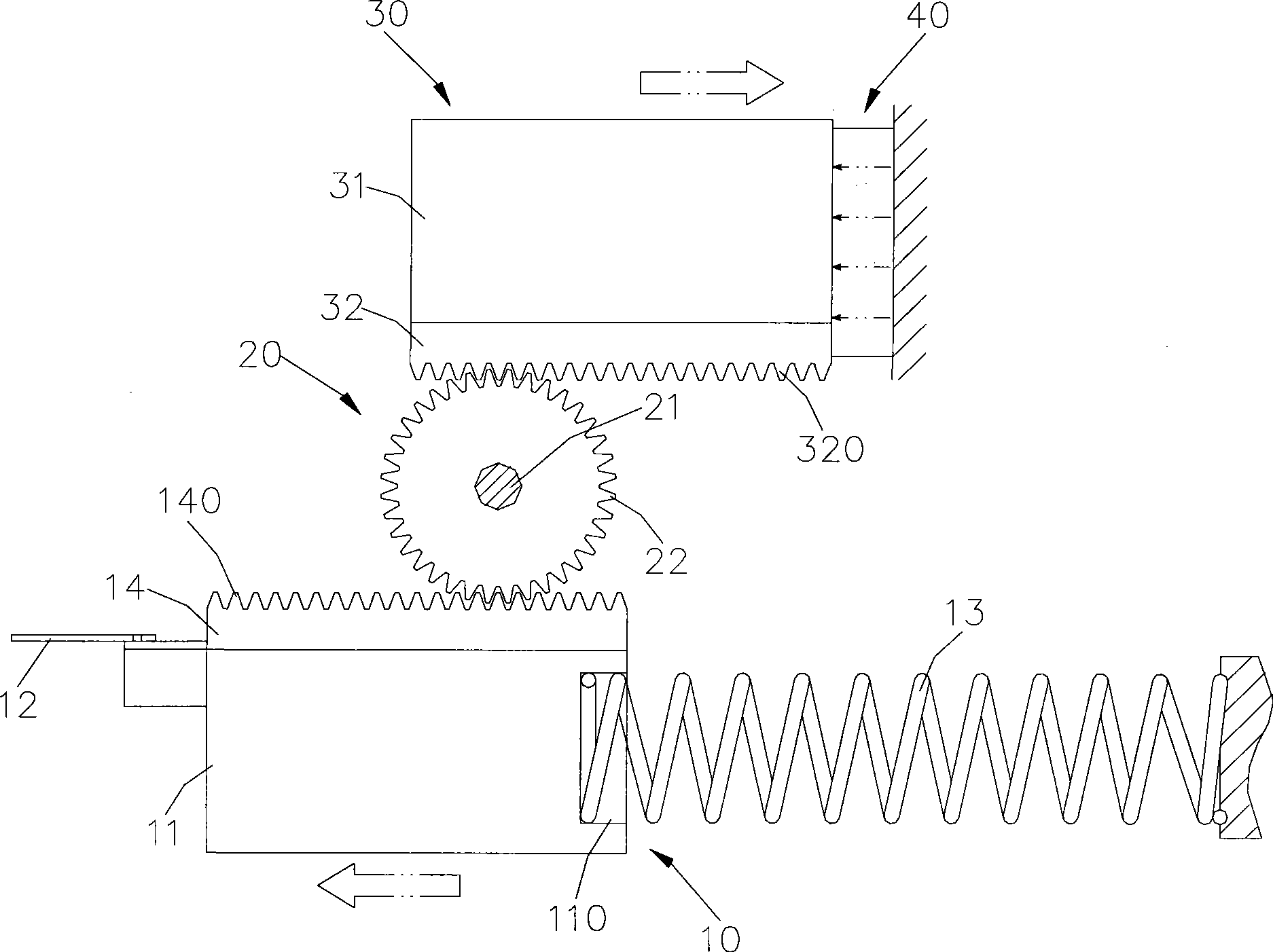

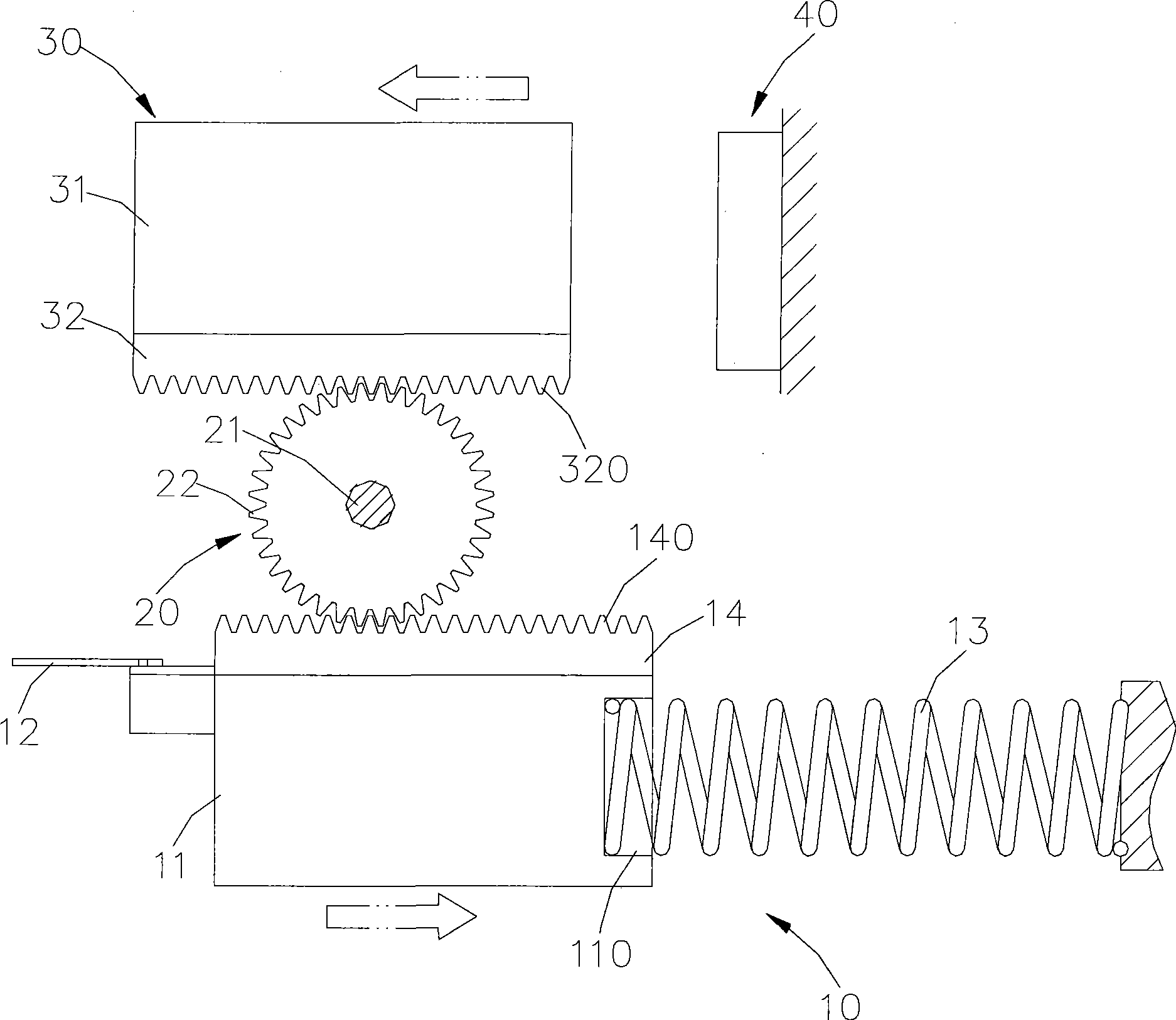

Adapter device of tandem bicycle

InactiveUS20130022390A1Improve safetyEliminate reaction forceYielding couplingConvertible cyclesEngineeringLow speed

The creation is an adapter device for tandem bicycle. The tandem bicycle consists of the bicycle and the connected bicycle. The adapter device comprises the universal joint and twist apparatus. The universal joint is connected to the scheduled placed of the seat tube, so the reaction force caused by rugged roads can be eliminated by the device when riders make a turn. About the twist apparatus, which links the connected bicycle, the flexible components in the twist apparatus can make the preceding part of bicycle more stable at the start or at low speed in riding, so the bicycle can have good stability and mobility, and is easy to ride.

Owner:BIPEACE ENTERPRISE

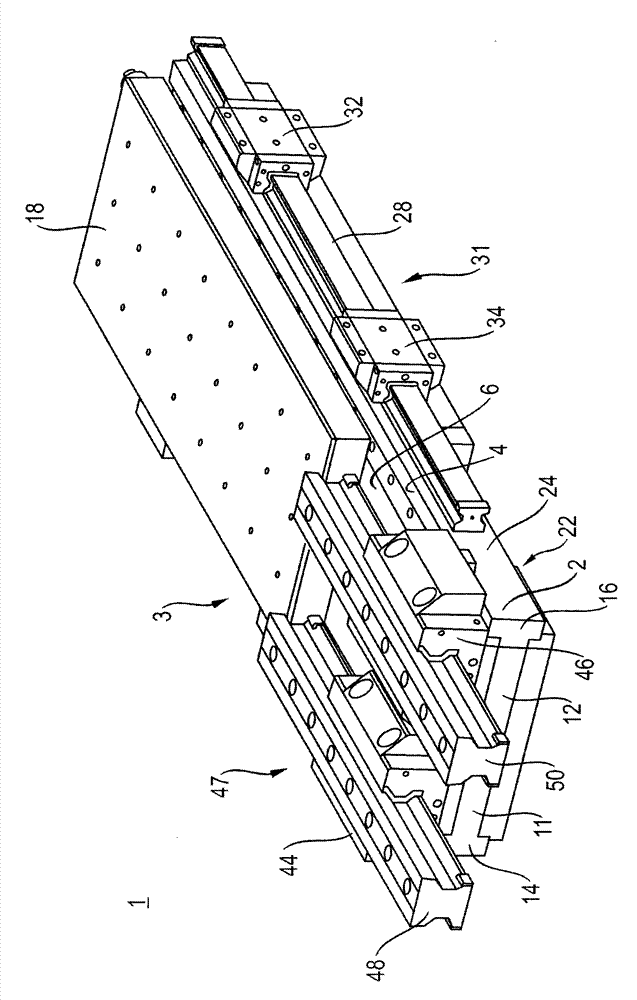

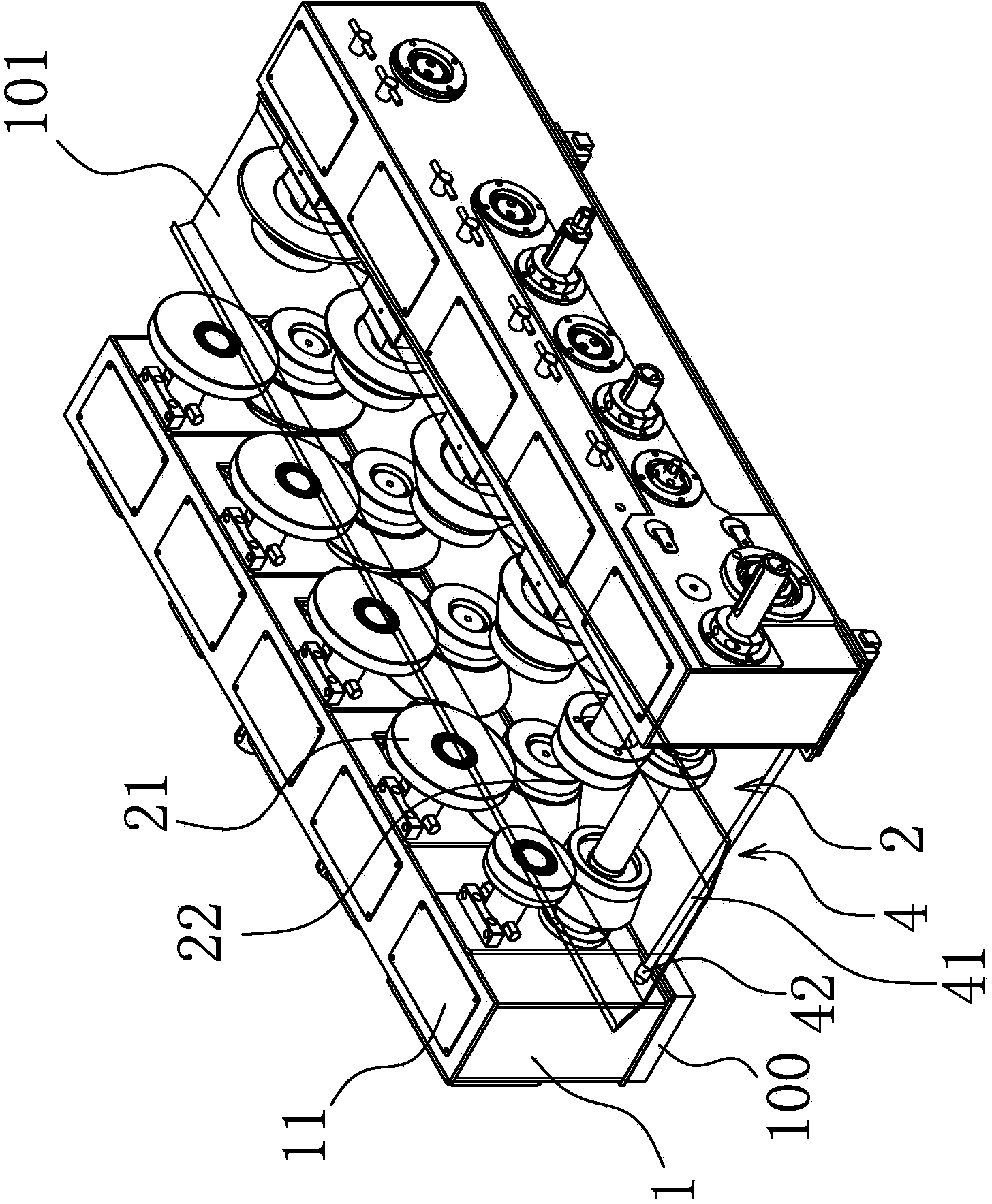

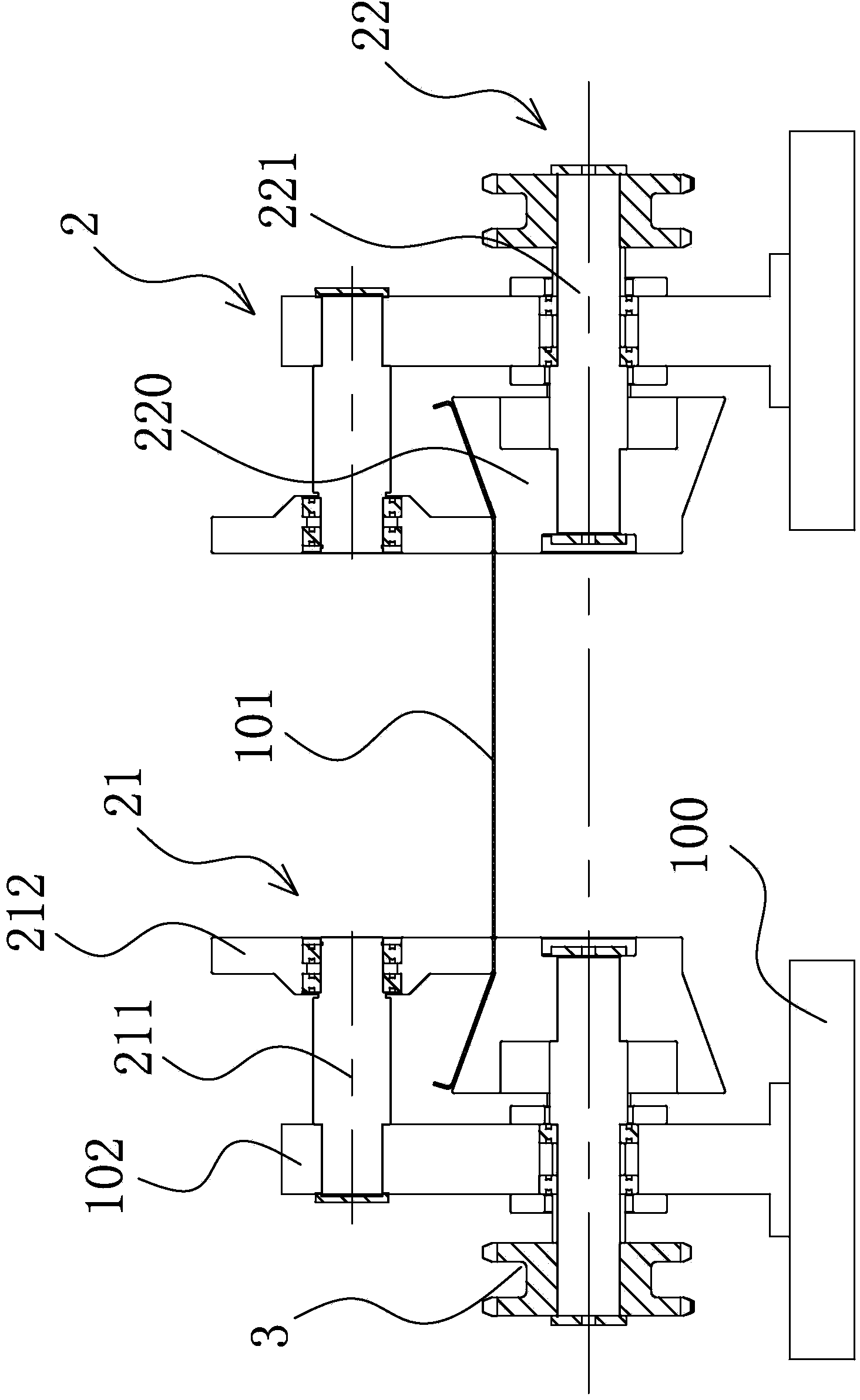

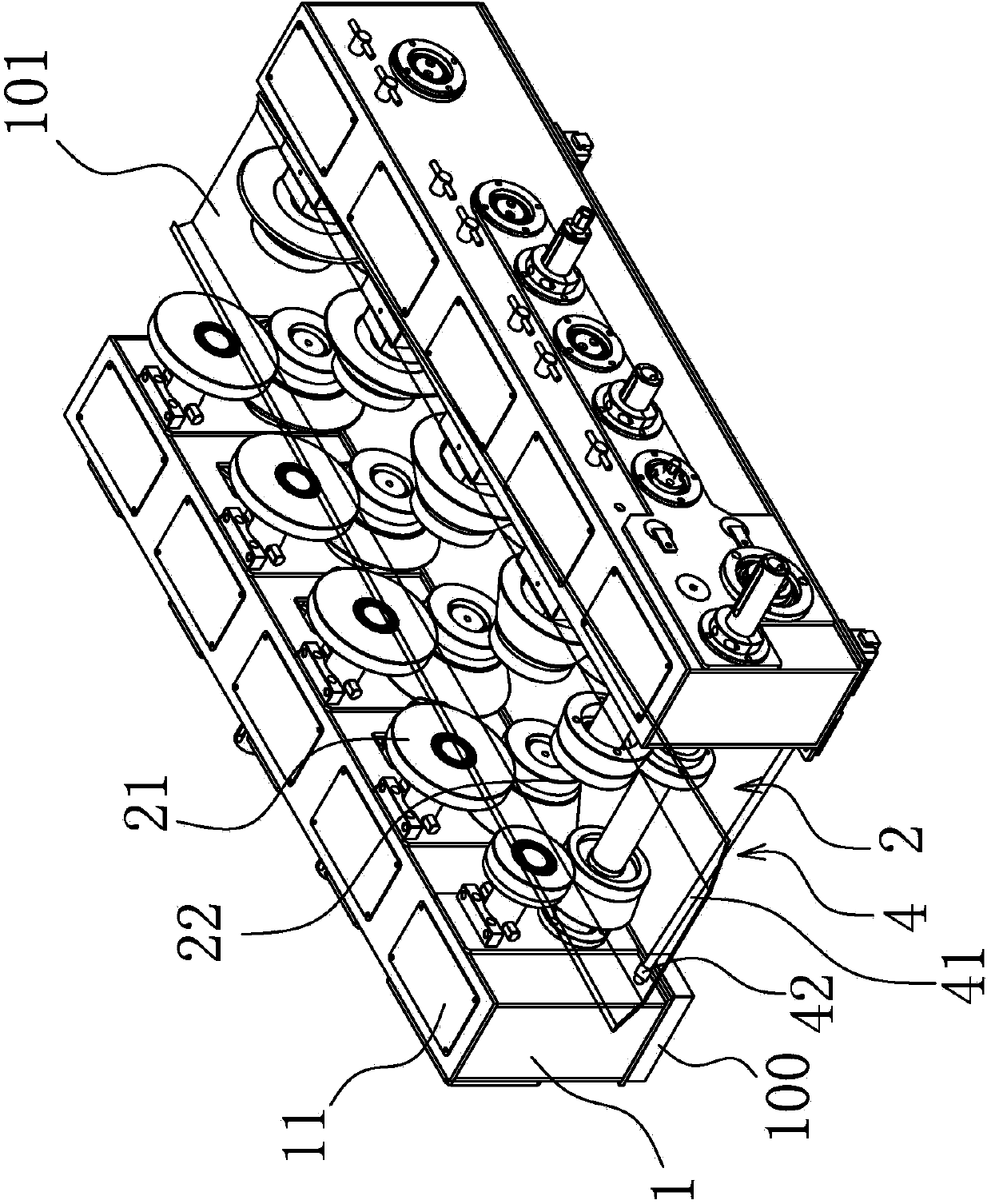

Linear Motor Assembly And Machine Tool With Linear Motor Assembly

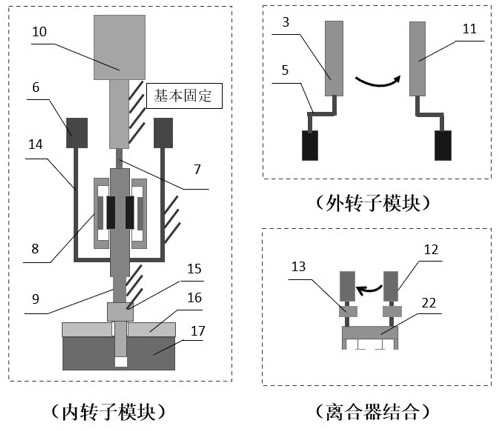

InactiveCN104723154ALow costActive connectionFeeding apparatusLarge fixed membersEngineeringLinear motor

The present invention discloses a linear motor assembly used for a stepping machine tool. The linear motor assembly is provided with a linear motor with two secondary units which are arranged on a supporting plate of a sliding support, and each secondary unit is equipped with a primary unit. The supporting plate is sandwiched between the primary units, and the sliding support guides and supports movably along a longitudinal direction via at least one linear guide device. The sliding support can apply an operating force on a cutter at the end side, wherein the operating force is basically vertical with a longitudinal axis to play part.

