Patents

Literature

766results about How to "Widely produced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

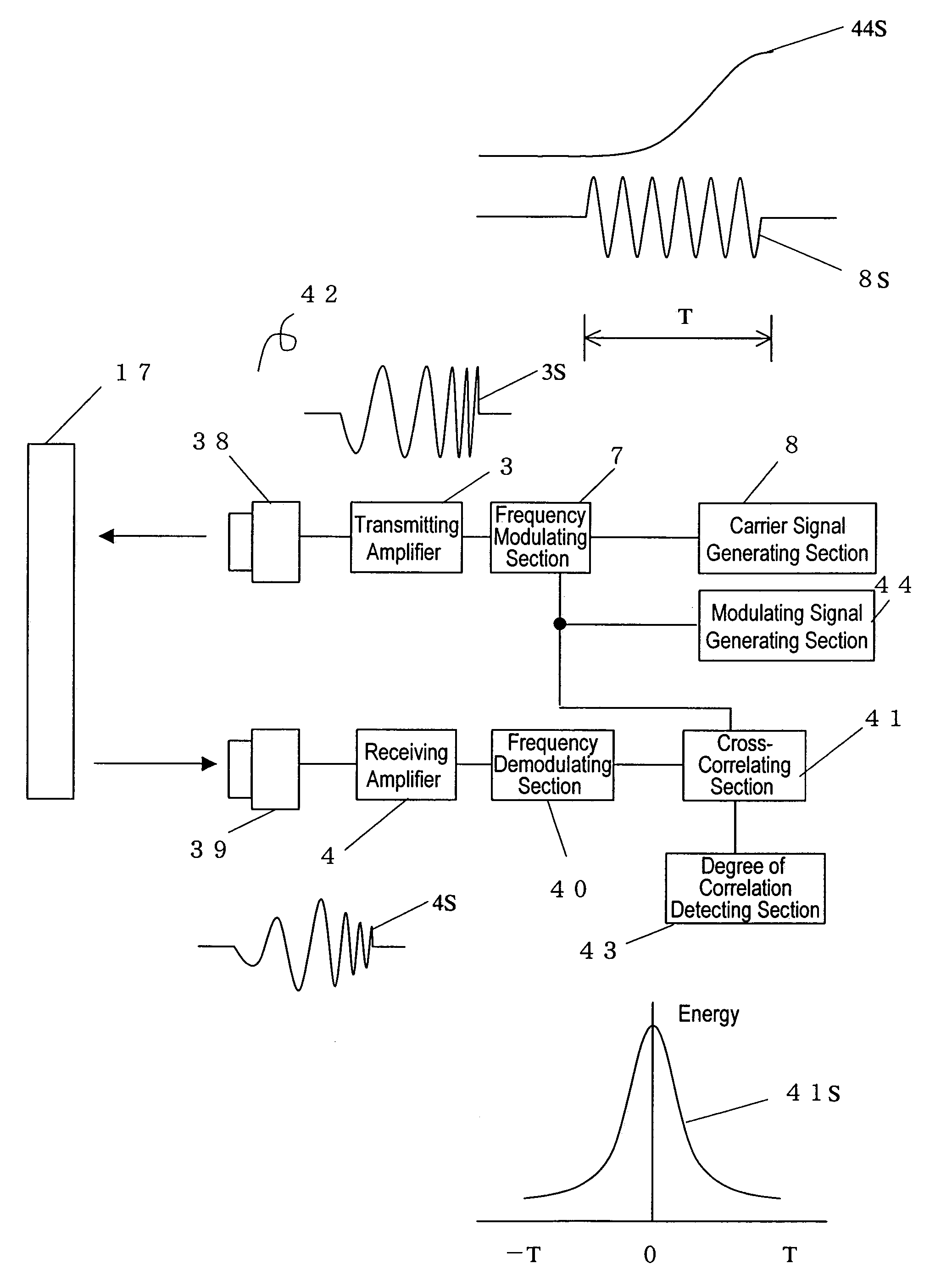

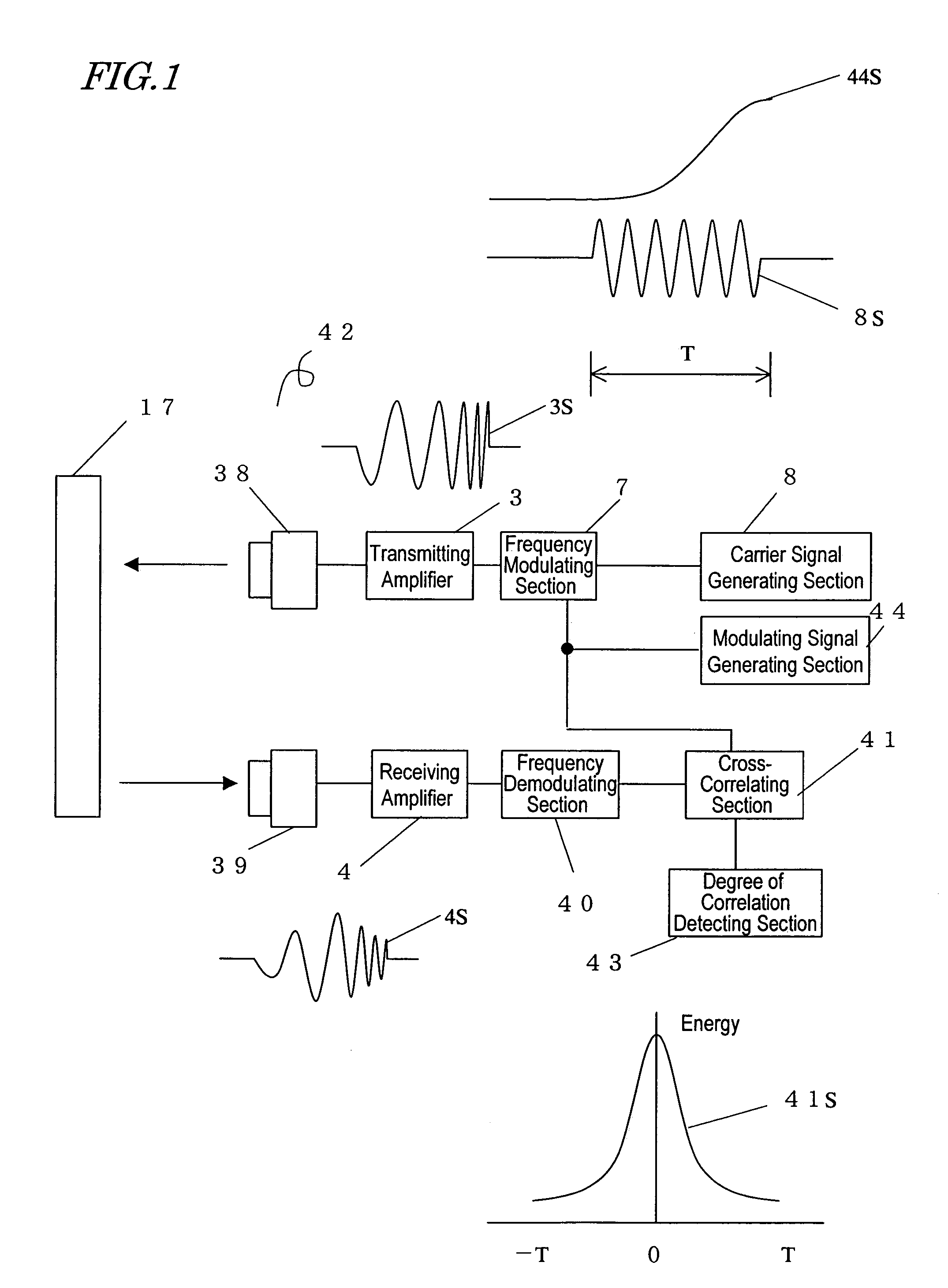

Ultrasonic distance measure

ActiveUS7046015B2Simple configurationHigh precision measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesResistance/reactance/impedenceUltrasonic sensorResonance

An ultrasonic distance measure includes: transmitting and receiving ultrasonic transducers with changeable resonant / resonance frequencies; a driving section generating a frequency-modulated drive signal to drive the transducer and transmit an ultrasonic wave; a transmitting control voltage generating section for generating a control voltage to change the resonant / resonance frequency of The transducer and applying it to the transducer in transmitting the ultrasonic wave; a receiving control voltage generating section for generating a control voltage to change the resonant / resonance frequency of the transducer and applying it to the transducer when a controllable amount of time delay has passed since The drive signal was generated; and a receiving section for sensing the intensity of a signal received as the ultrasonic wave at the transducer.

Owner:PANASONIC CORP

Wear resistant polytetrafluoroethylene material and preparation method thereof

The application discloses a wear resistant polytetrafluoroethylene material and a preparation method thereof. The method comprises steps of: preparing polytetrafluoroethylene, aluminum oxide, bronze powder, silica, glass fiber, LCP, a coupling agent, graphite, molybdenum disulfide, GF, a flame retardant, UHMWPA, POM, PC and nano-titanium dioxide in parts by weight; mixing the substances; and extruding the mixture. For a product, the tensile strength is 27-32 MPa, and the breaking elongation is 300-320%; the Shore hardness is 60-80, and the abrasion amount is 0.001-0.005 mg; and the relative density is 2.6-2.8, and the wear width is 3.4-3.5 mm / h.

Owner:苏州市德莱尔建材科技有限公司

PVC cable material and preparation method thereof

ActiveCN103275427AHigh oxygen indexExcellent flexibility and electrical insulationPlastic/resin/waxes insulatorsThermal ageingPlasticizer

The invention discloses a PVC (polyvinyl chloride) cable material which comprises the following components by mass: 100 parts of PVC, 5-15 parts of heat stabilizer, 10-60 parts of plasticizer, 1-15 parts of lubricant, 0.1-1 part of antioxygen, 2-10 parts of fire retardant, 5-10 parts of calcined clay, 10-40 parts of calcium carbonate, and 0.1-0.5 part of UV-329; the oxygen index of the PVC cable material reaches up to be 33%, the dielectric constant is 4.2, the smoke density per the unit mass of smoke is 10-12 g, thermal ageing quality loss is 15-18 g / m<2>, the volume resistivity is 8*1015 omega / cm at the temperature of 20 DEG C, the volume resistivity is 6*1015 omega / cm at the temperature of 70 DEG C, the tensile strength is 18-19 MPa, the tensile strength retention rate is 99%, and the PVC cable material resists is heat-resistant and cold-resistant, is difficult to volatilize, is pumping-resistant and excellent in flexibility and electric insulation property, can be widely produced and can replace the conventional material continuously.

Owner:DAISHAN POWER SUPPLY CO STATE GRID ZHEJIANG ELECTRIC POWER CO +1

LDPE fishing net filament

InactiveCN103739907AWidely producedConjugated synthetic polymer artificial filamentsArtifical filament manufacturePhosphorous acidWear resistant

The invention relates to an LDPE (low-density polyethylene) fishing net filament, which comprises, by mass, 100 parts of LDPE; 0.3-0.5 part of UV-531; 0.3-0.5 part of DLTP; 0.3-0.5 part of zinc stearate; 0.5-1 part of barium stearate; 0.2-0.5 part of a light stabilizer; 10-15 parts of polybutadiene; 1-3 parts of carbon black; 5-10 parts of sodium hydrogen carbonate; 20-40 parts of butyl rubber; 20-40 parts of CPE; 2-3 parts of dibasic lead phosphite; and 25-45 parts of EVA. The product can tolerate a high temperature of 150-160DEG C and a low temperature of -30DEG C, has tensile strength of 10-20MPa, tensile elongation of 400-600%, and knot strength of 1.5-2MPa. Being light-fast and wear resistant, the product can be widely produced and be used for replacing existing materials continuously.

