Patents

Literature

426results about How to "Excellent mold release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

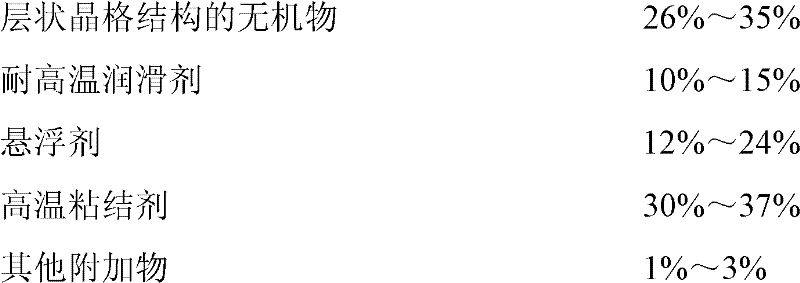

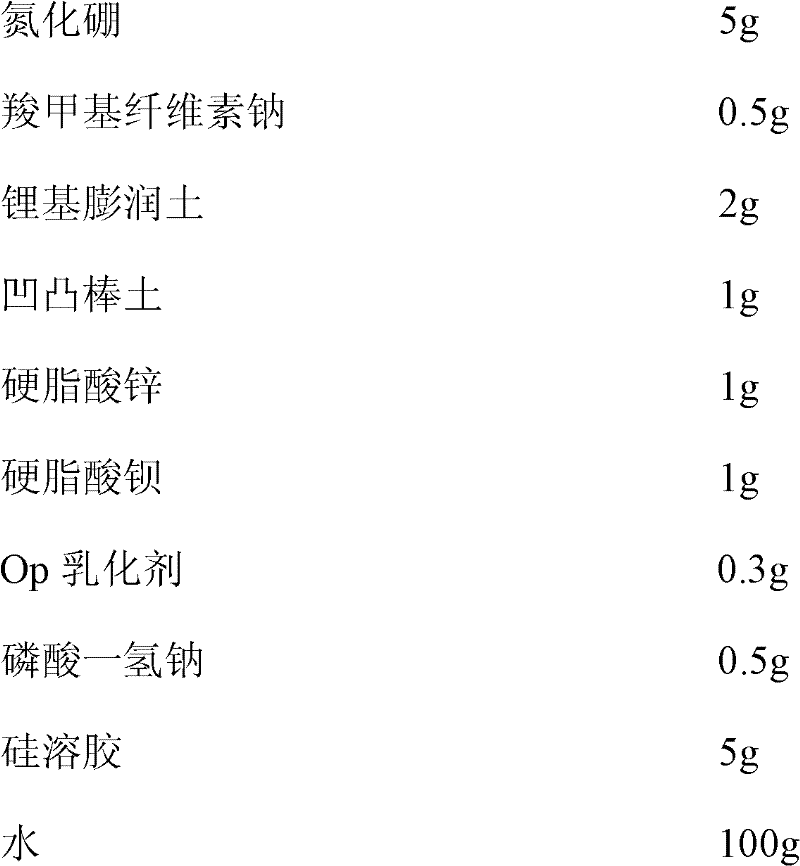

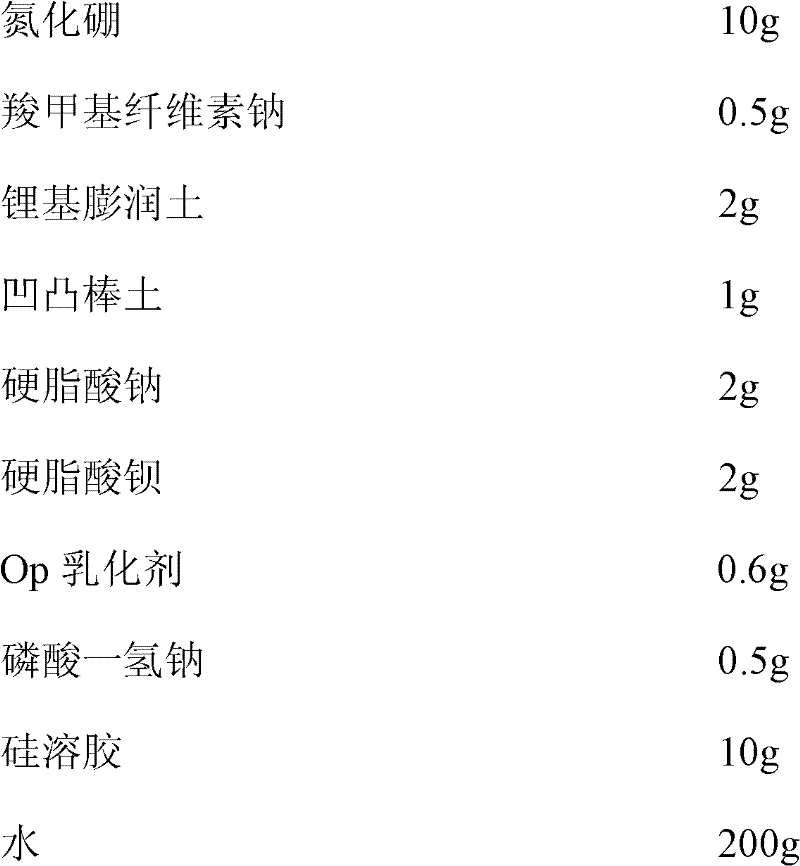

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Sugar-free bread and method for producing the same

The invention relates to a sugar-free bread, characterized by comprising the materials with the following components: high-gluten flour 150-900 parts, low-gluten flour 200-800 200-800 parts, water-free ghee 50-200 parts, sugar-free modifier 50-200 parts, sugar-free milk 10-150 parts, egg 50-10 parts, bread modifier 1-20 parts, yeast 10-20 parts, ghee 200-800 parts. The inventive technology avoids coldness or heat in fed materials contacted with yeast, causing the yeast to exert optimal fermentation ability. The prepared sugar-free nutritious bread is deeply favored by wide consumers.

Owner:天津金世制药有限公司

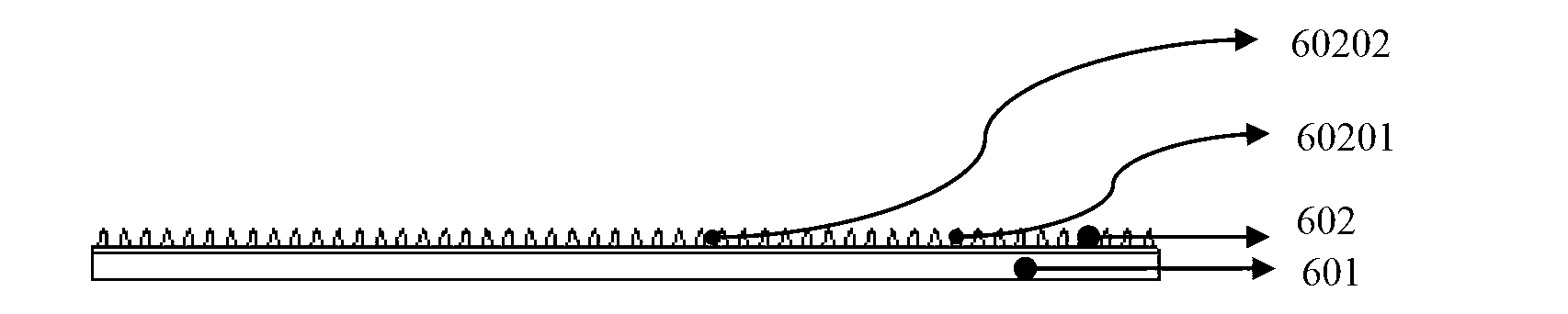

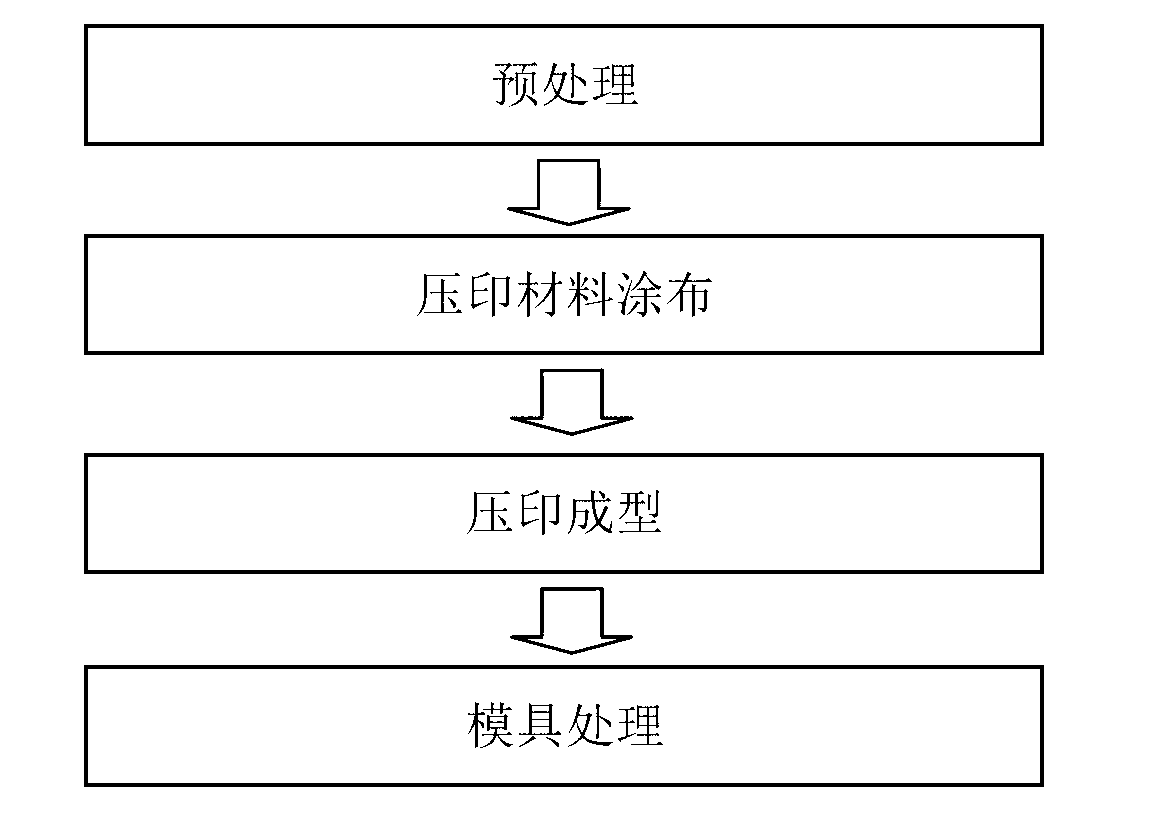

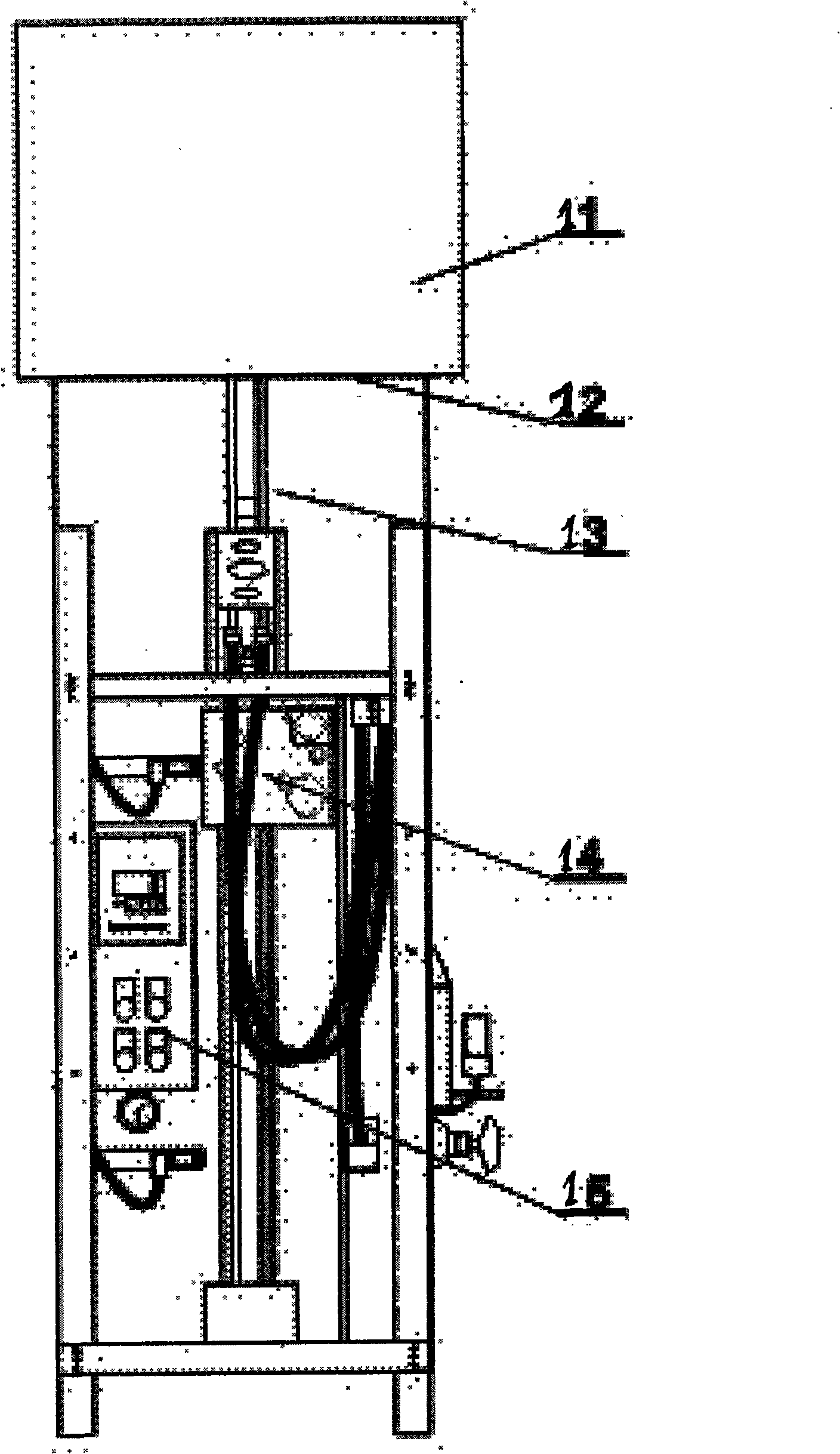

Large-area nanometer imaging device and large-area nanometer imaging method

ActiveCN103235483ASolution to short lifeEasy maintenanceDecorative surface effectsPhotomechanical apparatusUltravioletEngineering

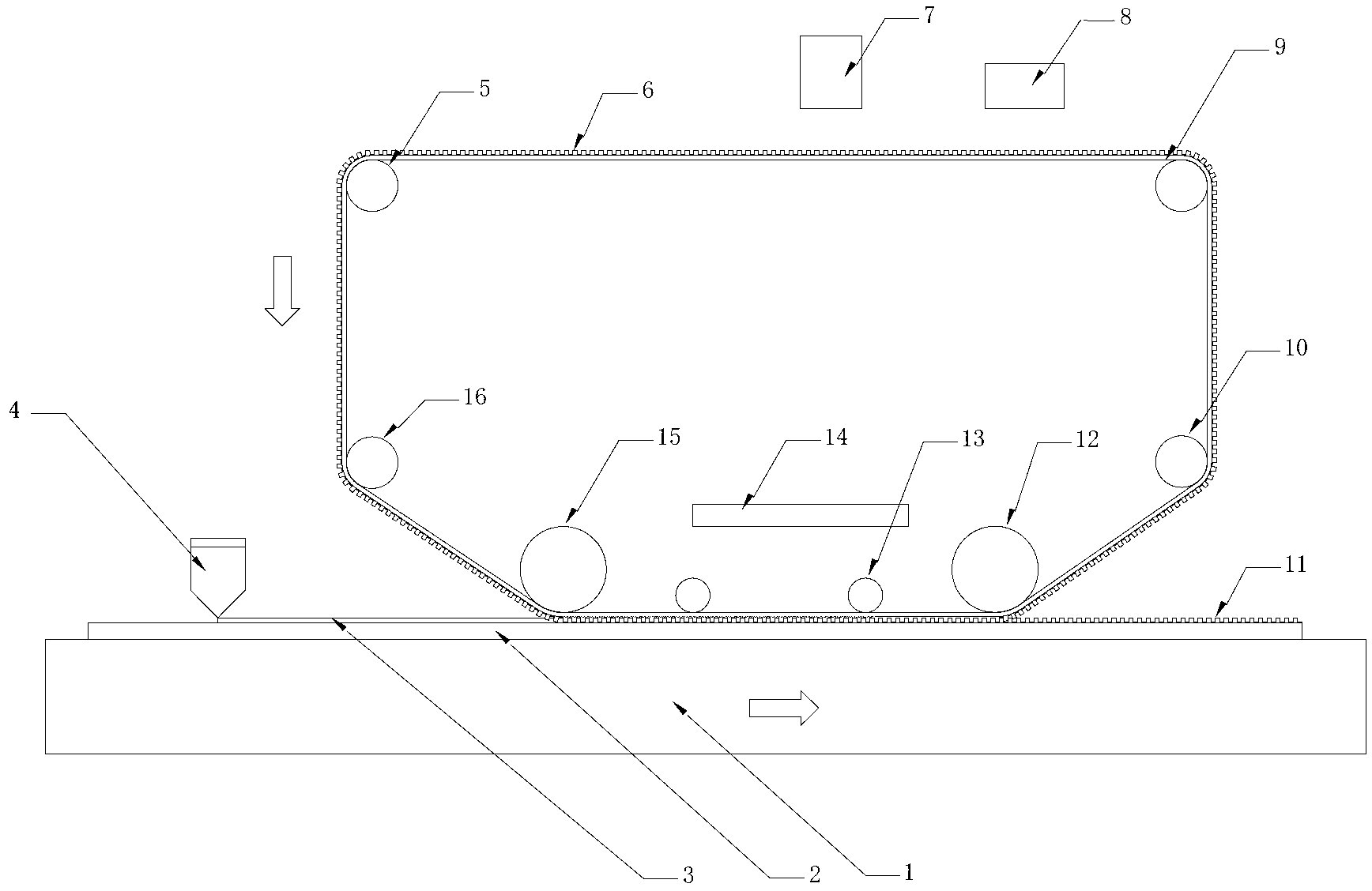

The invention discloses a large-area nanometer imaging device and a large-area nanometer imaging method. The device comprises a piece-supporting platform, a substrate, a coating device, mould feeding devices, a belt-shaped module, a release agent spraying device, a module cleaning device, an auxiliary impression device, an UV (Ultraviolet) solidifying device, an impression device and the like. The method for realizing large-area nanometer imaging based on the device comprises the following steps of: (1) pretreating; (2) coating an impression material; (3) performing impression molding; and (4) processing a mould. The large-area nanometer imaging device and the large-area nanometer imaging method, provided by the invention, have the advantages that a nanostructure on a non-smooth rigidity line with an oversized size is manufactured in an efficient and low-cost large-scale manner, an industrial-grade solution is provided for large-area nanometer imaging of a large-size rigidity substrate, and the large-area nanometer imaging device and the large-area nanometer imaging method are applied in industry large-scale manufacture such as high-performance glass, solar panels, panel displays, micro-optics devices and LEDs (light-emitting diodes).

