Patents

Literature

32 results about "Cyclohexylisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

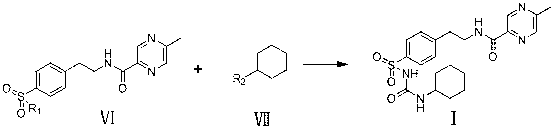

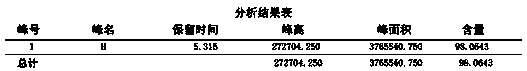

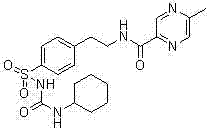

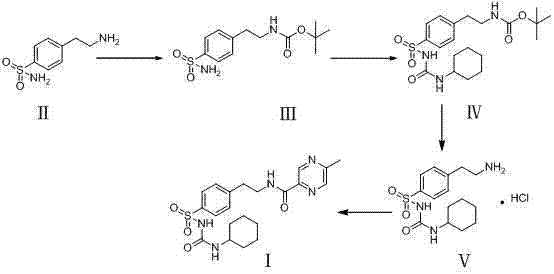

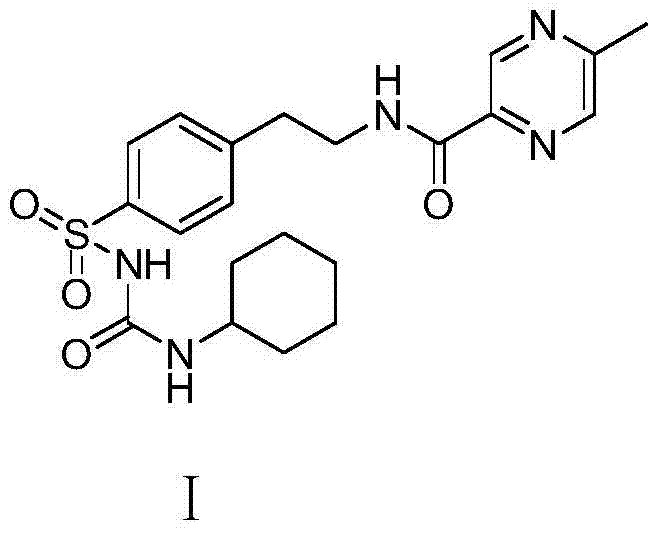

Novel synthesis route of glipizide

The invention relates to a novel synthesis route of glipizide, which is characterized by comprising the following steps of protecting 4-(2-amino ethyl)benzenesulfonic acid ammonia (II) by Boc anhydride to obtain a compound (III); reacting the compound (III) with cyclohexyl isocyanate to obtain a compound (IV); carrying out deprotection on the compound (IV) to obtain a compound (V); and reacting the compound (V) with 2-methyl-5-pyrazine carboxylic acid to obtain the glipizide (I) with the single impurity which is less than or equal to 0.5% and the high purity which is more than or equal to 99%. The process is simple, the yield is high, the purity is high and the single impurity is low; and the process is environment-friendly and industrial production is easy to realize.

Owner:WUHAN WUYAO PHARMA

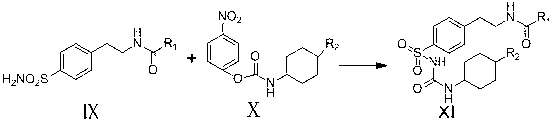

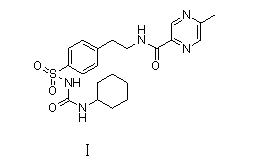

Preparation of glimepiride raw material

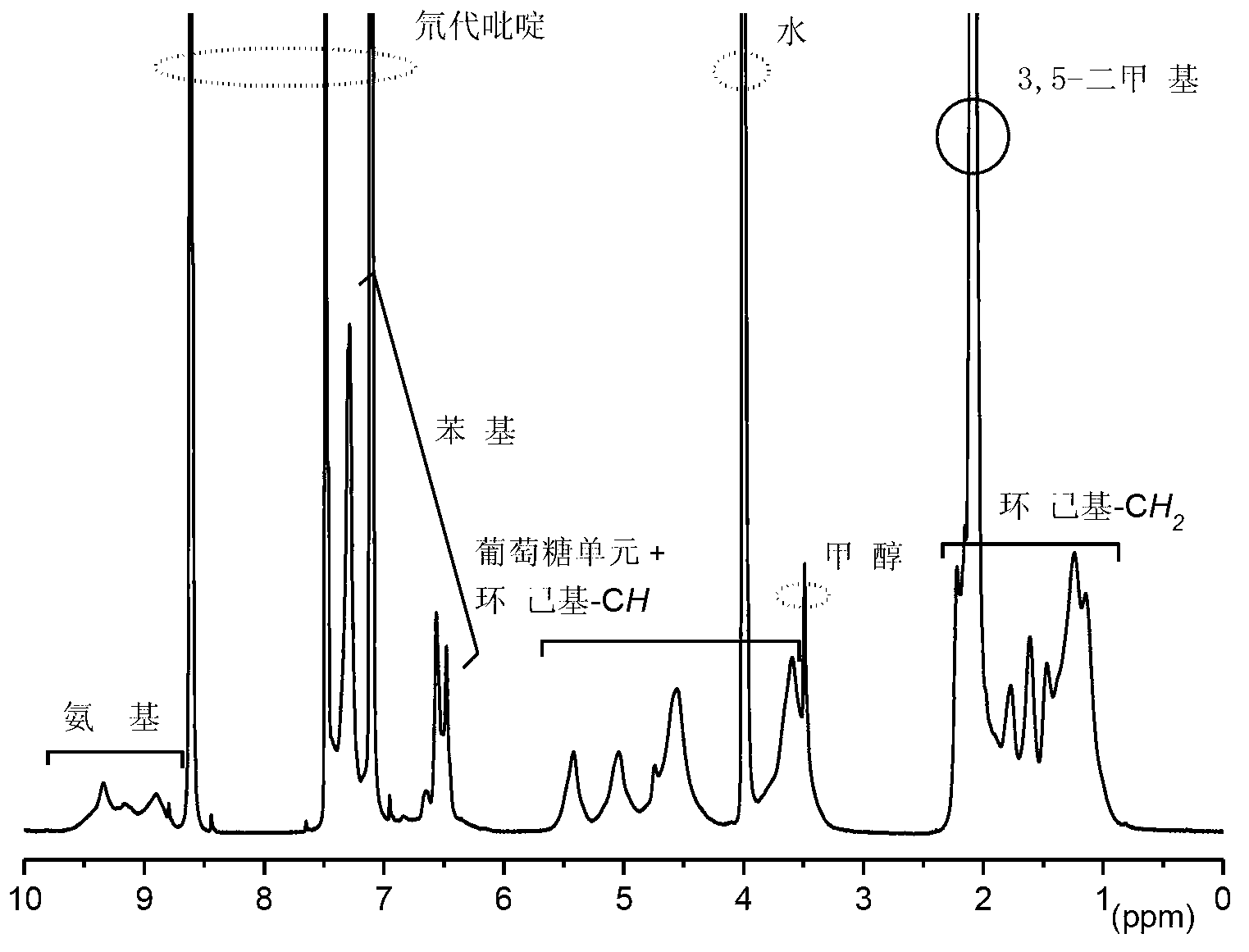

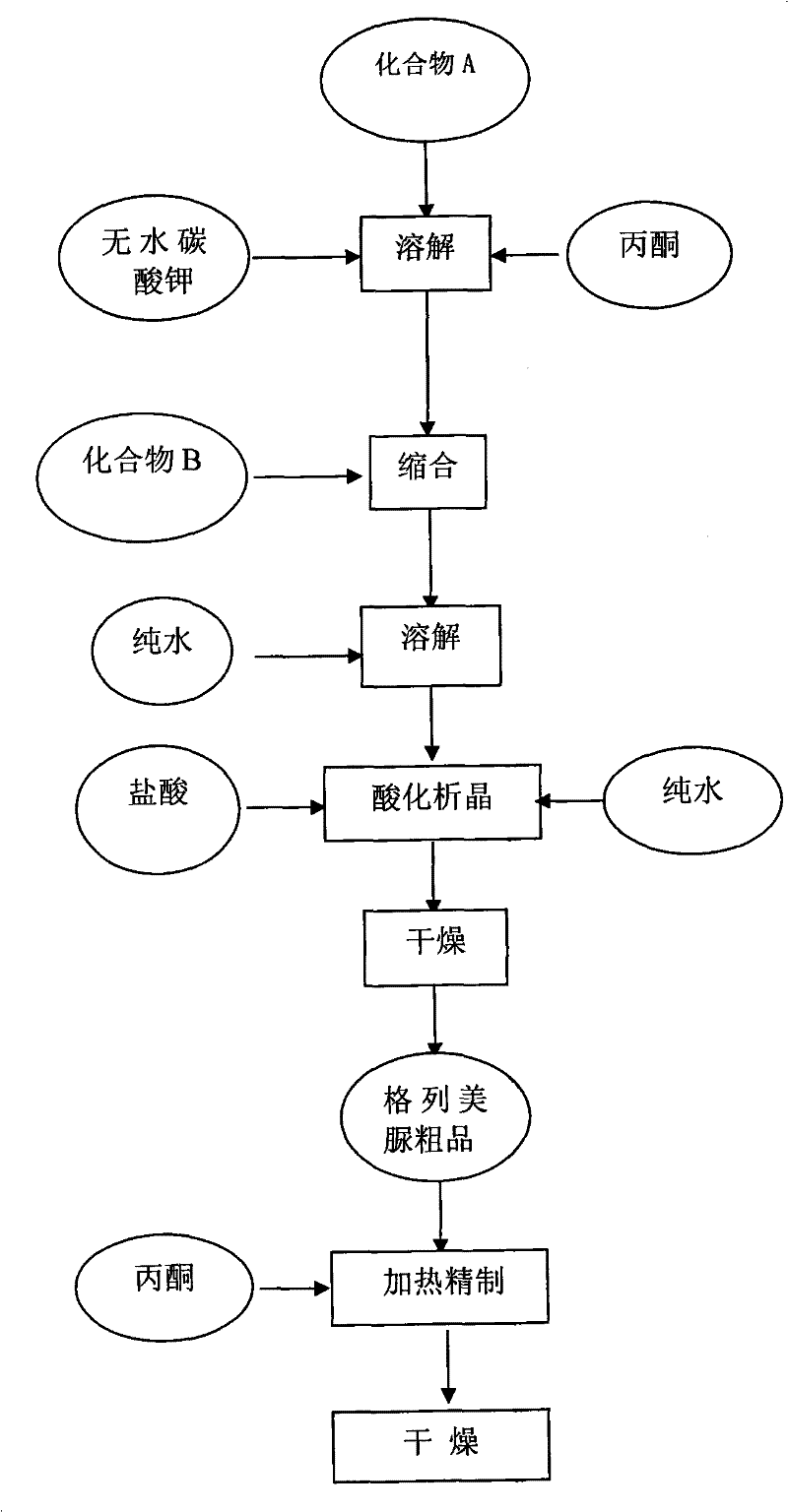

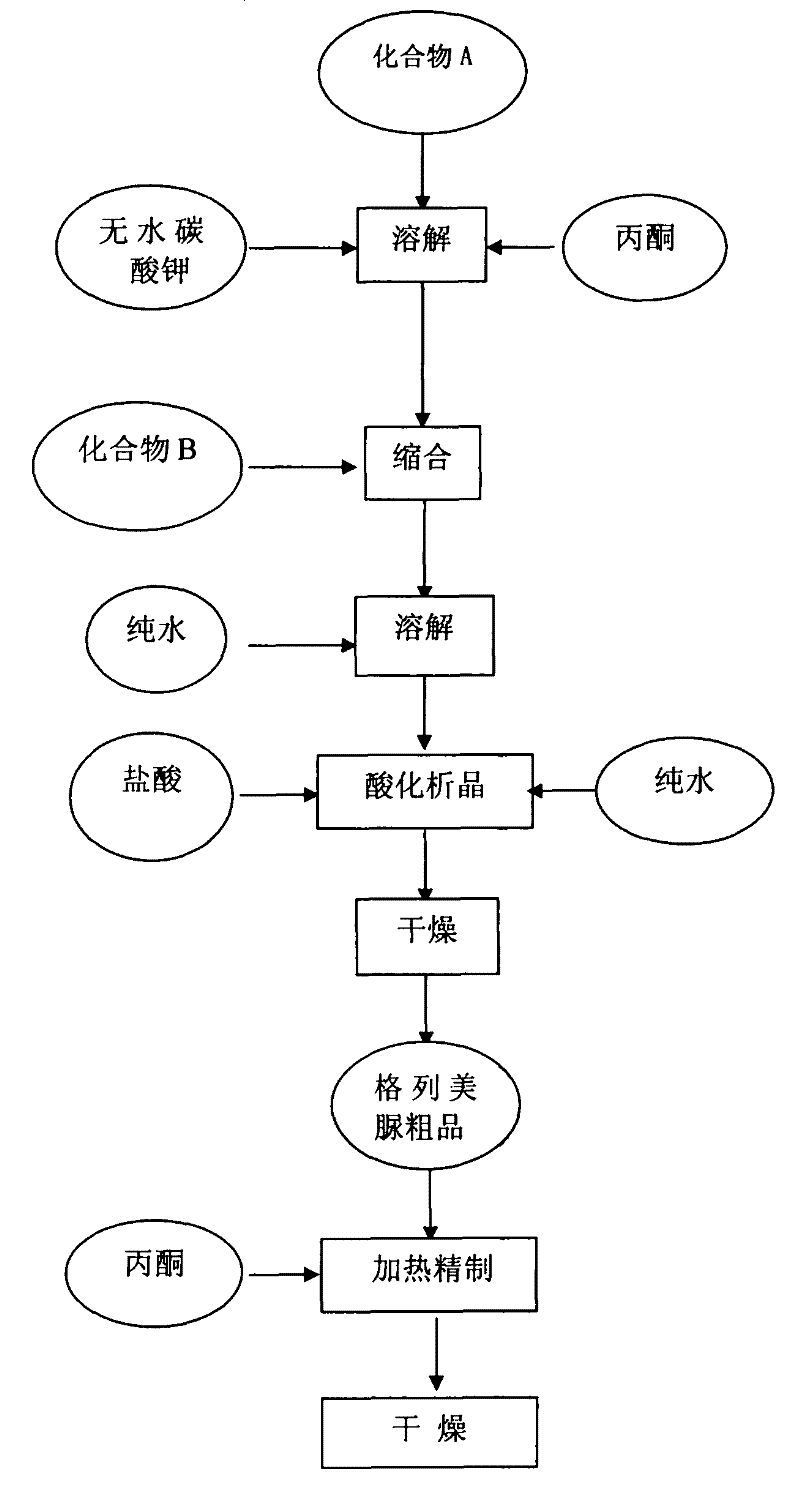

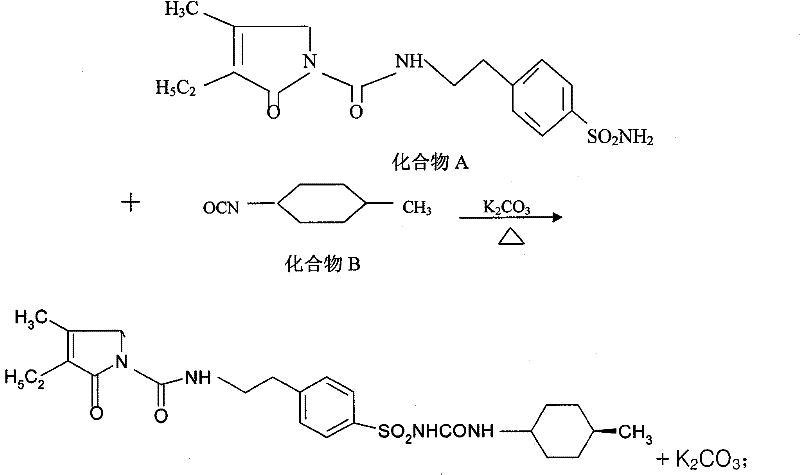

ActiveCN101486674AReduce usageResidue reductionOrganic chemistryMetabolism disorderCyclohexylisocyanateMass ratio