Owner:ROBERT BOSCH GMBH

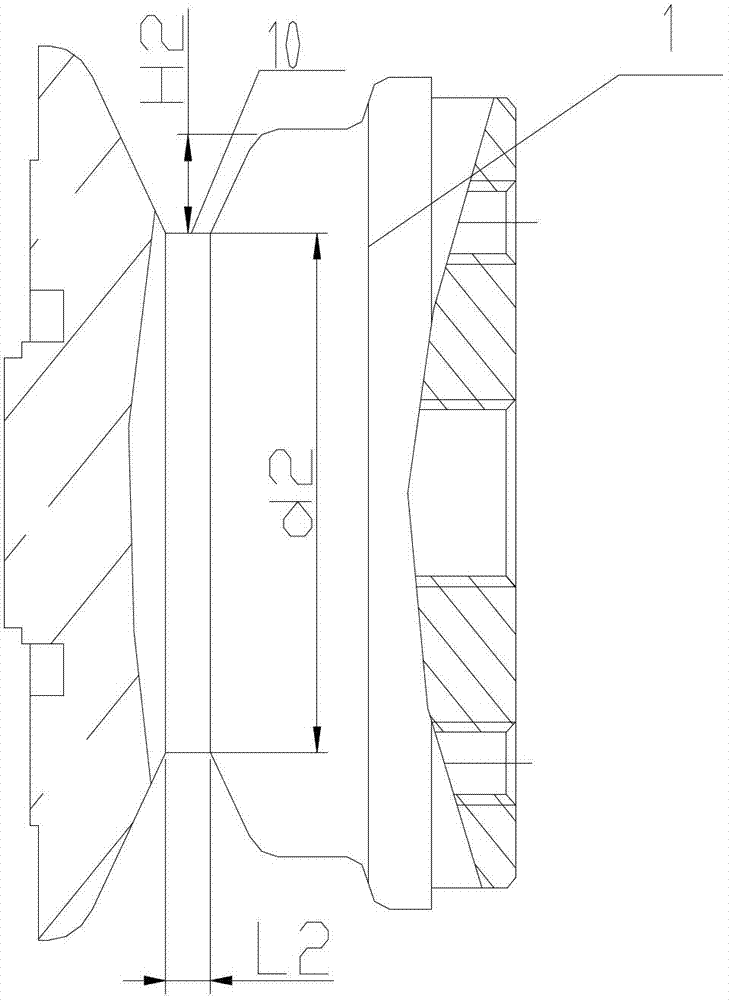

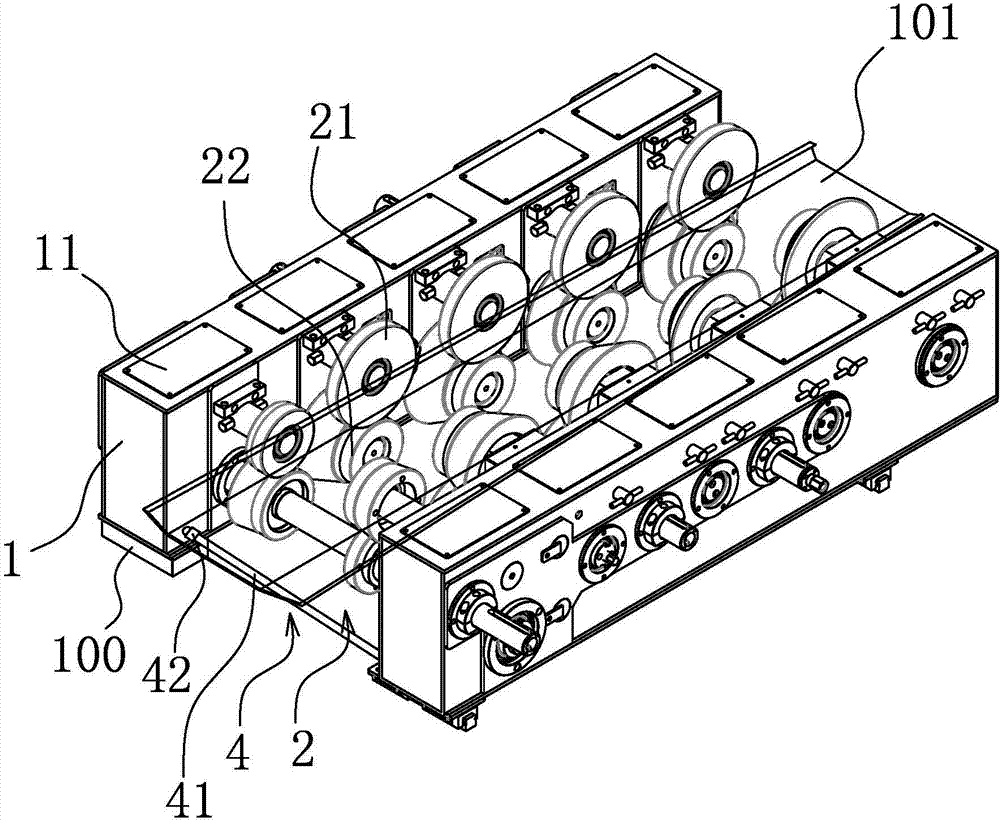

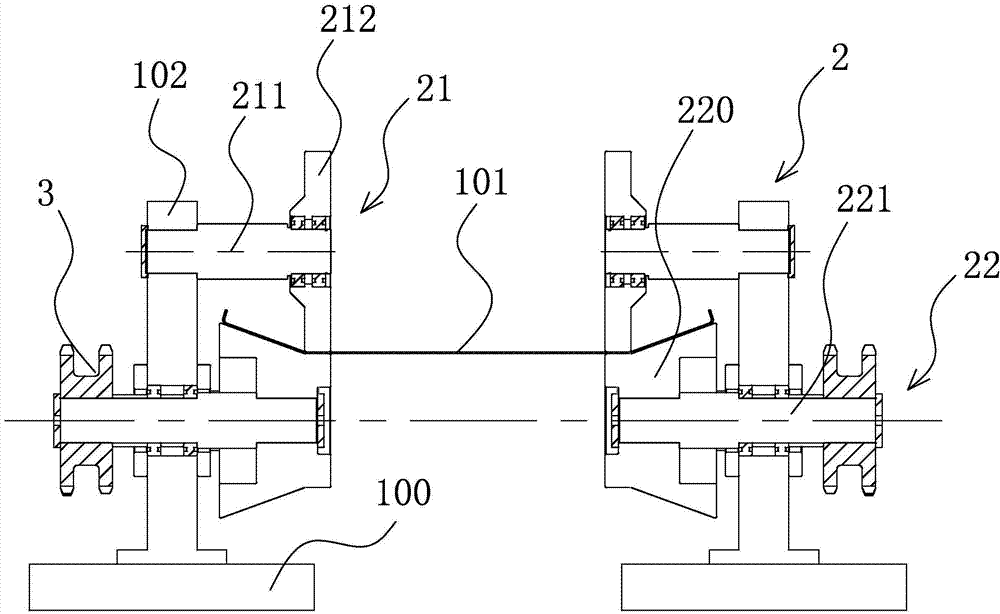

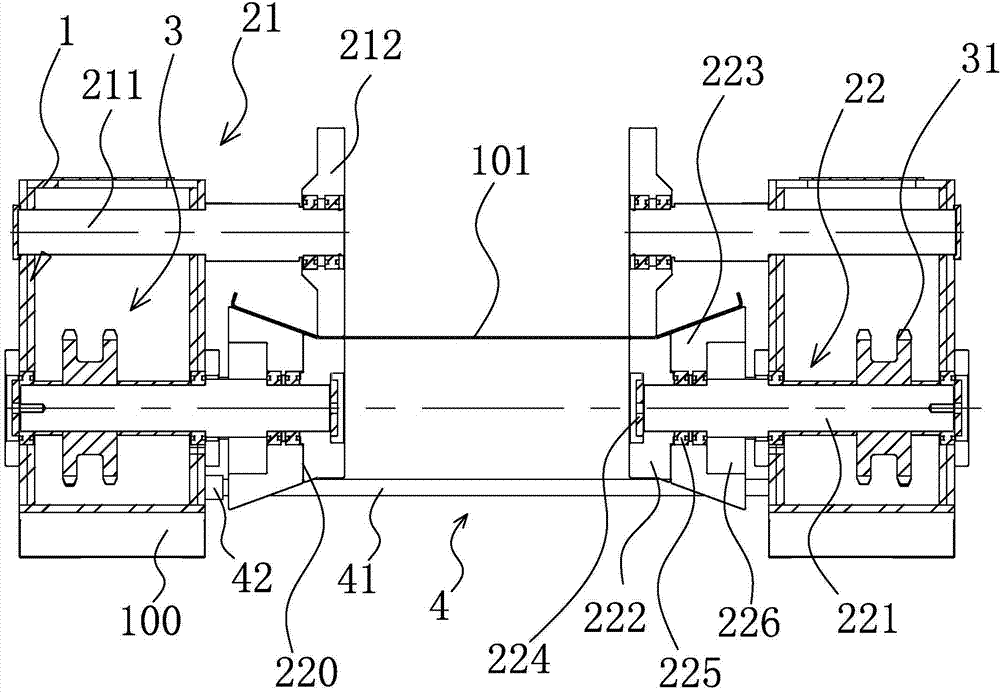

Novel purline molding device

InactiveCN104028593AImprove rigidityEliminate reaction forceMetal working apparatusProcessing accuracyEnergy consumption

The invention provides a novel purline molding device, belongs to the technical field of mechanical equipment, and solves the technical problems that the machining in the prior art is time-consuming and labor-consuming, and the precision cannot be ensured. The novel purline molding device comprises a machine seat, wherein two transmission box bodies are oppositely arranged on the machine seat; the distance between the two transmission box bodies is adjustable on the machine seat; a plurality of positioning holes are formed in the side walls of the transmission box bodies; roller molding mechanisms are detachably mounted on the transmission box bodies through the positioning holes; each roller molding mechanism comprise an upper roller component and a lower roller component; each lower roller component is connected with a drive mechanism; each drive mechanism is arranged in the corresponding transmission box body. The novel purline molding device has the advantages of high machining precision, low machining cost, low energy consumption, high safety and the like.