Owner:QINGDAO BONA PHOTOELECTRIC EQUIP

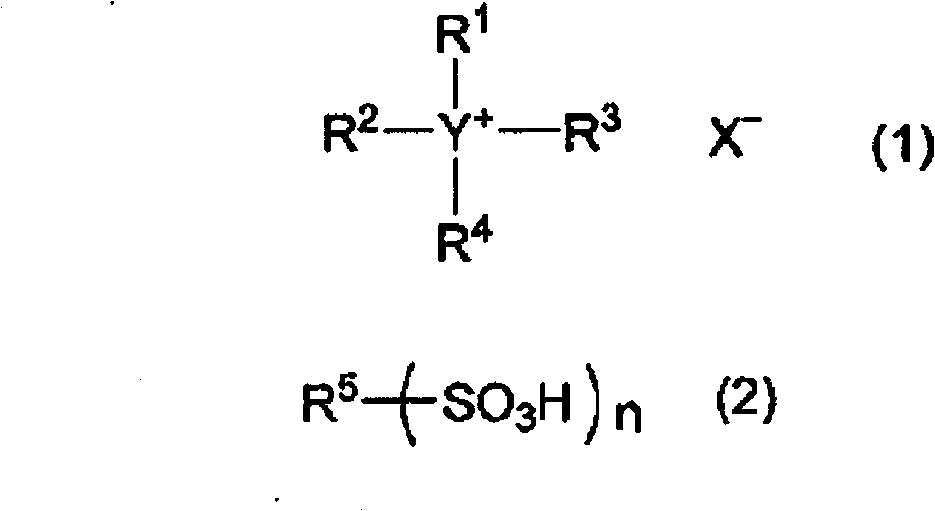

Aromatic polycarbonate resin composition and process for producing the same

InactiveCN101023134AImprove flame retardant performancePrevent molten drippingIon contentIon chromatography

A process of manufacturing the resin compositon and a method of preventing the melt dripping during combustion of the resin composition. The flame retardancy of the above aromatic polycarbonate resin composition comprising the fluorine-containing organic metal salt compound is improved. An aromatic polycarbonate resin composition containing a fluorinated organometal salt compound. The resin composition has improved flame retardancy. The resin composition comprises (1) 100 parts by weight of an aromatic polycarbonate resin (ingredient (A)), (2) 0.005-0.6 parts by weight of a fluorinated organometal salt (ingredient (B)) having a fluoride ion content as measured by ion chromatography of 0.2-20 ppm by weight, and (3) at least one ingredient selected from the group consisting of a flame retardant (ingredient (C)), fatty acid ester (ingredient (D)), ultraviolet absorber (ingredient (E)), polytetrafluoroethylene having fibril-forming ability (ingredient (F)), filler (ingredient (G)), silicate mineral (ingredient (H)), and titanium dioxide pigment (ingredient (I)). Also provided is a method of preventing a resin composition from melting / dripping upon combustion.

Owner:TEIJIN LTD

Fluorine-free aluminum zinc alloy water base release agent and preparation method thereof

InactiveCN102658351AProtection temperatureAdjustable temperatureFoundry mouldsFoundry coresWater basedSilicone oil

The invention discloses a fluorine-free aluminum zinc alloy water base release agent and a preparation method thereof, relates to a release agent, and provides the fluorine-free aluminum zinc alloy water base release agent which has the advantages of high dilution ratio, stable performance and superior release effect and the preparation method thereof. The fluorine-free aluminum zinc alloy water base release agent comprises the following raw materials: polyethylene wax, dimethyl silicone oil, hydroxyl silicone oil, a composite emulsifier, a sterilizing preservative and water. The fluorine-free aluminum zinc alloy water base release agent is prepared by the following steps of: uniformly stirring tween, sodium carboxylate, polyether nonionic surfactant and fatty alcohol in water; adding thepolyethylene wax, the dimethyl silicone oil, the hydroxyl silicone oil and the balance of water; heating to 60-80 DEG C; stirring at a constant temperature for 1-3 hours; then adding the sterilizing preservative; and uniformly stirring.

Owner:厦门汉旭硅材料科技有限公司

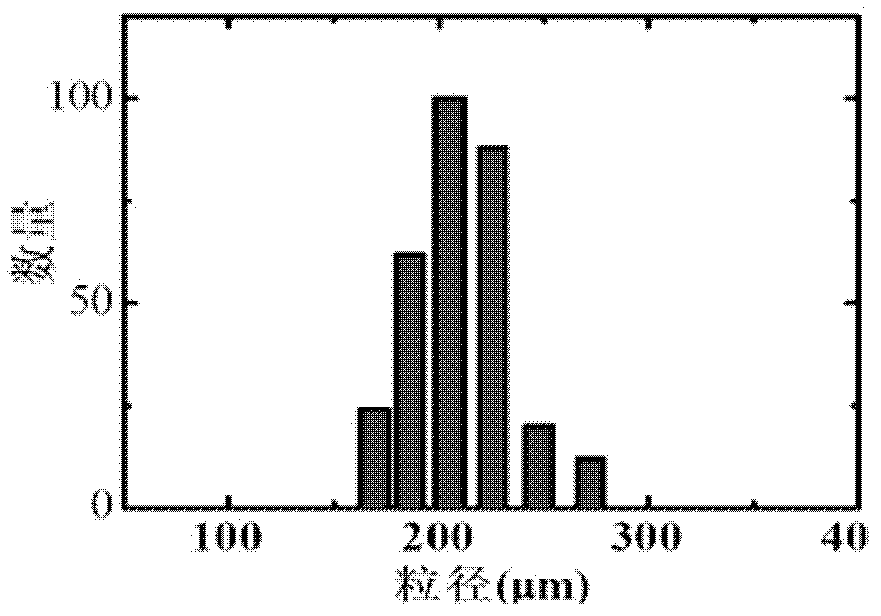

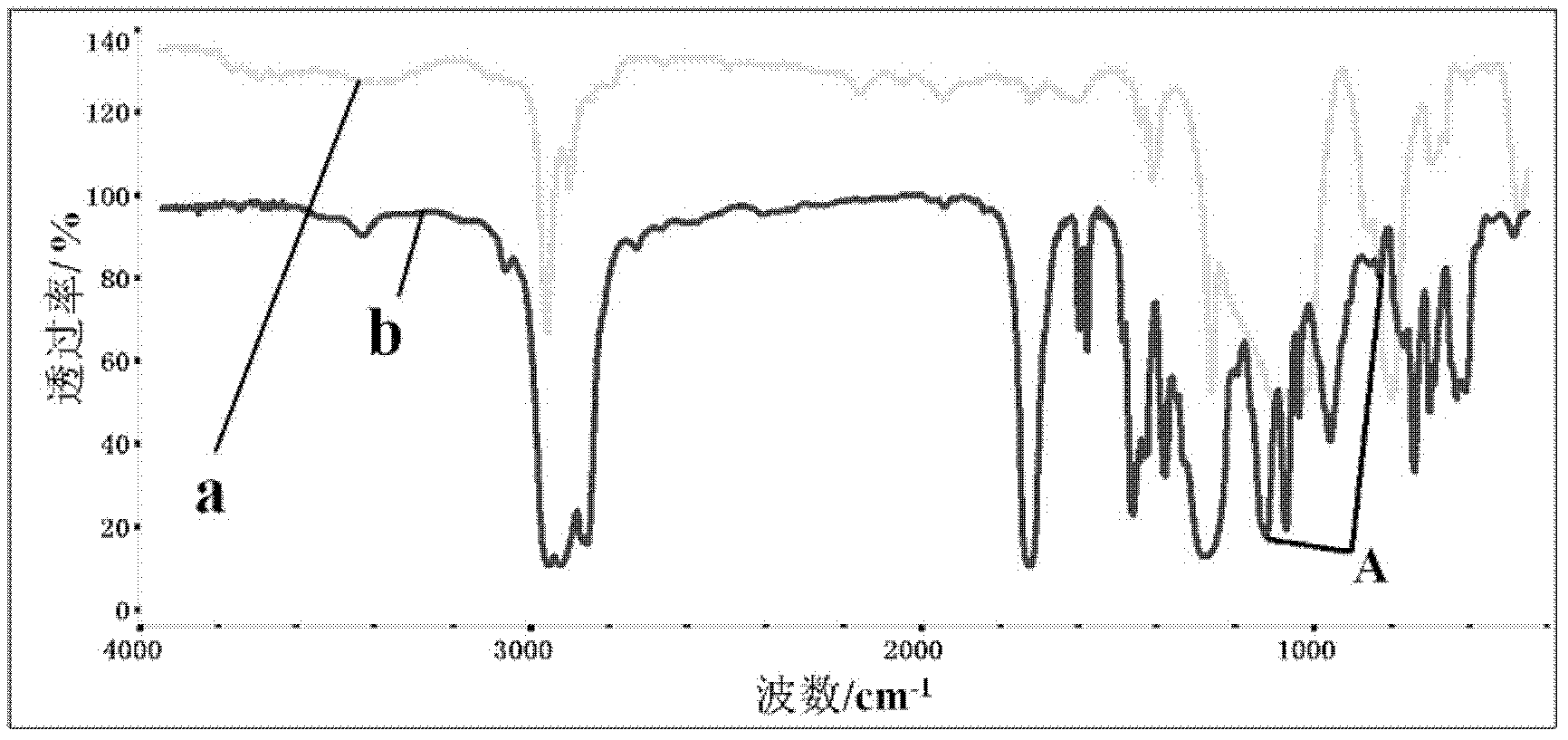

Polysilsesquioxane (POSS) modified vegetable oil emulsion mold release agent and preparation method thereof

InactiveCN102504924AExcellent mold release and peeling performanceExcellent mold releaseLubricant compositionEmulsionVegetable oil

The invention discloses a polysilsesquioxane (POSS) modified vegetable oil emulsion mold release agent and a preparation method thereof. The mold release agent is obtained by taking vegetable oil as a substrate and POSS-vegetable oil polymer as a modifier and adding an emulsifier, an antifoaming agent and a stabilizer. The mold release agent comprises the following raw materials in percentage by mass: 10 to 20 percent of vegetable oil, 0.1 to 1 percent of POSS-vegetable oil polymer, 1 to 3 percent of emulsifier, 0.2 percent of antifoaming agent, 0.1 percent of stabilizer and the balance of deionized water. The mold release agent has a good mold release effect and high peeling performance, is environment-friendly and is harmless to human bodies, the surface of concrete is smooth, flat and non-defective after a mold is released, a little concrete is adhered to the mold, and a template is not corroded.