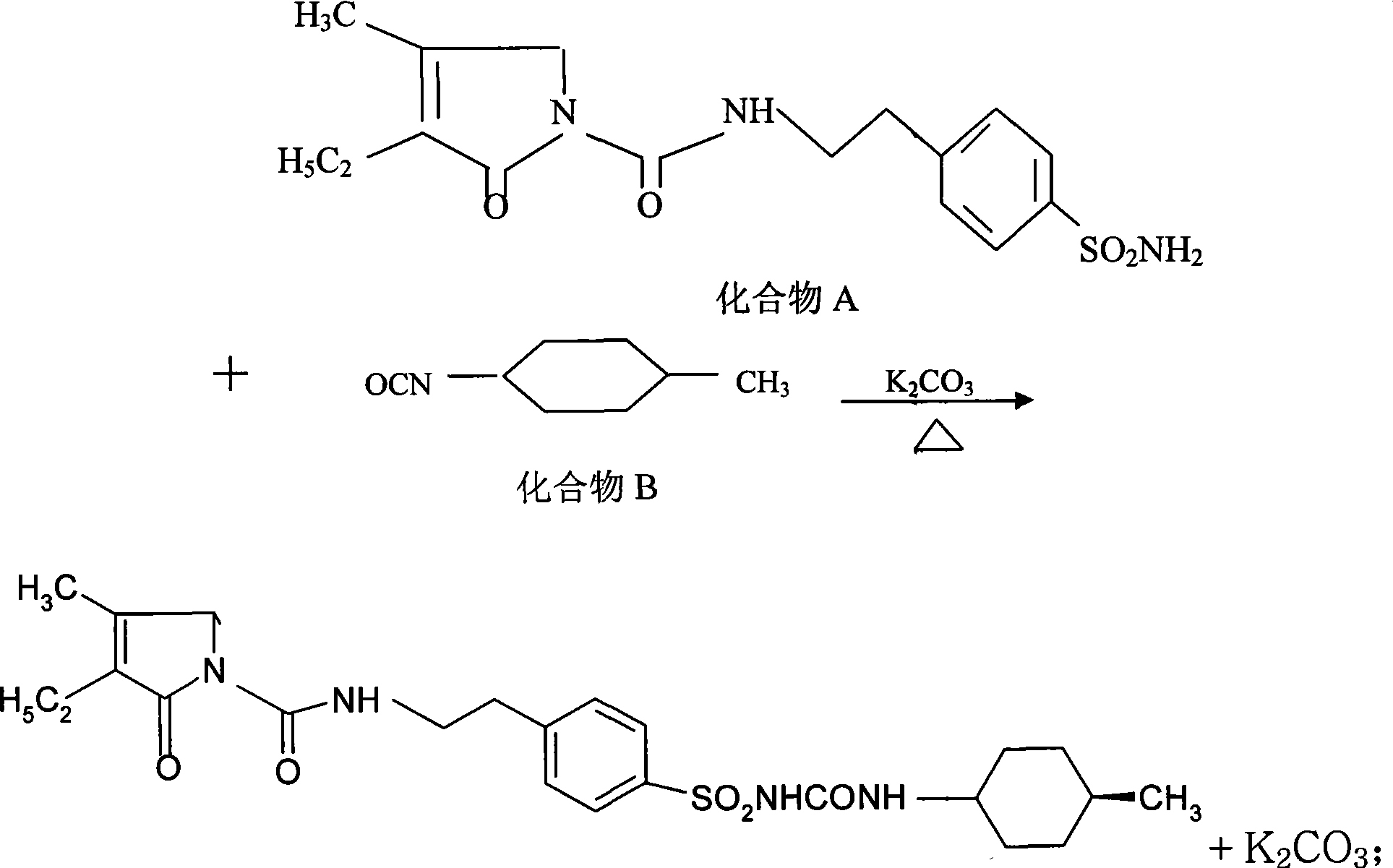

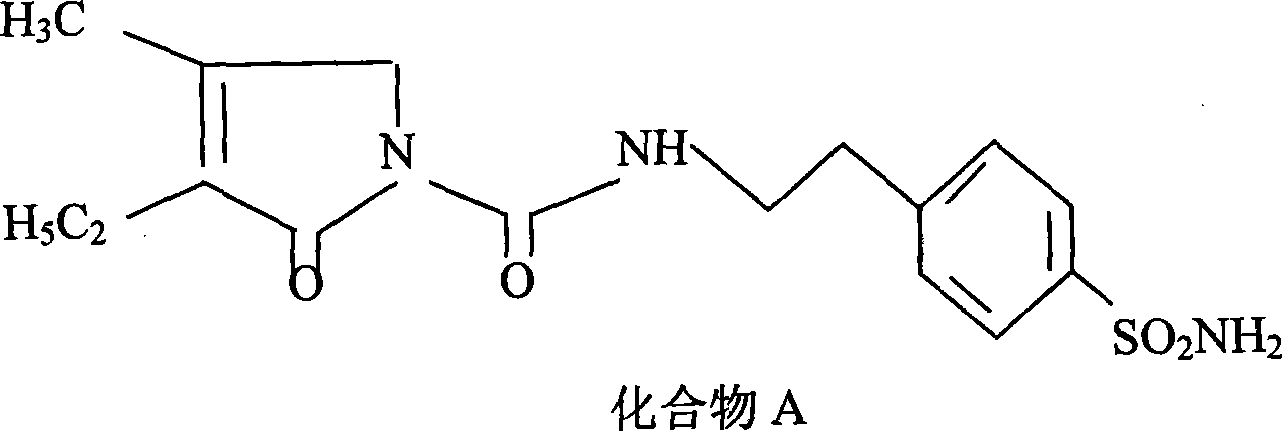

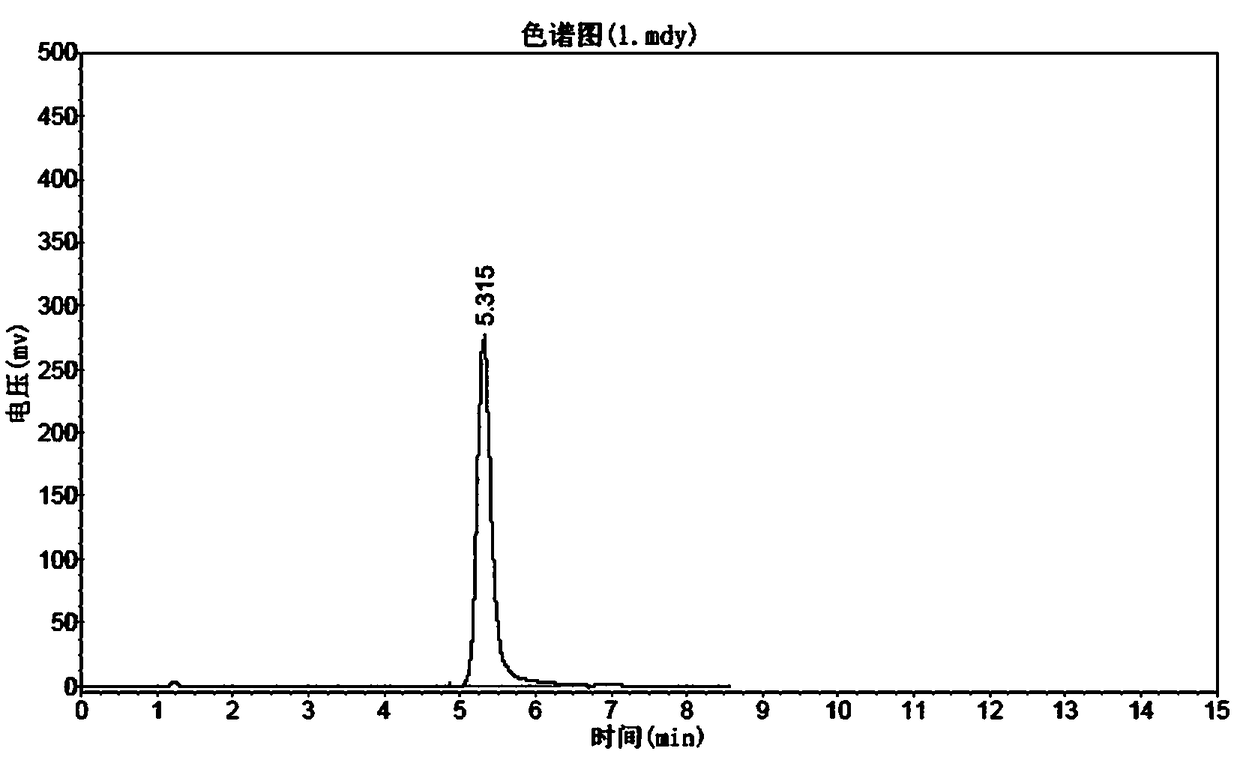

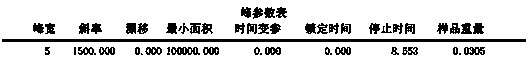

The invention discloses a preparation method of Glimepiride raw material, which comprises the following steps in sequence: in the presence of K2CO3, a condensation reaction is carried out between a compound A: 4-[2-(3-ethyl-4-methyl-2-keto-3-pyrroline-1-formamido)-ethyl]-benzene sulfonamide and a compound B: trans-4-methyl-cyclohexyl isocyanate of the same molar weight in an organic solvent. The mass ratio of the compound A and K2CO3 is 1:0.8-0.9; the mixture synthetic fluid of a crude Glimepiride product and K2CO3 is filtered in a suction way, and then an extract is added into pure water and dissolved to form a solution. The solution is filtered for removing impurities to obtain the aqueous solution of Glimepiride; a hydrochloric acid solution is added into the aqueous solution of the Glimepiride for acidification and then a crude product is separated; acetone is added into the crude Glimepiride product and then refined, filtered in a suction manner, dried in a vacuum environment to obtain a pure Glimepiride product. The method has the advantages of simplifying the synthetic route, selecting mature intermediates as raw materials, adding K2CO3 for promoting the condensation reaction, avoiding the use of chloroform, reducing the residual organic solvent, and being applicable to industrialized production.

Owner:JIANGSU WANBANG BIOPHARMLS +1

Novel solid polymer catalyst for synthesizing dicyclohexylcarbodiimide

InactiveCN101524650AThe synthesis process is simpleRaw materials are easy to getOrganic-compounds/hydrides/coordination-complexes catalystsImino compound preparationCyclohexylisocyanateReaction temperature

The invention discloses a preparation method for a solid organophosphorus catalyst for synthesizing dicyclohexylcarbodiimide and use. The preparation process for the solid polymer catalyst is characterized in that an intermediate obtained by reaction of PCl3 and propylene oxide is orderly reacted with isoprene, diethanolameine, alkali and allyl chloride to generate monomers of diallyl ether-1-diethanolamine-3-methyl-3-phosphol-1-oxides which are initiated by BPO to generate the solid organophosphorus polymer catalyst. The catalyst is used for catalyzing and condensing cyclohexyl isocyanate to obtain the dicyclohexylcarbodiimide, the dosage is between 0.1 and 0.5 percent, and the reaction temperature for removing carbon dioxide by condensation is between 50 and 170 DEG C. The catalyst has simple synthesis process and low cost and can be recycled.

Owner:重庆市化工研究院有限公司

Preparation method of efficient and low-toxicity acaricide hexythiazox

InactiveCN108558787AReduce pollutionEmission reductionOrganic chemistryCyclohexylisocyanateThioketone

The invention discloses a preparation method of efficient and low-toxicity acaricide hexythiazox. Performing cyclization reaction on 2-amino-1-(4-chlorphenyl) propyl sulfate hydrochloride and carbon disulfide in a reaction flask under the normal-pressures alkaline condition to generate 5-(4-chlorphenyl)-methylthiazoline-2-thioketone; adding methylbenzene, the 5-(4-chlorphenyl)-methylthiazoline-2-ketone and a catalyst into the reaction flask, and dripping cyclohexyl isocyanate to perform addition reaction to obtain a hexythiazox product. By the preparation method, a cyclization technique of the 2-amino-1-(4-chlorphenyl) propyl sulfate hydrochloride and carbon disulfide under the normal-pressures alkaline condition replaces a toxic and polluted carbon oxide sulfur cyclization process, drainage of acid wastewater is greatly reduced, normal-pressure reaction replaces pressurized reaction, and industrial mass production is facilitated. According to the method, carcinogenic raw materials are omitted, toxic and lacrimatory benzyl mercaptane is avoided, production environments are improved, environmental pollution is reduced, and the content of an acquired hexythiazox original medicine is98% or more.

Owner:JIANGSU HEBEN BIOCHEM

Novel synthesis route of glipizide

The invention relates to a novel synthesis route of glipizide, which is characterized by comprising the following steps of protecting 4-(2-amino ethyl)benzenesulfonic acid ammonia (II) by Boc anhydride to obtain a compound (III); reacting the compound (III) with cyclohexyl isocyanate to obtain a compound (IV); carrying out deprotection on the compound (IV) to obtain a compound (V); and reacting the compound (V) with 2-methyl-5-pyrazine carboxylic acid to obtain the glipizide (I) with the single impurity which is less than or equal to 0.5% and the high purity which is more than or equal to 99%. The process is simple, the yield is high, the purity is high and the single impurity is low; and the process is environment-friendly and industrial production is easy to realize.

Owner:WUHAN WUYAO PHARMA

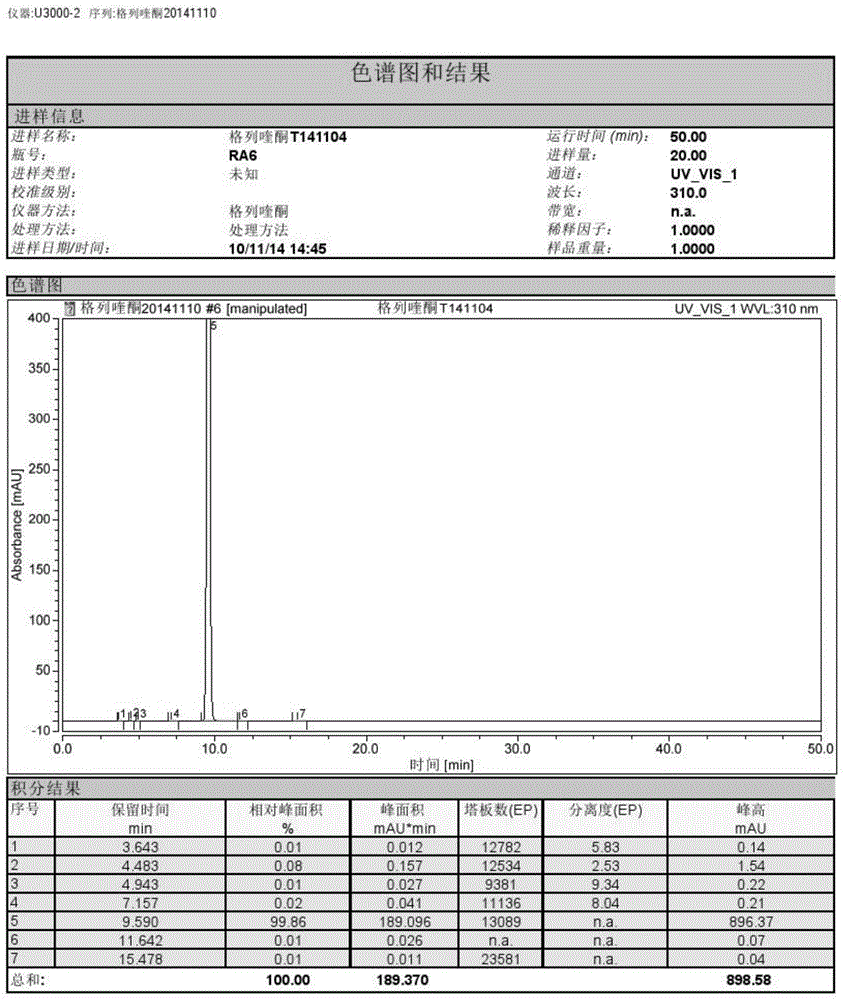

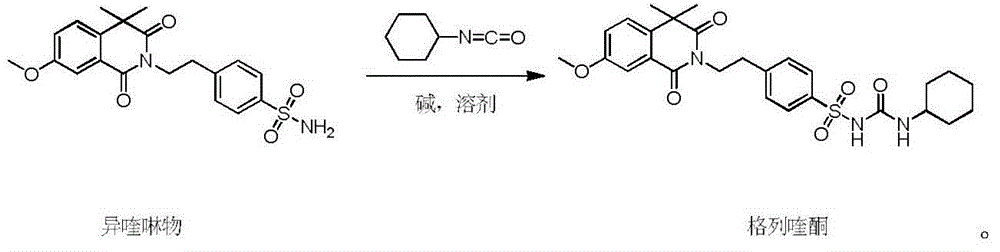

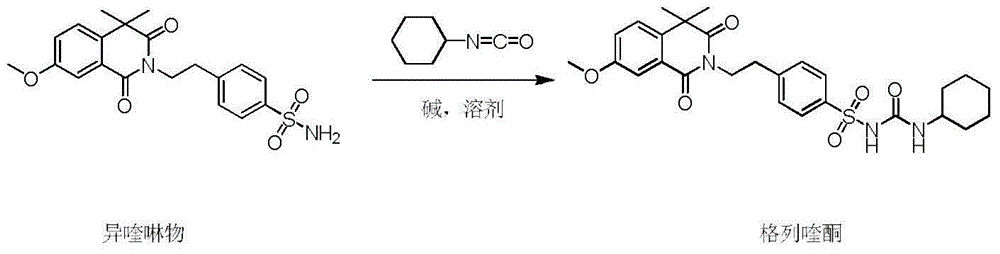

Gliquidone preparation method

The invention discloses a gliquidone preparation method. According to the preparation method, isoquinoline and cyclohexyl isocyanate carry out condensation reactions in a solvent in the presence of an alkali to generate gliquidone. 2,5-dimethyl tetrahydrofuran is taken as the solvent, isoquinoline can be well dissolved in 2,5-dimethyl tetrahydrofuran, while gliquidone is difficult to dissolve in 2,5-dimethyl tetrahydrofuran; thus, only a little amount of water is needed in the post treatment, the generated wastewater is largely reduced; the used alkali is common inorganic alkalis such as anhydrous potassium carbonate, and the like, is nontoxic, and is easy to process. The boiling point of 2,5-dimethyl tetrahydrofuran is low, 2,5-dimethyl tetrahydrofuran is easy to recover, moreover, the system is not afraid of water, the solvent can be circularly used, the production cost is reduced, the refluxing temperature is adopted, the operation is easy, the reactions last for 6 hours, and the method is rapid and efficient.