Owner:WUJIANG DONGXIN PLASTIC PACKAGING PLANT

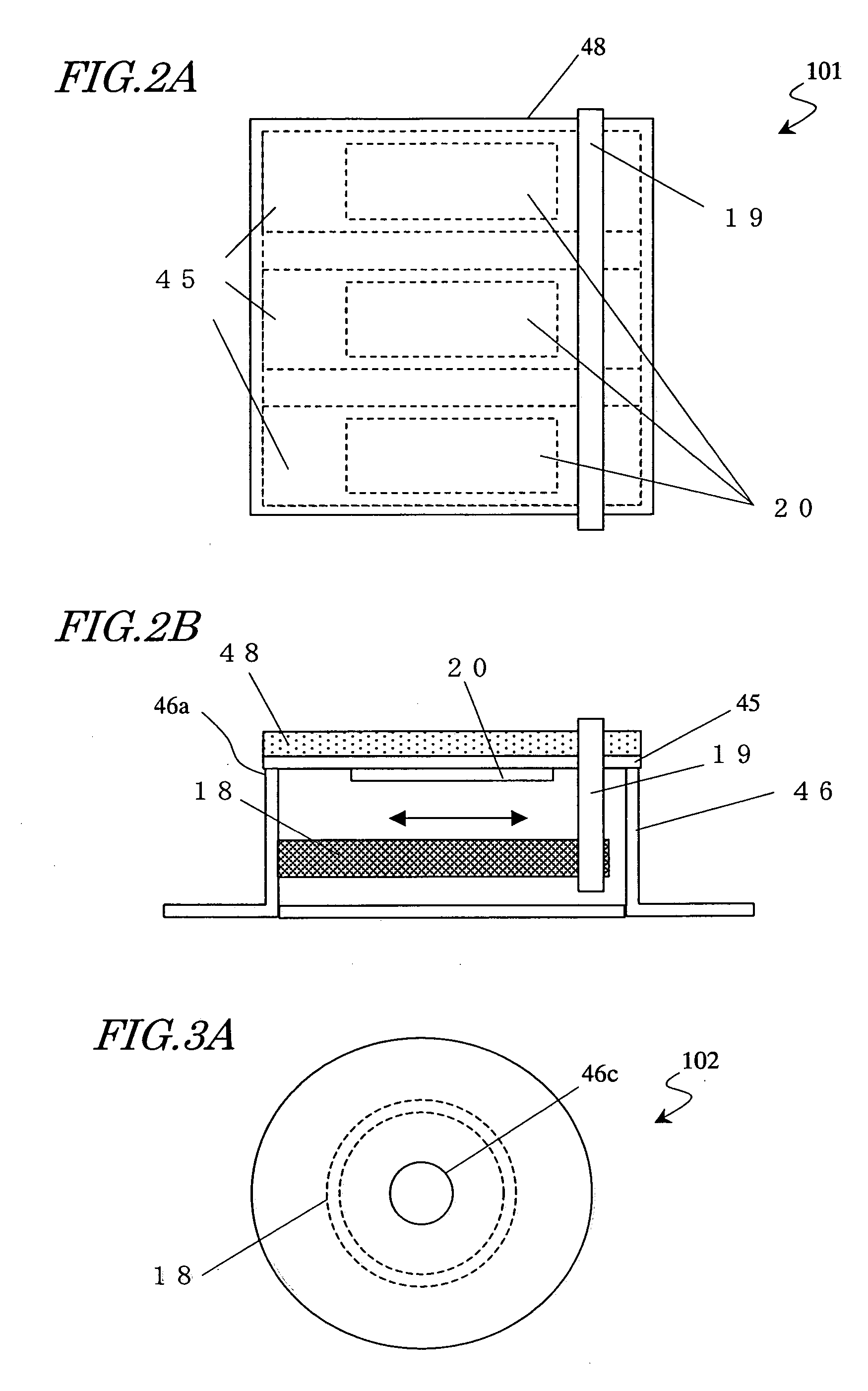

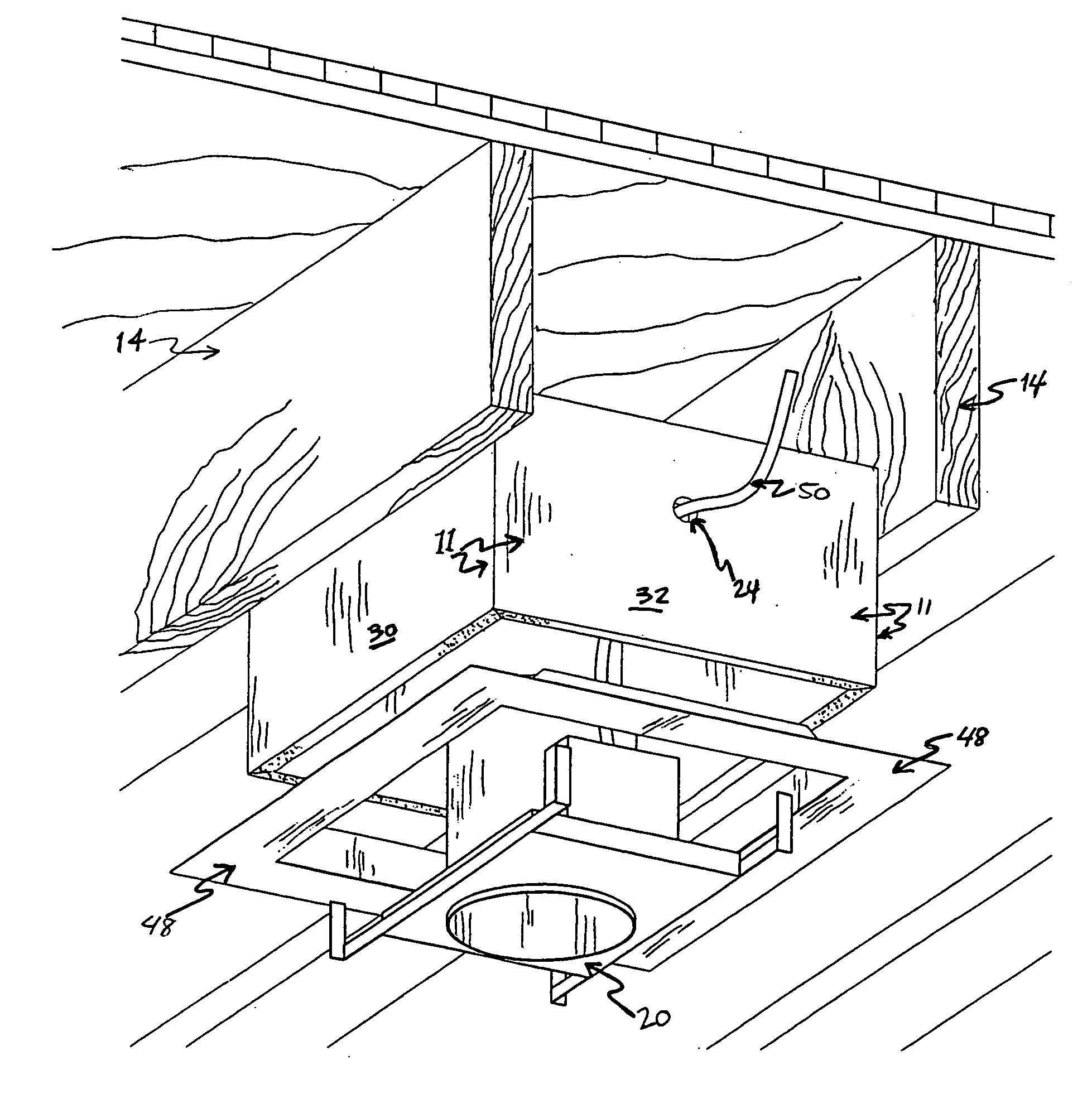

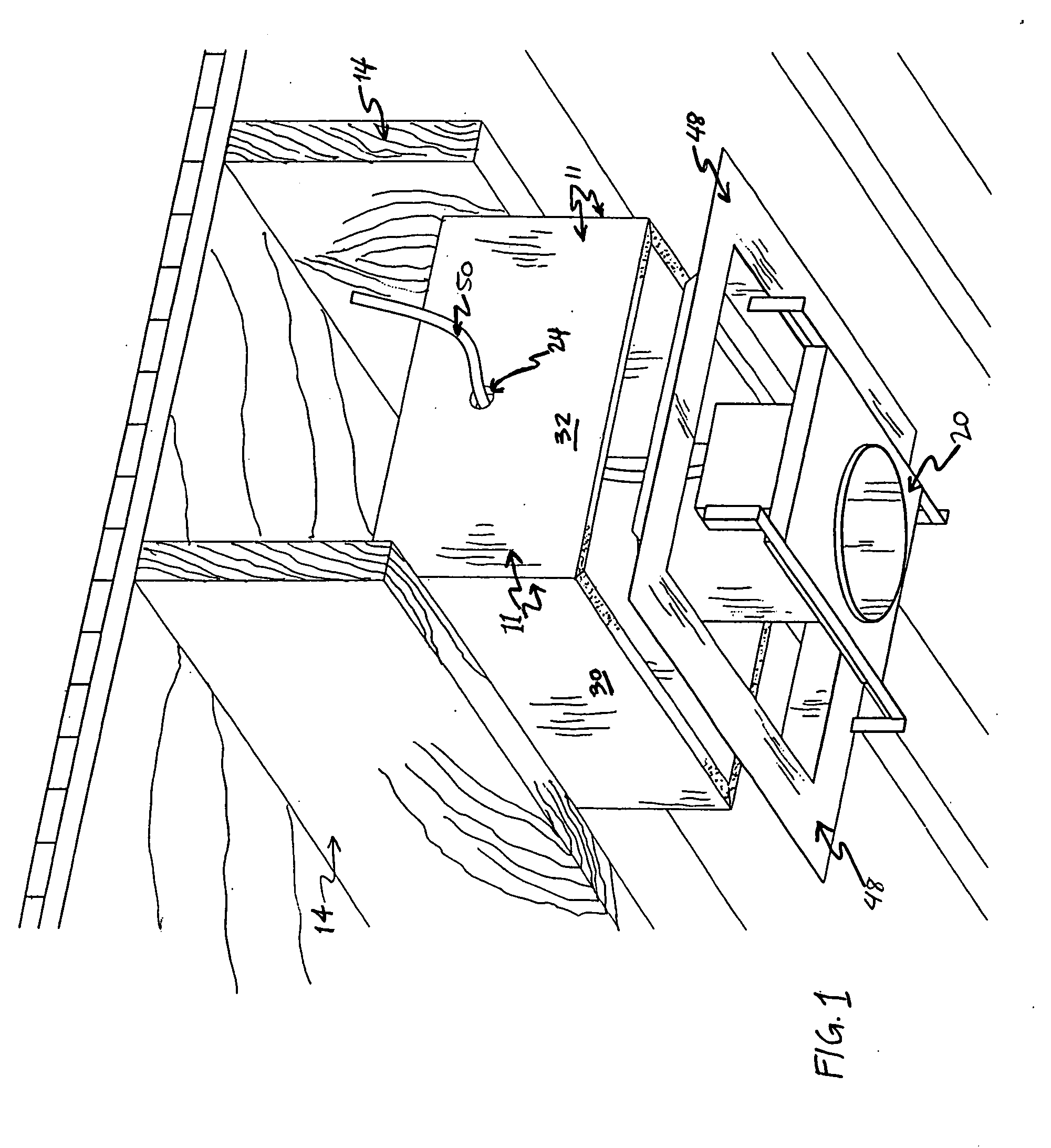

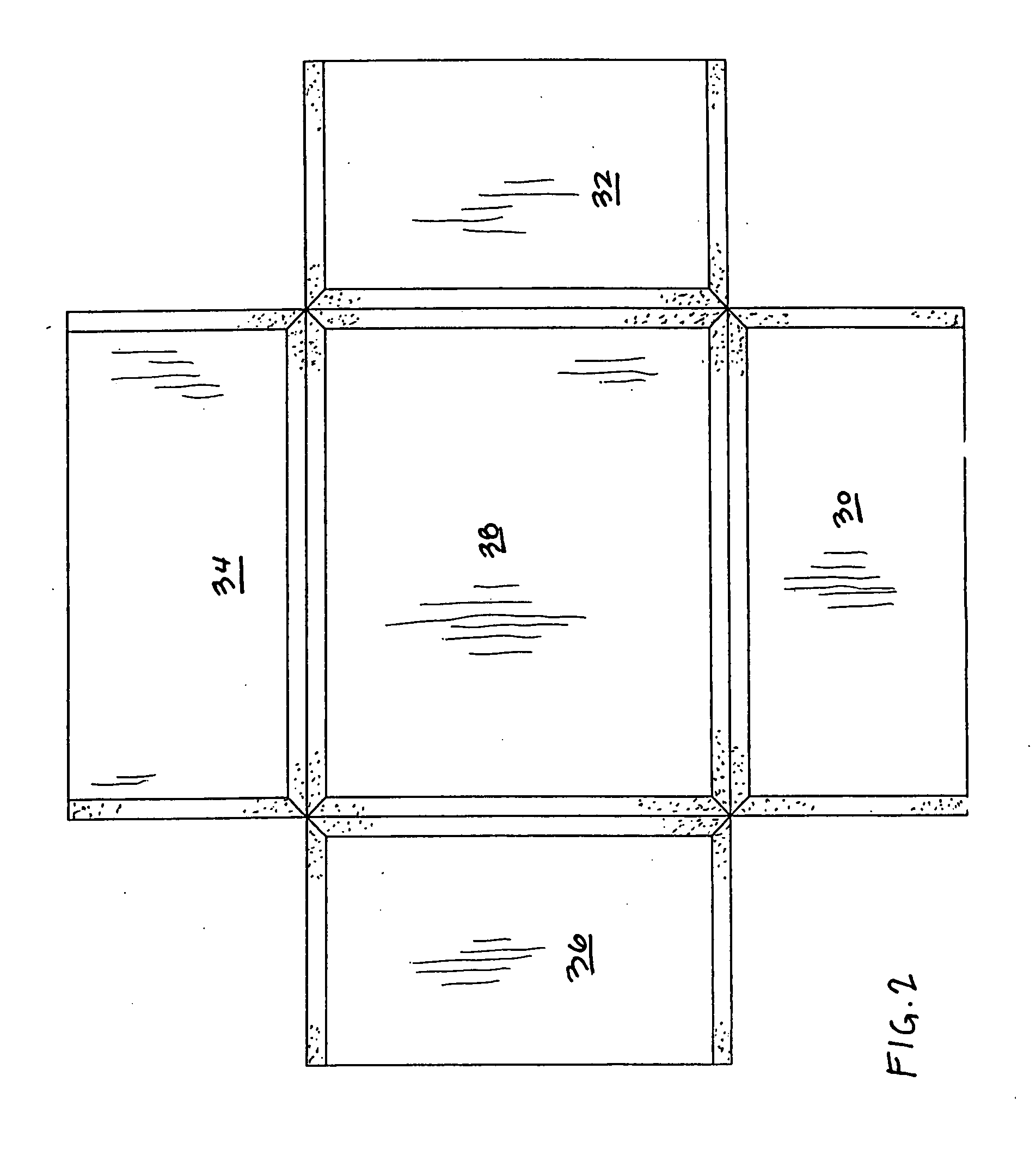

Recessed ceiling fixture enclosure

An enclosure for use in conjunction with a recessed ceiling fixture is provided which includes a substantially rectangular housing defining a top wall and side walls constructed from a single piece of fire-resistant gypsum wallboard. The housing is fastened to continuous stamped metal support flange depend inwardly from bottom edges of side walls of the housing to facilitate mounting of the housing between spaced apart building joists. The recessed fixture is mounted to the interior of the support flange after installation of the housing between the building joists.

Owner:MOENCH JOHN P

HDPE (high-density polyethylene) cable sheath material

ActiveCN103304879AImprove toughnessWidely producedPlastic/resin/waxes insulatorsMasterbatchPolymer science

The invention relates to an HDPE (high-density polyethylene) cable sheath material. The HDPE cable sheath material comprises the following components in parts by weight: 100 parts of HDPE, 0.1-5 parts of melt viscosity modifier, 0.01-2 parts of heat stabilizer, 0.01-10 parts of white oil, 1-80 parts of toughener, 0.01-10 parts of carbon black masterbatch, 0.01-10 parts of antioxidant and 0.01-10 parts of nucleating agent; the melt flow rate of a product is more than 10g / 10min, which is greatly improved in comparison with the melt flow rate of 0.1-0.3g / 10min of the existing cable sheath material; the elongation rate is 500%, which is greatly improved in comparison with the elongation rate of 23% of the existing HDPE; the tensile strength is 10-20MPa, and the density is 0.959-0.965g / cm<3>; the brittle temperature of the product is -70 DEG C, the volume resistivity is more than 2*1016 omega.cm, the breakdown strength is 20KV / mm, and the resistance to environmental stress cracking is not less than 50h; and the product has the advantages of good toughness, aging resistance and resistance to chemical corrosion, and can be widely produced and used for continuously replacing existing materials.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Circulated cooling water compounded scale inhibitor and preparation method thereof

InactiveCN105036359AReduce contentReduce spawn rateTreatment using complexing/solubilising chemicalsPhosphoric Acid EstersMeth-

The invention discloses a circulated cooling water compounded scale inhibitor and a preparation method of the circulated cooling water compounded scale inhibitor. The circulated cooling water compounded scale inhibitor is prepared by weighing polyaspartic acid, 1-hydroxy ethylidene-1,1-diphosphonic acid, polyepoxysuccinic acid, amino trimethylene phosphonic acid, deionized water, sodium hexametaphosphate, a dispersing agent, polyhydric alcohol phosphate ester, organic polybasic phosphonic acid, acrylic acid-acrylic acid phosphonic hydroxypropyl acrylate and organic solvent according to a ratio in parts by weight. According to the circulated cooling water compounded scale inhibitor and the preparation method, disclosed by the invention, the content of phosphor in a water treatment agent is reduced, the generation rate of calcium phosphate scales is reduced, and the corrosion inhibition speed ranges from 0.001mm / a to 0.01mm / a; the scale inhibition rate is up to 98 to 100 percent; the expiration date is long, the circulated cooling water compounded scale inhibitor can be stored for one month under 60 to 70 DEG C, and the scale inhibition effect is up to 99 to 100 percent.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