Owner:HEFEI UNIV OF TECH

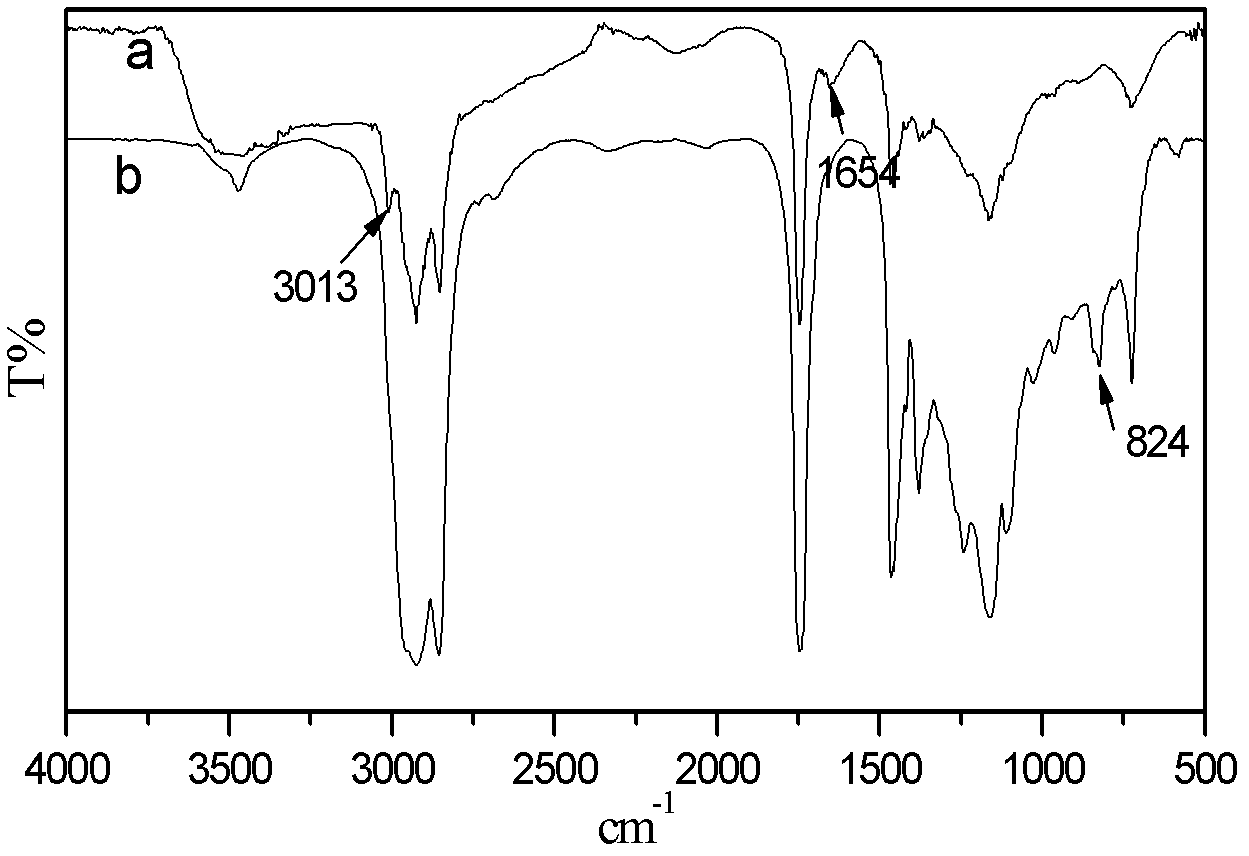

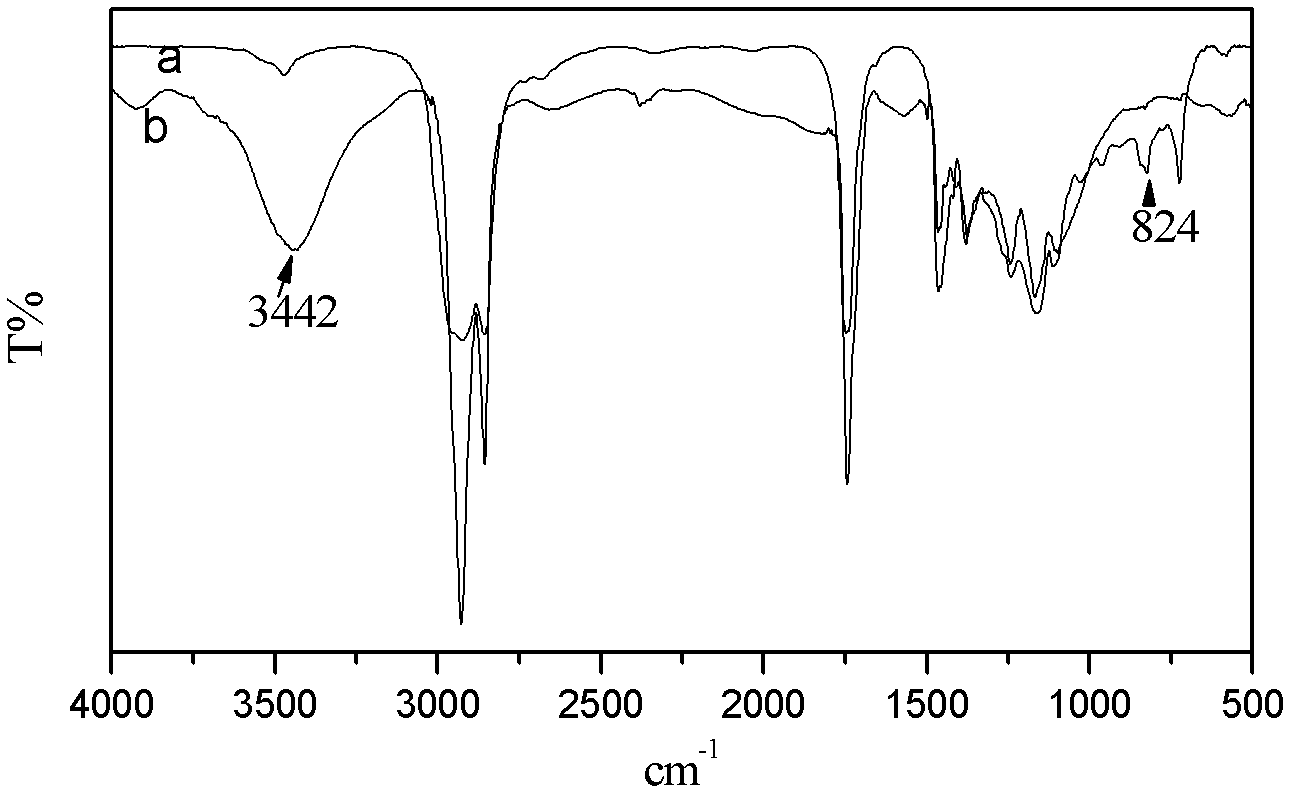

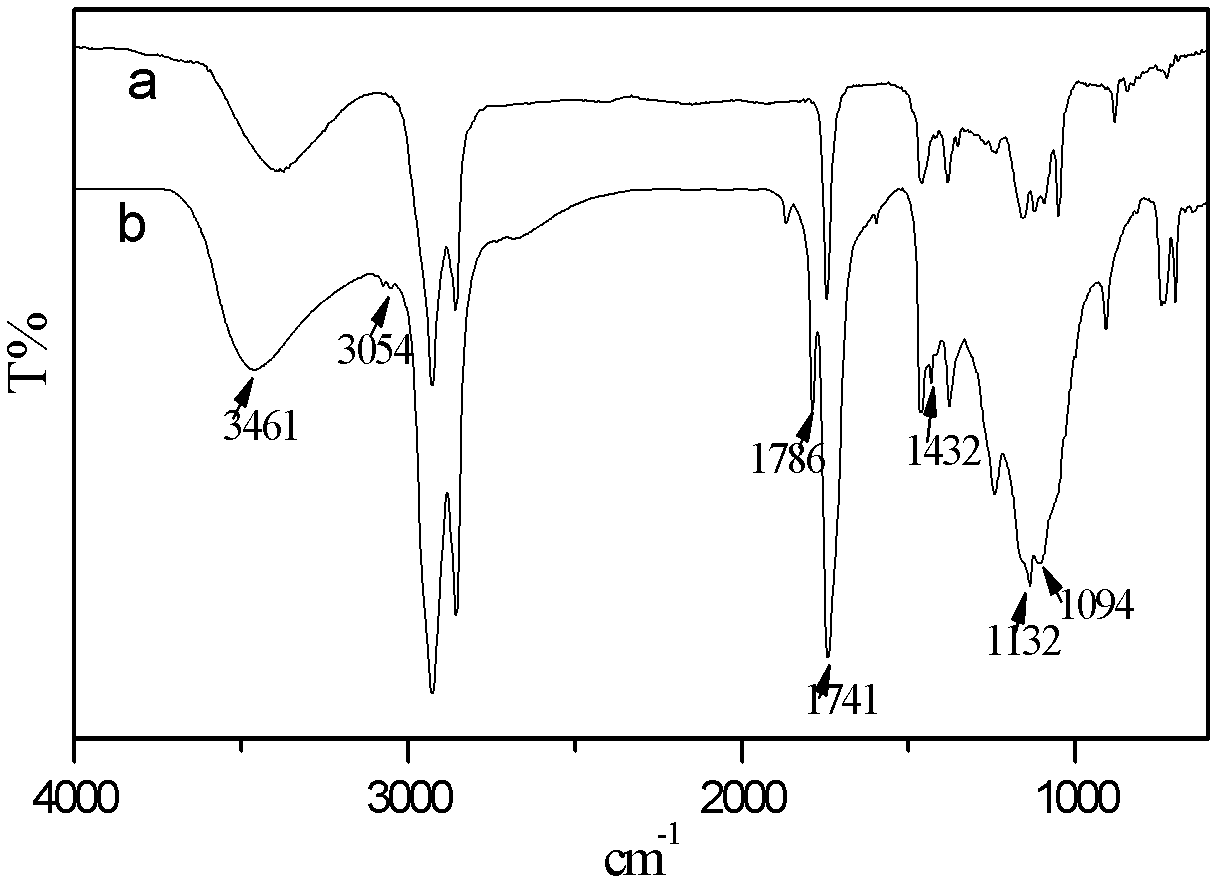

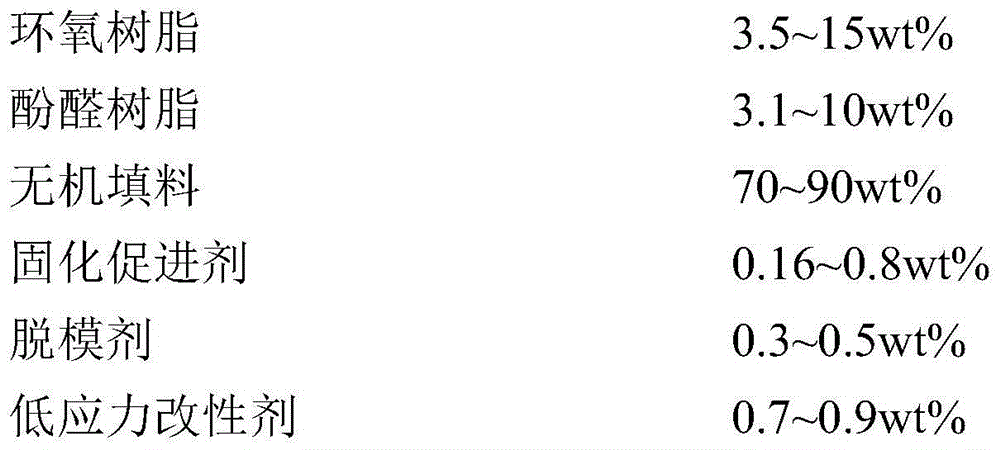

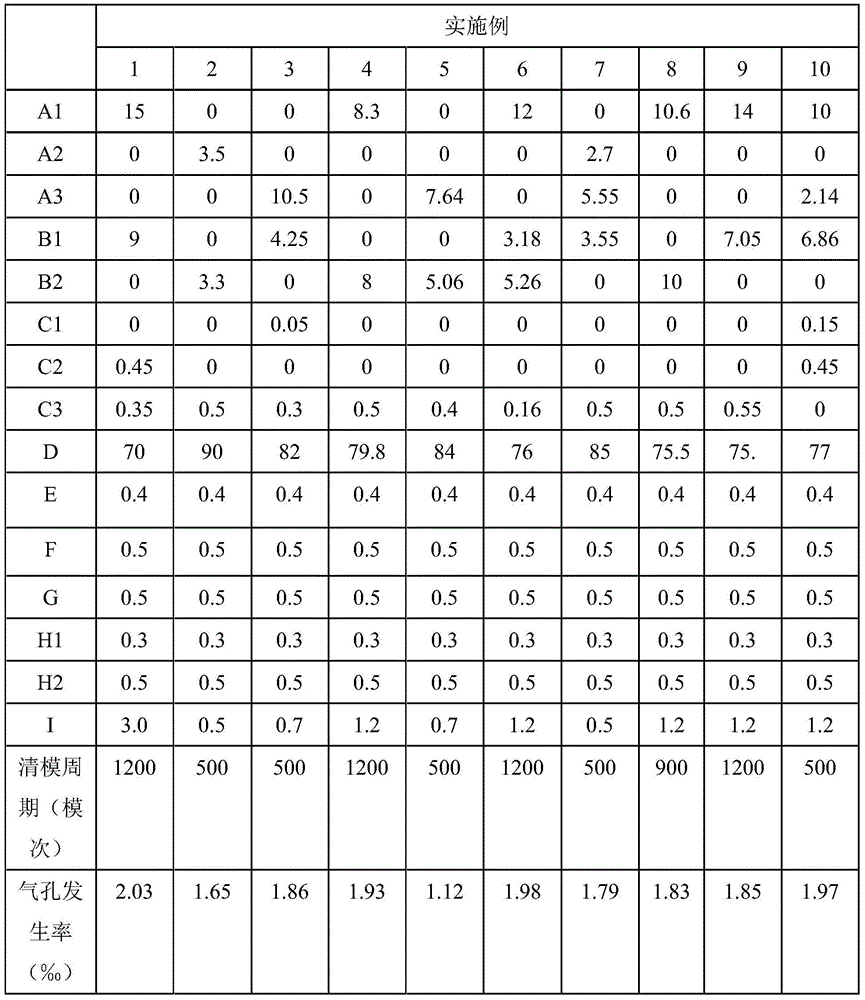

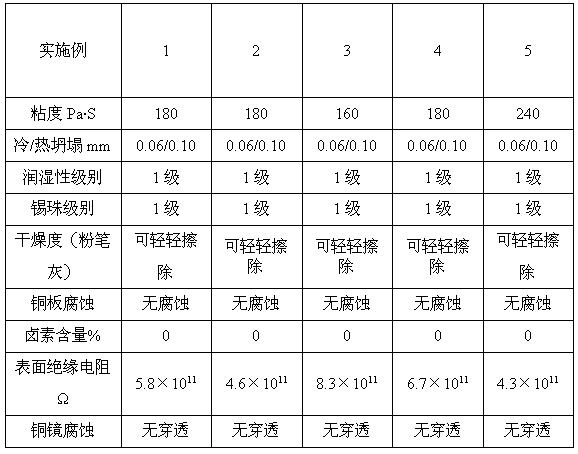

Epoxy resin composition for semiconductor packaging, and preparation method thereof

InactiveCN105778409AExcellent encapsulation and moldabilityExcellent mold releaseSemiconductor/solid-state device manufacturingFirming agentFire retardant

The invention relates to an epoxy resin composition for semiconductor packaging, and a preparation method thereof. The preparation method comprises the following steps: adding a curing agent phenolic resin, a curing accelerator, a mold lubricant, a fire retardant and a low stress modifier to a reaction kettle, carrying out hot melting mixing at 120-180DEG C, stirring until uniformity, cooling the obtained mixture to room temperature, crushing the cooled mixture, carrying out ball milling, and sieving the ball-milled mixture by a sieve; uniformly stirring the above obtained powder, epoxy resin, an inorganic filler, a coloring agent and a silane coupling agent in a high speed stirrer; and mixing and extruding the above obtained mixture in a double screw extruder, cooing the extruded mixture, and crushing the cooled mixture to obtain the epoxy resin composition for semiconductor packaging. The epoxy resin composition for semiconductor packaging has the advantages of increase of the yield in the packaging process, good mold release performance, great increase of the packaging frequency, and reduction of the incidence rate of pores in packaged bodies in packaging of semiconductor devices and integrated circuits.

Owner:BEIJING SHOUKEHUA MICRO ELECTRONICS

Precision polishing technique for stainless steel printed circuit board

the invention discloses a precise polishing technology of stainless steel printing circuit, which comprises the following steps: electrolyzing to remove oil; cleaning working piece; removing burr through electrolyzing; polishing; inactivating; cleaning; drying. the electrolyte at electrolyzing disposal contains 1.62-1.65% sulfuric acid, 0.56-0.60% phosphoric acid and 97.76-97.80% water. the electrolyte at electrolyzing precise polishing contains 24-28% sulfuric acid, 47-51% phosphoric acid, 0.02-0.04% ammonia sulfate, 0.01-0.03% ammonium phosphate, 0.03-0.04% cellulose, 0.005-0.007% saccharin and 21.1-28.9% water.

Owner:SHENYANG POLYTECHNIC UNIV

Halogen-free soldering flux for lead-free solder paste

InactiveCN104175023AImprove adhesionWide viscosity rangeWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

The invention relates to the technical field of welding materials, in particular to a halogen-free soldering flux for lead-free solder paste. The halogen-free soldering flux for the lead-free solder paste comprises the following components in percentage by mass: 20 to 35 percent of solvent, 30 to 45 percent of rosin, 5 to 10 percent of surfactant, 10 to 20 percent of organic acid, 3 to 10 percent of antioxidant and 2 to 8 percent of thixotropic agent. According to the halogen-free soldering flux, a rosin mixture consisting of hydrogenated rosin and polymerized rosin at a weight ratio of 1:(1-3) is adopted, so that higher adhesive force of the solder paste is ensured; the proportion of the solvent and the rosin in the soldering flux is regulated, so that the viscosity range of the solder paste is wider; by the compounding of multiple organic acids, the prepared soldering flux is free of halogen, and has higher activity; the antioxidant for preparing the soldering flux is one or a combination of more than two of methylbenzotriazole, an antioxidant BHT, CHIMASSORB3030, benzimidazole and methylimidazole; the solder paste prepared from the soldering flux is long in service life, and has good de-molding effects.

Owner:JIANGSU BOQIAN NEW MATERIALS

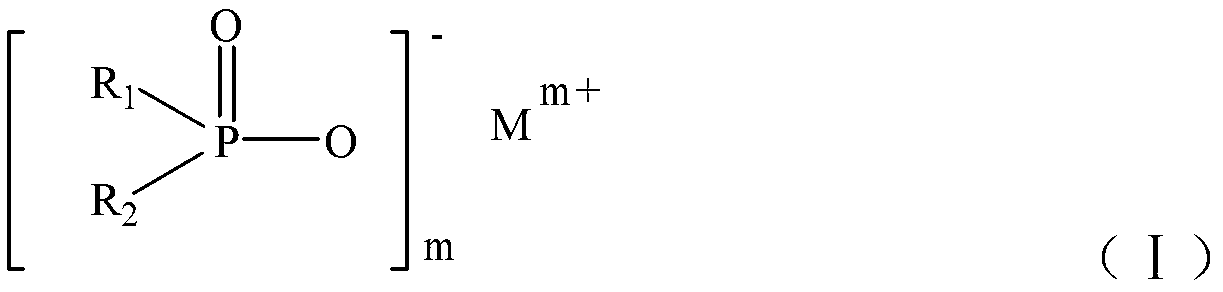

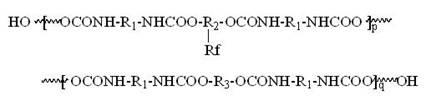

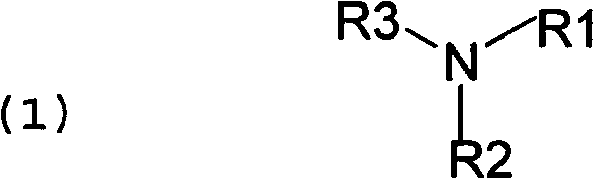

Halogen-free flame retardant thermoplastic polyamide composition

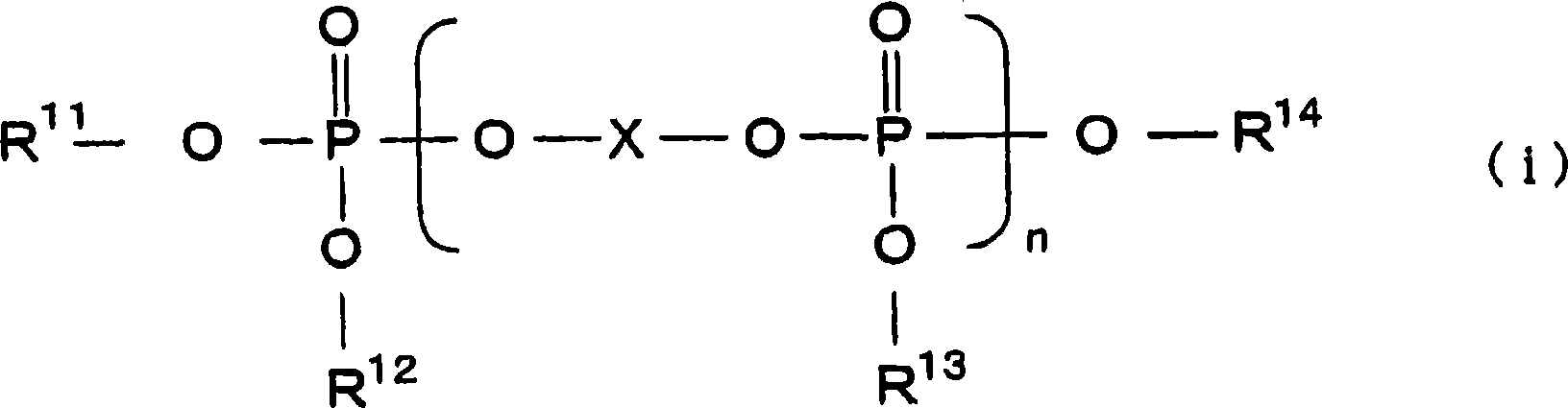

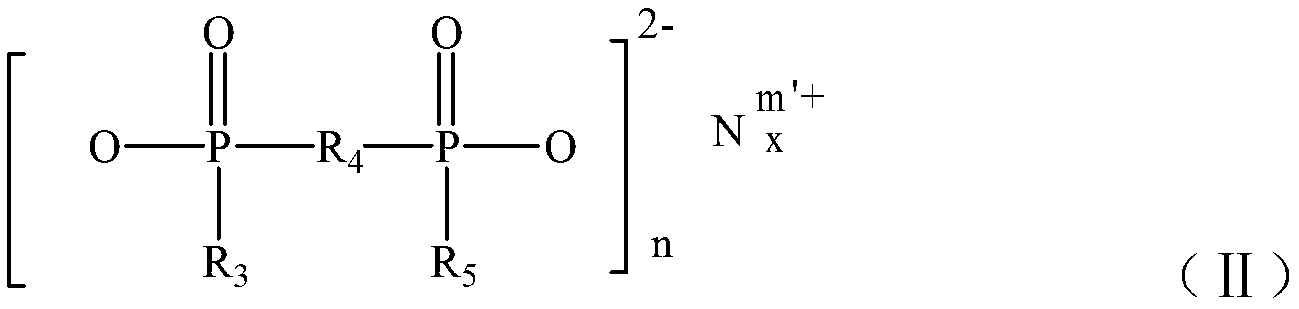

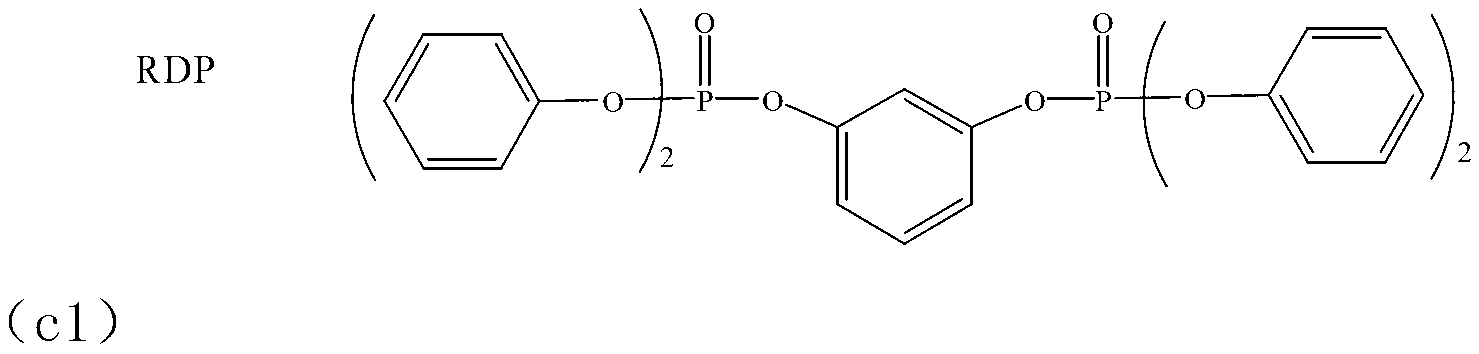

The invention provides a halogen-free flame retardant thermoplastic polyamide composition. The composition comprises the following components: 20-80wt% of at least one thermoplastic polyamide (A), 1-10wt% of at least one organic modified polydimethylsiloxane (B), 3-20wt% of at least one aromatic phosphate (C), 3-25wt% of at least one of phosphinates (D) with a structure shown in formula (I) and / or bi-phosphinates (D) with a structure shown in formula (II), 0-40wt% of reinforced fibers (E) and 0-40wt% of an inorganic filler (F). By utilizing the halogen-free flame retardant thermoplastic polyamide composition, the high fluidity, high surface quality, high flame retardance and excellent demoulding performance are combined together, the operation is simple, and the prepared composition is environment-friendly.

Owner:浙江通力新材料科技股份有限公司

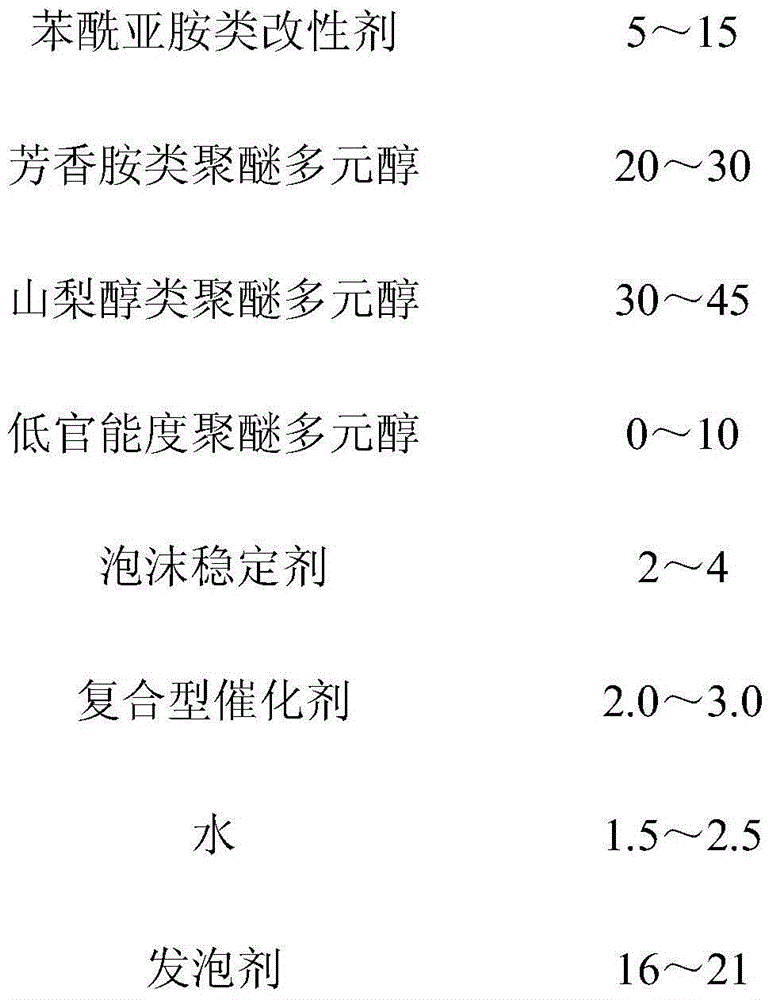

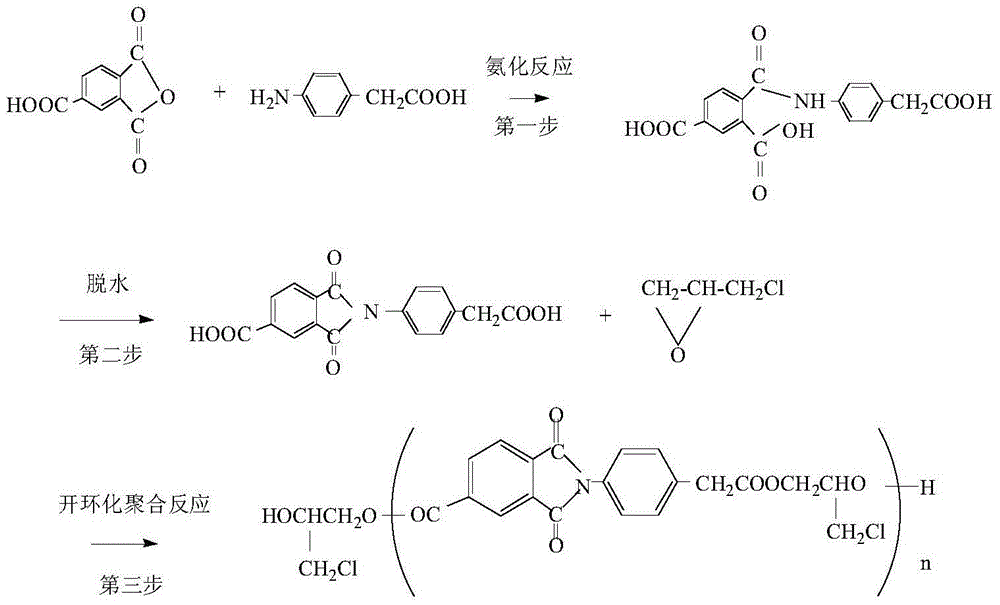

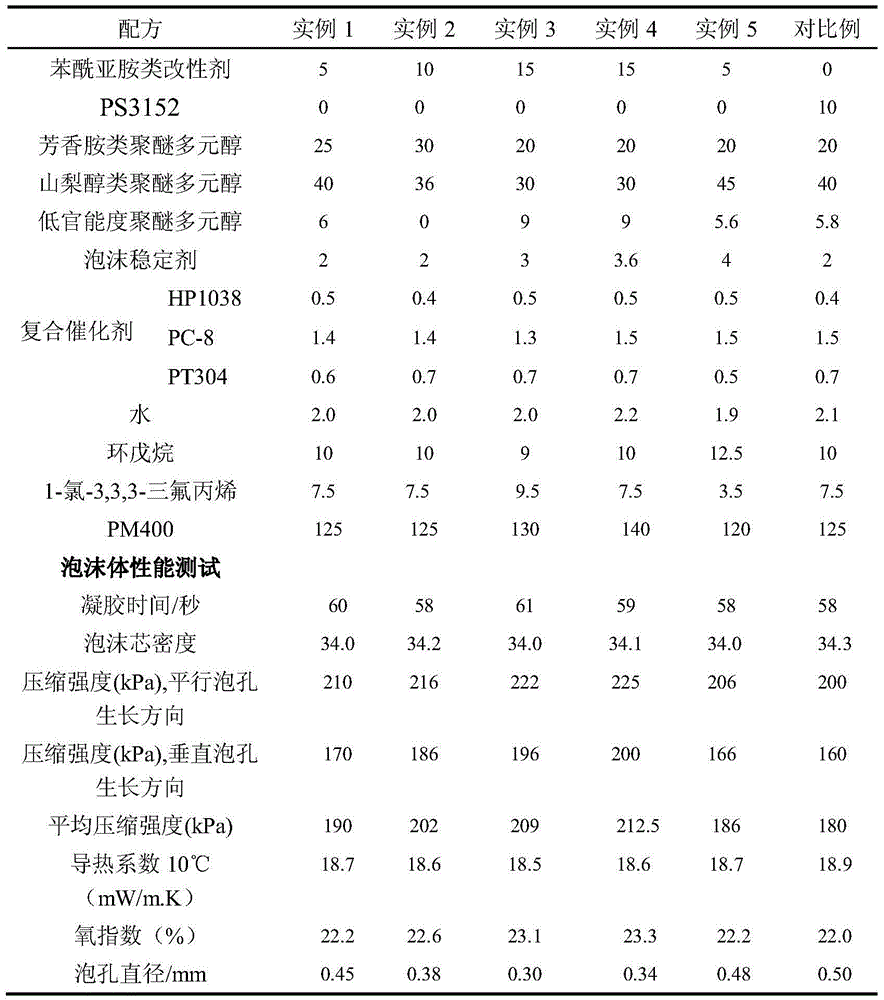

High-strength polyurethane rigid foam as well as preparation method and application thereof