Owner:天津市亨必达化学合成物有限公司

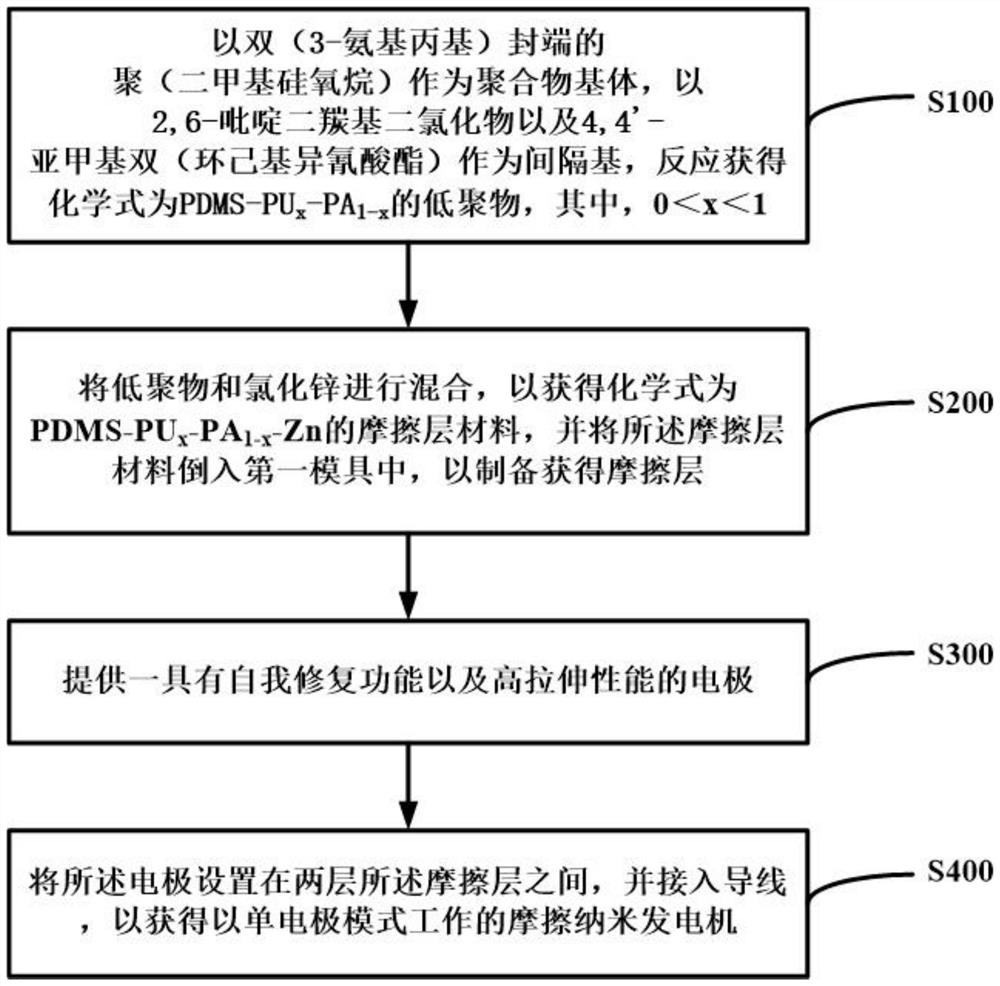

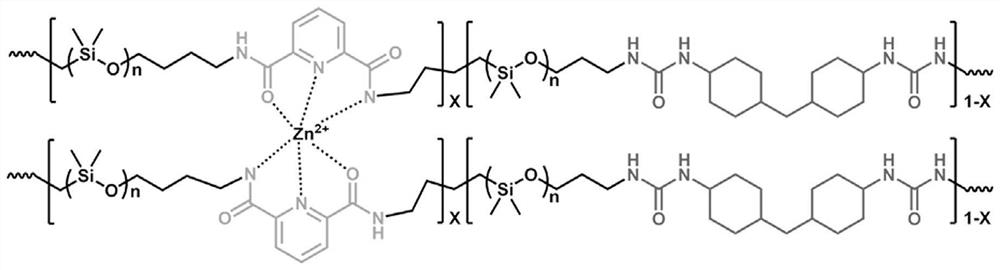

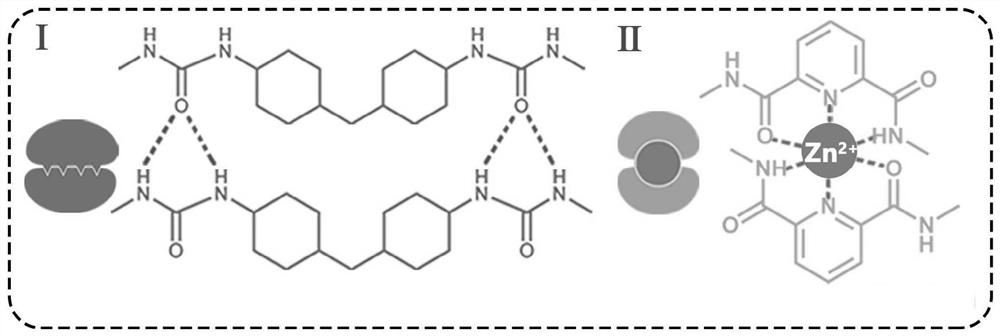

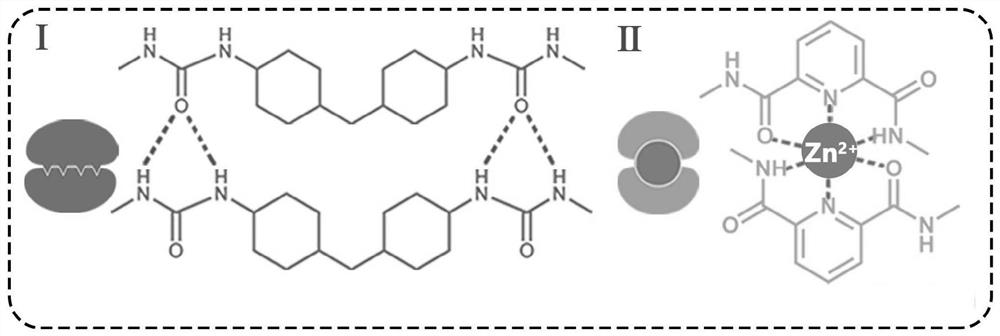

Preparation method of friction nano-generator and friction nano-generator

PendingCN112491293AFast self-healingRestore power outputFriction generatorsPolymer scienceCyclohexylisocyanate

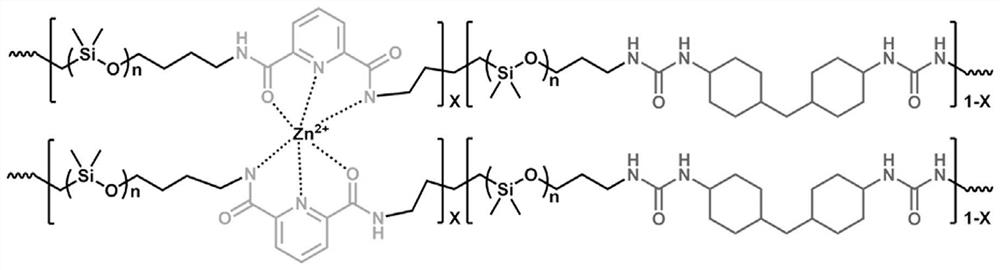

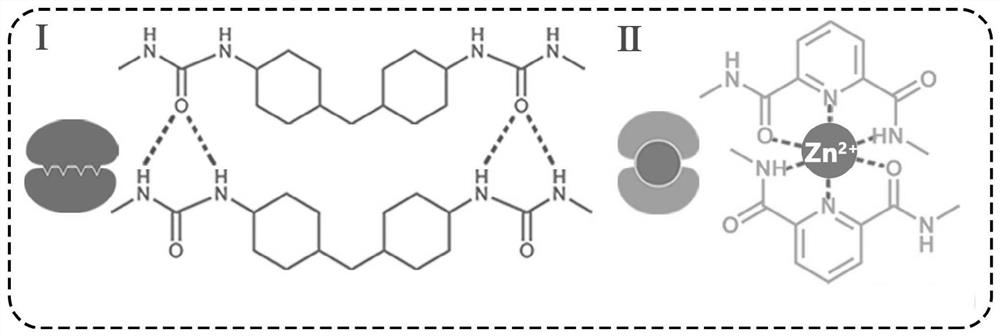

The invention provides a preparation method of a self-repairing material and application of the self-repairing material. The preparation method comprises the following steps: taking bis (3aminopropyl)-terminated poly (dimethylsiloxane) as a polymer matrix, taking 2, 6-pyridine dicarbonyl dichloride and 4, 4'-methylene bis (cyclohexyl isocyanate) as spacer groups, and reacting to obtain an oligomerwith a chemical formula of PDMS-PUx-PA1-x, where x is more than 0 and less than 1; and mixing the oligomer with zinc chloride to obtain the friction layer material of which the chemical formula is PDMS-PUx-PA1-xZn. According to the embodiment of the invention, a silicon-oxygen chain of polydimethylsiloxane is used as a matrix, and the double cross-linking effect of ion complexing and hydrogen bonds is introduced through chain extension, so that the self-repairing material with high tensile property and excellent self-repairing property is synthesized.

Owner:SUZHOU UNIV

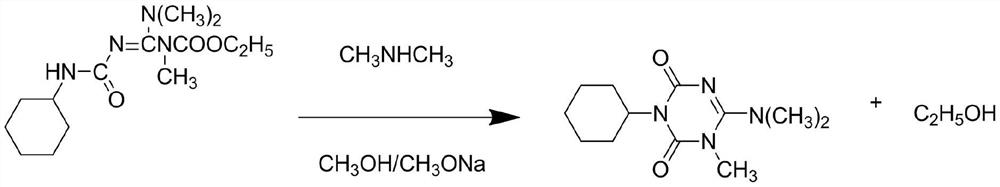

Production process of N-(N-cyclohexylamide-N', N'-dmethyl amidine)-N-methyl ethyl carbamate

InactiveCN106380425ASuitable for mass productionShort processCarboxylic acid nitrile preparationOrganic compound preparationEthyl chloroformateMethyl carbamate

The invention relates to a production process of N-(N-cyclohexylamide-N', N'-dmethyl amidine)-N-methyl ethyl carbamate. The process consists of: taking cyanamide, ethyl chloroformate, dimethyl sulfate, dimethylamine, cyclohexyl isocyanate and the like are adopted as the main raw materials, and carrying out condensation, synthesis, alkaline hydrolysis, synthesis and other reactions so as to obtain N-(N-cyclohexylamide-N', N'-dmethyl amidine)-N-methyl ethyl carbamate. With yield up to 85%, the production process has the advantages of short technological process, simple preparation, production safety and good prospects, and is suitable for large-scale plant production.

