A polymerization catalyst for polythiourethanes, polymerizable liquid composition and process for the production of organic polythiourethane glass with a high refractive index

A technique for polymerizing catalysts and polymerizing compositions, which is applied in the fields of plexiglass, polymerizable liquid compositions, and organic polythiourethane glass, and can solve the problems of being unsuitable for industrial-scale production of optical products and inability to obtain polymerizable liquid compositions. Achieve good optical properties, improve toughness and impact strength, and good mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] Composition No. 1 consisting of components (A), (B) and (C) in the amounts indicated in Table 1 was prepared according to the invention.

[0154] Component (A)

[0155] Component (A) consists of 4,4'-methylenebis(cyclohexylisocyanate).

[0156] Component (B)

[0157] Components obtained by mixing bis(3-mercaptopropionate)ethylene glycol and 2,3-bis((2-mercaptoethyl)thio)-1-propanethiol at 25°C and a pressure of 10 mbar (B).

[0158] Component (C)

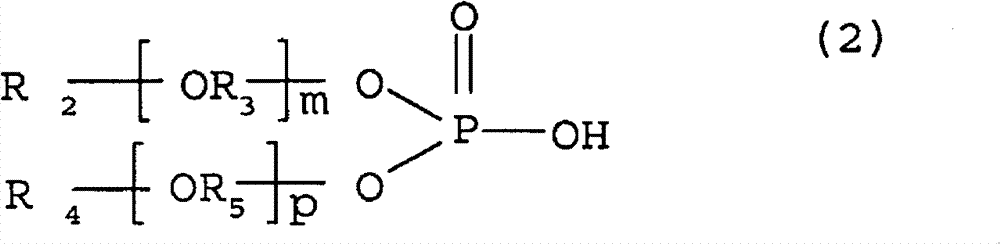

[0159] Component (C) was obtained by mixing triethylamine and di(2-ethylhexyl)phosphate at 25°C.

[0160] Table 1

[0161]

[0162] Abbreviation

[0163] H12MDI=4,4'-methylene bis(cyclohexyl isocyanate)

[0164] GDMP = bis(3-mercaptopropionate) ethylene glycol

[0165] DMPT=2,3-bis((2-mercaptoethyl)thio)-1-propanethiol

[0166] TEA = triethylamine

[0167] Bis(2-EHP) = bis(2-ethylhexyl) phosphate

[0168] Casting (manual casting)

[0169] 1,500 g of component (A) and 9 g of previously prepared component...

Embodiment 2

[0182] According to the operation procedure of Example 1, compositions 2 to 5 of the present invention were prepared, which consisted of components (A), (B) and (C) in the amounts and conditions shown in Table 4.

[0183] Table 4

[0184]

[0185] The initial viscosity was measured on the degassed clear solution thus obtained, and then the viscosity at the same temperature was measured in successive times to obtain the values shown in Table 5.

[0186] table 5

[0187]

[0188] The above data indicate a pot life of more than 2 hours in each case and are therefore suitable for the production of optical articles on an industrial scale by manual casting techniques.

[0189] The data presented in Table 5 also show how the stability of the inventive mixture can be varied by adjusting the catalyst concentration and the molar ratio between the two components of the catalyst.

[0190] The polymerizable compositions Nos. 2 to 4 thus obtained were poured into glass molds and p...

Embodiment 3

[0195]Composition No. 6 consisting of components (A), (B) and (C) in the amounts indicated in Table 7 was prepared according to the invention.

[0196] Component (C) is obtained by mixing the following products at 25°C:

[0197] 1,2,2,6,6-Pentamethyl-4-piperidinyl sebacate methyl ester (25% by weight) and bis(1,2,2,6,6-pentamethyl-4-piperidine base) sebacate (75% by weight);

[0198] Bis(2-ethylhexyl) phosphate (Bis(2-EHP)).

[0199] Table 7

[0200]

[0201] The initial viscosity was measured on the degassed clear solution thus obtained, and then the viscosity at the same temperature was measured in successive times, obtaining the values shown in Table 8.

[0202] Table 8

[0203]

[0204] The above data indicate a pot life of more than 2 hours in each case and are therefore suitable for the production of optical articles on an industrial scale by manual casting techniques.

[0205] The polymerizable composition No. 6 thus obtained was poured into a glass mold an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com