Medical LDPE(low-density polyethylene) antibacterial plastic and preparation method thereof

The application discloses medical an LDPE(low-density polyethylene) antibacterial plastic and a preparation method thereof. The method comprises the following steps: weighing materials in parts by weight: LDPE, magnesium hydroxide powder, sorbitol single zinc stearate ester, sodium aluminate, LLDPE(linear low density polyethylene), magnesium sulphate, a fire retardant, EVA(ethylene-vinyl acetate), chitosan, an antioxidant 2002, a coupling agent, polybutylene, styrene, zinc stearate and a UV-531(ultraviolet absorbent); uniformly mixing the materials, and then extruding the mixed materials to make grains so as to obtain the plastic. The longitudinal tensile strength of products is 10-30 MPa, and the lateral tensile strength is 5-25 MPa; the antibacterial rate to enterobacteria is 90-95%, and the antibacterial rate to golden staphylococcocci is 99.5-99.9%; the longitudinal elongation rate is 250-350%, and the lateral elongation rate is 300-500%; the transparency is 85-90%.

Owner:SUZHOU BEC BIOLOGICAL TECH

Waterproof packaging material and preparing method thereof

The invention discloses a waterproof packaging material and a preparing method thereof. The waterproof packaging material is prepared from PVC, plasticizer, lead stearate, butadiene-acrylonitrile rubber powder, EBSO, magnesium silicate, TDI, sulfur, zinc oxide and tribasic lead sulfate. The notch impact strength of the packaging material is 4-6 Kj / m<3>, the tensile strength is 40-60 MPa, and Brinell hardness is 20-24; tensile strength is lost by 0.05-0.25% after the packaging material is thermally aged for 2 months at the temperature of 80 DEG C, and tensile strength is lost by 0.001-0.02% after the packaging material is naturally aged for 2 months; according to combustibility, the packaging material is self-extinguished when away from a fire, and the tear strength is 36-40 kN / m. The raw materials are simple and easy to obtain, the preparing method is simple, and the elongation is 40-180%.

Owner:SUZHOU DINGLI PACKAGING

Polypropylene woven bag

The invention relates to a polypropylene woven bag, which is composed of, by mass, 100 parts of PP(polypropylene); 15-20 parts of LDPE; 0.05-0.2 part of an antioxidant 1010; 1-5 parts of white oil; 1-5 parts of zinc white; 1-5 parts of PP-g-MAH; 0.1-0.5 part of an antioxidant DLTP; 0.2-1 part of zinc stearate; 5-10 parts of titanium dioxide; 0.05-0.25 part of DCP; 0.025-0.05 part of UV-327; 0.5-1 part of a coupling agent; and 10-20 parts of calcium carbonate. The product has tensile strength of 5-10MPa, elongation of 25-30%, fineness of 180-200, and has no change after 24h of soaking in strong alkali. The product is acid and alkali resistant and wear resistant, can be widely produced and used for replacing existing materials continuously.