Owner:宿迁市万和泰化工有限公司

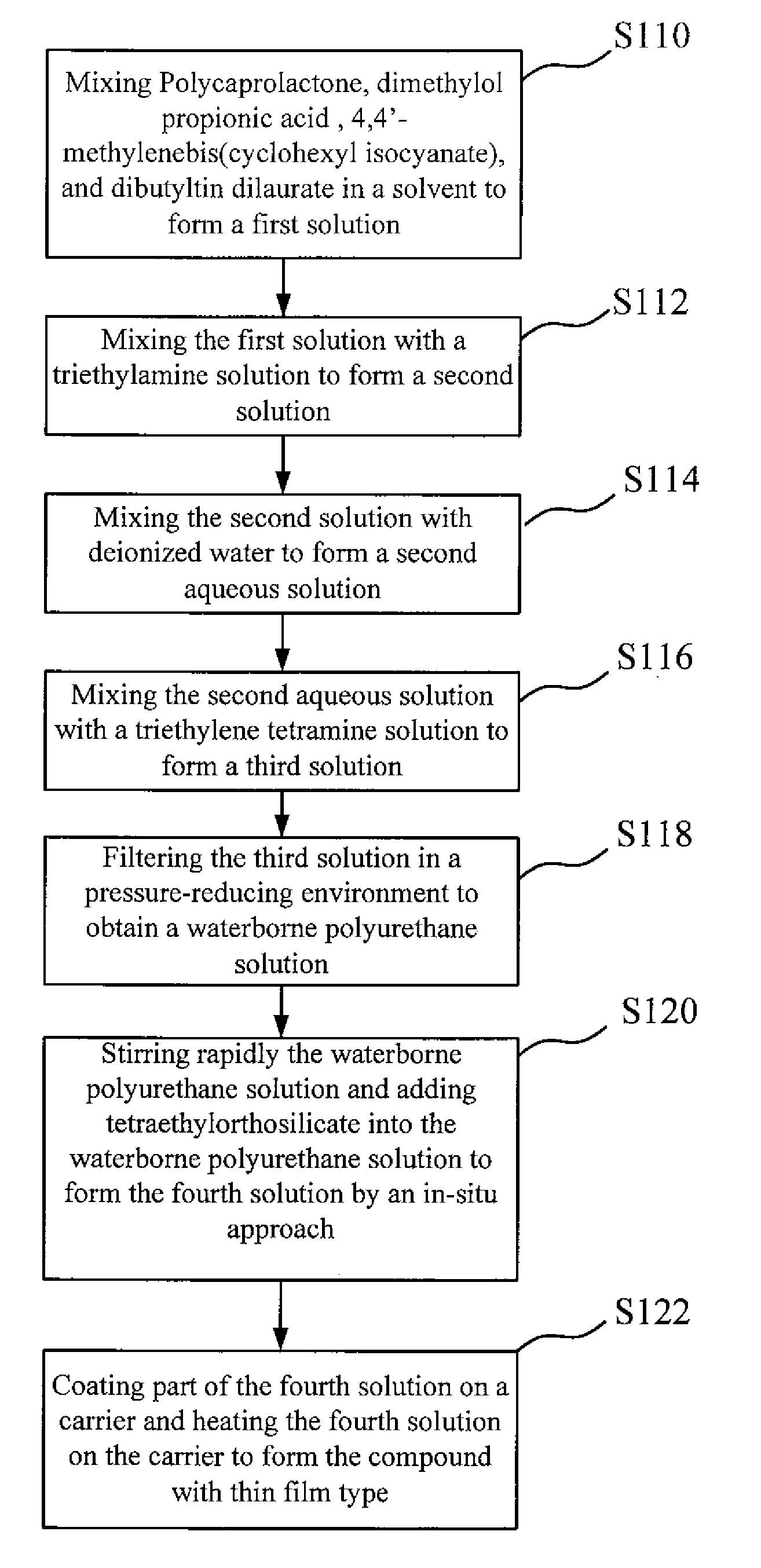

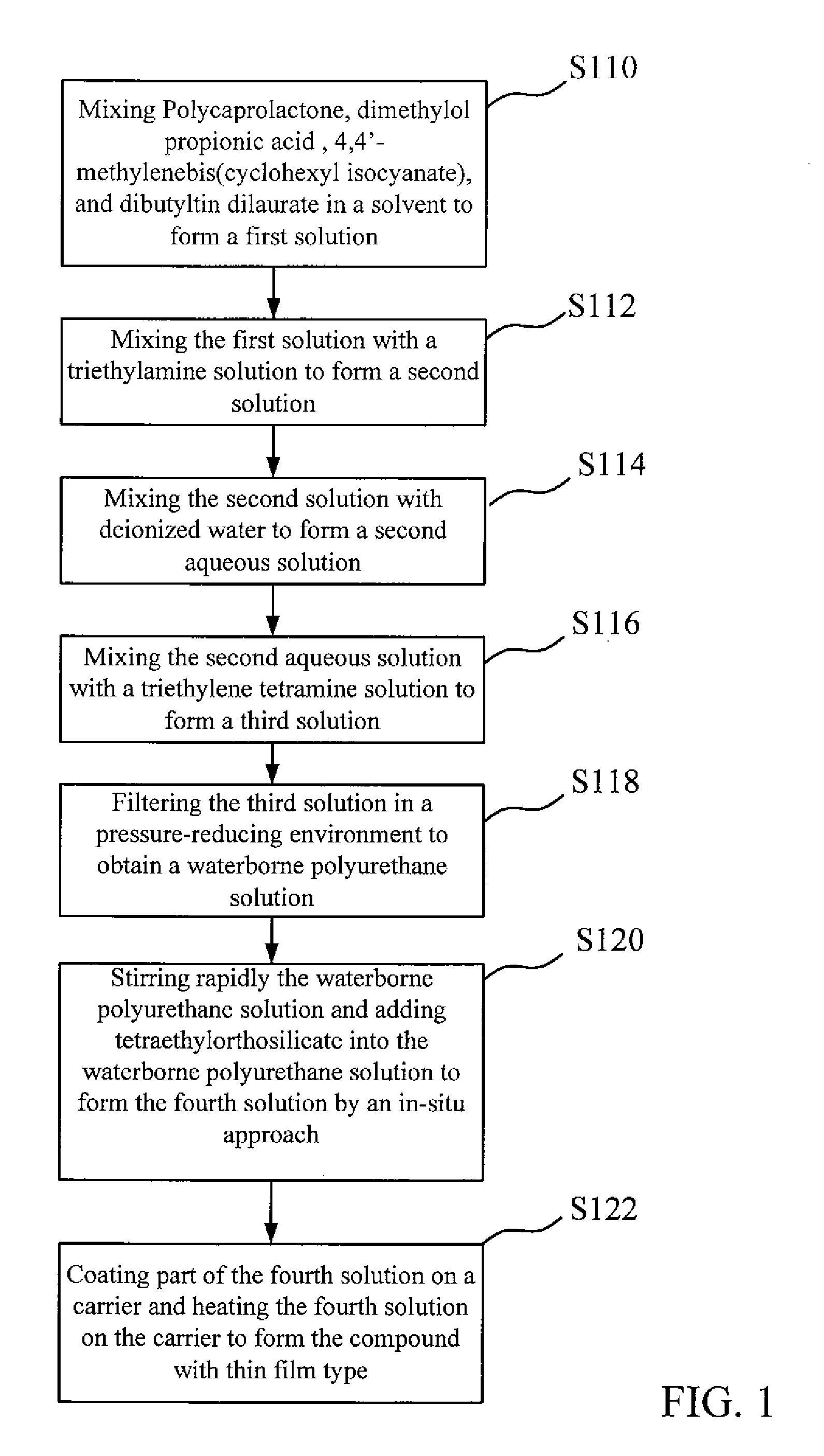

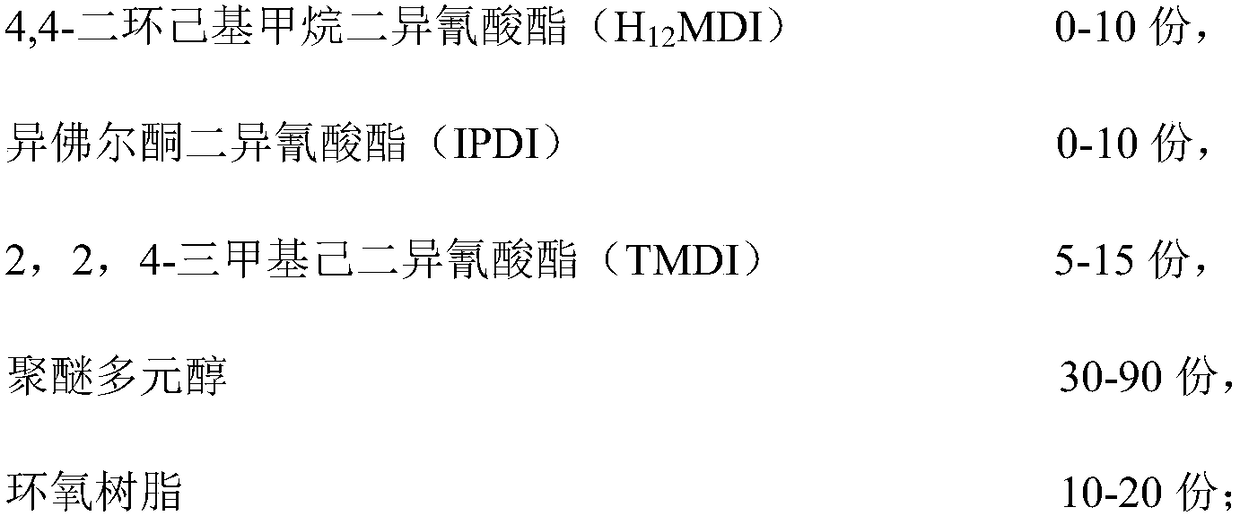

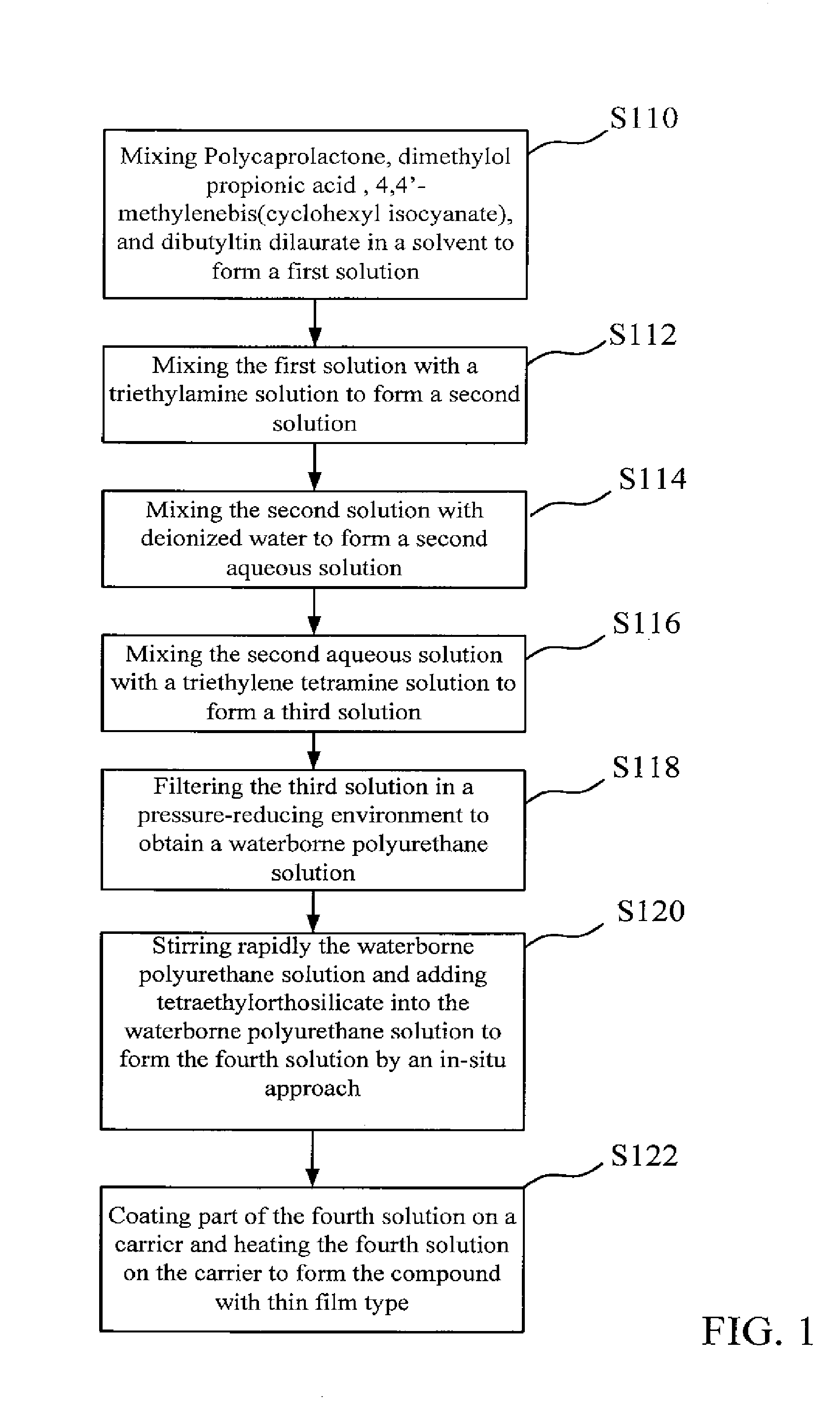

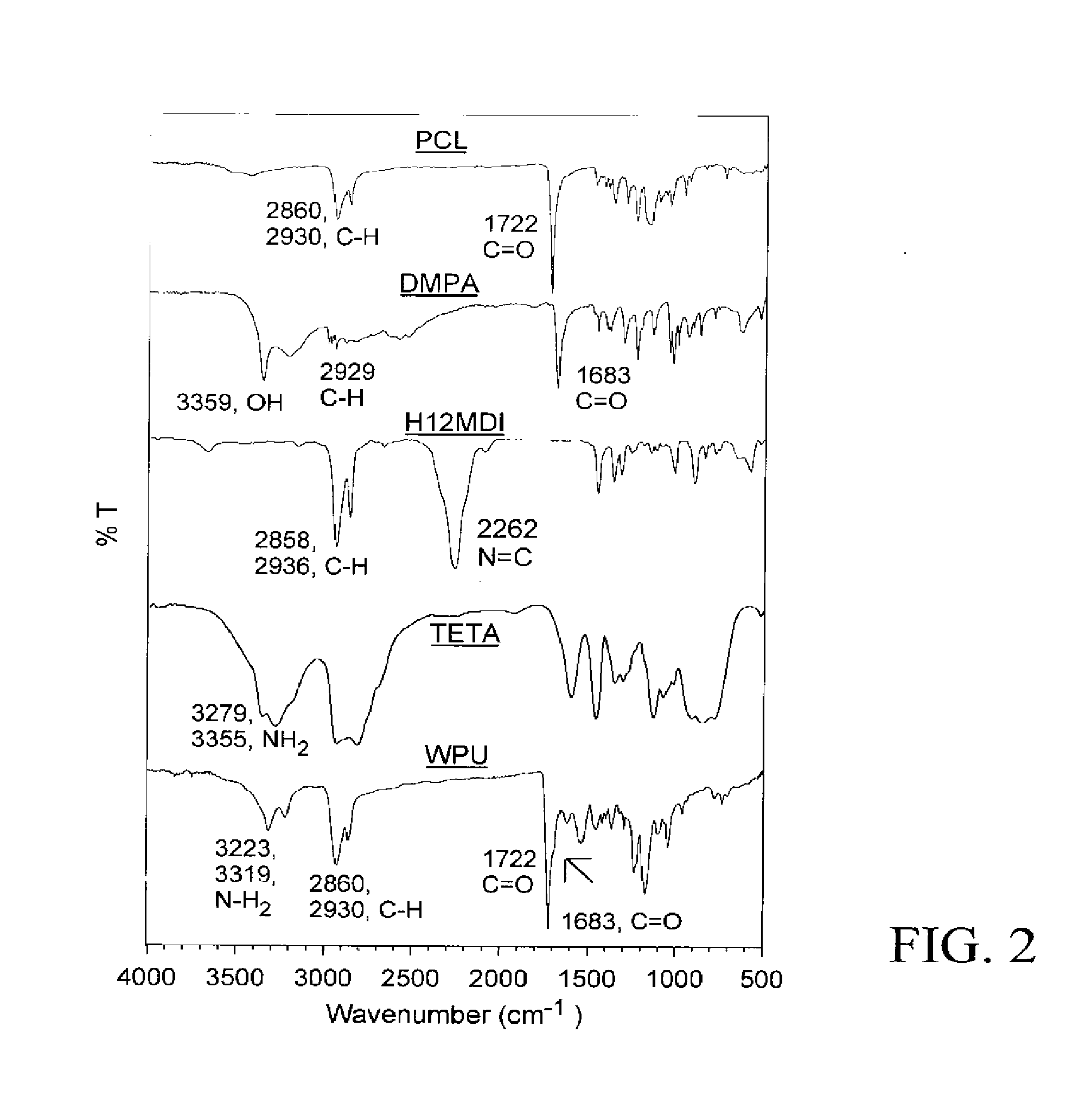

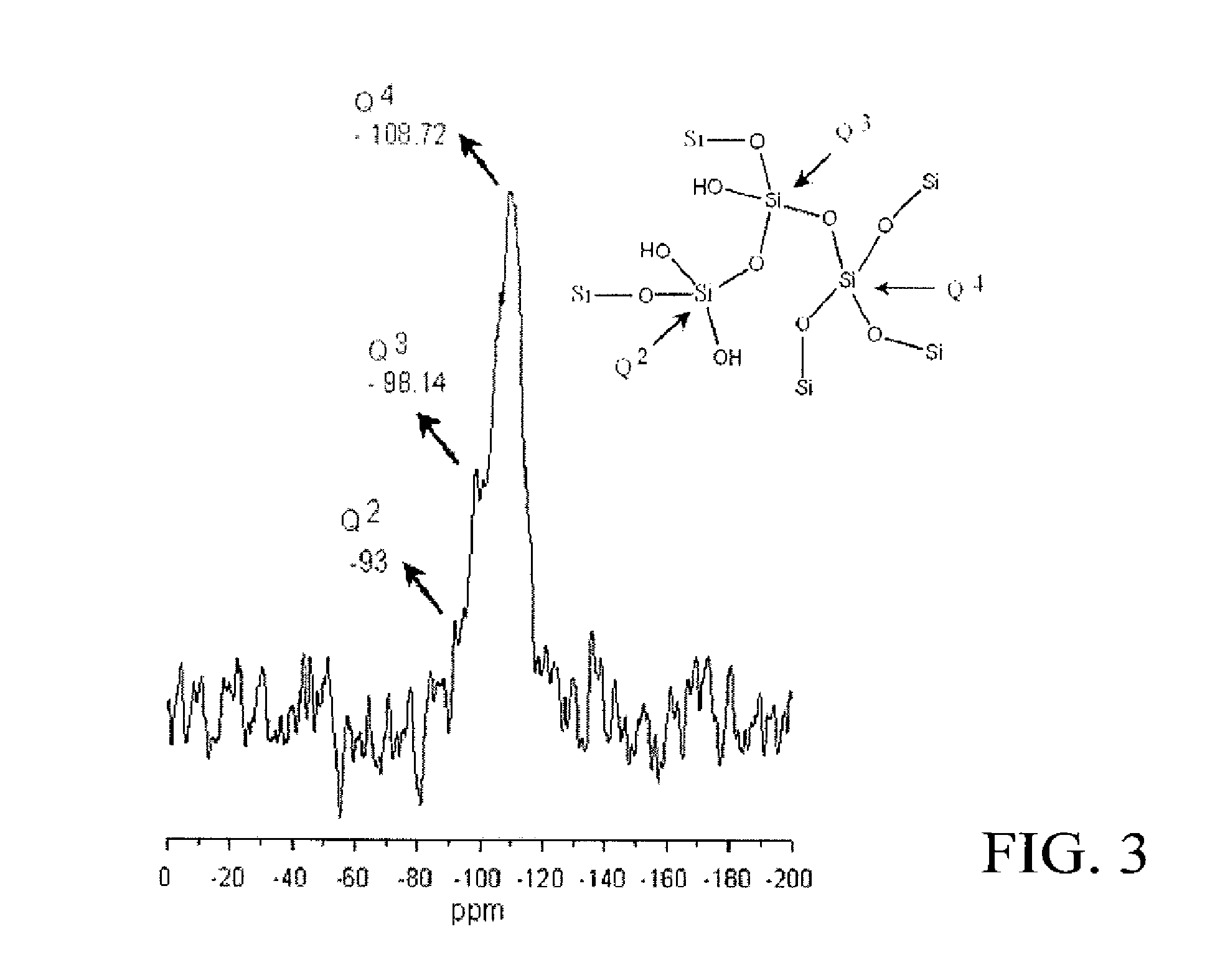

Compound and method for producing the same

ActiveUS20100143597A1Pretreated surfacesPolyurea/polyurethane coatingsPropanoic acidCyclohexylisocyanate

