Composite coating used for surface of glass die and electroplating method thereof

A composite coating and glass mold technology, applied in coatings, electrolytic coatings, etc., can solve problems such as defective products, and achieve the effects of less pollution, low friction coefficient, and high temperature resistance and oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

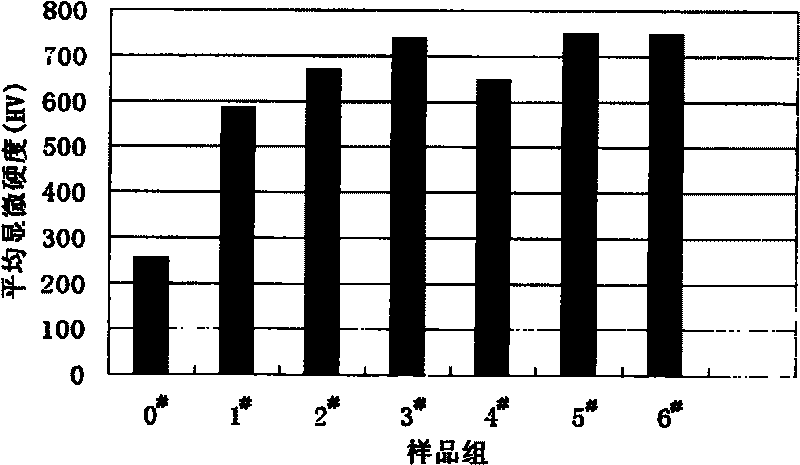

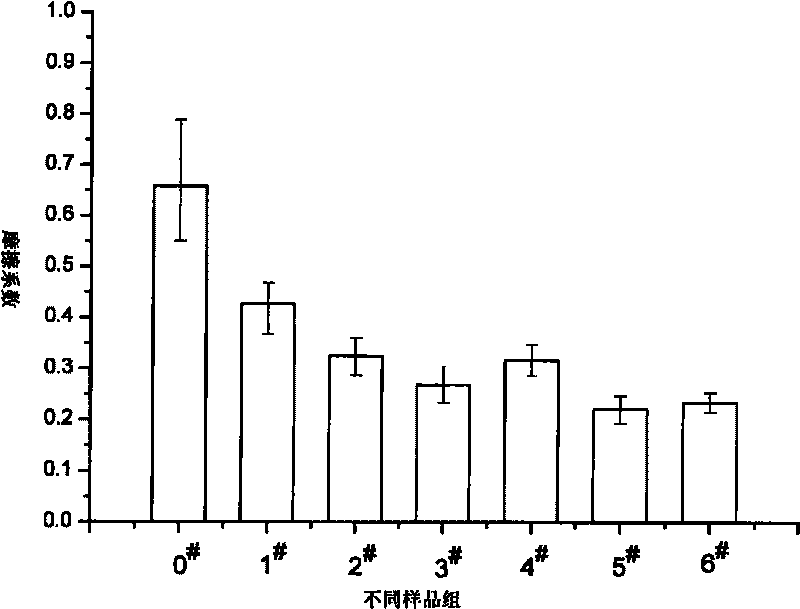

[0029] Plating Ni-W-CeO on glass mold stainless steel samples (30mm×30mm×5mm) 2 Composite coating to obtain sample 2#. The composite coating is based on Ni-W and contains CeO 2 Microparticles, each component by weight percentage is as follows: Ni content is 51%, W content is 44.5%, CeO 2 The content is 4.5%, and the thickness of the obtained composite coating is 20 μm.

[0030] The above-mentioned electroplating method for the composite coating on the surface of the glass mould, the steps are as follows:

[0031] (1) To CeO first 2 Particles are dispersed: 2.5g CeO 2 Put the particles into 15ml of acetone, ultrasonically disperse for 20 minutes, then dry, then add 20ml of deionized water, and then add 0.2g of ethylenediamine as a co-deposition accelerator, 0.15g of triton X- 100, ultrasonically dispersed for 1 hour to obtain CeO 2 particle dispersion;

[0032] (2) 22.5gNa 2 WO 4 2H 2 O, 10gNiSO 4 ·6H 2 O, 36.25gC 6 h 8 o 7 ·H 2 O and 31.25ml NH 3 ·H 2 O was a...

Embodiment 2

[0038] Plating Ni-W-CeO on glass mold stainless steel samples (30mm×30mm×5mm) 2 Composite coating to obtain sample 3#. The composite coating is based on Ni-W and contains CeO 2 Particles, each component by weight percentage is as follows: Ni content is 49%, W content is 43%, CeO 2 The content is 8%, and the thickness of the obtained composite coating is 25 μm.

[0039] The above-mentioned electroplating method for the composite coating on the surface of the glass mould, the steps are as follows:

[0040] (1) To CeO first 2 Particles are dispersed: 5g CeO 2 Put the particles into 20ml of acetone, ultrasonically disperse for 15 minutes, then dry, then add 10ml of deionized water, after that, add 0.2g of cetyltrimethylammonium bromide as a co-deposition accelerator, 0.2g as a dispersion aid agent emulsifier TX-10, ultrasonically dispersed for 2 hours to obtain CeO 2 particle dispersion;

[0041] (2) 22.5gNa 2 WO 4 2H 2 O, 10gNiSO 4 ·6H 2 O, 36.25gC 6 h 8 o 7 ·H 2 ...

Embodiment 3

[0046] Plating Ni-W-La on a glass mold stainless steel sample (30mm×30mm×5mm) 2 o 3 Composite coating to obtain sample 4#. The composite coating is based on Ni-W and contains La 2 o 3 Microparticles, each component by weight percentage is as follows: Ni content is 52%, W content is 45%, La 2 o 3 The content is 3%, and the thickness of the obtained composite coating is 20 μm.

[0047] The above-mentioned electroplating method for the composite coating on the surface of the glass mould, the steps are as follows:

[0048] (1) First to La 2 o 3 Particles are dispersed: first 10g La 2 o 3 Put the particles into 15ml of acetone, ultrasonically disperse for 20 minutes, then dry, then add 20ml of deionized water, then add 0.15g of polyethylene polyamine as co-deposition accelerator, 0.2g of emulsifier NP- 10. Ultrasonic dispersion for 1 hour to obtain La 2 o 3 particle dispersion;

[0049] (2) 17.5gNa 2 WO 4 2H 2 O, 15gNiSO 4 ·6H 2 O, 32.5gC 6 h 8 o 7 ·H 2 O and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com