Owner:HANGZHOU YIBO MACHINERY

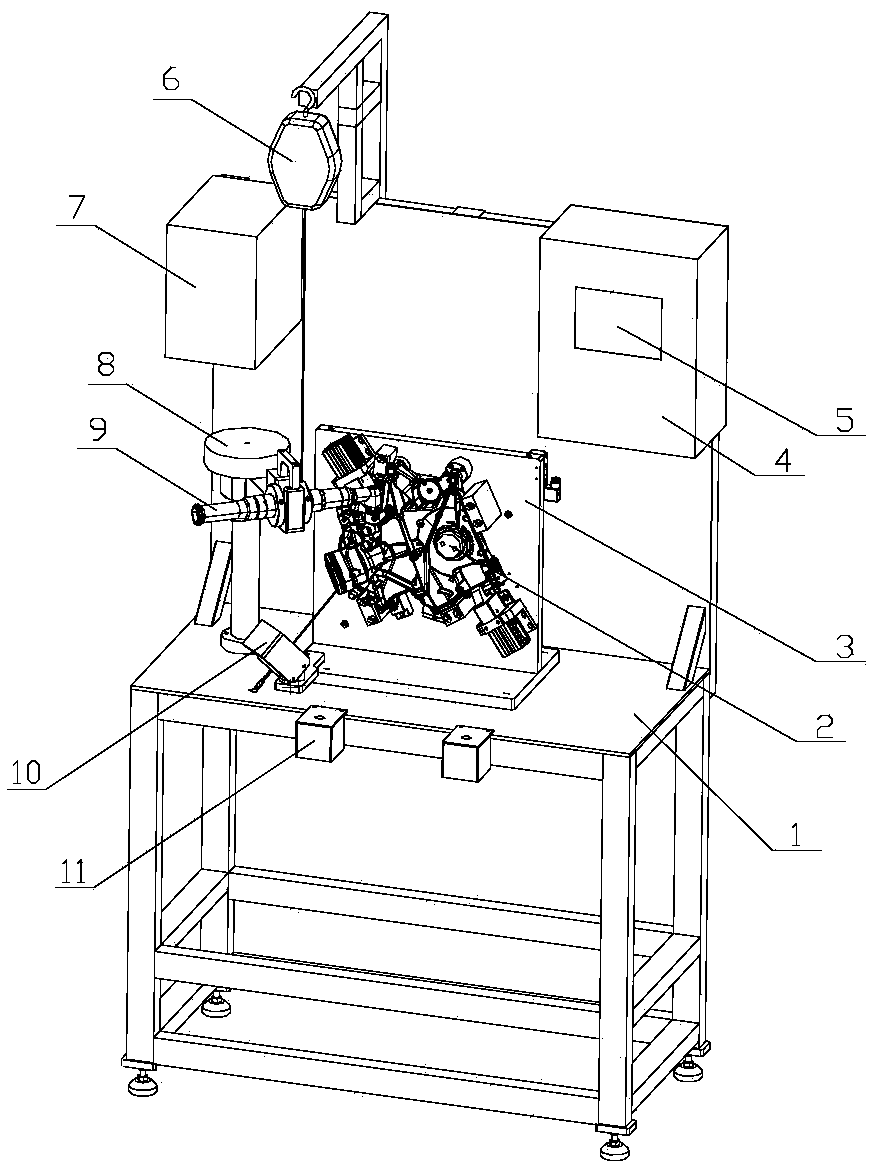

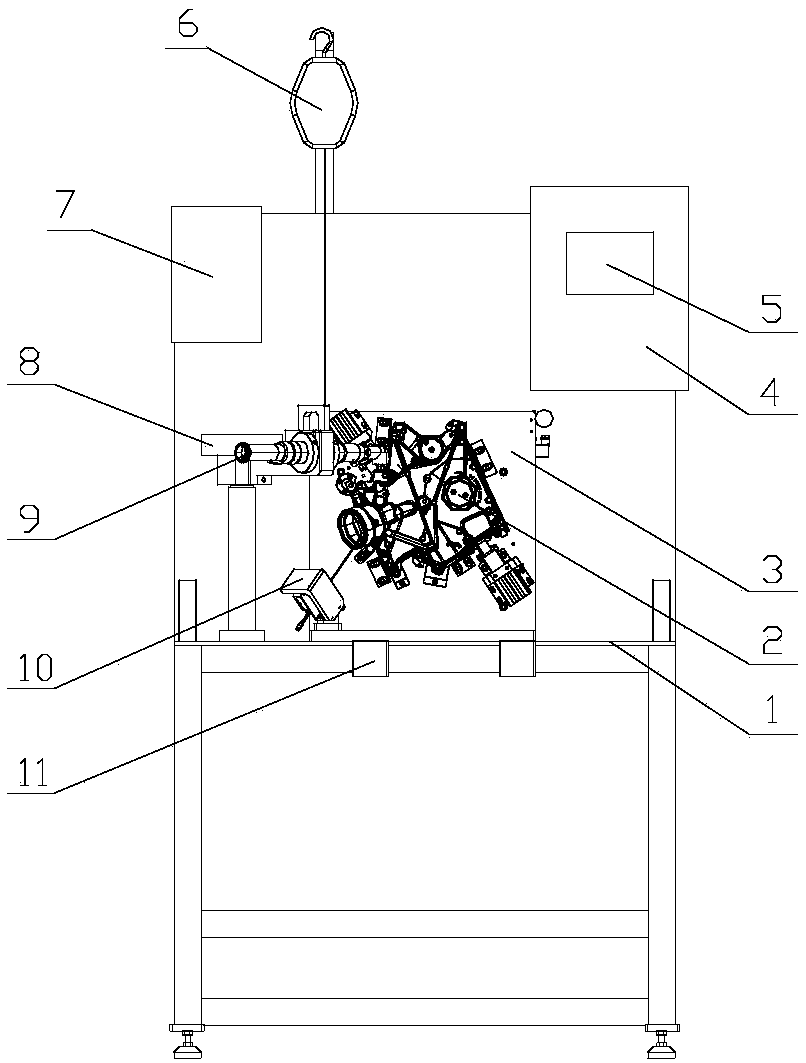

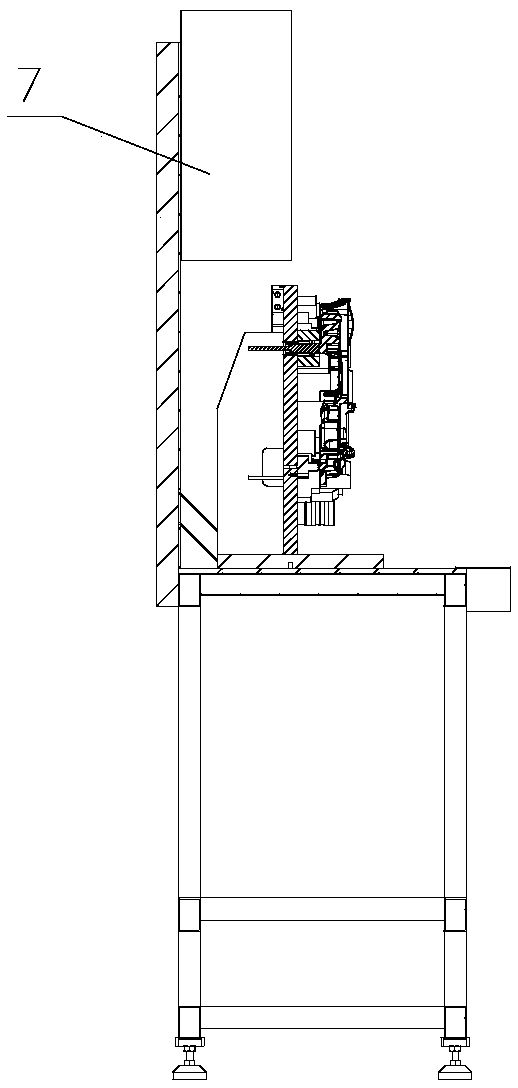

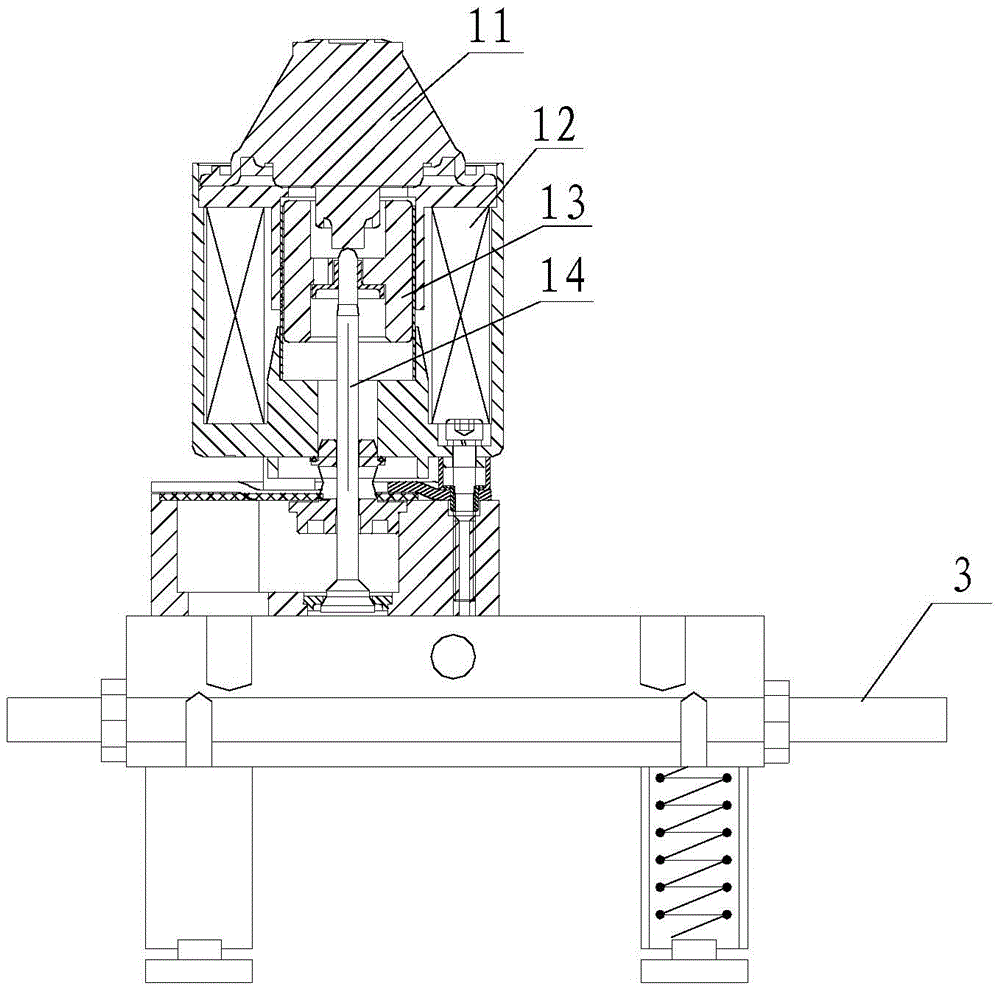

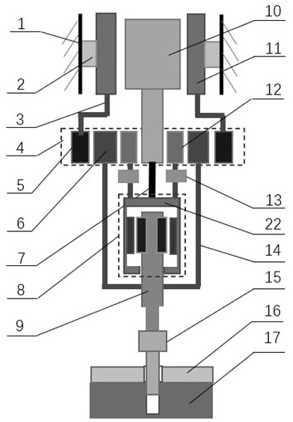

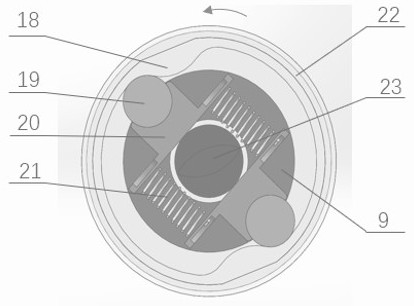

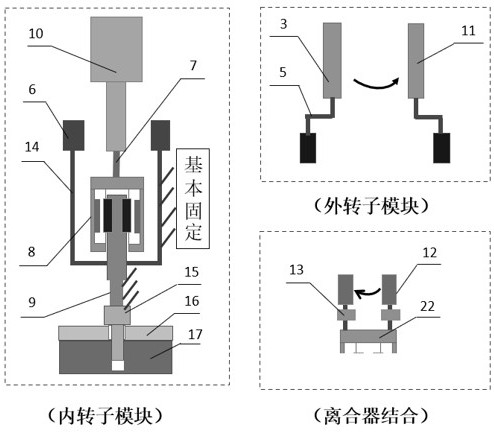

Assembly error-proofing special machine and method used for gear chamber chain cover part of automobile engine

PendingCN108747321AInstall correctlyGuaranteed assembly qualityVehicle componentsMetal working apparatusLaser sensorEngineering

The invention discloses an assembly error-proofing special machine used for a gear chamber chain cover part of an automobile engine, and further discloses an assembly error-proofing method used for the gear chamber chain cover part of the automobile engine. The assembly error-proofing special machine comprises a worktable (1). The worktable (1) comprises a horizontal working face and a vertical working face. The assembly error-proofing special machine further comprises a fixture body (3). A positioning block is arranged on the fixture body (3). A rotating power-assisted arm (8) is arranged onone side of the fixture body (3), the rotating power-assisted arm (8) clamps and supports an electric torque spanner (9), and a laser sensor detecting device (10) is arranged below the electric torquespanner (9). According to the assembly error-proofing special machine, through accurate alarming prompt of the laser sensor detecting device arranged on the worktable, a whole oil temperature adjuster valve body and a hexagonal blocking head are mounted correctly in place, so that the assembly quality of products is ensured, the production efficiency is improved, and meanwhile the assembly error-proofing special machine has the advantages of easy operation, low labor intensity, low cost and the like.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

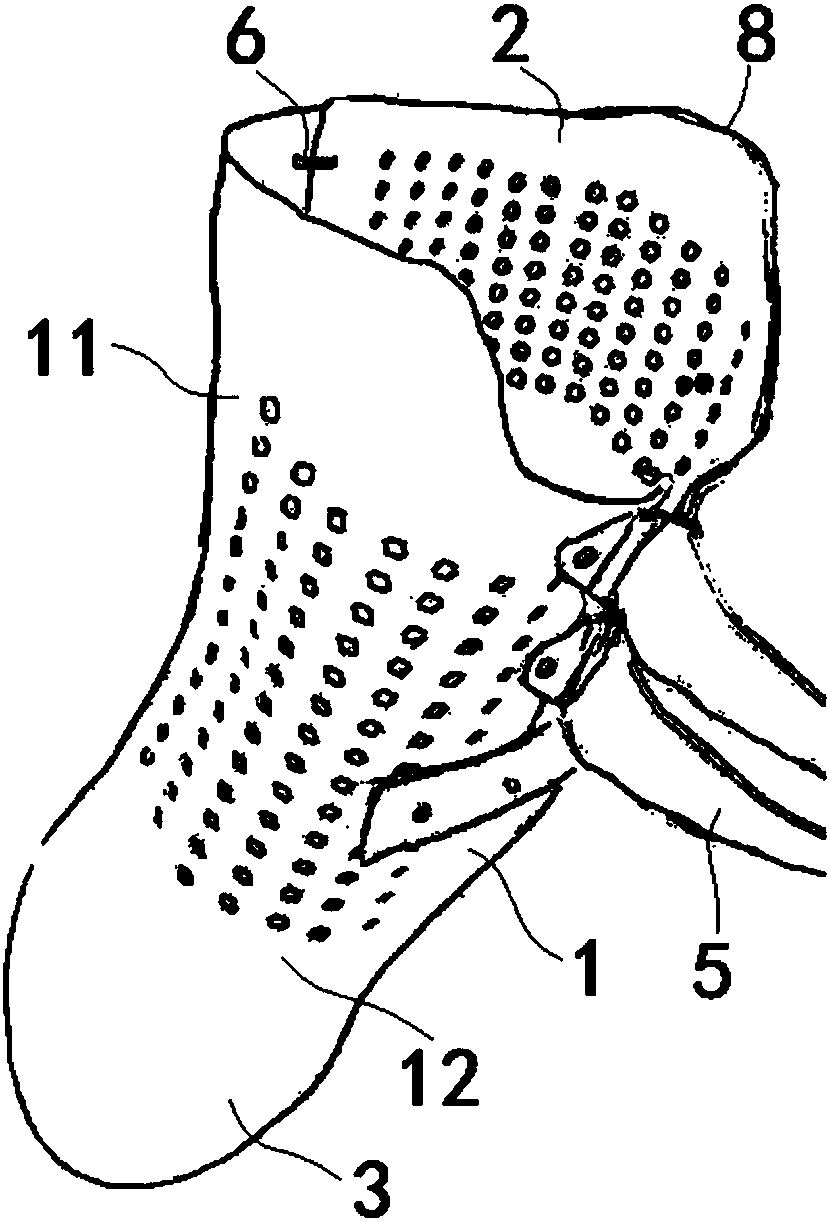

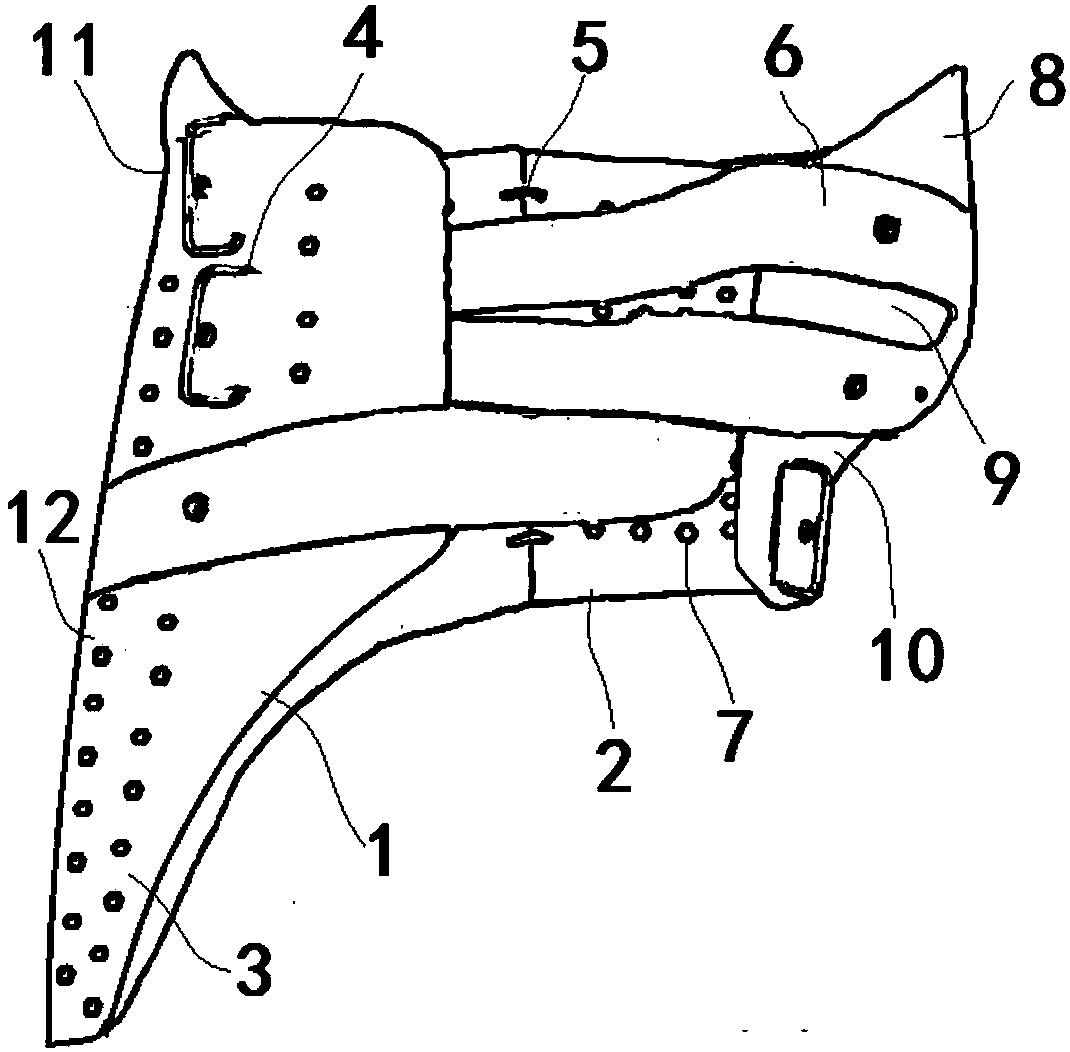

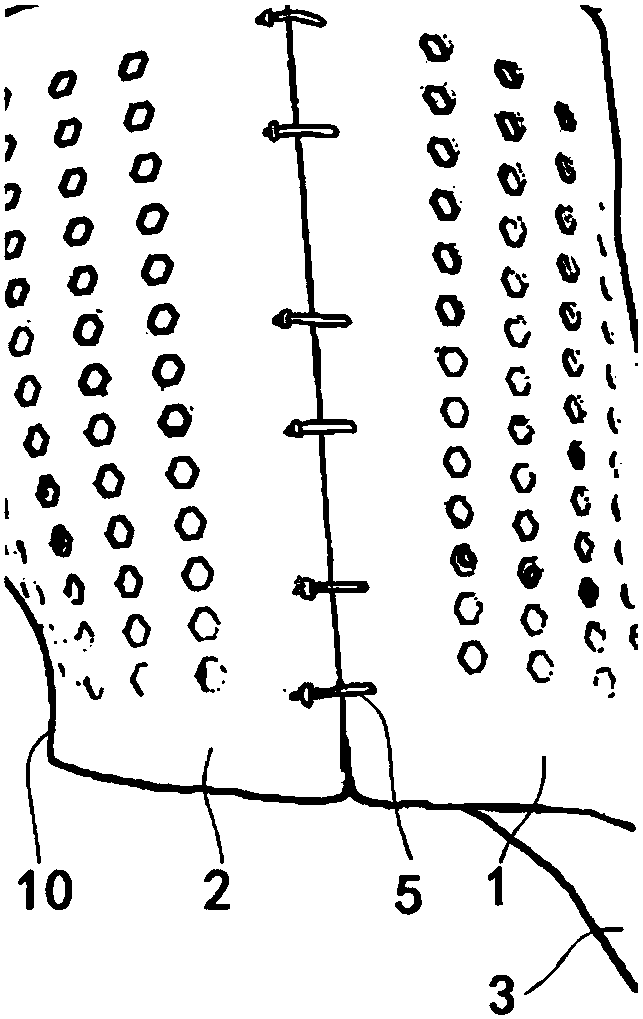

Nighttime human scoliosis orthopedic support and design method thereof

PendingCN108245298AEliminate reaction forceGood orthopedic effectAdditive manufacturing apparatusOrthopedic corsetsScoliosisTrochanter

The invention discloses a nighttime human scoliosis orthopedic support and a design method thereof. The orthopedic support comprises a first piece and a second piece; the first piece comprises a lowerfemoral great trochanter positioning portion and an upper top thoracic vertebra positioning portion; the second piece comprises an upper underarm positioning portion and a lower top lumbar vertebra positioning portion; the top thoracic vertebra positioning portion and the top lumbar vertebra positioning portion are recessed inwardly; a lower side area of the underarm positioning portion and an upper side area of the femoral great trochanter positioning portion form projections outwardly; the top thoracic vertebra positioning portion is lower than the underarm positioning portion, the femoralgreat trochanter positioning portion is lower than the top lumbar vertebra positioning portion, and the first piece and the second piece are in an asymmetrical structure. The orthopedic support has the advantage of remarkable improvement of comfort of users and orthopedic effects.