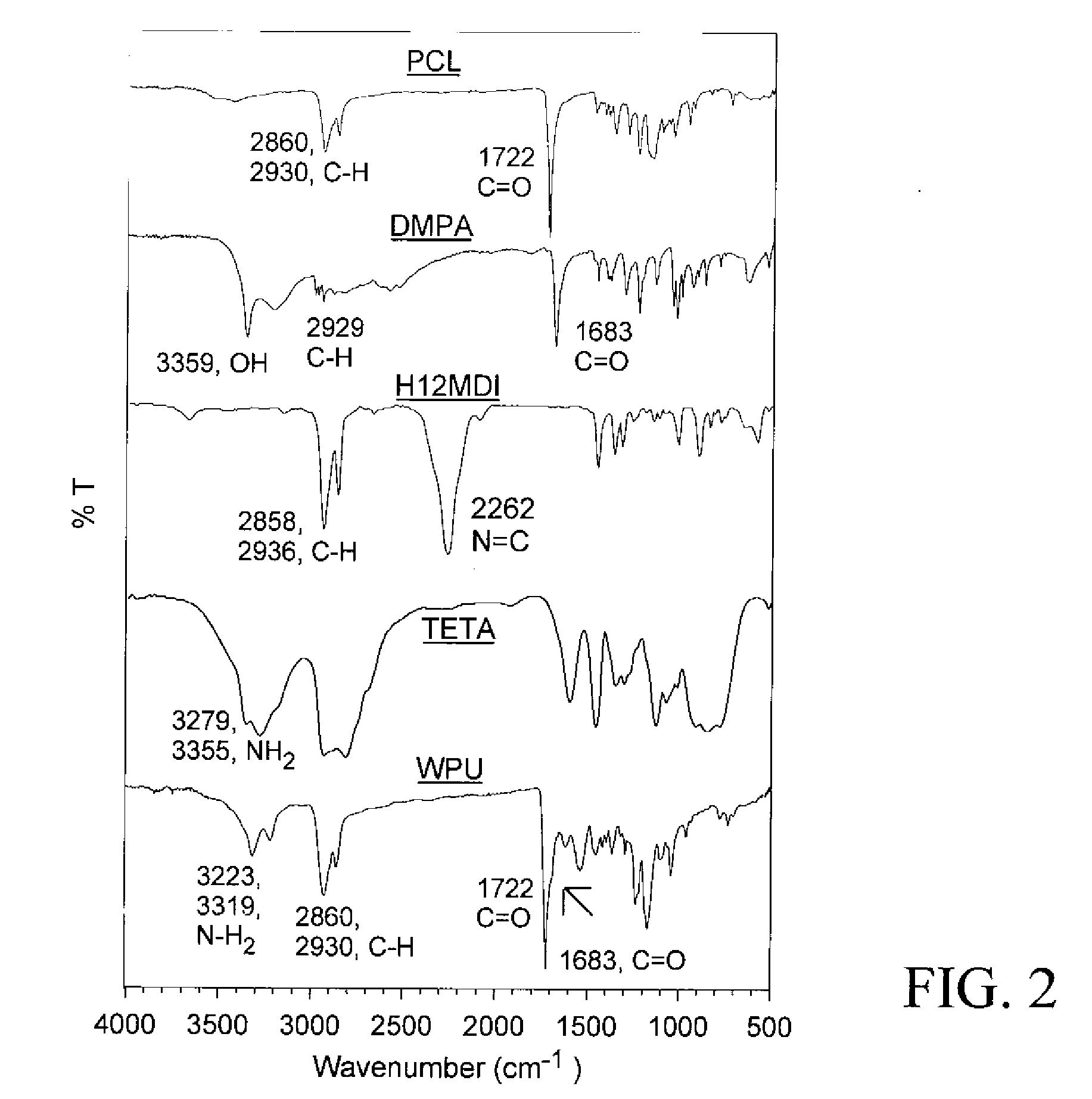

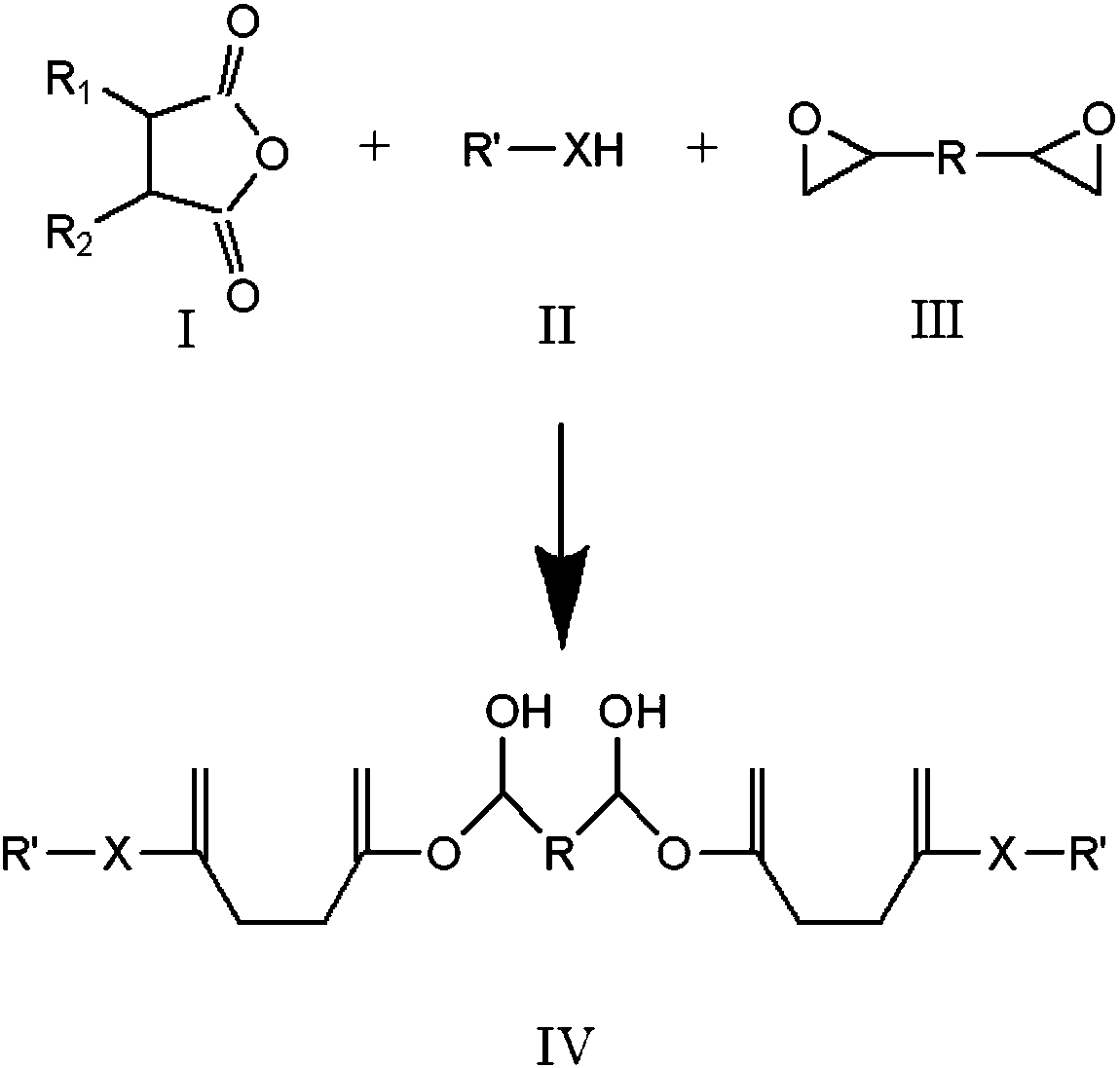

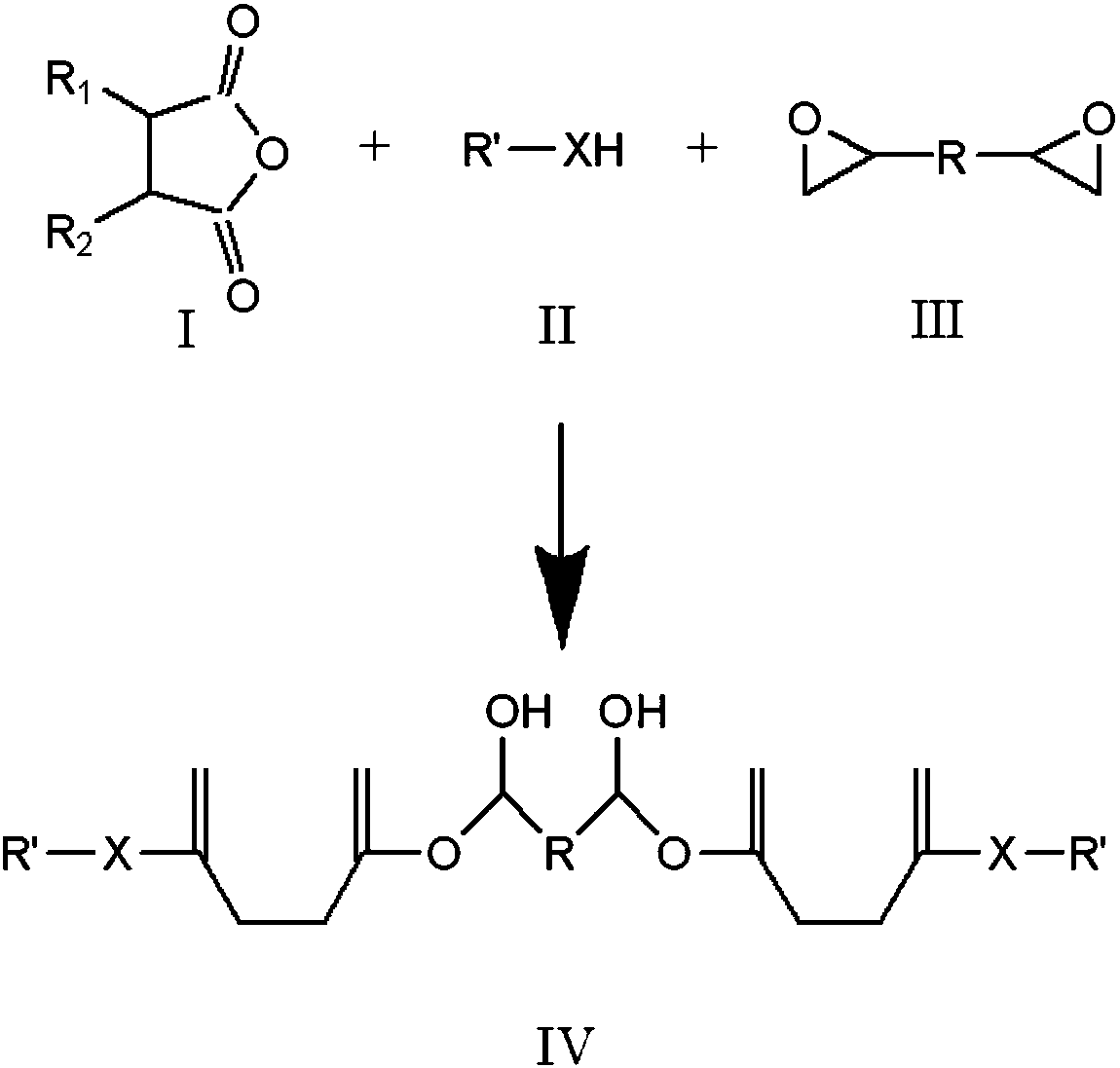

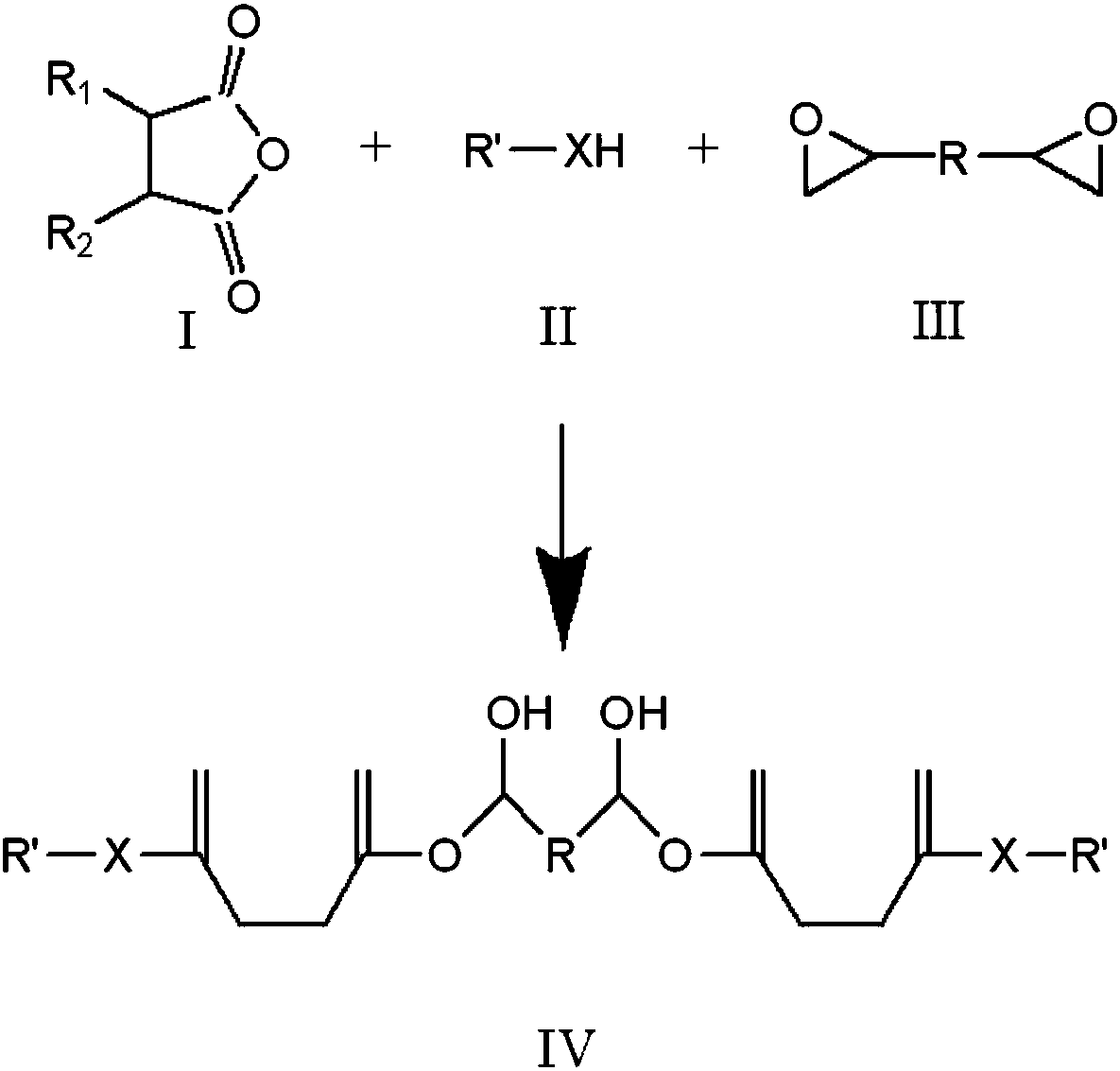

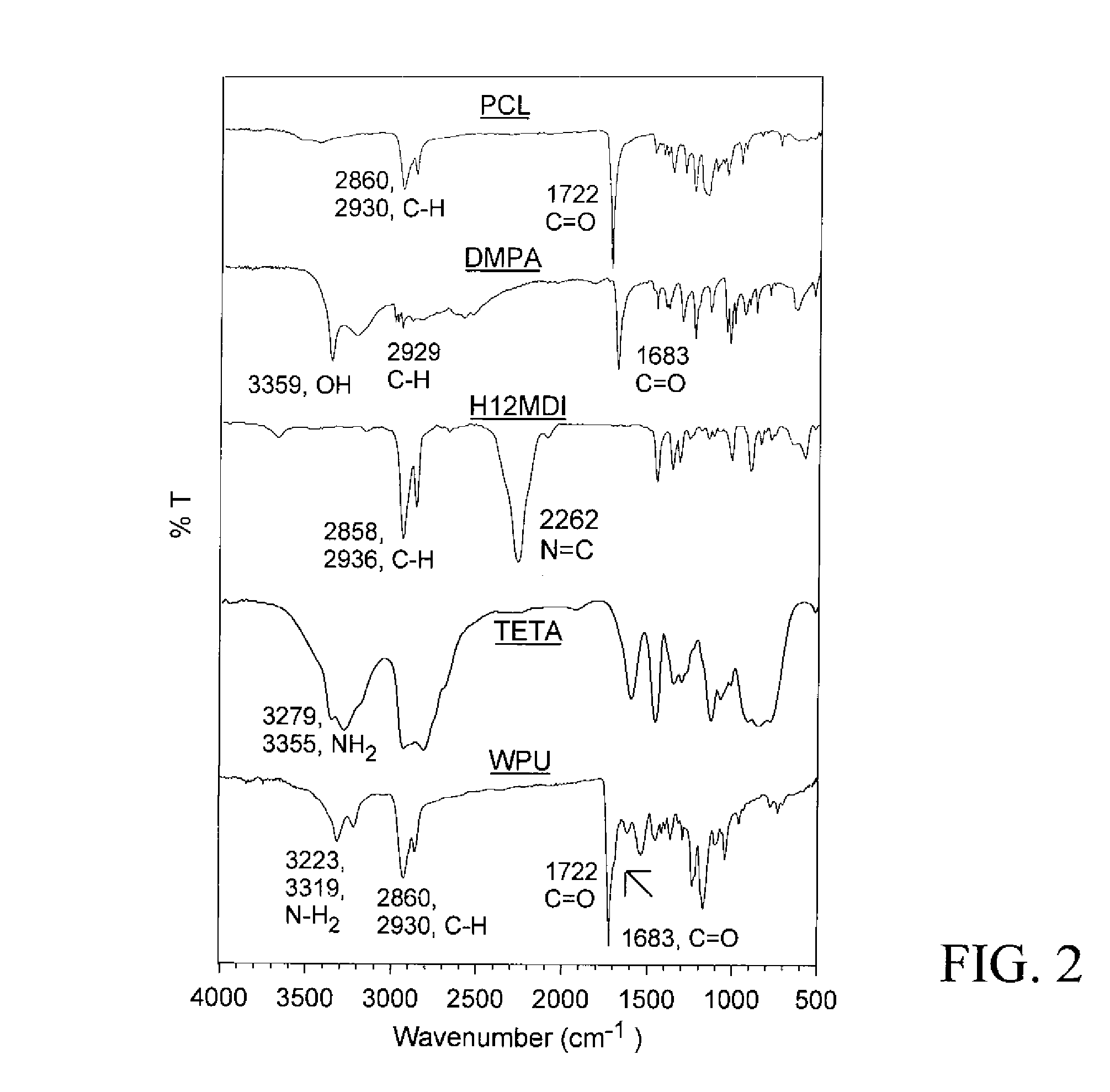

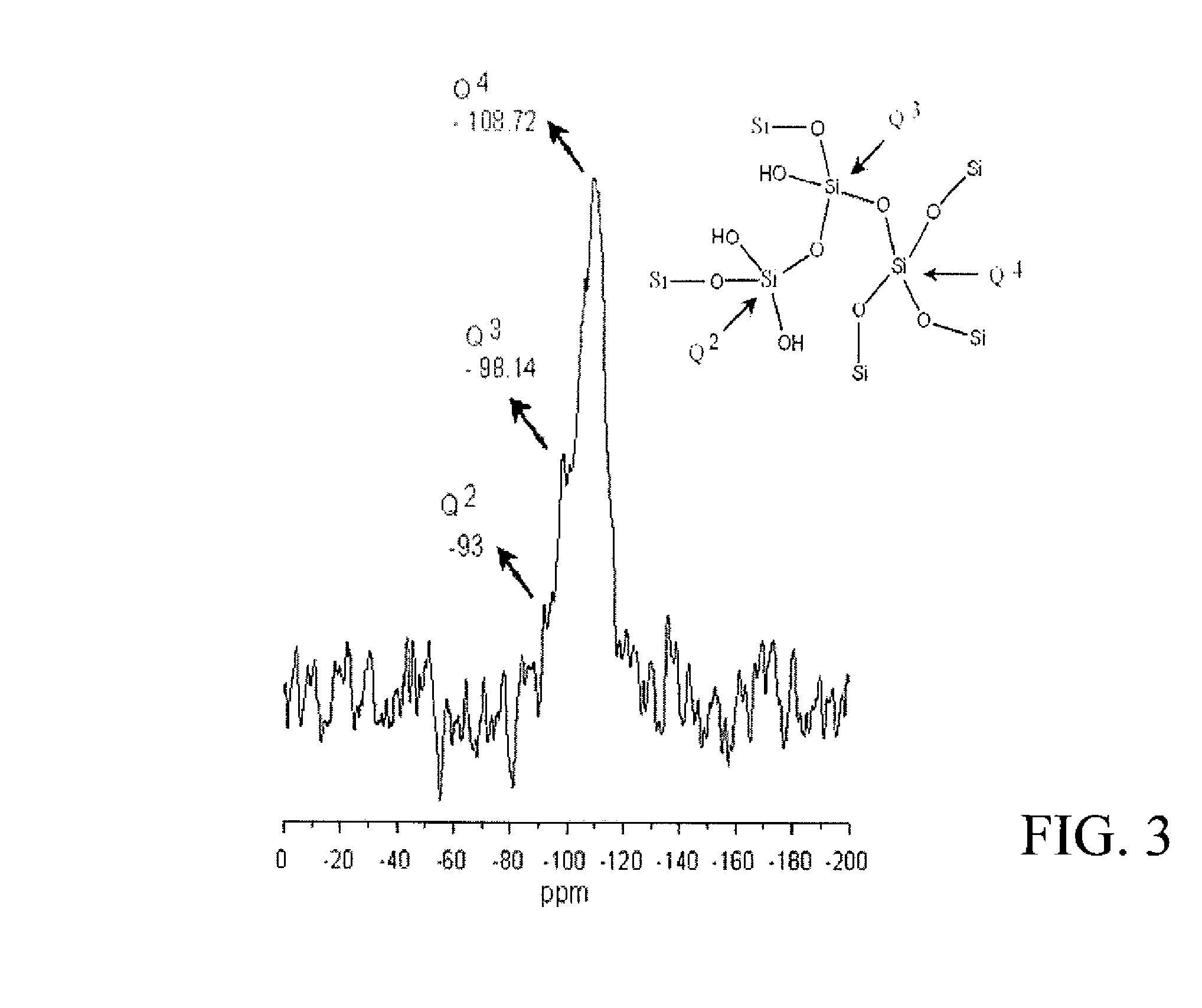

The invention provides a compound and method of producing the same. The method of the invention includes the following steps. First of all, Polycaprolactone (PCL), dimethylol propionic acid (DMPA), 4,4′-methylenebis (cyclohexyl isocyanate) (H12MDI), and dibutyltin dilaurate (DBT) are mixed in a solvent in the first place and a solution is formed. This solution is then mixed with triethylamine (TEA) and triethylene tetramine (TETA). After that, amino-terminated anionic waterborne polyurethane (WPU) is produced. A sol-gel process is proceeded with a mixture of amino-terminated anionic waterborne polyurethane, tetraethylorthosilicate (TEOS) without any extra catalyst, and a compound, waterborne polyurethane-silica nanocomposite materials, is eventually produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

Acrylic carboxyl polyurethane powder coating for ceramic

ActiveCN104312417AIncreased durabilitySparkling noPolyurea/polyurethane coatingsPowdery paintsCyclohexylisocyanateLithium hydroxide

The invention discloses an acrylic carboxyl polyurethane powder coating for ceramic. The coating is prepared from the following raw materials: 1, 6-hexanediol, dehydrated castor oil, dibutyltin dilaurate, glycerol, cyclohexyl isocyanate, lithium hydroxide, an imitator, linseed oil, hexahydrophthalic anhydride, calcium boheic acid, pigments, rosin, dimethyl adipate, toluene diisocynate and methyl methacrylate. The product density is 135-155g / cm<3>, and the coating soaked in water for 60-70 days is free from soaking and falling phenomena. The tensile strength is 20-30MPa, the shore hardness is 40-60, and the coating soaked in a 5% hydrochloric acid solution for 40-60 days is free of abnormalities. The adhesive force is levels 1-2, the impact strength is 550-650N / cm, and the coating soaked in saturated calcium hydroxide for 25-35 days is free from bubbling and wrinkling; the glossiness is 110-130%, and the gloss retention is 92-96% after being manually accelerated and aged for 500 hours.

Owner:XIAN SICONG FINE CHEM

Two-component solvent-free reactive-type polyurethane hot melt adhesive applied to soft package industry and using method of hot melt adhesive

InactiveCN108587549AHigh modulusStrong adhesionPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentChemistryCyclohexylisocyanate

The invention discloses a two-component solvent-free reactive-type polyurethane hot melt adhesive applied to a soft package industry. The polyurethane hot melt adhesive is a two-component reactive-type polyurethane hot melt adhesive, uses methylene-bis(4-cyclohexylisocyanate) and an acid anhydride modified polyol as main raw materials and has more excellent environmental protection performance; the adhesive has higher modulus and stronger adhesion at the initial stage of using and a fast curing speed, and is more suitable for improvement of production efficiency and quality management and control of soft package; and using of the methylene-bis(4-cyclohexylisocyanate) makes the cured adhesive more resistant to hydrolysis and chemicals and have better yellowing resistance.

