Environment-friendly heavy anti-corrosion waterproof material special for bridge pavement and preparation method thereof

A waterproof material, heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc. Achieve the effect of reducing road construction and maintenance costs, extending service life and increasing weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] An environment-friendly special heavy-duty anti-corrosion and waterproof material for bridge pavement, including main agent I component and auxiliary agent P component, and the mass ratio of I component to P component is 1:1;

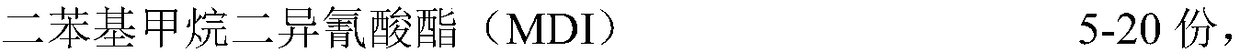

[0064] Wherein, I component is made of the raw material that comprises following parts by weight:

[0065]

[0066]

[0067] The isocyanate group content of the prepared I component is 5.20%

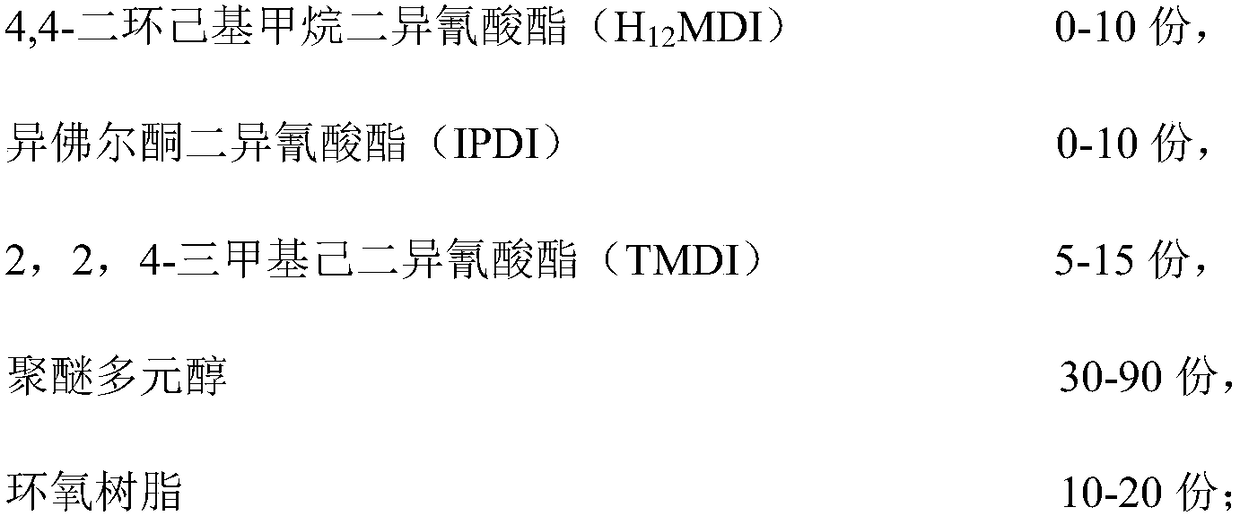

[0068] The P component is made from raw materials comprising the following parts by weight:

[0069]

[0070]

[0071] Wherein, the active nanocomposite alloy factor is prepared by a method comprising the following steps:

[0072] (1) Get 1 part of calcium-based nanoscale powder nano calcium carbonate;

[0073] (2) Add the nanoscale powder in the step (1) to the ester solvent ethyl acetate containing a mixture of organosilicon coupling agent and titanate coupling agent and mix, nanoscale powder, coupling agent, Solvent mass ratio is 1: (0.003...

Embodiment 2

[0076] An environment-friendly special heavy-duty anti-corrosion and waterproof material for bridge pavement, including main agent I component and auxiliary agent P component, and the mass ratio of I component to P component is 1:1;