Owner:广州医科大学附属第三医院荔湾医院

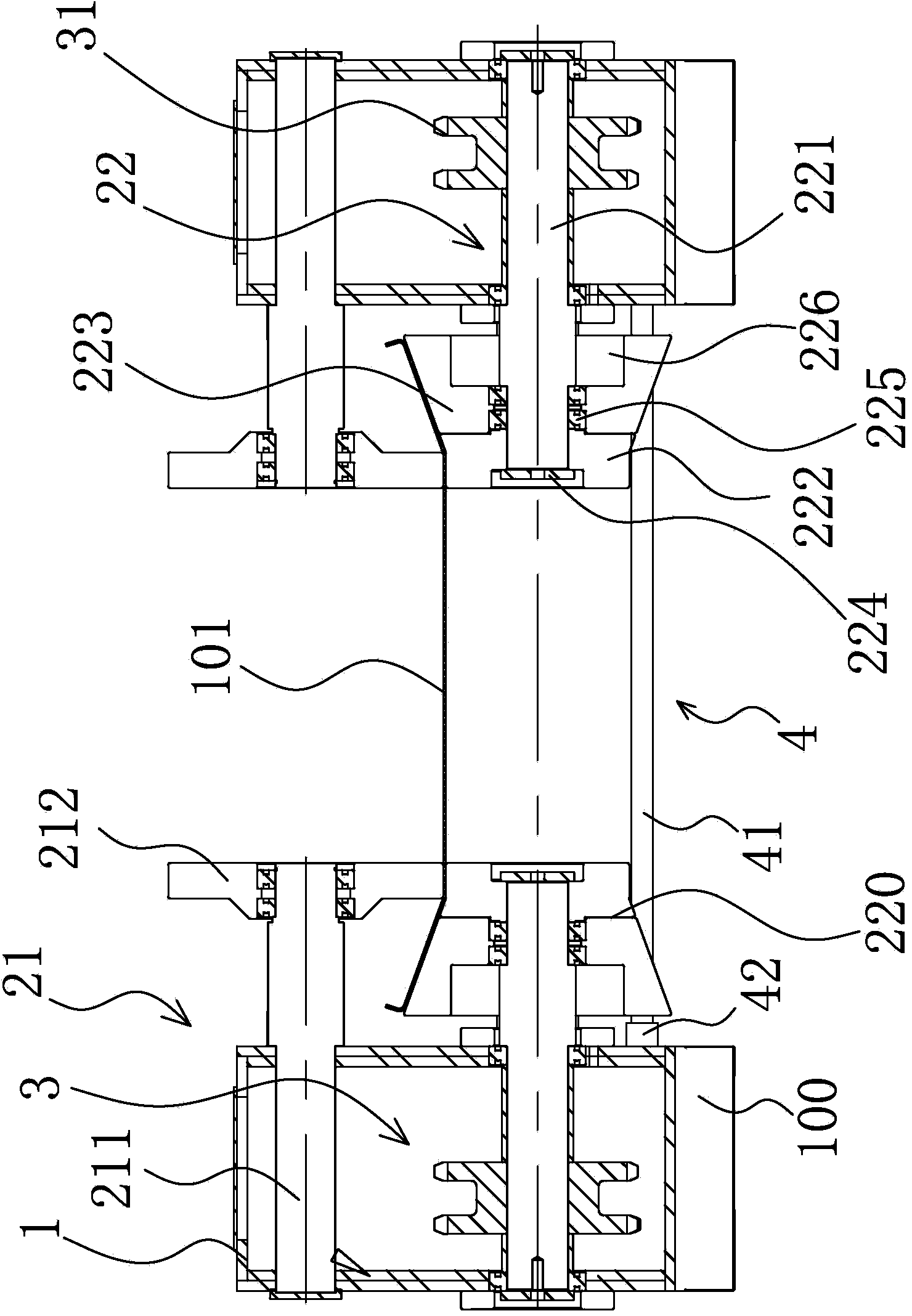

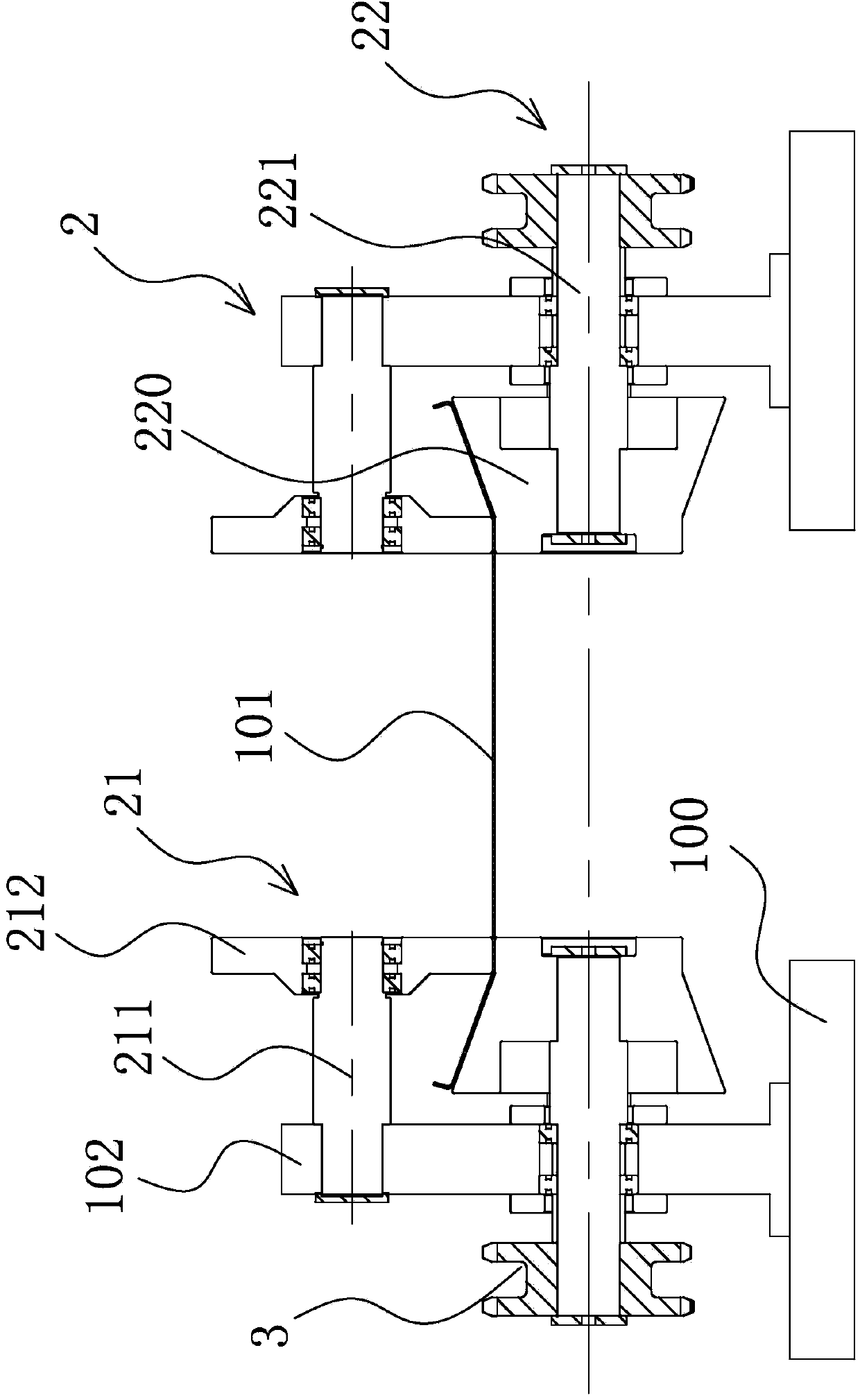

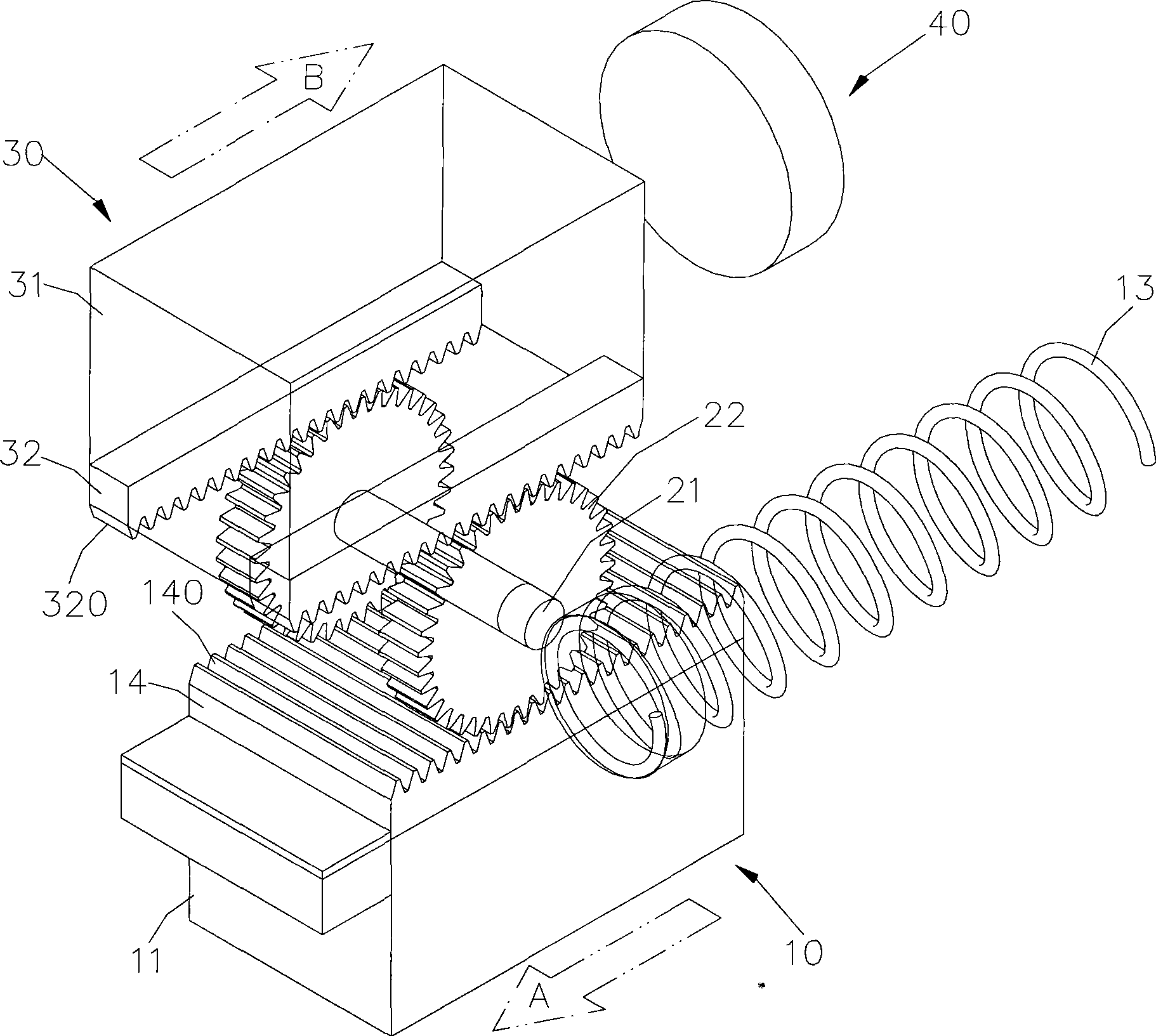

C/Z purlin exchange production line

The invention provides a C / Z purlin exchange production line, and belongs to the technical field of mechanical equipment. The C / Z purlin exchange production line solves the technical problems that time and labor are wasted in machining, precision cannot be ensured and the like in the prior art. The C / Z purlin exchange production line comprises an emptying device, a feeding leveling device, a roll forming device and a receiving device which are sequentially connected, the roll forming device comprises a base, two transmission cases are oppositely arranged on the base, the distance between the two transmission cases on the base can be adjusted, the side walls of the transmission cases are provided with a plurality of positioning holes, a roller forming mechanism is detachably mounted on the transmission cases through the positioning holes and comprises an upper roller component and a lower roller component, and a gear reversing mechanism is further arranged on the roll forming device. The C / Z purlin exchange production line has the advantages of high machining precision, low machining cost, low energy consumption, high safety and the like.

Owner:HANGZHOU YIBO MACHINERY

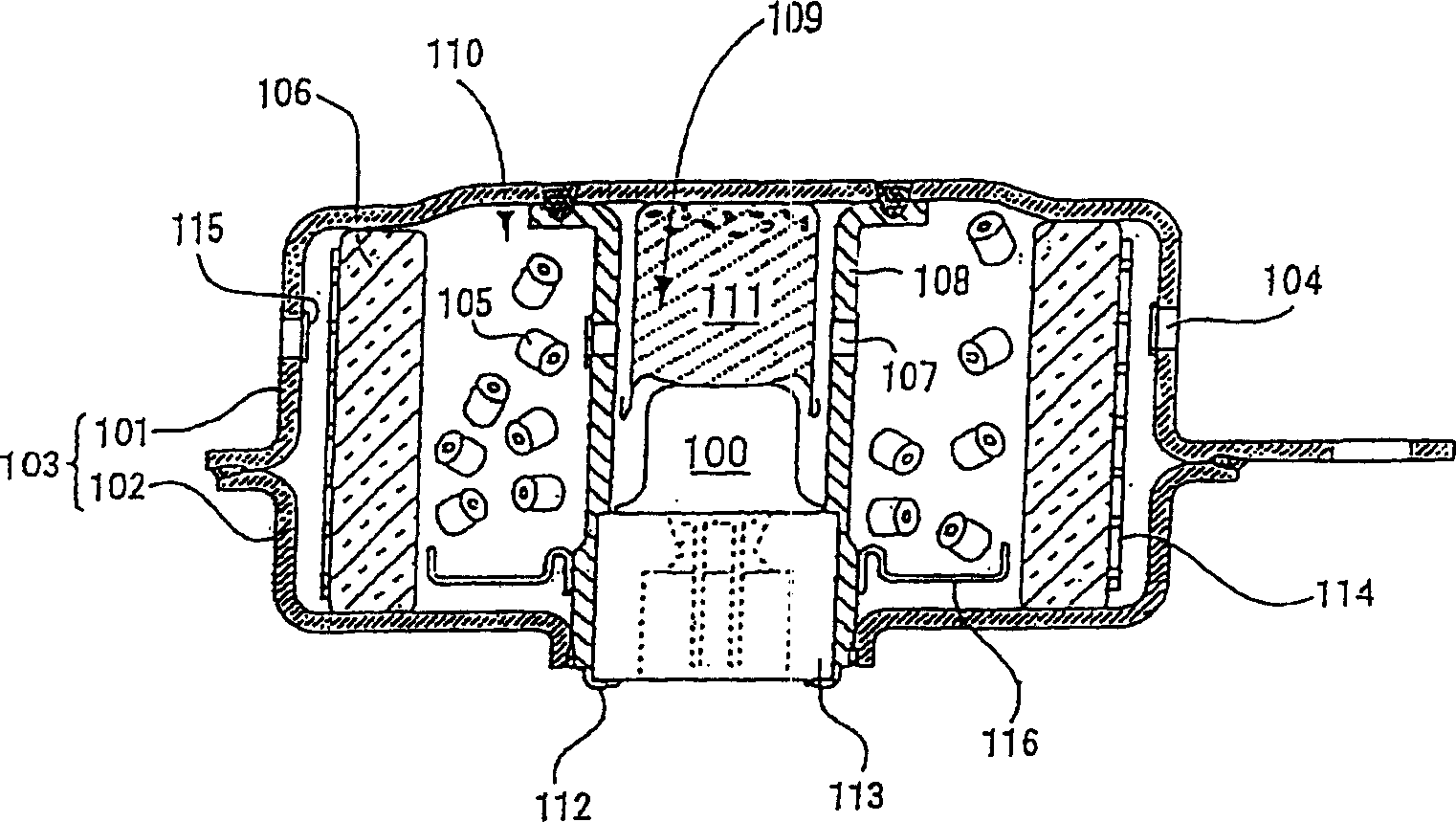

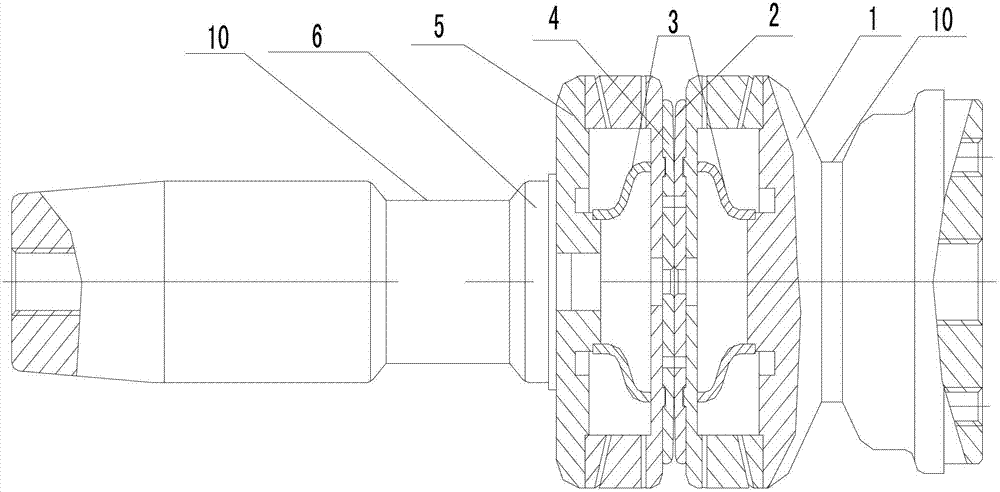

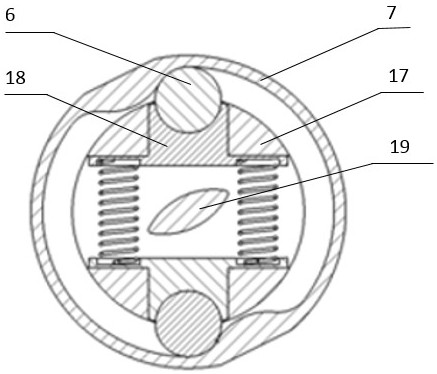

Low-bounce vacuum arc extinguish chamber structure

ActiveCN103050332AReduce intensityReduce wearHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

The invention discloses a low-bounce vacuum arc extinguish chamber structure. The low-bounce vacuum arc extinguish chamber structure is characterized by comprising a cup saucer (5), wherein the inner side of the cup saucer (5) is connected with a static contact (2) and a moving contact (4); an annular groove (7) is formed in the inner side connected with the cup saucer (5); an inner ring surrounded by the annular groove (7) is a middle stress part (9); and one end of each reinforcing rib (3) is connected with the middle stress part (9) on the cup saucer (5). According to the low-bounce vacuum arc extinguish chamber structure, the pressure intensity is increased by changing the stress area under the condition that the pressure is not changed; a workpiece is impelled to generate tiny plastic deformation due to the effect of high pressure intensity, so that the acting force is absorbed and removed; and the acting force is reduced, so that shorten bouncing time is shortened, the bouncing amplitude is reduced, the probability of contact heating or fusion welding is reduced, aggravation of electric wear of the contact is avoided, and the service life of the vacuum arc extinguish chamber is prolonged.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

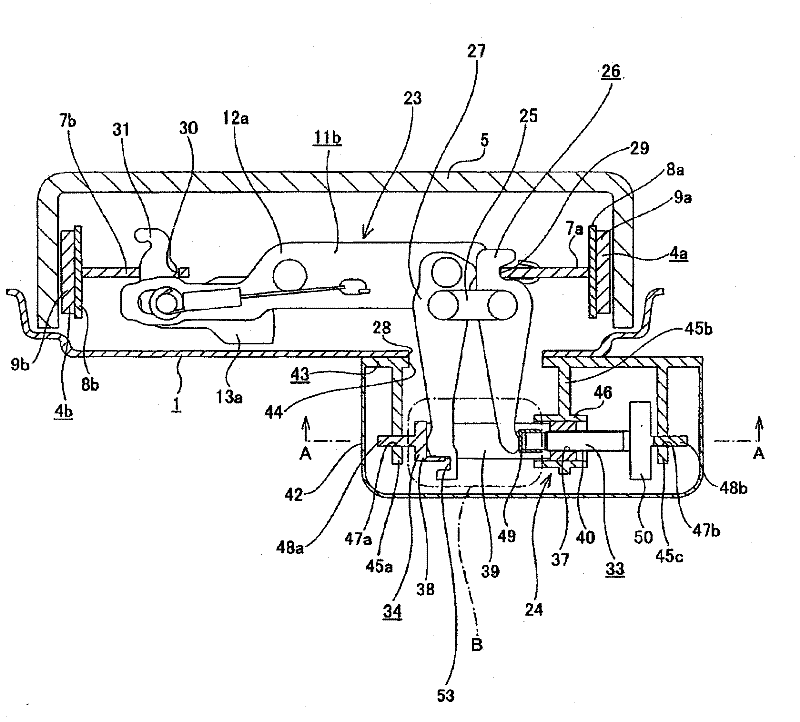

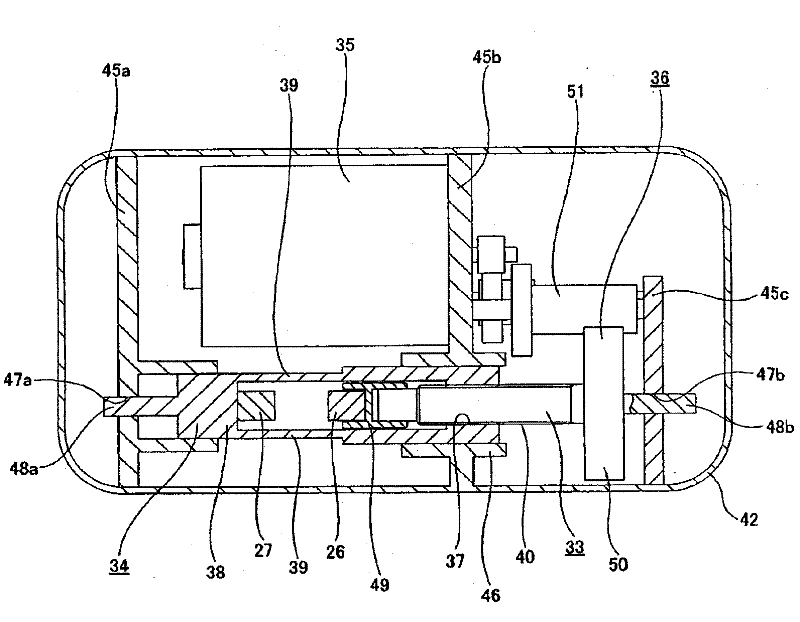

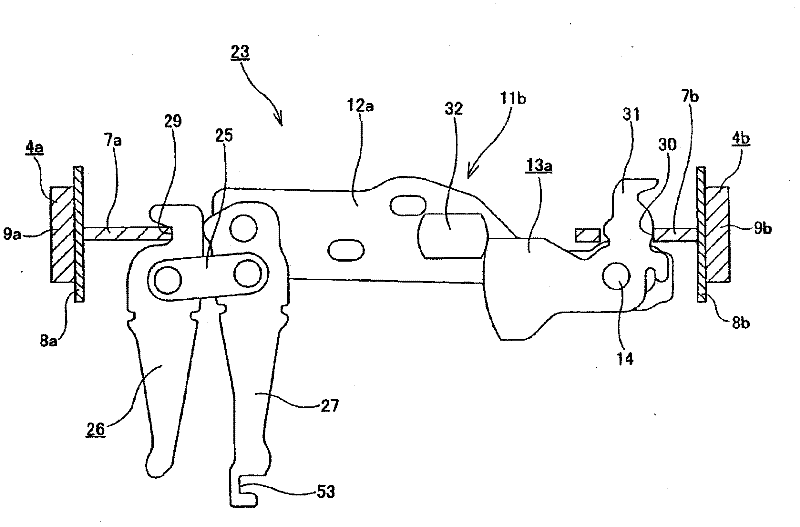

Drum brake type parking brake device

InactiveCN102245925AIncrease the gapConducive to lightweightBrake actuating mechanismsSlack adjustersMiniaturizationEngineering

Achieved is a structure wherein there is adopted a link type force multiplication device that causes only a small transmission loss, wherein, as a result, miniaturization and weight saving can be brought about by using an electric motor with a relatively small output, and wherein, in addition, reaction force accompanying braking is offset in the aforementioned force multiplication device, with the result that no large force is applied to the connection between this force multiplication device and a back plate (1). A connection link (25), a strut (11c), and both first and second extension levers (26, 27) constitute an extension and retraction device (23). During braking, the base ends of both these levers (26, 27) are pressed in opposite directions to each other by both first and second pressing members (43, 33). Reaction force accompanying braking is offset in the connection link (25) section, with the result that no large force is applied to the back plate (1) or the like.

