Rubber composition and sealing material for plasma treatment device

A technology of rubber composition and compound, which is applied in the field of rubber composition and sealing material for plasma treatment equipment, and achieves the effects of excellent plasma resistance, safe manufacturing, and good mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

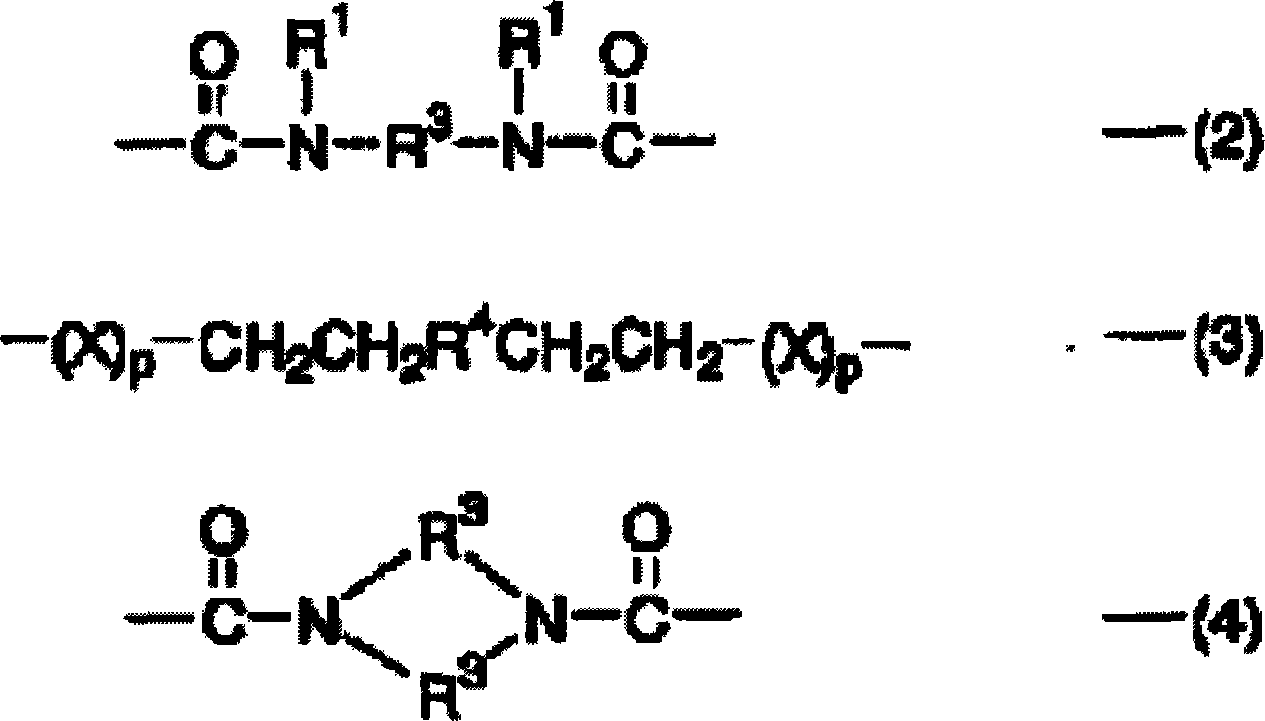

[0158] In "Daiel G912" which is a cross-linkable fluorine-containing rubber {peroxide-curable 3-component fluorine-containing copolymer = vinylidene fluoride (CF 2 =CH 2 ) / hexafluoropropylene (CF 3 -CF=CF 2 ) / tetrafluoroethylene (CF 2 = CF 2 ), fluorine content 71% by mass, Mooney viscosity ML 1+10 (100° C.) 76, manufactured by Daikish Kogyo Co., Ltd. }, mixed with "SIFEL8070A / B" (manufactured by Shin-Etsu Chemical Co., Ltd.), cross-linking agent {"パヘキサ25B", manufactured by NOF Corporation, 2,5-dimethyl-2,5-di(t- Butyl peroxy) hexane}, and a co-crosslinking agent {"TAIC" produced by Nippon Chemical Industry Co., Ltd., triallyl isocyanurate} were kneaded at a temperature of 60° C. for 1.0 hour using an open mixer, A rubber composition is obtained. This "SIFEL8070A / B" is a platinum group compound catalyst for an addition reaction containing a reactive fluorine-containing compound (b), a reactive organosilicon compound (c), and (b) and (c), and passes (b) and The reaction ...

Embodiment 2~5

[0164] In Example 1, except that the compounding ratio composition etc. were changed as shown in Table 1, it carried out similarly to Example 1, and obtained the molded body.

[0165] Under the above-mentioned test conditions, the normal physical properties, compression set (%), fixation test (N), and plasma resistance (weight loss rate (%), conditional shielding for 3 hours) shown in Table 1 were measured for the obtained molded body.

[0166] The results are shown in Table 1.

Embodiment 6

[0168] In Example 1, primary to secondary vulcanization was performed in the same manner as in Example 1, except that the secondary vulcanization conditions were changed from 200° C.×12 hours to 180° C.×12 hours as shown in Table 1, to obtain molded articles.

[0169] Under the above-mentioned test conditions, the normal physical properties, compression set (%), fixation test (N), and plasma resistance (weight loss rate (%), conditional shielding for 3 hours) shown in Table 1 were measured for the obtained molded body.

[0170] The results are shown in Table 1.

[0171] In Example 6, it can be seen from Table 1 that the unreacted component is "present", but it is only a very small amount, and the basic normal physical properties, compression set, fixation, and plasma resistance are all good, and there is no problem. The sealing material can be used without any problem if it is located close to piping or the like outside the wafer processing chamber. In addition, "exist" in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com