Solid 3D printing system for space component in-orbit manufacturing and repairing by using cold spraying and method

A 3D printing and cold spray technology, applied in the field of space 3D printing, can solve the problems of difficult repair of high-performance components, difficult to control molten pool behavior, and burning of alloying elements, so as to avoid throat wear, fine grains, and reduce burning. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

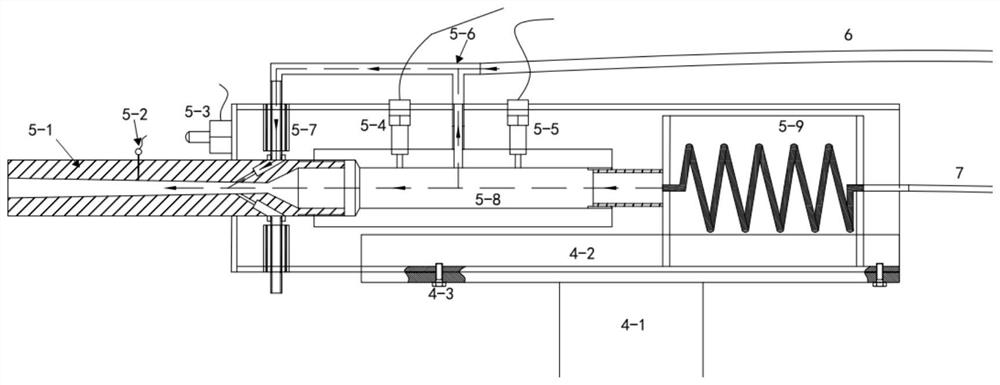

[0064] 3D printing pure Cu in space. Figure 5 Accelerated acceleration behavior of 5-20 μm Cu powder. Among them: the nozzle inlet diameter is 20mm, the throat diameter is 2.7mm, the outlet diameter is 5.7mm, the length of the straight section is 20mm, the length of the contraction section is 30mm, the length of the expansion section is 170mm, the angle of the powder feeding inlet is 45°, the confluence point is 20mm from the nozzle throat; the working gas It is hydrogen, the pressure is 3MPa, the temperature is 300K (room temperature); the powder feeding gas is also hydrogen, the pressure is 1.5MPa, the temperature is 300K (room temperature); the spraying powder is spherical Cu with a diameter of 5μm, 10μm, and 20μm, the spraying distance is 30mm, and the initial particle velocity 20m / s, initial temperature 300K. After being accelerated by the nozzle, the air velocity is up to 3200m / s, and there is an instantaneous drop at the exit position (at 0.17m), and then rises again....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com