Owner:AKEBONO BRAKE IND CO LTD

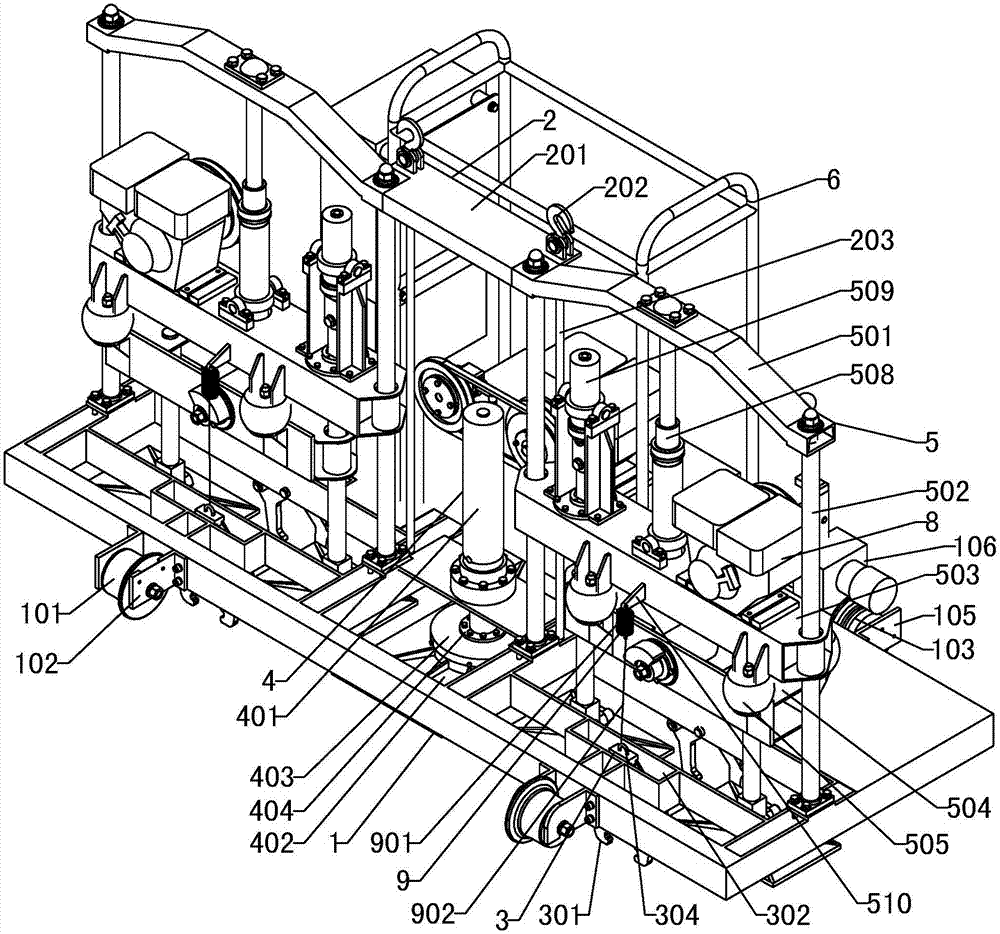

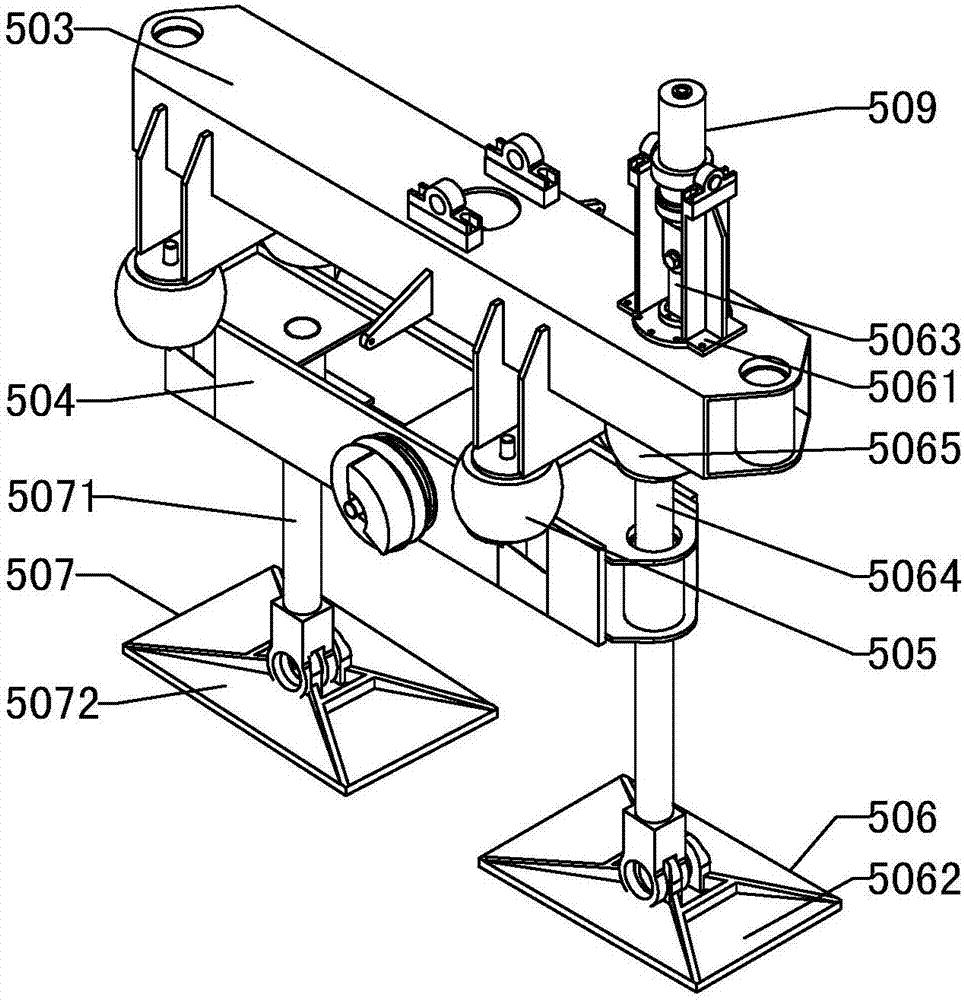

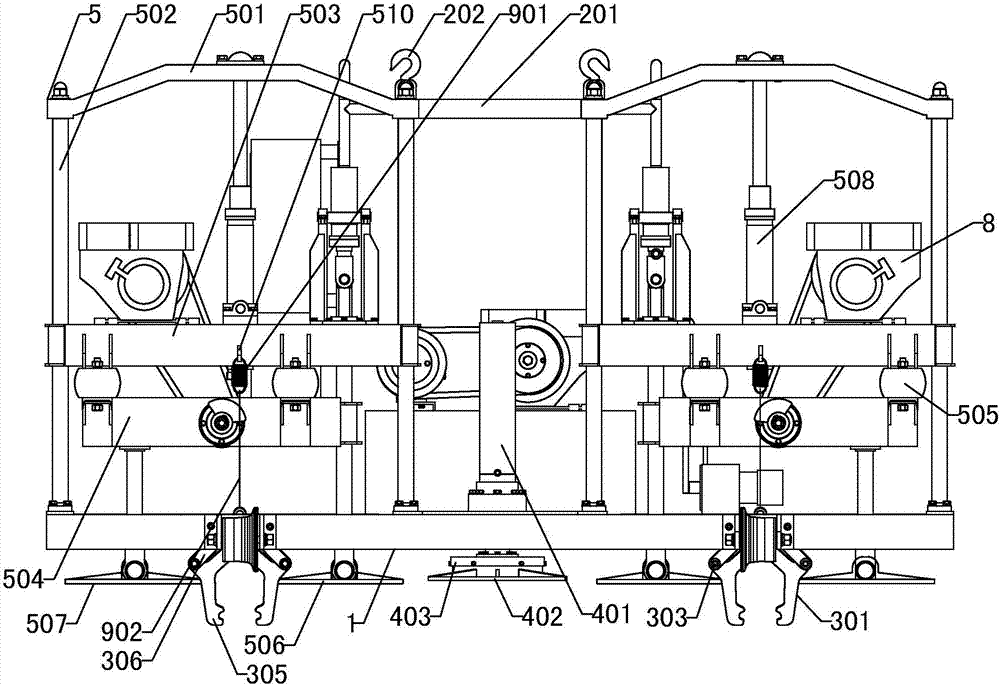

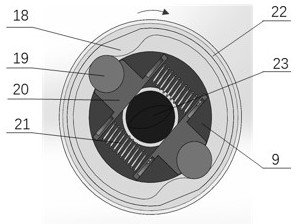

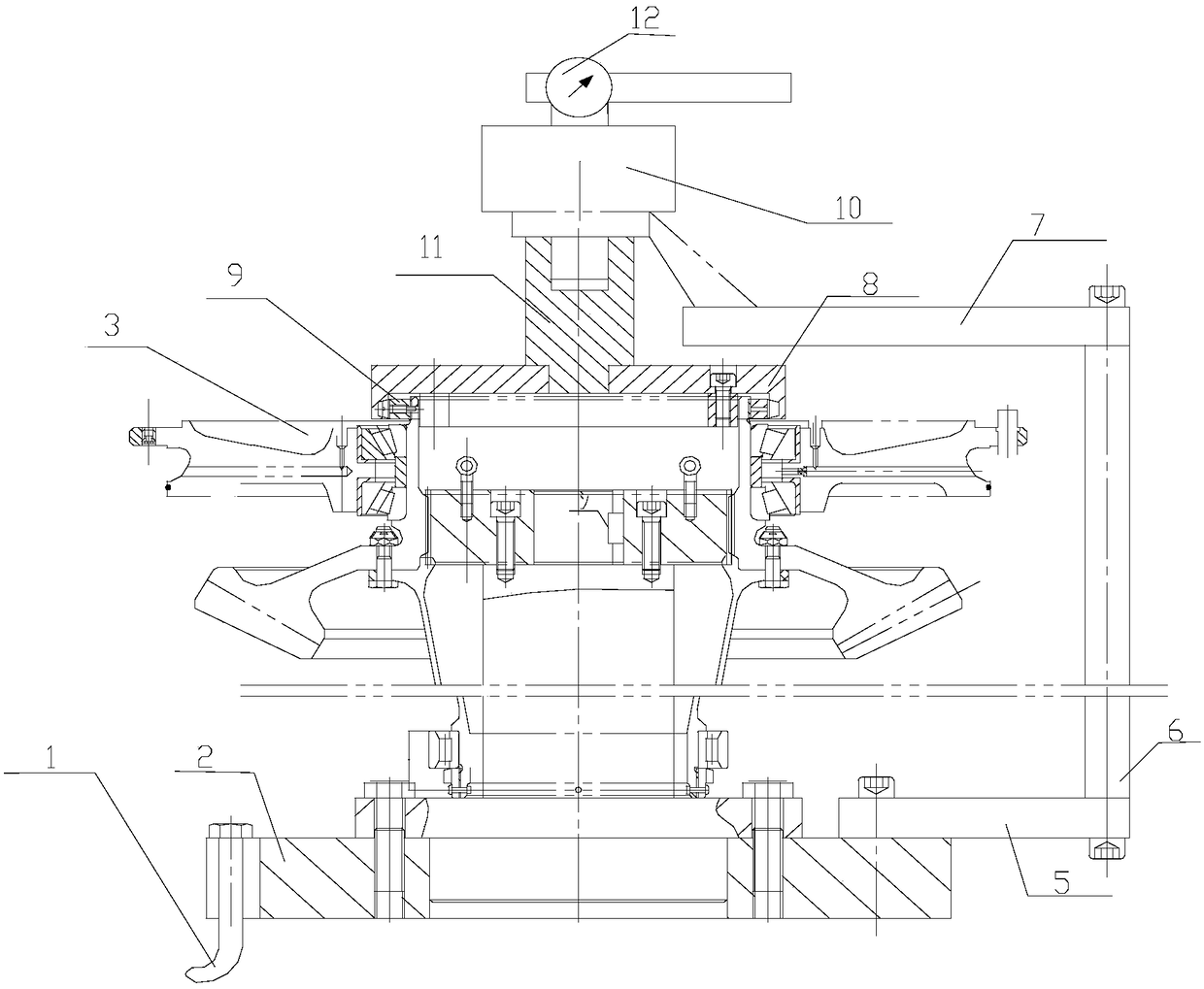

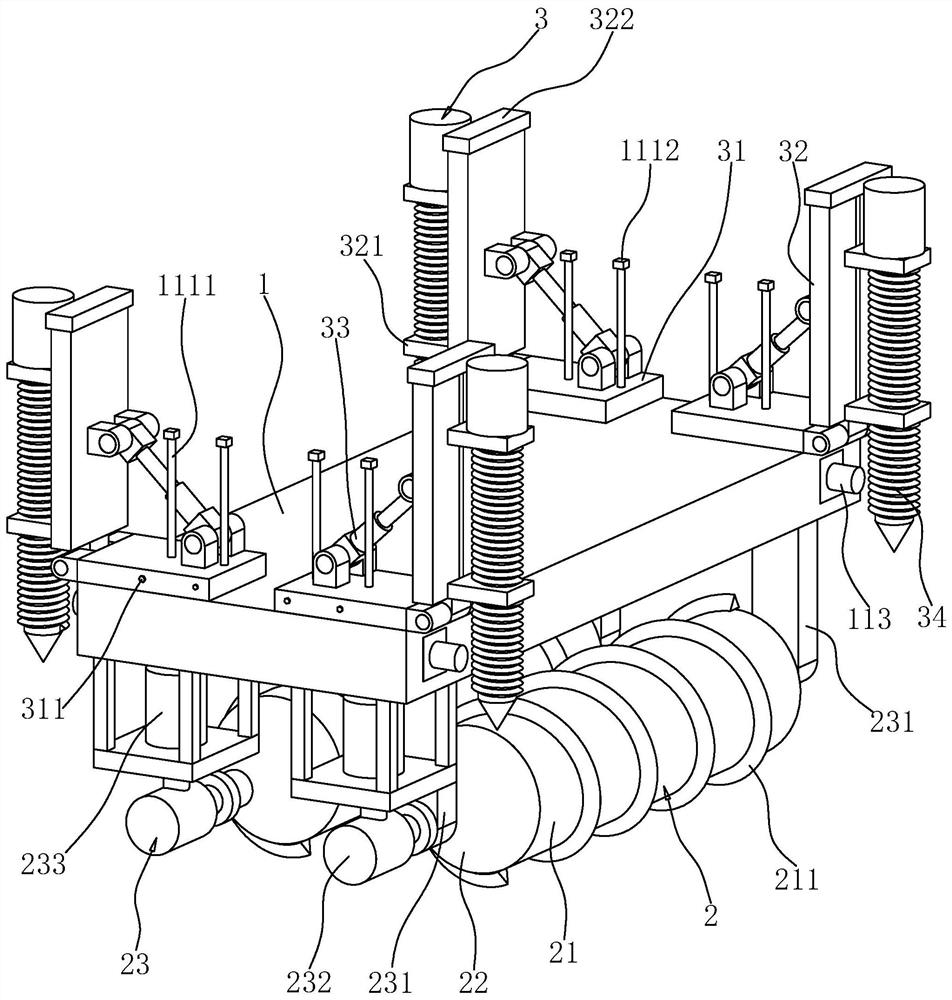

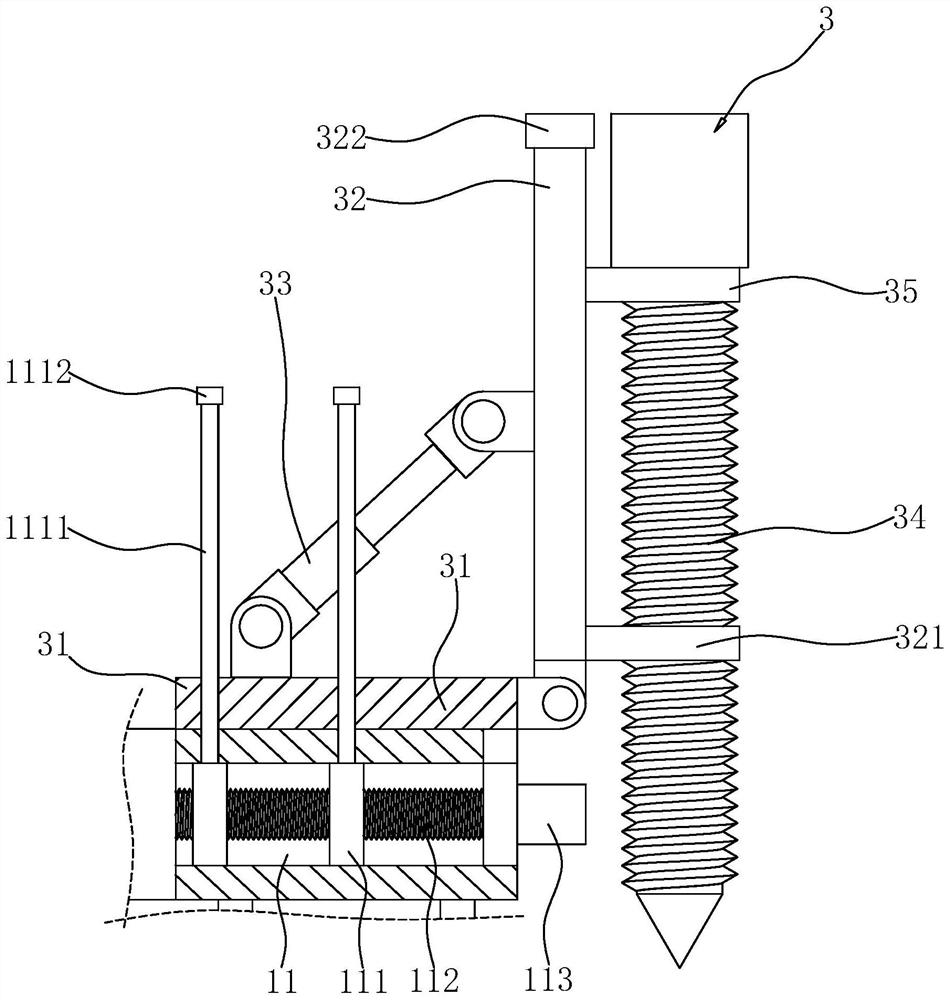

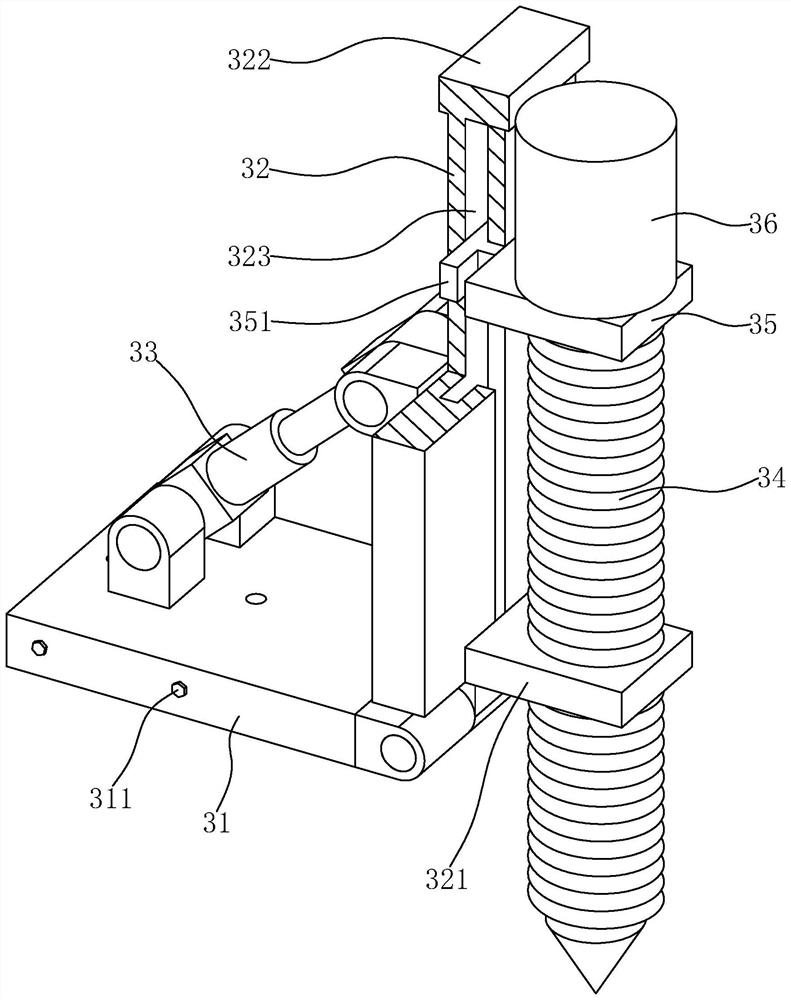

Small-sized automatic hydraulic railway line tamping car

The invention relates to a small-sized automatic hydraulic railway line tamping car, belonging to the field of railway line maintenance equipment. The small-sized automatic hydraulic railway line tamping car is characterized by comprising tamping mechanisms (5) and a travelling chassis (1), wherein travelling mechanisms are respectively arranged at the lower parts of the front side and the rear side along the travelling direction of the travelling chassis (1); the upper part of the travelling chassis (1) is divided into a front area and a rear area by taking the travelling direction as a benchmark; the two groups of tamping mechanisms (5) parallel to a railway line sleeper are respectively arranged at the left side and the right side of the front area; two groups of rail clamping mechanisms (3) are respectively arranged at the front side and the rear side of each group of tamping mechanism (5); a travelling down mechanism (4) capable of driving a whole machine to go up and down and rotate is arranged in the middle of the travelling chassis (1). The small-sized automatic hydraulic railway line tamping car is electromechanical integrated artificial intelligent equipment, and all operations such as transferring the equipment, automatically tamping and enabling the equipment to travel up and down can be realized by one person, so that not only is manpower greatly saved, but the working quality is also improved; the small-sized automatic hydraulic railway line tamping car has little interference to driving, and realizes the industrial upgrading of railway line turnout tamping operation from mechanization to automation.