ActiveCN104672420AIncrease internal rotation resistanceImprove rigidityRigid structureAromatic amine

The invention discloses high-strength polyurethane rigid foam, as well as a preparation method and application thereof. The invention introduces a benzoyl imide reinforced polyurethane modifier with a rigid structure; the benzoyl imide reinforced polyurethane modifier, the corresponding high-viscosity aromatic amine polyether polyol, low functionality polyether polyol, special silicon oil for increasing isotropy of the foam, a catalyst with a specific structure, water and a foaming agent are used for preparing the premixed polyether polyols and react with the polyisocyanates to generate the high-strength polyurethane foam. The polyurethane rigid foam provided by the invention has the characteristics of low batch charging density, high compressive strength, low heat conductivity coefficient and good size stability under low temperature, and can be used in the household appliance inside insulating materials such as the fridge, the refrigerator, the solar energy, the gas water heater and the disinfection cabinet.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

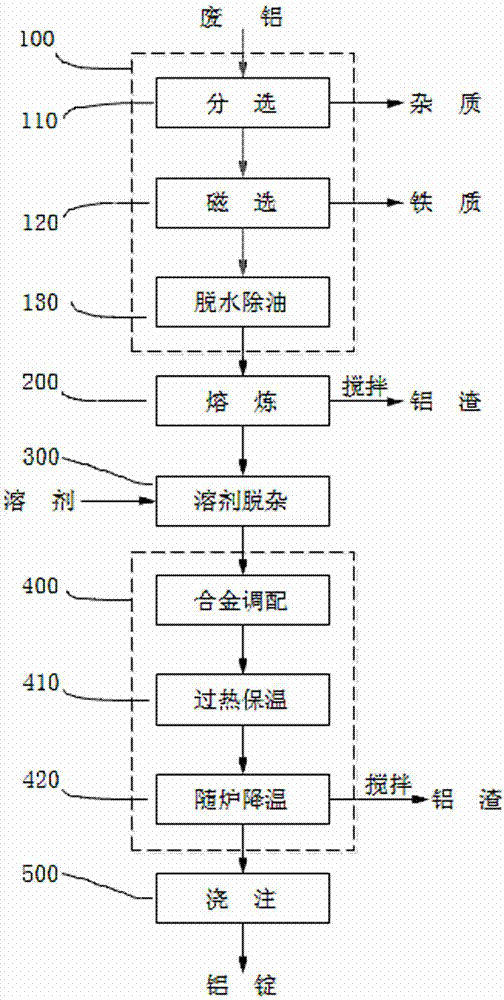

Method for efficiently regenerating cast aluminum alloy by aluminum scraps

The invention discloses a method for efficiently regenerating cast aluminum alloy by aluminum scraps. The method for efficiently regenerating cast aluminum alloy by aluminum scraps comprises the following processes of: screening, smelting, alloy-mixing and pouring, wherein the screening process specifically comprises the following step of: removing impurities and moisture in the aluminum scraps; the smelting process specifically comprises the step of melting and stirring the aluminum scraps after the screened aluminum scraps are charged, so that the slag is removed; the alloy-mixing process specifically comprises the following steps of: adding 9%-11% (in percentage by weight) of Si and 0.8%-1.1% of Fe when the temperature of the impurity-removed aluminum scrap solution reaches 680 DEG C to 740 DEG C, keeping the temperature after the components are uniformly stirred and removing the slag; and the casting process specifically comprises the following step of: pouring the slag-removed molten aluminum to the mould to obtain the cast aluminum alloy ingot or the aluminum alloy casting piece. According to the method for efficiently regenerating cast aluminum alloy by aluminum scraps, the aluminum scraps are enabled to reach the technical requirements of the cast aluminum alloy by aluminum scrap screening and alloy mixing, and therefore, the method has the advantages of being simple in process, strong in aluminum scrap adaptability, stable in aluminum alloy stability, low in cost, and high in aluminum recycling rate.

Owner:YUNNAN AOKAI TECH DEV

Water-soluble lubricating oil

InactiveCN1575330AImprove machinabilityGood stamping performanceDischarging arrangementOther chemical processesOil and greaseMetalworking

The water-soluble lubricating oil composition of this invention contains animal fats and oils and / or plant fats and oils, and the nonionic surfactant of polyoxyethylene sorbitol fatty acid ester. The water-soluble lubricating oil composition of this invention is excellent in emulsion stability, and it can reduce environmental pollution. It is suitably as metal processing oils such as cutting oil and plastic working oils, and release agent such as asphalt mixture adhesion prevention agent and concrete release agent.