Owner:WUJIANG DONGXIN PLASTIC PACKAGING PLANT

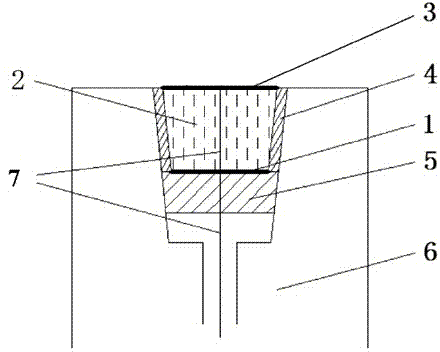

Platinum electrode for high-temperature high-pressure hydrothermal system and preparation method thereof

ActiveCN104749234AGood mechanical strength at high temperatureModerate hardnessMaterial electrochemical variablesPlatinumOptoelectronics

The invention discloses a platinum electrode for a high-temperature high-pressure hydrothermal system and a preparation method of the platinum electrode. The platinum electrode is composed of a substrate (6), a circular truncated cone shaped high-temperature insulating mat (5), a high-temperature insulating taper sleeve (4), a circular truncated cone shaped high-temperature insulating ceramic (2), an inert metal sheet (1), a spongy inert metal layer (3) and an electrode lead wire (7), wherein one end of the substrate is provided with a taper hole and the other end of the substrate is provided with an axis through hole; the convergent end of the taper hole is provided with the circular truncated cone shaped high-temperature insulating mat, the divergent end of the taper hole is provided with the high-temperature insulating taper sleeve and the circular truncated cone shaped high-temperature insulating ceramic, the electrode lead wire and the spongy inert metal layer are arranged on the axis and the large circular surface of the circular truncated cone shaped high-temperature insulating ceramic, and the inert metal sheet is arranged between the circular truncated cone shaped high-temperature insulating mat and the circular truncated cone shaped high-temperature insulating ceramic. Compared with the existing various high-pressure hydrothermal platinum electrodes, the platinum electrode solves the difficult problems that the existing cold-sealing type platinum electrode at home and abroad has poor stability and reliability and the hot-sealing type platinum electrode cannot be used in a high-pressure hydrothermal environment at higher than 400 DEG C.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

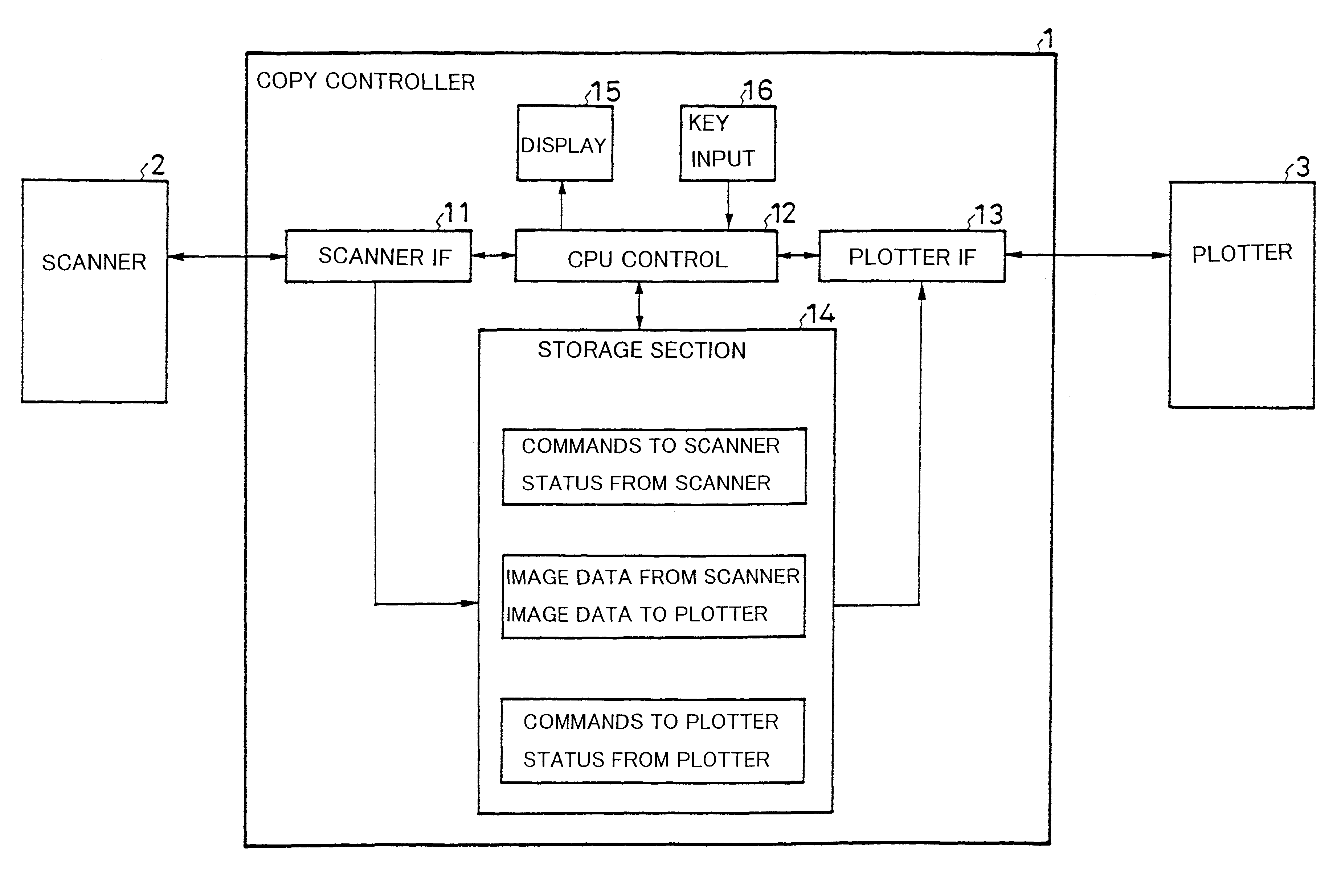

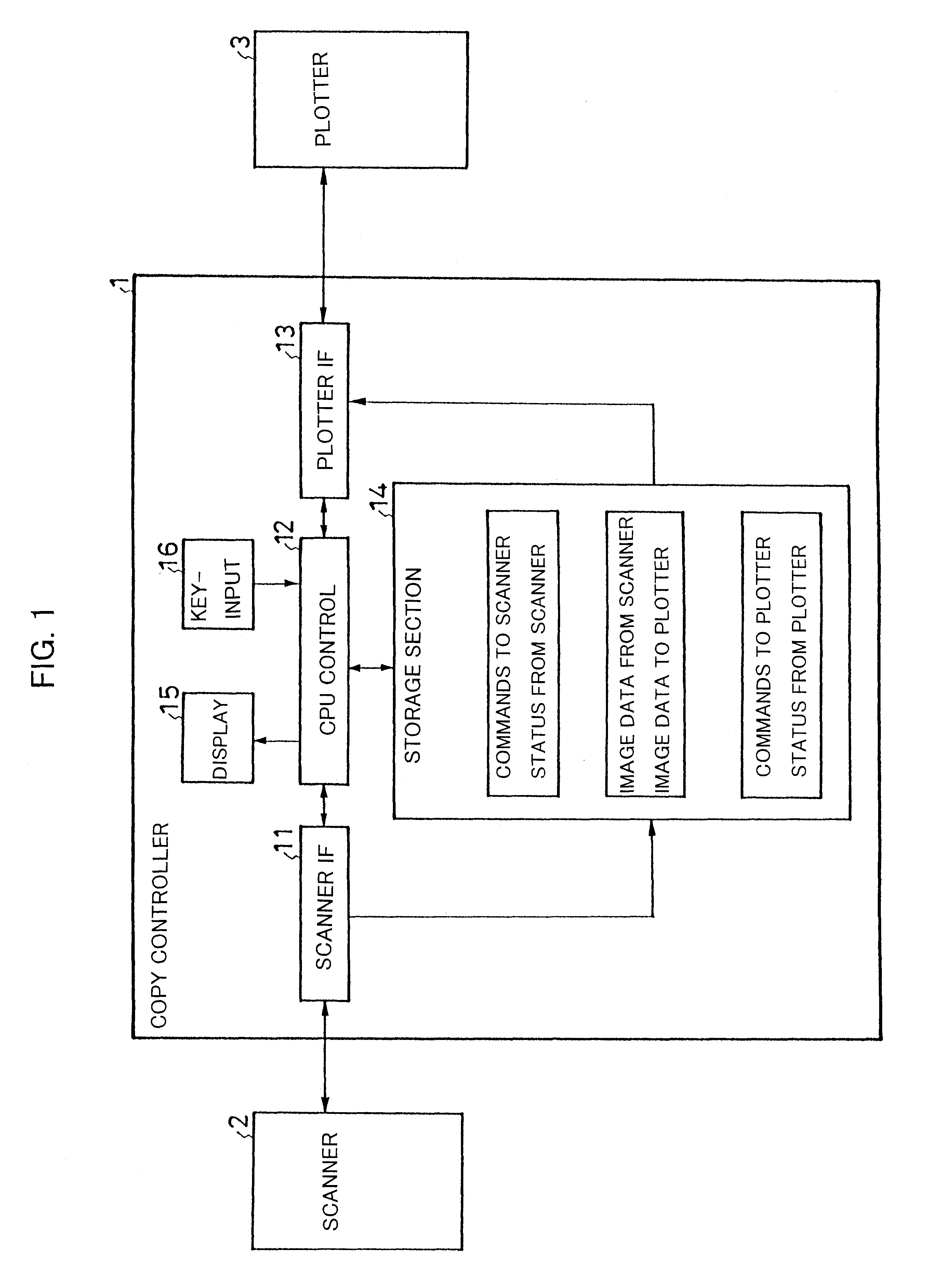

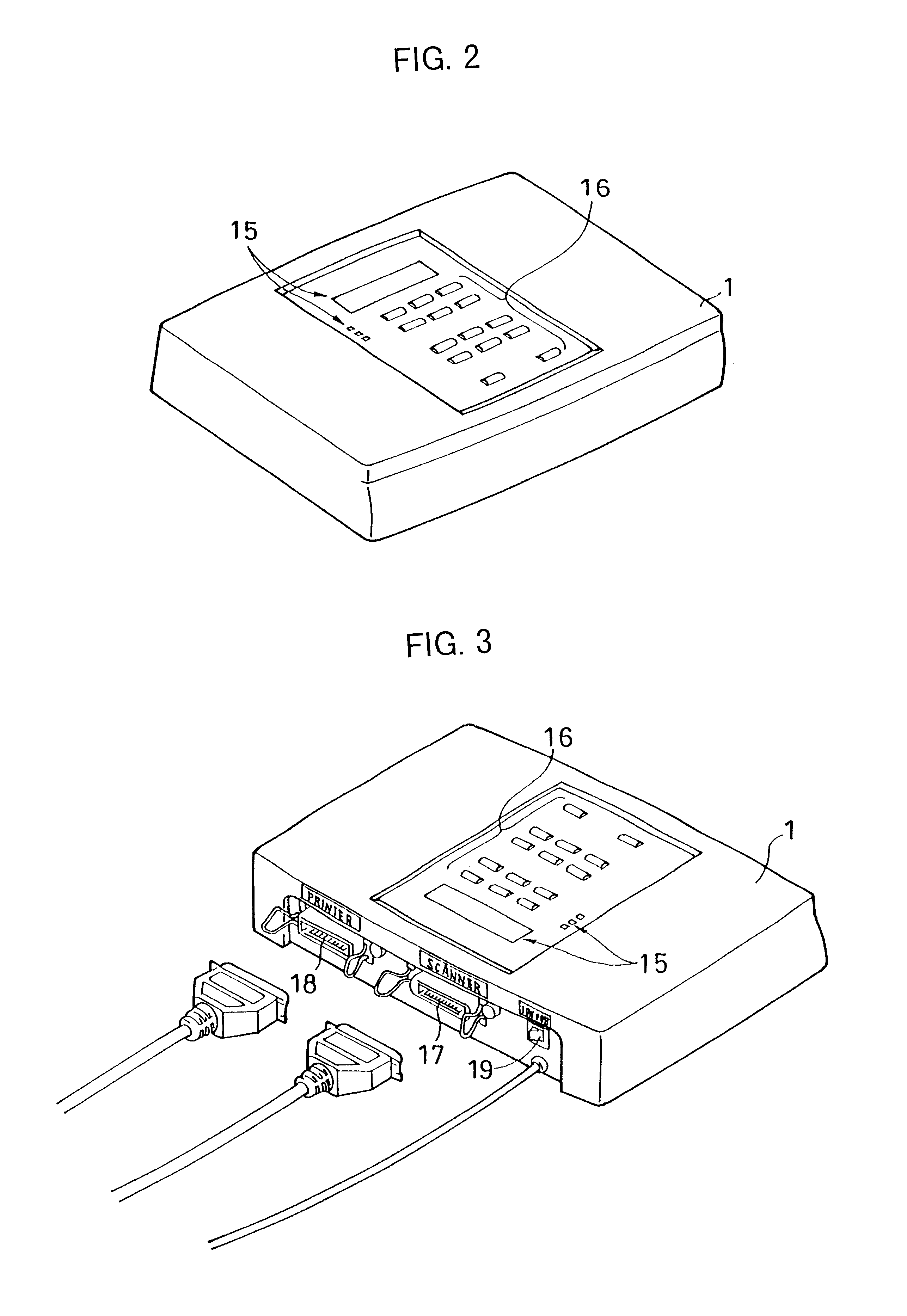

Copy system and copy controller

InactiveUS6256105B1Easy to operateWidely producedDigital computer detailsImage memory managementImaging processingImaging data

A copy system includes a copy controller which is connected to a scanner and a plotter via interface sections. Based on key input from a key-input section, the CPU control section of the copy controller inputs image data from the scanner one line or one block at a time and stores the image data into a storage section. After the image data is subjected to image processing, the CPU control section immediately outputs the image data to the plotter one line or one block at a time.