Owner:淄博洁翔机电科技开发有限公司

Counterforce counteraction device of neil catcher

InactiveCN101386183AEliminate reaction forceSimple structureStapling toolsNailing toolsEngineeringCounterforce

The invention provides a counterforce bucking device for a box nailing machine. The box nailing machine is provided with a drive device, a rotating piece and a balance weight device, wherein, the drive device is linked with the rotating piece and the balance weight device, when the drive device of the box nailing device is actuated for action, the balance weight device is driven by the rotating piece to generate counterforce, thereby bucking acting force after the box nailing machine is actuated, and achieving the aim of safe application, simple assembly and other high practicalities for a user.

Owner:SHENZHEN MORGAN FUWANG TECH CO LTD

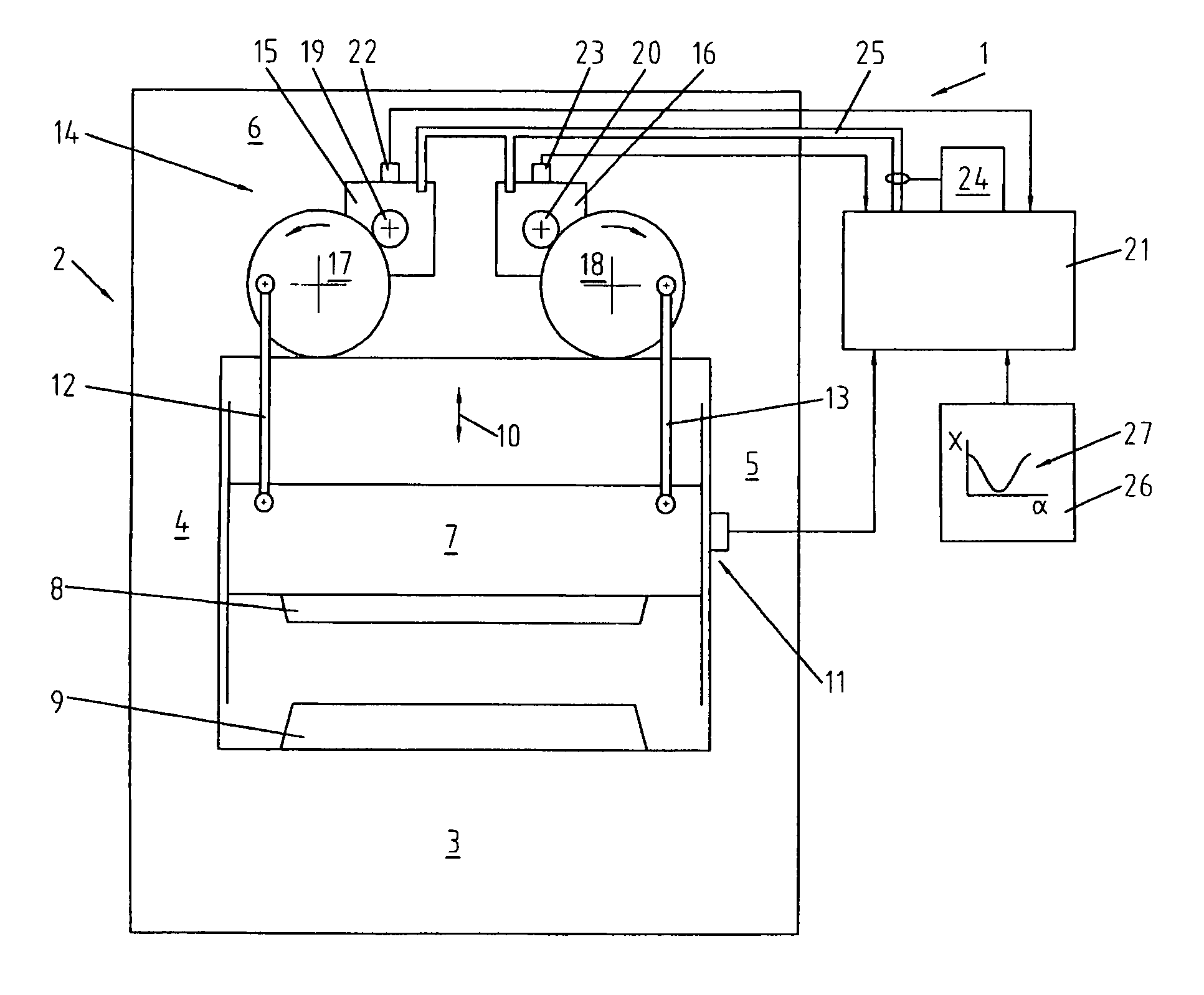

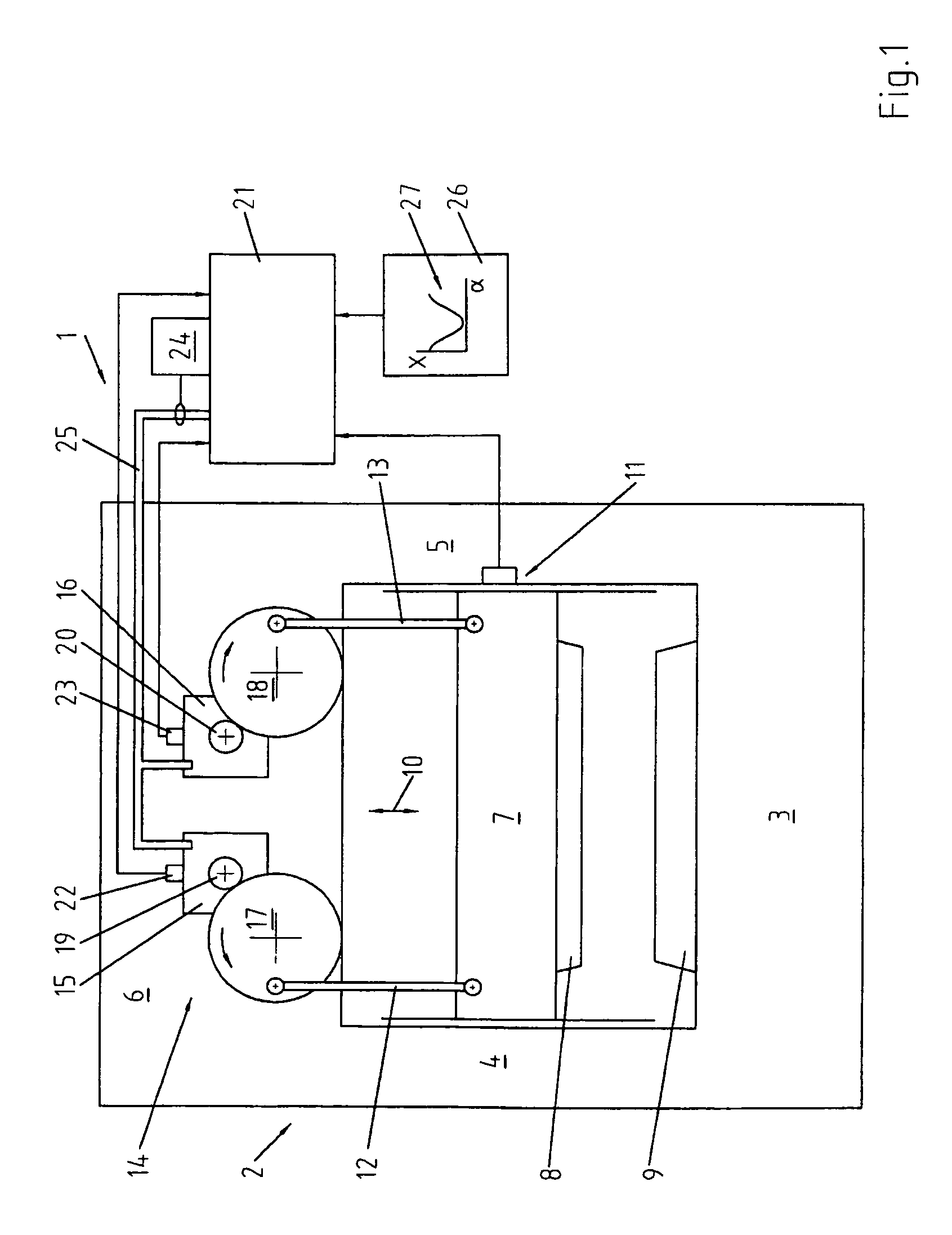

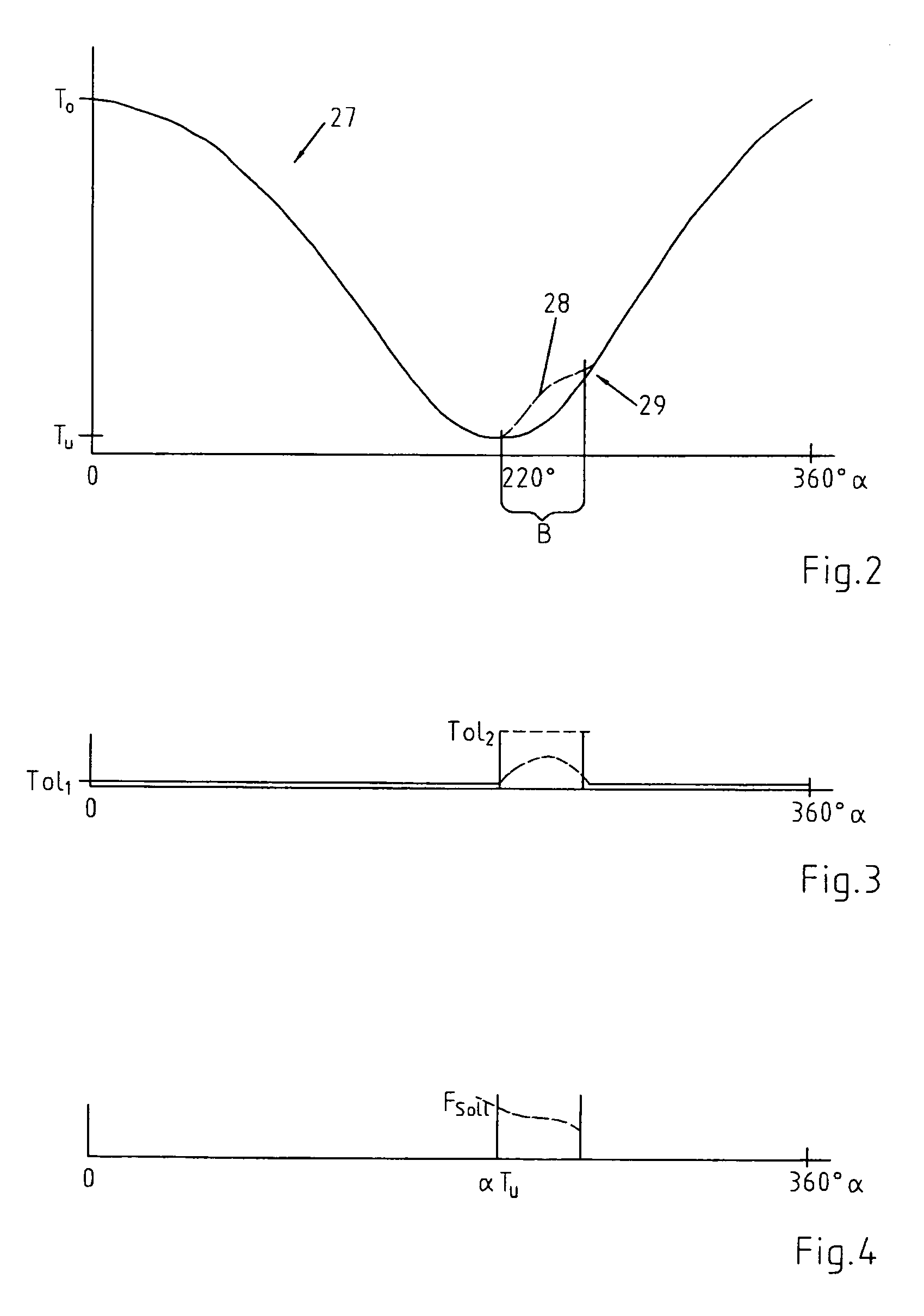

Plunger drive with load profile adaptation

InactiveUS9114583B2Reduction of the effective torqueReduce heat loadPress ramServo pressLoad profile

A method of operating a servo press and apparatus therefore, including a press plunger and a servo drive and such a press, the press plunger is operated in accordance with a predetermined guide angle / position-curve based on a guide angle α and the movement of the plunger is controlled in accordance with this curve with a tolerance which depends on the guide angle α.

Owner:SCHULER PRESSEN GMBH & CO KG

Rotor wing type toy plane stable in landing

The invention provides a rotor wing type toy plane stable in landing and relates to the field of toy planes. The rotor wing type toy plane stable in landing comprises a plane body and plane wings disposed on the plane body, fixing blocks are fixedly mounted at the bottom of the plane body, a buffering plate is disposed below the fixing blocks, and a load bearing block is fixedly mounted on the topof the buffering plate; connecting blocks are fixedly mounted on both sides of the top of the load bearing block, the tops of the connecting blocks are welded to the bottoms of pressing rods, and thetops of the pressing rods penetrate through the fixing blocks and extend into inner cavities of the fixing blocks. The fixing blocks are arranged, and partition plates, first lifting plates, second lifting plates are arranged in the fixing blocks for cooperating with hydraulic oil, so that the pressure generated during landing of the plane is buffered through the cooperation among the hydraulic oil, the first lifting plates and the second lifting plates, the reaction force of the ground to the plane during landing of the plane is counteracted, correspondingly landing of the plane is more stable, and the plane is protected from damage during landing.

Owner:杭州大晨显示技术有限公司

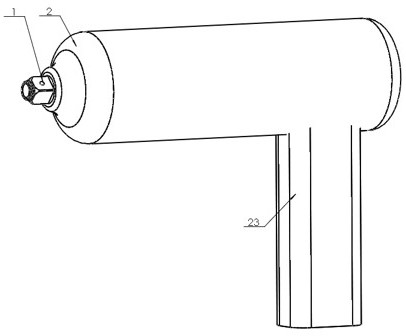

Recoil-free netting cleaning plate

InactiveCN111014099AReduce disturbanceSimple structureCleaning using toolsCleaning using liquidsStructural engineeringHigh pressure water

The invention provides a recoil-free netting cleaning plate. The plate comprises a watertight protective shell, wherein a nozzle is arranged at the front end of the watertight protective shell, the nozzle is connected with a main body pipeline, an air inlet and a water inlet are formed in the end, close to the nozzle, of the main body pipeline, a piston is arranged inside the end, far away from the nozzle, of the main body pipeline, and a spring is arranged at the rear part of the piston. According to the cleaning plate, a recoil eliminating part is arranged, huge disturbance caused by cavitation jet flow is eliminated, meanwhile, the working mode that high-pressure water and a cleaning brush are adopted for netting cleaning at the same time is adopted, and the precision and the cleaning efficiency of the cleaning plate are greatly improved, and the cleaning plate is simple in structure and free of recoil.