Owner:THE NISSHIN OILLIO GRP LTD

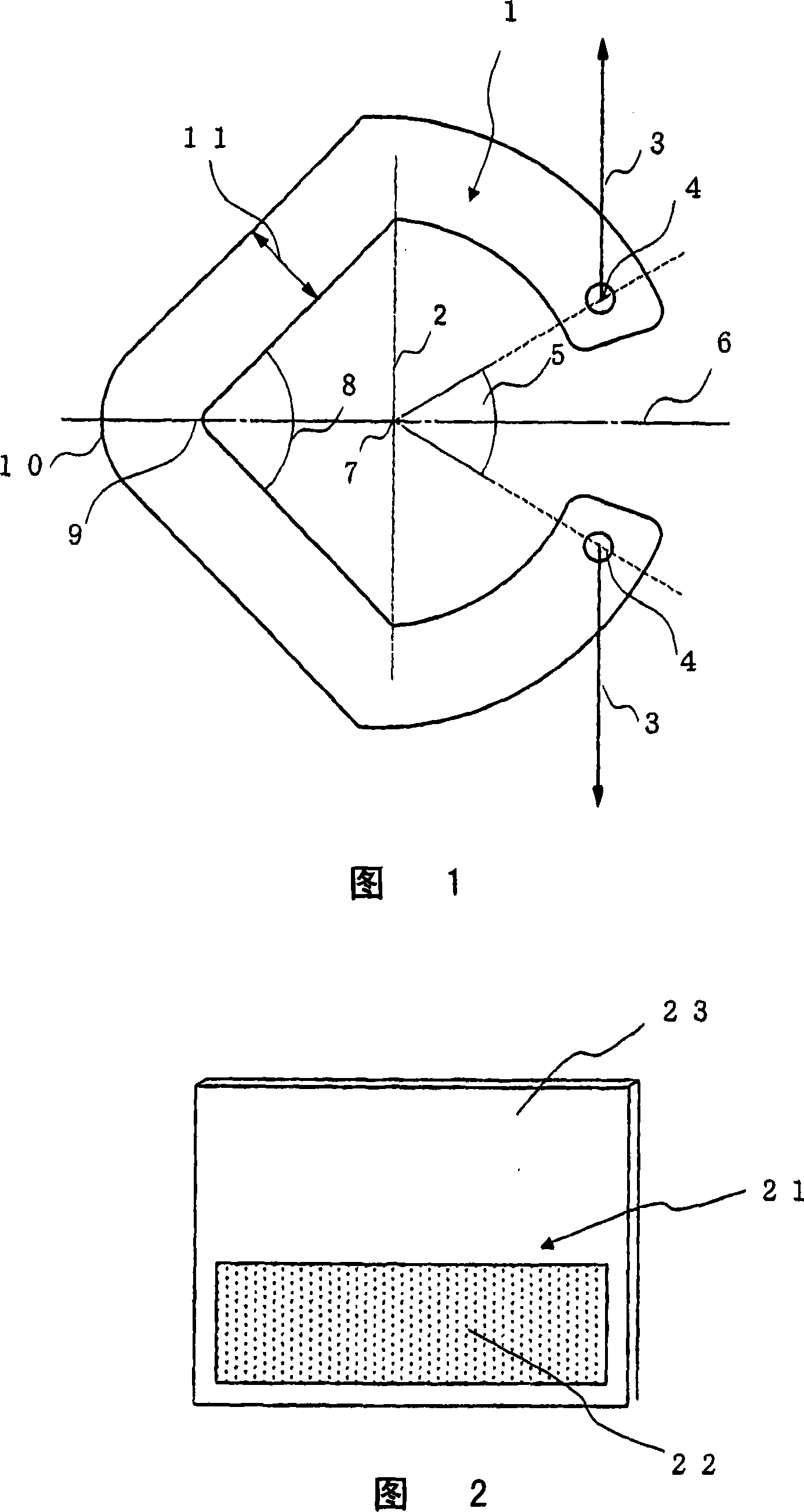

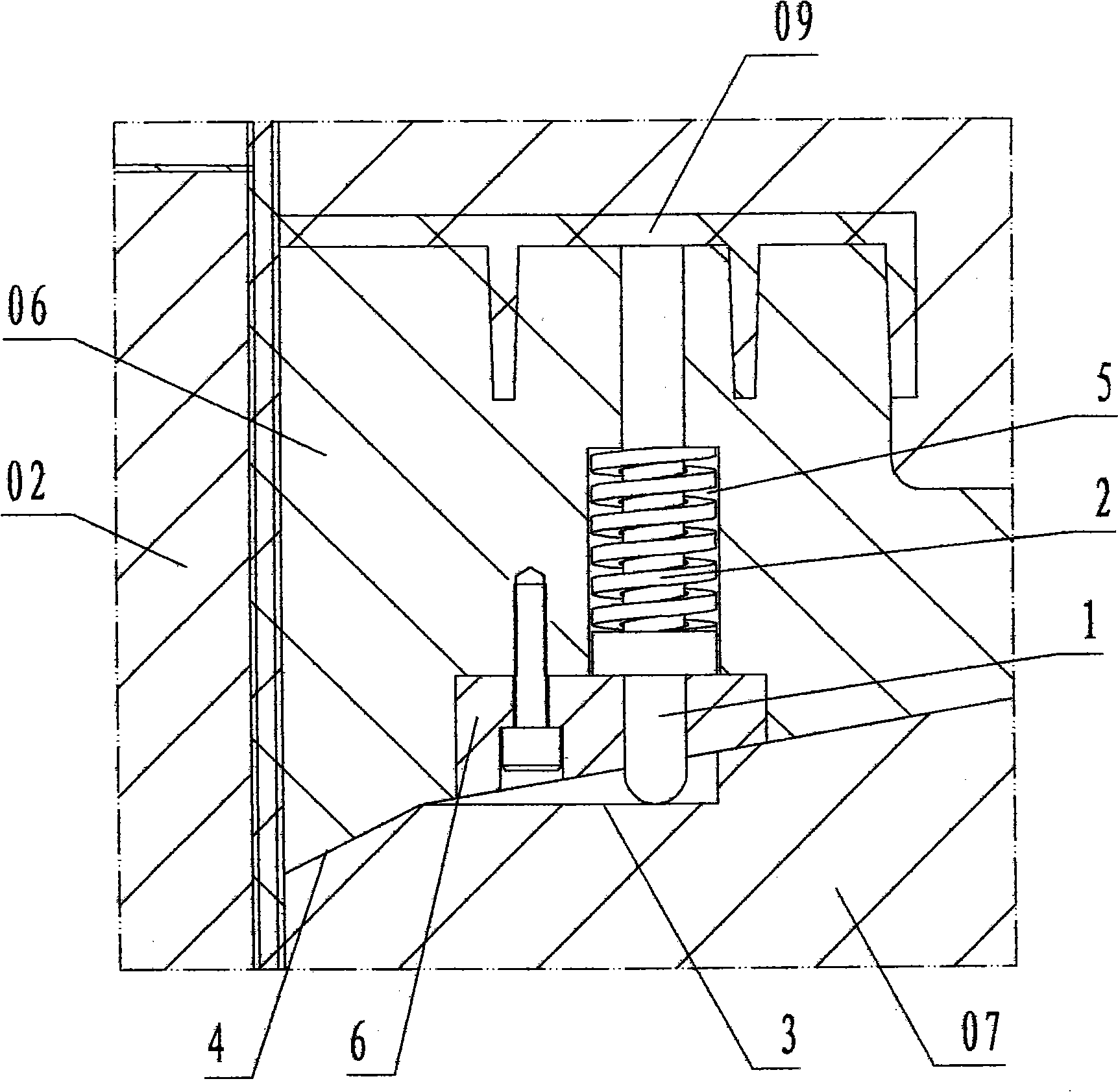

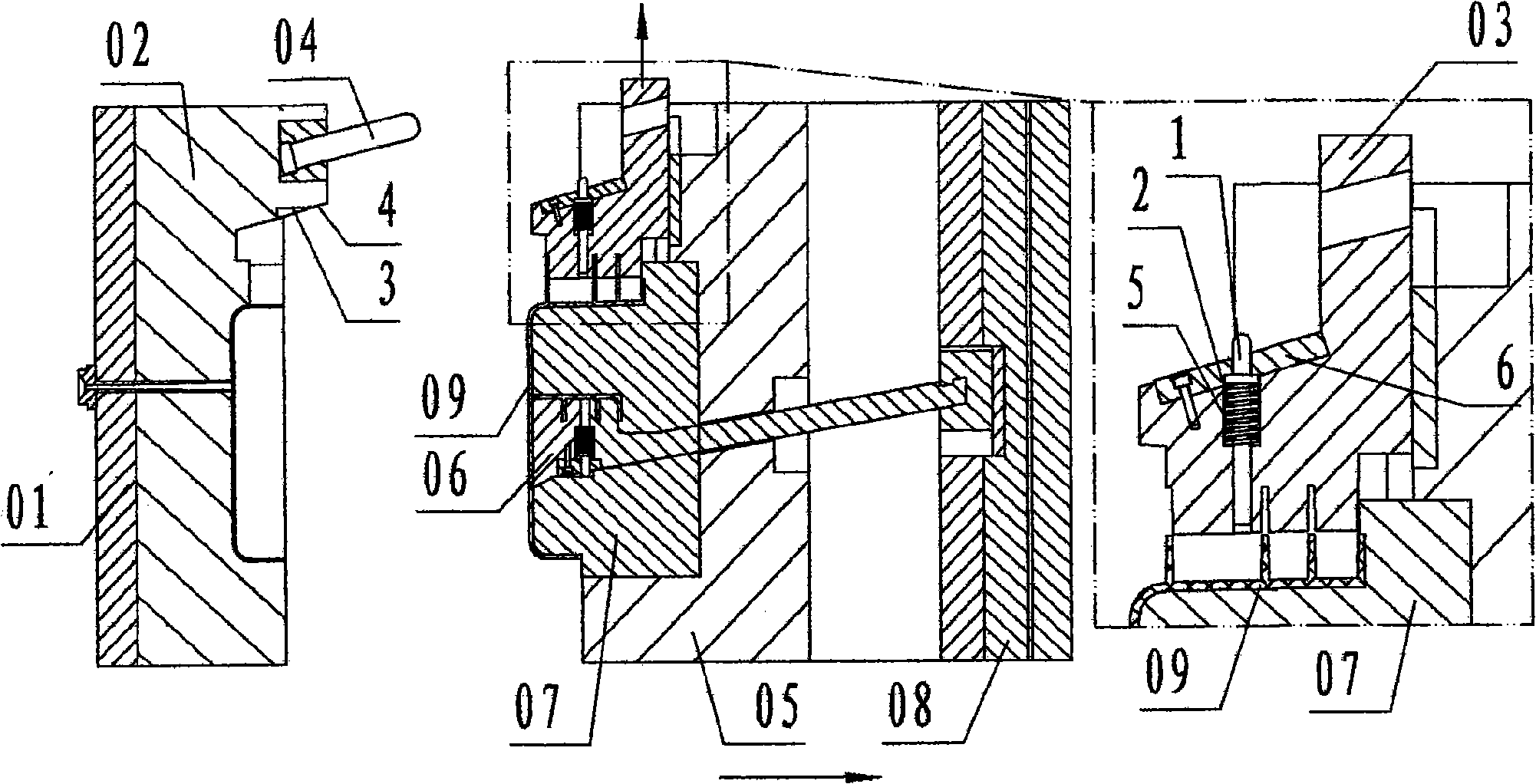

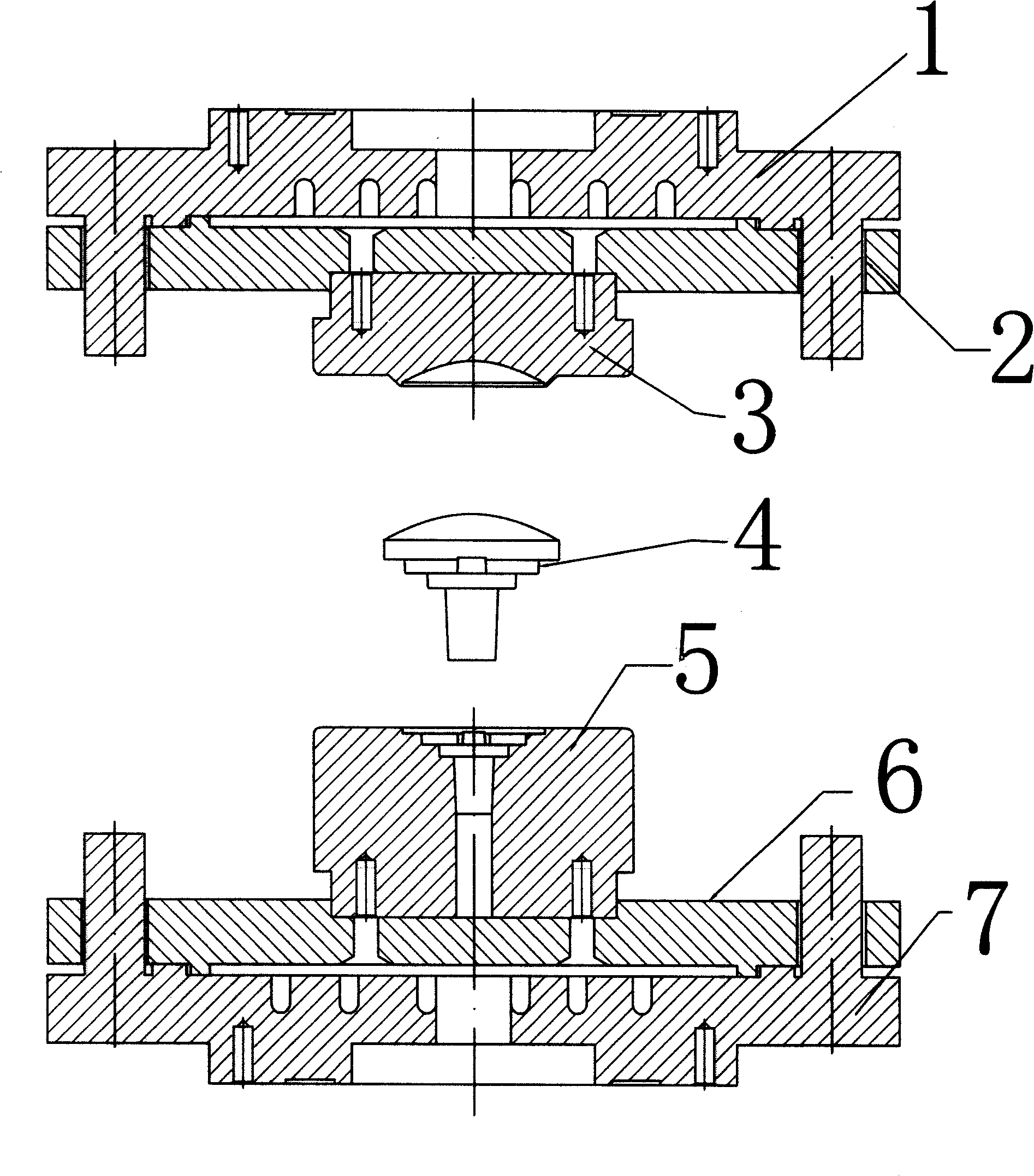

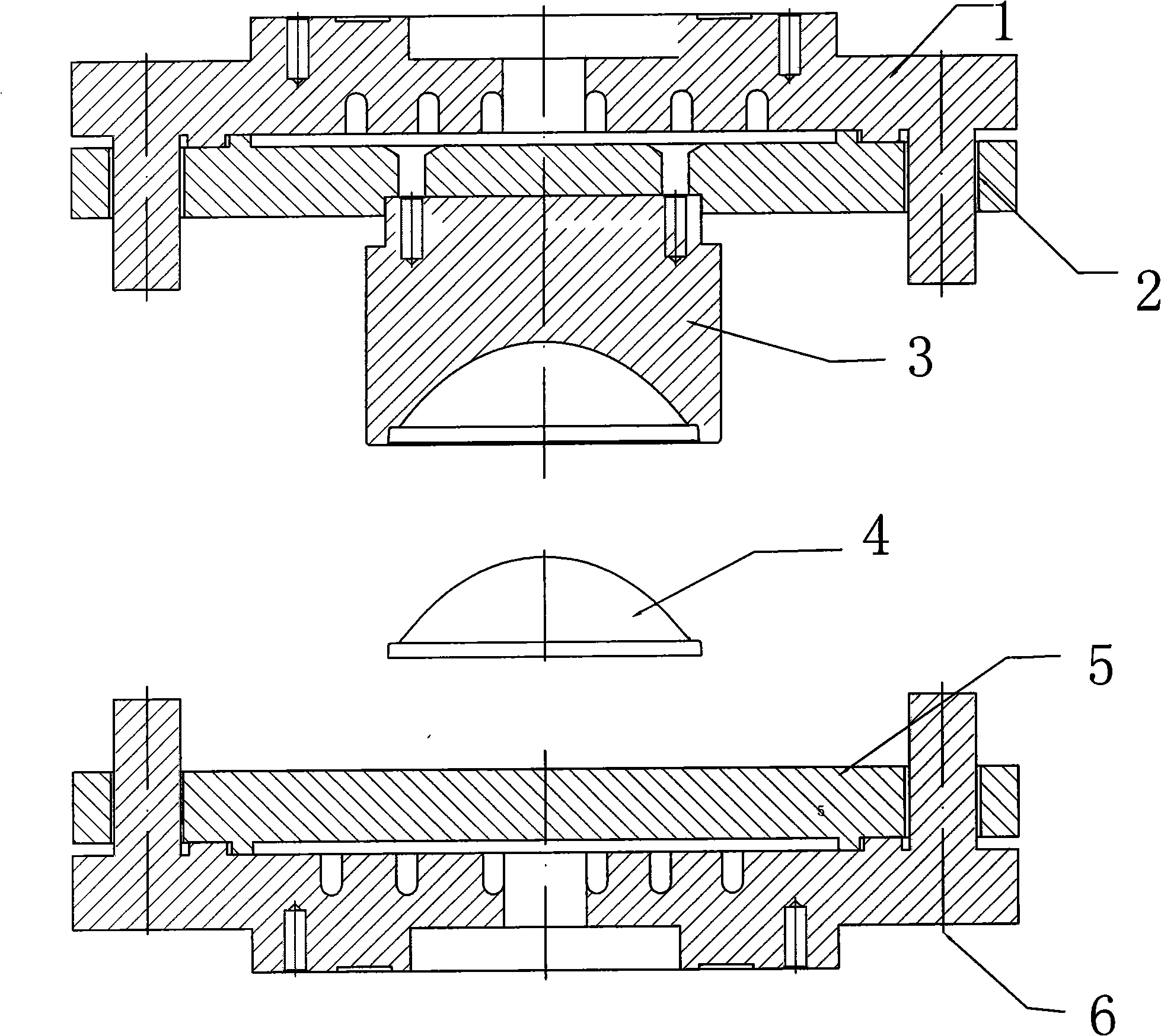

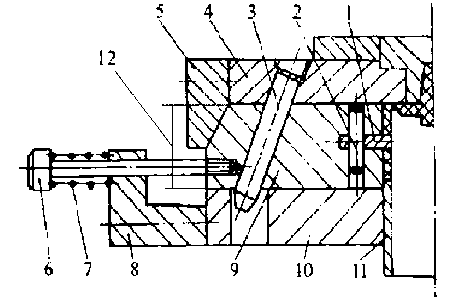

Time-delay drawing protection technical apparatus for injection mold slide block thimble and inclined jacking block thimble

The invention discloses a technical device for protecting delayed pulling of a slider push rod and an ejector cam insert push rod of an injection mold. The device comprises a push rod (1), a spring (2), a delayed straight plane (3), a reset inclined plane (4) and a check block (5). The device adopts demoulding technical proposal of transverse delayed pulling consisting of the push rod, the spring, the straight plane and the inclined plane; in the pulling movements of a transverse mechanism of an injection molded part, the push rod is used to support the injection molded part to force the injection molded part and a slider or an ejector cam insert to loose and delay, so as to guarantee products are not damaged in the transverse demoulding process. The device solves the problems that the mould has a complicated structure and high cost, and actual demoulding effect is not ideal, etc. because the prior art adopts the technical proposals that a secondary transverse pulling mechanism such as an oil cylinder is adopted, demoulding inclination of the injection molded part is increased and demoulding is carried out through exhaust, etc. The device achieves the aims of simple and reliable mechanism, low cost, ideal demoulding effect and suitability for applying injection molds with difficult demoulding; meanwhile, the device has universal meaning for technical progress of injection mold demoulding.

Owner:NINGBO YUEFEI MOLD

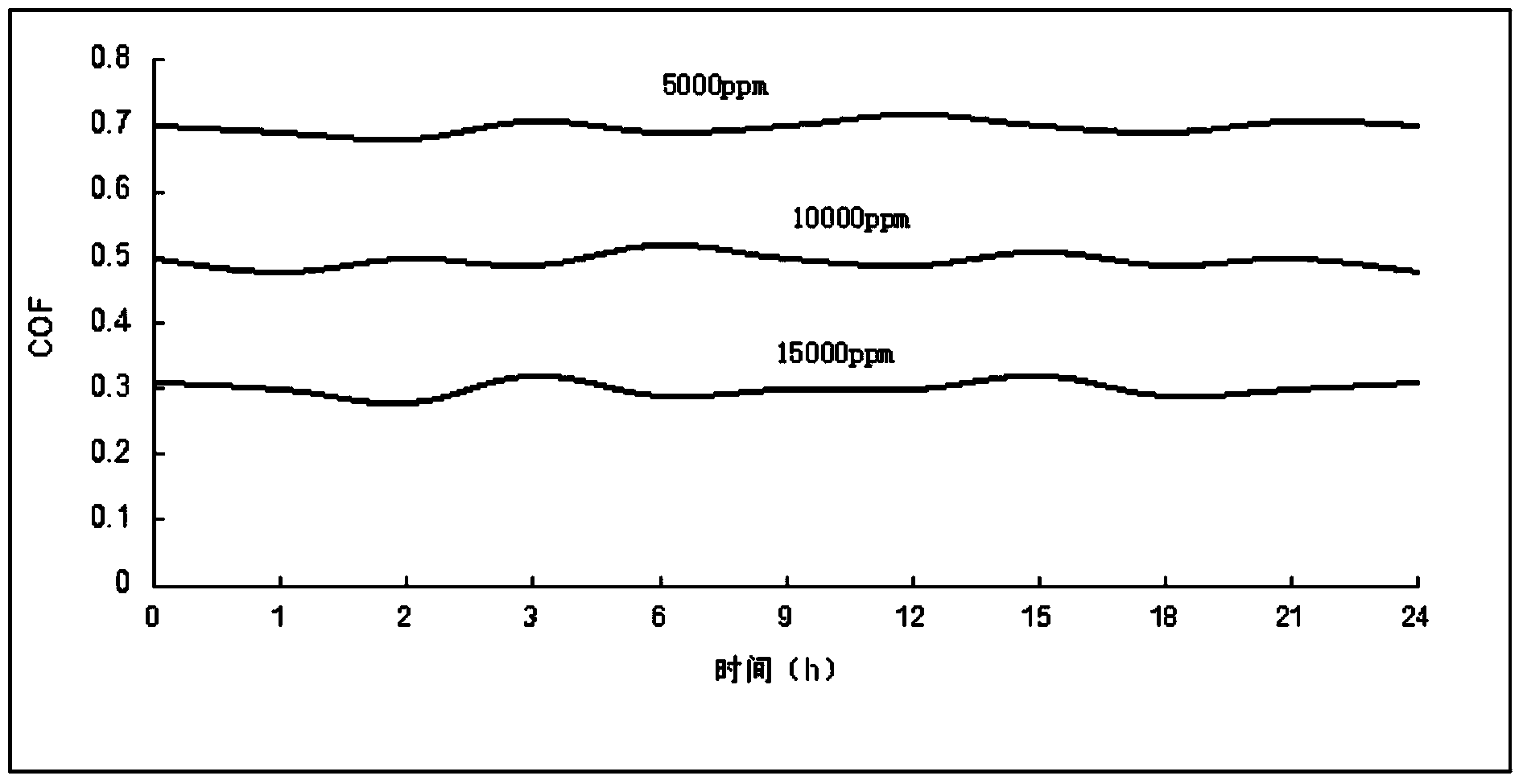

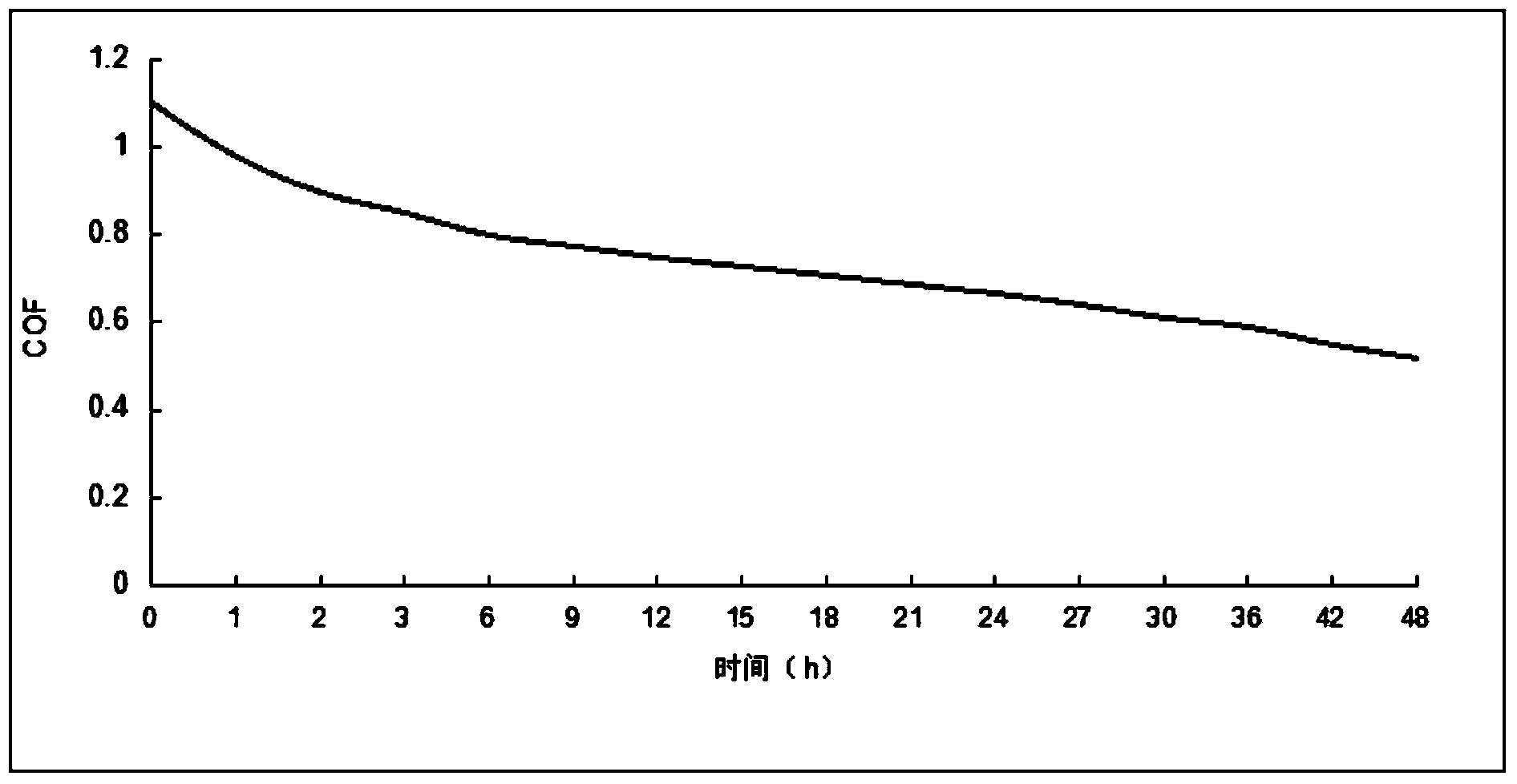

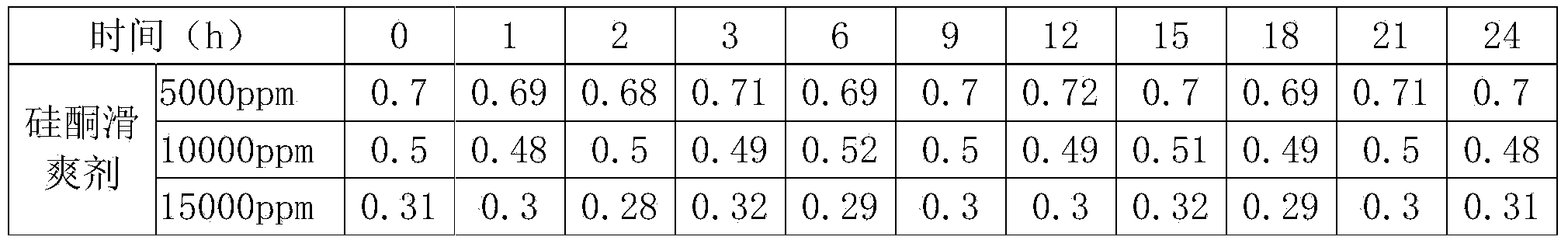

Casting polypropylene film with controllable friction coefficient and preparation method thereof

InactiveCN104015448AHigh in active ingredientsGood compatibilityFlexible coversWrappersPolymer sciencePolypropylene

The invention discloses a casting polypropylene film with a controllable friction coefficient and a preparation method thereof, belonging to the technical field of packaging materials. The casting polypropylene film sequentially comprises a corona layer, a middle layer and a heat-seal layer with a thickness ratio of (20-30) to (50-65) to (15-20). The corona layer is made from homo-polypropylene or polypropylene random copolymer, the middle layer is made from isotactic homo-polypropylene, and the heat-seal layer comprises 90wt%-98wt% of propylene copolymer, 1wt%-3wt% of adhesion resisting agent and 1wt%-7wt% of macromolecule slip agent, namely silicone master batch. The preparation method sequentially comprises the following steps: mixing materials, extruding to form a film, cooling for shaping, measuring thickness, aureoling, trimming, reeling, performing aging treatment, and slitting. The heat-seal layer is uniformly dispersed in main body resin by the macromolecule slip agent, and the slip agent is well compatible with the main body resin due to high molecular weight, and thus a film surface friction coefficient is prevented from being changed by migration of the macromolecule slip agent due to temperature of a storage or usage environment.

Owner:永新股份(黄山)包装有限公司

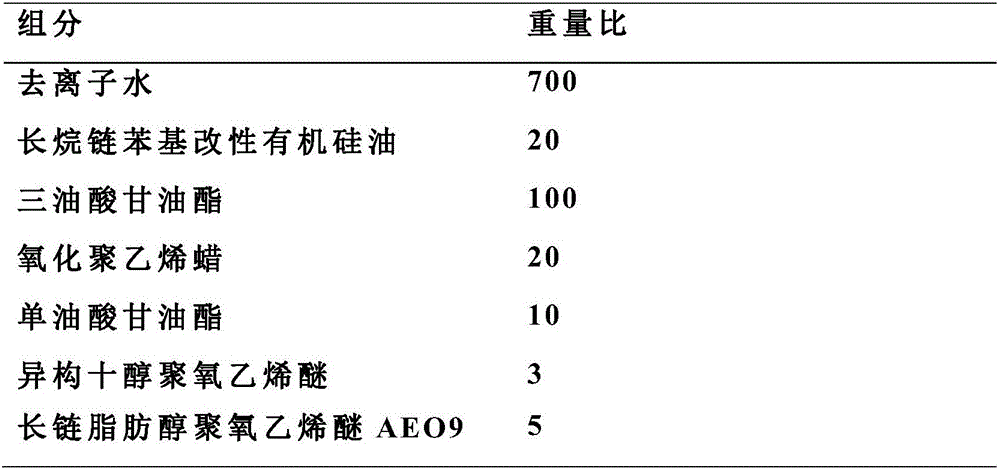

Water-based alumium alloy releasing agent and preparing method thereof

ActiveCN105728639AGuaranteed high temperature performanceReduce environmental pollutionFoundry mouldsFoundry coresWaxIon

The invention discloses a water-based alumium alloy releasing agent. The water-based alumium alloy releasing agent comprises, by mass, 20-30 parts of long alkyl chain phenyl modified organic silicone oil, 100-150 parts of olein, 20-40 parts of oxidized polyethlene wax, 10-15 parts of glycerol mono-oleate, 700-850 parts of deionized water, 3-8 parts of isomeric alcohol ethoxylates and 5-10 parts of long-chain fatty alcohol-polyoxyethylene ether. According to the environment-friendly die casting releasing agent, the long alkyl chain phenyl modified organic silicone oil with the low proportion and plant oil with the high proportion serve as composite lubricating oil, the high-temperature performance of the releasing agent is guaranteed, and the environment pollution is greatly reduced. After composite emulsification is conducted on the environment-friendly die casting releasing agent through a composite surfactant, preparing is simple, and the obtained releasing agent is excellent in releasing effect.