Owner:SILVER SEIKO LTD

PVC decorative plate

The invention discloses a PVC decorative plate. The PVC decorative plate comprises following ingredients, by mass, 100 parts of PVC, 5 to 8 parts of MBS, 1 to 3 parts of carbon black, 2 to 4 parts of DOP, 50 to 80 parts of active heavy calcium carbonate, 4 to 6 parts of CPE, 1 to 5 parts of epoxidized soybean oil, 5 to 7 parts of tribasic lead sulfate, 2 to 5 parts of dibasic lead phosphate, 4 to 6 parts of a modifier, 1 to 4 parts of paraffin, 2 to 3 parts of barium stearate, and 0.5 to 1 part of lead stearate. Product relative density ranges from 0.9 to 0.95, bending strength ranges from 55 to 65MPa, impact strength ranges from 380 to 400MPa, tensile strength ranges from 80 to 85MPa, oxygen index ranges from 30 to 35%. The PVC decorative plate is high in hardness, is antistatic, can be used for replacing existing materials continuously, and large-scaled production is realized.

Owner:WUJIANG DONGXIN PLASTIC PACKAGING PLANT

A fatigue-resistant PVC insulated cable material

ActiveCN103289252AImprove fatigue resistanceWon't crackPlastic/resin/waxes insulatorsInsulated cablesPlasticizerThermal deformation

A fatigue-resistant PVC insulated cable material comprises the following components, in parts by weight: 100 parts of PVC; 25-80 parts of a plasticizer; 3-15 parts of a thermal stabilizer; 0.1-2parts of a smooth agent; 5-80 parts of acetylene carbon black; 0.05-2 parts of bisphenol A; 0.1-2 parts of an antioxidant; and 1-10 parts of dibasic lead phthalate. The fatigue-resistant PVC insulated cable material has good fatigue resistance, and will not crack after repeated bending for 6-8 million times; and has Shore hardness of 91-95, and a wire resistant temperature of 110-120 DEG C; tensile strength of 25-35MPa, and elongation at break of 420-450%; a thermal deformation rate of 10-15%, a volume resistivity of 8*10<12> omega.cm, and dielectric strength of 25MV / m; and has antistatic, anti-aging and anti-chemical corrosion properties, and can be widely produced and replaces existing materials constantly.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

An LLDPE (Linear low-density polyethylene) material for communication cable jackets

ActiveCN103289180AHigh tensile strengthWidely producedPlastic/resin/waxes insulatorsInsulated cablesCarbon blackAntioxidant

An LLDPE (Linear low-density polyethylene) material for communication cable jackets is composed of the following components, in parts by weight: 100 parts of LLDPE, 10-25 parts of LDPE, 5-20 parts of PP, 0.01-2 parts of a thermal stabilizer, 1-20 parts of carbon black, 0. 1-10 parts of an antioxidant, and 0.1-10 parts of PE wax; has a product melt flow rate of greater than 2g / 10min which is greatly improved compared with the product melt flow rate of 0.1-0.3g / 10min in existing materials for cable jackets, an elongation rate of 850%, which is greatly improved compared with the elongation rate of 400% in existing LLDPE materials; and a tensile strength of 16-21MPa, and a density of 0.94-0.95g / cm3. The product does not fracture at -80 DEG C, has a volume resistivity of greater than 2*10<14> omega.cm, a dielectric strength of 28 -35KV / mm, and environmental stress crack resistance of greater than or equal to 30h; the product is flame retardant, anti-microbial, acid and alkaline resistant, and wear-resistant, and can be widely produced to replace existing materials

