Recoil-free netting cleaning plate

A technology for cleaning discs and recoil, applied to cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of low cleaning efficiency, difficult and unfavorable positioning of cleaning discs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples describe the present invention in more detail.

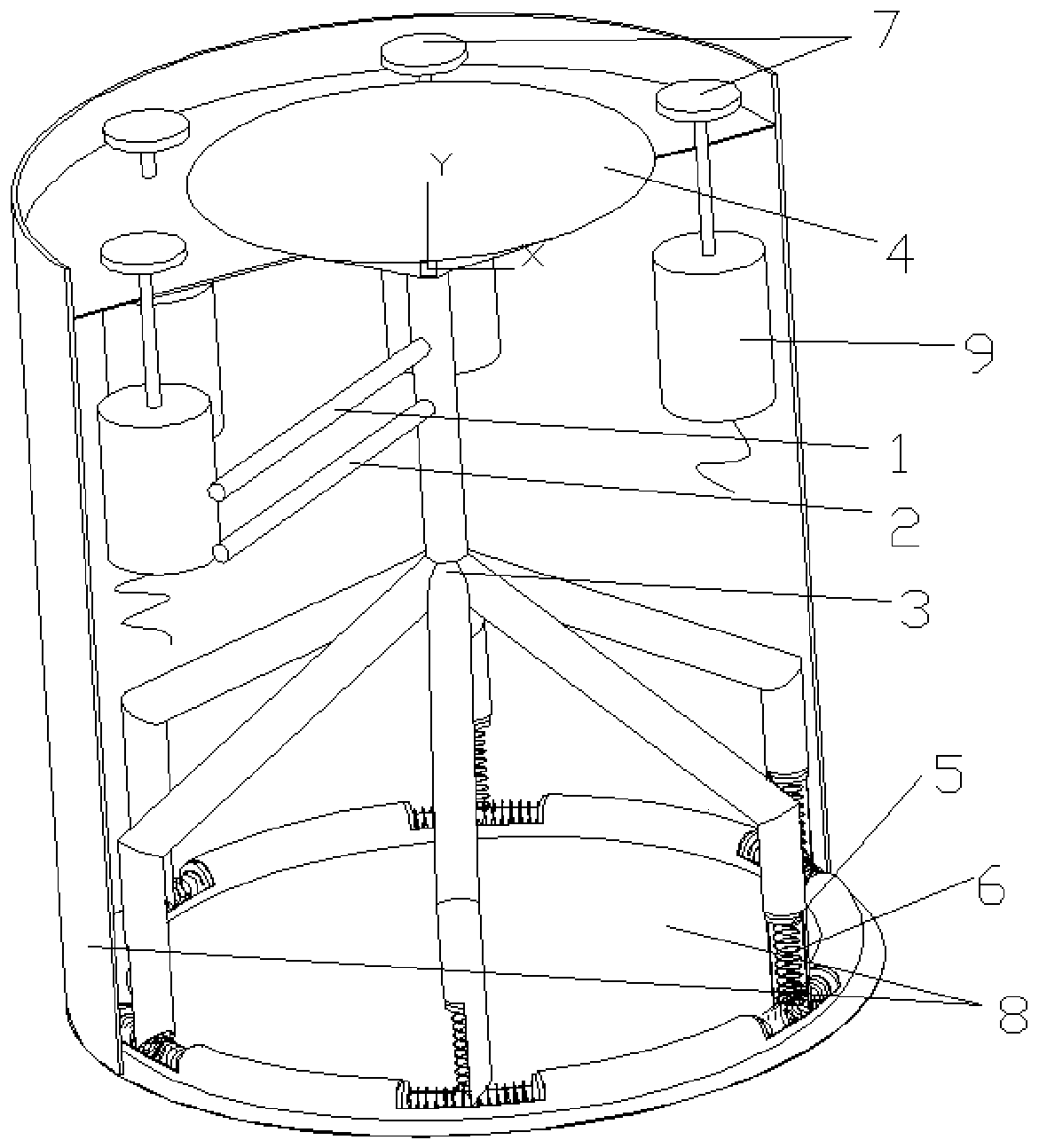

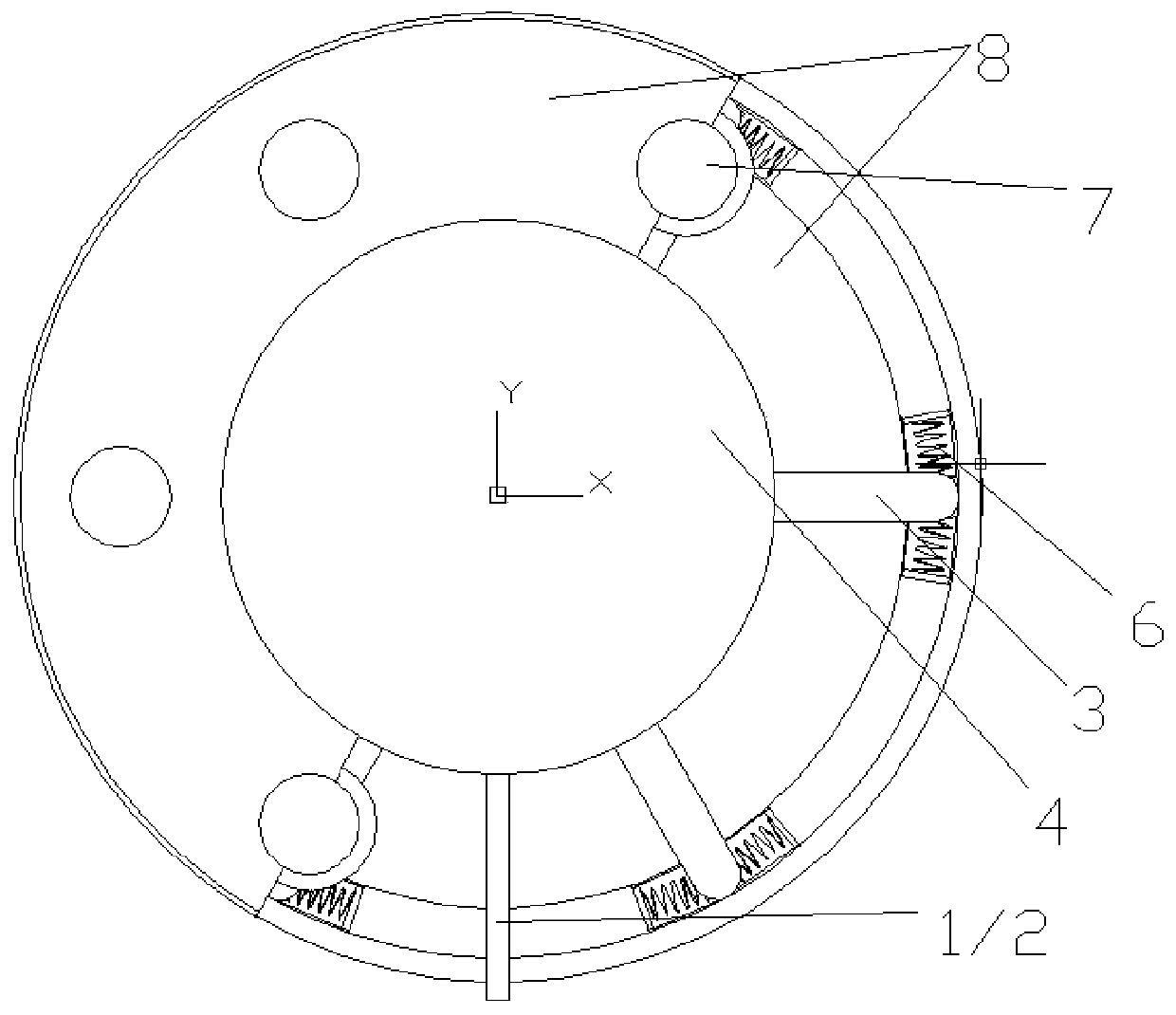

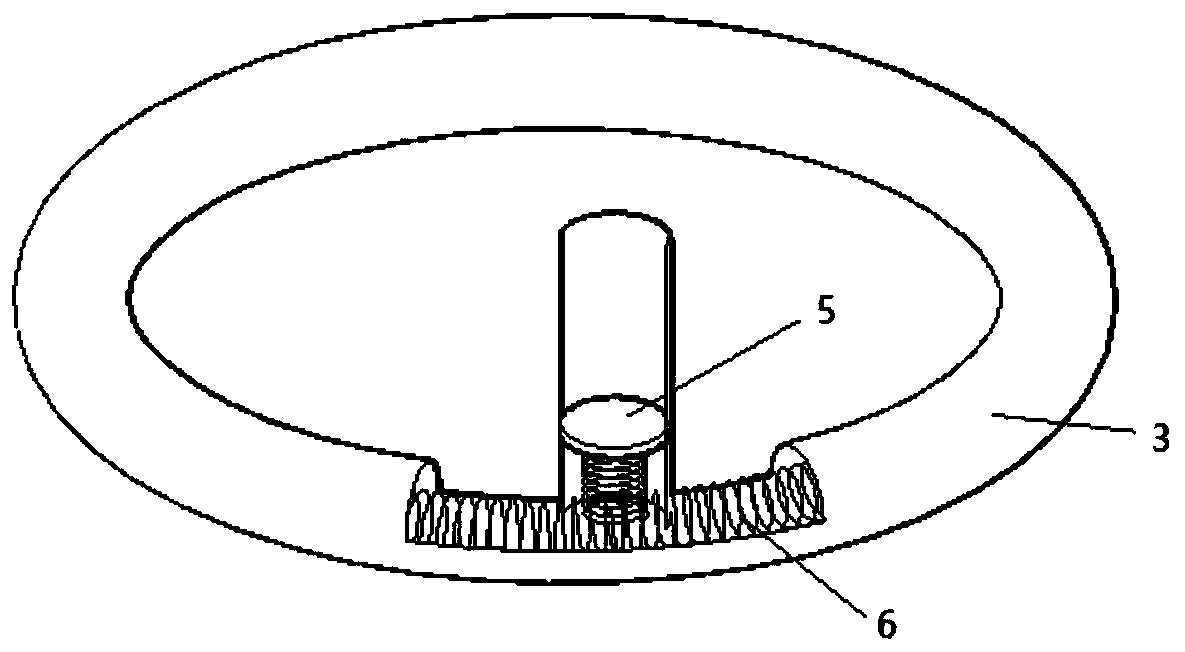

[0018] combine Figure 1-Figure 3 , The first embodiment of the recoilless net clothes cleaning tray of the present invention includes a watertight protective shell 8, a nozzle 7 is arranged at the front end of the watertight protective shell, the nozzle is connected to the main pipeline 3, and an air inlet 1 is arranged at the end of the main pipeline near the nozzle With the water inlet 2, a piston 5 is arranged inside the end of the main pipeline away from the nozzle, and a spring 6 is arranged at the rear of the piston.

[0019] On the basis of the first embodiment, the second embodiment of the present invention improves the main pipeline. The end of the main pipeline close to the nozzle is a straight pipe, and the end of the main pipeline away from the nozzle includes an annular pipe and 3-8 (optimally 6) connecting pipes, each connecting pipe is connected to the straight pipe Between the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com