Owner:SUZHOU XINGYE MATERIALS TECH

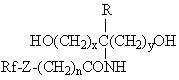

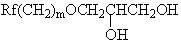

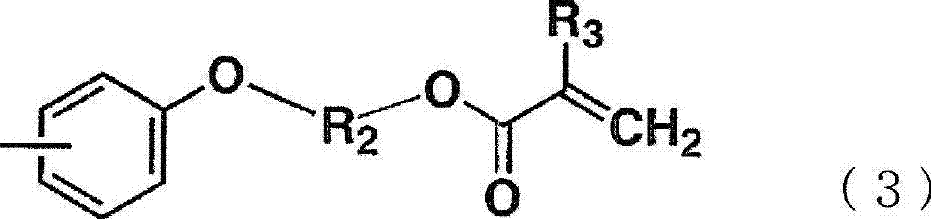

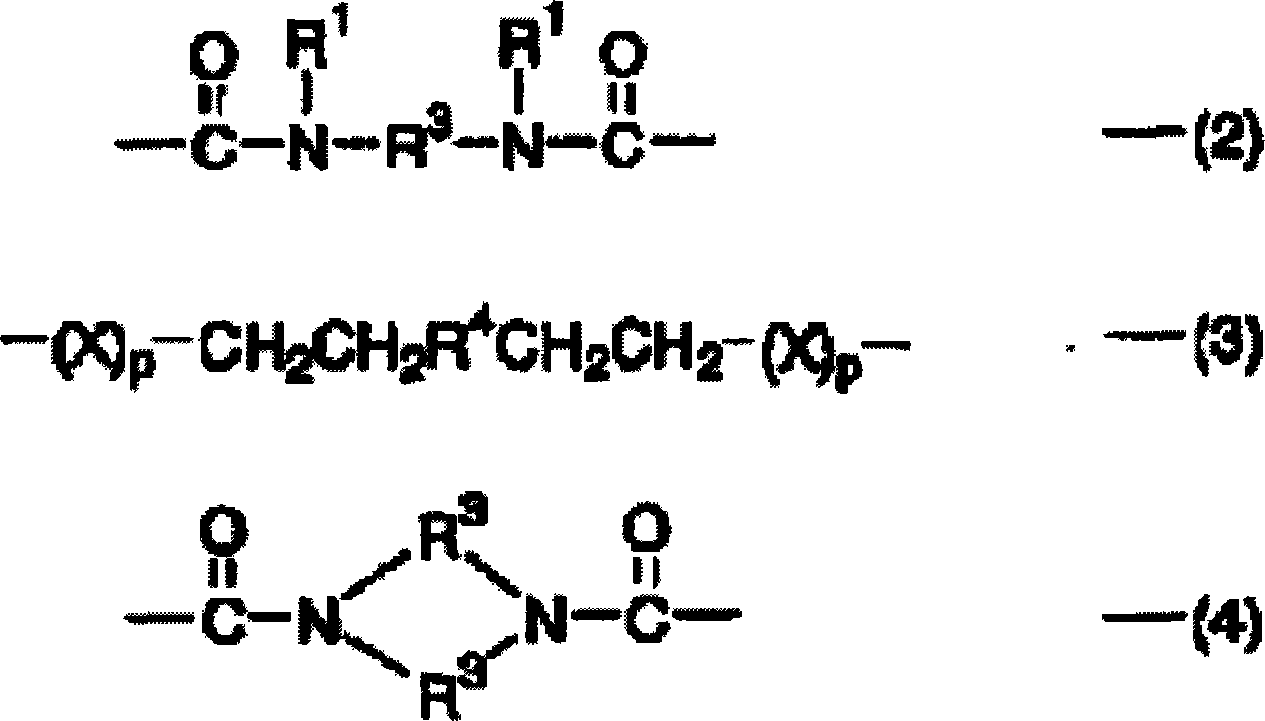

Polyester type polyurethane material with side chain containing fluorine and preparation method thereof

The invention provides a polyurethane material with a side chain containing fluorine, which is formed by copolymerizing a flexible chain section formed by common commercial polyester dibasic alcohol and a rigid chain section formed by diisocyanate and a chain extender, and is characterized in that the chain extender is dihydric alcohol with a side chain containing a perfluor alkyl group or mixture formed by the dihydric alcohol with the side chain containing the perfluor alkyl group and other low-molecule dihydric alcohol or diamine. The invention further provides a preparation method of the polyurethane material with the side chain containing the fluorine. Due to the fact that the chain extender is connected onto a polyurethane main chain (hard section) in a side chain mode, the movement of a fluorocarbon side chain is hardly limited by the polyurethane main chain while the fluorocarbon side chain can remarkably change a phase structure of the polyurethane (separation degree of a soft section and the hard section), and the novel polyurethane material is provided with good surface performance and body performance.

Owner:SICHUAN UNIV

Release agent of sand mould and sand core and preparing process thereof

InactiveCN101199984AReduce manufacturing costExcellent mold releaseFoundry mouldsFoundry coresChemical compositionSolvent

Disclosed is a release agent used for sand mold and sand core, which is characterized in that the release agent is made from the compound of stearate, iron oxide red, organobentonite paste, binder and solvent oil. The quality percentage of the main chemical composition is: stearate:12 to 49, iron oxide red: 2 to 8, organobentonite paste: 10 to 40, binder: 0.3 to 2; and the rest is solvent oil. Using the release agent can greatly reduce the bonding power and the mold release resistance of mold and core on the die set. Thus the using period of the die set is increased.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

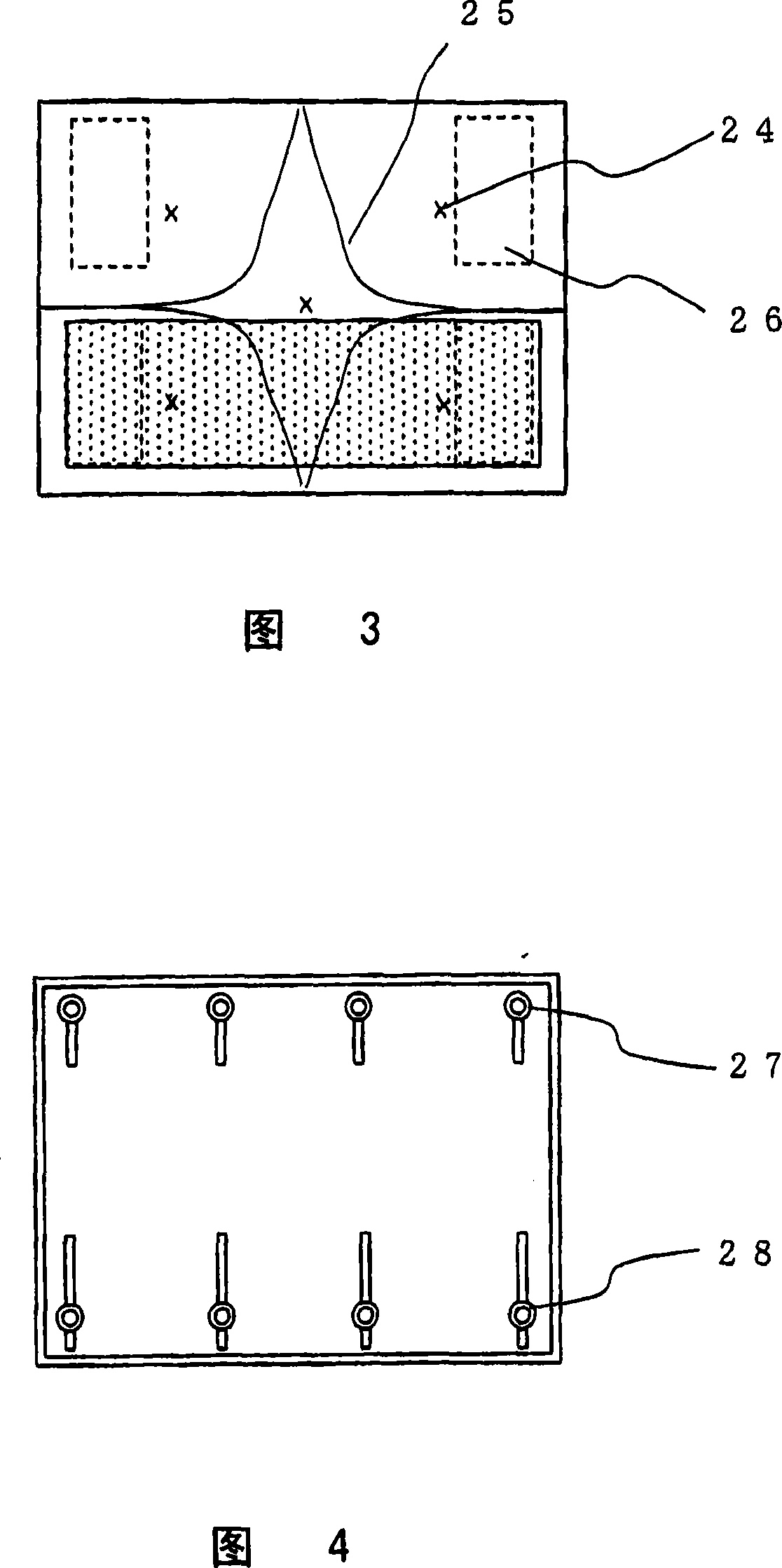

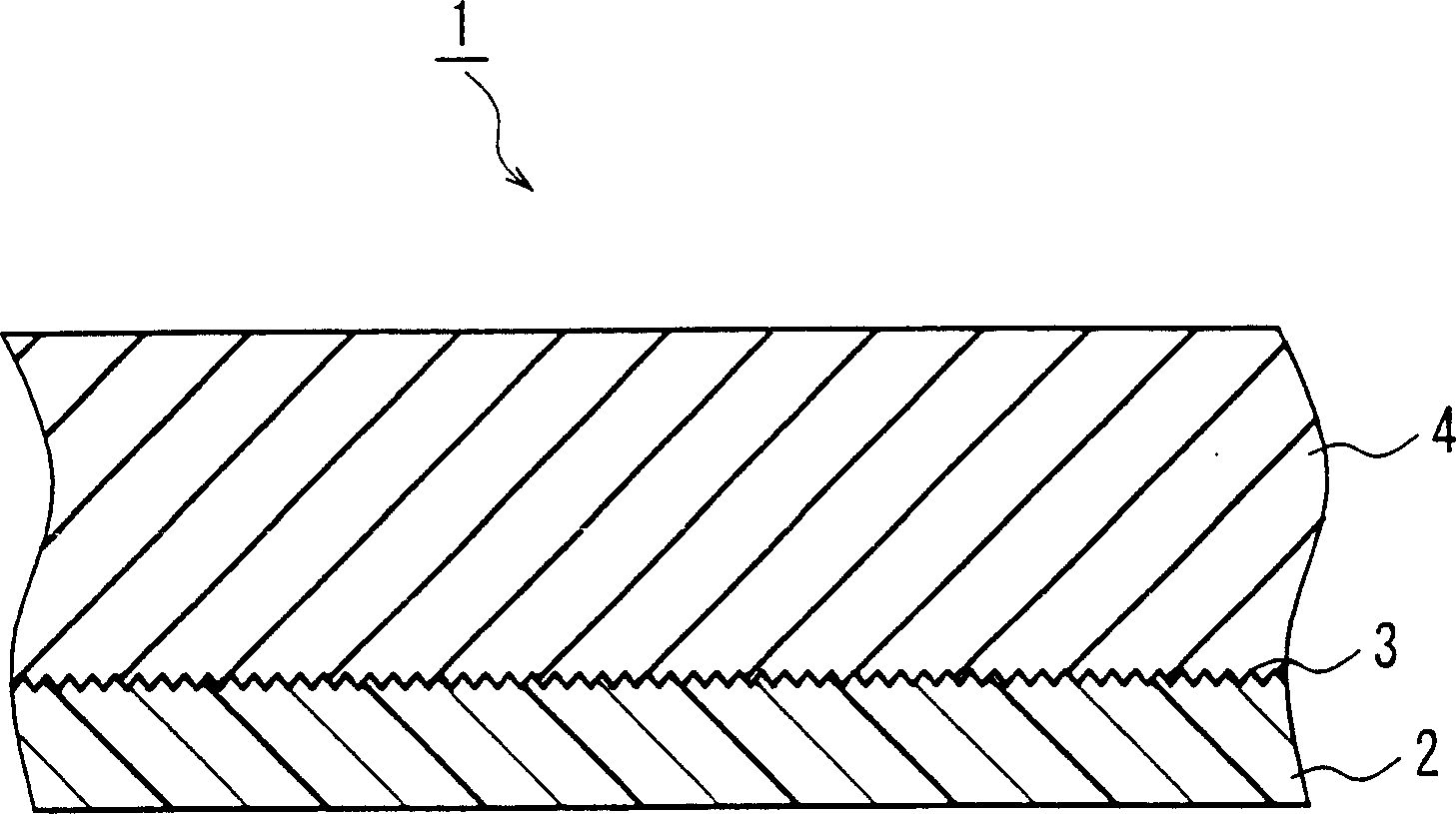

Thermal pressuring separating type sheets and its mfg. method

InactiveCN1498840AGood electrificationIncreased durabilityStatic indicating devicesSynthetic resin layered productsElectrically conductiveEngineering

There is a surface activation treated face 3 on at least one face of a glass fiber reinforced electrically conductive fluoro resin sheet 2. A dividing sheet 1 for hot press bonding is obtained by integrating the surface activation treated face 3 of the fluoro resin sheet and a vulcanized heat conductive electrically conductive silicone rubber laminate 4. The manufacturing method the dividing sheet comprises performing a surface activation treatment on at least one side of the glass fiber reinforced electrically conductive fluoro resin sheet 2, and integrating the surface activation treated face 3 of the fluoro resin sheet and the vulcanized silicone rubber laminate 4, in which the laminate was made by impregnating a glass cloth with electrically conductive fluoro resin mixture, sintering to form composite sheet, coating liquid heat conductive electrically conductive silicone rubber on at least one face of the sheet and thermally curing to form integrated laminate. Therefore, a dividing sheet for hot press bonding with high anti-electrostatic effect, excellent dividing capability and high durability can be provided.

Owner:FUJI POLYMER INDUSTRIES CO LTD

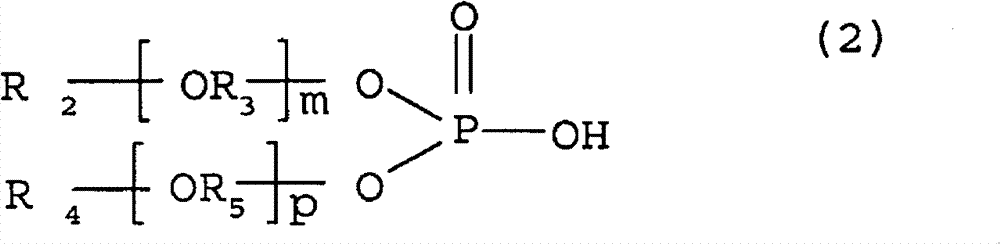

A polymerization catalyst for polythiourethanes, polymerizable liquid composition and process for the production of organic polythiourethane glass with a high refractive index

ActiveCN102906143AExcellent mold releaseReactiveRecord information storageOptical recording/reproducingIsocyanatePhosphoric acid

Polymerization catalysts are described for organic polythiourethane glass which do not contain organometallic compounds, and consisting of a mixture of a tertiary aliphatic amine and a disubstituted phosphoric acid in a molar ratio ranging from 1 / 1.3 to 1 / 20. Polymerizable liquid compositions of the polythiourethane type are also described, essentially consisting of three components (A), (B) and (C), wherein component (A) contains at least one cycloaliphatic diisocyanate monomer wherein the weight percentage of free isocyanate groups in said component (A) ranges from about 20% to about 50% by weight, preferably from about 25% to about 40% by weight, with respect to the total weight of component (A); component (B) contains at least one polythiol having a molecular weight ranging from 50 to 1,200 g / moles, preferably from 100 to 1000 g / moles, and a functionality ranging from 2 to 5, preferably from 2 to 4, said components (A) and (B) being present in a weight ratio varying from 0.5:1 to 2:1; component (C) being said polymerization catalyst. The process is also described for the production of organic glass starting from said polymerizable liquid compositions of the polythiourethane type.