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY +1

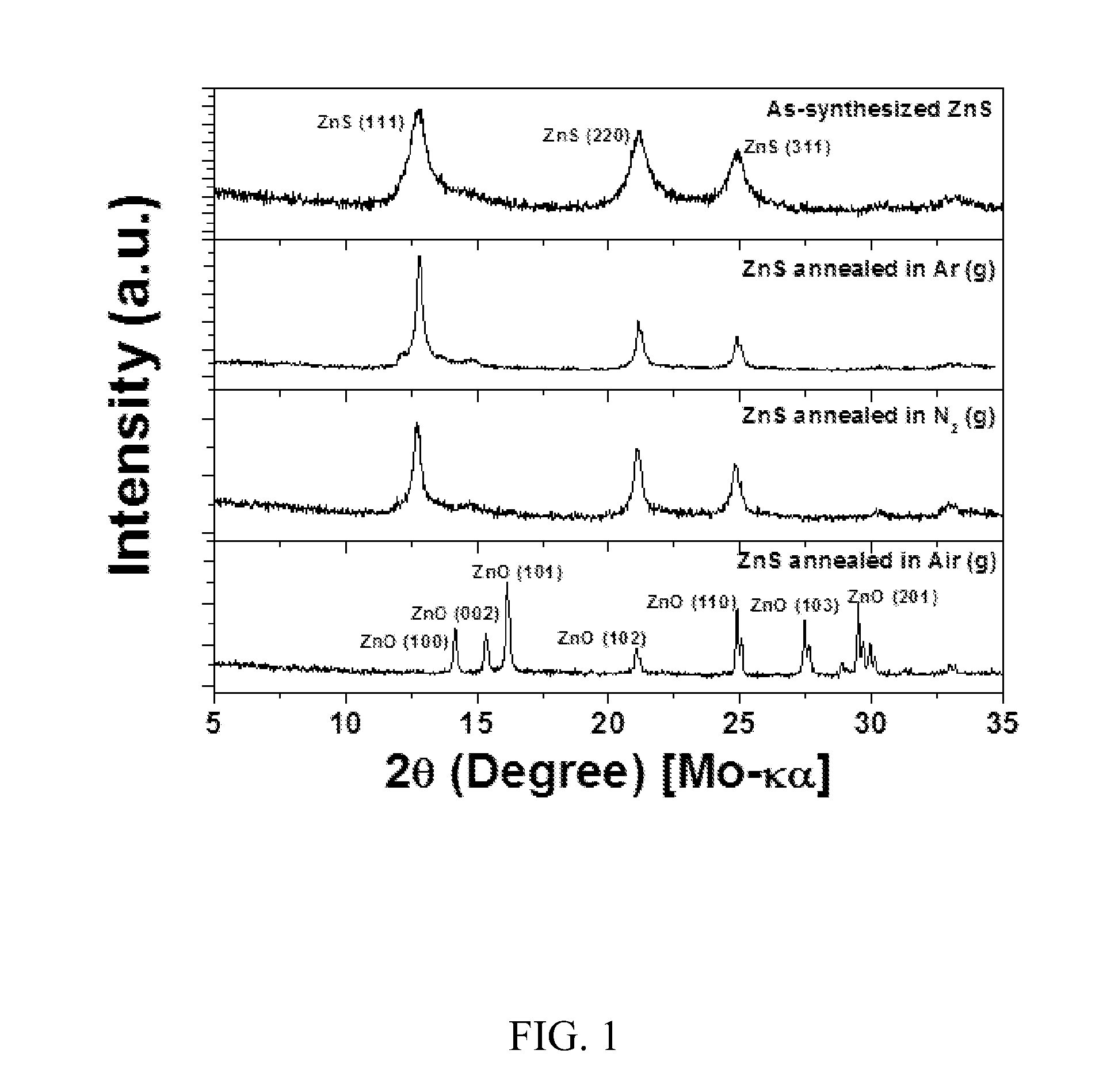

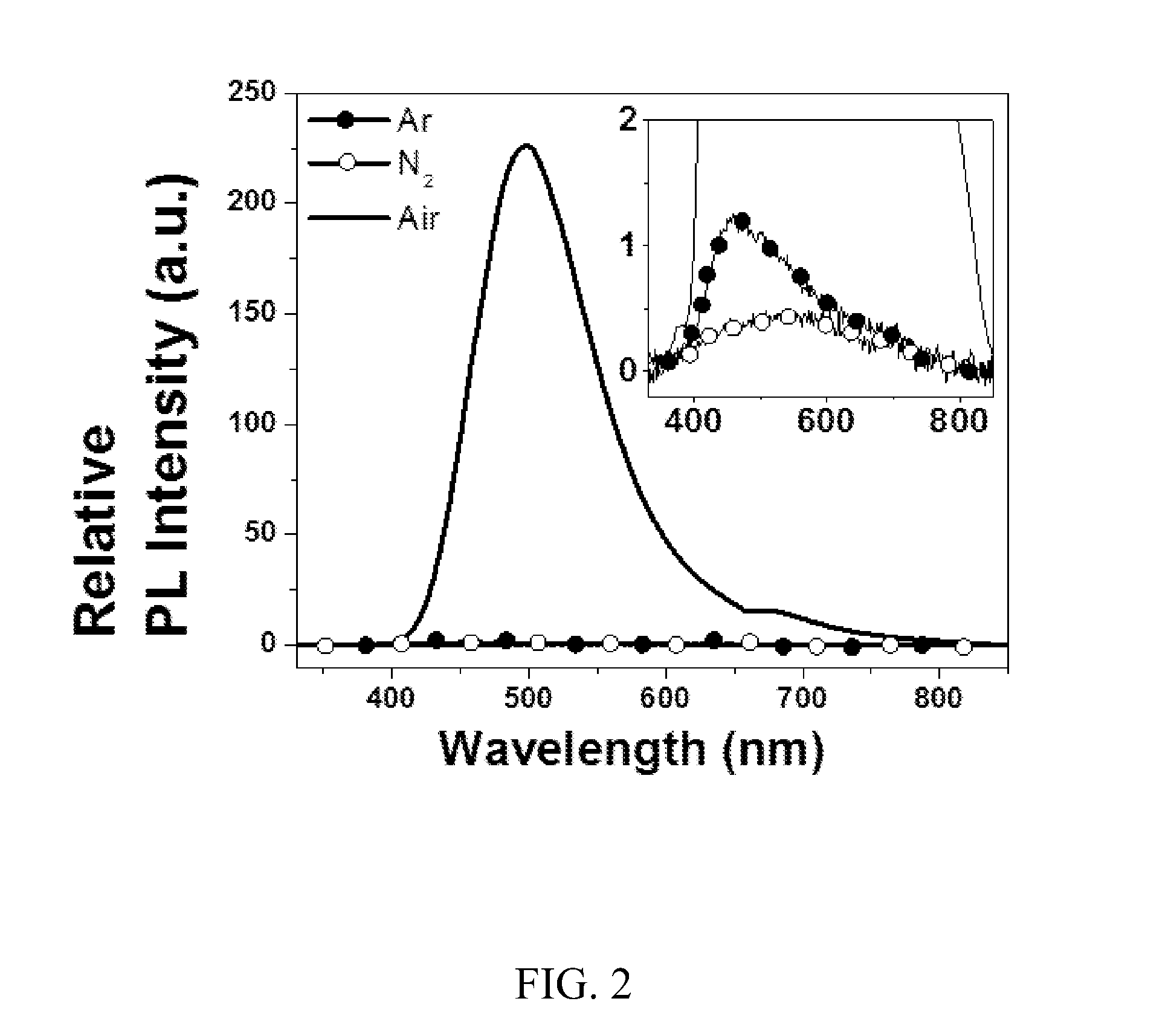

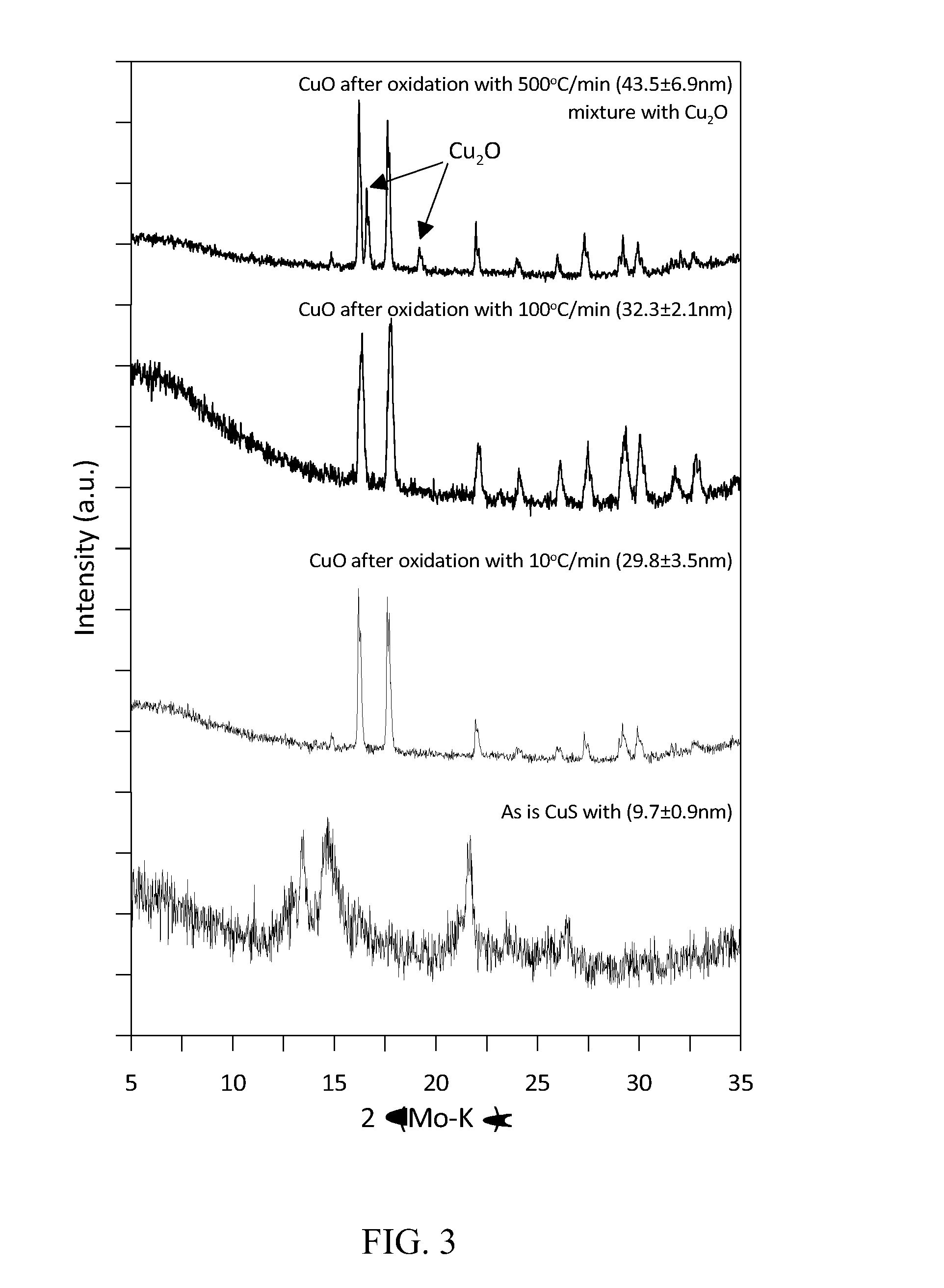

Method for synthesizing metal oxide particles

InactiveUS20140273147A1Without burdensome complexityCost efficient and simpleFermentationMetalMaterials science

The invention is directed to a method for producing metal oxide particles, the method comprising subjecting non-oxide metal-containing particles to an oxidation step that converts the non-oxide metal-containing particles to said metal oxide particles. The invention is also directed to the resulting metal oxide compositions. In particular embodiments, non-oxide precursor particles are produced by microbial means, and the produced non-oxide precursor particles subjected to oxidation conditions under elevated temperature conditions (e.g., by a thermal pulse) to produce metal oxide particles or a metal oxide film.

Owner:UT BATTELLE LLC

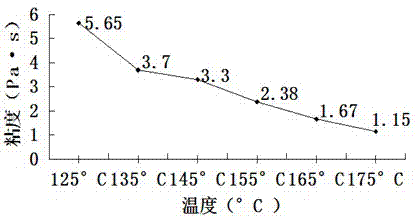

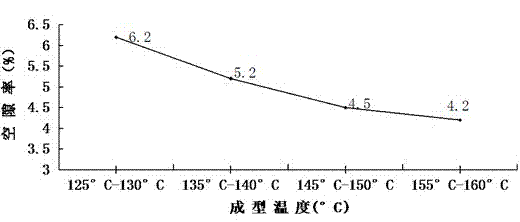

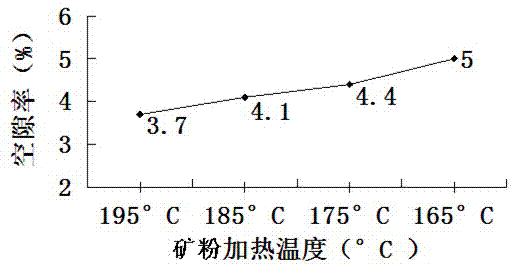

Warmly-mixed TOR (trans-polyoctenamer rubber reactive modifier) rubber asphalt mixture and preparation method thereof

ActiveCN103396043AImprove working environmentLower working environmentClimate change adaptationPolymer scienceAsphalt

The invention provides a warmly-mixed TOR (trans-polyoctenamer rubber reactive modifier) rubber asphalt mixture and a preparation method thereof. The warmly-mixed rubber asphalt mixture comprises TOR rubber asphalt prepared in situ. The TOR rubber asphalt comprises a TOR, rubber powder, asphalt, aggregates, mineral powder and a warm mixing agent, wherein the weight ratio of the rubber powder to the asphalt is 18:100, the weight ratio of the TOR to the rubber powder is 4.5:100, the weight ratio of the TOR rubber asphalt to the sum of the aggregates and the mineral powder is 6:100, the weight ratio of the aggregates to the mineral powder is 88:12, and the weight ratio of the warm mixing agent to the asphalt is 3:100. The invention further provides the preparation method for the warmly-mixed TOR rubber asphalt mixture. The preparation method comprises the following process steps of: preparing the TOR rubber asphalt, preprocessing the aggregates, adding the TOR rubber asphalt, the warm mixing agent and the mineral powder, and molding, so as to prepare the warmly-mixed TOR rubber asphalt mixture. According to the preparation method, the advantages of the TOR rubber asphalt mixture and a warm mixing technique are combined, so that the TOR rubber asphalt mixture has the advantages that the construction conditions can be improved, and the resource conservation, the energy conservation and the environment protection can be realized.

Owner:YANGZHOU UNIV

Candy packaging bag and preparation method thereof

The invention discloses a candy packaging bag and a preparation method thereof. The candy packaging bag is prepared by weighting the following components in parts by weight: LDPE (Low-Density Polyethylene), DOP (Dioctyl-Phthalate), PP (Propene Polymer), 4,5-epoxytetrahydroisooctyl phthalate, PS (Poly Styrene), zinc stearate, a thickening agent, calcium stearate, tricresyl phosphate, silicon oxide, a toughening agent, CPE (Chlorinated Polyethylene), triphenyl phosphite, MBS (Methyl Methacrylate) and epoxy soybean oil octyl ester, evenly mixing, extruding, granulating and then drawing, winding, inspecting and warehousing. The light transmittance of the product is 95-98%, the longitudinal tensile strength is 45-55MPa, the transverse tensile strength is 20-30MPa, the longitudinal elongation at break is 450-550%, the transverse elongation at break is 850-950%, the longitudinal tear strength is 120-130N / mm and the transverse tear strength is 140-150N / mm.

Owner:周佳瑜

Flame retardant HDPE cable material and preparation method thereof

The invention discloses a flame retardant HDPE cable material and a preparation method thereof. HDPE, CPE, antimony trioxide, red phosphorus, aluminum hydroxide, polyethylene wax, an antioxidant DLTP, carbon black, an antioxidant DNP, an antioxidant CA and a heat stabilizer are weighed according to a proportion by weight part. The product has tensile strength of 20-40MPa and elongation of 200-600%, is high temperature resistant to a temperature of 160-180DEG C, and has high strength, tensile yield strength of 25-45MPa, a melt flow index of 6-10g / 10min, embrittlement performance of no crack at -70DEG C, and dielectric strength of 26-28MV / m. Also, the flame retardant HDPE cable material has the advantages of low cost, simple operation, and high dielectric strength and insulation performance.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