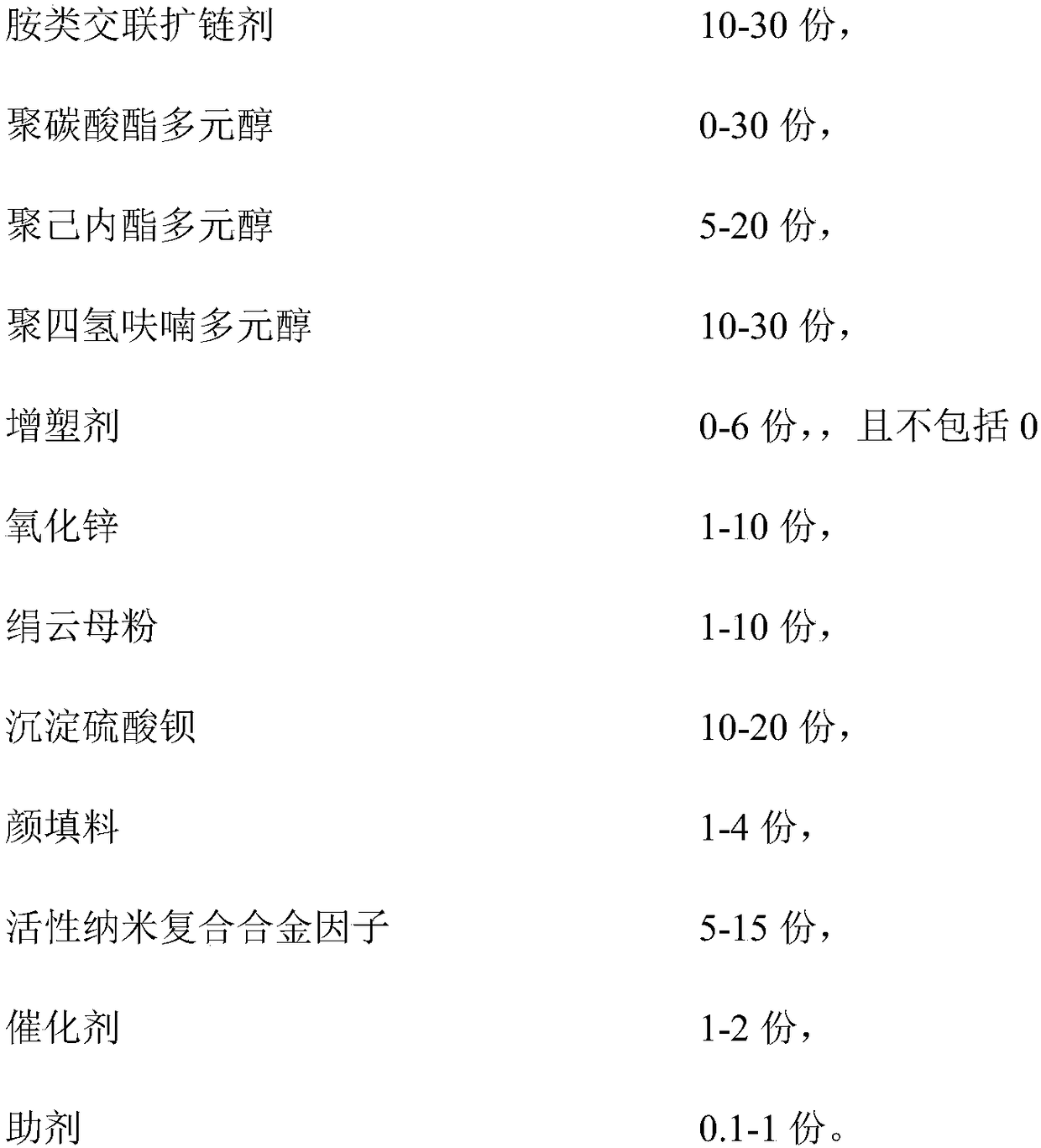

[0077] Wherein, I component is made of the raw material that comprises following parts by weight:

[0078]

[0079]

[0080] The isocyanate group content of the prepared I component is 4.90%

[0081] The P component is made from raw materials comprising the following parts by weight:

[0082]

[0083] Wherein, the active nanocomposite alloy factor is prepared by a method comprising the following steps:

[0084] (1) Take 0.7 parts of calcium-based nano-scale powder nano-calcium carbonate and silicon-based nano-scale powder nano-SiO 2 , and mix, calcium-based nanoscale powder: silicon-based nanoscale powder=9:1 (mass ratio);

[0085] (2) Add the nano-scale powder in the step (1) to the ester solvent butyl acetate containing a mixture of...

Embodiment 3

[0088] An environment-friendly special heavy-duty anti-corrosion and waterproof material for bridge pavement, including main agent I component and auxiliary agent P component, and the mass ratio of I component to P component is 1:1;

[0089] Wherein, I component is made of the raw material that comprises following parts by weight:

[0090]

[0091] The isocyanate group content of the prepared I component is 5.40%

[0092] The P component is made from raw materials comprising the following parts by weight:

[0093]

[0094] Wherein, the active nanocomposite alloy factor is prepared by a method comprising the following steps:

[0095] (1) Take 1.8 parts of silicon-based nano-scale powder nano-SiO 2 ;

[0096] (2) Add the nano-scale powder in the step (1) to the ketone solvent acetone containing organosilicon coupling agent and mix, wherein, the mass ratio of nano-scale powder, coupling agent and solvent is 1:(0.003-0.005 ): 5, the silicone coupling agent is KH550;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com