Owner:MITSUI CHEM INC

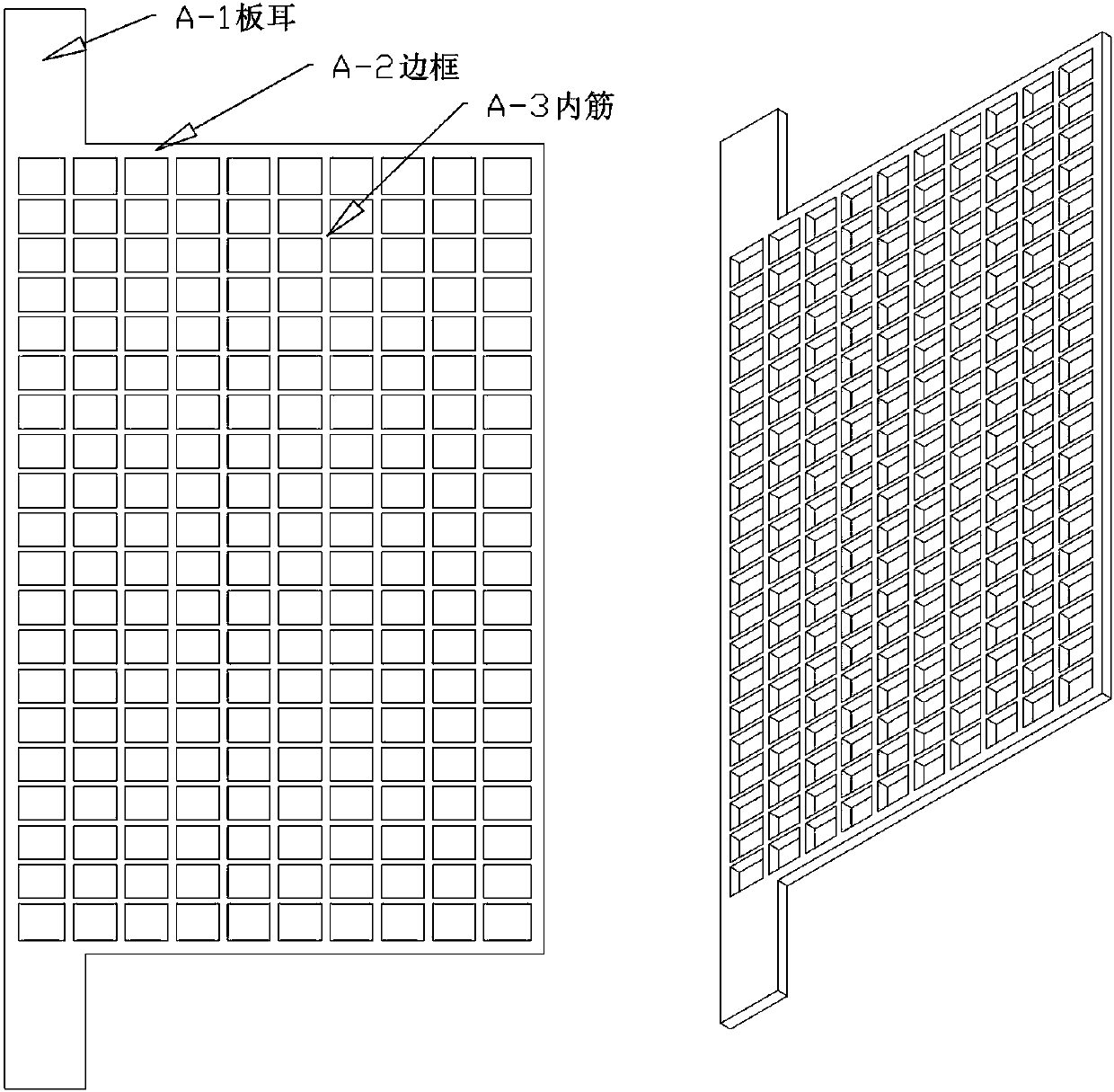

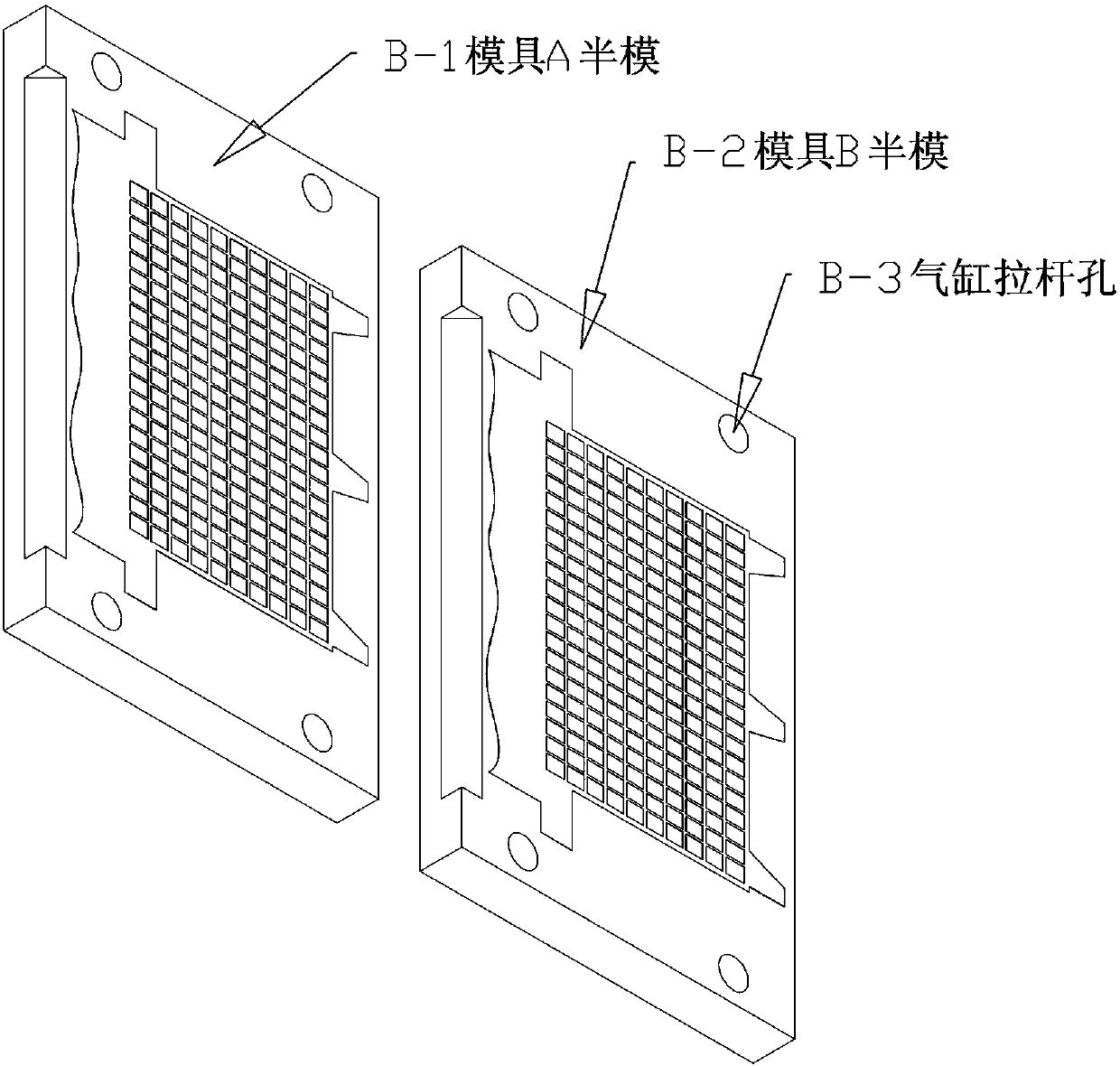

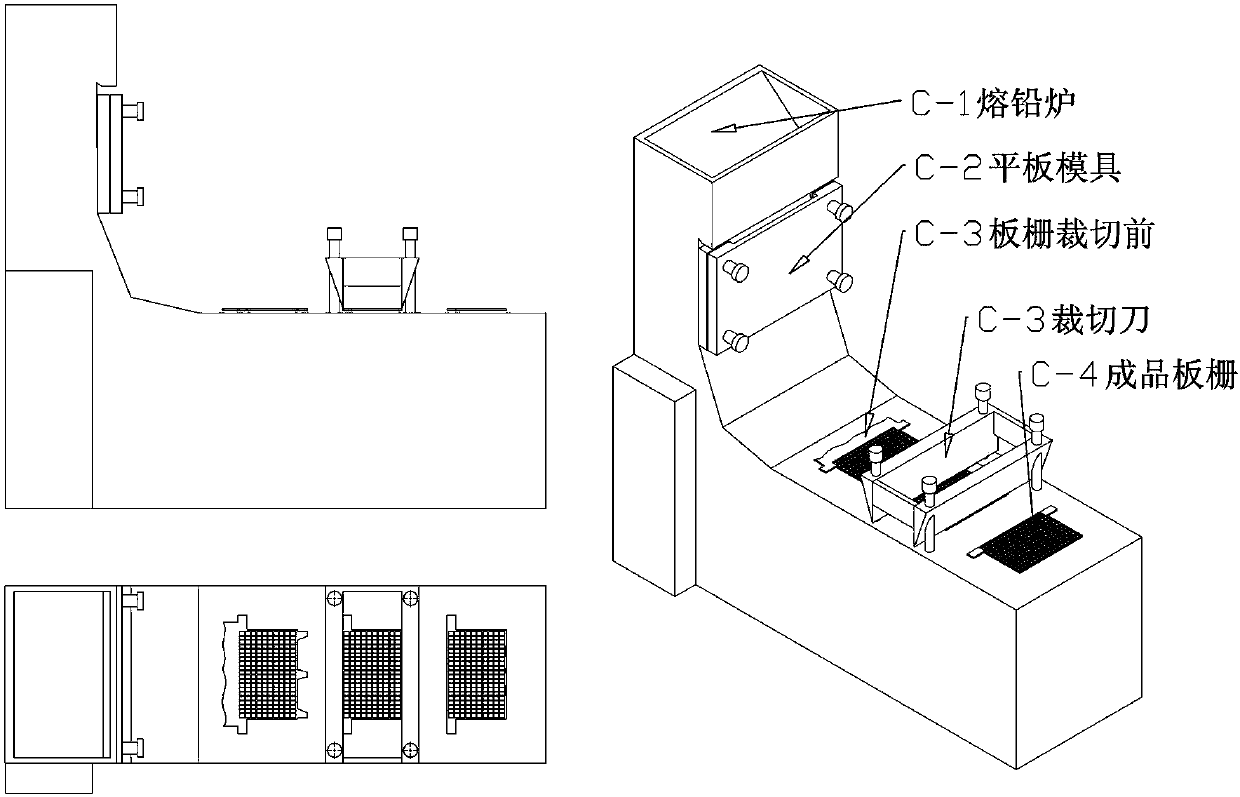

Storage battery grid mold release agent and preparation method thereof

ActiveCN103624211AHeat dissipation fastIncrease productivityFoundry mouldsFoundry coresCell fabricationManufacturing engineering

The invention belongs to the field of storage battery manufacturing technology, and particularly relates to a storage battery grid mold release agent and a preparation method thereof. The storage battery grid mold release agent is prepared from the following raw materials in parts by weight: 0.3-0.7 part of bone glue, 0.4-0.8 part of polyethylene, 0.4-0.8 part of kieselguhr, 0.2-0.5 part of glass water, 0.3-0.7 part of aluminum dihydrogen phosphate, 2-4 parts of cork powder of 200-300 meshes, 2-4 parts of cork powder of 700-800 meshes, and 88.5-94.4 parts of water. The storage battery grid mold release agent is easy to bond, high-temperature-resistant and smooth to exhaust; the prepared grid has fewer pores, thus being easily formed in casting.

Owner:HENAN CHAOWEI POWER SUPPLY

Curable resin composition, cured article and optical artical

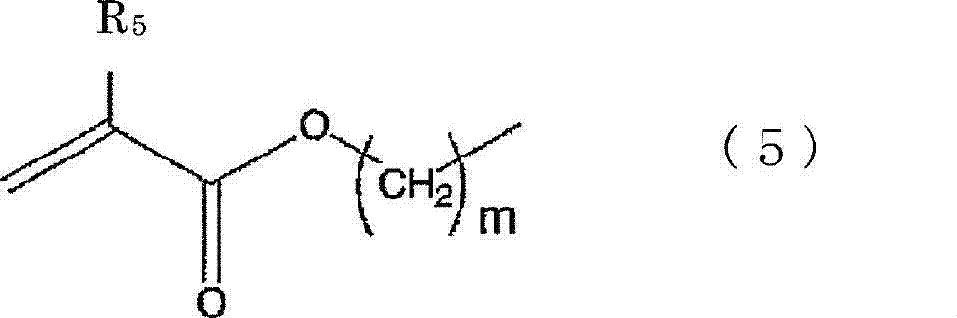

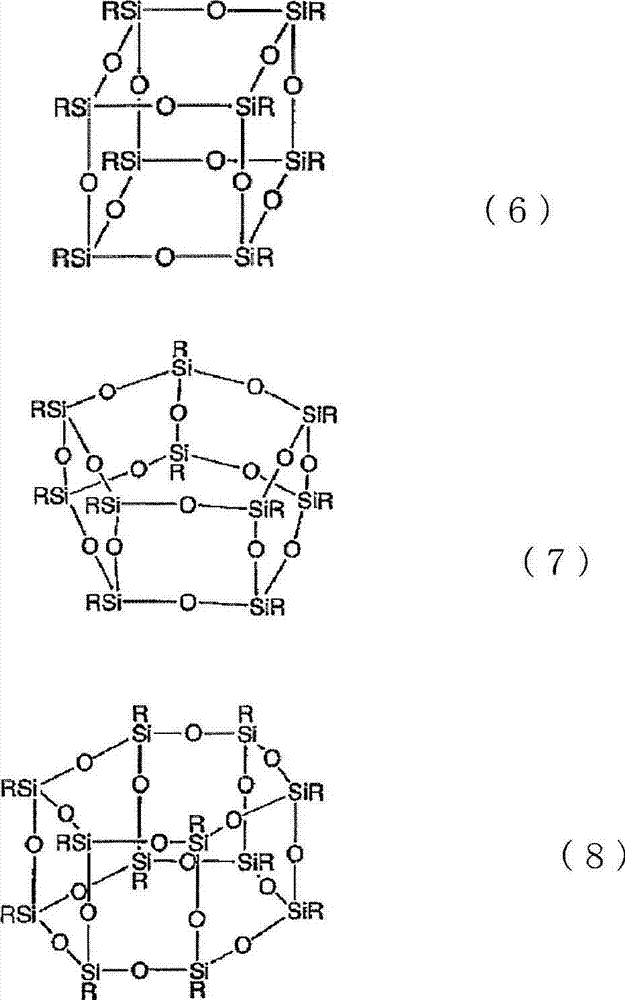

InactiveCN103172803AGood transferabilityExcellent optical propertiesOptical elementsHeat resistanceSolvent

The invention provides a curable resin composition and a cured article thereof, wherein excellent optical characteristic, heat resistance, precise metal mould transfer-printing performance are provided, and the curable resin composition is excellent material for preparing an optical lens and a prism. The curable resin composition contains 20 to 80 wt% of a component (A) which has a plurality of reactive unsaturated group, Mw is 2000 to 100000 and the toluene and so on can be dissolved in solvent soluble multi-functional co-polymers; 5.0 to 50 wt% of the (B) component the [R1SiO 3 / 2 ] n, wherein R1 is provided with methyl propylene acyl organic functional groups, n is 10 or 8 or 12 and the organic polymer silsesquioxane as main component of organic silicon resin; 5.0 to 75wt % of a component (C) is in the molecule have 1 to 6 methyl propylene acyl of methyl acrylic ester; and 0.1 to 10 wt% d of the ingredient (D) which is the initiator.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

Hot press molding technique for special optical glass element

InactiveCN101293727AImprove work efficiencySave moneyGlass pressing apparatusGlass productionSlow coolingOpto electronic

The invention relates to a hot-press forming technique for special optical glass elements, which is carried out by three steps and comprises heating process, forming process and slow cooling process; the hot-press forming technique is characterized in that:1) the heating process: heating high precision optical elements and an optical glass precision high temperature softening furnace to the high temperature of 1200 DEG C and heating the special optical elements and optical glass raw materials to above the softening temperature Tg to reach forming requirements; 2) the forming process: putting the softened high precision optical elements and the optical glass raw materials in a heat insulation metal module and taking a single piece by hands to put the single piece in the environment within the temperature range of 300 to 650 DEG C for the press forming; 3) the slow cooling process: using a tunnel-typed annealing furnace for lowering temperature and annealing at the temperature of 700 to 400 DEG C for about 4 hours. The novel technique adopted by the invention accelerates the production speed, greatly improve the working efficiency of a forming machine, meanwhile improves working efficiency per unit hour, thus leading components to reach comparatively high size precision, surface shape precision and surface roughness and opening the era of non ball surfaced optical glass components being widely used as photoelectric instruments.

Owner:杭州宇福光学有限公司

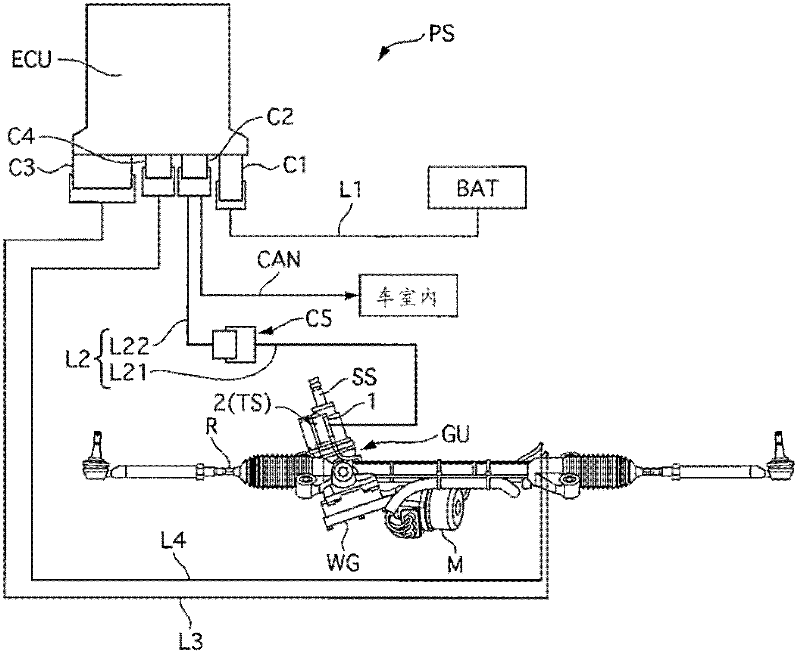

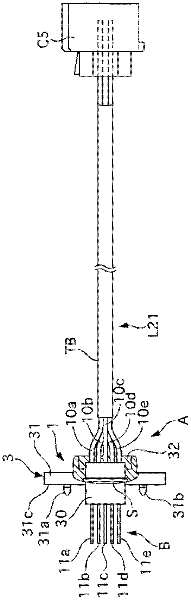

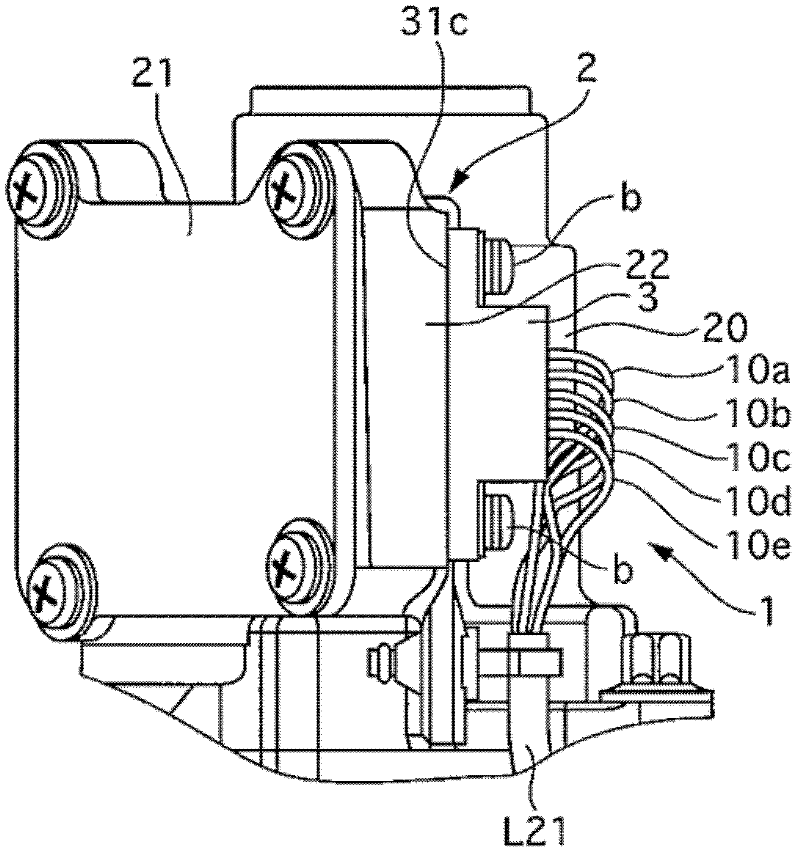

Connector and production method

InactiveCN102570141AEfficient filling operationsPrevent immersionVehicle connectorsElectrically conductive connectionsAdhesiveFixed position

The present invention relates to a connector and a production method. The connector has a simple structure and maintains good waterproof characteristics. The connector has a molding unit (30) and a sealing unit (32). The molding unit is formed by that the uncovered portions (B) of covered wires (10a-10e) project on the x positive side from a first end of the molding unit and the covered portions (A) of covered wires (10a-10e) project on the x negative side from a second end of the molding unit, and thereby holding the conducting lines to fix positions of the conducting lines relative to one another. The sealing member of an adhesive (32) adheres to the second end of the molding unit (30) on the x negative side and adheres to the outer circumferential surface of the insulating covering of the covered segment of each covered wire (10a-10e) .