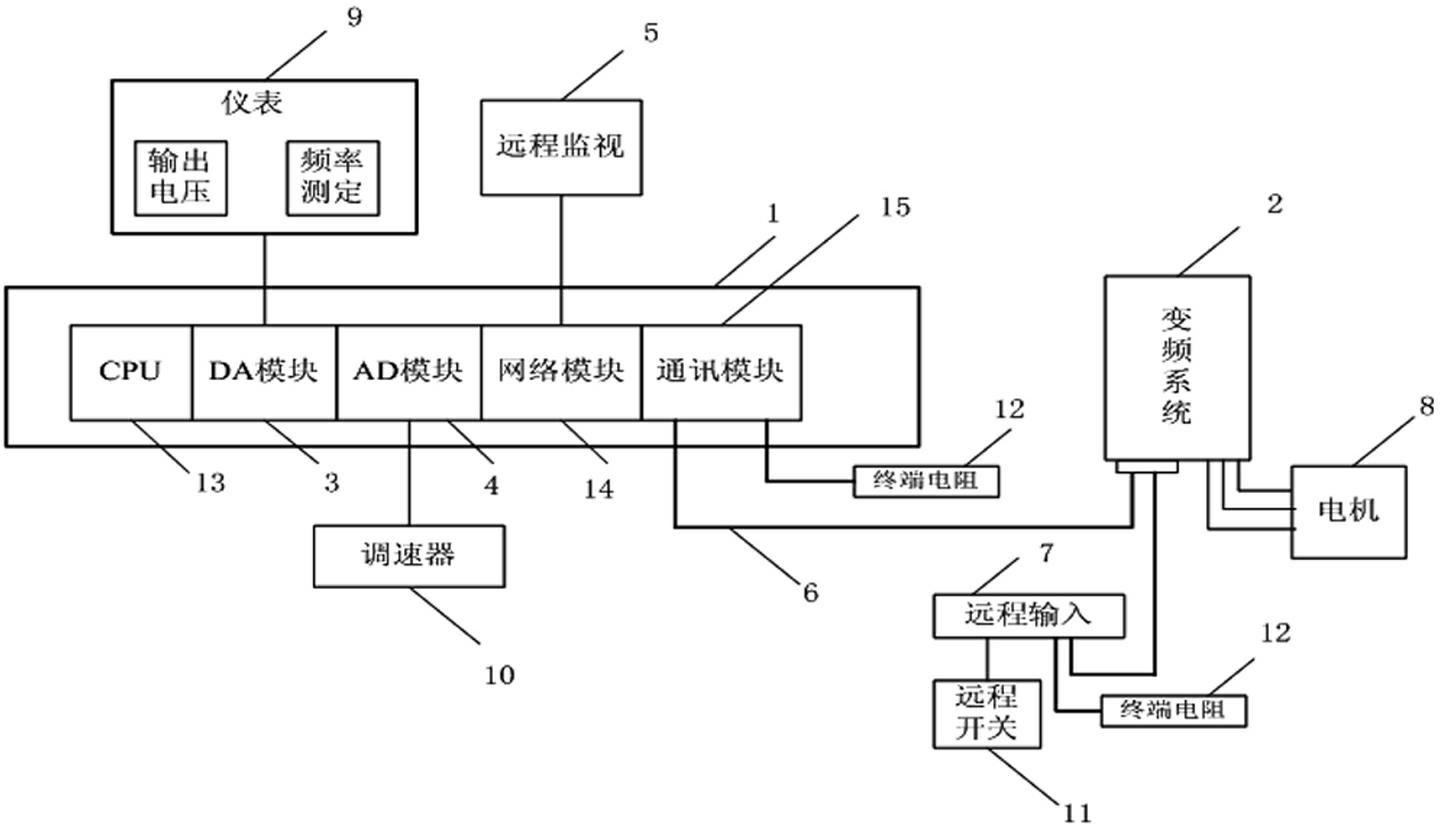

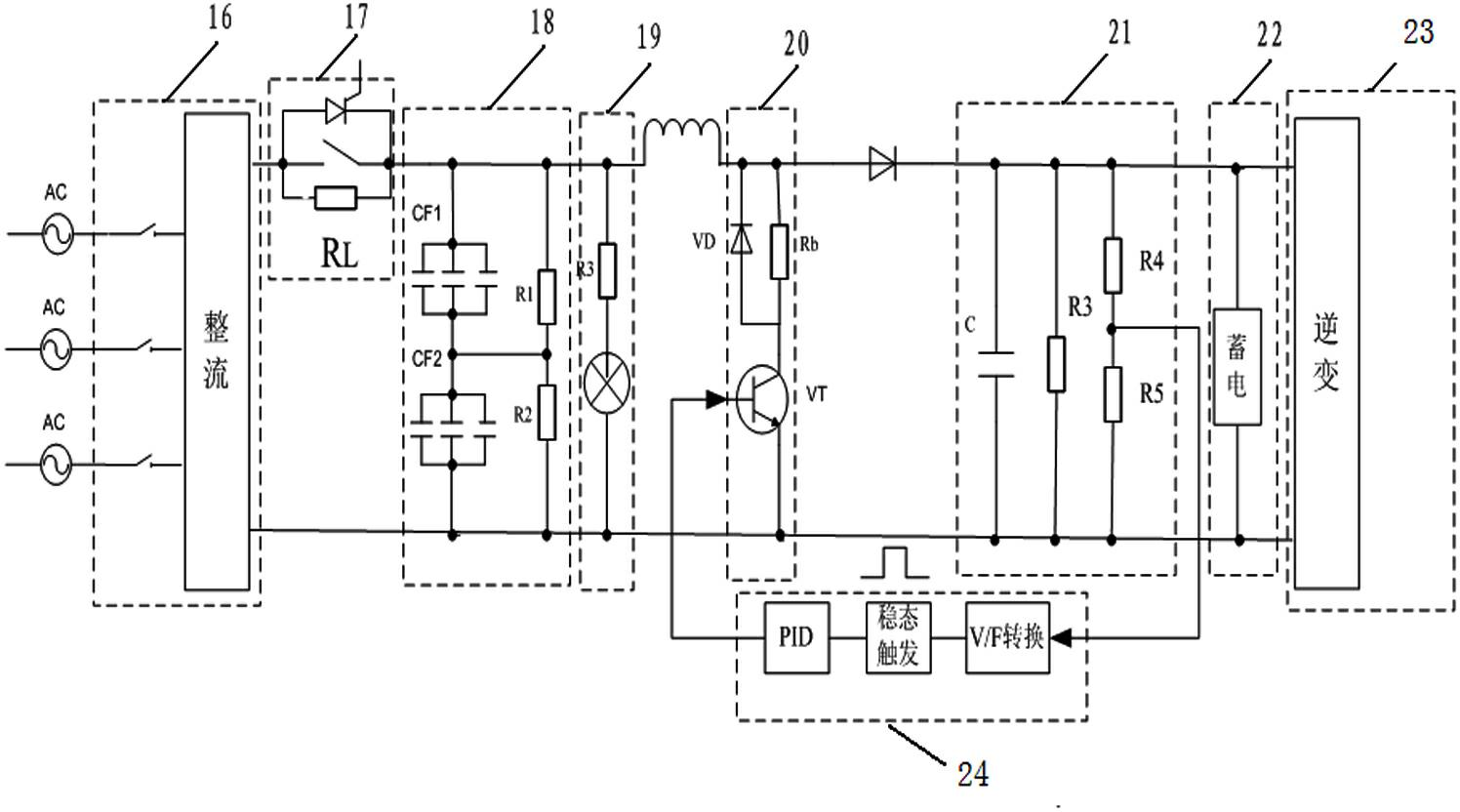

Booster chopping technology-based variable-frequency voltage stabilizing control system and method

ActiveCN102354984ASignificant energy savingGood anti-interference abilitySingle network parallel feeding arrangementsAc motor stoppersEmbedded systemProgram logic

The invention relates to a voltage stabilizing system, in particular to a boost chopping technology-based variable-frequency voltage stabilizing control system and a method, which belong to the electric automation field. The booster chopping technology-based variable-frequency voltage stabilizing control system mainly comprises a host computer, a program logic controller (PLC) 1, a variable-frequency system 2, a CC-LINK on-site bus 6, a remote monitor 5, a speed regulator 10 and a boost voltage frequency control conversion circuit; the PLC 1 is connected with the variable-frequency system 2 in a communication way through the CC-LINK on-site bus 6; the signal input end of the PLC 1 is respectively connected with an energy storage signal, an energy release signal and an alarming signal, and then the PLC 1 operates and processes the inputted data through a central processing unit CPU 13; and the output of the stabilized voltage of the system can be realized through a voltage / frequency (V / F) conversion circuit 24. The voltage stabilizing control system has good filter performance, a good energy-saving effect, good static performance and good dynamic performance, realizes the real-time monitoring, and improves the transmission accuracy and reliability of the control signal.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +3

PVC neutron shielding material and preparation method thereof

ActiveCN104072916AWidely producedSynthetic resin layered productsShieldingSOYBEAN SEED OILMagnesium stearate

The invention discloses a PVC neutron shielding material and a preparation method thereof. The method comprises the following steps: weighing PVC, epoxidized soybean oil, calcium stearate, dibutyltin maleate, boron carbide, UV-9, barium stearate, magnesium stearate, diphenyl sulfone, MBS, a heat stabilizer, titanium dioxide, polypropylene glycol and a plasticizer, mixing the raw materials, and carrying out mixed refining, piece pulling, sized dicing, pressing and cooling off, wherein the product impact strength is 5 to 10 MPa, the oxygen index is 35%, the bending strength is 15 to 25 MPa, the tensile strength is 15 to 35 MPa, and the Vicat heat-resisting temperature is 60 to 70 DEG C. The PVC neutron shielding material and the preparation method can be used for wide production and unceasingly replacement of the conventional materials.

Owner:河北凯成包装股份有限公司

High-strength polypropylene packaging bag and preparation method thereof

The invention discloses a high-strength polypropylene packaging bag and a preparation method thereof. The high-strength polypropylene packaging bag comprises the following raw materials: polypropylene, a coupling agent, glass fibers, white oil, LDPE, an antioxidant 1010, DCP, calcium stearate, calcium carbonate and POE. The high-strength polypropylene packaging bag has high notch impact resistant strength, the tensile strength is 220-260 MPa, and the breaking elongation rate is 500-900%; the Vicat softening point is 125-145 DEG C, and the bending strength is 25-45 MPa; the high-strength polypropylene packaging bag is resistant to heat and corrosion, the raw materials are simple and easy to obtain, the preparation method is simple, and the notch impact strength is 65-75 kJ / m2, so that the high-strength polypropylene packaging bag can be widely produced and continuously used for replacing the existing materials.

Owner:SUZHOU DINGLI PACKAGING

PC instrument panel and preparation method thereof

The application discloses a PC instrument panel and its preparation method. The preparation method comprises the following steps: weighing (by weight) PC, LDPE, UHMWPE, polyethylene glycol, HDPE, glass fibre, a compatilizer, GF, MBS, styrene-butadiene rubber, a coupling agent, EVA, PET, acrylic acid ester and ABS, drying, extruding, pulling pieces, granulating, and carrying out injection molding. The product is characterized in that light transmittance is 85-95%; tensile strength is 120-140 MPa; bending strength is 170-190 MPa; notch impact strength is 75-95 kJ / m<2>; young modulus is 6.5-7.5 GPa; elongation at break is 80-100%; and vicat softening point is 125-145 DEG C.