Owner:广东华粘新材料研究有限公司

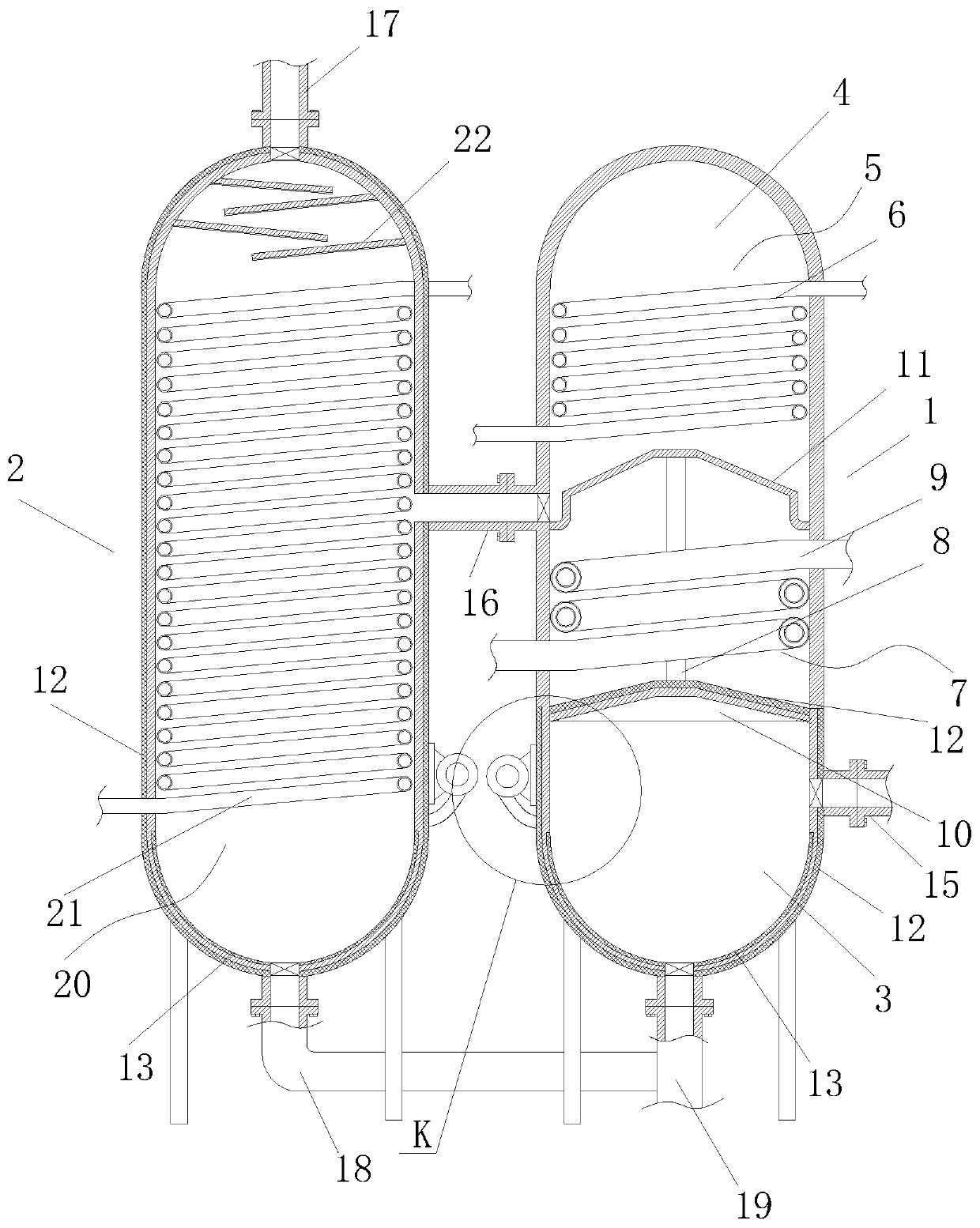

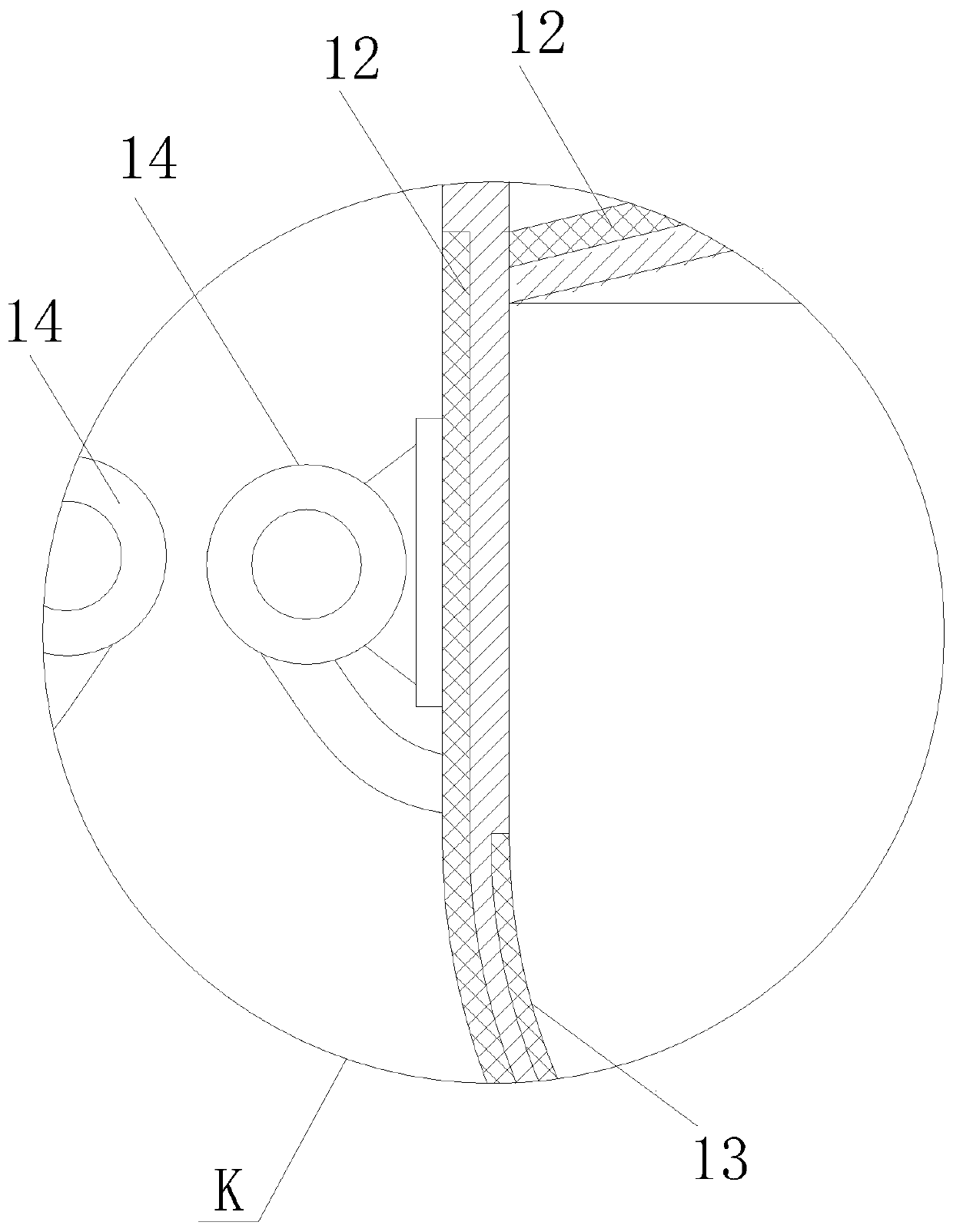

Cyclohexyl isocyanate rectification column

InactiveCN110433517AImprove distillation efficiencyHigh rectification efficiency, high rectification purityIsocyanic acid derivatives purification/separationFractional distillationRefluxThermal insulation

The invention discloses a cyclohexyl isocyanate rectification column, which comprises a first-stage column and a second-stage column. The first-stage column is provided with a reflux plate and a partition plate inside, wherein the part, below the partition plate, in the first-stage column is an evaporation chamber; the part, above the reflux plate, in the first-stage column is a condensation chamber; the side wall of the evaporation chamber is connected to a feeding pipe; the bottom of the evaporation chamber is connected to a discharging pipe and is provided with an electric heating plate; the condensation chamber is provided with a condensation mechanism inside, and is connected to the evaporation chamber through a pipe; a thermal insulation mechanism is arranged outside the pipe; the bottom of the condensation chamber is connected to the second-stage column through a communicating pipe; the bottom of the second-stage column is connected to a secondary discharging pipe; the top of the second-stage column is connected to a gas discharging pipe; and a heating mechanism is arranged inside the second-stage column. The rectification column has a simple structure, a high rectificationefficiency and high rectification purity.

Owner:ANHUI GUANGXIN AGROCHEM

Environment-friendly and wear-resistant water-borne wood paint

InactiveCN107858083AHigh bonding strengthImprove compactnessPolyurea/polyurethane coatingsDibutyl tin dilaurateCyclohexylisocyanate

The invention discloses an environment-friendly and wear-resistant water-borne wood paint comprising a component A and a component B; the weight ratio of the component A to the component B is 100:(3-5); the component A comprises the raw materials in parts by weight: 90-100 parts of main materials, 10-18 parts of diatomite, 8-12 parts of fumed silica, 3-7 parts of sepiolite powder, 20-30 parts of attapulgite composite, 2-4 parts of thickener, 2-4 parts of cinnamon essential oil, 2-4 parts of defoaming agent, 1.5-2.5 parts of wetting agent, 2-4 parts of dispersant, 1.5-2.5 parts of flatting agent and 60-80 parts of water; and the component B comprises the raw materials in parts by weight: 10-16 parts of methylene-bis(4-cyclohexylisocyanate), 8-12 parts of dibutyltin dilaurate and 20-40 partsof propylene glycol methyl ether acetate. The environment-friendly and wear-resistant water-borne wood paint is extremely good in crosslinking density, scratch resistance and wear resistance and capable of not only reducing the content of harmful gases in air, but also emitting pleasant fragrance, quieting the heart and calming the nerves as well as increasing the work efficiency.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Modified filler and heat-conducting glue, and preparation methods and application thereof

ActiveCN113512235AGood adhesionImprove permeabilityNon-macromolecular adhesive additivesPolymer scienceMeth-