Owner:HITACHI ASTEMO LTD

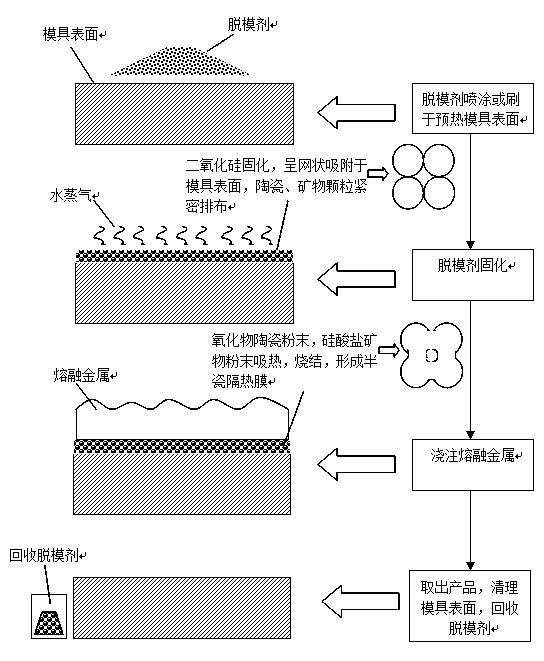

Mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding

ActiveCN103537613AIncrease contact interfaceReduce porosityFoundry mouldsFoundry coresThermal fatiguePhysical chemistry

The invention provides a mold-releasing type complexing agent with effects of resisting a high temperature of more than 1450 DEG C, insulating heat and demolding and a preparation method thereof. The mold-releasing type complexing agent comprises the following raw materials in percentage by weight: 20-60% of nano colloidal silicon dioxide solution; 5-30% of composite oxide ultramicro (0.1-1.0 microns) powder including Na, Mg, Ca, Fe, Li, Al, Si, B, Zr and other elements; 0.2-2% of water-based dispersing agent;0.02-0.5% of water-based thickening agent and the balance of water; and the sum of the weight of the components is 100%. According to the mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding, the nano colloidal silicon dioxide solution is cooperated with the ultramicro (0.1-1.0 microns) multielement composite oxide powder, so that the excellent performances of high temperature resistance, heat insulation, demolding, environment protection and the like are achieved, the thermal fatigue resistance of the mold surface is effectively improved, and the service life of the mold is prolonged. The mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding is particularly applicable to using at the part of a mold directly contacting molten steel in fired mold casting and other high temperature forming technologies of metal.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

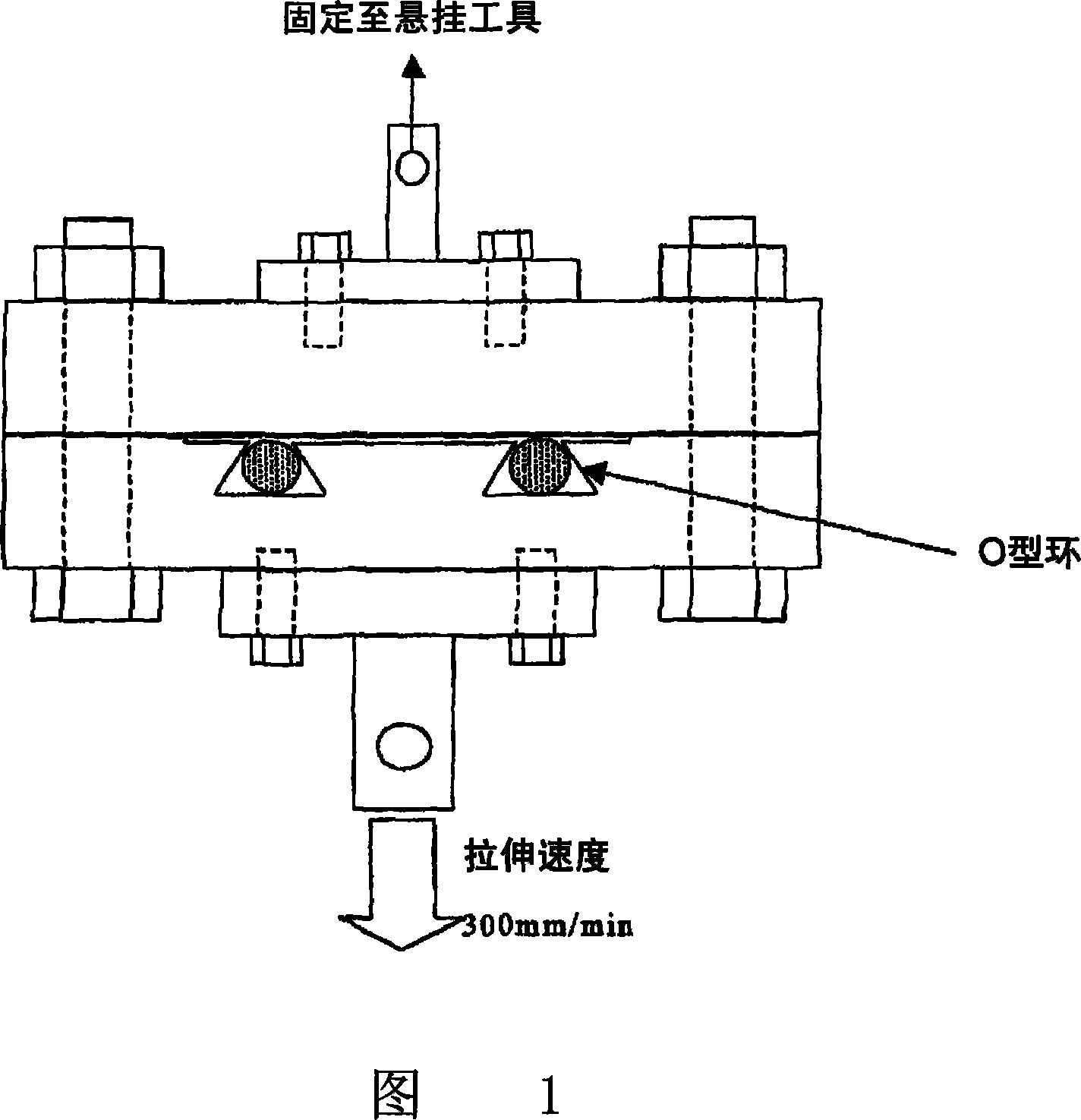

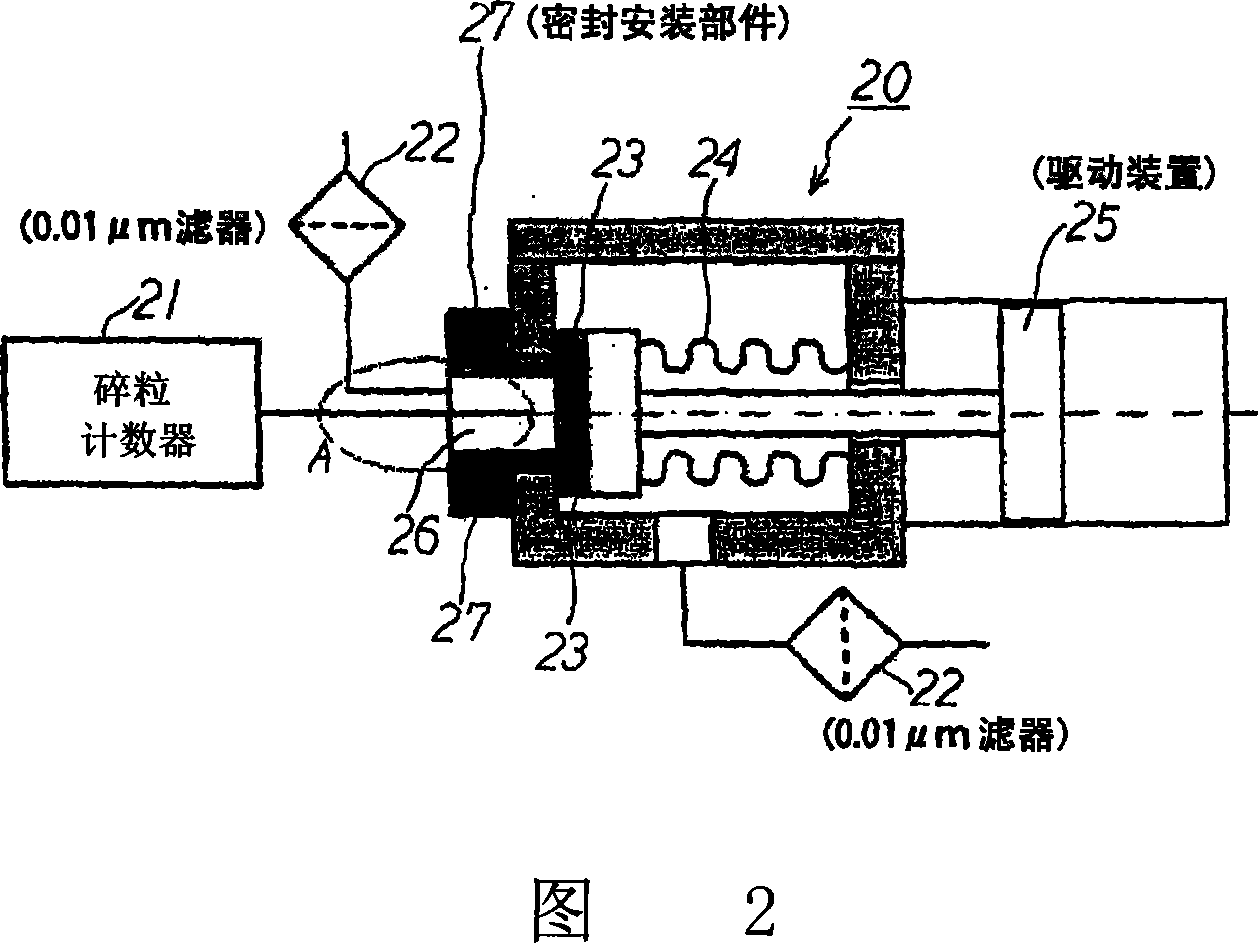

Rubber composition and sealing material for plasma treatment device

A rubber composition which comprises (a) a crosslinkable fluororubber, (b) a reactive fluorine-containing compound (except the crosslinkable fluororubber (a)) having a divalent perfluoropolyether structure or divalent perfluoroalkylene structure and containing, in the terminal or a side chain thereof, two or more of alkenyl groups capable of conducting an addition reaction at least with a hydroxyl group in the following organic silicon compound (c), and (c) a reactive organic silicon compound having two or more of hydroxyl groups in the molecule thereof and being capable of conducting an addition reaction with an alkenyl group in the above compound (b), in such amounts wherein the total amount of (b) and (c) is 1 to 10 parts by weight relative to 100 parts by weight of said rubber (a), and further comprises a vulcanizing agent and optionally a co-crosslinking agent; and a sealing agent for a plasma treatment device, which is produced by subjecting said composition to the primary vulcanization and forming, and then subjecting unreacted components in the resultant formed article to the secondary vulcanization in a vacuum oven, to thereby reduce the amount of a gas which is an unreacted component and may be discharged. The above sealing agent for a plasma treatment device is less prone to cause the stick or adhesion onto a mating member, is free from the problem of generation of particles and from the contamination by a discharged gas, even in the case of continuous use for a long period of time at a high temperature, in particular, in a semiconductor manufacturing process or the like, and can be produced at a low cost.

Owner:NIPPON VALQUA IND LTD

Hot mould centrifugal cast iron pipe mold paint and preparation method thereof

ActiveCN101693281AImprove breathabilityGood heat insulationFoundry mouldsFoundry coresSodium BentoniteEconomic benefits

The invention relates to a hot mould centrifugal cast iron pipe mold paint and a preparation method thereof. The invention mainly solves the technical difficulties of poor quality and low yield and poor economic benefit of a cast iron pipe produced by the traditional paint. The technical scheme is achieved as follows: the hot mould centrifugal cast iron pipe mold paint comprises the following components in percentage by weight: 14-16 percent of kaoline, 14-16 percent of burned diatomite, 2-4 percent of sodium base bentonite, 2-3.5 percent of talcpowder and 64-68 percent of water. The preparation method comprises the following steps: firstly, adding the kaoline, the burned diatomite, the sodium base bentonite and the talcpowder in percentage by weight into a mixing pan for dry mixing; secondly, adding 1 / 4 of water with weight percentage of 64-68 percent into the mixing pan; thirdly, mixing and rolling into a hard paste material for storage for later use; fourthly, when in use, putting the material into a wheel-rolling mixer, adding the left 3 / 4 of water into the wheel-rolling mixer for mixing-rolling and obtaining the mold paint when the concentration reaches 1.2.

Owner:绛县恒通铸造有限公司

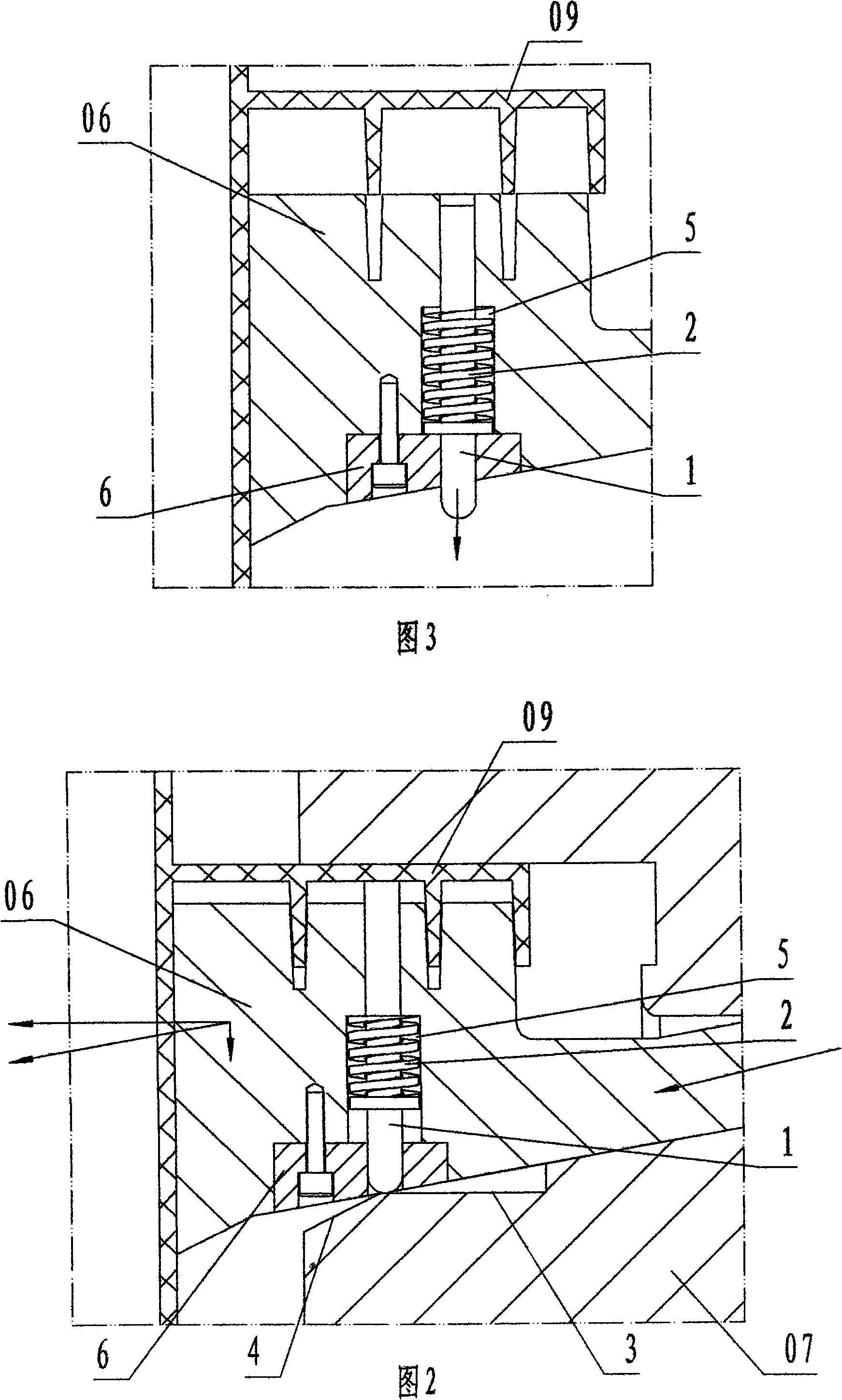

Core-pulling and demoulding combination device

The invention declares a core-pulling and demoulding combination device, which comprises a fixed template and a movable template forming a cavity, wherein a slide block, an inclined guide post, a lateral mold core, a positioning mechanism and an ejector rod are arranged in the cavity; the lateral mold core is hinged to the slide block; the ejector rod and the inclined guide post are fixed in the cavity; the positioning mechanism comprises a compression spring and a bolt; the inclined guide post is fixed on the fixed template; the lateral mold core is hinged to the slide block through a pin; during mold opening, the fixed template move upwards, the inclined guide post drives the slide block to move to the left in a guide sliding chute in the movable template, so as to complete the core-pulling action; in order to guarantee that during mold closing, the inclined guide post can accurately enter into an inclined hole in the slide block to facilitate reset of the slide block, a positioning device is arranged on the mechanism; and with the bolt and the compression spring, the slide block is propped against a spacing stop block for positioning when withdrawn. During the whole process, the demoulding and core-pulling are good in processing property, the cost is low, and therefore, the device provided by the invention is suitable for medium and small sized injection moulded pieces.

Owner:AIMBON (CHENGDU) ELECTRIC APPLICANCE CO LTD

Molding sand for gravity casting and preparation process thereof

ActiveCN106077421AContain ineffective ingredientsExcellent mold releaseFoundry mouldsFoundry coresSodium BentoniteMaterials science

The invention discloses molding sand for gravity casting and a preparation process thereof. The molding sand comprises 100 parts of mixed sand, 0.8-1.2 parts of bentonite, coal dust accounting for 30-50% of the bentonite by mass, and 3-5 parts of water; and the 100 parts of mixed sand is prepared by mixing 93-96 parts of old sand with 4-7 parts of new sand, and the above-mentioned parts are by mass. Homogeneous and qualified clay green sand with stable performance can be obtained through the molding sand for gravity casting and the preparation process thereof.

Owner:SUZHOU DONGHAI GLASS MOLD

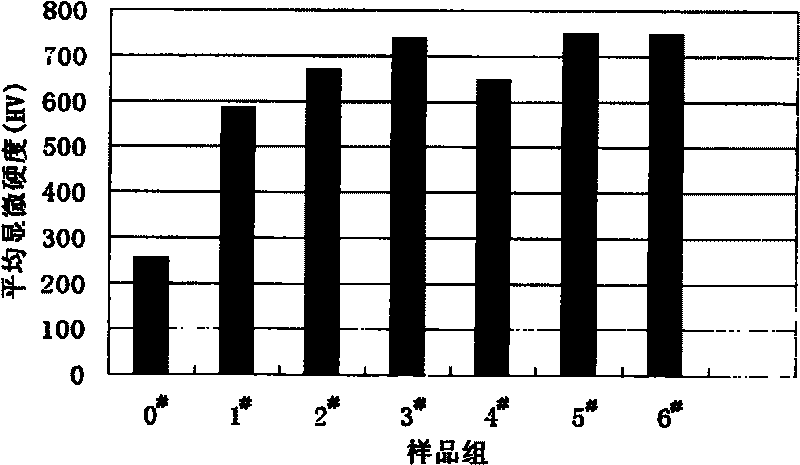

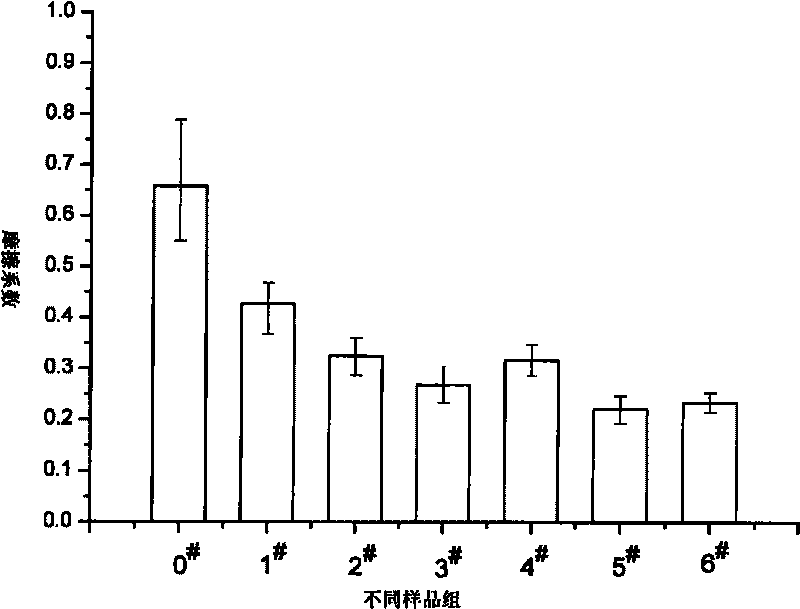

Composite coating used for surface of glass die and electroplating method thereof

InactiveCN101723599AImprove wear resistanceImprove high temperature oxidation resistanceElectrolytic coatingsMetallic materialsSodium tungstate

The invention discloses a composite coating used for the surface of a glass die and an electroplating method thereof, which belong to the technical field of surface treatment of metal materials. The composite coating uses Ni-W as matrix, contains rare-earth oxide particles, and comprises the following components in percentage by weight: 41 to 52 percent of Ni, 44 to 47 percent of W and 1 to 15 percent of rare-earth oxide. The method comprises the following steps: adding the rare-earth oxide particles into electroplating solution which uses sodium tungstate and nickel sulfate as main salts to form plating solution, and controlling the contents of the sodium tungstate, the nickel sulfate and the rare-earth oxide particles and the category and content of a co-deposition accelerator, pH value, current density and plating solution stirring to obtain the rare-earth oxide doped Ni-W composite coating. The composite coating has the advantages of simple process, little pollution, safety, low comprehensive cost, high coating hardness, abrasion resistance and high-temperature oxidation resistance and good self-lubricating performance, and has lower friction coefficient in opposite friction with the molten glass so that the die has good release performance.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com