Owner:苏州市德莱尔建材科技有限公司

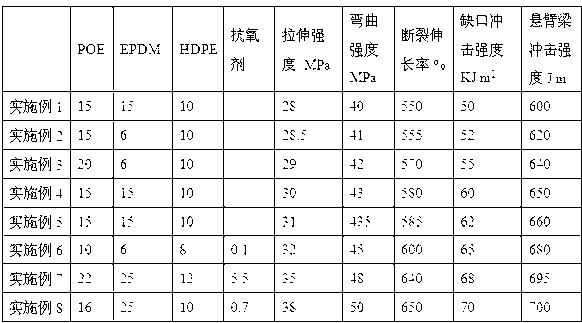

Polypropylene (PP) material for automobile bumper

The invention discloses a polypropylene (PP) material for an automobile bumper. The PP material comprises the following components in parts by mass: 100 parts of PP, 10-50 parts of ABS, 5-20 parts of an impact-resistant modifier, 1-20 parts of a compatilizer, 1-20 parts of high-density polyethylene (HDPE), 1-30 parts of ethylene-propylene-diene monomer (EPDM), 5-40 parts of a lubricating agent, 1-10 parts of wollastonite and 1-50 parts of calcium carbonate. The melt index of the product is more than 10g / 10 minutes; compared with the 0.1-0.25 g / 10 minutes of the conventional material, the melt index of the product is greatly improved; the tensile strength is 28-38MPa, the bending strength is 40-50 MPa, and the elongation at break is 550-650 percent; the thermal deformation temperature is 125-130 DEG C, the product resists the temperature of 40 DEG C below zero, the notch impact strength of the product is 50-70 KJ / m<2>, the cantilever beam impact strength is 600-700L / m, and the cantilever beam impact strength at the temperature of 40 DEG C below zero is 70-80L / m; and moreover, the product is excellent in impact resistance, high in ageing resistance, high in chemical corrosion resistance and high in fire resistance, can be widely produced and can continuously replace the conventional materials.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

Thermal storage warm-keeping fabric finishing agent and preparation method thereof

ActiveCN102628215ARealize the function of keeping warmNice appearanceFibre treatmentThermal energy storageWater soluble

The invention discloses a thermal storage warm-keeping fabric finishing agent, comprising the following components in parts by weight: 30-60 parts by weight of mixed nano powder of MoO3 and medical stone, 5-10 parts by weight of dispersant, 10-20 parts by weight of water-soluble acrylic resin and 30-50 parts by weight of water, wherein percents by weight of MoO3 nano powder and medical stone powder in the mixed nano powder of MoO3 and medical stone are respectively 50-70% and 30-50%, and average particle size of the mixed nano powder of MoO3 and medical stone is less than or equal to 15nm; and the dispersant is sodium phosphate aqueous solution with the mass percent concentration of 10%. The thermal storage warm-keeping fabric finishing agent disclosed by the invention has good thermal storage warm-keeping function and ultraviolet-resistant function, can be widely applied to various fabrics made from various chemical fibers, pure cotton and blends and can be used for making warm-keeping fabrics in various uses. Besides, the invention also discloses a preparation method of the thermal storage warm-keeping fabric finishing agent.

Owner:上海沪正实业有限公司

Polyethylene tearing film and preparation method thereof

The invention discloses a polyethylene tearing film and a preparation method thereof. The polyethylene tearing film comprises the following raw materials: polyethylene, an antioxidant, barium sulfate, organic montmorillonite, a silane coupling agent, DOP (dioctyl phthalate), nano titanium dioxide, zinc oxide whiskers, polyethylene wax and CPE (chlorinated polyethylene). The polyethylene tearing film has the tensile strength of 3-4 g / den and the break elongation rate of 10-30%; the polyethylene tearing film is low in density, good in toughness, good in wear resistance and high in tensile strength, and has the linear density of 5-25 kg / m; the polyethylene tearing film is good in heat resistance and good in flowability, the raw materials are simple and easily available, the preparation method is simple, and the polyethylene tearing film can be widely produced and continuously replaces an existing material.

Owner:SUZHOU DINGLI PACKAGING

Polypropylene woven bag and preparation method thereof

The invention discloses a polypropylene woven bag and a preparation method thereof. The polypropylene woven bag comprises the following raw materials: PP (polypropylene), an ultraviolet absorbent, calcium carbonate, zinc white, titanium dioxide, an antioxidant 1010, an antioxidant 168, an antioxidant DLTP, talcum powder and dioctyl bisphthalate. The polypropylene woven bag has the impact strength of 30-50 kJ / m<2> and the tensile strength of 35-55 MPa; the polypropylene woven bag is low in density, good in toughness, good in wear resistance and high in tensile strength, and has the bending strength of 1,850-2,250 MPa and the breaking force of 30-50 N; the polypropylene woven bag is good in heat resistance and good in flowability, the raw materials are simple and easily available, the preparation method is simple, and the polypropylene woven bag has the melting point of 130-170 DEG C and the elongation rate of 200-400%, can be widely produced and continuously replaces an existing material.

Owner:SUZHOU DINGLI PACKAGING

Polylactic acid toughening modification plastic and preparation method thereof

The invention discloses polylactic acid toughening modification plastic and a preparation method thereof. The polylactic acid toughening modification plastic is prepared from PLA, PBAT, PEG, calcium stearate, stearic acid, ACR, PBT, PC, epoxypropane and tributyl citrate. The transverse product shrinkage is 1.1-1.5%, the longitudinal product shrinkage rate is 1.2-1.6%, the shrinkage ratio is 1.3-1.7, vicat softening temperature is 120-140 DEG C, the tensile strength is 75-95 MPa, the impact strength is 85-105 kJ / m<2>, the elongation at break is 300-500%, the friction coefficient is 0.15-0.35, and the bending strength of 75-95 MPa.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

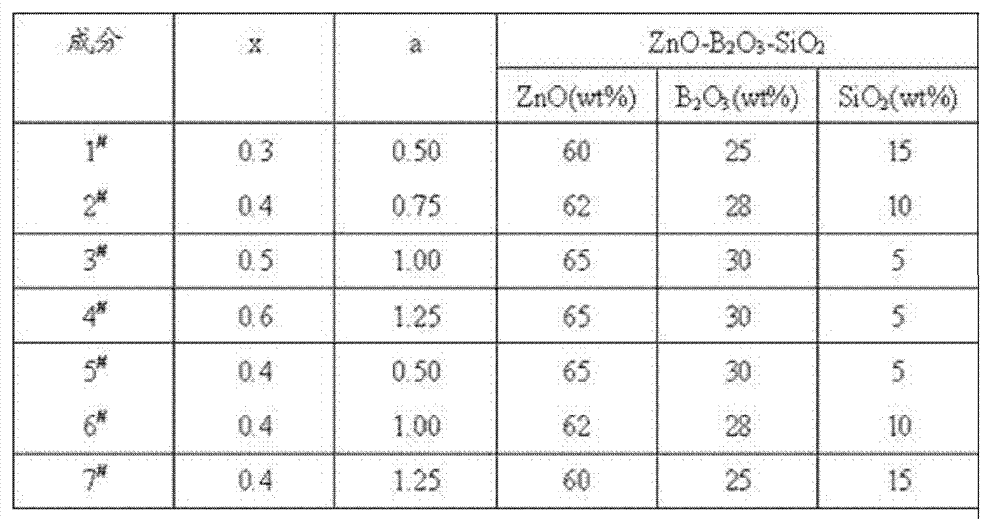

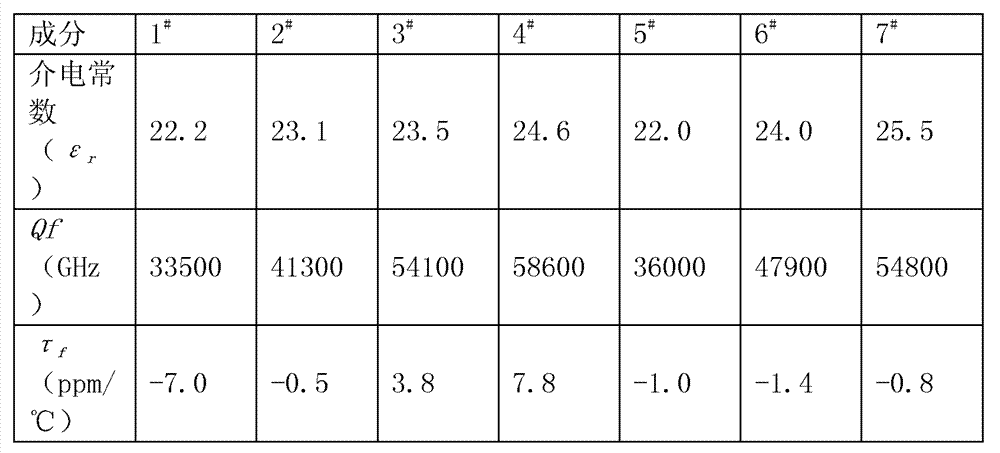

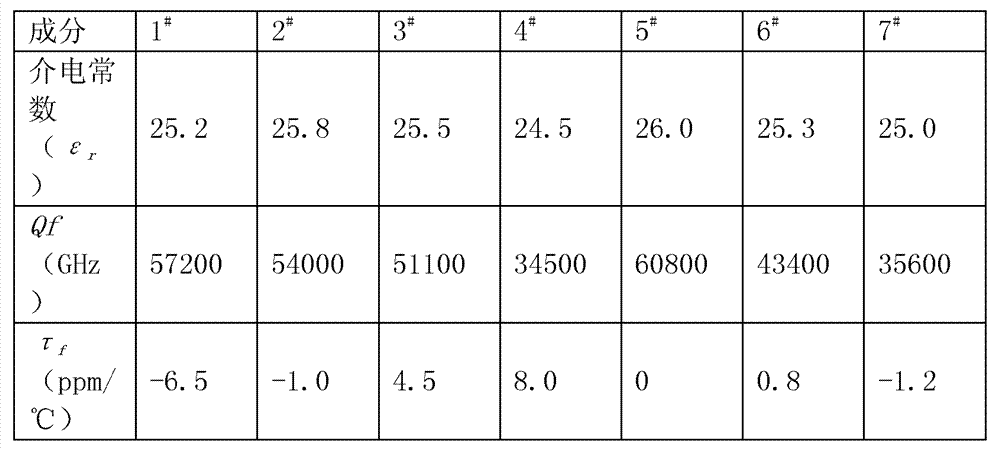

Low temperature sintering temperature-stable microwave dielectric ceramic material and preparation method thereof

ActiveCN103922725AExcellent microwave dielectric propertiesLower sintering temperatureChemical compositionMicrowave

The present invention discloses a low temperature sintering temperature-stable microwave dielectric ceramic material and a preparation method thereof. According to the present invention, the formula comprises a base material and a sintering auxiliary agent, wherein the chemical composition expression formula of the base material is (1-x)Li2ZnTi3O8-xLi2TiO3, x is more than or equal to 0.3 and is less than or equal to 0.6, the sintering auxiliary agent is ZnO-B2O3-SiO2 glass powder, the amount of the sintering auxiliary agent is a% of the weight of the base material, and a is more than or equal to 0.50 and is less than or equal to 1.25; the ceramic preparation process sequentially comprises: respectively pre-synthesizing Li2ZnTi3O8 powder and Li2TiO3 powder in a calcination manner, preparing a base material according to the molar ratio of the composition formula (1-x)Li2ZnTi3O8-xLi2TiO3, adding ZnO-B2O3-SiO2 glass powder, and carrying out ball milling, molding, molding agent removing and sintering to obtain the product; and the product sintering temperature can be reduced to below 950 DEG C, the relative dielectric constant [epsilon]r can be adjusted within 22-26, the quality factor Qf is up to 33500-61200 GHz, and the resonant frequency temperature coefficient [tau]f is -7.0-8.0 ppm / DEG C and is close to zero, such that the product can become a new LTCC material so as to be widely produced and continuously replace the existing material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

PVC master batch and preparation method thereof

The invention discloses a PVC master batch and a preparation method thereof. According to the preparation method, PVC, ESBO, DOP, ACR, paraffin, carbon black, lead stearate, barium stearate, cadmium stearate, PE wax, antimonous oxide and titanium dioxide are weighed in parts by weight, the product is high in strength, the tensile strength is 50MPa-90MPa, the tensile modulus is 3200MPa -3600MPa, and the Shore hardness is 60D-80D; the appearance of the product is uniform and glossy, the color intensity is 95%-115%, the impact strength is 15kJ / m<2>-35kJ / m<2>, the thermal deformation temperature is 120-140 DEG C, the bending strength of the product is 15MPa-55MPa, the bending modulus is 2GPa-4GPa, the elongation at break is 100%-140%, and the melt flow index is 7g / min-11g / min; and the cost is low, the operation is simple, and the PVC master batch can be widely applied to the production and can be used for continuously replacing existing materials.

Owner:陈逸君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com