Owner:GUANGZHOU BAIYUN CHEM IND

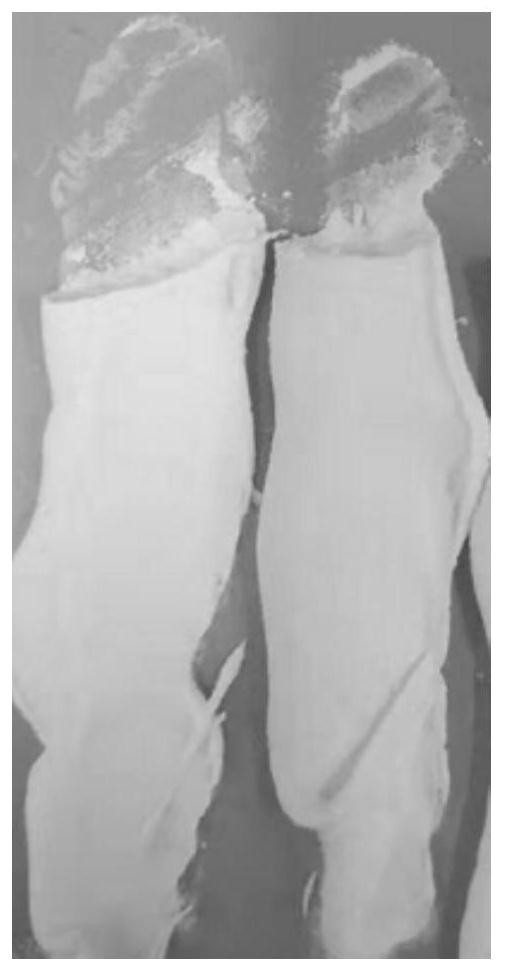

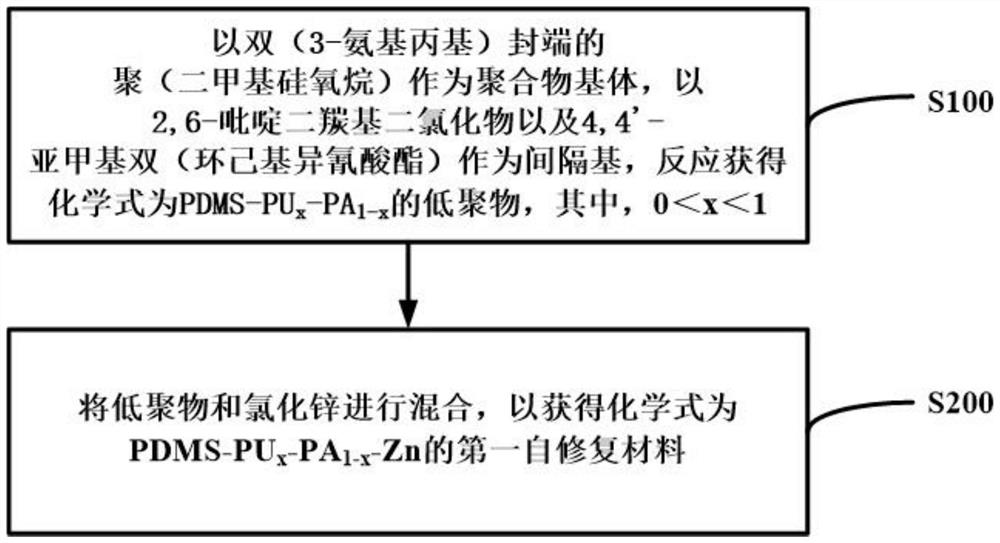

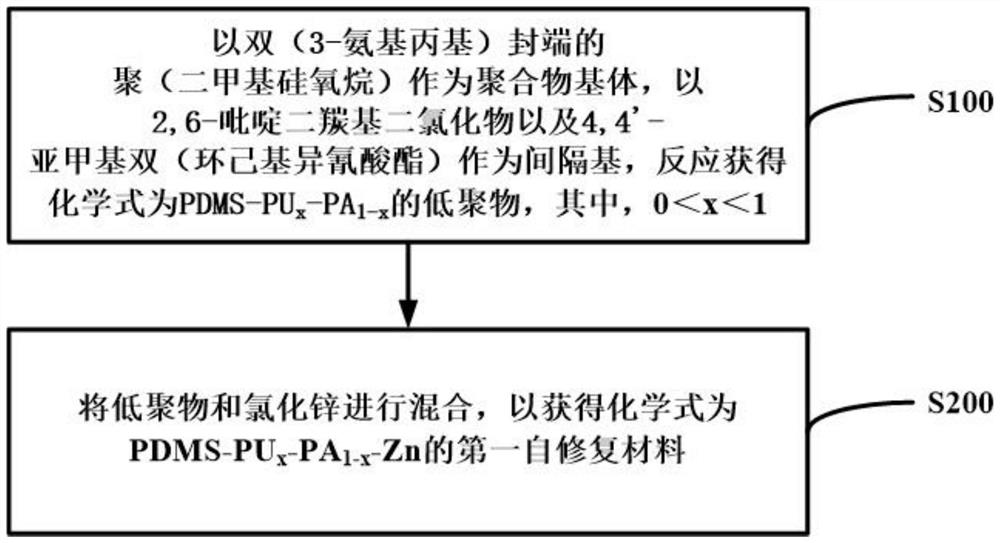

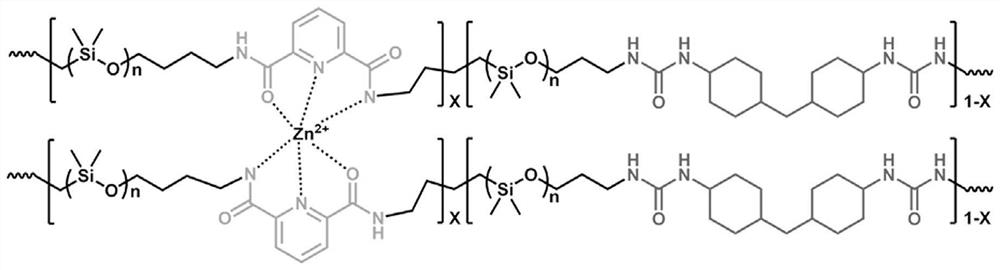

Preparation method of self-repairing material and application of self-repairing material

ActiveCN112358620AEasy to stretchExcellent self-healing performanceFriction generatorsPolymer scienceCyclohexylisocyanate

The invention provides a preparation method of a self-repairing material and application of the self-repairing material. The preparation method comprises the following steps: taking bis (3-aminopropyl)-terminated poly (dimethylsiloxane) as a polymer matrix, taking 2, 6-pyridine dicarbonyl dichloride and 4, 4'-methylene bis (cyclohexyl isocyanate) as spacer groups, and reacting to obtain an oligomer with a chemical formula of PDMS-PUx-PA1-x, where x is more than 0 and less than 1; and mixing the oligomer with zinc chloride to obtain the first self-repairing material of which the chemical formula is PDMS-PUx-PA1-x-Zn. According to the embodiment of the invention, a silicon-oxygen chain of polydimethylsiloxane is used as a matrix, and the double cross-linking effect of ion complexing and hydrogen bonds is introduced through chain extension, so that the self-repairing material with high tensile property and excellent self-repairing property is synthesized.

Owner:SUZHOU UNIV

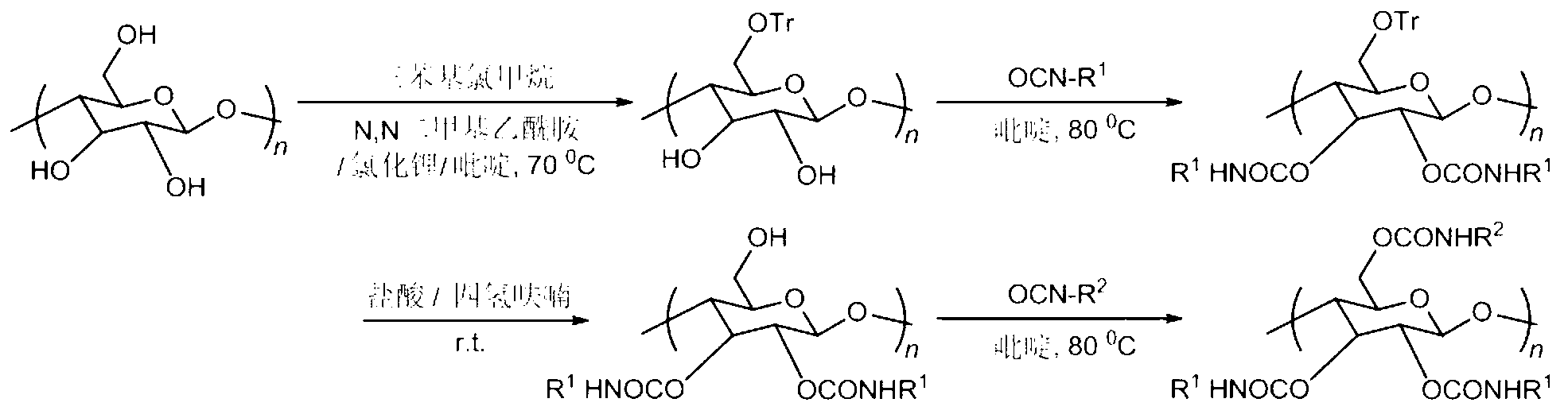

Cellulose derivative simultaneously containing cyclohexyl carbamate and phenyl carbamate and preparation method of cellulose derivative

InactiveCN103172755AMature technologyEasy to operateOther chemical processesLithium chlorideCarbamate

The invention provides a cellulose derivative simultaneously containing cyclohexyl carbamate and phenyl carbamate and a preparation method of the cellulose derivative. The method comprises the following steps of: carrying out vacuum drying on cellulose, carrying out stirring reflux in anhydrous N,N-dimethyl acetamide, cooling to room temperature, then, adding lithium chloride, reheating, adding anhydrous pyridine, refluxing, then, adding superfluous triphenylchloromethane, and carrying out continuous stirring reflux; after vacuum drying, carrying out refluxing in anhydrous pyridine, then, adding superfluous phenyl isocyanate, stopping reaction, completely washing by using methanol, and carrying out vacuum drying; dissolving into tetrahydrofuran solution containing hydrochloric acid so as to carry out hydrolysis; and fully dissolving into anhydrous pyridine, adding superfluous cyclohexyl isocyanate, stopping reaction, adding methanol, and carrying out vacuum drying, thereby obtaining the cellulose derivative simultaneously containing cyclohexyl carbamate and phenyl carbamate. According to the method, the adopted cellulose is wide in source, is cheap and is easily available, and a synthesis process is simple, mature, easy to control and high in yield. The method can be applied to large-scale batch production.

Owner:HARBIN ENG UNIV

Preparation of glimepiride raw material

ActiveCN101486674BReduce usageResidue reductionOrganic chemistryMetabolism disorderMass ratioCyclohexylisocyanate

The invention discloses a preparation method of Glimepiride raw material, which comprises the following steps in sequence: in the presence of K2CO3, a condensation reaction is carried out between a compound A: 4-[2-(3-ethyl-4-methyl-2-keto-3-pyrroline-1-formamido)-ethyl]-benzene sulfonamide and a compound B: trans-4-methyl-cyclohexyl isocyanate of the same molar weight in an organic solvent. The mass ratio of the compound A and K2CO3 is 1:0.8-0.9; the mixture synthetic fluid of a crude Glimepiride product and K2CO3 is filtered in a suction way, and then an extract is added into pure water anddissolved to form a solution. The solution is filtered for removing impurities to obtain the aqueous solution of Glimepiride; a hydrochloric acid solution is added into the aqueous solution of the Glimepiride for acidification and then a crude product is separated; acetone is added into the crude Glimepiride product and then refined, filtered in a suction manner, dried in a vacuum environment to obtain a pure Glimepiride product. The method has the advantages of simplifying the synthetic route, selecting mature intermediates as raw materials, adding K2CO3 for promoting the condensation reaction, avoiding the use of chloroform, reducing the residual organic solvent, and being applicable to industrialized production.

Owner:JIANGSU WANBANG BIOPHARMLS +1

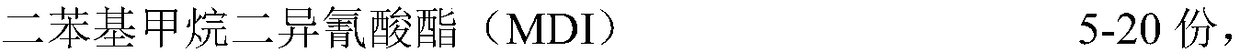

Environment-friendly heavy anti-corrosion waterproof material special for bridge pavement and preparation method thereof

InactiveCN109504256AImprove flexibilityImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesCross-linkEpoxy

The invention provides an environment-friendly heavy anti-corrosion waterproof material special for a bridge pavement. The environment-friendly heavy anti-corrosion waterproof material special for thebridge pavement is prepared from a main agent I component and an accessory agent P component, wherein a mass ratio of the I component to the P component is 1 to 1; the I component is prepared from the following raw materials: diphenyl-methane-diisocyanate, methylene-bis(4-cyclohexylisocyanate), isophorone diisocyanate, 2,2,4-trimethylhexamethylene diisocyanate, polyether polyol and epoxy resin; the P component is prepared from the following raw materials: an amine cross-linking chain extender, polycarbonate polyol, polycaprolactone polyol, polytetrahydrofuran polyol, a plasticizer, zinc oxide, sericite powder, precipitated barium sulphate, pigment and filler, an active nano compound alloy factor, a catalyst and an auxiliary. After the anti-corrosion waterproof material is applied to the bridge pavement, the comprehensive pavement performance of the bridge pavement is greatly improved, the service life of a road is prolonged, and corrosion and leakage caused by an external environmentare prevented.

Owner:CHANG HAI TIANJIN CHEM TECH DEVCO

Compound and method for producing the same

ActiveUS8142857B2Pretreated surfacesPolyurea/polyurethane coatingsPropanoic acidCyclohexylisocyanate

The invention provides a compound and method of producing the same. The method of the invention includes the following steps. First of all, Polycaprolactone (PCL), dimethylol propionic acid (DMPA), 4,4′-methylenebis (cyclohexyl isocyanate) (H12MDI), and dibutyltin dilaurate (DBT) are mixed in a solvent in the first place and a solution is formed. This solution is then mixed with triethylamine (TEA) and triethylene tetramine (TETA). After that, amino-terminated anionic waterborne polyurethane (WPU) is produced. A sol-gel process is proceeded with a mixture of amino-terminated anionic waterborne polyurethane, tetraethylorthosilicate (TEOS) without any extra catalyst, and a compound, waterborne polyurethane-silica nanocomposite materials, is eventually produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

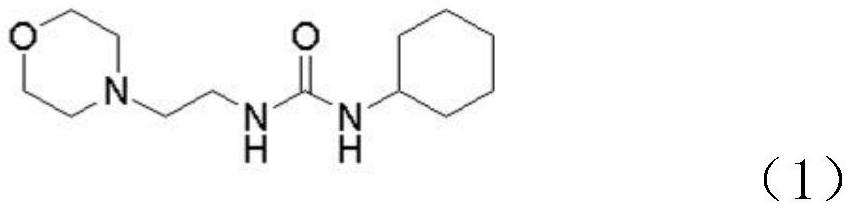

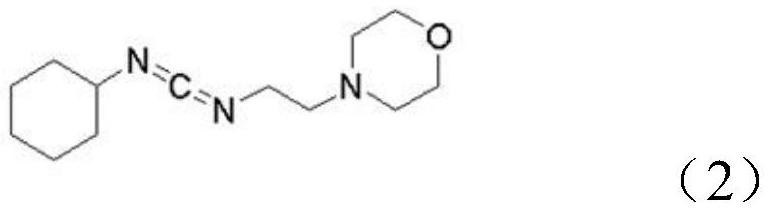

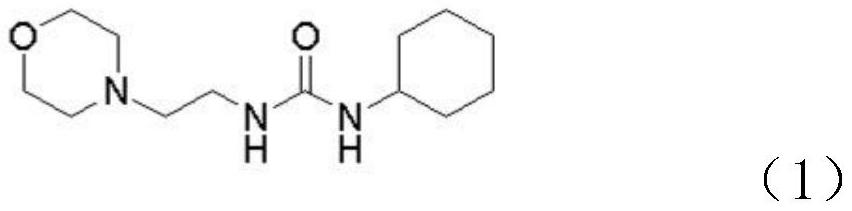

Preparation method of 1-cyclohexyl-2-(morpholinoethyl) carbodiimide methyl p-toluenesulfonate

ActiveCN112759563ALow toxicityImprove experiment safetySulfonic acids salts preparationMorpholineCyclohexylisocyanate

The invention provides a preparation method of 1-cyclohexyl-2-(morpholinoethyl) carbodiimide methyl p-toluenesulfonate, and the method comprises the following steps: S1, adding N-(2-aminoethyl) morpholine into a first organic solvent, and dropwise adding cyclohexyl isocyanate to generate an intermediate 1; S2, carrying out intramolecular dehydration reaction on the intermediate 1 to obtain an intermediate 2; S3, enabling the intermediate 2 to react with methyl p-toluenesulfonate, so as to generate the 1-cyclohexyl-2-(morpholinoethyl) carbodiimide methyl p-toluenesulfonate. According to the preparation method of the 1-cyclohexyl-2-(morpholinoethyl) carbodiimide methyl p-toluenesulfonate disclosed by the embodiment of the invention, a product with high purity can be smoothly obtained, and the method is good in operability, higher and stable in yield and easily available in raw materials.

Owner:SUZHOU HIGHFINE BIOTECH

A kind of acrylic acid carboxyl polyurethane powder coating for ceramics

ActiveCN104312417BIncreased durabilityWidely producedPolyurea/polyurethane coatingsPowdery paintsCyclohexylisocyanateLithium hydroxide

The invention discloses an acrylic carboxyl polyurethane powder coating for ceramic. The coating is prepared from the following raw materials: 1, 6-hexanediol, dehydrated castor oil, dibutyltin dilaurate, glycerol, cyclohexyl isocyanate, lithium hydroxide, an imitator, linseed oil, hexahydrophthalic anhydride, calcium boheic acid, pigments, rosin, dimethyl adipate, toluene diisocynate and methyl methacrylate. The product density is 135-155g / cm<3>, and the coating soaked in water for 60-70 days is free from soaking and falling phenomena. The tensile strength is 20-30MPa, the shore hardness is 40-60, and the coating soaked in a 5% hydrochloric acid solution for 40-60 days is free of abnormalities. The adhesive force is levels 1-2, the impact strength is 550-650N / cm, and the coating soaked in saturated calcium hydroxide for 25-35 days is free from bubbling and wrinkling; the glossiness is 110-130%, and the gloss retention is 92-96% after being manually accelerated and aged for 500 hours.

