Method for efficiently regenerating cast aluminum alloy by aluminum scraps

A high-efficiency regeneration technology for casting aluminum alloys, which is applied in the field of non-ferrous metal smelting, can solve problems such as weak adaptability of waste aluminum, poor quality of recycled aluminum, and low recovery rate of waste aluminum, so as to ensure quality stability, low cost, and reduce harmful The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

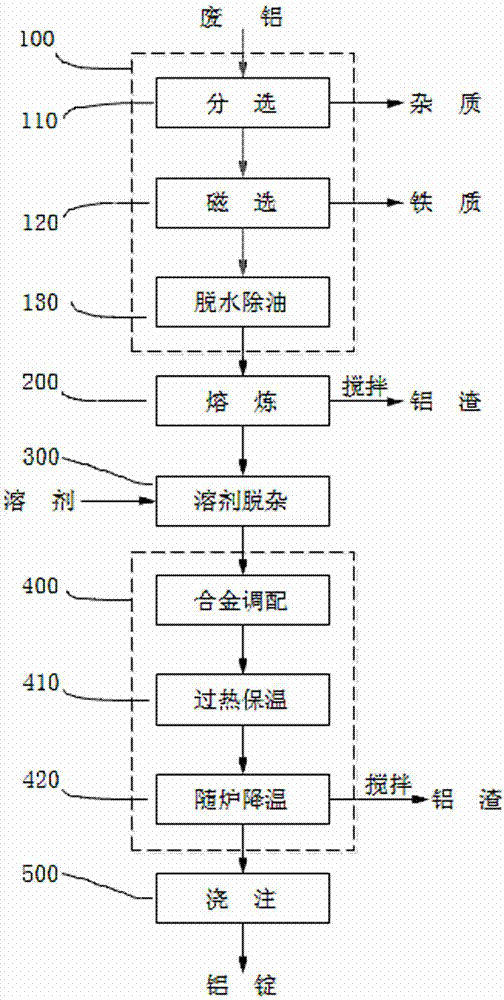

Image

Examples

Embodiment 1

[0036] Take 500kg of recycled aluminum chips, manually sort to remove impurities, remove iron filings by electromagnetic screening, bake at 200°C for 10 minutes, and then press to obtain prefabricated aluminum blocks; add prefabricated aluminum chips to a round top-opening aluminum melting furnace Heat to melt and mechanically stir evenly to remove unmelted impurities and scum on the surface; then add 1.35kg of NaCl and 1.65kg of KCl eutectic mixture as solvent; 50kg of Si and 4.5kg of Fe are evenly melted into the molten aluminum by electromagnetic stirring, then continue to heat the molten aluminum to 1000°C, keep the temperature for 1 hour, and then cool down with the furnace until the temperature of the molten aluminum is 740°C to remove floating slag; The molten aluminum comes out of the furnace and is poured into an aluminum ingot casting mold to obtain a recycled cast aluminum alloy ingot.

Embodiment 2

[0038]Take 300kg of recycled aluminum chips and 900kg of recycled miscellaneous aluminum blocks, manually sort to remove impurities, respectively remove iron filings through electromagnetic screening, and then bake at 300°C for 6 minutes before being released from the oven, and the aluminum chips are pressed to obtain prefabricated aluminum blocks; the prefabricated aluminum chips and The miscellaneous aluminum blocks are alternately put into the reverberatory furnace to heat and melt, and use permanent magnetic stirring to evenly remove unmelted impurities and scum on the surface; then add 1.6kg of NaCl, 1.85kg of KCl, and 0.15kg of NaCl 3 AlF 6 The mixture is used as a solvent; after the solvent is completely melted, when the temperature of the molten aluminum reaches 740°C, add 108kg of Si and 13kg of Fe, and use electromagnetic stirring to melt them evenly into the molten aluminum, then continue to heat the molten aluminum to 950°C, and then After heat preservation for 1.5...

Embodiment 3

[0040] Take 800kg of recycled miscellaneous aluminum, after mechanical crushing, manual sorting to remove impurities, and electromagnetic screening to remove iron filings, and then bake at 250°C for 12 minutes before being released from the furnace; add prefabricated miscellaneous aluminum into the reverberatory furnace to heat and melt, and use electromagnetic stirring to evenly , to remove unmelted impurities and scum on the surface; then add 0.3kg of graphite, 1.5kg of NaNO 3 , 1kg of NaCl and 1.2kg of refractory brick debris mixture as a solvent; after the solvent is completely melted, when the temperature of the molten aluminum reaches 700°C, add 80kg of Si and 6.4kg of Fe, and use electromagnetic stirring to make it evenly melt into the aluminum After melting, continue to heat the molten aluminum to 1030°C, keep the temperature for 0.8 hours, and then cool it down with the furnace until the temperature of the molten aluminum is 760°C to remove floating slag; the molten al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com