Owner:HARBIN ENG UNIV

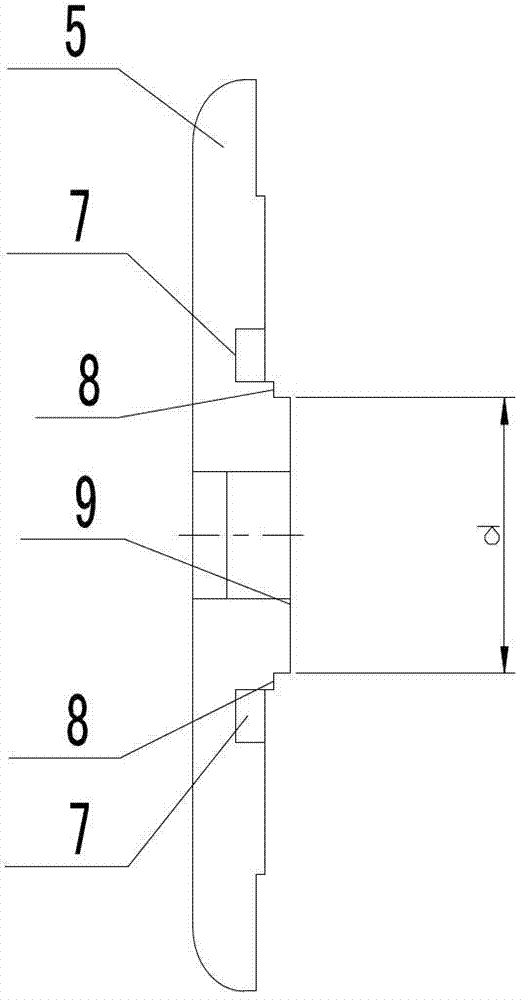

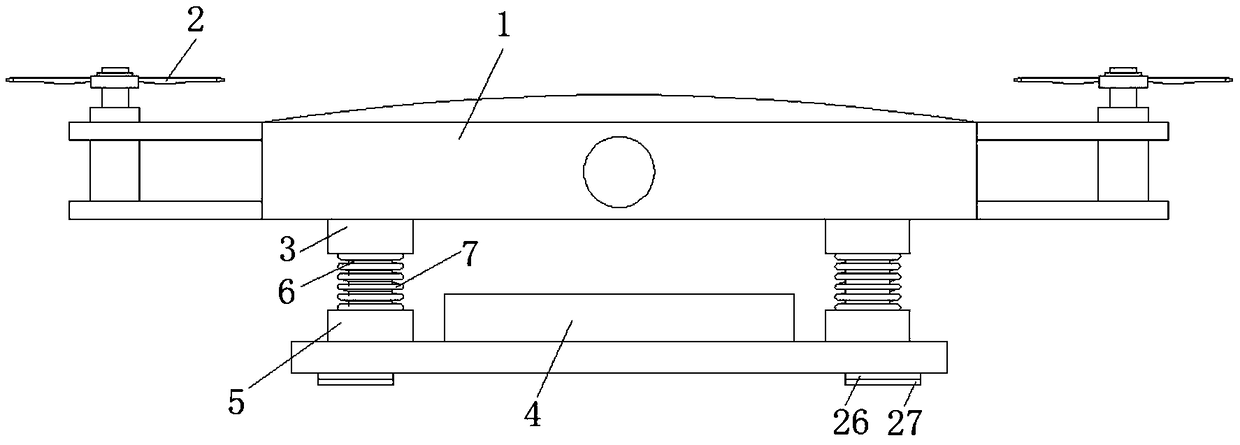

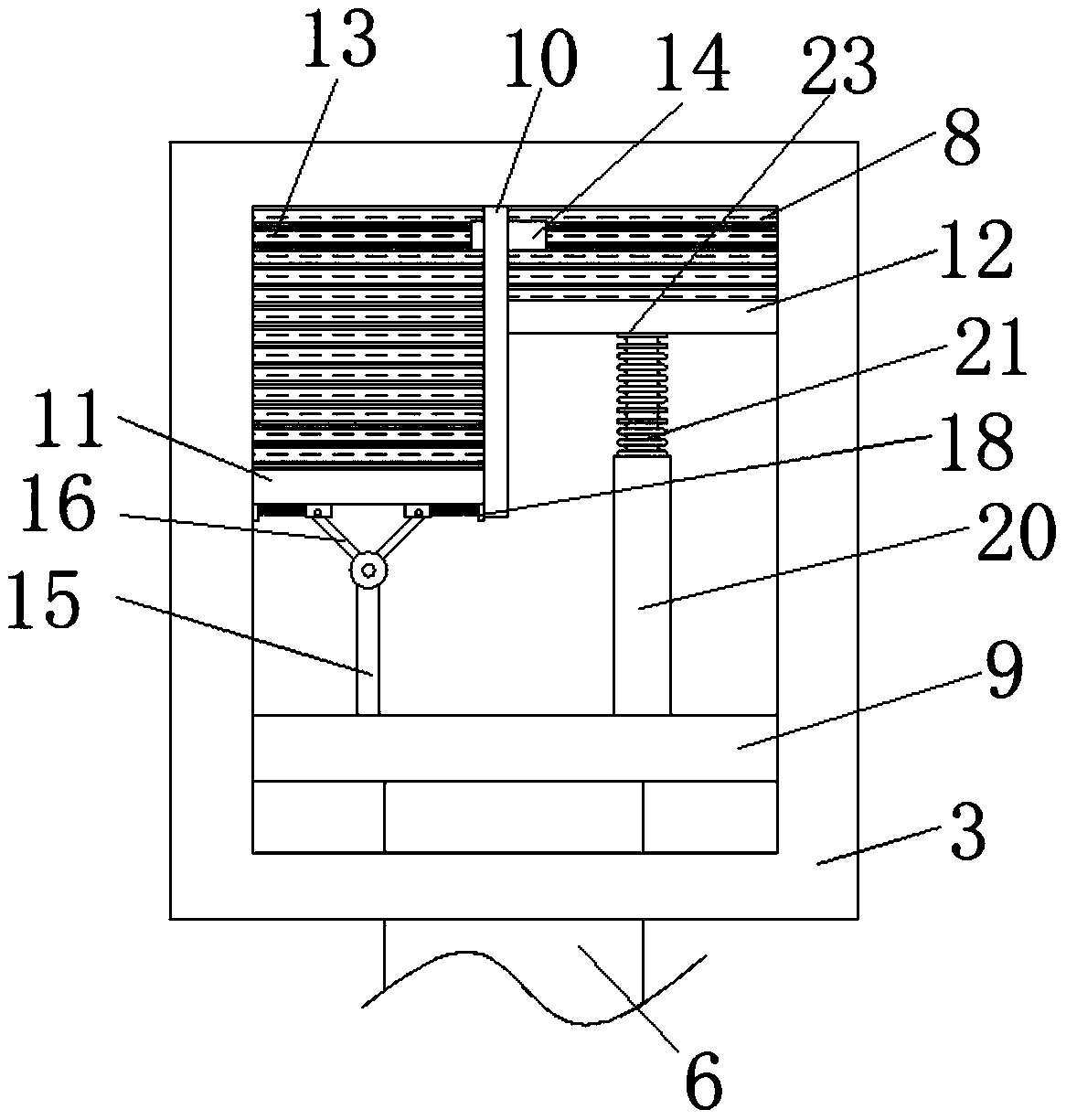

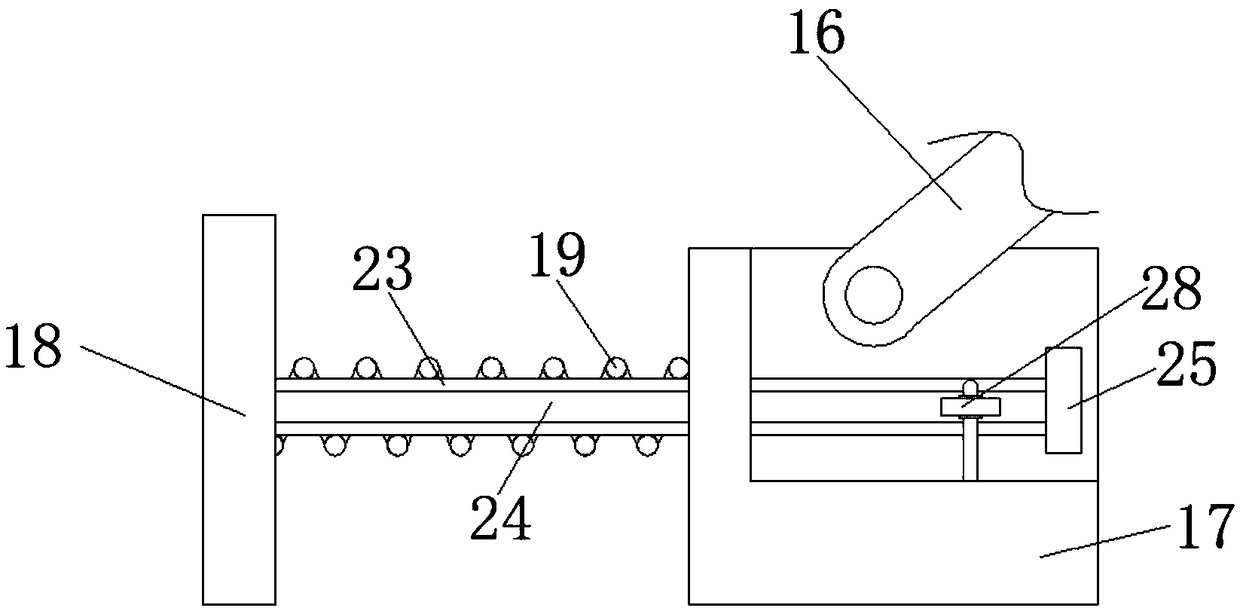

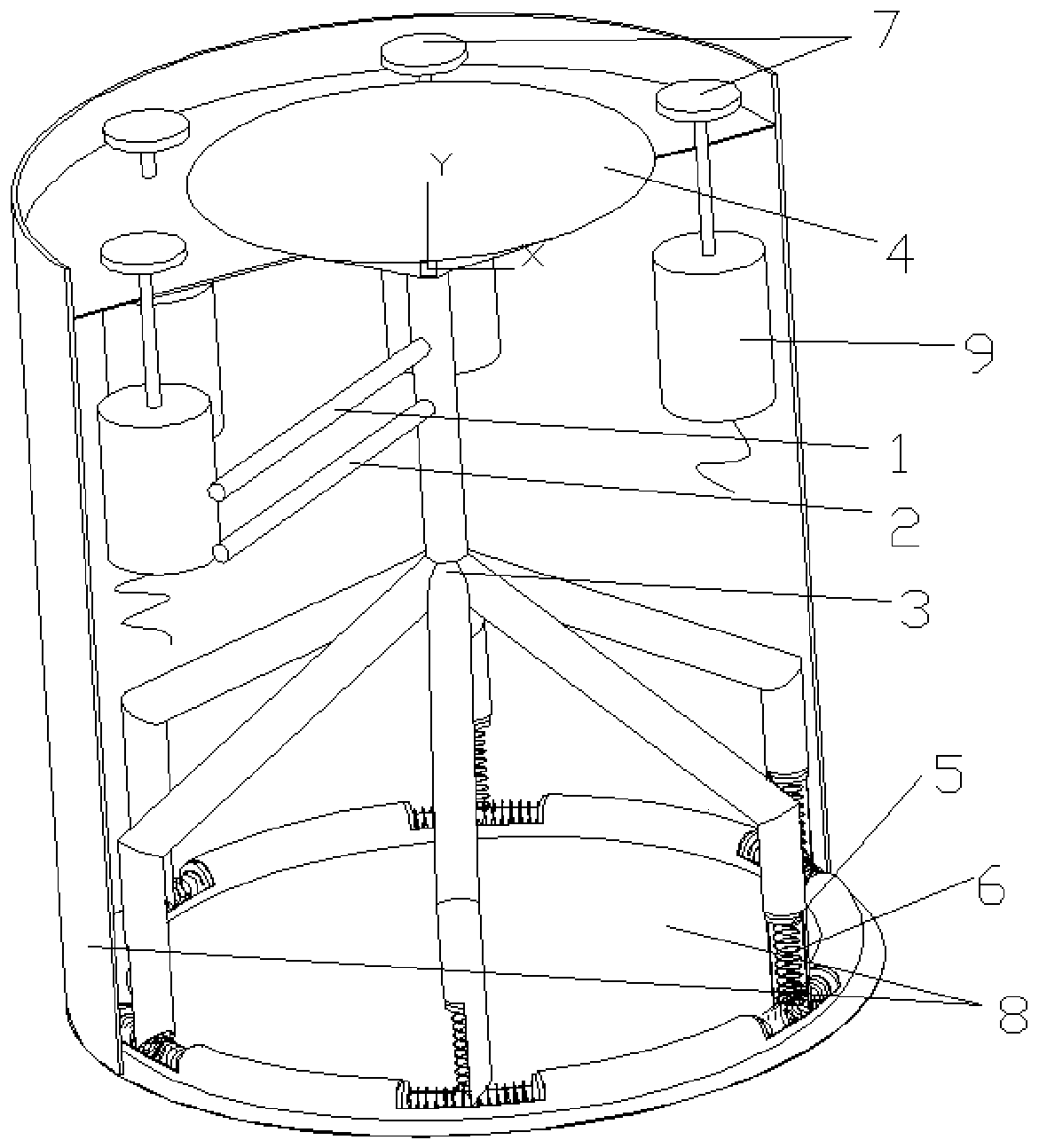

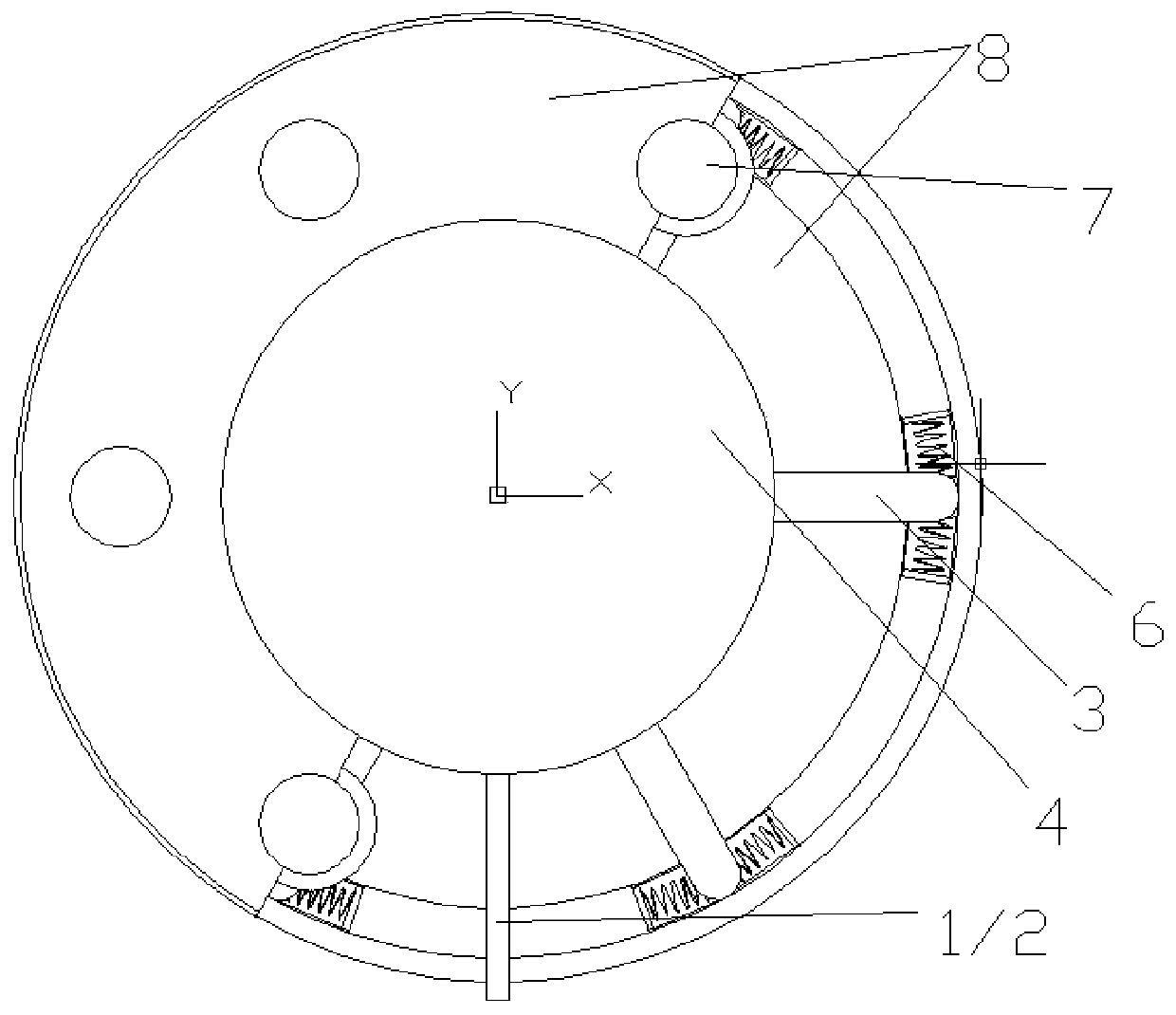

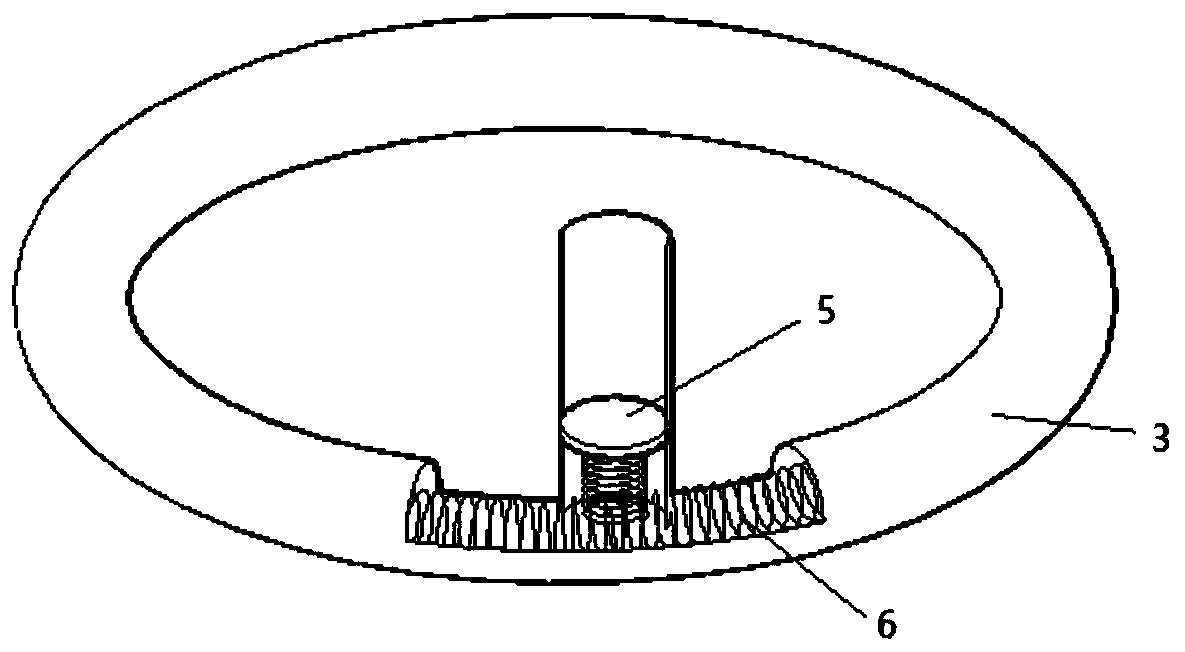

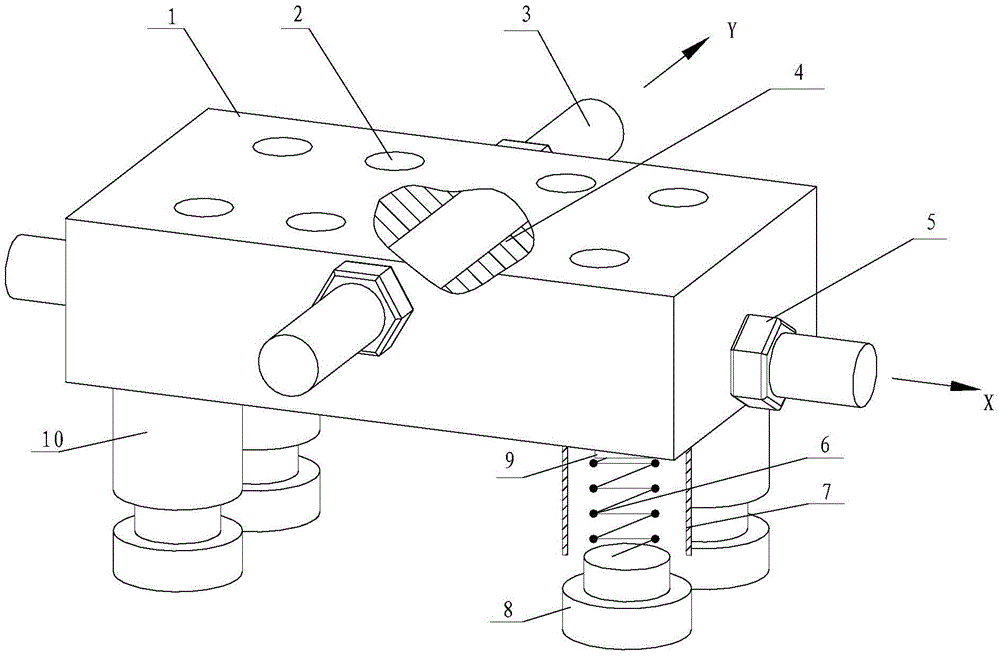

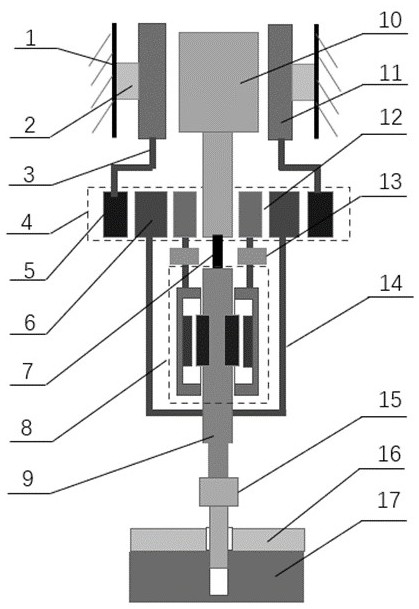

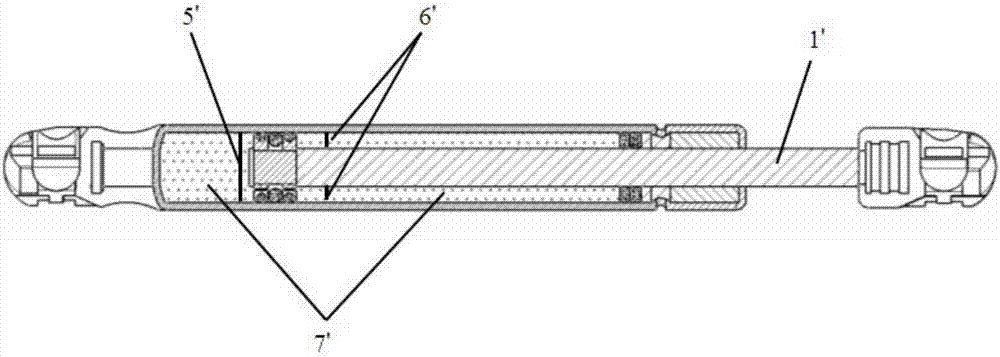

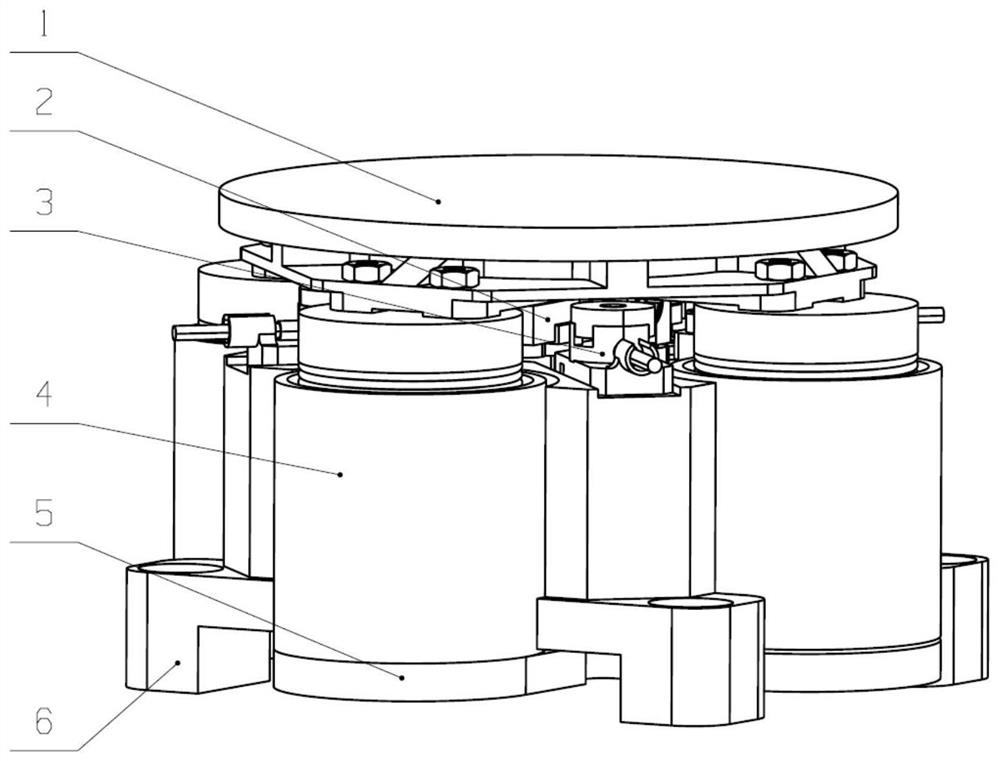

A shock-absorbing tool for durability test

ActiveCN103969013BEliminate shockEliminate reaction forceMachine part testingVibration testingShock testMechanical engineering

The invention discloses an endurance test shock absorption tool which comprises an installation flat plate (1) and suspension column feet (10). Two side faces of the installation flat plate (1) are provided with through holes (4) respectively in the X direction and the Y direction. The through holes (4) vertically intersect to be of a crossed structure. Two balance screw rods (3) are arranged in the through holes (4) respectively. Locking nuts (5) are arranged at the two ends of each balance screw rod (3) respectively, the suspension column feet (10) are arranged at the four corners of the installation flat plate (1), and each suspension column foot (10) is composed of a pagoda-shaped spring (6), a sheath (7), a spring bottom seat (8) and a spring upper seat (9). The sheaths (7) are arranged outside the pagoda-shaped springs (6), the spring bottom seats (8) are arranged at the lower ends of the pagoda-shaped springs (6), and the spring upper seats (9) are arranged at the upper ends of the pagoda-shaped springs (6). The spring upper seats (9) are connected with the installation flat plate (1) which is provided with installation fixing screw holes (2). The endurance test shock absorption tool enables the center of gravity of an irregular structure to shift, and the irregular structure is balanced by adjusting the balance screw rod in the X direction and the balance screw rod in the Y direction, certain impact force and reaction force of the endurance test shock absorption tool body on a work table board can be eliminated, and the endurance test shock absorption tool is simple in structure, durable, and low in manufacturing cost.