Owner:XIAN SICONG FINE CHEM

Compound and method for producing the same

InactiveUS20120101203A1Special tyresPolyurea/polyurethane coatingsPropanoic acidDibutyl tin dilaurate

The invention provides a compound and method of producing the same. The method of the invention includes the following steps. First of all, Polycaprolactone (PCL), dimethylol propionic acid (DMPA), 4,4′-methylenebis (cyclohexyl isocyanate) (H12MDI), and dibutyltin dilaurate (DBT) are mixed in a solvent in the first place and a solution is formed. This solution is then mixed with triethylamine (TEA) and triethylene tetramine (TETA). After that, amino-terminated anionic waterborne polyurethane (WPU) is produced. A sol-gel process is proceeded with a mixture of amino-terminated anionic waterborne polyurethane, tetraethylorthosilicate (TEOS) without any extra catalyst, and a compound, waterborne polyurethane-silica nanocomposite materials, is eventually produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

Polyester material with high toughness and preparation method thereof

The invention relates to a high-toughness polyester material and a preparation method thereof, and the polyester material comprises the following components in parts by weight: 10-25 parts of aromatic alcohol, 5-8 parts of cyclohexyl isocyanate, 20-40 parts of polybasic organic acid, 22-45 parts of 1, 7-heptanediol, 1-3 parts of dinonyl naphthalene sulfonic acid, 4-10 parts of microcapsules, 1-4 parts of an initiator and 2-4 parts of an auxiliary agent. The multi-element organic acid is selected from one or a mixture of two of L-tartaric acid and dihydromuconic acid, the multi-element organic acid is the mixture of the L-tartaric acid and the dihydromuconic acid, the ratio of the amount of substance of the L-tartaric acid to the dihydromuconic acid is 1: 4, the wall material of the microcapsule is polyethylene with the molecular weight smaller than 10000, the core material of the microcapsule is a mixture of sodium alginate and nano titanium dioxide, and the core material of the microcapsule is a mixture of sodium alginate and nano titanium dioxide. The mass ratio of the sodium alginate to the nano titanium dioxide is 1: 3. The toughness of the prepared polyester material is improved while the strength of the polyester material is guaranteed, and the application range of the polyester material is widened.

Owner:河南源宏高分子新材料有限公司

A preparation method of self-healing material and application of the self-healing material

ActiveCN112358620BEasy to stretchExcellent self-healing performanceFriction generatorsPolymer scienceCyclohexylisocyanate

The invention provides a preparation method of a self-repairing material and an application of the self-repairing material. The preparation method comprises the following steps: using bis(3-aminopropyl)-terminated poly(dimethylsiloxane) as a polymer matrix, using 2,6-pyridinedicarbonyl dichloride and 4,4'- Methyl bis(cyclohexyl isocyanate) is used as a spacer, and the chemical formula obtained by the reaction is PDMS‑PU x -PA 1‑x The oligomer, wherein, 0<x<1; The oligomer and zinc chloride are mixed to obtain a chemical formula of PDMS‑PU x -PA 1‑x ‑Zn's first self-healing material. According to the embodiment of the present invention, the silicon oxide chain of polydimethylsiloxane is used as the matrix, and the double cross-linking effect of ion complexation and hydrogen bonding is introduced through chain extension, and a compound with high tensile properties and excellent self-sufficiency is synthesized. Self-healing materials with healing properties.

Owner:SUZHOU UNIV

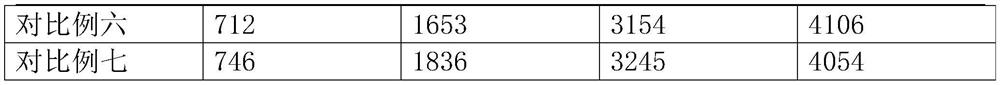

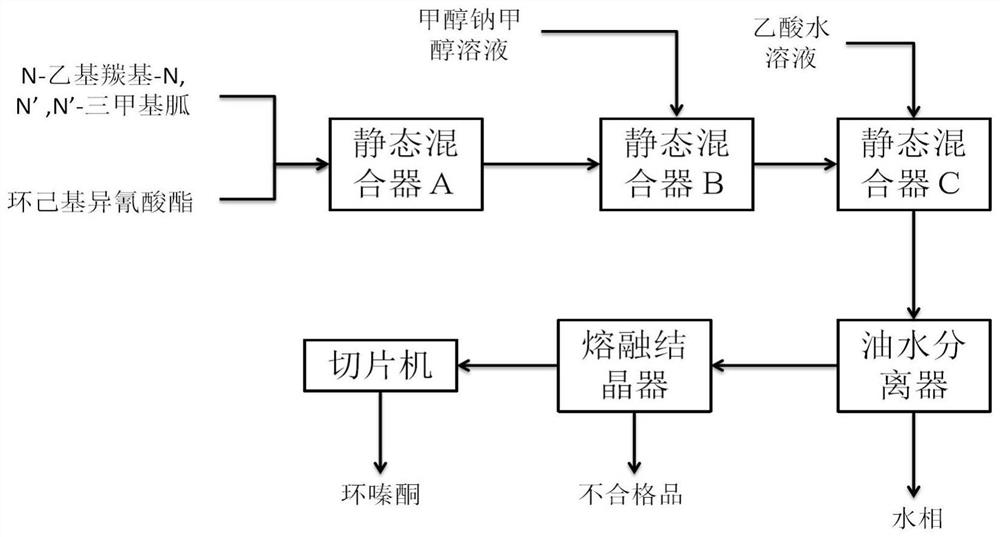

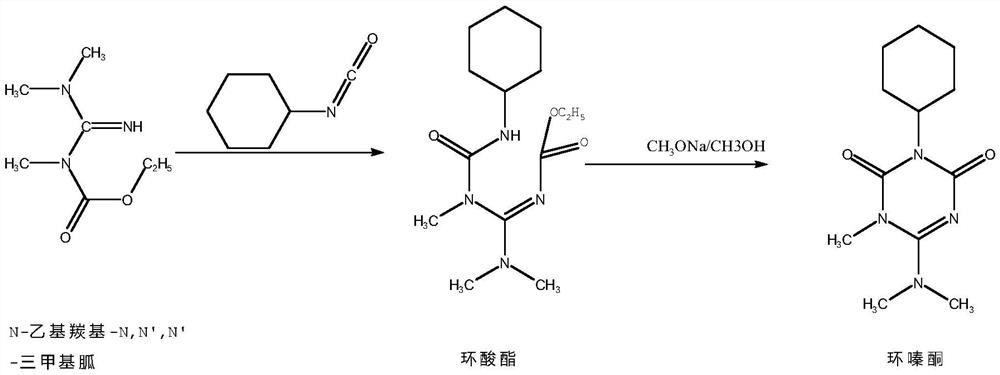

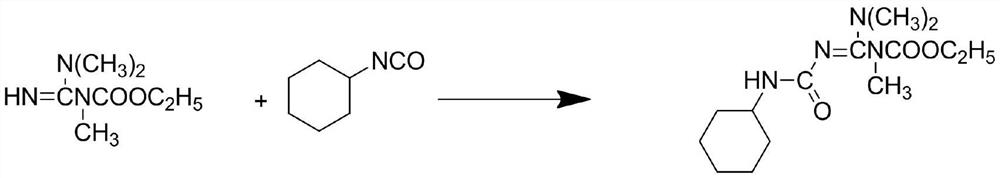

Method for synthesizing hexazinone through continuous solvent-free reaction

The invention discloses a method for synthesizing hexazinone through continuous solvent-free reaction. The method comprises the following steps: preparing a cyclic acid ester compound, synthesizing hexazinone and purifying hexazinone. According to the invention, N-ethylcarbonyl-N,N',N'-trimethylguanidine and cyclohexyl isocyanate are subjected to a reaction according to a certain ratio (molar ratio of 1:1) in a static mixer A at normal temperature, a mixed solution passes through a static mixer B to generate hexazinone under the action of a catalyst sodium methoxide, the generated hexazinone is subjected to acid washing neutralization through a static mixer, an organic phase enters a melt crystallizer, crystallizing is performed, and slicing is performed after qualification, so that hexazinone with the content of more than 99% and the yield of about 95% can be obtained; and n-hexane and toluene solvents do not need to be added, so that the problem of solvent volatilization does not need to be considered in the processes of neutralizing, water washing, distilling and drying of hexazinone, the production cost can be saved, and the problem that during solvent crystallization, a part of hexazinone is taken away from the mother liquor does not need to be considered so as to improve the yield.

Owner:江苏禾裕泰化学有限公司

High-solid low-viscosity mirror synthetic leather treatment agent and preparation method thereof

The invention discloses a high-solid low-viscosity mirror synthetic leather treatment agent and a preparation method thereof. The high-solid low-viscosity mirror synthetic leather treatment agent comprises a main agent and a curing agent, wherein the main agent adopts 3-isocyanate methylene-3,5,5-trimethylcyclohexyl isocyanate, 3-isocyanatopropyltrimethoxysilane and (1S,2S)-(+)-2-benzyl cyclohexylisocyanate as a mixed base material, adopts dibutyltin dilaurate as a catalyst, adopts a mixture of dimethyl carbonate and vinyl acetate as a solvent, and also comprises polyether polyol and micromolecular polyols. The curing agent comprises a flatting agent, a foaming agent, tetrabutyl titanate, butyl butyrate and dibutylester nylon acids. The main agent and the curing agent are uniformly mixedto obtain the high-solid low-viscosity mirror synthetic leather treatment agent disclosed by the invention. The solid content of the synthetic leather treatment agent reaches 80 percent at most. The synthetic leather treatment agent is relatively low in initial viscosity, thereby facilitating the manual operation, and improving the utilization rate of the treatment agent; and after a period of time, the viscosity is greatly improved, so that the actual production and life requirement can be met.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

A kind of high-solid low-viscosity mirror synthetic leather treatment agent and preparation method thereof

The invention discloses a high-solid low-viscosity mirror synthetic leather treatment agent and a preparation method thereof. The high-solid low-viscosity mirror synthetic leather treatment agent comprises a main agent and a curing agent, wherein the main agent adopts 3-isocyanate methylene-3,5,5-trimethylcyclohexyl isocyanate, 3-isocyanatopropyltrimethoxysilane and (1S,2S)-(+)-2-benzyl cyclohexylisocyanate as a mixed base material, adopts dibutyltin dilaurate as a catalyst, adopts a mixture of dimethyl carbonate and vinyl acetate as a solvent, and also comprises polyether polyol and micromolecular polyols. The curing agent comprises a flatting agent, a foaming agent, tetrabutyl titanate, butyl butyrate and dibutylester nylon acids. The main agent and the curing agent are uniformly mixedto obtain the high-solid low-viscosity mirror synthetic leather treatment agent disclosed by the invention. The solid content of the synthetic leather treatment agent reaches 80 percent at most. The synthetic leather treatment agent is relatively low in initial viscosity, thereby facilitating the manual operation, and improving the utilization rate of the treatment agent; and after a period of time, the viscosity is greatly improved, so that the actual production and life requirement can be met.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

A method for the continuous solvent-free reaction synthesis of hexazinone

The invention discloses a method for synthesizing hexazinone through continuous solvent-free reaction, which comprises preparation of cyclic ester compound, synthesis of hexazinone and purification of hexazinone. This application uses N-ethylcarbonyl-N,N',N'-trimethylguanidine and cyclohexyl isocyanate in a certain ratio (molar ratio 1:1) after the static mixer A reacts at room temperature, and the mixed solution passes through static Mixer B generates hexazinone under the action of catalyst sodium methoxide. After the generated hexazinone is pickled and neutralized by the static mixer, the organic phase enters the melting crystallizer and crystallizes. After passing the test, it can be sliced to obtain a content greater than 99%. , the yield of hexazinone is about 95%. This application does not need to add n-hexane and toluene solvents, and there is no need to consider the problem of solvent volatilization in the process of neutralization, washing, distillation and drying of hexazinone, which can save production cost, and there is no need to consider the problem that a part of hexazinone is also taken away in the mother liquor during solvent crystallization, thereby improving the effect of yield.

Owner:江苏禾裕泰化学有限公司

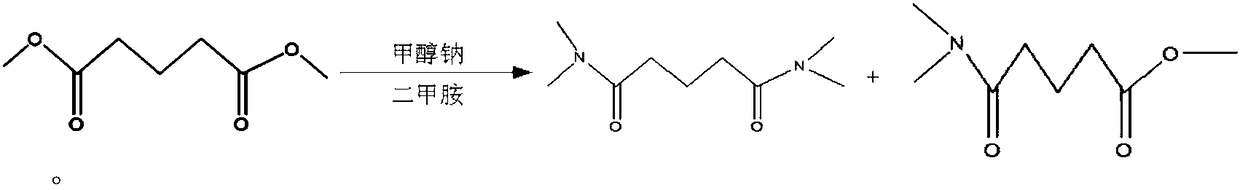

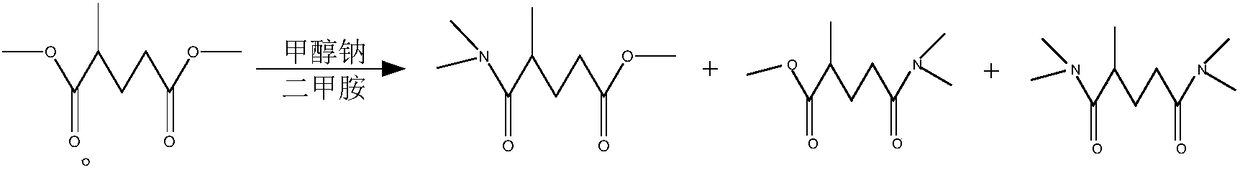

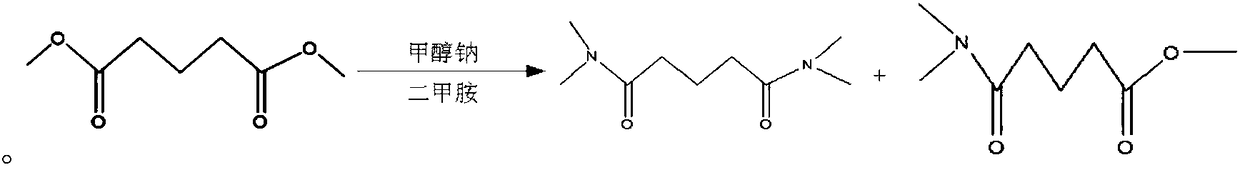

A kind of preparation method of resin containing water-soluble plasticizer and polyurethane

ActiveCN105647160BHigh molecular weightNot volatileOrganic compound preparationCarboxylic acid amides preparationMolten stateDistillation

The invention relates to a preparation method of a resin containing a water-soluble plasticizer and polyurethane. The method comprises the following steps: adding dimethyl glutarate or dimethyl glutarate homologs of which the 2,3,4 carbon sites are provided with methyl or hydroxyl into a closed reaction kettle, charging dimethylamine gas, and carrying out amide ester exchange reaction according to the ratio of the dimethylamine and the dimethyl glutarate or dimethyl glutarate homologs of which the 2,3,4 carbon sites are provided with methyl or hydroxyl of 2.1-2.4; adding a phosphoric acid water solution into the reaction kettle to generate dimethylamine phosphate and sodium phosphate; transferring the mixture treated in the step 2 into a filter kettle, and filtering to remove the dimethylamine phosphate and sodium phosphate; carrying out reduced pressure distillation to remove methanol and water; adding cyclohexyl isocyanate to remove the dimethylamine and water, thereby obtaining the water-soluble plasticizer; adding the water-soluble plasticizer prepared by the steps 1-5 into molten-state polyurethane.

Owner:姜琪

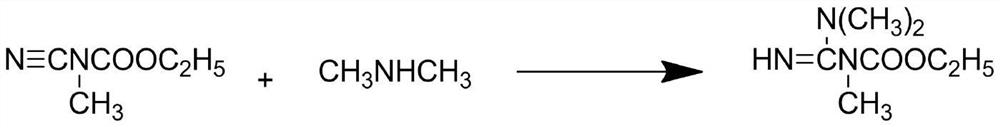

Production process for improving yield of hexazinone

The invention discloses a production process for improving the yield of hexazinone. The production process comprises the following steps: S1, generating ethyl cyanocarbamate by using cyanamide and ethyl chloroformate, and synthesizing a methyl substance from ethyl cyanocarbamate and dimethyl sulfate under the catalytic condition of a catalyst; S2, synthesizing a guanidine derivative from the methyl substance and dimethyl amine; S3, extracting the guanidine derivative for multiple times by using chloroform; S4, carrying out desolvation treatment on the guanidine derivative; S5, reacting the guanidine derivative with cyclohexyl isocyanate under the condition of taking methyl benzene as a solvent to synthesize a hexazinone intermediate; S6, carrying out cyclization reaction on the hexazinoneintermediate and sodium methoxide to prepare hexazinone, and carrying out water washing treatment; step S7, purifying and drying hexazinone to obtain a hexazinone prodrug product; the production process disclosed by the invention is easy for industrial production and strong in practicability, and solves the technical problem of low yield of hexazinone prodrug products in the prior art.

Owner:ANHUI GUANGXIN AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com