Owner:WUXI LONGSHENG TECH

Torque wrench with very low reactive force to operator

ActiveCN111791173AEliminate reaction forceReduce work intensityPower driven toolsPower switchingTorque transmission

The invention discloses a torque wrench with very low reactive force to an operator. The torque wrench includes a power assembly, a transmission assembly, and an output assembly. When the wrench is used, partial threads of a bolt (15) are screwed into a threaded hole of a base (17), the bottom of an output (9) is fabricated with the bolt (15), then a power source switch is opened and the tightening operation is carried out, when a torque sensor monitors that an output torque value is basically stable, maximum output torque is achieved, and power source is broken and the tightening is finished.A wrench outer shell (1) is separated from the whole system of torque transfer when the wrench works so that the operator does not need to be subjected to the reactive force. The torque wrench has the beneficial effects that the reactive force to the operator is basically zero in the working process, the labor intensity can be greatly reduced, the requirement of human engineering can be met, thedevelopment process of unmanned, intelligent, and robotized torque wrench can be accelerated, and high use value can be achieved.

Owner:SICHUAN UNIV

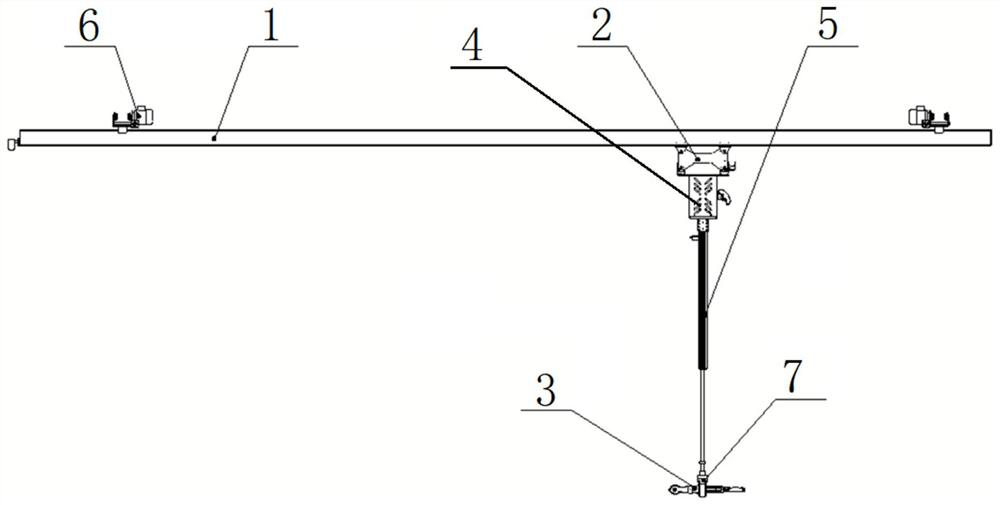

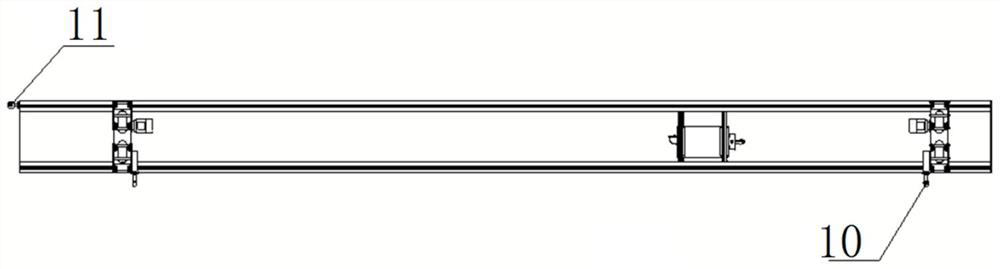

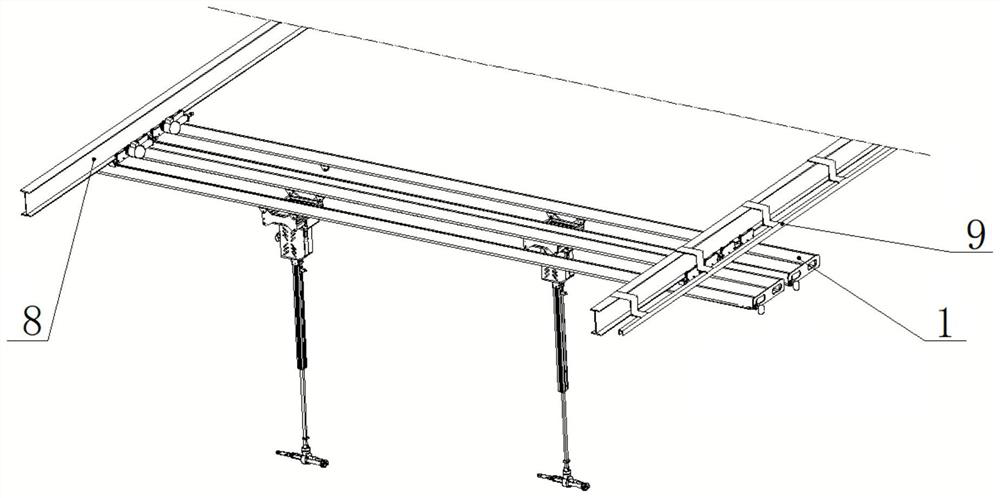

Electric truss type intelligent assembly workstation

PendingCN112809357ALightweight and flexibleGood orientationMetal working apparatusMotor driveElectrical control

The invention provides an electric truss type intelligent assembly workstation. The electric truss type intelligent assembly workstation comprises a plurality of KBK suspension beams, a plurality of movable tackles, a plurality of wired electric servo torque wrenches and a plurality of rectangular pipe anti-torque assisting arms. The movable tackles are arranged on the KBK suspension beams, each rectangular pipe anti-torque assisting arm comprises a spring balancer arranged on the corresponding movable tackle and a rectangular pipe counter-force arm arranged on the spring balancer, the wired electric servo torque wrenches are arranged at one end of the rectangular pipe counter-force arms, and motor driving assemblies are arranged at the two ends of the KBK suspension beams. The motor driving assemblies are selected from gear motors. According to the electric truss type intelligent assembly work station, the motor driving assemblies are adopted, the work station moves flexibly and conveniently, the work station and a crown block share a rail in the actual operation process, interference can be effectively avoided through electrical control, effective avoiding can be achieved through two-side movement, the utilization rate of an on-site rail is high, and placement of equipment below is not affected.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

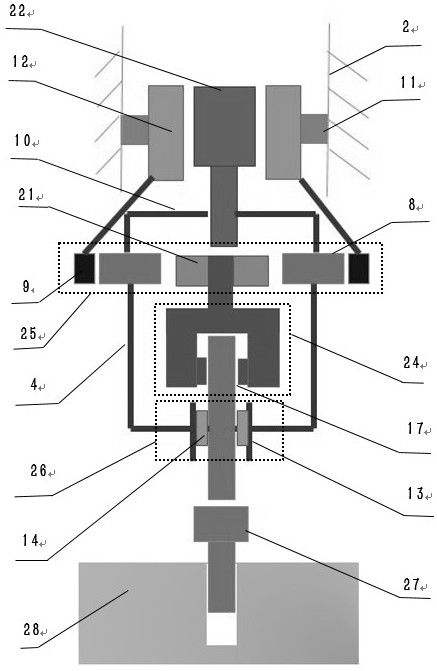

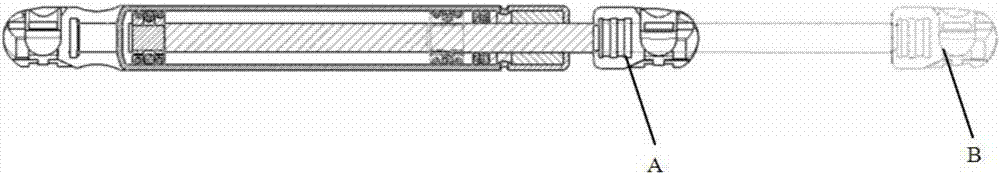

Torque wrench with extremely low counter-acting force to operator

The invention discloses a torque wrench with an extremely low counter-acting force to an operator. The torque wrench comprises a power assembly, a transmission assembly and an output assembly. Duringuse, a part of thread of a screw (27) is screwed into a threaded hole of a workpiece (28), the wrench and a bolt (15) are assembled, and then a power supply switch is turned on to start a fastening operation. By separating a wrench housing (2) from a whole system of torque transfer, the operator needs not to bear the counter-acting force. The torque wrench has the beneficial effects that in the working process, the counter-acting force to the operator is substantially zero, so that the labor intensity can be reduced greatly; the demand of human engineering is met; the unmanned, intelligent, robotized development progress of the torque wrench is accelerated; and the torque wrench is of very high use value.

Owner:SICHUAN UNIV

Torque wrench with extremely low reaction force to operator

ActiveCN111791172AEliminate reaction forceReduce work intensityPower driven toolsPower switchingTorque transmission

The invention discloses a torque wrench with extremely low reaction force to an operator. The torque wrench comprises a power assembly, a transmission assembly and an output assembly, when the torquewrench is used, firstly, a part of threads of a bolt (15) are screwed into a threaded hole of a base (17), the bottom of an output shaft (9) is assembled with the bolt (15), then a power switch is turned on, tightening operation is started, when a torque sensor monitors that the output torque value is basically stable and reaches the maximum output torque, the power supply is cut off, and tightening is finished; and a wrench shell (1) is separated from the whole torque transmission system, so that the operator does not need to bear counter-acting force. The torque wrench has the beneficial effects that the reactive force on an operator in the working process is basically zero, the labor intensity can be greatly reduced, the requirement of human engineering is met, the unmanned, intelligentand robotic development process of the torque wrench is accelerated, and the torque wrench has very high use value.

Owner:SICHUAN UNIV

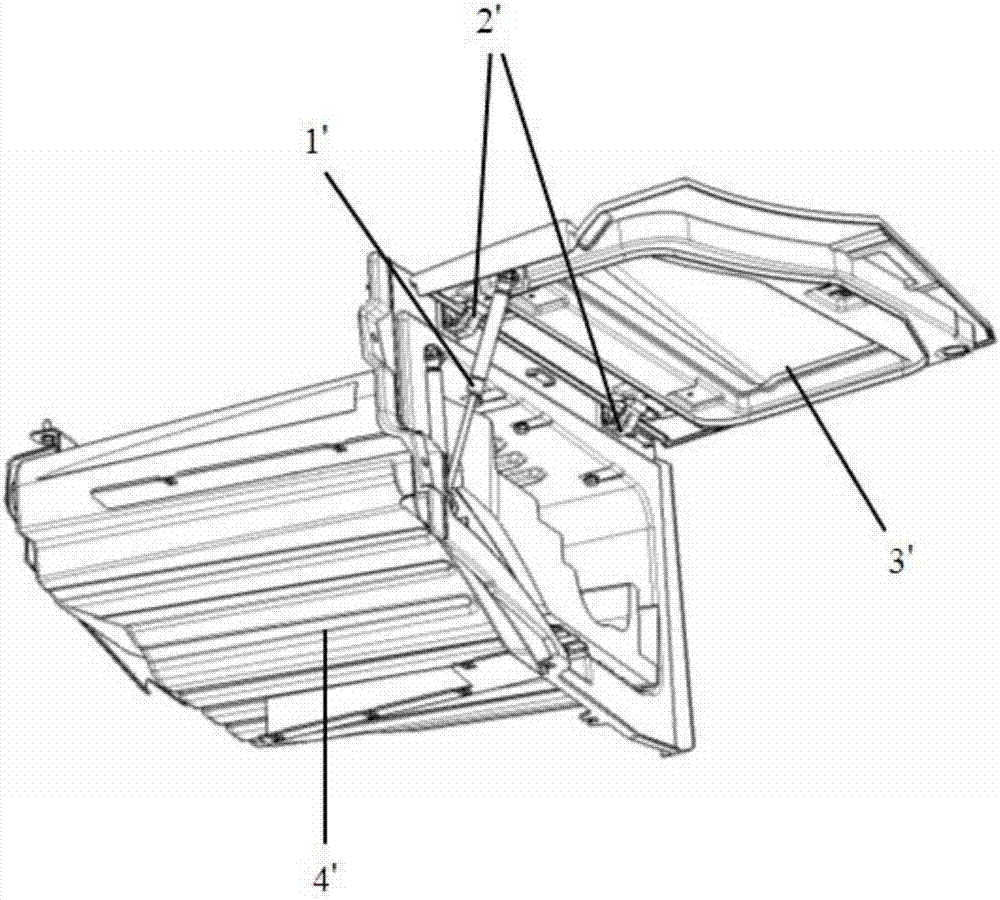

Light door opening and supporting mechanism

InactiveCN107339033AEliminate reaction forceEliminate the effects ofWing fastenersConvex structureElastic component

The invention provides a light-duty door opening support mechanism, comprising: a pipe body, an elastic component fixed on the wall of the pipe body, and a limit shaft located in the pipe body, the second end of the limit shaft is composed of an extrusion section, a limit The extruding section is a ring-shaped convex structure, and its outer diameter and the outer diameter of the matching section are larger than the outer diameter of the limiting section; the spring is arranged in the elastic box and blocked by the limiting head. Those constitute elastic components. When opening, the limit shaft moves forward under the opening force of the light door. When the limit head passes through the extrusion section and snaps into the limit section, the limit shaft stops moving to realize the limit of the light door. Compared with the prior art, the present invention cancels the high-pressure working gas, reduces energy consumption and production cost, eliminates the influence of ambient temperature on the opening support function, and the reaction force received by the light-duty door in the closed state, and at the same time reduces the The limitation of installation layout improves the versatility.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Nut screwing device

PendingCN108098666AEliminate reaction forceGuarantee the safety of useSpannersWrenchesControl theoryTorque wrench

The invention relates to a nut screwing device. The nut screwing device comprises a base, an anchor bolt, a nut wrench, a connecting rod, a torque multiplier and a dial type torque wrench, wherein the base 2 is fixed to the ground by virtue of the anchor bolt, a part is fixedly installed on the base, the torque multiplier is arranged just on the upper part of a to-be-disassembled nut and is fixedto the base by virtue of an anti-rotation plate, a vertical plate and a lower transverse plate, the moment input end of the torque multiplier is connected with the dial type torque wrench, the momentoutput end of the torque multiplier is fixedly connected with the nut wrench by virtue of the connecting rod, and the nut wrench is matched with the to-be-disassembled nut. According to the nut screwing device, the large-moment and large-diameter nut can be screwed and disassembled by adopting small moment and small space, the use safety is guaranteed, the unnecessary cost loss caused by repair or replacement of a new product is reduced, and the production cycle is shortened.

Owner:HARBIN DONGAN ENGINE GRP

Electric power engineering surveying device

ActiveCN112096279AImprove excavation efficiencyReduce labor consumptionDerricks/mastsBorehole/well accessoriesPower engineeringMechanical engineering

The invention relates to an electric power engineering surveying device. The electric power engineering surveying device comprises a supporting plate, wherein a plurality of soil digging mechanisms are arranged on the lower side of the supporting plate; each soil digging mechanism comprises a soil digging roller which is rotatably connected to the supporting plate; each soil digging roller is parallel to the horizontal plane; a spiral soil digging sheet is arranged on the peripheral surface of each soil digging roller; a driving mechanism for driving the soil digging rollers to rotate is arranged on the supporting plate; and a plurality of soil digging positioning mechanisms for fixing the supporting plate are arranged on the supporting plate. The electric power engineering surveying device has the effects of improving the digging efficiency of pit exploration and reducing labor consumption of workers.

Owner:北京国电天瑞工程勘测设计有限公司

Reactive-force-free fast reflecting mirror based on flexible support

PendingCN114578504ASatisfy the degree of freedom requirementNo friction effectMountingsSolar thermal energy generationPlane mirrorEngineering

The invention belongs to the field of fast reflectors, and discloses a flexible support-based reaction-force-free fast reflector, which comprises a plane reflector assembly, a flexible support assembly, a sensor assembly, an actuator, a reaction plate and a base, the flexible support assembly comprises an upper flexible support and a lower flexible support, and the plane mirror assembly is connected with the base through the upper flexible support; the reaction plate is connected with the other side of the base through a lower flexible support; the number of the sensor assemblies and the number of the actuators are both four, the sensor assemblies and the actuators are evenly distributed on the plane mirror assembly in a staggered mode, one ends of the sensor assemblies are connected with the plane mirror assembly, the other ends of the sensor assemblies are connected with the base, one ends of the actuators are connected with the plane mirror assembly, and the other ends of the actuators are connected with the reaction plate. According to the fast reflecting mirror, the counter-acting force of the fast reflecting mirror is eliminated, the influence of the motion of the fast reflecting mirror on the base is greatly reduced, and the performance of the whole system is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

c/z purlin interchange production line

Owner:HANGZHOU YIBO MACHINERY

Method for repairing shoe sole

The invention relates to a method for repairing a shoe sole. The method comprises the following steps: judging if adding a waterproof stage to the bottom of a sole area on an original shoe sole; polishing a high-front and low-rear circular arc on a front 1 / 3 part of the sole area of the shoe sole or the newly added waterproof stage, wherein the difference of front and rear height of the bottom of the front 1 / 3 part of the sole area of the shoe sole is 2cm-3cm; polishing inner side thinner than outer side on the 2 / 3 part of the sole area of the shoe sole or the newly added waterproof stage, wherein the inner side is 1mm-3mm thinner than the outer side; polishing a groove from front to rear on the middle part of rear 2 / 3 part of the sole area of the shoe sole or the newly added waterproof stage, wherein the groove depth is 0.5mm-1mm; and polishing the groove from left to right on a sole acting point corresponding to the rear 2 / 3 part of the sole area of the shoe sole or the newly added waterproof stage, wherein the groove depth is 0.1mm-0.2mm. The shoe sole can guarantee smooth blood circulation of sole, can relieve the fatigue and pain of the foot and can protect the foot sole from blistering under the effect of ultrahigh friction and stress and even from ankle sprain phenomenon; the shoe is difficult to be worn; and the service life of the shoe is prolonged.

Owner:刘井元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com